电动叉车设备操作说明书

- 格式:doc

- 大小:623.00 KB

- 文档页数:2

电动叉车安全操作规程和维护保养电动叉车是一种广泛应用于仓储物流领域的搬运设备,具有灵活、高效、环保等优点。

为确保电动叉车的安全性能和工作效率,以及延长其使用寿命,必须遵守相关的操作规程和进行定期的维护保养。

下面将详细介绍电动叉车的安全操作规程和维护保养。

一、安全操作规程1. 熟悉电动叉车的使用说明书:在使用电动叉车之前,必须仔细阅读使用说明书,并按照说明书的要求进行操作。

2. 穿戴防护装备:使用电动叉车时,必须穿戴符合安全要求的防护装备,包括安全帽、防护鞋、防护眼镜等。

3. 检查车辆状态:在每次使用电动叉车之前,应检查车辆的状态,包括轮胎气压、制动系统、驾驶室、仪表、灯具等。

4. 注意载荷的重心和稳定性:在搬运物品时,必须注意载荷的重心和稳定性,确保物品不会倾斜或掉落。

5. 低速行驶:在操作电动叉车时,应低速行驶,不得超速行驶或急转弯,以防止意外事故的发生。

6. 注意行车道和指示标志:在仓库内行驶时,必须遵守行车道和指示标志,不得乱行乱停,确保安全通行。

7. 注意行人和其他车辆:在行车过程中,必须特别注意行人和其他车辆的存在,避免与其发生碰撞事故。

8. 定期维护保养:定期对电动叉车进行维护保养,包括清洁车身、润滑部件、检查电池情况等,确保车辆的正常运行。

9. 停车时注意安全:在停车时,必须选择平稳的停车场地,将车辆熄火并拉起手刹,锁好车门,以防止车辆滑移或他人非法操作。

10. 远离危险区域:在操作电动叉车时,必须尽量远离危险区域,如边缘、斜坡、悬崖、化学品存储区等。

二、维护保养1. 清洁车身:定期清洁电动叉车的车身,包括外壳、制动器、轮胎等,以减少灰尘和腐蚀物对车辆的损害。

2. 检查液位:定期检查电动叉车的液位,包括润滑油、制动液、冷却液等,补充不足及时更换。

3. 检查电池情况:定期检查电池的情况,包括电解液的液位、充电状态等,确保电池正常运行。

4. 润滑部件:定期对电动叉车的润滑部件进行润滑,包括轮轴、传动轴、传动链等,保持其正常运转并减少磨损。

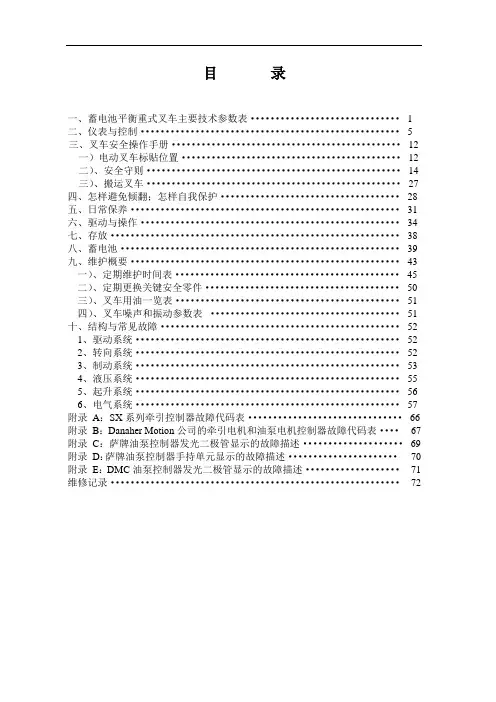

目录一、蓄电池平衡重式叉车主要技术参数表 (1)二、仪表与控制 (5)三、叉车安全操作手册 (12)一)电动叉车标贴位置 (12)二)、安全守则 (14)三)、搬运叉车 (27)四、怎样避免倾翻;怎样自我保护 (28)五、日常保养 (31)六、驱动与操作 (34)七、存放 (38)八、蓄电池 (39)九、维护概要 (43)一)、定期维护时间表 (45)二)、定期更换关键安全零件 (50)三)、叉车用油一览表 (51)四)、叉车噪声和振动参数表 (51)十、结构与常见故障 (52)1、驱动系统 (52)2、转向系统 (52)3、制动系统 (53)4、液压系统 (55)5、起升系统 (56)6、电气系统 (57)附录A:SX系列牵引控制器故障代码表 (66)附录B:Danaher Motion公司的牵引电机和油泵电机控制器故障代码表 (67)附录C:萨牌油泵控制器发光二极管显示的故障描述 (69)附录D:萨牌油泵控制器手持单元显示的故障描述 (70)附录E:DMC油泵控制器发光二极管显示的故障描述 (71)维修记录 (72)一、蓄电池平衡重式叉车主要技术参数表(1)FE4F16~18(AC)系列四轮前桥驱动蓄电池平衡重式叉车特性1.2 型号FE4F16 FE4F16AC FE4F18 FE4F18AC(2)、FE3R16AC 后轮驱动三支点蓄电池平衡重式叉车1.3 驱动方式: 电动 电动 1.4 操作方式:座驾式 座驾式 1.5 额定荷载能力 Q(公斤) 1600 1750 1.6 荷载中心距 C(毫米) 500 500 1.8 前悬距 x(毫米) 410 410 1.9 轴距 y(毫米)1250 1250重 量2.1 含蓄电池(参见6.5)时自重 公斤 2996 3006 30763086 2.2 满载时桥负载,前/后 公斤3996/5004004/5024356/5204364/5222.3 空载时桥负载,前/后 公斤 1196/1800 1200/1806 1220/1856 1224/1862 车体 轮子3.1 前轮规格 6.50-10-10PR 6.50-10-10PR 3.2后轮规格5.00-8-8PR5.00-8-8PR3.6 前轮轮距 b 10(毫米) 890 890 3.7 后轮轮距 b 11(毫米) 920 920 基 本 尺 寸4.1 门架/货叉架倾仰角底,前倾/后倾 α/β(°) 6/12 6/12 4.2 门架缩回高度 h 1(毫米) 1995 1995 4.3 自由提升高度 h 2(毫米) 150 150 4.4 提升高度 h 3(毫米) 3000 3000 4.5 门架伸展高度 h 4(毫米) 3918 3918 4.7 护顶架高度 h 6(毫米) 2110 2110 4.8 座位高度 h 7(毫米) 1060 1060 4.12 牵引销高度 h 10(毫米) 350 350 4.19 总长 l 1(毫米) 2960 2960 4.20 车体长度(不含货叉) l 2(毫米) 2010 2010 4.21 总宽 b 1(毫米) 1070 1070 4.22 货叉尺寸 s/e/l(毫米) 40×100×95040×100×9504.24 货叉架宽度 b 3(毫米) 920 920 4.32 轴距中心离地间隙 m 2(毫米) 130 130 4.33 工作通道,1000×1200(跨货叉放置)托 Ast(毫米) 3525 3525 4.35 转弯半径 Wa(毫米) 19001900性能参数5.1 行驶速度,满/空载 公里/小时 14/1315/1314/12.515/135.2 提升速度,满/空载 米/秒 0.27/0.37 0.25/0.37 5.3 下降速度,满/空载 米/秒 0.35/0.42 0.33/0.42 5.7 爬坡能力,满/空载S 2 30分钟 % 6/9 5.5/8.5 5.8 最大爬坡能力,满/空载S 2 5分钟 % 10/189.5/17 电 机 6.1驱动电机功率 S 2 60 min 千瓦586.386.2 提升电机功率 S 3 15% 千瓦7.5 7.5 6.4 蓄电池电压/额定容量K 5 伏/安培小时 48/400 48/400 6.5 蓄电池重量 公斤 650 650 其 它8.2 属具工作压力 兆帕 14.5 14.5 8.3 属具油量 升/分钟 30 30 8.4 驾驶员耳边噪音水平,根据 EN 12 053 分贝70708.3 属具油量升/分钟108.4 驾驶员耳边噪音水平,根据 EN 12 053 分贝65二、仪表与控制1、FE4F16-18(AC)系列1.制动踏板2.手制动操纵杆3.换向操纵杆4.方向盘5.喇叭按钮6.仪表显示器7.钥匙开关 8.升降操纵杆9.倾斜操纵杆 10.组合开关11.紧急按钮 12.加速踏板2、FE3R16AC1.喇叭按钮2.加制动液盖3.制动踏板4.手制动操纵杆5.换向操纵杆6.方向盘7.钥匙开关 8.组合开关9.仪表显示器 10.加速踏板11.升降操纵杆 12.倾斜操纵杆13.属具操纵杆一)、组合仪表㈠直流仪表(FE4F16/FE4F18)1 —左转灯指示2 —大灯指示3 —小灯指示4 —未用5 —未用6 —手刹指示7 —右转指示8 —蓄电池电量不足指示9 —错误代码/蓄电池电量百分比10 —蓄电池电量足指示11 —维修指示12 —等待指示13 —电池电压㈡交流仪表(FE4F16AC/FE4F18AC/FE3R16AC)A —通讯指示灯B —故障指示灯C —低电量报警灯D —限速指示灯E —加速指示灯F —手刹指示灯G —进入菜单按钮H —限速按钮I —加速度切换按钮J —向左选择按钮K —向右选择按钮L —查看按钮M —液晶显示屏钥匙开关钥匙开关有开/关,将换向操纵杆置中位,放松加速踏板,然后将钥匙顺时针转到“开”位置。

林德h18叉车说明书

林德叉车的启动步骤如下:

1. 确保叉车处于停车状态,手刹和换挡杆在空挡位置。

2. 检查油箱油量和电池电量,确认充足。

3. 拉动油门杆至怠速位置。

4. 打开钥匙开关,待指示灯亮起。

5. 按下踏板型刹车,同时踩下离合器,发动机启动。

6. 叉车启动后,将油门杆缓慢推至正常工作位置。

7. 等发动机预热一段时间后,叉车即可正常工作。

林德电动叉车新手入门教程:

1. 学习叉车基础知识:在使用叉车之前,您需要了解叉车的基础知识,如叉车的各个部分、工作原理、安全操作和维护等。

2. 熟悉叉车控制器:电动叉车的控制器是叉车的大脑,您需要学习如何正确地使用控制器来控制叉车的方向、速度和升降高度等。

3. 学习如何正确地驾驶叉车:在驾驶叉车时,您需要注意安全,包括行驶速度、方向控制、转弯半径和避让障碍物等。

4. 熟悉叉车的防护装置:叉车配备了各种安全防护装置,如紧急停车装置、安全带和警示器等,您需要熟悉这些装置的使用方法。

5. 掌握叉车的维护和保养:正确的维护和保养是确保叉车长期稳定运行的关键,您需要学习如何定期检查叉车的各个部分、更换损坏的部件和清洁叉车等。

电动叉车司机安全技术操作规程一、入职前培训1. 参加由公司安排的电动叉车驾驶培训课程,学习叉车的基本理论知识、操作技能和安全注意事项。

2. 熟悉公司的电动叉车操作规程和安全管理制度,了解个人责任和义务。

二、装载与卸载货物1. 在装载货物前,确认货物的尺寸、重量和稳定性,确保货物可以安全、平稳地装载到叉车上。

2. 调整叉车的叉臂或货叉,使其与货物匹配并保持水平,确保货物不会倾斜或掉落。

3. 在装载或卸载过程中,确保货物安全放置在叉车上,不得超出叉车的载重能力。

4. 使用叉车的倾斜功能(如果有的话)时,谨慎操作,确保货物平稳地倾斜或倾倒。

三、行驶与转弯1. 在行驶前,检查并确保电动叉车的刹车、转向和灯光等功能正常工作。

2. 遵守交通规则,行驶时保持适当的车速,不得超速行驶或急加速、急刹车。

3. 在叉车前进时,注意观察前方和周围的环境,确保道路畅通,避免与其他车辆、行人或障碍物发生碰撞。

4. 在转弯时,减速并给其他车辆、行人让路,确保安全通过。

注意观察后方和盲区,防止意外发生。

四、堆垛与取货1. 在堆垛前,检查并确保堆垛区域的平整度和稳定性,确保堆垛物料的安全。

2. 在堆垛或卸下物料时,确保叉车的车厢保持稳定,以防物料倾斜或掉落。

3. 在堆垛或取货时,仔细操作叉车的上升、下降、前后倾斜等功能,确保货物安全地放置或取下。

4. 注意堆垛物料的高度和重量,确保叉车不会超出其额定载重能力,并避免超高堆垛。

五、维护与保养1. 定期检查电动叉车的轮胎、制动系统、转向系统、电池和充电设备等关键部件,及时发现并修复故障。

2. 定期清洁叉车的外观和机械部件,保持叉车的良好状态,防止灰尘、污垢等影响操作安全和性能。

3. 定期给叉车添加润滑油和润滑剂,并保持关键部件的润滑状态,以减少磨损和故障。

六、应急预案与安全意识1. 在紧急情况下,立即停车并采取适当措施,保证自身和他人的安全。

2. 掌握灭火器的使用方法,并知道紧急疏散通道和集合点的位置。

工贸企业电瓶叉车安全操作规程范文一、前言电瓶叉车是一种常用的工业装卸设备,广泛应用于仓库、物流和生产线等场所。

为了保障工作人员和设备的安全,制定并严格执行电瓶叉车安全操作规程至关重要。

本文将详细介绍电瓶叉车的安全操作规程,以便工贸企业能够有针对性地管理和操作该设备。

二、电瓶叉车操作人员的要求1. 必须经过电瓶叉车操作培训,并持有相应的操作证件;2. 操作人员必须具备良好的身体素质和健康状况,能够承受长时间的工作强度;3. 操作人员必须具备良好的心理素质,能够冷静应对突发事件。

三、电瓶叉车的日常检查1. 在每天工作开始前,操作人员必须对电瓶叉车进行日常检查;2. 检查项目包括:轮胎气压、制动系统、转向系统、灯光和信号系统等;3. 若发现任何异常或故障,操作人员必须立即停止使用,并通知维修人员进行修理。

四、电瓶叉车的操作准则1. 在操作前,操作人员必须穿戴好安全防护装备,包括头盔、安全鞋、手套等;2. 在操作过程中,必须保持身体平衡,时刻注意叉车的倾斜情况;3. 操作人员必须保持专注,不可分心或进行嬉闹行为;4. 在操作过程中,必须遵循交通规则,不可超速行驶或闯红灯;5. 在行驶过程中,遇到行人或其他障碍物时,必须及时减速或停车,并保持一定的安全距离;6. 在装卸货物时,必须保证货物的稳定性,防止货物掉落或损坏;7. 在操作结束后,必须将电瓶叉车停在指定的停车位置,并及时关闭电源。

五、电瓶叉车的维护保养1. 定期检查电瓶叉车的电池情况,包括电量、电压和电解液等;2. 经常清洁电瓶叉车的外部和内部零部件,确保其正常运行;3. 定期检查车辆的润滑油和液压油,必要时进行更换;4. 在可能的情况下,应经常对电瓶叉车进行维修和保养,确保其正常运行;5. 若发现任何异常或故障,必须立即停止使用,并通知维修人员进行修理。

六、应急处理措施1. 在使用电瓶叉车过程中,若发生意外事故,操作人员必须保持冷静,迅速切断电源,并通知相关人员;2. 在使用电瓶叉车过程中,若发生火灾,操作人员必须迅速带领其他人员撤离现场,并通知消防部门;3. 在使用电瓶叉车过程中,若发生泄漏或溢出现象,操作人员必须立即停止使用,并采取相应的环保措施,防止污染环境。

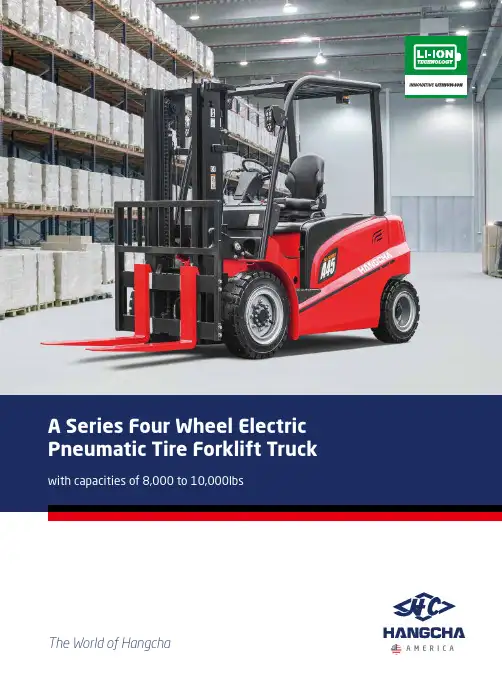

HANGCHA provides Li-Ion battery (LiFePO4) with 10 years or 20000 hours warranty.AppearanceIt follows the entire profile of appearance of A series, with clear lines on side of the truck, and smooth transition to counter weight. These lines are shaped as an integral whole, with powerful visual tension./High PerformanceElectromagnetic brake is used as service brake, instead of traditional hand brake, which realizes intelligent parking brake, with lower labor intensity of the operator, and higher safety.Soft landing system lowers descending speed automatically when fork reaches the height range of 3.9-2.4” from the ground, so as to reduce vibration of the entire truck, and provide e ective protection for goods.Full AC configuration includes AC traction motor + AC pump motor; With higher performance of entire truck, and longer battery life.E cient driving control system of high-frequency MOSFET integratedcontroller guarantees smooth and accurate control on driving and lifting, superior speed regulation performance, with regenerative braking, reverse braking,anti-slipping on slope and other functions, resulting in more e cient, safer, and more comfortable operations.The application of load sensing hydraulic power steering technology realizes reliable, sensitive, and easy steering; distribution of optimized oil in steering oil circuit and working oil circuit increases e ciency of hydraulic system.LED lights for entire truck reduce energy consumption.//////MaintenanceFully-openable cover enables easy maintenance of battery.Easy-to-open airtight cover plate realizes easier debugging and maintenance of electric control system, and avoids the system from invasion of rain and dust.The brushless, maintenance-free AC drive motor reduces operation cost significantly.The option of side roll out battery is very convenient for fast, e cient, and safe replacement of battery, and is suitable for continuous work conditions.////StabilityThe internationally advanced parallelarrangement is adopted for traction motor, and the battery is sunken to chassis,resulting in lower gravity center and better stability of entire truck.Flexible steering system, with smaller turning radius, allows stable turnaround within confined passageway.//ComfortThe adjustable, small-diameter steering wheel with tilt designed based onergonomics o ers good hand feeling, and the seat can also be adjusted forward and backward, which can provide best driving position for the operator.Head-up display are applied to increase visibility, operability of meters, thus with higher driving safety.Silent running of entire truck, with extremely small vibration, o ers more comfortable acoustical environment for the operator.Integrated control valve makes levers be placed at the most comfortable position for hands, resulting in lower labor intensity of the operator.////Reliability & SafetyMajor electrical components such as motor controller, contactor, power plug, and emergency power o switch are all of foreign famous brands.Major load bearing parts such as carriage, drive axle, steering axle, and mast are all designed with high strength to satisfy high-strength work conditions.As a standard configuration, the emergency power o switch complies with European safety standards.Dual overload protection systems ofelectronic and hydraulic modes are adopted.////8000lbs A Series Mast SpecificationA Series Four Wheel Electric Pneumatic Tire Forklift TruckAC4: meansCURTIS AC traveling system with AC Pump system, full-AC systemD i s t i n g u i s h i n g m a r kW e i g h tT y r e s , c h a s s i sD i m e n s i o n sP e r f o r m a n c e D a t aA d d i t i o n d a t aE l e c t r i c -e n g i n eHANGCHA GROUP CO.,LTD.Manufacturer (abbreviation)HCFA ModelManufacturers type designationDrive: electric (battery or mains), diesel, petrol, fuel gas Operator type: sit-down Load capacity/rated load Load centre distanceLoad distance, centre of drive axle to fork Wheelbase Service WeightAxle loading, laden front/rear Axle loading, unladen front/rearTyres: solid rubber, superelastic, pneumatic, polyurethane Tyre size, front Tyre size, rearWheels, number front rear (x = driven wheels)Tread, front Tread, rearTilt of mast/fork carriage forward/backward Height, mast lowered Free lift LiftHeight, mast extended Height of overhead guard STD.Seat height/stand height Coupling height Overall length Length to face of forks Overall width Fork dimensionsFork carriage DIN 15 173 --- ISO 2328, class/type A,B Fork-carriage width Distance between fork-arms Ground clearance, laden, below mast Ground clearance, centre of wheelbase Aisle width for pallets 39.4 x 47.2 crossways Aisle width for pallets 31.5 x 47.2 crossways Turning radius Internal turning radius Travel speed, laden/unladen Lift speed, laden/unladen Lowering speed, laden/unladen Drawbar pull, laden/unladen Max. Drawbar pull, laden/unladen Gradeability, laden/unladen Max. gradeability, laden/unladenAcceleration time, laden/unladen (0-10m)Service brake Parking brakeDrive motor rating S2 60 min Lift motor rating at S3 15%Battery acc. to DIN 43 531/35/36 A,B,C, no Battery voltage, nominal capacity K5Battery weight Battery dimensionsEnergy consumption acc. to VDI cycle Min. battery weight Max. battery weight Type of drive control ManufacturerOperating pressure for attachments Oil volume for attachmentsSound level at the driver´s ear according to EN / DIN 12 053Towing coupling, type DINHydraulic Tank - capacity (drain & refill)1.11.21.31.41.51.61.81.92.12.22.33.13.23.33.53.63.74.14.24.34.44.54.74.84.124.194.204.214.224.234.244.254.314.324.334.344.354.365.15.25.35.55.65.75.85.95.105.116.16.26.36.46.56.66.76.86.98.18.28.38.48.59.1Q (lbs)c (in)x (in)y (in)lbs lbs lbsb 10 (in)b 11 (in)Grad h 1 (in)h 2 (in)h 3 (in)h 4 (in)h 6 (in)h 7 (in)h 10 (in)l 1 (in)l 2 (in)b 1 (in)s/e/l (in)b 3 (in)b 5 (in)m 1 (in)m 2 (in)Ast (in)Ast (in)Wa (in)b 13 (in)mph fpm fpm lbf lbf %%s kW kW V/Ah lbs l/b/h(in)kWh/h lbs lbs bar l/min dB (A)liter FB40CPD40-AC4electric sit-down 80002421.677.51477121010/25797253/7518pneumatic 250 - 1523x10 - 122x/245.246.26/11865.9118.1164.190.948.813.7157.3115.256.61.9/4.8/42.1ISO2328 3A49.212.2/49.24.35.9172.8180.7103.931.88.6/8.653.1/84.684.6/94.93687 /3822539514.5/15.516/285.2/5.4Hydraulic electric 16.6 AC 25.4 AC DIN 43536A 80/700410740.5×33.7×30.912.539684299MOSFET/AC CURTIS 1856575Φ24 Pin 10.1FB45CPD45-AC4electric sit-down 90002421.677.51532222597/26457341/7981pneumatic 250 - 1523x10 - 122x/245.246.26/11865.9118.1164.190.948.813.7157.3115.256.61.9/5.9/42.1ISO2328 3A49.212.2/49.24.35.9172.8180.7103.931.88.3/8.651.1/82.686.5/94.43507/3642584514/1515/275.3/5.5Hydraulic electric 16.6 AC 25.4 AC DIN 43536A 80/700410740.5×33.7×30.91339684299MOSFET/AC CURTIS 1856575Φ24 Pin 10.1FB50CPD50-AC4electric sit-down 100002421.877.51591724206/27337352/8565pneumatic 28x12.5- 1523x10 - 122x/245.246.26/11865.9118.1164.190.948.813.7158.9116.857.82.1/5.9/42.1ISO2328 3A49.212.2/49.24.35.9174.2182105.331.88/8.349.2/78.786.5/94.43417/3507607013/1414/255.4/5.6Hydraulic electric 16.6 AC 25.4 AC DIN 43536A 80/700410740.5×33.7×30.913.539684299MOSFET/AC CURTIS 1856576Φ24 Pin 10.1LOAD CHART51.243.335.427.619.7(”)10000900080007000600050004000(lbs) 10000lbs9000lbs8000lbsa=7.9” safety clearanceAST=a+Wa+X+BOptions///////////////////Solid pneumatic tire Non-marking tyre3rd or 4th hydraulic function 98.4-196.8” duplex mast 157.5-236.2” triplex mast Rear working LED light Rear handle with horn Integrated side shift Other attachments Other dimension forksSpecial carriage and backrest Battery side extractionMinilever control on the adjustable armrest Suspension seat FreezerFull closed cabin Blue spot light Strobe lightLeft and right mirror/////////////Standard Specification////////High e ciency AC driving motor Multi-functions instrument Rubber floor mat PC PlatfondEmergency disconnect switch Pneumatic tyreElectronic parking brake Battery slung removing 2-way-valveLED combination headlight LED rear combination lightPanoramic rearview mirror (in the middle position of the overhead guard)118” duplex mastAdjustable steering columnFull electronic controlled traveling, lifting and steering Horn and reversing buzzer CAN-BUS systemLow noise gear pump (Brand: Shimadzu, Made in Japan)Full hydraulic power steering Soft landing systemOPS systemISO9001:2015ISO14001:2015HANGCHA GROUP CO., LTD. reserves the right to make any changes without notice concerning colors, equipment, or specifications detailed in this brochure, or to discontinue individual models. The colors of trucks, delivered may di er slightly from those in brochures.2020 V E R S I O N 1/C O P Y R I G H T 2020/04Follow us onFacebookFollow us on YouTubeFollow us on WeChatCompany address:10405-A Granite Street Charlotte,NC 28273HC FORKLIFT AMERICA CORPORATION**********************Toll Free :888-652-8395Phone :980-888-8335 Fax :980-888-8336A M E R I C A。

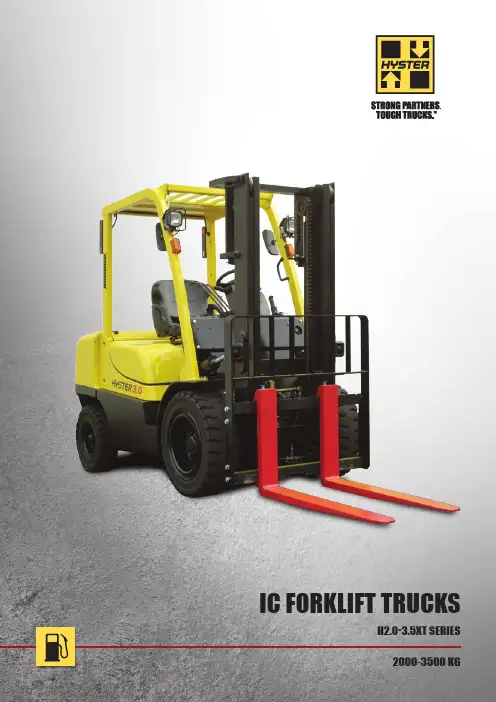

2000-3500 KGH2.0-3.5XT SERIES IC FORKLIFT TRUCKSn Hydrostatic Steer AxleMaximum durability, increased steer angle and steering control for easy manoeuvring and lower maintenance. New steer knob synchroniser system returns the steer knob to the same position when travelling in a straight line – improves operator comfort and control.n H yster ® Stability Mechanism ™The patented stability system reduces truck sway during turns, improving lateral stability. This innovative design allows for confident travel over uneven surfaces.n Engine CoverT he tough steel engine cover is hinged at the rear, offering excellent service access to the engine compartment.Each of these advancements demonstratesHyster’s commitment to be a strong partner and provide the toughest trucks for even the most challenging applications.HYSTER ®2.0-3.5XT SERIES FEATURESnI ntegral SideshiftThe optional Hyster-designed integral sideshift provides excellent visibility and affords greater capacities than carriage-mounted sideshifts.nH eavy-Duty Drive AxleThe full floating drive axle enhances dependability and reliability for a longer service life. Hyster premium self-adjusting brakes provide excellent inching and stopping power.nR emovable Floor PlateOne piece, steel floor plate removes for easy service access. A thick moulded rubber mat reduces noise and vibration.n Advanced Dash DisplayAmonochrome LCD displays all status – mounted on the steer column for easy operator viewing.nH assle-Free HydraulicsIn-tank hydraulic filter for cleaner fluid, longer life componentry.n Steer ColumnThe steering column is offset to the left and the standard synchronous steering function returns the spinner knob to the same position when driving ahead to give a consistent and comfortable driving position.n Hyster ® Vista ™ MastThe new range of Vista™ masts are wider for improved forward visibility. The masts are trunnion mounted for less wear and easier maintenance.EQUIPMENT AND WEIGHT:Weights (line 2.1) are based on the following specifi cations: Complete truck with 3000mm TOF 2-stage limited free lift mast, with standard hook type carriage, 1070mm forks with manual hydraulics, overhead guard and standard pneumatic shaped solid drive and steer tyres.Specification data is based on VDI 2198.D I S T I N G U I S H I N G M A R K1.1 Manufacturer (abbreviation) 1.2 Manufacturer’s type designation Model Engine / transmission1.3 Drive: electric (battery or mains), diesel, petrol, fuel gas1.4 Operator type: hand, pedestrian, standing, seated, order-picker 1.5 Rated capacity/rated load Q (t)1.6 Load centre distancec (mm)1.8 Load distance, centre of drive axle to fork x (mm)1.9 Wheelbasey (mm)5.1 Travel speed, laden/unladen km/h 5.1.1 Travel speed, laden/unladen, backwards km/h 5.2 Lift speed, laden/unladen m/s 5.3 Lowering speed, laden/unladen m/s 5.5 Drawbar pull, laden/unladen † N 5.7 Gradeability, laden/unladen †† % 5.10 Service brake 7.1 Engine manufacturer/type 7.2 Engine power according to ISO 1585 6 kW 7.3 Rated speed min–1 7.3.1 Torque at 1/min Nm/min–1 7.4 Number of cylinders/displacement (-)/cm 3 7.5 Fuel consumption according to MIL 268C cycle l/h or kg/h 7.1 Battery voltage/nominal capacity S (V)/(Ah) 8.1 Type of drive unit 8.11 Service brake 8.12 Parking brake 10.1 Operating pressure for attachments bar 10.2 Oil volume for attachments ³ l/min 10.3 Hydraulic oil tank, capacity l 10.4 Fuel tank, capacity l 10.7 Sound pressure level at the driver’s seat < J dB (A)10.8Towing coupling, type DIN3.1 Tyres: L = pneumatic, V = solid, SE = pneumatic-shaped solid 3.2 Tyre size, front (standard tread)3.2.1 Tyre size, front (dueal tread) 3.3 Tyre size, rear3.5 Wheels, number front/rear (x = driven wheels)3.6 Tread, front (standard/dueal tread) b 10 (mm) 3.7 Tread, rearb 11 (mm)4.1 Tilt of mast/fork carriage forward/backward a /b (°)4.2 Height, mast lowered h 1 (mm) 4.3 Free lift ¶ h 2 (mm) 4.4 Lift ¶ h 3 (mm) 4.5 Height, mast extended è h 4 (mm) 4.7 Height of overhead guard (cabin) h 6 (mm) 4.8 Seat height relating to SIP/stand height ¢ h 7 (mm) 4.12 Coupling height h 10 (mm) 4.19 Overall length l 1 (mm) 4.20 Length to face of forks l 2 (mm) 4.21 Overall width G b 1/b 2 (mm) 4.22 Fork dimensions ISO 2331 s/e/l (mm) 4.23 Fork carriage ISO 2328, class/type A, B 4.24 Fork carriage width l b 3 (mm) 4.31 Ground clearance, laden, below mast m 1 (mm) 4.32 Ground clearance, centre of wheelbase m 2 (mm) 4.34.1 Aisle width for pallets 1000 × 1200 crossways u Ast (mm) 4.34.2 Aisle width for pallets 800 × 1200 crossways u Ast (mm) 4.35 Turning radius W a (mm) 4.41 90° intersecting aisle (with pallet L = 1000mm x W = 1200mm) (mm) 4.42 Step height (from ground to running board) (mm) 4.43 Step height (between intermediate steps and floor) (mm)P E R F O R M A N C E D A T A C O M B U S T I O N E N G I N E A D D I T I O N A L D A T AD I ME N S I O N ST Y R E S /C H A S S I SH2.0XT - AD H2.5XT - ADH3.0XT - BD H3.5XT - BD Yanmar 2.6LYanmar 2.6LYanmar 3.3LYanmar 3.3L Basic Basic Basic Basic Powershift Powershift Powershift Powershift 1-speed 1-speed 1-speed 1-speed Diesel Diesel Diesel Diesel Seated Seated Seated Seated 2 2.5 3 3.5 500 500 500 500 480 480 505 520 1625162517001700HYSTER HYSTERHYSTERHYSTER3480 3610 3810 3940 4350 4435 4940 5055 4755 725 5500 810 6525 825 7450 990 1565 1915 1515 2295 1780 2570 1880 3060 L L L SE 7.00-12-12PR 7.00-12-12PR 28x9-15-12PR 28x9-15 SOLID 7.00-12-12PR 7.00-12-12PR 7.00-12-12PR 6.00-15 SOLID 6.0-9-10PR 6.0-9-10PR 6.50-10-10PR 6.50-10 SOLID 2x 2 2x 2 2x 2 2x 2 970 1405 970 1405 1010 1405 1010 1330 1000 1000 1000 1000 6 10 6 10 6 10 6 10 1995 1995 2060 2140 155 155 160 165 3050 3050 3055 3060 4120 4120 4125 4125 2130 2130 2150 2150 990 990 1010 1010 350 350 350 350 3470 3685 3835 3905 2550 2615 2765 2835 1160 1590 1160 1590 1230 1590 1230 1490 40 / 122 / 1070 40 / 122 / 1070 45 / 122 / 1070 50 / 150 / 1070 II II III III 1020 1020 1070 1070 120 120 140 140 190 190 210 210 3845 3905 4050 4115 3645 3705 3850 3915 2185 2245 2365 2415 2025 2090 2195 2235 410 410 430 430 290 290 290 29017.5 19 17.5 19 17.5 18.5 17.5 18 17.5 19 17.5 19 17.5 18.5 17.5 18 620 670 610 670 560 570 475 490 495 520 495 520 495 520 495 520 16700 16700 22300 20400 26 26 22 23 27 22 21 19 Hydraulic Hydraulic Hydraulic Hydraulic Yanmar/4TNE92 Yanmar/4TNE92 Yanmar/4TNE98 Yanmar/4TNE98 29 29 43 43 2050 2050 2300 2300 143 1400 143 1400 189 1600 189 1600 4 2659 4 2659 4 3319 4 3319 2.7 2.8 3.4 3.6 12 64 12 64 12 64 12 64 AutomaticAutomatic Automatic Automatic Hydraulic Hydraulic Hydraulic Hydraulic Hand Hand Hand Hand 181 181 181 157 71 71 82 71 38.0 38.0 40.0 40.0 69.0 69.0 69.0 69.0 - - - - HookHookHookHookEQUIPMENT AND WEIGHT:Weights (line 2.1) are based on the following specifi cations: Complete truck with 3000mm TOF 2-stage limited free lift mast, with standard hook type carriage, 1070mm forks with manual hydraulics, overhead guard and standard pneumatic shaped solid drive and steer tyres.Specification data is based on VDI 2198.5.1 Travel speed, laden/unladen km/h 5.1.1 Travel speed, laden/unladen, backwards km/h 5.2 Lift speed, laden/unladen m/s 5.3 Lowering speed, laden/unladen m/s 5.5 Drawbar pull, laden/unladen † N 5.7 Gradeability, laden/unladen †† % 5.10 Service brake 7.1 Engine manufacturer/type 7.2 Engine power according to ISO 1585 6 kW 7.3 Rated speed min–1 7.3.1 Torque at 1/min Nm/min–1 7.4 Number of cylinders/displacement (-)/cm 3 7.5 Fuel consumption according to MIL 268C cycle l/h or kg/h 7.1 Battery voltage/nominal capacity S (V)/(Ah) 8.1 Type of drive unit 8.11 Service brake 8.12 Parking brake 10.1 Operating pressure for attachments bar 10.2 Oil volume for attachments ³ l/min 10.3 Hydraulic oil tank, capacity l 10.4 Fuel tank, capacity l 10.7 Sound pressure level at the driver’s seat < J dB (A)10.8 Towing coupling, type DIN3.1 Tyres: L = pneumatic, V = solid, SE = pneumatic-shaped solid 3.2 Tyre size, front (standard tread)3.2.1 Tyre size, front (dueal tread) 3.3 Tyre size, rear3.5 Wheels, number front/rear (x = driven wheels)3.6 Tread, front (standard/dueal tread) b 10 (mm) 3.7 Tread, rearb 11 (mm)4.1 Tilt of mast/fork carriage forward/backward a /b (°)4.2 Height, mast lowered h 1 (mm) 4.3 Free lift ¶ h 2 (mm) 4.4 Lift ¶ h 3 (mm) 4.5 Height, mast extended è h 4 (mm) 4.7 Height of overhead guard (cabin) h 6 (mm) 4.8 Seat height relating to SIP/stand height ¢ h 7 (mm) 4.12 Coupling height h 10 (mm) 4.19 Overall length l 1 (mm) 4.20 Length to face of forks l 2 (mm) 4.21 Overall width G b 1/b 2 (mm) 4.22 Fork dimensions ISO 2331 s/e/l (mm) 4.23 Fork carriage ISO 2328, class/type A, B 4.24 Fork carriage width l b 3 (mm) 4.31 Ground clearance, laden, below mast m 1 (mm) 4.32 Ground clearance, centre of wheelbase m 2 (mm) 4.34.1 Aisle width for pallets 1000 × 1200 crossways u Ast (mm) 4.34.2 Aisle width for pallets 800 × 1200 crossways u Ast (mm) 4.35 Turning radius W a (mm) 4.41 90° intersecting aisle (with pallet L = 1000mm x W = 1200mm) (mm) 4.42 Step height (from ground to running board) (mm) 4.43 Step height (between intermediate steps and floor) (mm)P E R F O R M A N C E D A T AC O M B U S T I O N E N G I N EA D D I T I O N A L D A T AD I ME N S I O N ST Y R E S /C H A S S I SH2.0XT - AL H2.5XT - AL H3.0XT - BL K21 2.1L K21 2.1L K25 2.5L Basic Basic Basic Powershift Powershift Powershift 1-speed 1-speed 1-speed L PG L PG L PG Seated Seated Seated 2.0 2.5 3.0 500 500 500 465 465 490 1625 1625 1700 HYSTER HYSTER HYSTER3390 3520 3720 3850 4260 4345 4730 660 5455 765 6335 925 1530 1850 1470 2250 1635 2670 L L L 7.00-12-12PR 7.00-12-12PR 28x9-15-12PR 7.00-12-12PR 7.00-12-12PR 7.00-12-12PR 6.0-9-10PR 6.0-9-10PR 6.50-10-10PR 2x 2 2x 2 2x 2 970 1405 970 1405 1010 1405 1000 1000 1000 6 10 6 10 6 10 1995 1995 2060 155 155 160 3050 3050 3055 4120 4120 4125 2130 2130 2150 990 990 1010 350 350 350 3470 3685 3835 2550 2615 2765 1160 1590 1160 1590 1230 1590 40 / 122 / 1070 40 / 122 / 1070 45 / 122 / 1070 II II III 1020 1020 1070 120 120 140 190 190 210 3845 3905 4050 3645 3705 3850 2185 2245 2365 2025 2090 2195 410 410 430 290 290 29018 19.5 18 19.5 19 20 18 19.5 18 19.5 19 20 525 580 515 580 515 575 495 520 495 520 495 520 18900 18900 19000 30 26 26 22 24 22 Hydraulic Hydraulic Hydraulic GCT/K21 GCT/K21 GCT/K25 31 31 34 2250 2250 2100 144 1600 144 1600 173 1600 4 2065 4 2065 4 2488 1.8 1.9 2.3 12 28 12 28 12 28 AutomaticAutomatic Automatic Hydraulic Hydraulic Hydraulic Hand Hand Hand 181 181 181 65 65 74 38.0 38.0 40.0 - --- 78 78 80 HookHookHookEQUIPMENT AND WEIGHT:Weights (line 2.1) are based on the following specifi cations: Complete truck with 3000mm TOF 2-stage limited free lift mast, with standard hook type carriage, 1070mm forks with manual hydraulics, overhead guard and standard pneumatic shaped solid drive and steer tyres.Specification data is based on VDI 2198.D I S T I N G U I S H I N G M A R K1.1 Manufacturer (abbreviation) 1.2 Manufacturer’s type designation Model Engine / transmission1.3 Drive: electric (battery or mains), diesel, petrol, fuel gas1.4 Operator type: hand, pedestrian, standing, seated, order-picker 1.5 Rated capacity/rated load Q (t)1.6 Load centre distancec (mm)1.8 Load distance, centre of drive axle to fork x (mm)1.9 Wheelbasey (mm)5.1 Travel speed, laden/unladen km/h 5.1.1 Travel speed, laden/unladen, backwards km/h 5.2 Lift speed, laden/unladen m/s 5.3 Lowering speed, laden/unladen m/s 5.5 Drawbar pull, laden/unladen † N 5.7 Gradeability, laden/unladen †† % 5.10 Service brake 7.1 Engine manufacturer/type 7.2 Engine power according to ISO 1585 6 kW 7.3 Rated speed min–1 7.3.1 Torque at 1/min Nm/min–1 7.4 Number of cylinders/displacement (-)/cm 37.5 Fuel consumption according to MIL 268C cycle l/h or kg/h 7.1 Battery voltage/nominal capacity S (V)/(Ah) 8.1 Type of drive unit8.11 Service brake8.12 Parking brake 10.1 Operating pressure for attachments bar 10.2 Oil volume for attachments ³ l/min 10.3 Hydraulic oil tank, capacity l 10.4 Fuel tank, capacity l 10.7 Sound pressure level at the driver’s seat < J dB (A)10.8Towing coupling, type DIN3.1 Tyres: L = pneumatic, V = solid, SE = pneumatic-shaped solid 3.2 Tyre size, front (standard tread)3.2.1 Tyre size, front (dueal tread) 3.3 Tyre size, rear3.5 Wheels, number front/rear (x = driven wheels)3.6 Tread, front (standard/dueal tread) b 10 (mm) 3.7 Tread, rearb 11 (mm)4.1 Tilt of mast/fork carriage forward/backward a /b (°)4.2 Height, mast lowered h 1 (mm) 4.3 Free lift ¶ h 2 (mm) 4.4 Lift ¶ h 3 (mm) 4.5 Height, mast extended è h 4 (mm) 4.7 Height of overhead guard (cabin) h 6 (mm) 4.8 Seat height relating to SIP/stand height ¢ h 7 (mm) 4.12 Coupling height h 10 (mm) 4.19 Overall length l 1 (mm) 4.20 Length to face of forks l 2 (mm) 4.21 Overall width G b 1/b 2 (mm) 4.22 Fork dimensions ISO 2331 s/e/l (mm) 4.23 Fork carriage ISO 2328, class/type A, B 4.24 Fork carriage width l b 3 (mm) 4.31 Ground clearance, laden, below mast m 1 (mm) 4.32 Ground clearance, centre of wheelbase m 2 (mm) 4.34.1 Aisle width for pallets 1000 × 1200 crossways u Ast (mm) 4.34.2 Aisle width for pallets 800 × 1200 crossways u Ast (mm) 4.35 Turning radius W a (mm) 4.41 90° intersecting aisle (with pallet L = 1000mm x W = 1200mm) (mm) 4.42 Step height (from ground to running board) (mm) 4.43 Step height (between intermediate steps and floor) (mm)P E R F O R M A N C E D A T A C O M B U S T I O N E N G I N E A D D I T I O N A L D A T AD I ME N S I O N ST Y R E S /C H A S S I SH2.0XT - AG H2.5XT - AG H3.0XT - BG K21 2.1LK21 2.1LK25 2.5L Basic Basic Basic Powershift Powershift Powershift 1-speed 1-speed 1-speed Petrol Petrol Petrol Seated Seated Seated 2.0 2.5 3.0 500 500 500 465 465 490 1625162517003390 3520 3720 3850 4260 4345 4730 660 5455 765 6335 925 1530 1850 1470 2250 1635 2670 L L L 7.00-12-12PR 7.00-12-12PR 28x9-15-12PR 7.00-12-12PR 7.00-12-12PR 7.00-12-12PR 6.0-9-10PR 6.0-9-10PR 6.50-10-10PR 2x 2 2x 2 2x 2 970 1405 970 1405 1010 1405 1000 1000 1000 6 10 6 10 6 10 1995 1995 2060 155 155 160 3050 3050 3055 4120 4120 4125 2130 2130 2150 990 990 1010 350 350 350 3470 3685 3835 2550 2615 2765 1160 1590 1160 1590 1230 1590 40 / 122 / 1070 40 / 122 / 1070 45 / 122 / 1070 II II III 1020 1020 1070 120 120 140 190 190 210 3845 3905 4050 3645 3705 3850 2185 2245 2365 2025 2090 2195 410 410 430 290 290 29018 19.5 18 19.5 19 20 18 19.5 18 19.5 19 20 525 580 515 580 515 575 495 520 495 520 495 520 18900 18900 19000 30 26 26 22 24 22 Hydraulic Hydraulic Hydraulic GCT/K21 GCT/K21 GCT/K25 31 31 34 2250 2250 2100 144 1600 144 1600 173 16004 2065 4 2065 4 2488 2.7 2.9 3.3 12 28 12 28 12 28 Automatic Automatic Automatic Hydraulic Hydraulic Hydraulic Hand Hand Hand 181 181 181 65 65 74 38.0 38.0 40.0 69.0 69.0 69.0 78 78 80 HookHookHookHYSTER HYSTERHYSTEREQUIPMENT AND WEIGHT:Weights (line 2.1) are based on the following specifi cations: Complete truck with 3000mm TOF 2-stage limited free lift mast, with standard hook type carriage, 1070mm forks with manual hydraulics, overhead guard and standard pneumatic shaped solid drive and steer tyres.Specification data is based on VDI 2198.5.1 Travel speed, laden/unladen km/h 5.1.1 Travel speed, laden/unladen, backwards km/h 5.2 Lift speed, laden/unladen m/s 5.3 Lowering speed, laden/unladen m/s 5.5 Drawbar pull, laden/unladen † N 5.7 Gradeability, laden/unladen †† % 5.10 Service brake 7.1 Engine manufacturer/type 7.2 Engine power according to ISO 1585 6 kW 7.3 Rated speed min–1 7.3.1 Torque at 1/min Nm/min–1 7.4 Number of cylinders/displacement (-)/cm 37.5 Fuel consumption according to MIL 268C cycle l/h or kg/h 7.1 Battery voltage/nominal capacity S (V)/(Ah) 8.1 Type of drive unit8.11 Service brake8.12 Parking brake 10.1 Operating pressure for attachments bar 10.2 Oil volume for attachments ³ l/min 10.3 Hydraulic oil tank, capacity l 10.4 Fuel tank, capacity l 10.7 Sound pressure level at the driver’s seat < J dB (A)10.8Towing coupling, type DIN3.1 Tyres: L = pneumatic, V = solid, SE = pneumatic-shaped solid 3.2 Tyre size, front (standard tread)3.2.1 Tyre size, front (dueal tread) 3.3 Tyre size, rear3.5 Wheels, number front/rear (x = driven wheels)3.6 Tread, front (standard/dueal tread) b 10 (mm) 3.7 Tread, rearb 11 (mm)4.1 Tilt of mast/fork carriage forward/backward a /b (°)4.2 Height, mast lowered h 1 (mm) 4.3 Free lift ¶ h 2 (mm) 4.4 Lift ¶ h 3 (mm) 4.5 Height, mast extended è h 4 (mm) 4.7 Height of overhead guard (cabin) h 6 (mm) 4.8 Seat height relating to SIP/stand height ¢ h 7 (mm) 4.12 Coupling height h 10 (mm) 4.19 Overall length l 1 (mm) 4.20 Length to face of forks l 2 (mm) 4.21 Overall width G b 1/b 2 (mm) 4.22 Fork dimensions ISO 2331 s/e/l (mm) 4.23 Fork carriage ISO 2328, class/type A, B 4.24 Fork carriage width l b 3 (mm) 4.31 Ground clearance, laden, below mast m 1 (mm) 4.32 Ground clearance, centre of wheelbase m 2 (mm) 4.34.1 Aisle width for pallets 1000 × 1200 crossways u Ast (mm) 4.34.2 Aisle width for pallets 800 × 1200 crossways u Ast (mm) 4.35 Turning radius W a (mm) 4.41 90° intersecting aisle (with pallet L = 1000mm x W = 1200mm) (mm) 4.42 Step height (from ground to running board) (mm) 4.43 Step height (between intermediate steps and floor) (mm)P E R F O R M A N C E D A T A C O M B U S T I O N E N G I N E A D D I T I O N A L D A T AD I ME N S I O N ST Y R E S /C H A S S I SH2.0XT - AT H2.5XT - ATH3.0XT - BT K21 2.1LK21 2.1LK25 2.5L Basic Basic Basic Powershift Powershift Powershift 1-speed 1-speed 1-speed Dual fuelDual fuelDual fuel Seated Seated Seated 2.0 2.5 3.0 500 500 500 465 465 490 1625162517003390 3520 3720 3850 4260 4345 4730 660 5455 765 6335 925 1530 1850 1470 2250 1635 2670 L L L 7.00-12-12PR 7.00-12-12PR 28x9-15-12PR 7.00-12-12PR 7.00-12-12PR 7.00-12-12PR 6.0-9-10PR 6.0-9-10PR 6.50-10-10PR 2x 2 2x 2 2x 2 970 1405 970 1405 1010 1405 1000 1000 1000 6 10 6 10 6 10 1995 1995 2060 155 155 160 3050 3050 3055 4120 4120 4125 2130 2130 2150 990 990 1010 350 350 350 3470 3685 3835 2550 2615 2765 1160 1590 1160 1590 1230 1590 40 / 122 / 1070 40 / 122 / 1070 45 / 122 / 1070 II II III 1020 1020 1070 120 120 140 190 190 210 3845 3905 4050 3645 3705 3850 2185 2245 2365 2025 2090 2195 410 410 430 290 290 29018 19.5 18 19.5 19 20 18 19.5 18 19.5 19 20 525 580 515 580 515 575 495 520 495 520 495 520 18900 18900 19000 30 26 26 22 24 22 Hydraulic Hydraulic Hydraulic GCT/K21 GCT/K21 GCT/K25 31 31 34 2250 2250 2100 144 1600 144 1600 173 16004 2065 4 2065 4 2488 2.7 1.8 2.9 1.9 3.3 2.3 12 28 12 28 12 28 Automatic Automatic Automatic Hydraulic Hydraulic Hydraulic Hand Hand Hand 181 181 181 65 65 74 38.0 38.0 40.0 69.0 69.0 69.0 78 78 80 HookHookHookHYSTER HYSTERHYSTERNOTESValues shown are for standard equipment. When using non-standard equipment, these values may change. Please contact your Hyster dealer for information.The rated capacities shown are for masts in a vertical position on trucks equipped with standard or sideshift carriage, and nominal length forks.Masts above the maximum fork heights shown in the mast table are classified as high lift, and depending on the tyre/tread configuration may require reduced capacity, restricted back tilt or wide tread.Specification data based on standard carriage, load backrest and 1070mm forks.2-stage Full Free Lift2-stage Limited Free Lift3-stage Full Free LiftMaximum fork height (mm)Back tilt Overalllowered height (mm)Overall Extended height (mm)v Overall Extended height (mm)♦Free lift (top of forks) (mm) v2140229023902490269028402940309031902190234024402590279020402110219023402440259026902790294010 3060 38454125 165 10 3360 4145 4425 165 10 3560 4345 4625 165 10 3760 4545 4825 165 10 4060 4845 5125 165 6 4360 5145 5425 165 6 4560 5345 5625 165 6 4860 5645 5925 165 6 50605845612516510 3085 3850 4150 1070 10 3385 4150 4450 1220 10 3585 4350 4650 1320 10 3835 4600 4900 1470 6 4185 4950 5250 1670 6 4125 4970 5190 920 6 4335 5180 5400 990 6 4575 5420 5640 1070 6 4825 5670 5890 1220 6 5025 5870 6090 1320 6 5325 6170 6390 1470 6 5525 6370 6590 1570 6 5725 6570 6790 1670 66025 6870 7090 1775H3.0-3.5XT - Capacity Chart in kgMaximum fork height (mm)Maximum fork height (mm)Maximumfork height (mm)Maximumfork height (mm)2-stage Full Free Lift2-stageLimited Free Lift30503350355037504050435045504850505030003390359038404190413543454585484050355335553556856035306033603560376040604360456048605060308533853585383541854130434045804830503053305530573060303055335535553755405543554555485550553080338035803830418041254335457547055025532555255725602530603360356037604060436045604860506030853385358538354185413043404580483050305330553057306030500 LC 600 LC 700 LC 3000 2920 2680 3000 2920 2680 3000 2910 2670 3000 2910 2670 3000 2900 2660 3000 2890 2650 2950 2860 2610 2880 2770 2540 2830 2720 2490 3000 2920 2670 3000 2910 2670 3000 2900 2660 3000 2900 2660 3000 2890 2650 3000 2890 2650 3000 2890 2650 2950 2830 2610 2930 2810 2560 2860 2720 2490 2770 2630 2430 2720 2590 2380 2680 2520 2310 2590 2450 2240500 LC 600 LC 700 LC 3500 3390 3110 3500 3380 3100 3500 3380 3100 3500 3380 3100 3500 3360 3090 3500 3360 3080 3450 3310 3040 3380 3240 2970 3330 3170 2930 3500 3380 3100 3500 3380 3100 3500 3370 3090 3500 3370 3090 3500 3350 3080 3500 3340 3070 3500 3340 3060 3450 3290 3020 3380 3220 2950 3330 3150 2900 3240 3080 2810 3020 2990 2770 2790 2790 2720 2470 2490 2470500 LC 600 LC 700 LC3000 2800 2580 3000 2800 2570 3000 2790 2570 3000 2790 2560 3000 2780 2550 3000 2770 2550 2950 2720 2520 2880 2650 2450 2830 2610 2400 3000 2800 2570 3000 2790 2570 3000 2790 2560 3000 2780 2560 3000 2770 2550 3000 2780 2550 3000 2770 2550 2950 2720 2490 2930 2700 2470 2860 2610 2400 2770 2540 2340 2720 2490 2290 2650 2430 2220 2560 2340 2150500 LC 600 LC 700 LC 3500 3250 2990 3500 3240 2980 3500 3240 2980 3500 3240 2980 3500 3220 2970 3500 3220 2960 3450 3170 2930 3380 3110 2860 3330 3060 2810 3500 3250 2990 3500 3240 2980 3500 3240 2980 3500 3230 2970 3500 3220 2960 3500 3230 2970 3500 3220 2960 3450 3170 2900 3380 3110 2860 3330 3060 2810 3240 2970 2720 3020 2900 2680 2810 2790 2630 2490 2490 24703-stageFull Free LiftPneumatic Shaped Solid TyresH3.0XTH3.5XTH3.0XTH3.5XTWithout sideshiftWithout sideshiftWith integral sideshiftWith integral sideshift10l l b b b xWa100mma 2100mma 2Asth h h h sQcαll y l h h h m m βb x40003500300025002000150010005000250500750100012501500H3.5XT H3.0XT H2.5XT H2.0XT40003500300025002000150010005000250500750100012501500H3.5XTH3.0XT H2.5XT H2.0XTTRUCK DIMENSIONS= Centre of gravity of unladen truck Ast = W a + x + l 6 + a (see lines 4.34.1 & 4.34.2) a = Minimum operating clearance(VDI standard = 200 mm BITA recommendation = 300 mm) l 6= Load lengthRATED CAPACITIESLoad centreDistance from front of forks to centre of gravity of load.Rated loadBased on vertical masts up to 4310 mm.Load centre (mm)Standard CarriageIntegral Sideshift CarriageLoad centre (mm)R a t e d l o a d (k g )R a t e d l o a d (k g )NOTE:Specifications are affected by the condition of the vehicle and how it is equipped, as well as the nature and condition of the operating area. Inform your dealer of the nature and condition of the intended operating area when purchasing your Hyster T ruck.GStandard / wide / dual ¶Top of forksè add 32mm with load backrest¢ Full suspension seat in depressed position l Without load backrest, add 32mm with load backrestuStacking aisle width (lines 4.34 & 4.34.1 &4.34.2) are based on the V .D.I. standard calculation as shown on illustration. The British Industrial Truck Association recommends the addition of 100 mm to the total clearance (dimension a) for extra operating margin at the rear of the truck 6Engine power entries are shown as net values ††at 1.6 km/h†at 4.8km/h. Gradeability figures are provided for comparison of tractive performance, but are not intended toendorse the operation of the vehicle on the stated inclines. Follow instructions in the operating manual regarding operation on inclines.q to 15m (per VDI 2198 December 2012)SBattery ampere hour (Ah) nominal capacity ratings are estimated.³ Variable< With and without cab.♦Noise levels are reduced by 3dB(A) with ECO-eLo mode engaged.JLpaz, Measured according to the test cycles and based on the weighting values contained in EN12053¬Lwaz, Measured according to the test cycles and based on the weighting values contained in EN12053.MAST TABLES:v without load backrest♦ with load backrestNOTICECare must be exercised when handling elevated loads. When the carriage and/or load is elevated, truck stability is reduced. It is important that the mast tilt in either direction is kept to a minimum when loads are elevated.Operators must be trained and must read, understand and follow the instructions contained in the Operating Manual.All values are nominal values and they are subject to tolerances. For further information, please contact the manufacturer.Hyster products are subject to change without notice.Lift trucks illustrated may feature optional equipment. Values may vary with alternative configurations.STANDARD FEATURES & OPTIONSSTANDARD EQUIPMENTComplete truck equipped with:n2-Stage limited free lift Vista™ mast with lift height of 3035mmn Hook-type carriage with 1070mm high load backrest (LBR) n1070mm long forksn Y anmar 2.6L Diesel or GCT K21 Petrol / LPG engine (H2.0-2.5XT)n Y anmar 3.3L Diesel or GCT K25 Petrol / LPG engine (H3.0-3.5XT)n Powershift transmission+ Mechanical inching+ Neutral start function+ Heavy duty clutch platesn Directional control levern Single pedal inch braken N on-suspension vinyl seat (not available with seat side hydraulic control Mini levers)n Pneumatic tyresn 2 Hydraulic leversn Standard integrated dash display+ Monochrome LCD panel– Real time clock– Hour meter– Fasten seatbelt– F uel level with low fuel warning buzzer (Petrol & Dieselfuel only)+ Service Indicators– Service required– Coolant temperature with high temp warning buzzer– Alternator with warning buzzer– Transmission oil temperature with warning buzzer– Engine oil pressure with low pressure warning buzzer– Glow lamp (Diesel fuel engine only)– Error messagen Key starting with anti-restart functionn Hydrostatic steering with steer knob synchronisern Adjustable vinyl seatn Electric Hornn Infinitely adjustable steering columnn Rubber floor matn High air intaken Counterweight exhaustn Integral tie downsn Operator’s seat beltn Serpentine radiatorn Hyster Stability Mechanism™ (HSM)n Swing down LPG tank bracket Cabinn S tandard Over Head Guard (OHG) with rain gutter and cup holdern 78 dB(A) standard noise level for Petrol/LPG engine optionn 83.5 dB(A) standard noise level for Diesel engine optionn 12 months / 2000 hours manufacturer’s warrantyn Operator’s manualn Compliance with ISO 3691 / JIS D 6202OPTIONAL EQUIPMENTMastsn 2-Stage limited free lift Vista™ masts with up to 4855mm lift heightn 2-Stage full free lift Vista™ masts with up to 3390mm lift height n 3-Stage full free lift Vista™ masts with up to 6035mm lift heightCarriagesn Integral side shift (ISS) carriageHydraulic Valve and Leversn 3-function cowl mounted hydraulic levers with or without interlock for clampingn 4-function cowl mounted hydraulic levers with or without interlock for clampingForksn Fork lengths are available from 1070mm to 1520mmControlsn S eparate Inch brake and brake pedals for sure handling on steep inclinesn Mini levers with adjustable armrestDash Displayn Speedometer with speed alarm and warning buzzern Travel speed limitern Digital load weight displaySeatsn Full suspension vinyl seatBrakesn Heavy duty drum brakesEnvironmentaln Vertical exhaustn 2-way catalytic mufflern Spark arrestor mufflern High capacity radiatorn High mount pre-cleanern Dual element air filter for Petrol/LPG engine optionn Tandem air filter for Diesel engine optionOthern H ydraulic cut-out seat interlock (prevents travel when operator seatbelt is not used)n L ight Kit consisting of 2 Halogen front head lights, 2 front turn indicators plus rear combination (turn indicators, reversingand brake) lights and reverse alarmn 2 rear vision mirrorsn Rear work light (switch or reverse operated)。

叉车操作作业指导书第一章简介1.1 目的叉车操作作业指导书的目的是为了提供叉车操作员一个全面的指导,帮助他们掌握叉车的安全操作技巧,减少事故发生的可能性,保障人员和设备的安全。

1.2 适用范围本指导书适用于所有需要操作叉车的人员,包括新手和有经验的操作员。

1.3 定义叉车:一种用于搬运和堆放物料的机械设备,具有叉形或者其他装载机构。

第二章安全规定2.1 操作员要素2.1.1 资格要求:操作员需要获得叉车驾驶证。

持证人员需定期参加培训和考试,以保持和提高操作技能。

2.1.2 健康要求:操作员必须身体健康,不能患有对操作叉车有影响的疾病或身体状况。

2.1.3 年龄要求:操作员必须满18周岁以上。

2.2 安全装备2.2.1 安全帽:操作员在操作叉车时必须佩戴安全帽,以防止头部受到撞击。

2.2.2 安全鞋:操作员必须穿戴牢固、防滑的安全鞋,以防止脚部受伤。

2.2.3 手套:操作员在搬运物料时可以佩戴手套,以保护手部。

2.2.4 可视性设备:叉车必须配备前后视镜,以提高操作员的可视性。

2.2.5 安全带:若叉车配备了安全带,操作员在施工中要始终系好安全带。

2.3 操作规定2.3.1 载荷限制:操作员必须了解叉车的载荷限制,并严格按照规定进行搬运操作。

2.3.2 速度限制:操作员必须按照道路标志和规定的速度行驶,切勿超速。

2.3.3 稳定性:操作员必须保持叉车的稳定性,切勿急转、急刹车,以免造成叉车翻倒。

2.3.4 视野:操作员必须保持良好的视野,切勿将物料或障碍物遮挡视线。

2.3.5 通行规则:操作员在行车过程中必须遵守交通规则,礼让行人和其他车辆。

第三章操作技巧3.1 叉车的基本操作3.1.1 起动和停车:操作员在起动叉车前必须确认周围环境安全,启动叉车前警告他人,并注意板车是否停稳。

3.1.2 方向控制:操作员必须熟悉叉车的操控杆和踏板,准确操作方向控制。

3.1.3 速度控制:操作员必须根据道路和货物的情况调节叉车的速度,避免超速和急停。

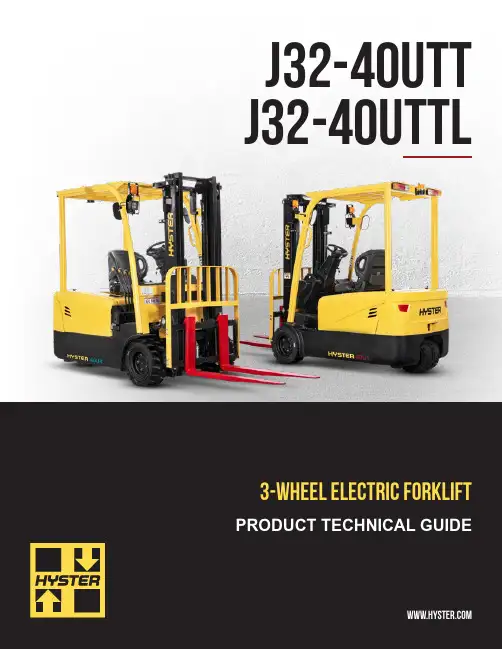

J32-40UTT J32-40UTTL23Hyster uses the above ITA formula to calculate right angle stack on our 3 and 4 wheel trucks with a zero turn steer axle and counter rotating load wheels.Some documentation incorrectly calculates right angle stack on a 3-wheel zero-turn truck with counter rotating load wheels using the following formula:Right angle stack = OTR + Load distance + Load length. This formula generates a value which is invalid and lower than actual right angle stack.When making comparisons, be sure the correct ITA formula is used to calculate right angle stack.(For a 40” wide by 48” long)*RL=rated load, NL=no loadCERTIFICATION: Hyster lift trucks meet the design and construction requirements of B56.1-1969, per OSHA Section 1910.178(a)(2), and also comply with the B56.1 revision in effect at time of manufacture. Certification of compliance with the applicable ANSI standards appears on the lift truck. Performance specifications are for a truck equipped as described under standard equipment on this technical guide. Performance specifications are affected by the condition of the vehicle and how it is equipped, as well as by the nature, condition of the operating area, proper service and maintenance of the vehicle. If these specifications are critical, the proposed application should be discussed with your dealer.4J32-35UTT/J32-35UTTL MAST CHARTJ40UTT/J40UTTL MAST CHART56Battery type: “EO” (without cover)Battery compartment length is measured front to rear. Battery compartment width is measured across the truck Battery lead: length 250 mm (10”), position “B”, 2/0 AWGJ32-35UTTJ40UTT0.59 (15)0.59 (15)24.69 (627)24.80 (630)7.09 (180)1.97 (50)0.79 (20)32.68 (830)22.83 (580)0.20 (5)9.84 (250)0.59 (15)0.59 (15)24.69 (627)29.06 (738)7.09 (180)1.97 (50)22.83 (580)32.68 (830)0.79 (20)0.20 (5)9.84 (250)7。

J-GX SERIESABOUT HYSTERHyster supplies a complete range of warehouse equipment, IC and electric counterbalanced trucks, container handlers and reach stackers. Hyster is committed to being much more than a lift truck supplier.Our aim is to offer a complete partnership capable of responding to the full spectrum of material handling issues; whether you need professional consultancy on your fleet management, fully qualified service support, or reliable parts supply, you can depend on Hyster.Our network of highly trained dealers provides expert, responsive local support. They can offer cost-effective finance packages and introduce effectively managed maintenance programmes to ensure that you get the best possible value.Our business is dealing with your materials handling needs so you can focus on the success of your business today and in the future.HYSTER J-GX SERIES BROCHUREPAGE 02Hyster is known for maintaining strong partners through tougher trucks, which has led to the innovation of the Hyster ® J1.5-3.5GX counterbalanced electric rider. Bringing together all of the factors important to you, the J1.5-3.5GX maintains a leading edge in today’s continuously evolving market.FEATURING THE J1.5-3.5GXDependabilityn Through a redesigned drive axle, this battery electricunit now shares the same robust structure as its internal combustion equivalent.n AC motor technology on traction and integrated hoist/steering allows the truck to work reliably over long runs and in demanding work cycles, reducing downtime significantly.Productivityn Offering excellent manoeuvrability for narrow aisleapplications, a refined short chassis option is offered for the 2 tonne and 3.5 tonne models to facilitate all application requirements.n Through an integrated turning speed control system,truck lean is minimised to provide the operator with an enhanced feel of control and confidence in fast paced applications.n AC controlled traction and integrated hydraulic/steermotors provide optimised responsiveness to the operator, providing the most efficient load handling in the toughest of applications.n The option of horizontal battery extraction enables an easyexchange of batteries to drastically increase uptime.Ergonomicsn An ergonomically designed operator’s compartmentprovides a comfortable and highly productive environment for the driver. This is demonstrated through ample floor space as well as easy on/off access via a low step height.n The functional rear assist grip with horn enables theoperator easy access to the horn, as well as comfort while reversing. n Through the redesign of the Vista ™ Mast, the operator isprovided with optimised vision of the load being handled as well as obstacles in front of the forklift.Low Cost of Ownershipn Customisable performance settings allow energyefficiency to be ideally balanced with productivity, delivering high throughput at a lower operating cost.n Increased battery life up to 8.5 hours in standardperformance mode, and 9.5 hours in Eco mode increases uptime and reduces electricity costs.n Fault code registry enables diagnostic ease. This enablescutting-edge maintenance planning for lowering costs and increasing productivity.Serviceabilityn Troubleshooting manual relevant to all fault codes in theactive registry enables quick and proficient fault realisation and rectification.n Drop battery box (DBB) layout enables easy access tomotors, pumps and controllers for servicing.n LED light assemblies provide an extended life overhalogen alternatives.Total Truck Reliabilityn With the reputation for delivering world-class productreliability and to show our confidence in the J-GX series, it makes sense to back them with industry leading warranty.n That’s why Hyster is offering the J-GX series with astandard of 2 years/4,000 hours* manufacturer warranty and lifetime chassis warranty.* Comprises of 1 year/2,000 hours on complete truck and 2 years/4,000 hours on powertrain.PAGE 03HYSTER J-GX SERIESBROCHUREFEATURESThe inner mast clearance (between the hoist chains) provides ample visibility to enhance operator efficiency.OPTIMISED MAST VISIBILITY11AC controlled motor sends power back to the battery during braking, increasing uptime.REGENERATIVE BRAKING44Productivity enhancement through an automatic speed reduction based on load and steer tyre angle.AUTOMATIC SPEED CONTROL5Interactive dash display shows the most relevant information to the truck’s current status.INTERACTIVE DASH DISPLAY22Directs a light onto the load and racking to illuminate the workspace while working at heights.CARRIAGE LIGHT*33*Optional feature.HYSTER J-GX SERIES BROCHUREPAGE 04566Alignment between the rotation of the steering wheel and steer tyres, enabling the steering wheel to always return to the same position.SYNCHRONOUS AND POWER ASSIST STEERING77Operator presence system which will disengage the trucks functions if the operator leaves the seat.TRAVEL AND HYDRAULIC HANDLING INTERLOCKBattery located at the lower back region of the truck to improve layout and accessibility of motors and controllers.DROP BATTERY BOX88Optional horizontal extraction provides ease of access for battery removal/replacement to reduce downtime.HORIZONTAL BATTERY EXTRACTION*99Provides an alert to pedestrians and users of mobile equipment that forklifts are operational in the area.BLUE PEDESTRIANAWARENESS LIGHT (PAL)*1010A refined operator’s compartment provides ease of access and driver comfort.OPERATOR COMFORT1111PAGE 05HYSTER J-GX SERIESBROCHUREHYSTER J-GX SERIES BROCHUREPAGE 06PAGE 07HYSTER J-GX SERIESBROCHUREHYSTER J-GX SERIESBROCHUREPAGE 08J1.5-1.8GX2-Stage LFLMaximum Fork HeightmmForkThicknessmmBack TiltdegOverallLoweredHeightmmOverallExtendedHeight*mmFree Lift*mm3035351019954105145 3335351021454405145 3535351022454605145 3735351023454805145 403535625955105145 433535627455405145 453535628455605145 483535629955905145 5035356309561051452-Stage FFL3025351019954095925 33253510214543951075 35253510224545951175 37253510234547951275 41253562595519515253-Stage FFL402535618955095825 437535619955445925 452535620455595975 4825356214558951075 5125356224561951175 5425356234564951275 6025356259570951525J2.0GXS2-Stage LFLMaximumFork HeightmmForkThicknessmmBack TiltdegOverallLoweredHeightmmOverallExtendedHeight*mmFree Lift*mm 3040401019954105150 3340401021454405150 3540401022454605150 3740401023454805150 404040625955105150 434040627455405150 454040628455605150 484040629955905150 5040406309561051502-Stage FFL3030401019954095930 33304010214543951080 35304010224545951180 37304010234547951280 41304062595519515303-Stage FFL403040618955095830 438040619955445930 453040620455595980 4830406214558951080 5130406224561951180 5430406234564951280 6030406259570951530PAGE 09HYSTER J-GX SERIESBROCHUREMAST SPECIFICATIONSJ3.5GXS 2-Stage LFLMaximumFork HeightmmFork Thickness mmBack Tilt degOverall Lowered Height mmOverall Extended Height*mmFree Lift*mm306050102140413016533605010229044301653560501023904630165376050102490483016540605010269051301654360506284054301654560506294056301654860506309059301655060506319061301652-Stage FFL30855010219041551120338550102340445512703585501024404655137038355010259049051520418550102790525517203-Stage FFL41305062040520097043405062110541010404580506219056501120483050623405900127050305062440610013705330506259064001520553050626906600162057305062790680017206030506294071001870J2.0-2.5GX 2-Stage LFLMaximum Fork HeightmmFork Thicknessmm Back TiltdegOverallLowered Height mm OverallExtended Height*mm Free Lift*mm 305040101995412015533504010217044201553550401022704620155375040102420482015540504010262051201554350406277054201554550406287056201554850406302059201555050406312061201552-Stage FFL3000401019954070925339040102270446012003590401023704660130038404010252049101450419040102720526016503-Stage FFL4135406197052059004345406204054159704585406212056551050484040622055910113550354062270610512005335406237064051300553540624706605140056854062520675514506035406272071051650J3.0GX 2-Stage LFLMaximumFork HeightmmFork Thickness mmBack Tilt degOverall Lowered Height mmOverall Extended Height*mmFree Lift*mm305545102060412516033554510221044251603555451023104625160375545102440482516040554510264051251604355456279054251604555456289056251604855456304059251605055456314061251602-Stage FFL30804510214041501070338045102290445012203580451023904650132038304510254049001470418045102740525016703-Stage FFL412545619905195920433545620605405990457545621405645107047054562225577511555025456239060951320532545625406395147055254562640659515705725456274067951670602545628907095182050010001500200400600 80010001200 1400 L o a d C a p a c i t y (k g ) Load Centre (mm)J1.5GXJ2.0GXS 0500 10001500 2500 3000 3500 4000 0200400600 800100012001400L o a d C a p a c i t y (k g ) Load Centre (mm)J2.0GX J2.5GXJ3.0GX J3.5GXS20002500L o a d C a p a c i t y (k g )J1.8GX2000 L o a d C a p a c i t y (k g )HYSTER J-GX SERIES BROCHUREPAGE 10nn n n n n n n n nn n n n nn nn nn n n nn nn nn n nn n nnn n n nn n nn n nn n n nn n nn nMANAGE COST,OPTIMISE PRODUCTIVITY AND PROTECT YOUR ASSETSHyster ® Tracker SystemTake your fleet operation to the next level withwireless asset management from Hyster. HysterTracker System provides true wireless fleetmanagement, can drive fleet efficiency, improvesoperator performance, reduces your carbon footprintand lowers your overall material handling costs.n Manage your total cost of operationn Ensure maximum productivity from your lift truck investmentn Monitor operator behaviour, promote safetyn Convenient web-based access, and your choiceof three levels of managementData is great, and your Hyster Dealer will make it work for youHyster Tracker System is a great addition to yourmanagement toolkit. And when you partner withyour Hyster Dealer, you get the best of both worlds – great fleet data plus the unmatched knowledge andexperience that can help you get the most out of every truck in your fleet.PAGE 11HYSTER J-GX SERIES BROCHUREHYSTER J-GX SERIES BROCHUREPAGE 12Contact your local Hyster Dealer /Hysterasiapacific @Hyster_APHYSTER ASIA PACIFIC 1 Bullecourt Avenue, Milperra NSW, Australia 2214Tel: +61 (2) 9795 3800 Fax: +61 (2) 9792 8484No. 49, Jalan Astaka V8/84A, Bukit Jelutong,40150 Shan Alam, Selangor, MalaysiaTel: +603 7831 3385.AU HYSTER ®DEALERS is a Registered Trademark.HYSTER is a Registered Trademark. STRONG PARTNERS. TOUGH TRUCKS. EZXCHANGE, HSM and VISTA are trademarks in the United States and certain other jurisdictions. © Hyster Asia Pacific 2016. All rights reserved. Printed in Australia. Specifications and details in this brochure are subject to change without prior notification. Please consult with your Hyster dealer for the most up to date information and to confirm exact capacities. BR0000045/V1.0 Contact your nearest Hyster Dealershipby visiting .au。

手动电甁叉车操作规程范本第一章总则第一条为保证人员安全,确保作业质量,减少货物的损坏和设备的故障,制定本规程。

第二条定义1. 手动电动叉车:指以人力或电力为驱动力,用于搬运、装卸货物的专用设备。

2. 操作人员:指经过培训,取得相应操作资格,负责手动电动叉车搬运货物的人员。

第三条适用范围本规程适用于公司内所有手动电动叉车操作人员,在任何手动电动叉车操作作业中必须严格遵守。

第二章操作要求第四条操作资格1. 手动电动叉车操作人员必须经过培训,并取得操作资格证书方可上岗。

2. 操作人员应定期进行岗前教育和专业培训,不得擅自使用未取得资格的设备。

第五条安全检查1. 操作人员在上岗前,应检查手动电动叉车的工作状况,确保设备正常运行。

2. 检查项目包括但不限于:刹车、转向、喇叭、灯光、液压系统、各种报警装置等。

3. 如发现异常情况,应及时上报,并由专业人员进行检修。

第六条员工着装1. 操作人员必须配戴安全帽、安全鞋,并穿着合适的工作服装。

2. 操作人员不得穿戴过宽过长的衣物,以免影响操作时的视线和行动。

3. 不得穿戴任何妨碍操作的手饰、项链等饰品。

第七条搬运货物1. 搬运货物前,必须对货物进行认真检查,确保货物放置稳定、没有明显破损或泄漏。

2. 搬运货物时,应根据货物的形状、重量和重心合理选择叉头插入货物的位置和角度。

3. 搬运货物时,应确保货物与车身之间有足够的安全距离,以免发生碰撞或压倒等事故。

第八条操作技巧1. 操作人员应熟悉手动电动叉车的各种操纵装置和仪器仪表的使用方法。

2. 操作过程中,应保持警觉,时刻注意周围环境,预防障碍物和人员的突然出现。

3. 操作时,应稳定车身,平稳开动,并遵守交通规则,保持安全行车间距。

第三章安全注意事项第九条预防酒后操作1. 操作人员严禁饮酒后操作手动电动叉车。

2. 在完成作业前,操作人员不得饮酒。

3. 操作人员在工作时间内严禁饮酒。

第十条环境安全1. 在操作手动电动叉车之前,应检查作业环境,确保地面平整、没有积水或其他障碍物。

1-3吨蓄电池叉车使用保养说明书一、蓄电池叉车驾驶、操作的安全规程1.“安全第一”是驾驶员和单位管理者必须牢记的,按照我公司叉车使用维护说明书和驾驶员手册进行安全操作,这是必须要遵守的。

2. 叉车运输2.1 叉车在运输过程中要按规定捆扎;2.2 刹位停车制动,平衡重用方木垫好;2.3 覆盖防雨用具,以免淋湿或暴晒;2.4起吊是按叉车“起吊标牌”所注位置进行。

3. 停车注意事项3.1 货叉放到地面;3.2 关闭电锁,所有操纵杆放在空位,拔下电源插头;3.3 拉紧手刹;3.4 长期停用的叉车,应使车轮架空,蓄电池应每月充电一次。

4.使用前的准备4.1 阅读说明书和随机文件,熟悉仪表和各操纵机构位置,驾驶员要了解叉车结构性能,要持有驾照方可操作;4.2 检查仪表是否正常;4.3 检查蓄电池电压是否在正常范围之内,电解液比重及液面高度是否适宜;4.4 检查电气系统各接头及插头接触是否可靠,踏板调速是否灵活;4.5 检查脚制动及手制动是否可靠;4.6 检查液压油及制动液是否正常;4.7检查照明及信号灯是否正常。

5.操作注意5.1 注意机械,液压,电气及控制器的性能和工作状态;5.2 接通电源,打开钥匙开关,先确定好方向开关位置,转动方向盘看叉车是否转动正常,缓踩调速踏板,保持适当的起动加速;5.3 观察电压表的电压,若电压表低于41V,应立即停止运行,进行充电或更换蓄电池;5.4转弯时要提前减速行驶;5.5行驶与堆垛货物时,不宜联合操作,在路面较差的场地作业时,应减低起重量和运行速度;5.6不准超载,如货物体积较大,重心前移时,应遵守负荷曲线标牌的定额;5.7货叉距离合适,避免偏载;5.8货物靠近叉壁,尽可能将货物降低,门架后倾,叉车方可行驶;5.9为保证安全,货叉下禁止站人,货叉上禁止站人起升;5.10货物起升下降时,初速度不可太快;5.11门架前倾,后倾至极限位置或货叉起升至最大高度时,必须将操作手柄迅速回到中间位置;5.12叉车运载货物时,应尽量避免紧急制动,防止货物抛击受损或伤人。

CDP15中力电叉车说明书CDP15中力电动叉车使用说明书驾驶员在行驶时必须遵循CDP15中力电动叉车使用说明书使用说明和安全守则,与危险区域保持适当的距离以免受伤,叉车必须按照下列规定使用。

1. 驾驶员必须了解叉车的使用说明,熟悉叉车的结构和性能,穿戴适当的衣服鞋帽,佩戴好各种劳动保护用品。

2.只有年满18周岁,经过专门严格培训,考试合格,持证上岗。

严禁无证驾驶操作该叉车。

3.负责叉车的驾驶员不得允许未经认可的人驾驶叉车或站到货叉及站台上。

4. 叉车在歪曲路段或狭窄过道行驶,以及经过门或不规则路面时,操作人员必须减速。

5. 叉车严禁在凸凹不平的道路上行驶。

6. 驾驶员在叉车工作区域内工作时必须远离其他人员,如有危险立即发出警告。

如有人不理警告还留在工作区域时,操作人员必须停止作业。

7. 禁止将叉车停在有运动部件活动的区域里,严禁站在叉车的固定部件上。

8. 驾驶员应尽量避免突然停车及快速换向行驶。

9. 在允许的最大斜坡上行驶时,驾驶员必须保持货物始终在叉车上,同时减速。

10.驾驶员驾驶时必须确定视野清楚,回动时无障碍物。

11.如用起重机吊运叉车,必须货叉向前进入(首先确定起重机有足够的起重载荷)。

12.绝对禁止断开或拆除安全装置。

13.无论哪种情况下,叉车都不允许超载。

14.驾驶员必须确保载荷均匀有序的堆放在货叉上,不得偏置,否则易造成侧倾翻。

15.货物外形尺寸不得超出1000(长)×800(宽)×1000(高)。

16.当货叉处于上部位置时,禁止移动叉车,只有在拾起或放下载荷时,才允许这样操作。

17.载货行驶时货叉离地的最大高度不得超过300mm。

18.开始工作之前,驾驶员必须检查。

a.操控装置及刹车性能必须灵敏。

b.货叉状况正常完好。

c.前、后轮没有损坏。

d.电池已充电并固定好,各元器件清洁干燥。

e.所有的安全装置都处于工作状态。

19.一旦电池电压指示表发出信号,只剩20%电荷时,叉车必须停止使用进行充电,而且必须在完全充满后方可拔下充电器进行使用,严禁电池未充满就断开充电器与电源。

1.2-2t前移式蓄电池叉车CQD12/14/16/20HCQD12/14/16/20H-C1CQD12/14/16/20H-MCQD12/14/16/20H-MC1浙江杭叉工程机械股份有限公司2007年5月第4版前言承蒙购买杭叉股份叉车,在此深表谢意。

1.2-2吨系列前移式蓄电池叉车适用于狭窄通道和有限空间内作业,具有高起升、高承载能力,是仓库、超市、车间内装卸和堆垛的理想工具。

本使用维护说明书第一部分介绍了前移式蓄电池叉车的正确使用方法,第二部分介绍了前移式蓄电池叉车的常见故障,为了保证安全和充分发挥您所购买的堆垛叉车的性能,有关操作人员和维修人员,务必在使用前熟读说明书。

如有不明之处请与杭叉股份销售公司或代理商联络。

该系列叉车通过CE认证。

CQD12/14/16/20H-M 、CQD12/14/16/20H-MC1为特殊订货产品,与CQD12/14/16/20H、CQD12/14/16/20H-C1相比较,仅支腿的稍窄,其余均相同。

○C2007年5月第4版浙江杭叉工程机械股份有限公司目录前言第一部分操作与保养 (1)主要部件名称 (1)仪表与控制 (2)安全规则 (7)叉车结构和稳定性 (11)新叉车的磨合 (13)操作前检查 (14)驱动与操作 (16)存放 (17)电瓶 (18)维护 (24)定期维护时间表 (25)定期更换关键安全件 (30)螺栓拧紧力矩一览表 (31)叉车用油一览表 (31)叉车的搬运、吊起 (32)前移式蓄电池叉车主要技术参数表 (33)第二部分结构与故障 (35)传动系统 (35)转向系统 (37)制动系统 (38)液压系统 (39)起升系统 (41)电气系统 (42)。

目录目录 (1)第一章产品系列介绍 (2)第二章驱动器尺寸 (3)第三章端子定义 (4)第四章功能码简表(行走驱动器) (6)第五章功能码简表(转向驱动器) (13)第六章端子通信接线及调试 (15)6.1单独行走驱动接线图 (15)6.2调试说明 (15)第七章CANOPEN通信接线及调试 (17)7.1单独行走驱动接线图 (17)7.2调试说明 (17)7.3CAN通信简介 (18)第八章MODBUS通讯接线及调试 (23)8.1单独行走驱动接线图 (23)8.2调试说明 (23)8.3组网方式 (24)8.4接口方式 (24)8.5通讯方式 (24)8.6协议格式 (24)8.7协议功能 (26)8.8几点说明 (31)8.9应用举例 (32)第九章驱动器故障说明 (34)9.1故障灯显示 (34)附录驱动器面板操作说明 (35)第一章产品系列介绍第一章产品系列介绍表1-1叉车驱动器系列图1-1驱动器型号说明第二章驱动器尺寸第二章驱动器尺寸2.1行走驱动器尺寸图:图2-1单独行走驱动器尺寸图2.2行走驱动器+转向驱动器二合一尺寸图:图2-2单独行走驱动器尺寸图第三章端子定义3.1二合一端子定义图3-1二合一端子定义图图3-1二合一配线概图3.2行走驱动器端子定义图3-3一合一端子定义图图3-4一合一配线概图第四章功能码简表(行走驱动器)表4-1功能码简表(行走驱动器)说明注:AI1:行走电机油门信号(0~5V)第五章功能码简表(转向驱动器)表5-1功能码简表(转向驱动器)说明注:AI4:方向盘方向角度位置信号。

(电位器信号)A2、B2:转向电机编码器信号,实时监控方向角度参与驱动器控制。

SW1:转向电机原点光电开关,转向电机对中信号。

第六章端子通信接线及调试6.1单独行走驱动接线图B-、B接电池正负;U、V、W接电机输入,直流有刷接U、W。

图6-1驱动器接线6.2调试说明1.驱动器上电。

上电前确保电池电压与驱动器匹配。

设备名称 电升堆高机(电动叉车) 设备功能

装卸 文件编号 设备型号

TDB 厂 商 台冠机械

版 本 B0 一﹑结构﹕

二﹑操作步骤﹕

1. 打开电门锁﹐检查电压表电压是否在规定范围(5-14.2V)﹔

2. 右手握住升降操纵杆缓慢向前推﹐此时两载重叉会往上升﹐到达预定位置后﹐把操纵杆缓慢向后拉﹐载重叉会往下降﹐直到下降完毕﹔

3. 停机后关电门锁﹐并且拔出钥匙。

三﹑注意与保养﹕

1. 本车充电在220V/50HZ 的AC 线路上充电﹐若电压表指针低于5V 时﹐则要充电。

2. 电池的充电压应严格限定在1

3.8V-1

4.2V 范围内。

3. 便用时电池余容量不得低于1/4否则容易引起电池无法充电。

4. 作业时本车最大承载1500kg ﹐严禁超负荷使用。

载重物时﹐必须把货叉放至最低﹐方可拉动叉车。

核 准 审 核 制 作 日 期

电压表

保险管 升降操纵手柄 电源指示灯 充电指示灯 电源开关 充电开关。