复合材料专业英语-讲稿汇总

- 格式:doc

- 大小:75.50 KB

- 文档页数:21

复合材料与工程专业专业英语复合材料原理中文英文复合材料composite material基体matrix增强体reinforcement纤维fiber颗粒particle晶须whisker纳米管nanotube石墨烯graphene复合效应composite effect复合理论composite theory增强机制reinforcement mechanism界面interface界面层interphase界面粘结强度interfacial bond strength界面物理化学interfacial physical chemistry聚合物基复合材料polymer matrix composite (PMC)金属基复合材料metal matrix composite (MMC)陶瓷基复合材料ceramic matrix composite (CMC)碳-碳复合材料carbon-carbon composite (C-C)遗态复合材料biomimetic composite分级结构复合材料hierarchical composite剪切增稠柔性复合材料shear thickening fluid composite (STFC)连续缠绕工艺filament winding process拉挤工艺pultrusion process注射成型工艺injection molding process压缩成型工艺compression molding process热压工艺hot pressing process热等静压工艺hot isostatic pressing process (HIP)化学气相沉积法chemical vapor deposition (CVD)物理气相沉积法physical vapor deposition (PVD)液相浸渗法liquid phase infiltration (LPI)气相浸渗法gas phase infiltration (GPI)反应浸渗法reaction infiltration (RI)自蔓延高温合成法self-propagating high-temperature synthesis (SHS)电泳沉积法electrophoretic deposition (EPD)溶胶-凝胶法sol-gel method复合材料工艺中文英文复合材料工艺学composite material processing science复合材料加工技术composite material processing technology复合材料成型方法composite material forming method复合材料固化方法composite material curing method复合材料后处理方法composite material post-processing method复合材料接头技术composite material joint technology复合材料修复技术composite material repair technology复合材料表面处理技术composite material surface treatment technology复合材料工艺参数composite material process parameters复合材料工艺性能composite material process performance复合材料工艺缺陷composite material process defects复合材料工艺模拟composite material process simulation复合材料工艺优化composite material process optimization手糊法hand lay-up method喷射成型法spray-up method真空吸附法vacuum bagging method自动糊层机法automatic tape laying method (ATL)自动纤维放置法automated fiber placement method (AFP)树脂传输成型法resin transfer molding method (RTM)树脂膜层叠加成型法resin film infusion method (RFI)真空辅助树脂传输成型法vacuum assisted resin transfer molding method (VARTM)真空辅助树脂注射成型法vacuum assisted resin injection molding method (VARI)树脂浸渍拉挤成型法resin impregnation pultrusion method树脂浸渍缠绕成型法resin impregnation winding method树脂浸渍编织成型法resin impregnation weaving method预浸料成型法prepreg molding method预浸料自动糊层机法prepreg automatic tape laying method预浸料自动纤维放置法prepreg automated fiber placement method预浸料真空吸附法prepreg vacuum bagging method预浸料热压成型法prepreg hot pressing method预浸料热等静压成型法prepreg hot isostatic pressing method预浸料自动模具线成型法prepreg automatic mold line method (AML)模塑复合材料成型法molded compound molding method压缩模塑复合材料成型法compression molded compound molding method注射模塑复合材料成型法injection molded compound molding method转移模塑复合材料成型法transfer molded compound molding method挤出模塑复合材料成型法extrusion molded compound molding method热解复合材料制备方法pyrolysis composite preparation method复合材料结构设计中文英文复合材料结构设计composite material structural design复合材料结构分析composite material structural analysis复合材料结构优化composite material structural optimization复合材料结构可靠性composite material structural reliability复合材料结构失效模式composite material structural failure mode复合材料结构失效准则composite material structural failure criterion复合材料结构强度composite material structural strength复合材料结构刚度composite material structural stiffness复合材料结构稳定性composite material structural stability复合材料结构疲劳性能composite material structural fatigue performance 复合材料结构断裂韧性composite material structural fracture toughness 复合材料结构损伤容限composite material structural damage tolerance复合材料层合板composite material laminate复合材料夹层板composite material sandwich panel复合材料桁架composite material truss复合材料梁composite material beam复合材料板壳composite material plate-shell复合材料管壳composite material tube-shell复合材料网格壳composite material grid-shell复合材料蜂窝板composite material honeycomb panel纤维方向角fiber orientation angle层厚比thickness ratio层间剪切模量interlaminar shear modulus层间剪切强度interlaminar shear strength层间正应力强度因子interlaminar normal stress intensity factor层间剪应力强度因子interlaminar shear stress intensity factor层间断裂韧度interlaminar fracture toughness层间脱层interlaminar delamination层间裂纹扩展速率interlaminar crack propagation rate层间裂纹扩展阻力曲线interlaminar crack resistance curve (R-curve)层内应力分布intralaminar stress distribution层内应变分布intralaminar strain distribution层内失效模式intralaminar failure mode层内失效准则intralaminar failure criterion复合材料力学中文英文复合材料力学composite material mechanics复合材料弹性理论composite material elasticity theory复合材料弹塑性理论composite material elasto-plasticity theory复合材料粘弹性理论composite material viscoelasticity theory复合材料热弹性理论composite material thermoelasticity theory复合材料非线性力学composite material nonlinear mechanics复合材料动力学composite material dynamics复合材料疲劳力学composite material fatigue mechanics复合材料断裂力学composite material fracture mechanics复合材料损伤力学composite material damage mechanics复合材料微观力学composite material micromechanics复合材料宏观力学composite material macromechanics复合材料多尺度力学composite material multiscale mechanics复合材料本构关系composite material constitutive relation复合材料本构方程composite material constitutive equation复合材料本构模型composite material constitutive model复合材料本构参数composite material constitutive parameter复合材料本构参数识别方法composite material constitutive parameter identification method纤维增强复合材料单元细胞模型fiber reinforced composite unit cell model纤维增强复合材料等效模量计算方法fiber reinforced composite equivalent modulus calculation method纤维增强复合材料等效泊松比计算方法fiber reinforced composite equivalent poisson ratio calculation method纤维增强复合材料等效热膨胀系数计算方法fiber reinforced composite equivalent thermal expansion coefficient calculation method纤维增强复合材料等效热导率计算方法fiber reinforced composite equivalent thermal conductivity calculation method 纤维增强复合材料等效电导率计算方法fiber reinforced composite equivalent electrical conductivity calculation method 纤维增强复合材料等效介电常数计算方法fiber reinforced composite equivalent dielectric constant calculation method 颗粒增强复合材料单元细胞模型particle reinforced composite unit cell model颗粒增强复合材料等效模量计算方法particle reinforced composite equivalent modulus calculation method颗粒增强复合材料等效泊松比计算方法particle reinforced composite equivalent poisson ratio calculation method颗粒增强复合材料等效热膨胀系数计算方法particle reinforced composite equivalent thermal expansion coefficient calculation method颗粒增强复合材料等效热导率计算方法particle reinforced composite equivalent thermal conductivity calculation method 颗粒增强复合材料等效电导率计算方法particle reinforced composite equivalent electrical conductivity calculation method 颗粒增强复合材料等效介电常数计算方法particle reinforced composite equivalent dielectric constant calculation method 晶须增强复合材料单元细胞模型whisker reinforced composite unit cell model晶须增强复合材料等效模量计算方法whisker reinforced composite equivalent modulus calculation method晶须增强复合材料等效泊松比计算方法whisker reinforced composite equivalent poisson ratio calculation method晶须增强复合材料等效热膨胀系数计算方法whisker reinforced composite equivalent thermal expansion coefficient calculation method晶须增强复合材料等效热导率计算方法whisker reinforced composite equivalent thermal conductivity calculation method 晶须增强复合材料等效电导率计算方法whisker reinforced composite equivalent electrical conductivity calculation method晶须增强复合材料等效介电常数计算方法whisker reinforced composite equivalent dielectric constant calculation method 纳米复合材料中文英文纳米复合材料nanocomposite material纳米粒子nanoparticle纳米纤维nanofiber纳米管nanotube纳米线nanowire纳米带nanoribbon纳米棒nanorod纳米片nanosheet纳米球nanosphere纳米星nanostar纳米花nanoflower纳米棘轮nanoratchet纳米泡沫nanofoam纳米多孔材料nanoporous material纳米气凝胶nanoaerogel纳米海绵nanosponge纳米网格nanogrid纳米蜂窝结构nanohoneycomb structure纳米层状结构nanolayered structure纳米纤维素复合材料nanocellulose composite material石墨烯复合材料graphene composite material二维纳米材料复合材料two-dimensional nanomaterial composite material量子点复合材料quantum dot composite material全息纳米复合材料holographic nanocomposite material超分子纳米复合材料supramolecular nanocomposite material生物医用复合材料中文英文生物医用复合材料biomedical composite material生物相容性biocompatibility生物降解性biodegradability生物吸收性bioabsorbability生物活性bioactivity生物力学性能biomechanical performance生物功能化biofunctionalization药物缓释drug delivery组织工程tissue engineering骨组织工程bone tissue engineering软骨组织工程cartilage tissue engineering皮肤组织工程skin tissue engineering神经组织工程nerve tissue engineering血管组织工程vascular tissue engineering心脏组织工程cardiac tissue engineering肝脏组织工程liver tissue engineering肾脏组织工程kidney tissue engineering胰腺组织工程pancreas tissue engineering肺组织工程lung tissue engineering骨水泥复合材料bone cement composite material骨替代材料复合材料bone substitute material composite material 骨修复板复合材料bone fixation plate composite material骨钉复合材料bone screw composite material骨髓钉复合材料bone nail composite material骨髓钉复合材料bone nail composite material人工关节复合材料artificial joint composite material人工韧带复合材料artificial ligament composite material人工心脏瓣膜复合材料artificial heart valve composite material人工血管复合材料artificial blood vessel composite material 人工角膜复合材料artificial cornea composite material人工耳蜗复合材料artificial cochlea composite material人工牙齿复合材料artificial tooth composite material人工皮肤复合材料artificial skin composite material人工肝脏复合材料artificial liver composite material复合材料测试与评价中文英文复合材料测试与评价composite material testing and evaluation复合材料测试方法composite material testing method复合材料测试标准composite material testing standard复合材料测试仪器composite material testing instrument复合材料测试数据composite material testing data复合材料测试结果composite material testing result复合材料测试分析composite material testing analysis复合材料评价方法composite material evaluation method复合材料评价指标composite material evaluation index复合材料评价模型composite material evaluation model复合材料评价系统composite material evaluation system复合材料评价报告composite material evaluation report静态力学性能测试static mechanical performance test动态力学性能测试dynamic mechanical performance test疲劳性能测试fatigue performance test断裂性能测试fracture performance test热性能测试thermal performance test电性能测试electrical performance test光学性能测试optical performance test磁学性能测试magnetic performance test磁学性能测试magnetic performance test损伤性能测试damage performance test环境适应性能测试environmental adaptability performance test 耐腐蚀性能测试corrosion resistance performance test耐磨性能测试wear resistance performance test耐老化性能测试aging resistance performance test耐辐射性能测试radiation resistance performance test耐火性能测试fire resistance performance test耐水性能测试water resistance performance test耐化学品性能测试chemical resistance performance test。

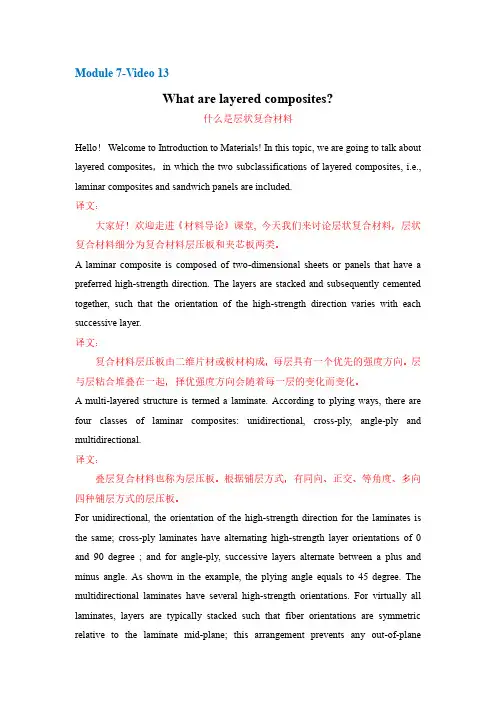

Module 7-Video 13What are layered composites?什么是层状复合材料Hello!Welcome to Introduction to Materials! In this topic, we are going to talk about layered composites,in which the two subclassifications of layered composites, i.e., laminar composites and sandwich panels are included.译文:大家好!欢迎走进《材料导论》课堂, 今天我们来讨论层状复合材料,层状复合材料细分为复合材料层压板和夹芯板两类。

A laminar composite is composed of two-dimensional sheets or panels that have a preferred high-strength direction. The layers are stacked and subsequently cemented together, such that the orientation of the high-strength direction varies with each successive layer.译文:复合材料层压板由二维片材或板材构成,每层具有一个优先的强度方向。

层与层粘合堆叠在一起,择优强度方向会随着每一层的变化而变化。

A multi-layered structure is termed a laminate. According to plying ways, there are four classes of laminar composites: unidirectional, cross-ply, angle-ply and multidirectional.译文:叠层复合材料也称为层压板。

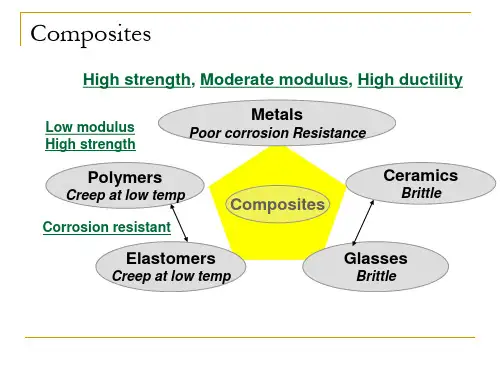

复合材料与工程英语介绍范文Composite materials are materials made from two or more constituent materials with significantly different physical or chemical properties. These materials when combined, work together to produce a material with characteristics different from the individual components. The resulting composites can provide unique advantages, such as increased strength, reduced weight, and improved durability.复合材料是由两种或两种以上具有明显不同物理或化学性质的组分材料制成的材料。

这些材料在结合时,共同产生具有不同于单个组分的特征的材料。

由此产生的复合材料可以提供独特的优势,例如增加强度、减轻重量和提高耐久性。

One common example of a composite material is fiberglass, which is made of glass fibers embedded in a polymer matrix. The combination of the strong, lightweight glass fibers with the flexible, durable polymer creates a material that is both strong and lightweight, making it ideal for a wide range of applications. From aerospace and automotive components to sports equipment andconstruction materials, fiberglass composites are used in diverse industries.一个常见的复合材料例子是玻璃纤维,它是由玻璃纤维嵌入聚合物基质而制成的。

有关于介绍复合材料方面的英语作文全文共10篇示例,供读者参考篇1Title: Let's Talk About Composite Materials!Hey guys, do you know what composite materials are? Today, we are going to learn all about them!So, composite materials are made up of two or more different materials combined together. For example, think about a chocolate chip cookie - it's made from chocolate chips and cookie dough. Just like that, composite materials combine different materials to make them stronger, lighter, or more durable.One cool thing about composite materials is that they can be made from all sorts of stuff like fibers, metals, or plastics. They are used in lots of things we use every day, like sports equipment, airplanes, cars, and even buildings! They help make things stronger and last longer.One famous example of a composite material is carbon fiber. It's super strong and lightweight, which makes it perfect forthings like bicycles and tennis rackets. Another example is fiberglass, which is used in boats and cars to make them more durable.Composite materials are also great for the environment because they can be recycled and reused. This helps reduce waste and protect our planet.So, next time you see something made from composite materials, remember how cool and useful they are! They are like the superheroes of materials, making our world a better place. Let's give a big cheer for composite materials! Yay!篇2Composite materials are super cool! They are made by combining two or more materials to create a new material with special properties. For example, carbon fiber is a composite material made from carbon fibers and a plastic resin. It is super strong and lightweight, making it perfect for things like aircraft, sports equipment, and even space shuttles.One cool thing about composite materials is that you can customize them to have different properties. By changing the type of materials used, the way they are arranged, or how theyare combined, you can create a material that is strong, flexible, heat-resistant, or even conductive.Another awesome thing about composite materials is that they can be made to be very durable. Unlike some traditional materials that can rust, corrode, or wear out quickly, composite materials can last a long time without needing to be replaced. This makes them perfect for things like bridges, buildings, and even prosthetic limbs.Overall, composite materials are a super cool and versatile type of material that can be used in all sorts of applications. Whether you're building a rocket ship, a skateboard, or a new type of car, composite materials are a great choice for creating something strong, lightweight, and long-lasting. So next time you see something made from carbon fiber or fiberglass, you'll know just how awesome composite materials really are!篇3Title: Amazing Composite MaterialsHey guys! Today I want to talk to you about something really cool - composite materials! Have you ever heard of them before? If not, don't worry, I'll explain everything to you.First of all, what are composite materials? Well, composite materials are made up of two or more different materials that are combined to make a new material. These materials have special properties that make them super strong, lightweight, and durable.One of the coolest things about composite materials is that they can be tailored to have specific properties. For example, some composite materials are super strong and are used to make things like airplanes and cars. Other composite materials are flexible and are used to make things like sports equipment and shoes.One of the most common types of composite materials is carbon fiber. Carbon fiber is made up of carbon atoms that are bonded together to form long, thin fibers. These fibers are then woven together to create a super strong and lightweight material that is used in all kinds of products.So, next time you see a cool sports car or a fancy airplane, remember that they are made using composite materials. Isn't that amazing? I hope you learned something new today. Thanks for listening!篇4Hey guys, do you know what composite materials are? They are super cool materials made by combining two or more different materials together. They are used in a lot of things we see every day, like airplanes, cars, sports equipment, and even buildings!Composite materials have some special properties that make them really awesome. For example, they are lightweight but super strong, so they are perfect for making things that need to be both durable and easy to move around. They are also resistant to heat and chemicals, so they can be used in all kinds of different environments.One cool thing about composite materials is that they can be designed to have specific properties. By changing the types of materials used and the way they are combined, engineers can create composites with different strengths, stiffness, and flexibility. This makes them really versatile and useful for all kinds of applications.There are lots of different types of composite materials, like carbon fiber, fiberglass, and Kevlar. Each type has its own unique properties and uses. For example, carbon fiber is super strong and lightweight, so it is often used in high-performance sports equipment and aerospace applications. Fiberglass is moreflexible and easy to mold, so it is commonly used in boat hulls and car bodies. And Kevlar is incredibly strong and resistant to impact, so it is often used in bulletproof vests and protective gear.In conclusion, composite materials are amazing materials that have revolutionized the way we design and build things. They are strong, lightweight, and versatile, making them ideal for a wide range of applications. So next time you see a cool sports car or high-tech gadget, remember that it might be made of composite materials!篇5Introduction to Composite MaterialsHey everyone! Today I want to talk to you about composite materials. Do you know what composite materials are? Well, let me tell you!Composite materials are materials made from two or more different types of materials. These materials are combined to create a new material that has better properties than the individual materials on their own. Pretty cool, right?There are many different types of composite materials. Some examples include fiberglass, carbon fiber, and Kevlar. These materials are used in a wide range of applications, from building materials to sports equipment to aerospace technology.One of the main advantages of composite materials is that they are strong and lightweight. This makes them perfect for use in things like airplanes, boats, and cars. Composite materials are also resistant to corrosion, which means they last longer than traditional materials.Another great thing about composite materials is that they can be designed to have specific properties. This means that engineers can tailor the material to meet the exact requirements of a particular application. Pretty cool, right?In conclusion, composite materials are a really important and versatile type of material. They are strong, lightweight, and can be customized to meet specific needs. So next time you see a cool sports car or a high-tech airplane, remember that it might be made from composite materials!篇6Composite materials are super cool! They are made by combining two or more different materials to create a newmaterial with amazing properties. There are many different types of composite materials, such as fiberglass, carbon fiber, and even Kevlar.One of the coolest things about composite materials is that they are super strong and lightweight. This makes them perfect for building things like airplanes, cars, and even sports equipment. For example, carbon fiber is often used to make high-performance bicycles because it is so light and strong.Another great thing about composite materials is that they can be molded into almost any shape. This allows manufacturers to create products that are not possible with traditional materials. For example, fiberglass can be molded into complex shapes, which is why it is often used to make boat hulls.Composite materials are also resistant to corrosion and can withstand harsh environmental conditions. This makes them ideal for outdoor applications, such as building materials for bridges or even wind turbine blades.In conclusion, composite materials are awesome because they are strong, lightweight, versatile, and durable. They are revolutionizing the way we build things and are sure to play a big role in the future of technology and innovation. So next time yousee something made of composite materials, remember how cool and special they are!篇7Hello everyone, today I am going to talk about composite materials. Composite materials are really cool and interesting because they are made up of two or more different materials. It's like having superpowers when you combine different things together!Composite materials are made by mixing materials like carbon fiber, fiberglass, or Kevlar with a liquid resin. The mixture is then put into a mold and shaped into whatever you want it to be. It's like making a cake but instead of flour and eggs, you're using cool stuff like carbon fiber!One awesome thing about composite materials is that they are super strong and lightweight. That's why they are used in things like airplanes, cars, and sports equipment. Imagine playing baseball with a bat made of composite materials - you could hit a home run every time!Another cool thing about composite materials is that they can be made to be really flexible or really stiff, depending onwhat you need them for. So you can have a surfboard that bends with the waves or a golf club that stays stiff when you hit the ball.In conclusion, composite materials are amazing because they are strong, lightweight, and versatile. They are the superheroes of materials! I hope you learned something new today about composite materials. Thanks for listening!篇8Title: All About Composite MaterialsHello everyone! Today I want to talk to you about composite materials. Do you know what composite materials are? Well, let me explain it to you in a simple way.Composite materials are made by combining two or more different materials to create a new material with enhanced properties. These materials are lightweight but strong, and they can be found in many things around us, like cars, airplanes, boats, and even sports equipment like tennis rackets and golf clubs.There are different types of composite materials, such as fiberglass, carbon fiber, and Kevlar. These materials are used in different ways depending on the properties needed for the finalproduct. For example, carbon fiber is very strong and lightweight, so it is often used in high-performance sports cars and bicycles.One of the great things about composite materials is that they can be customized to meet specific requirements. This means that manufacturers can create materials with the exact properties needed for a particular application.In conclusion, composite materials are amazing because they combine the best properties of different materials to create something new and improved. So, next time you see a cool sports car or a sleek airplane, remember that it's all thanks to composite materials!That's all for now. Thanks for listening!篇9Hi everyone, today I'm going to talk about composite materials. Composite materials are super cool because they are made up of two or more materials that have different properties. When you combine them together, you get a material that is stronger, lighter, or more durable than each of the individual materials on their own.One example of a composite material is fiberglass. It's made by combining glass fibers with a resin to create a strong and lightweight material that is often used in boats, cars, and even some sports equipment. Another example is carbon fiber, which is super strong and used in aerospace and high-performance sports equipment.Composite materials are used in so many different things because they have so many great properties. They can be made to be really strong, really light, resistant to heat or chemicals, and even flexible. That's why they're used in everything from buildings and bridges to cars and airplanes.So next time you see a cool sports car or a shiny airplane, remember that it's probably made with composite materials. They're the future of materials and are making our world stronger, lighter, and more awesome!篇10Title: Let's Talk about Composite MaterialsHey everyone! Today I want to talk about something super cool – composite materials! Have you ever heard of them before? Well, if you haven't, don't worry because I'm going to tell you all about them.So, composite materials are made up of two or more different kinds of materials that are combined together. These materials work together to create a new material that has properties that are different from the original materials. How cool is that?One example of a composite material is fiberglass. Fiberglass is made by combining glass fibers with a plastic resin. The glass fibers give the material strength and stiffness, while the plastic resin holds everything together. This makes fiberglass a super strong and lightweight material that is used in all kinds of things like boats, cars, and even surfboards!Another example of a composite material is carbon fiber. Carbon fiber is made by combining carbon fibers with a resin. This material is super strong and lightweight, making it perfect for things like airplanes and sports equipment.Composite materials are used in so many things because they are stronger, lighter, and more durable than traditional materials. They can also be designed to have specific properties, like being heat-resistant or waterproof.I think composite materials are really amazing because they show us how different materials can work together to create something totally new and awesome. So next time you seesomething made out of fiberglass or carbon fiber, remember that it's all thanks to composite materials!。

复合材料与工程英语介绍范文英文回答:Composite Materials in Engineering: A Comprehensive Overview.Introduction.Composite materials, often referred to as advanced materials, are gaining significant prominence in various engineering applications due to their unique combination of properties. These materials comprise two or more distinct phases or constituents, typically a reinforcing phase and a matrix phase. The reinforcing phase provides strength and stiffness, while the matrix phase holds the reinforcement together and transfers loads.Types and Properties.Composite materials encompass a wide range ofcombinations, with the most common types being fiber-reinforced composites, laminated composites, and polymer-matrix composites (PMCs). Fiber-reinforced composites, such as carbon fiber reinforced polymers (CFRPs), offer exceptional strength-to-weight ratios, stiffness, and thermal stability. Laminated composites, like fiberglass composites, combine multiple layers of material with different orientations, providing tailored mechanical and thermal properties. PMCs, such as glass-reinforced plastics (GRPs), exhibit high strength and durability, along with ease of fabrication.Applications.The versatility of composite materials has led to their adoption in numerous engineering sectors. In the aerospace industry, composites are prized for their lightweight and high strength-to-weight ratios, enabling the construction of lighter and more fuel-efficient aircraft. In the automotive industry, composites find applications in body panels, chassis components, and interior trims, offering improved strength, weight reduction, and corrosionresistance. In the construction industry, composites are used for structural elements such as beams, columns, and panels, providing superior strength, durability, andweather resistance.Advantages.Composite materials offer several advantages over traditional materials. Their high strength-to-weight ratio makes them lightweight and strong, allowing for efficient load-bearing applications. They possess excellent corrosion resistance, reducing the need for protective coatings and enhancing durability in harsh environments. Additionally, composites exhibit tailored mechanical and thermal properties, allowing engineers to optimize them forspecific applications.Challenges.Despite their numerous advantages, composite materials also face some challenges. One challenge lies in their cost, as they are typically more expensive to produce thantraditional materials. Another challenge is the difficultyin fabrication, as the manufacturing processes for composites require specialized equipment and expertise. Furthermore, the repair of composite structures can be complex and costly, necessitating advanced techniques and skilled technicians.Future Outlook.Composite materials continue to attract significant research and development efforts, driven by the demand for advanced and lightweight materials with tailored properties. Advancements in manufacturing technologies, such asadditive manufacturing and automated layup, are expected to reduce production costs and streamline fabrication. Additionally, the development of novel composite materials, including bio-based and self-healing composites, holds promise for sustainable and innovative applications.中文回答:复合材料在工程中的应用,全面综述。

复合材料专业英语Composite materials, also known as composite, are materials made from two or more constituent materials with significantly different physical or chemical properties. These materials when combined, produce a material with characteristics different from the individual components. Composite materials are widely used in various industries due to their high strength, lightweight, and corrosion resistance properties.One of the key advantages of composite materials istheir high strength-to-weight ratio. This means that composite materials can be much stronger than traditional materials such as metal or plastic, while still being lightweight. This makes them ideal for applications where weight is a critical factor, such as in aerospace and automotive industries.Another advantage of composite materials is their corrosion resistance. Unlike metals, which can corrode over time when exposed to moisture and other environmental factors, composite materials are generally more resistantto corrosion. This makes them suitable for use in harsh environments such as marine or chemical processing.Composite materials are also known for their versatility. By varying the types of materials used, the manufacturing process, and the design, composite materials can betailored to specific applications. This allows for the creation of materials with unique properties and characteristics that are not possible with traditional materials.In terms of applications, composite materials are usedin a wide range of industries including aerospace, automotive, construction, marine, and sports equipment. In aerospace, composite materials are used to make lightweight and strong aircraft components, reducing fuel consumption and increasing efficiency. In automotive, compositematerials are used to make body panels, reducing weight and improving fuel efficiency. In construction, composite materials are used to make beams, columns, and other structural elements, increasing strength and durability.Overall, composite materials offer a wide range of advantages and applications, making them a popular choicefor many industries. As technology advances and new materials are developed, the use of composite materials is expected to continue to grow.复合材料,也称为复合材料,是由两种或更多具有显著不同物理或化学性质的成分材料制成的材料。

复合材料英语(共5则)第一篇:复合材料英语复合材料英语复合材料专业术语高性能的长纤维增强热塑性复合材料:(LF(R)T)Long Fiber Reinforced Thermoplastics 玻璃纤维毡增强热塑性复合材料:(GMT)Glass Mat Reinforced Thermoplastics 短玻纤热塑性颗粒材料:(LFT-G)Long-Fiber Reinforce Thermoplastic Granules 长纤维增强热塑性复合材料:(LFT-D)Long-Fiber Reinforce Thermoplastic Direct 玻纤:Glass Fiber玄武岩纤维:Basalt Fibre(BF)碳纤维:CFRP芳纶纤维:AFRP(Aramid Fiber)添加剂:Additive树脂传递模塑成型:(RTM)Resin Transfer Molding 热压罐:autoclave热压罐成型:autoclave moulding热塑性复合材料缠绕成型:filament winding of thermoplastic composite 热塑性复合材料滚压成型:roll forming of thermoplastic composite 热塑性复合材料拉挤成型:pultrusion of thermoplastic composite 热塑性复合材料热压罐/真空成型:thermoforming of thermoplastic composite 热塑性复合材料液压成型:hydroforming of thermoplastic composite 热塑性复合材料隔膜成型:diaphragm forming of thermoplastic composite 离心浇注成型:centrifugal casting moulding泡沫贮树脂成型:foam reserve resin moulding 环氧树脂基复合材料:epoxy resin matrix composite 聚氨酯树脂基复合材料:polyurethane resin matrix composite 热塑性树脂基复合材料:thermoplastic resin matrix composite 玻璃纤维增强树脂基复合材料:glass fiber reinforced resin matrix composite 碳纤维增强树脂基复合材料:carbon fiber reinforced resin matrix composite 芳纶增强树脂基复合材料:aramid fiber reinforced resin matrix composite 混杂纤维增强树脂基复合材料:hybrid fiber reinforced resin matrix composite 树脂基复合材料层压板:resin matrix composite laminate 树脂基纤维层压板:resin matrix fiber laminate树脂基纸层压板:resin matrix paper laminate 树脂基布层压板:resin matrix cloth laminate树脂基木质层压板:resin matrix wood laminate 纤维增强金属层压板:fiber reinforced metallaminate 吸胶材料:bleeding materials;bleeder脱模布:release cloth 喷射成型:spray-up moulding纤维缠绕成型:filament winding 压机模压成型:press moulding拉挤成型:pultrusion process 预压时间:dwelling time预吸胶:debulking固化:curing 加压时机:pressure applying opportunity固化周期:curing cycle 固化温度:curing temperature脱模剂:mold release agent一、玻璃纤维:GFRP 空心纤维:hollow fiber非织造物:nonwovens, nonwoven fabric 毡:mat连续原丝毡:continuous strand mat, continuous filament mat 短切原丝毡:chopped strand mat 干切原丝:dry chopped strands 湿切原丝:wet chopped strands复合毡:combination mat薄毡:veil,tissue织物:fabric 机织物:woven fabric电子布:electronic fabric, PCB cloth 无捻粗纱布/方格布:roving cloth, woven rovings 机织带:woven tape 编织物:braided fabric单向布:unidirectional fabric, UD 网布:mesh fabric, scrim非织造网布:nonwoven scrim, laid scrim陶瓷加工:ceramic processing表格:tabulation氧化铝陶瓷管:alumina tube 有机物:organics化学品安全说明书:material safety data sheets(MSDS)天然橡胶:nature rubber碳黑:carbon black颗粒:particle 中大颗粒增强复合材料:large-particle reinforced composites 弥散强化复合材料:dispersion-strengthened composites 原子或分子水平:atomic or molecular level增强机理:mechanism of reinforcement直径:diameter 晶须:whiskers单晶:single crystals硼:boron 多晶或非晶体材料:polycrystalline or amorphous material 片状结构:laminar composites夹层结构:sandwich panels 低密度:less-dense硬度:stiffness强度:strength 延展性:ductility 冲击强度:impact resistance 断裂韧性:fracture toughness 拉伸:tension压缩:compression脆性材料:brittle material 延性材料:ductile material弹性材料:elastic material 拉伸试验:tensile test树脂:resin增强体:reinforcement 耐磨性:abrasion resistance陶瓷加工:ceramic processing表格:tabulation氧化铝陶瓷管:alumina tube 有机物:organics化学品安全说明书:material safety data sheets(MSDS)天然橡胶:nature rubber碳黑:carbon black颗粒:particle 中大颗粒增强复合材料:large-particle reinforced composites 弥散强化复合材料:dispersion-strengthened composites 原子或分子水平:atomic or molecular level增强机理:mechanism of reinforcement直径:diameter 晶须:whiskers单晶:single crystals硼:boron 多晶或非晶体材料:polycrystalline or amorphous material 片状结构:laminar composites夹层结构:sandwich panels 低密度:less-dense硬度:stiffness强度:strength 延展性:ductility 冲击强度:impact resistance 断裂韧性:fracture toughness 拉伸:tension压缩:compression脆性材料:brittle material 延性材料:ductile material弹性材料:elastic material 拉伸试验:tensile test树脂:resin增强体:reinforcement 耐磨性:abrasion resistanceAcetyl||乙酰Acid-proof paint||耐酸涂料, 耐酸油漆 Acrylic fiber||丙烯酸纤维Acrylic resin||丙烯酸树脂 Active filler||活性填料 Adapter assembly||接头组件 Addition polyimide||加成型聚酰亚胺 Addition polymer||加聚物 Adjusting valve||调整阀,调节阀 Adhersion assembly||粘合装配Adhersion bond||胶结Adjustable-bed press||工作台可调式压力机Adjuster shim||调整垫片Adjusting accuracy||调整精度,调校精度Admissible error||容许误差 Admissible load||容许载荷 Adsorbed layer||吸附层Advanced composite material||先进复合材料,高级复合材料Advanced development vehicle||试制车,预研样车AE(Automobile Engineering)||汽车工程技术 Aeolotropic material||各向异性材料Aerated plastics||泡沫塑料, 多孔塑料Aerodynamic body||流线型车身 Aft cross member||底盘/车架后横梁 Air bleeder||排气孔 Air clamp||气动夹具Air deflector||导流板;导风板,气流偏转板Air intake manifold||进气歧管 Air servo||伺服气泵 Air-tight joint||气密接头 All-plastic molded||全塑模注的All polyster seat||全聚酯座椅Alligatoring||龟裂,涂膜皱皮,表面裂痕Amino resin||氨基树脂Angular test||挠曲试验Anti-chipping primer||抗破裂底漆(底层涂料)Apron||防护挡板Aramid fibre composites||芳胺纤维复合材料Assembly drawing||装配图 Assembly jig||装配夹具 Assembly part||装配件,组合件 Autoclave forming||热压罐成型 Autocorrection||自动校正Automatic compensation||自动补偿 Automatic feed||自动进料Automobile instrument||汽车仪表板Automotive transmission||汽车传动装置,汽车变速器Auxiliary fasia console||副仪表板Axial strain||轴向应变Axle bushing||轴衬Axle fairing||底盘车桥整流罩A Stage||A 阶段(某些热固性树脂聚合作用的初期阶段)AAC(Auxiliary Air Control)||辅助空气控制ABC(Active Body Control)||主动式车身控制装置 Abherent||阻粘剂Ability meter||测力计,性能测试仪ABL(Ablative)||烧蚀剂Ablation||烧蚀Ablative composite material||烧蚀复合材料 Ablative insulative material||烧蚀绝热材料Ablative polymer||烧蚀聚合物Ablative prepreg||烧蚀性预浸料Ablative resistance||耐烧蚀性ABR(Acrylate Butadience Rubber)||丙烯酸丁二烯橡胶Abradant material||研磨材料,磨料 Abrade||研磨;用喷砂清理Abrasion||磨耗Abrasion coefficient||磨耗系数Abrasion loss||磨耗量,磨损量Abrasion performance||磨耗性 Abrasion-proof material||耐磨材料Abrasion resistant paint||耐磨涂料 Abrasion test||磨损试验Abrasive blast system||喷砂清理系统 Abrasive cloth||砂布Abrasive disc||砂轮盘,砂轮片Abrasive finishing||抛光Abrasive paper||砂纸 Abrasive resistance||耐磨性ABS(Acrylonitrile Butadiene Styrene)resin||ABS树脂,丙烯腈-丁二烯-苯乙烯(热塑性)树脂ABSM(American Bureau of Standard Materials)||美国标准材料局Absolute dynamic modulus||绝对动态模量 Absolute error||绝对误差Absorbent material||吸收性材料,吸收性物质,吸声材料,吸收剂Absorber||减振器,阻尼器,缓冲器ACA(Automotive Composite Alliance)||汽车复合材料协会ACC(Automatic Clutch Control)||自动离合器操纵控制Accelerant||促进剂,加速剂Accelerated aging test||加速老化试验,人工老化试验Accelerator pedal shaft||加速踏板轴 Accelerator pump nozzle||加速泵喷嘴 Acceptable life||有效使用寿命Acceptance test specification||验收测试规范 Access panel||罩板,盖板Accessory||配件,附属品Accessory equipment||辅助设备Accessory kit||附件包,成套附件 Accumulator can||储电池外壳Accumulator package||蓄压器组件,蓄压器单元Accuracy in calibration||校准精度 Accuracy of finish||最终加工精度 Accuracy ofmanufacture||制造精度 Accuracy of positioning||定位精度Accuracy of repetition||重现精度,复制精度Acetal matrix composites||缩醛树脂基复合材料Acetal plastic||缩醛塑料,聚甲醛塑料 Acetal resin||缩醛树脂 Acetamide||乙酰胺Acetate fiber||醋酸纤维,乙酸纤维 Acetone||丙酮Back corner panel||后围角板Back panel||后围板Back side panel||后侧板 Back wall pillar||后围立柱 Backer||衬料Baffler||挡板,阻尼器;导流叶片Bag Molding||气囊施压成型(袋模法)Baggage holder||行李架Barrier coat||阻挡层;防渗涂层Batch mixing||分批混合,批混 Batching unit||分批加料装置 Bearing assembly||轴承组合件Biaxial winding||双角缠绕, 双轴缠绕Binder fiber||粘合纤维 Bipolymer||二元共聚物Bismaleimide composites||双马来酰亚胺复合材料Blank placement||坯料的放置 Blanket||玻璃纤维毡;坯料Blanking press||冲压机, 冲割压力机 Blending resin||掺合树脂BMC(Bulk Moulding Compound)||团状膜塑料BMI(Bismaleimide)||双马来酰亚胺 Body back panel||车身后板 Body back wall||车身驾驶室后围 Body bracket||车身支架Body control module||车身控制模块Body frame(Body skeleton)||车身骨架 Body front panel||车身驾驶室前围板Body monocoque||单壳体车身,单壳式结构车身Body outer panel||驾驶室覆盖件;驾驶室覆盖件 Body structural member||车身结构件 Body trim||车身装饰件Bonded riveted structure||胶铆结构 Bonnet||发动机罩Brake||制动器Brake arrangement||制动装置Brinell hardness test||布氏硬度试验 Brittle coating||脆性涂层 Bulk coat||整体涂层Bulk heat treatment||整体热处理Bulk moulding compound||(增强塑料)预制整体模塑料Bumper bracket(holder)||保险杠托架 Bus brake system||客车制动系Butt flange||对接法兰Butt joint||对接接头;对接Butterfly valve||节流阀,节气门BWI(Body In White)||白车身Cab deflector shield||驾驶室导流板 Cab fairing||驾驶室整流罩 Cab floor||驾驶室地板 Cab mounting||驾驶室悬置CAD(Computer Aided Design)||计算机辅助设计CAE(Computer Aided Engineering)||计算机辅助工程设计Calibration tolerance||校准公差Calibrating instrument||校准仪表Camouflage paint||覆面漆, 盖面涂料, 伪假漆 Cantilever beam impact test||悬臂梁冲击试验Carbon-felt reinforced carbon composites||碳毡增强碳复合材料Carbon fiber clutch||碳纤维离合器 Carbon filament cloth||碳丝织物Case extension||外壳的伸出部分,延伸外壳Casing gasket||外壳密封垫Catalyst manifold||固化剂总成Catalyst pump||固化剂泵Catalyst ratio||固化剂比率Cavity||模槽,型腔;凹模Cavity block||阴模 Cavity depth||模槽深度Cellular board||蜂窝状板,多孔板 Cellular plastics||泡沫塑料,多孔塑料 Centre boss||轮毂Centre pin||销轴,枢轴,主销Centrifugal casting moulding||离心浇铸成型Centrosymmetry||中心对称层板Ceramic matrix composites||陶瓷基复合材料 Charge||填充气体,填充料 Chasis||底盘;机壳,车架Chlorinated polyethlene||聚氯乙烯 Chopped fiber||短切纤维Chopped random mat||短切无序毡 Chopped strand||短切原丝CIRTM(Co-Injection RTM)||共注射RTM Clamping fixture||夹具,夹紧装置Clamping force||夹持力,合模力Class A surface||A级表面Clear coat||透明涂层,透明罩漆,清漆层 Clear coat finish||清漆涂层 Clicker die||冲模Climb milling||同向铣削, 顺铣Clipping press||切边压力机Closure pressing speed||合模速度CMM(Closed Mould Moulding)||闭合模塑 CMT(Compression Molding||挤压成型工艺CNC(Computerized Numerical Control)||电脑数值控制Coarse grinding||粗磨,用砂轮初加工Coating defect||涂层缺陷Collision test||碰撞试验,撞车试验Combination property||综合性能Concept design||概念设计Convection modulus||对流模量Convergence test||收敛试验Cooling fixture||冷却夹具Cooling tower||冷却塔 Crazing||龟裂,细裂纹 Cresol resin||甲酚树脂 Cutting felt||毡的剪切Cutting-off bushing||环形下料模;下料环 Damped structure||阻尼缓冲结构 Damper bracket||件振器支架 Dashboard illumination||仪表板照明 Dash trimming||前围板衬板 Deburring||去毛刺,倒角,除飞边Deepdrawing forming||深拉成型Deflection test||挠曲试验Dent resistance||耐冲击性Design freedom||设计自由度Detail drawing||祥图,零件图 Die assembly||压模装置Die casting||压模铸件,压模铸法 Dimethyl fomamide||二甲基甲酰胺Dimethyl ketone||二甲基甲酮;丙酮Dip pretreatment||浸渍预处理 Die prime coat||浸渍打底漆 Dimensional stability||尺寸稳定性Dip coating||浸涂 Dip forming||浸渍成型Durability testing||耐久性试验,寿命试验Dwell||保压,暂停加压;滞留时间 Dynamometer||测力计Edge effect||边缘效应,边界效应Edge feed||边缘进料Edge gate||侧浇口 Ejection force||脱模力 Ejector||起模杆Ejector guide pillar||推板导套Ejector housing||支架Elasticizer||增塑剂Elastomeric composites||高弹体复合材料 Elongation at break||断裂延伸率 Energy absorbing foam||吸能泡沫塑料 Epoxy resin||环氧树脂 Ether ketone||酮醚 Explosion proof||防爆Exterior body panelling||车身外板部蒙皮 Exterior trim||外饰,外饰件 Fabric composites||织物复合材料 Fabric impregnation||织物浸渍Fabric preform||织物预成型Fabric prereg||织物预浸料Fabrication parameter||制造参数Fabrication procedure||制造工序Fabricating machinery||加工设备Face plate coupling||法兰式连接Factory primer||工厂底漆,工厂防锈漆Fairing||整流罩,整流装置Fairing panel||前裙板 Fascia bracket||仪表板支架 Fascia mask||仪表板罩板Fastening clamp||夹紧装置,紧固夹子 Fatigue tension test||拉伸疲劳性试验FCM(Fibrous Composite material)||纤维复合材料FEA(Finite Element Anlysis)||有限元分析Feed system||供料系统 Feeding pump||供给泵 Feeding speed||进给速度Female groove||凹模Female mould(tooling)||阴模Fender||翼子板;护板 Fender apron||挡泥板Fender inner panel||翼子板内衬护板Fiber composite laminate||纤维复合材料层板 Fiber mat layer||纤维毡层Finisher(Finishing component)||装饰件 Flange||法兰, 凸缘Flange fitting||法兰式管接头 Flash||毛边Flash mold||毛边模具Front sheet metal||车前板制件 Fuselage fairing||机身整流装置Gage kit||仪表组,仪表套件 Gas cavity||气泡,砂眼 Gauge panel||仪表板Gear assembly||齿轮传动装置, 减速器 Gearbox cover||变速器壳盖Gear bracket support||齿轮托支架Gel coat||胶衣,凝胶涂层Gel coat drum||胶衣圆桶Gel coat flow monitor||胶衣流量监控器 Gel time||凝胶时间Glass fiber winding machine||玻璃纤维缠绕机 Glass wool||玻璃棉Glass yarn||玻璃丝Guiding device||导向装置Gunk||预混料Gusset||角撑件Gutter channel||流水槽Hand lay-up ||手工铺叠,手工铺贴 Hardness testing machine||硬度测试仪 Hauling truck||拖车Header board outside panel||前板外板 Headrest||靠枕Heat barrier material||隔热材料 Heat forming||热成型High molecular material||高分子材料High pressure bag molding||高压袋成型工艺 High pressure injection moulding||高压注射成型,高压注射模塑High-strength structural adhesives||高强度结构粘合剂此资源来自:由FanE『翻译中国』http;//整理。