谢宁DOE教材

- 格式:ppt

- 大小:462.50 KB

- 文档页数:34

Shainin DOE所属分类:质量管理工具目录 [隐藏]∙谢宁方法概述∙谢宁方法的主要内容∙经典方法、田口方法以及谢宁方法比较编辑谢宁方法概述实验设计(DOE)方法一直在发展、丰富和完善,美国人多里安·谢宁(Dorian Shainin)总结了七种新的DOE应用技术:多变图技术、零件搜索技术、成对比较技术、变量搜索技术、完全析因技术、改进效果检查及实验设计的回归分析。

编辑谢宁方法的主要内容1、多变图技术根据以往经验确定影响质量的可能要素,例如工人班次、机床、原材料、工艺变量等,每隔一段时间抽取连续生产的几件产品,按需观察的这些要素的几种情况分别测试质量特性,画成图表进行比较分析,以确定引起波动的原因。

2、零件搜索技术根据以往经验确定影响产品质量的可疑零件,随机选取几个好的产品和坏的产品,将坏产品上的可疑零件与好产品上的对应零件进行交换,重新装配后进行质量特性参数的测量、比较、分析,以找到影响产品质量的主要零件。

3、成对比较技术随机选取5对以上的好的和坏的产品,用各种方法测试其各种参数并比较其不同之处,以确定影响产品质量的主要原因。

成对比较技术适用于不可拆卸的产品。

4、变量搜索技术与零件搜索有许多相似之处,都是逐个替换,进行测试比较,以搜索引起产品质量波动的主要原因,但变量搜索是针对变量的,而零件搜索则是针对零件的。

5、完全析因技术采用以上四项技术,寻找出4个以下的主要因素,这些因素按全部因素所有水平的一切组合逐次进行实验,研究这些因素的主效应和相互之间的交互作用,以确定最佳的因素水平匹配方案。

6、改进效果检查令B为改进后的工序,而C为改进前的工序。

为了验证改进效果,可以设定风险率a(第Ⅰ类风险)和b(第Ⅱ类风险),随机抽取B和C两种产品(样本量由风险率决定),进行假设检验,以确定在规定的风险率下,B产品是否优于C产品。

7、实验设计的回归分析对散布数据作出散布图,应用回归理论,诊断出对产品影响大和小的因素,从而找出影响产品质量波动的主要原因,并根据波动大小,确定各因素的目标值和容差。

qsconsult www.qsconsult.be1 Willy VandenbrandeShainin: A concept for problemsolvingLecture at the Shainin conferenceAmelior11 December 20092Dorian Shainin (1914 –2000)•Aeronautical engineer (MIT –1936)•Design Engineer for United Aircraft Corporations •Mentored by his friend Joseph M. Juran•Reliability consultant for Grumman Aerospace (Lunar Excursion Module)•Reliability consultant for Pratt&Whitney (RL-10 rocket engine)•Developed over 20 statistical engineering techniques for problem solving and reliability •Started Shainin Consultants in 1984, his son Peter is currentCEO.Dorian Shainin and ASQ•15th ASQ Honorary Member (1996)•First person to win all four major ASQ medals•In 2004 ASQ created the Dorian Shainin Medal–For outstanding use of unique or creativeapplications of statistical techniques in thesolving of problems related to the quality of aproduct or service.3Dorian Shainin•Not very well known outside USA (compared to Deming, Juran)•1991: Publication of first edition of“World Class Quality”by Keki Bothe •2000: Second edition (Keki and Adi Bothe)•Books brought attention to Shainin methods, but are very biased.4Problem Solving •Focus is on variation reductionLSL USLLSL = Lower Specification Limit USL = Upper Specification LimitBeforeAfter5Problem Solving•But also …LSLAfterBefore6Basic Shainin assumption•The pareto principle of vital few and trivial many.•Only a few input variables are responsible for a large part of the output behavior.–Red X TM–Pink X TM–Pale Pink X TM•Problem solving becomes the hunt for the Red X TM7Shainin tools•Recipe like methods / statistics in the background•Comparing extremes allows easier detection of causes–BOB Best of Best–WOW Worst of Worse•Non parametrics with ranking tests in stead of calculations with hypothesis tests•Graphical Methods•Working with small sample sizes•The truth is in the parts, not in the drawing: let the parts talk!8Preliminary activities•Define the critical output variable(s) to be improved (called problem Green Y®)•Determine the quality of the Measurement System used to evaluate the Green Y®–A bad measurement system can in itself beresponsible for excessive variation–Improvements can only be seen if they can bemeasured910Overview of Shainin toolsComponents Search Multi-Vari chart Paired Comparisons Variables Search Full FactorialsB vs CScatter Plots PrecontrolProduct / ProcessSearchRSM methodsPositrolProcess CertificationClue generatingFormal Doe toolsValidationOptimization AssuranceOngoing controlControl20 –1000 variables5 –20 variables4 or less variablesNo interactionsInteractionsGeneral comments•Gradually narrowing down the search•Clear logic–Analyzing–Improving–Controlling•Not all tools are “Shainin”tools•“What’s in a name?”–Positrol versus Control Plan–Process Certification versus Process Audit11Tool details•Overview of methods•More info on B vs C TM and Scatter Plots in workshops•Some more detail on–Multi-Vari chart–Paired Comparison TM and Product/ProcessSearch–Pre Control1213Clue Generating / Multi-Vari Chart Very useful tool and best applied beforebrainstorming causes on excess variationComments Samples taken in production on current process Could be a big measurement investment Sample SizeDivide total variation in categories Search for causes of variation in the biggest category first PrinciplesProblem type: excess variation Wide applicability ApplicationUnderstand the pattern of variation Define areas where not to look for problems Allow a more specific brainstorm ObjectiveMulti-Vari Chart•Breakdown of variation in 3 families:–Positional(within piece, between cavities, …)–Cyclical(consecutive units, batch-to-batch, lot-to-lot)–Temporal (hour-to-hour, shift-to-shift, …)1415Multi-vari Chart•If one family of variationcontains a large part oftotal variation, we canconcentrate oninvestigating variablesrelated to this family ofvariation.16Clue Generating / Component SearchTM Disassembly / reassembly requirement limitsapplication.Comments 2 = 1 BOB and 1 WOW Sample SizeSelect BOB and WOW unit Exchange components and observe behavior. Components that change behavior are Red X comp PrinciplesProblem type: assembly does not perform to spec Limitation: Disassembly / Reassembly must be possible without product change ApplicationFind the component(s) of an assembly that is (are) responsible for bad behavior Objective17Clue Generating / Paired ComparisonTM Practical application of “let the parts talk”Comments5 to6 pairs of 1 BOB and 1 WOWSample SizeSelect pairs of BOB and WOW units Look for differences Consistent differences to be investigated further PrinciplesProblem type: occasional problems in production flow ApplicationFind directions for further investigationObjectivePaired Comparisons TM: method•Step1: take1 good and 1 bad unit–As close as possible in time–Aim for BOB and WOW units•Step2: note the differences between these units (visual, dimensional, mechanical, chemical, …). Let the parts talk!•Step3: take a second pair of good and bad units.Repeat step218Paired Comparisons TM: method •Step4: repeat this process with third, fourth, fith, …pair until a pattern of differences becomes apparent. •Step5: don’t take inconsistent differences into account. Generally after the fith or sixth pair theconsistent differences that cause the variationbecome clear.1920Clue Generating / Product/Process Search Tukey test is alternative for t-testWidely applicable methodProblem: available data (process parameters)Comments 8 BOB and 8 WOW units / batches Sample SizeSelect sets of BOB and WOW units –batches -..Add product data / process parameters and rank Apply Tukey test to determine important parameters PrinciplesProblem type: Various types of problems ApplicationPreselection of variables out of a large group of potential variables ObjectiveProduct/Process Search: example•Transmission assemblies rejected for noise.•Components search shows idler shaft as responsible component•One of the parameters of idler shaft is “out of round”•8 good / 8 bad units selected and measured for “out of round”2122Product/Process search: example0.0070.0110.0190.0170.0220.0140.0180.015Out of round good units(mm)0.0170.0210.0230.0240.0230.0160.0180.019Out of round bad units(mm)Tukey test procedure•Rank individual units by parameter and indicate Good / Bad.•Count number of “all good”or “all bad”from one side and vice versa from other side.•Make sum of both counts.•Determine confidence level to evaluate significance.2324Tukey test confidence levels99.9%1399%1095%790%6ConfidenceTotal end count25Tukey test: example0.0230.0230.0240.0160.0170.0180.0190.0210.0170.0180.0190.0220.0070.0110.0140.015BadGood Top end count (all good)4Bottom end count (all bad)3Overlap regionTukey test: example•Total end count = 4 + 3 = 7•95 % confidence that out-of-round idler shaft is important in explaining the difference in noise levels.2627Formal Doe tools / Variables SearchAlternative to fractional factorials on two levels Method comparable to components searchCommentsNumber of tests is determined by number of variables and quality of ordering.Sample Size List variables in order of criticality (process knowledge) and indicate good / bad level.Swap factor settings and observe behavior.Factors that change behavior (and interactions) are red X TM , Pink X TMPrinciplesProblem type: Various types of problemsAfter clue generating more then 4 potential variables leftApplicationDetermine Red X TM , Pink X TM including quantification of their effectObjective28Formal Doe tools / Full FactorialsWell established methodCommentsNumber of tests is determined by number of variables k (2k test combinations)Sample Size Classical DOE with Full Factorials at two levels Main Effects and interactions are calculated Principles Problem type: Various types of problems After clue generating 4 or less variables left Application Determine Red X TM , Pink X TM including quantification of their effectObjective29Formal Doe tools / B(etter) vs C(urrent)TMQuick validation that works well with big improvementsComments3 B and 3 C tests (each test can involve several units –test of variation reduction)All 3B’s must be better than all 3C’s Sample Size Create new process using optimum settings and compare optimum with current.Principles Problem type: Various types of problemsApplication Validation of Red X TM , Pink X TMObjective30Optimization / Scatter PlotsGraphical method that could easily be transformed to a statistical methodComments30 tests for each critical variableSample Size Do tests around optimum and use graphical regression to set tolerancePrinciples Problem type: Variation Reduction and optimizing signalApplication Fine tune best level and realistic tolerance for Red X TM , Pink X TM if no interactions are present Objective31Optimization / Response Surface Methods Method developed by George Box CommentsDepends on variables and surface.Sample SizeEvolutionary Operation (EVOP) to scan response surface in direction of steepest ascent PrinciplesProblem type: Variation Reduction and optimizing signal ApplicationFine tune best level and realistic tolerance for Red X TM , Pink X TM if interactions are present ObjectiveEVOP example3233Control / PositrolCan be compared with a Control Plan CommentsChecking frequency in the When columnSample SizeTable of What, How, Who, Where and When control has to be exercised. PrinciplesProblem type: all types ApplicationAssuring that optimum settings are kept Objective34Control / Process CertificationMix of 5S, Poka-Yoke, instructions, ISO 9000,audits,…Comments Checking frequency to be determined Sample SizeMake overview of things that could influence the process and install inspections, audits, …PrinciplesProblem type: all typesApplicationEliminating peripheral causes of poor quality Objective35Control / Pre ControlAlternative to classical SPCTraffic lights systemVery practical methodComments Checking frequency to be determinedSample SizeDivide total tolerance in colored zones and use prescribed sampling and rules to control the process.PrinciplesProblem type: control variation and setting of the process ApplicationContinuous checking of the quality of the process output Objective36Pre-Control: chart constructionUSL LSLTARGET ½TOL1/4 TOL1/4 TOLPre-control: use of chart1.Start process: five consecutive units ingreen needed as validation of set-up.2.If not possible: improve process.3.In production: 2 consecutive units4.Frequency: time interval between twostoppages (see action rules) / 6.3738Pre-control: action rulesStop and act 2 units in different yellow zoneStop and act1 unit in red zone Correct2 units in same yellow zoneContinue 1 unit in green and 1 unit in yellowzoneContinue 2 units in green zoneAction Result of samplesAfter an intervention: 5 consecutive units in green zone39Pre-control: exampleTime StartCorrect Startqsconsult www.qsconsult.be40 Willy VandenbrandeWilly Vandenbrande, Master TQM ASQ Fellow-Six Sigma Black Belt Montpellier 34B -8310 BruggeBelgië-BelgiumTel + 32 (0)479 36 03 75E-mail willy@qsconsult.be Website www.qsconsult.beQS Consult。

DOE实验设计-田口/经典/谢宁综合问题解决方法培训时间:2019年08月23-24日深圳培训费:3800元/人(含资料费、午餐费、专家演讲费、会务费)住宿可统一安排,费用自理培训对象:工程部门人员(特别是IE)、工程经理、工程技术骨干、质量经理、质量工程师咨询电话:400-086-8596认证费用:中级证书1000元/人;高级证书1200元/人(参加认证考试的学员须交纳此费用,不参加认证考试的学员无须交纳)备注:1.高级证书申请须同时进行理论考试和提交论文考试,学员在报名参加培训和认证时请提前准备好论文并随理论考试试卷一同提交。

2.凡希望参加认证考试之学员,在培训结束后参加认证考试并合格者,由“香港国际职业资格认证中心HKTCC”颁发与所参加培训课程专业领域相对应证书。

(国际认证/全球通行/雇主认可/联网查询)。

3.课程结束后20日内将证书快递寄给学员;∵〖课程背景〗DOE实验设计在产品诞生的整个过程中扮演了非常重要的角色,它是提高产品质量,改善工艺流程,优化设计的重要工具。

通过两天的课程,将通过对产品生成的各阶段的DOE应用,学习判别与选择不同的实验设计工具,解决相应的问题,同时相关人员了解DOE在自己工作中可以帮到什么。

通过我们六年的授课实践和不断研究,采用逻辑上的重整和合并,在两天的课程之内,将田口、经典和谢宁三种风格的DOE结合起来,不但是完全可以的,而且能保证内容上的翔实,困惑的解除,有助于快速掌握和灵活应用。

对DOE的整合是通过贯穿始终的产品诞生路径、质量与可靠性风险的线索,它是本课程的独家内容,会为学员带来特别的增值价值。

此外,课程提供持续的支持服务和交流活动,学员在课后应用中的问题,老师将提供持续的解答和辅导,很多学员都已经成为我们多年的朋友。

今天,DOE这个词给很多工程人员带来了困扰,很多误区由此而生:它是做6sigma才需要的。

它需要深入的统计数学基础,掌握起来非常困难,即使掌握了,距离解决问题也很远它能最终解决一切问题,但是耗费的周期很长如果没有其他部门的配合,发起部门就无法将试验设计做到有结果。

谢宁DOE(谢宁方法)主办单位: 上海普瑞思管理咨询有限公司时间地点:2010年10月22-23日苏州收费标准: 2600元/人(含培训费、资料费、午餐、培训证书等)课程背景谢宁DOE (谢宁方法)是由道林•谢宁(Dorian Shainin)研究开发的解决产品设计开发、过程设计开发和制造过程控制中的质量问题的系统方法和工具。

工具名称作为服务商标受法律保护,很少文章讨论,而公众不知详细内容,从SPC、DOE、数理统计和部件交换技求导出,用现成公式,而不需数理统计知识和计算,谢宁(Shainin)DOE工具作为一个由果到因系统解决问题的方法,采用从果到因的方式,以现有结果为起点,反向开展搜索根本原因。

谢宁(Shainin)DOE解决问题针对性强、不打断生产、效果好的优点。

“没有戴明,美国就不会有质量哲学;没有朱兰,美国就不会有质量的方向;没有谢宁,美国就无从解决质量问题”。

这句名言总结了美国最伟大的三位质量大师的贡献。

课程目标•提高对DOE的认识,从根本上摒弃依靠“啪脑袋”和“工程猜测”解决问题的传统陋习•了解应用DOE的必备条件•掌握谢宁DOE工具的应用步骤•掌握如何在Minitab中运行DOE•系统性地应用DOE工具,提高过程质量及生产效率学员要求具备基本的运算能力,了解统计概念,并有统计过程控制(SPC)和测量系统分析(MSA)的经验。

带电脑,会使用简单的Minitab软件功能。

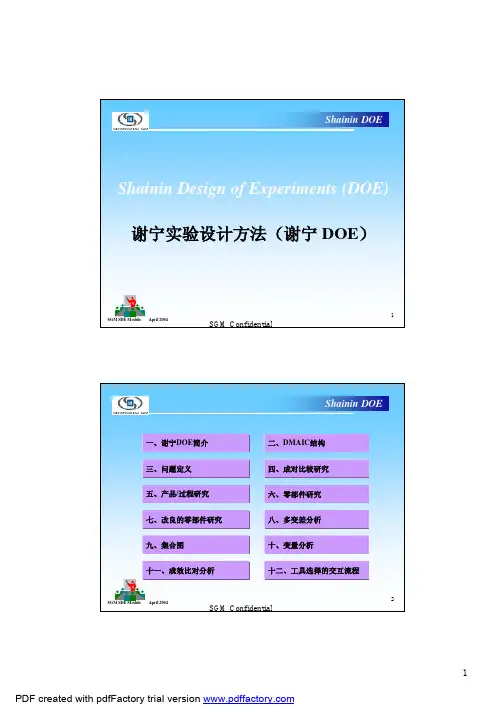

课程大纲一谢宁DOE介绍- 实验设计的质量改进哲学- 三种实验设计流派简介- 谢宁DOE的思考路径- DMAIC 分析结构- 基本统计技术复习- Minitab中的统计分析- 数据分析与质量控制二多层变差图- 多层变差模型- 分层法调查表- 多层变差图- 变差过程分析案例三 AVOVA具体分析、线索生成及筛选工具、特征化及建模工具- 正态概率图- Pareto- 主效果图- 交互效果图- ANOVA- 多元回归- 简化模式- 线索生成及筛选工具- 多变量图- 集中图- 元件搜索- 配对比较- 过程搜索- 特征化及建模工具- 变量搜索- 析因设计四优化工具、监控工具具体案例分析、DOE方法在运用和案例练习与操作- 散点图- 响应曲面法- 变量搜索- 析因设计- B vs C(改进效果检查- 积极控制- 过程认证- 预控制图- 谢宁DOE开展的流程- 判断的方法是否可以解决的具体问题- 问题的特征值是否可测量- 减少搜索范围- 确定根本因子- 量化因子的效应- 验证改进的建议- 确定工艺参数边界- 控制过程- 谢宁DOE方法全天课程中的要点回顾、讨论及解答- 谢宁DOE方法及运用案例练习与操作(分组讨论、实际操作)- 谢宁DOE方法的汇总与练习后分析(结合工厂自身的情况和老师进行探讨)讲师介绍徐老师现任排名前十世界500强企业亚太区质量经理,协助中国区各工厂推行GE北美质量体系及精益6西格玛系统,协助下属各工厂进行精益6西格玛推行。

谢宁DOE-快速解决复杂问题方法培训课程1对1培训及咨询、百度文库官方认证机构、提供不仅仅是一门课程,而是分析问题,解决问题的方法!管理思维提升之旅!(备注:具体案例,会根据客户行业和要求做调整)知识改变命运、为明天事业腾飞蓄能上海蓝草企业管理咨询有限公司蓝草咨询的目标:为用户提升工作业绩优异而努力,为用户明天事业腾飞以蓄能!蓝草咨询的老师:都有多年实战经验,拒绝传统的说教,以案例分析,讲故事为核心,化繁为简,互动体验场景,把学员当成真诚的朋友!蓝草咨询的课程:以满足初级、中级、中高级的学员的个性化培训为出发点,通过学习达成不仅当前岗位知识与技能,同时为晋升岗位所需知识与技能做准备。

课程设计不仅注意突出落地性、实战性、技能型,而且特别关注新技术、新渠道、新知识、创新型在实践中运用。

蓝草咨询的愿景:卓越的培训是获得知识的绝佳路径,同时是学员快乐的旅程,为快乐而培训为培训更快乐!目前开班的城市:北京、上海、深圳、苏州、香格里拉、荔波,行万里路,破万卷书!蓝草咨询的增值服务:可以提供开具培训费的增值税专用发票。

让用户合理利用国家鼓励培训各种优惠的政策。

报名学习蓝草咨询的培训等学员可以申请免费成为“蓝草club”会员,会员可以免费参加(某些活动只收取成本费用)蓝草club定期不定期举办活动,如联谊会、读书会、品鉴会等。

报名学习蓝草咨询培训的学员可以自愿参加蓝草企业“蓝草朋友圈”,分享来自全国各地、多行业多领域的多方面资源,感受朋友们的成功快乐。

培训成绩合格的学员获颁培训结业证书,某些课程可以获得国内知名大学颁发的证书和国际培训证书(学员仅仅承担成本费用)。

成为“蓝草club”会员的学员,报名参加另外蓝草举办的培训课程的,可以享受该培训课程多种优惠。

一.市场营销岗位及营销新知识系列课程《狼性销售团队建立与激励》《卓越房地产营销实战》《卓越客户服务及实战》《海外市场客服及实务》《互联网时代下的品牌引爆》《迎销-大数据时代营销思维与实战》《电子商务与网络营销-企业电商实战全攻略》《电子商务品牌成功之路-塑造高情商(EQ)品牌》《精准营销实战训练营》《卓越营销实战-企业成功源于成功的营销策划》《关系营销-卓越营销实战之打造双赢客户》《赢销大客户的策略与技巧》《如何做好金牌店长—提升业绩十项技能实训》二.财务岗位及财务技能知识系列《财务报表阅读与分析》《财务分析实务与风险管理》《非财务人员财务管理实务课程》《有效应收账款与信用管理控制》《总经理的财务课程》《财务体系人员的营销管理》《全面预算管理》《全面质量成本管理及实务》。

谢宁DOE-快速解决复杂问题方法培训●课程背景在流程优化的众多策略和方法中,美国质量专家多利安.谢宁发明和整合的试验设计DOE具有简捷、效果强大,改进成本低等优点。

谢宁DOE结合经典DOE方法,是解决企业经营生产中的一系列问题尤其是复杂问题无法替代的突破性方法。

谢宁DOE解决问题不仅针对性强,而且具有效果好,不打断生产的优点。

“没有戴明,美国就不会有质量哲学;没有朱兰,美国就不会有质量的方向;没有谢宁,美国就无从解决质量问题”。

这句名言总结了美国最伟大的三位质量大师的贡献。

本课程通过大量的故事/游戏,案例/讲解,讨论/练习等方式,由浅入深,生动演绎解决企业生产/工艺/质量/设计乃至管理问题的最佳途径。

●培训对象质量总监、质量经理、质量主管、质量工程师、质量技术员;技术总监、经理、工程师、技术员;产吕流程总监、经理、工程师、技术员;研发总监、经理、工程师;生产经理、生产主管以及想提高自己解决复杂问题能力的所有工程师(PE,ME,QA,SQE等)。

●培训时间2天●课程收获对企业而言,我们确保学员在培训完成后,大家能选用最简单、最实用、最强大的工具来解决实际中的质量问题。

有条件的企业(尤其是内训课程),可选取1个老大难问题作为课堂讨论/练习的一部分,随着课程的结束,最终找到问题的解决方案。

课程宗旨:培训是解决问题的开端,实践出真知,改善无止境。

●课程大纲第一章谢宁DOE基础一.变化二.中心趋势的度量三.离散度的度量四.总体与样本的统计量五.正态分布第二章谢宁DOE介绍一.谢宁介绍二.DOE(Design of Experiments)三.谢宁DOE概念定义第三章谢宁DOE的10大工具第一节初级DOE工具一.多变量分析1.多变量分析介绍2.多变量分析的步骤3.样例研究:设计多变量4.确定取样频率和所需部件的数量5.课堂练习6.MINITAB的操作二.集中图1.集中图介绍2.样例研究3.课堂练习三.部件调查1.部件调查介绍2.什么是交互作用3.交互作用图4.部件调查的步骤5.第一步列出可疑子部件,确定问题是否在装配过程中6.第二步调换好的和差的子部件来测试7.第三步最终调换8.第四步因子分析9.课堂练习10.课后练习四.成对数据比较1.成对数据比较介绍2.成对数据比较步骤3.成对数据比较的置信度4.样例研究一5.样例研究二6.练习一7.练习二确定导致问题的参数五.过程参数调查1.过程参数调查介绍2.注意事项3.过程参数调查的步骤4.课堂练习第二节高级DOE工具一.变量调查1.变量调查介绍2.变量调查的步骤3.第一步是否为试验确定了正确的参数和水平4.第二步区分重要的和不重要的参数5.第三步验证第2步中确定的重要参数是否真的重要6.第四步量化重要参数的数量和期望水平,以及它们的关联交互作用7.课堂练习二.全因子分析1.全因子分析介绍2.基本原则3.随机化与试验设计的关系4.全因子试验步骤5.样例研究6.课堂练习第三节确认改善效果一.测试原因确认1.测试原因确认介绍2.测试原因确认之目标3.测试原因确认的两种情况4.测试原因确认步骤5.样例研究一6.确定选择项之间的改进量7.置信水平的K值8.样例研究二9.课堂练习-110.课堂练习-2二.用变量调查作过程验证和确认1.变量调查作过程验证和确认介绍2.课堂练习第四节优化变量一.散布图1.散布图的相关性2.绘制散布图的步骤3.通过散布图决定公差4.利用散布图确定规格注意事项二.响应曲面图1.调优运算-2因子2.单纯形法-2因子第五节预控制图一.预控制图是什么二.预控制图的方法三.使用图表来查看预控制图的操作原则四.只有单边限制的预控制图五.控制图课堂练习培训总结与答疑。

《DOE——实验设计》【课程背景】如何以最低成本实战顾客满意最大化,是所有企业目前共同的目标。

但是,所有工程技术和管理人员都会面临一些设计问题而导致目标很难实现,DOE作为一种产品研发的最强大工具可以帮助管理者解决这些问题。

DOE(实验设计)不但可帮助研发工程师一开始从质量和成本进行最优化设计,而且可把产品工艺和使用因素都考虑周全,从而设计出先天性健壮产品(这恰恰是大多数工程师的困惑)。

同时DOE(实验设计)也是寻找原因、分析和优化复杂因子最强大的解决问题的工具和方法。

在不少日本企业,不懂DOE(实验设计)的工程师不能称之为合格的工程师。

DOE(实验设计)包括传统经典DOE(析因实验设计)、RSM(响应优化曲面)、混料DOE(生化行业最有用)、田口DOE(抗噪声设计)和谢宁DOE(快速解决问题实验设计),每种DOE(实验设计)各有其特点。

DOE(实验设计)除了与六西格玛其它工具联合起来发挥巨大功能外,本身也是一套系统地解决问题方法。

【课程目的】本课程重点针对从事产品研发人员和相关工程技术人员而设计。

旨在帮助学员系统、全面地应用DOE(实验设计)在产品研发、产品和过程之改善时分析重要因子,优化结果,提高产品和过程健壮性(先天性高免疫能力)。

通过本课程的学习, 使学员能掌握DOE工具,进行产品、过程的健壮设计及持续改进:理解DOE的原理;掌握MINITAB软件DOE主要菜单; 掌握DOE进行产品、过程改进的步骤和方法。

1、掌握DOE(实验设计)的基本概念和原理;2、掌握经典DOE(实验设计)、混料DOE(实验设计)、田口DOE(实验设计)区别及优缺点,能据问题需要选择合理DOE(实验设计);3、掌握如何应用析因试验从众多影响因素中筛选找出影响输出的主要因素,以最少的投入换取最大的收益;4、掌握如何对因子水平优化得到最佳输出,从而使产品质量得以提升,工艺流程最优化;5、掌握田口实验设计方法,提高产品和过程信噪比,提高健壮性;6、科学合理地安排试验,减少试验次数、缩短试验周期,提高经济效益;8、掌握如何应用MINITAB软件对DOE(实验设计)设计、数据分析、优化因子和预测输出。

DOE实验设计-田口/经典/谢宁综合问题解决方法蓝草咨询提供的训练培训课程以满足初级、中级、中高级的学员(含企业采购标的),通过蓝草精心准备的课程,学习达成当前岗位知识与技能;晋升岗位所需知识与技能;蓝草课程注意突出实战性、技能型领域的应用型课程;特别关注新技术、新渠道、新知识创新型知识课程。

蓝草咨询坚定认为,卓越的训练培训是获得知识的绝佳路径,但也应是学员快乐的旅程,蓝草企业的口号是:为快乐而培训为培训更快乐!蓝草咨询为实现上述目标,为培训机构、培训学员提供了多种形式的优惠和增值快乐的政策和手段,可以提供开具培训费的增值税专用发票。

∵〖课程背景〗DOE实验设计在产品诞生的整个过程中扮演了非常重要的角色,它是提高产品质量,改善工艺流程,优化设计的重要工具。

通过两天的课程,将通过对产品生成的各阶段的DOE应用,学习判别与选择不同的实验设计工具,解决相应的问题,同时相关人员了解DOE在自己工作中可以帮到什么。

通过我们六年的授课实践和不断研究,采用逻辑上的重整和合并,在两天的课程之内,将田口、经典和谢宁三种风格的DOE结合起来,不但是完全可以的,而且能保证内容上的翔实,困惑的解除,有助于快速掌握和灵活应用。

对DOE的整合是通过贯穿始终的产品诞生路径、质量与可靠性风险的线索,它是本课程的独家内容,会为学员带来特别的增值价值。

此外,课程提供持续的支持服务和交流活动,学员在课后应用中的问题,老师将提供持续的解答和辅导,很多学员都已经成为我们多年的朋友。

今天,DOE这个词给很多工程人员带来了困扰,很多误区由此而生:它是做6sigma才需要的。

它需要深入的统计数学基础,掌握起来非常困难,即使掌握了,距离解决问题也很远它能最终解决一切问题,但是耗费的周期很长如果没有其他部门的配合,发起部门就无法将试验设计做到有结果。

这些都是我们在看书,听讲座,参加研讨会之后产生的感觉。

我们耗费了很多时间去学习DOE,也许发现总是没有耐心学下去,而公司产品中的问题却依然存在,困扰我们的问题是如此的长期和顽固,挥之不去:这到底是装配过程的问题,还是设计问题或供应商来料问题?这到底是不是真正的原因?每个零件都合乎规格和要求,为什么装到一起就出问题?出厂前从来没有发现过,怎么到市场上就出现,甚至一开箱就出现?有些问题非常难再现出来,收集足够的数据用来进行正统的DOE分析也是不现实的,怎么办?谢宁DOE正是解决以上困扰的利器,与其说是它一种技术理论,不如说是一种思维方式,它是一个开放的思维平台,融合了众多用创造性思维解决问题的模式,在这一点上它体现了开放的思想,它不会嘲笑基层设备维修人员调试机器时用的逐项试验是乡巴佬,也不会蔑视班组长把少数几个不良样品进行可疑零件的互换是不登大雅之堂,没技术含量,甚至CEO都有可能蹲在在生产线用它在纸上随手写写画画,和工人一起分析问题,也许我们平时在分析不良样品的时候用的方法,正是谢宁DOE的组成部分,这些实实在在的行动,都被认为是非常可贵的,只不过,我们平时对一些问题困惑的原因是没有把那些方法运用合适,或者没有坚持到底。