污水处理厂高程设计参考

- 格式:docx

- 大小:129.43 KB

- 文档页数:10

污水处理厂高程设计参考一、引言污水处理厂的高程设计是指确定各处理单元之间的高度差和流向,以保证污水在处理过程中能够顺利流动,并达到处理效果。

本文将针对污水处理厂高程设计进行详细介绍。

二、设计原则1. 保证流动性:在设计过程中,应确保污水能够自然流动,避免死角和积水现象的发生。

2. 考虑处理工艺:根据污水处理工艺的特点,合理安排各处理单元之间的高度差和流向,以提高处理效果。

3. 节约能源:在设计过程中,应尽量减少泵站的使用,采用重力流动的方式来降低能耗。

4. 考虑维护和操作:设计时应考虑到维护和操作的便利性,确保设备的正常运行和维护。

三、高程设计步骤1. 采集基础数据:采集污水处理厂所在地的地形地貌、地下水位等基础数据,用于后续的设计计算。

2. 制定高程控制方案:根据处理工艺和设备布置方案,制定高程控制方案,确定各处理单元之间的高度差和流向。

3. 进行水力计算:根据设计流量和处理工艺,进行水力计算,确定各处理单元的水位和流速。

4. 设计污水管道:根据水力计算结果,设计污水管道的高程和坡度,确保污水能够顺利流动。

5. 设计泵站:如果需要使用泵站,进行泵站的设计,确定泵站的位置和泵的参数。

6. 进行校核和优化:对设计结果进行校核和优化,确保设计的合理性和安全性。

7. 编制设计报告:根据设计结果,编制污水处理厂高程设计报告,包括设计原理、计算过程和结果等内容。

四、实例分析以某污水处理厂为例,设计流量为10000m³/d,采用A2/O工艺进行处理。

根据设计原则和设计步骤,进行高程设计如下:1. 制定高程控制方案:根据A2/O工艺的特点,确定进水池、调节池、好氧池、缺氧池、沉淀池和出水池的高度差和流向。

2. 进行水力计算:根据设计流量和工艺要求,计算各处理单元的水位和流速。

3. 设计污水管道:根据水力计算结果,设计各处理单元之间的污水管道的高程和坡度。

4. 设计泵站:根据需要,设计泵站的位置和泵的参数,确保污水能够顺利流动。

陕西省咸阳市污水处理工程设计一、工程背景概况咸阳市位于陕西省关中平原中部,距省会西安25公里,全市辖2区10县1个县级市,总面积10196平方公里,总人口480万,市区人口43万,已形成了以电子、能化、医药、食品四大支柱产业和轻纺、机械、建材三大传统产业为主的工业布局. 渭河干流从南缘流过,在市境汇入的主要支流有漆水河、新河、沣河、泾河、石川河,其中泾河最大,形成了泾河、渭河两大水系,是该市的河流水系。

咸阳地处内陆中纬度地带,属暖温带大陆性季风气候。

年平均气温9~13.2℃,最热月平均气温21.2~26.5℃,最冷月−5.0~−0.9℃。

极端最高气温42℃,极端最低气温−24.9℃。

年日照时数2045小时。

多年平均降雨量577毫米,集中于7、8、9月,占总量的50~60%,受季风环流影响,冬季多北风和西北风,夏季多南风或东南风,市区全年主导风向为东北风,频率为18%,年平均风速2.55米/秒,最大冻土深度为0.5m ,地下水位为2~5m 。

该污水处理厂选址于东郊渭河北岸河堤与咸铜铁路交汇处的金家庄附近一块三角地带,场地地势平坦,由西北坡向东南,场地标高384.5~383.5米之间,位于城市中心区排水管渠未端。

厂区南邻人民路和渭河大堤,西北向为咸铜铁路,东边紧靠建材路,交通便利。

该选址适于建造大型污水处理厂。

二、水质水量及处理要求 (1)污水水量、水质 1)设计规模 ① 二级处理日处理能力 设计平均流量Q ave=100000m 3/d 小时平均流量q ave=4167m 3/h (或1158 L/s )设计最大流量Q max=5417m 3/h (或1505L/s ) 变化系数K Z=1.30② 三级处理日处理能力 设计平均流量Q ave=30000m 3/d 小时平均流量q ave=1250m 3/h (或347 L/s )设计最大流量Q max=1625m 3/h (或452 L/s )2)进水水质COD cr:500mg/L BOD 5:200mg/L SS :300mg/L NH 4+-N :35mg/L pH :7.0~8.5(2)污水处理要求1)二级处理COD cr≤120mg/L BOD 5≤30mg/L SS ≤30mg/L NH 4+-N ≤25mg/L pH :6~92)三级处理COD cr≤50mg/L BOD 5≤10mg/L SS ≤5mg/L NH 4+-N ≤15mg/L pH :7.0~8.0三、污水处理工艺流程设计图一、咸阳市污水处理工艺流程根据分析比较,选择AB 法污水处理工艺(简称“吸附-生物降解工艺”)。

本设计污水处理厂综合设计包括15个图纸,十分全面,具体详见报告后附图。

本报告附图全面详细。

图纸内容如下:A2O池,初沉池,幅流式二沉池,隔栅,工艺简单图,工艺流程图(高程图),回转耙式格栅除污机图,平面布置图,污泥浓缩池,厌氧消化池,钟式沉砂池等。

全为CAD制图。

下载后复制放大或打印可看清!题目20000m3/d城市污水处理厂综合设计专业: 环境工程年级: 2005级学号: 3105001286姓名: 莫笑伟指导教师:2008年12 月摘要我国水体污染主要来自两方面,一是工业发展超标排放工业废水,二是城市化中由于城市污水排放和集中处理设施严重缺乏,大量生活污水未经处理直接进入水体造成环境污染。

工业废水近年来经过治理虽有所减少,但城市生活污水有增无减,占水质污染的51%以上。

我国水体污染主要来自两方面,一是工业发展超标排放工业废水,二是城市化中由于城市污水排放和集中处理设施严重缺乏,大量生活污水未经处理直接进入水体造成环境污染。

工业废水近年来经过治理虽有所减少,但城市生活污水有增无减,占水质污染的51%以上。

本设计要求处理水量为20000m3/d的城市生活污水,设计方案针对已运行稳定有效的A2/O活性污泥法工艺处理城市生活污水。

A2O工艺由于不同环境条件,不同功能的微)能生物群落的有机配合,加之厌氧、缺氧条件下,部分不可生物降解的有机物(CODNB被开环或断链,使得N、P、有机碳被同时去除,并提高对COD的去除效果。

它可以同NB--时完成有机物的去除,硝化脱氮、磷的过量摄取而被去除等功能,脱氮的前提是NH3N应完全硝化,好氧池能完成这一功能,缺氧池则完成脱氮功能。

厌氧池和好氧池联合完成除磷功能。

关键词:城市生活污水,活性污泥,A2/O目录摘要 (III)目录 (IV)第一章设计概述 ······································································- 7 -1设计任务 ······································································- 7 - 2设计原则 ······································································- 7 - 3设计依据 ······································································- 8 - 第二章工艺流程及说明 ·····························································- 8 -1工艺方案分析 ································································- 8 - 2工艺流程 ······································································- 9 - 3流程各结构介绍 ·····························································- 9 -3.1格栅······························································································· - 9 -3.2沉砂池··························································································- 10 -3.3初沉池··························································································- 10 -3.4生物化反应池··············································································- 10 -3.5二沉池··························································································- 12 -3.6浓缩池··························································································- 12 - 第三章构筑物设计计算 ··························································· - 12 -1格栅 ·········································································· - 12 -1.1设计说明······················································································- 12 -1.2设计计算······················································································- 13 -2沉砂池 ······································································· - 16 -2.1设计说明······················································································- 16 - 3初沉池 ······································································· - 17 -3.1设计说明······················································································- 17 -3.2设计计算······················································································- 17 - 4生化池 ······································································· - 19 -4.1设计说明······················································································- 19 -4.2设计计算······················································································- 19 - 5二沉池 ······································································· - 26 -5.1设计说明······················································································- 26 -5.2设计计算······················································································- 26 - 6液氯消毒 ···································································· - 29 -6.1设计说明······················································································- 29 -6.2设计计算······················································································- 29 - 7污泥浓缩池 ································································· - 30 -7.1设计说明······················································································- 30 -7.2设计计算······················································································- 30 -8 污泥消化池 ································································· - 31 -8.1设计说明······················································································- 31 -8.2设计计算······················································································- 32 - 9浓缩污泥提升泵房 ························································ - 38 -9.1设计选型······················································································- 38 -9.2提升泵房······················································································- 38 -9.3污泥回流泵站··············································································- 38 -10污泥脱水间 ······························································· - 39 -10.1设计说明······················································································- 39 -11鼓风机房 ·································································· - 39 - 12恶臭处理系统 ···························································· - 39 -12.1设计说明······················································································- 39 -12.2设计计算······················································································- 39 -12.3风机选型······················································································- 40 - 第四章污水处理厂总体布置 ····················································· - 41 -1总平面布置 ································································· - 41 -1.1总平面布置原则··········································································- 41 -1.2总平面布置结果··········································································- 41 -2高程布置································································································- 42 -2.1高程布置原则··············································································- 42 - 第五章参考文献 ···································································· - 42 -第一章设计概述1设计任务本次课程设计的主要任务是完成某城市污水厂的A2/O工艺设计处理生活污水,处理水量为20000m3/d,按近期规划人口10万人计算(自定)。

本设计污水处理厂综合设计包括15个图纸,十分全面,具体详见报告后附图。

本报告附图全面详细。

图纸内容如下:A2O池,初沉池,幅流式二沉池,隔栅,工艺简单图,工艺流程图(高程图),回转耙式格栅除污机图,平面布置图,污泥浓缩池,厌氧消化池,钟式沉砂池等。

全为CAD制图。

下载后复制放大或打印可看清!题目20000m3/d城市污水处理厂综合设计专业: 环境工程年级: 2005级学号: 3105001286姓名: 莫笑伟指导教师:2008年12 月摘要我国水体污染主要来自两方面,一是工业发展超标排放工业废水,二是城市化中由于城市污水排放和集中处理设施严重缺乏,大量生活污水未经处理直接进入水体造成环境污染。

工业废水近年来经过治理虽有所减少,但城市生活污水有增无减,占水质污染的51%以上。

我国水体污染主要来自两方面,一是工业发展超标排放工业废水,二是城市化中由于城市污水排放和集中处理设施严重缺乏,大量生活污水未经处理直接进入水体造成环境污染。

工业废水近年来经过治理虽有所减少,但城市生活污水有增无减,占水质污染的51%以上。

本设计要求处理水量为20000m3/d的城市生活污水,设计方案针对已运行稳定有效的A2/O活性污泥法工艺处理城市生活污水。

A2O工艺由于不同环境条件,不同功能的微)能生物群落的有机配合,加之厌氧、缺氧条件下,部分不可生物降解的有机物(CODNB被开环或断链,使得N、P、有机碳被同时去除,并提高对COD的去除效果。

它可以同NB--时完成有机物的去除,硝化脱氮、磷的过量摄取而被去除等功能,脱氮的前提是NH3N应完全硝化,好氧池能完成这一功能,缺氧池则完成脱氮功能。

厌氧池和好氧池联合完成除磷功能。

关键词:城市生活污水,活性污泥,A2/O目录摘要 (III)目录 (IV)第一章设计概述 ······································································- 7 -1设计任务 ······································································- 7 - 2设计原则 ······································································- 7 - 3设计依据 ······································································- 8 - 第二章工艺流程及说明 ·····························································- 8 -1工艺方案分析 ································································- 8 - 2工艺流程 ······································································- 9 - 3流程各结构介绍 ·····························································- 9 -3.1格栅······························································································· - 9 -3.2沉砂池··························································································- 10 -3.3初沉池··························································································- 10 -3.4生物化反应池··············································································- 10 -3.5二沉池··························································································- 12 -3.6浓缩池··························································································- 12 - 第三章构筑物设计计算 ··························································· - 12 -1格栅 ·········································································· - 12 -1.1设计说明······················································································- 12 -1.2设计计算······················································································- 13 -2沉砂池 ······································································· - 16 -2.1设计说明······················································································- 16 - 3初沉池 ······································································· - 17 -3.1设计说明······················································································- 17 -3.2设计计算······················································································- 17 - 4生化池 ······································································· - 19 -4.1设计说明······················································································- 19 -4.2设计计算······················································································- 19 - 5二沉池 ······································································· - 26 -5.1设计说明······················································································- 26 -5.2设计计算······················································································- 26 - 6液氯消毒 ···································································· - 29 -6.1设计说明······················································································- 29 -6.2设计计算······················································································- 29 - 7污泥浓缩池 ································································· - 30 -7.1设计说明······················································································- 30 -7.2设计计算······················································································- 30 -8 污泥消化池 ································································· - 31 -8.1设计说明······················································································- 31 -8.2设计计算······················································································- 32 - 9浓缩污泥提升泵房 ························································ - 38 -9.1设计选型······················································································- 38 -9.2提升泵房······················································································- 38 -9.3污泥回流泵站··············································································- 38 -10污泥脱水间 ······························································· - 39 -10.1设计说明······················································································- 39 -11鼓风机房 ·································································· - 39 - 12恶臭处理系统 ···························································· - 39 -12.1设计说明······················································································- 39 -12.2设计计算······················································································- 39 -12.3风机选型······················································································- 40 - 第四章污水处理厂总体布置 ····················································· - 41 -1总平面布置 ································································· - 41 -1.1总平面布置原则··········································································- 41 -1.2总平面布置结果··········································································- 41 -2高程布置································································································- 42 -2.1高程布置原则··············································································- 42 - 第五章参考文献 ···································································· - 42 -第一章设计概述1设计任务本次课程设计的主要任务是完成某城市污水厂的A2/O工艺设计处理生活污水,处理水量为20000m3/d,按近期规划人口10万人计算(自定)。

高程计算污水处理厂的高程布置污水处理厂高程布置的任务是:确定各处理构筑物和泵房等的标高,选定各连接管渠的尺寸并决定其标高。

计算决定各部分的水面标高,以使污水能按处理流程在处理构筑物之间通畅地流动,保证污水处理厂的正常运行。

污水处理厂的水流常依靠重力流动,以减少运行费用。

为此,必须精确计算其水头损失(初步设计或扩初设计时,精度要求可较低)。

水头损失包括:(1)水流流过各处理构筑物的水头损失,包括从进池到出池的所有水头损失在内;在作初步设计时可按表1估算。

表1 处理构筑物的水头水损失构筑物名称水头损失(cm) 构筑物名称水头损失(cm)格栅 10~25 生物滤池(工作高度为2m时):沉砂池 10~25沉淀池:平流竖流辐流 20~40 1)装有旋转式布水器 270~28040~50 2)装有固定喷洒布水器 450~47550~60 混合池或接触池 10~30双层沉淀池 10~20 污泥干化场 200~350曝气池:污水潜流入池 25~50污水跌水入池 50~150(2)水流流过连接前后两构筑物的管道(包括配水设备)的水头损失,包括沿程与局部水头损失。

(3)水流流过量水设备的水头损失。

水力计算时,应选择一条距离最长、水头损失最大的流程进行计算,并应适当留有余地;以使实际运行时能有一定的灵活性。

计算水头损失时,一般应以近期最大流量(或泵的最大出水量)作为构筑物和管渠的设计流量,计算涉及远期流量的管渠和设备时,应以远期最大流量为设计流量,并酌加扩建时的备用水头。

设置终点泵站的污水处理厂,水力计算常以接受处理后污水水体的最高水位作为起点,逆污水处理流程向上倒推计算,以使处理后污水在洪水季节也能自流排出,而水泵需要的扬程则较小,运行费用也较低。

但同时应考虑到构筑物的挖土深度不宜过大,以免土建投资过大和增加施工上的困难。

还应考虑到因维修等原因需将池水放空而在高程上提出的要求。

在作高程布置时还应注意污水流程与污泥流程的配合,尽量减少需抽升的污泥量。

污水处理厂高程计算一、高程测量基本概念和方法1.高程概念:高程指的是一点相对于一些水平面的高低位置,通常使用基准面作为参照标准。

2.高程测量方法:常用的高程测量方法有水准测量法、网络大地测量法等。

在污水处理厂高程计算中,通常使用直接读表法、分水实测法等方法。

二、污水处理厂高程计算步骤1.制定高程控制点:根据具体情况,在污水处理厂的关键位置设置高程控制点,如进、出水口、隔油池底、曝气池底等。

2.进行高程测量:根据设定的高程控制点,使用合适的高程测量方法,进行实际的高程测量工作。

对于大面积的污水处理厂,需要建立高程网进行全面测量。

3.绘制高程图:根据测量结果,编制污水处理厂的高程图。

高程图可以直观地反映污水处理厂内各个位置的高低关系,并为后续的高程计算提供依据。

4.计算污水流向:在污水处理厂的高程计算中,首先需要确定污水的流向,即整个处理过程中各个设备的排布顺序和排水方向。

在此基础上,进行管道布置和高程计算。

5.确定设备高程:根据设备的功能和操作要求,确定各个设备的高程。

例如,在进、出水口处,需要保证水流的顺畅;在曝气池和沉淀池等位置,需要根据水流速度等参数,确定合适的设备高程。

6.管道高程计算:在设备高程确定后,按照污水流向和排列位置,逐一计算各个管道的高程。

通常包括进水管、排水管、曝气池进水管、固体液分离管等。

7.调整高程设计:在计算完成后,需要根据实际情况进行合理的调整。

如果发现存在高程不合理或超出范围的情况,需要对布置进行调整,确保整个污水处理系统的正常运行。

三、污水处理厂高程计算中的注意事项1.结构物高程计算:在计算过程中,需要考虑到结构物的高程,如墙体、屋面等。

这些结构物可能会影响到污水处理厂的高程设计。

2.高程范围限制:根据污水处理厂的具体要求和周围地形环境,需要确定高程的测量范围和限制条件。

同时,还需要考虑到未来的扩建和改造需求。

3.设备故障处理:在高程计算中,需要考虑到设备的故障情况。

污水处理厂高程设计参考污水处理厂高程设计是污水处理工程设计中的重要一环,它主要涉及到污水处理设备的流程排列、管道的布置以及剩余污泥的处理等方面。

一个合理的高程设计可以保证污水处理系统的正常运行和高效处理污水的能力。

以下是污水处理厂高程设计的参考内容。

1.设计原则(1)采用逐级下降的设计原则。

要求整个处理系统的各个单元之间高程逐级下降,以利于污水的自然流动和高效处理。

(2)保证设备的正常运行。

根据污水处理设备的运行特点,合理确定设备的高程,保证污水在设备内的流动速度达到处理效果所要求的数值。

(3)考虑管道的防渗漏措施。

在设计过程中,需要考虑管道的防渗漏措施,避免发生漏水现象,造成环境污染和设备损坏。

(4)合理考虑地形条件。

根据污水处理厂所处的地形条件,合理选择高程设计方案,避免地势低洼导致污水倒灌或者排放不畅的情况。

(5)考虑剩余污泥处理。

在高程设计中,需要考虑剩余污泥的处理情况,合理确定剩余污泥处理区域的高程,以便后续处理。

2.设备排列高程设计(1)根据不同的处理单元,合理选择设备的高程。

对于初沉池、好氧生化池、二沉池等设备,应根据设备的处理能力、污水流量和水质要求合理确定高程。

(2)设备之间应进行逐级下降。

根据处理单元的工艺流程要求,确保污水流动自然顺畅,避免过多的水泵耗能。

(3)加强设备之间的连接和集中控制。

合理设计设备的高程可以便于设备之间的连接和管理,提高污水处理效率。

3.管道布置高程设计(1)根据管道的材质、直径和流量确定高程。

不同直径的管道对于流体的输送具有不同的要求,应根据实际情况合理确定高程。

(2)根据管道的长度和水头损失确定高程。

长距离的管道会带来水头的损失,需要根据实际情况合理确定高程。

(3)设立阀门和流量调节措施。

在设计过程中,需要合理设置阀门和流量调节器,以便对每一段管道进行调节和控制,保证整个处理系统的正常运行。

4.剩余污泥处理区域高程设计(1)根据剩余污泥的产生量确定高程。

污水处理厂平面及高程设计平面布置及高程布置一、污水处理厂的平面布置污水处理厂的平面布置应包括:处理构筑物的布置污水处理厂的主体是各种处理构筑物。

作平面布置时,要根据各构筑物(及其附属辅助建筑物,如泵房、鼓风机房等)的功能要求和流程的水力要求,结合厂址地形、地质条件,确定它们在平面图上的位置。

在这一工作中,应使:联系各构筑物的管、渠简单而便捷,避免迁回曲折,运行时工人的巡回路线简短和方便;在作高程布置时土方量能基本平衡;并使构筑物避开劣质土壤。

布置应尽量紧凑,缩短管线,以节约用地,但也必须有一定间距,这一间距主要考虑管、渠敷设的要求,施工时地基的相互影响,以及远期发展的可能性。

构筑物之间如需布置管道时,其间距一般可取5-8m,某些有特殊要求的构筑物(如消化池、消化气罐等)的间距则按有关规定确定。

厂内管线的布置污水处理厂中有各种管线,最主要的是联系各处理构筑物的污水、污泥管、渠。

管、渠的布置应使各处理构筑物或各处理单元能独立运行,当某一处理构筑物或某处理单元因故停止运行时,也不致影响其他构筑物的正常运行,若构筑物分期施工,则管、渠在布置上也应满足分期施工的要求;必须敷设接连人厂污水管和出流尾渠的超越管,在不得已情况下可通过此超越管将污水直接排人水体,但有毒废水不得任意排放。

厂内尚有给水管、输电线、空气管、消化气管和蒸气管等。

所有管线的安排,既要有一定的施工位置,又要紧凑,并应尽可能平行布置和不穿越空地,以节约用地。

这些管线都要易于检查和维修。

污水处理厂内应有完善的雨水管道系统,以免积水而影响处理厂的运行。

辅助建筑物的布置辅助建筑物包括泵房、鼓风机房、办公室、集中控制室、化验室、变电所、机修、仓库、食堂等。

它们是污水处理厂设计不可缺少的组成部分。

其建筑面积大小应按具体情况与条件而定。

有可能时,可设立试验车间,以不断研究与改进污水处理方法。

辅助建筑物的位置应根据方便、安全等原则确定。

如鼓风机房应设于曝气池附近以节省管道与动力;变电所宜设于耗电量大的构筑物附近等。

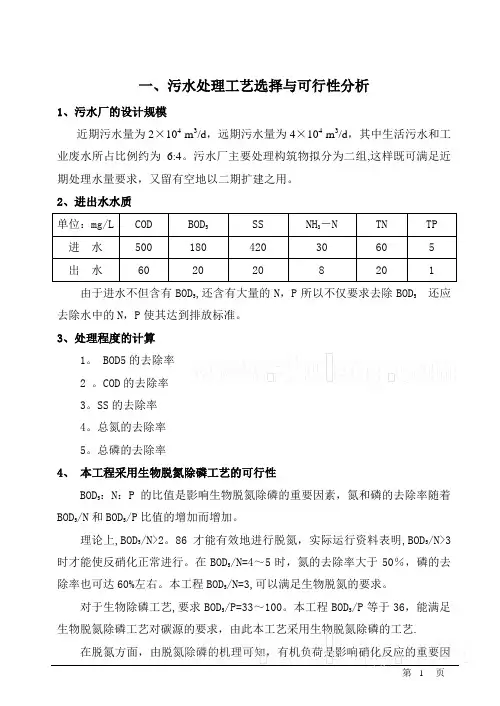

一、污水处理工艺选择与可行性分析1、污水厂的设计规模近期污水量为2×104 m3/d,远期污水量为4×104 m3/d,其中生活污水和工业废水所占比例约为6:4。

污水厂主要处理构筑物拟分为二组,这样既可满足近期处理水量要求,又留有空地以二期扩建之用。

2、进出水水质由于进水不但含有BOD5,还含有大量的N,P所以不仅要求去除BOD5还应去除水中的N,P使其达到排放标准。

3、处理程度的计算1。

BOD5的去除率2 。

COD的去除率3。

SS的去除率4。

总氮的去除率5。

总磷的去除率4、本工程采用生物脱氮除磷工艺的可行性BOD5:N:P的比值是影响生物脱氮除磷的重要因素,氮和磷的去除率随着BOD5/N和BOD5/P比值的增加而增加。

理论上,BOD5/N>2。

86才能有效地进行脱氮,实际运行资料表明,BOD5/N>3时才能使反硝化正常进行。

在BOD5/N=4~5时,氮的去除率大于50%,磷的去除率也可达60%左右。

本工程BOD5/N=3,可以满足生物脱氮的要求。

对于生物除磷工艺,要求BOD5/P=33~100。

本工程BOD5/P等于36,能满足素之一,在碳化与硝化合并处理工艺中,硝化菌所占的比例很小,约5%。

一般负荷小于0。

15kg BOD5/kgMLSS。

d时,处理系统的硝化反认为处理系统的BOD5应才能正常进行。

根据所给定的污水水量及水质,参考目前国内外城市污水处理厂的设计及运转经验,对于生活污水占比例较大的城市污水而言,以下几种方法最具代表性:A2/O法、AB法、生物滤池、循环式活性污泥法(改良SBR)、氧化沟法.5、工艺比较及确定又要适当去除N,P故可采用SBR 城市污水处理厂的方案,既要考虑去除BOD5或氧化沟法,或A2/O法。

A A2/O法A2/O工艺即缺氧/厌氧/好氧活性污泥法, A2/O法处理城市污水的特点:运行费用较传统活性污泥法低,曝气池池容小,需气量少,具有脱氮除磷功能,BOD5和SS去除率高,出水水质较好,工作稳定可靠,有较成熟的设计、施工及运行管理经验,产泥量较传统活性污泥法少;污泥脱水性能较好;无需设初沉池;对水质和水温度化有一定适应能力;另外,从节省能耗的角度看,A2/O可以充分利,回收了部分硝化反应的需氧量,反硝化反应所用硝化液中的硝态氧来氧化BOD5产生的碱度可以部分补偿硝化反应消耗的碱度,因此对含氮浓度不高的城市污水可以不另外加碱来调节PH。

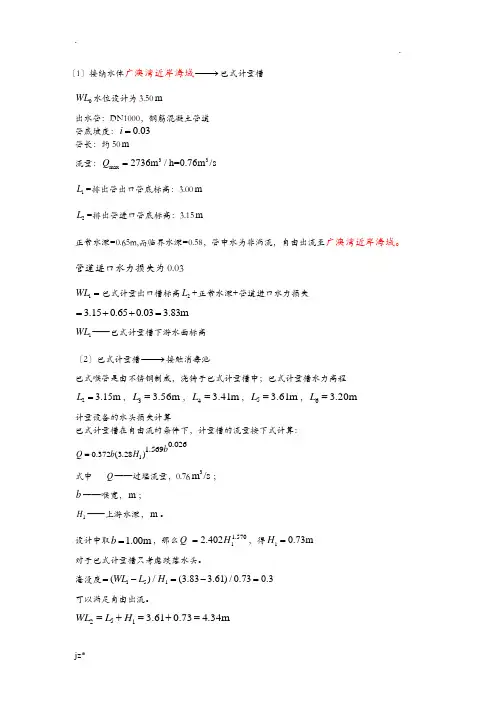

〔1〕接纳水体广澳湾近岸海域−−→巴式计量槽 0WL 水位设计为3.50m出水管:DN1000,钢筋混凝土管道管底坡度:0.03i =管长:约50m流量:33max 2736m /h=0.76m /s Q =1L =排出管出口管底标高:3.00m2L =排出管进口管底标高:3.15m正常水深=0.65m,而临界水深=0.58,管中水为非满流,自由出流至广澳湾近岸海域。

管道进口水力损失为0.031WL =巴式计量出口槽标高2L +正常水深+管道进口水力损失3.150.650.03 3.83m =++=1WL ——巴式计量槽下游水面标高〔2〕巴式计量槽−−→接触消毒池 巴式喉管是由不锈钢制成,浇铸于巴式计量槽中;巴式计量槽水力高程2 3.15m L =,3 3.56m L =,4 3.41m L =,5 3.61m L =,6 3.20m L =计量设备的水头损失计算巴式计量槽在自由流的条件下,计量槽的流量按下式计算:10.0261.5690.372(3.28)b Q b H =式中 Q ——过堰流量,0.763m /s ;b ——喉宽,m ;1H ——上游水深,m 。

设计中取 1.00m b =,那么11.5702.402Q H =,得10.73m H =对于巴式计量槽只考虑跌落水头。

淹没度151()/(3.83 3.61)/0.730.3WL L H =-=-=可以满足自由出流。

521 3.610.73 4.34m WL L H =+=+=2WL 为巴式计量槽上游水面标高[]3=(4.34 3.20) 1.680.39m/s v -⨯=0.75/3v 为巴式槽上游渠中流速320.05WL WL H =++∆(渠道等约为0.1m)4.340.050.1 4.49m =++=式中 3WL ——接触池出水堰下游水面标高73L WL =+自由跌落到3=4.49+0.05=4.54m WL堰长为3m堰上水头约为h =0.3m74 4.540.3 4.84m h WL L +=+==4WL 为接触池水面标高〔3〕接触池−−→配水池 DN800,L=10m管底坡度:0.003i =堰上水头约为h =0.3m254/290g WL WL ⨯+⨯+=出水(10)(0.98-0.50)弯头(0.40.98/2g )2⨯⨯⨯+40.0007+500.00095+配水井配进水管道和弯头(0.50.98/2g )+h4.840.0140.00280.0060.00350.0470.0250.3=+++++++5.24m =配水井溢流堰顶标高58L WL =+自由出流至5WL 标高5.240.1 5.34m =+=68 5.340.3 5.64m h WL L +=+==h ——堰上水头约为0.3m〔4〕配水井−−→SBR 反响池 760.010.01 5.66m WL WL +=+=7WL ——接触池进口处最大水位标高DN800,L=10m管底坡度:0.003i =,滗水器水力损失为0.05mSBR 反响池水位0.030.05 5.78m 87WL WL =++= (4)SBR 反响池−−→配水井 DN800,L=10m管底坡度:0.003i =堰上水头约为h =0.3m298/290g WL WL ⨯+⨯+=出水(10)(0.98-0.50)弯头(0.40.98/2g )2⨯⨯⨯+40.0007+500.00095+配水井配进水管道和弯头(0.50.98/2g )+h5.780.0140.00280.0060.00350.0470.0250.3=+++++++6.18m =配水井溢流堰顶标高99L WL =+自由出流至9WL 标高6.180.1 6.28m =+=109=6.280.3 6.58m h WL L ++==h ——堰上水头约为0.3m〔5〕配水井−−→初沉池 11100.1 6.580.1 6.68m WL WL =+=+=1011L WL =+自由出流至10WL 标高=6.68+0.1=6.78m式中 10L ——平流沉淀池出水槽渠底标高1210 6.780.2 6.98m WL L h =+=+=式中 12WL ——平流沉淀池出水槽水面标高h ——平流沉淀池出水自由跌落〔6〕平流沉淀池−−→钟式沉砂池 1312WL WL =+自由跌落到10 6.980.097.07m WL =+=堰宽为3m式中 13WL ——平流沉淀池出水处水面标高14130.17.070.17.17m WL WL =+=+=14WL ——平流沉淀池进水处水面标高1114L WL =+自由出流至12WL 标高=7.17+0.09=7.26m式中 11L ——平流沉淀池第二格集水槽末端标高15117.260.17.36m WL L h =+=+=式中 15WL ——平流沉淀池第二格集水槽水面标高1615WL WL +=平流沉淀池底部隔墙孔损失1h7.360.027.38m =+=取1h 为0.02m式中 16WL ——平流沉淀池第一格集水槽水面标高平流沉淀池与钟式沉砂池之间的管道连接DN800砼管,L=50m20.5m A =0.2m R =0.76/0.20.38m/s v ==20.6670.38/()0.00078400.2I ⎡⎤==⎣⎦⨯ 1716WL WL +=出水至平流沉淀池20.38500.00078⨯+⨯(1.1/2g)+转弯和从渠道进入管道2(0.50.38/2)g ⨯7.44=17WL ——钟式沉砂池出水渠堰末端水面标高1217L WL =+自由落水至13WL 标高7.440.1=+7.54m =式中 12L ——钟式沉砂池出溢流堰堰顶标高堰长2 2.55m =⨯=1.50.76 1.825Q h ==⨯⨯那么0.1910.2m h =≈12187.540.27.74m WL L h =+=+=式中 18WL ——钟式沉砂池最高水位〔7〕钟式沉砂池−−→细格栅 1918WL WL =+2个钟式沉砂池闸板孔损失2个闸板孔面积22 1.0 1.0 2.0m =⨯⨯= 0.76/2.00.38m/s v ==过闸板孔损失22.230.38/2g =⨯+水流减速转弯和格栅后涡流等大约0.02m 0.036m =那么19180.0367.740.0367.78m WL WL +=+==细格栅处渠道底标高12L =6.34m(1) 格栅水头损失计算0f h kh =20sin 2v h g ξα=,43=S b ξβ⎛⎫ ⎪⎝⎭ 式中 f h ——过栅水头损失,m ;0h ——计算水头损失,m ;k ——系数,格栅受污物堵塞后,水头损失增大的倍数,一般3k =;ξ——阻力系数,与栅条断面形状有关,,k 为系数,格栅受污物堵塞时水头损失增大倍数,与栅条断面形状有关,可按"给排水设计书册〔第5册〕"提供的计算公式和相关系数计算。

污水处理厂高程设计首先,进水口高程的设计是为了确保污水能够顺利进入处理设备。

进水口通常设置在污水管道的入口处,其高程应该比处理设备的最低高程稍高,以保证污水能够流向低处。

同时,进水口高程还需要考虑排水系统的设计,确保污水在进入处理设备之前能够进行初步分流和预处理,以减少对处理设备的负荷。

处理设备的高程设计是为了实现不同工艺单元之间的流动和水力平衡。

根据污水处理的工艺流程,处理设备通常包括进流均化池、沉淀池、曝气池、二沉池等。

这些设备的高程设计应考虑到进流均化、沉淀、曝气等各个阶段的流动要求,保证污水在各个工艺单元中能够顺利流动,同时避免混合和死水区的产生。

此外,处理设备的高程设计还需要考虑设备的尺寸和布局,确保设备的功能能够得到充分发挥。

出水口高程的设计是为了将处理后的水体安全排放。

出水口通常设置在污水处理系统的最低点,以利用自然落差将处理后的水体排放到周围的水体中。

出水口的高程还需要根据排放标准和环境要求进行设计,确保排放的水体符合相关的水质排放标准,不会对周围的水环境造成污染。

此外,污水处理厂的高程设计还应考虑雨水的收集和排放。

雨水收集系统通常包括雨水存储池、雨水调节池等设施,其高程设计应考虑雨水的流向和收集的需要。

雨水的排放通常通过雨水管道和沟渠等方式进行,其高程设计应确保雨水能够顺利排放到与污水处理系统分开的排放系统中,避免与污水混合。

综上所述,污水处理厂高程设计是为了保证污水处理过程的顺利进行以及处理后的水体的安全排放。

设计时需要考虑进水口、处理设备、出水口和雨水收集和排放等各个环节的高程要求,并结合工艺流程和排放标准进行科学合理的设计。

只有通过高程设计,才能够保证污水处理厂的正常运行,达到有效处理污水、保护环境的目标。

1处理流程高程设计为使污水能在各处理构筑物之间通畅流动,以保证处理厂的正常运行,需进行高程布置,以确定各构筑物及连接管高程.为降低运行费用和便于维护管理,污水在处理构筑物之间的流动已按重力流考虑为宜;污泥也最好利用重力流动,若需提升时,应尽量减少抽升次数。

为保证污泥的顺利自流,应精确计算处理构筑物之间的水头损失,并考虑扩建时预留的储备水头,高程图的比例与水平方向的比例尺一般不相同,一般垂直比例大,水平的比例小些[12]。

1。

1 主要任务污水处理厂污水处理流程高程布置的主要任务是:(1) 确定各处理构筑物和泵房的标高;(2)确定处理构筑物之间连接管渠的尺寸及其标高;(3)通过计算确定各部分的水面标高,从而能够使污水沿处理流程在处理构筑物之间畅通地流动,保证污水处理厂的正常运行。

1。

2 高程布置的一般原则(1)计算各处理构筑物的水头损失时,应选择一条距离最长、水头损失最大的流程进行较准确的计算,考虑最大流量、雨天流量和事故时流量的增加.并应适当留有余地,以防止淤积时水头不够而造成的涌水现象,影响处理系统的正常运行.(2)计算水头损失时,以最大流量(设计远期流量的管渠与设备,按远期最大流量考虑)作为构筑物与管渠的设计流量.还应当考虑当某座构筑物停止运行时,与其并联运行的其余构筑物与有关的连接管渠能通过全部流量.(3)高程计算时,常以受纳水体的最高水位作为起点,逆废水处理流程向上倒推计算,以使处理后废水在洪水季节也能自流排出,并且水泵需要的扬程较小。

如果最高水位较高,应在废水厂处理水排入水体前设置泵站,水体水位高时抽水排放。

如果水体最高水位很低时,可在处理水排入水体前设跌水井,处理构筑物可按最适宜的埋深来确定标高。

(4)在做高程布置时,还应注意污水流程与污泥流程的配合,尽量减少需要提升的污泥量.1。

3 污水高程计算在污水处理工程中,为简化计算一般认为水流是均匀流。

管渠水头损失主要有沿程水头损失和局部水头损失。

城市污水处理厂工艺设计毕业设计随着城市的快速发展和人口的不断增长,城市污水的排放量也日益增加。

为了保护生态环境,实现水资源的可持续利用,城市污水处理厂的建设变得至关重要。

本次毕业设计旨在设计一座高效、经济、环保的城市污水处理厂,以满足城市污水处理的需求。

一、设计任务与要求本次设计的城市污水处理厂处理规模为_____立方米/天,进水水质主要指标为:化学需氧量(COD)_____mg/L、生化需氧量(BOD₅)_____mg/L、悬浮物(SS)_____mg/L、氨氮(NH₃N)_____mg/L、总磷(TP)_____mg/L 等。

出水水质需达到国家《城镇污水处理厂污染物排放标准》(GB 18918-2002)中的一级 A 标准。

二、污水处理工艺流程选择1、预处理工艺城市污水首先进入格栅间,通过粗格栅和细格栅去除较大的悬浮物和漂浮物,以保护后续处理设备的正常运行。

然后进入沉砂池,去除污水中的砂粒等无机颗粒。

2、生物处理工艺经过预处理的污水进入生物处理单元。

常见的生物处理工艺有活性污泥法和生物膜法。

考虑到处理效果和运行稳定性,本设计选用改良型的 A²/O 工艺。

该工艺具有良好的脱氮除磷效果,能够有效去除污水中的有机物、氮和磷。

3、深度处理工艺生物处理后的污水进入深度处理单元,采用混凝沉淀和过滤工艺,进一步去除污水中的悬浮物、有机物和磷,确保出水水质达标。

4、消毒工艺为了杀灭污水中的病原微生物,采用紫外线消毒工艺,具有消毒效率高、不产生副产物等优点。

三、主要构筑物设计1、格栅间设计两道格栅,粗格栅间隙为_____mm,细格栅间隙为_____mm。

格栅间设置在地下,采用钢筋混凝土结构。

2、沉砂池选用平流式沉砂池,设计流速为_____m/s,有效水深为_____m,停留时间为_____s。

3、 A²/O 反应池分为厌氧区、缺氧区和好氧区,各区容积比例根据水质特点和处理要求进行设计。

反应池采用推流式,池体采用钢筋混凝土结构。

1处理流程高程设计为使污水能在各处理构筑物之间通畅流动,以保证处理厂的正常运行,需进行高程布置,以确定各构筑物及连接管高程。

为降低运行费用和便于维护管理,污水在处理构筑物之间的流动已按重力流考虑为宜;污泥也最好利用重力流动,若需提升时,应尽量减少抽升次数。

为保证污泥的顺利自流,应精确计算处理构筑物之间的水头损失,并考虑扩建时预留的储备水头,高程图的比例与水平方向的比例尺一般不相同,一般垂直比例大,水平的比例小些[12]。

主要任务污水处理厂污水处理流程高程布置的主要任务是: (1) 确定各处理构筑物和泵房的标高;(2) 确定处理构筑物之间连接管渠的尺寸及其标高;(3) 通过计算确定各部分的水面标高,从而能够使污水沿处理流程在处理构筑物之间畅通地流动,保证污水处理厂的正常运行。

高程布置的一般原则(1) 计算各处理构筑物的水头损失时,应选择一条距离最长、水头损失最大的流程进行较准确的计算,考虑最大流量、雨天流量和事故时流量的增加。

并应适当留有余地,以防止淤积时水头不够而造成的涌水现象,影响处理系统的正常运行。

(2) 计算水头损失时,以最大流量(设计远期流量的管渠与设备,按远期最大流量考虑)作为构筑物与管渠的设计流量。

还应当考虑当某座构筑物停止运行时,与其并联运行的其余构筑物与有关的连接管渠能通过全部流量。

(3) 高程计算时,常以受纳水体的最高水位作为起点,逆废水处理流程向上倒推计算,以使处理后废水在洪水季节也能自流排出,并且水泵需要的扬程较小。

如果最高水位较高,应在废水厂处理水排入水体前设置泵站,水体水位高时抽水排放。

如果水体最高水位很低时,可在处理水排入水体前设跌水井,处理构筑物可按最适宜的埋深来确定标高。

(4) 在做高程布置时,还应注意污水流程与污泥流程的配合,尽量减少需要提升的污泥量。

污水高程计算在污水处理工程中,为简化计算一般认为水流是均匀流。

管渠水头损失主要有沿程水头损失和局部水头损失。

出水排至长江,最高水位为。

总损失=构筑物的损失+沿程损失+局部损失,沿程水头损失按下式计算:iL L R C v h f ==22()式中 f h ——为沿程水头损失,m ;L ——为管段长度,m ; R ——为水力半径,m ;v ——为管内流速,m s ;C ——为谢才系数。

局部水头损失为: g v h m 22ξ=()式中 ξ——局部阻力系数,查阅《给排水设计手册第一册》获得。

构筑物初步设计时,构筑物水头损失可按经验数值计算。

污水流经处理构筑物的水头损失,主要产生在进出口和需要的跌水处,而流经处理构筑物本身的水头损失则较小。

本设计中若在设计计算过程中计算了的就用计算的结果,若在设计计算过程中没计算的就用经验值,各构筑物水头损失见表。

表 构筑物水头损失表管渠水力计算计量槽至出水口取一个进出口损失及一个90︒弯头损失,取局部阻力系数为:++=。

接触池至计量槽取一个进出口损失,取局部阻力系数为:+=。

二沉池至接触池取一个进出口损失及一个90︒弯头损失,取局部阻力系数为:0.11.01.12.2++=。

集配水井至二沉池取一个进出口损失,取局部阻力系数为: +=。

氧化沟至集配水井取一个进出口损失及二个90︒弯头损失,取局部阻力系数为:++=。

厌氧池至氧化沟取一个进出口损失,取局部阻力系数取为:+=。

沉砂池至厌氧池取一个进出口损失及一个90︒弯头损失,取局部阻力系数为:++=。

管渠水力计算见表。

表 污水管渠水力计算表污水处理高程计算及布置污水处理厂水力计算以接受处理后污水水体的最高水位作为起点,沿污水处理流程向上倒推计算,以使处理后的污水在洪水季节也能自流排出,同时,还要考虑挖土埋深的状况。

以为基准,设计中考虑污水管的非充满度(一般管径大于或等于1000mm时,最大充满度为)和管道的覆土厚度(一般不小于且不考虑冻土深度),城市污水主干管进入污水处理厂处的管径为1000m,管道水面标高为。

由于采用的DE氧化沟方案中二沉池、氧化沟占地面积大,如果埋深设计过大,一方面不利于施工,也不利于土方平衡,故按尽量减少埋深。

从降低土建工程投资考虑,接触消毒池水面相对高程定为±,这样布置亦利于排泥及排空检修。

计算结果见下表。

表构筑物及管渠水力计算表污泥处理构筑物高程布置(1) 污泥管道的水头损失管道沿程损失按下式计算:85.117.149.2⎪⎪⎭⎫ ⎝⎛⎪⎭⎫ ⎝⎛=H f Cv D L h()管道局部损失计算:g v h i 22ξ=() 式中 H C ——污泥浓度系数; D ——污泥管管径,m ; v ——管内流速,s m ;L ——管道长度,m ;ξ——局部阻力系数。

查《给水排水设计手册》可知:当污泥含水率为97%时,污泥浓度系数H C =71,管径为150-200mm 时,最小设计流速为s;污泥含水率为95%时,污泥浓度系数为H C =53, 管径为150-200mm 时,最小设计流速为1m/s 。

各连接管道的水头损失见下表。

表 连接管道的水头损失(2) 污泥处理构筑物水头损失当污泥以重力流排出池体时,污泥处理构筑物的水头损失以各构筑物的出流水头计算,浓缩池一般取,二沉池一般取。

(3) 污泥高程布置设计中污泥在二沉池到污泥浓缩池以及贮泥池到脱水车间得到提升,取脱水机房标高为53m,贮泥池泥面相对地标为,超高。

污泥高程布置计算如下表。

表污泥高程布置计算表高程计算污水厂厂址处的地坪标高基本在30米左右。

本设计中的高程计算分别为泵提升前和泵提升后两部分。

泵提升前按顺序计算,泵提升后按逆向计算。

污水厂主干道管采用钢筋混凝土圆管,按非满流设计,阻力系数为n=,坡度i=。

采用DN300钢筋混凝土圆管,L=150m,查表得Q= m3/s,i=时,v=s,设污水入口水位为,则沟道沿程水力损失:0.0031000.3i L m⨯=⨯=局部水力损失:220.510.0128229.8fvh mgξ==⨯=⨯合计:+=则格栅前水位为:格栅的水头损失为:栅后水位为:。

即泵前水位为:。

设计出水管的出水水位为29m,(1)消毒池至出水采用DN300钢筋混凝土圆管,L=30m,查表得Q=000209 m3/s,i=时,v=s 沿程阻力损失:0.0032000.6i L m⨯=⨯=局部水力损失:220.50.50.0064229.8fvh mgξ==⨯=⨯消毒池内部损失:。

合计:++=消毒池内水位为:29+=(2) SBR 反应池至消毒池采用DN200钢筋混凝土圆管,L=30m ,查表得Q= m 3/s ,i=时,v=s 沿程阻力损失:0.003300.09i L m ⨯=⨯=局部阻力损失:220.40.50.0041229.8f v h mg ξ==⨯=⨯(入管口) 220.40.750.0062229.8f v h m g ξ==⨯=⨯(90标准弯头1个)220.40.250.00205229.8f v h mg ξ==⨯=⨯(小管口进大管口)220.44.50.0369229.8f v h mg ξ==⨯=⨯(闸阀1/2开)采用DN400钢筋混凝土圆管,L=10m ,查表得Q= m 3/s ,i=时,v=s 沿程阻力损失:0.0031000.3i L m ⨯=⨯=局部阻力损失:220.4510.0104229.8f v h mg ξ==⨯=⨯(流入大容器) 220.450.170.0018229.8f v h mg ξ==⨯=⨯(闸阀全开)SBR 反应器内部损失: 合计: ++++++++=SBR 反应器内部水位为:+=。

(3) UASB 反应器至SBR 反应池采用采用DN200钢筋混凝土圆管,L=20m ,查表得Q= m 3/s ,i=时,v=s 沿程阻力损失:0.003200.06i L m ⨯=⨯=局部阻力损失:220.40.50.0041229.8f v h mg ξ==⨯=⨯(入管口) 220.40.750.0062229.8f v h m g ξ==⨯=⨯(90标准弯头1个)220.40.170.00138229.8f v h mg ξ==⨯=⨯(闸阀全开)采用DN400钢筋混凝土圆管,L=8m ,查表得Q= m 3/s ,i=时,v=s 沿程阻力损失:0.003500.15i L m ⨯=⨯=局部阻力损失:220.450.250.0026229.8f v h mg ξ==⨯=⨯(小管径流入大管径) 采用DN300钢筋混凝土圆管,L=15m ,查表得Q=000209 m 3/s ,i=时,v=s 沿程阻力损失:0.003450.135i L m ⨯=⨯=局部水力损失:220.50.750.0096229.8f v h mg ξ==⨯=⨯(90标准弯头1个) 220.50.150.0019229.8f v h mg ξ==⨯=⨯(大管径流入小管径)UASB 反应器内部跌水: 合计: +++++++++=UASB 反应器内水位为:+=(4) 厌氧消化池至UASB 反应器采用DN300钢筋混凝土圆管,L=30m ,查表得Q=000209 m 3/s ,i=时,v=s 沿程阻力损失:0.003500.15i L m ⨯=⨯=局部水力损失:220.50.50.0064229.8f v h mg ξ==⨯=⨯ 采用DN200钢筋混凝土圆管,L=50m ,查表得Q= m 3/s ,i=时,v=s 沿程阻力损失:0.003800.24i L m ⨯=⨯=220.40.250.00205229.8f v h m g ξ==⨯=⨯(大管口进小管口)220.40.750.0062229.8f v h m g ξ==⨯=⨯(90标准弯头1个)220.410.0081229.8f v h mg ξ==⨯=⨯(入反应池)厌氧消化池内部损失:。

合计:+++++++=厌氧消化池水位:+=(5) 调节池至厌氧消化池采用DN300钢筋混凝土圆管,L=35m ,查表得Q=000209 m 3/s ,i=时,v=s沿程阻力损失:0.003900.27i L m⨯=⨯=局部水力损失:220.5(0.51)0.019229.8fvh mgξ==+⨯=⨯调节池内部损失:合计:++=.调节池内部水位为:+=(6)沉淀池至调节池采用DN300钢筋混凝土圆管,L=25m,查表得Q=000209 m3/s,i=时,v=s 沿程阻力损失:0.003650.195i L m⨯=⨯=局部水力损失:220.5(0.51)0.019229.8fvh mgξ==+⨯=⨯沉淀池内部损失:合计:++=.沉淀池内部水位为+=(7)沉砂池至沉淀池采用DN300钢筋混凝土圆管,L=35m,查表得Q=000209 m3/s,i=时,v=s 沿程阻力损失:0.003350.105i L m⨯=⨯=局部水力损失:220.5(0.51)0.019229.8fvh mgξ==+⨯=⨯沉沙池内部损失:.合计:+++=沉沙池内部水位为:+=。