Piston items

- 格式:doc

- 大小:36.50 KB

- 文档页数:2

Tractors: 20 Cockshutt & E2 Co-op After # 962; 20K, 22, 23 (Mustang), 82, 101 Jr, 102 Jr Massey Harris;QTY ITEM #DESCRIPTIONLETTERED ITEMS INCLUDED IN KIT1985244Out-of-Frame Kit O4 4 4181236181311181312STD Piston Assembly (3-1/8 1-1/4 Grooves).020 Piston Assembly (3-1/8 1-1/4 Grooves).030 Piston Assembly (3-1/8 1-1/4 Grooves)O4181313.040 Piston Assembly (3-1/8 1-1/4 Grooves)4181314.060 Piston Assembly (3-1/8 1-1/4 Grooves) 3-1/8 1-1/4 4181315.080 Piston Assembly (3-1/8 1-1/4 Grooves)4 4181316181317STD Ring Set (3-1/8 1-1/4).020 Ring Set (3-1/8 1-1/4)O4181318.030 Ring Set (3-1/8 1-1/4)4181319.040 Ring Set (3-1/8 1-1/4)4181321.060 Ring Set (3-1/8 1-1/4) 3-1/8 1-1/4 4181322.080 Ring Set (3-1/8 1-1/4)4 4181323181324STD Ring Set (3-1/8 1-3/16).020 Ring Set (3-1/8 1-3/16)4181325.030 Ring Set (3-1/8 1-3/16)4181326.040 Ring Set (3-1/8 1-3/16) 3-1/8 1-3/16 4181327.060 Ring Set (3-1/8 1-3/16)4 4181328181329STD Ring Set (3-3/32 1-1/4).020 Ring Set (3-3/32 1-1/4)4181331.030 Ring Set (3-3/32 1-1/4)4181332.040 Ring Set (3-3/32 1-1/4)3-3/32 1-1/4 4181333.060 Ring Set (3-3/32 1-1/4)4101157Notched Repair Liner (3.378" OD / 7.500" OAL)4101158Notched Repair Liner (3.4405" OD / 7.500" OAL)4101146Universal Repair Liner (3.378" OD / 9.250" OAL)4101147Universal Repair Liner (3.4405" OD / 9.250" OAL)APPLICATION: Combines: 35 & Super 35 Massey Ferguson; Forklifts & Power Units;Tractors: 20 Cockshutt & E2 Co-op After # 962; 20K, 22, 23 (Mustang), 82, 101 Jr, 102 Jr Massey Harris;1 281372 STD Rod Bearing Set (2-LH & 2-RH) O1 281373 .010 Rod Bearing Set (2-LH & 2-RH)1 281374 .020 Rod Bearing Set (2-LH & 2-RH)1 281375 .030 Rod Bearing Set (2-LH & 2-RH)1 281376 .040 Rod Bearing Set (2-LH & 2-RH)1 281377 .060 Rod Bearing Set (2-LH & 2-RH)1 281396 STD Main Bearing Set wo/Thrust Washer1 281397 .010 Main Bearing Set wo/Thrust Washer1 281398 .020 Main Bearing Set wo/Thrust WasherSingle Flange Front 1 281399 .030 Main Bearing Set wo/Thrust WasherWasher Optional 1 281316 Thrust Washer1 281411 STD Main Bearing Set wo/Thrust Washer1 281412 .010 Main Bearing Set wo/Thrust Washer1 281413 .020 Main Bearing Set wo/Thrust Washer1 281414 .030 Main Bearing Set wo/Thrust WasherFlangeless Front 1 281415 Thrust WasherWashers Optional 1 281416 Thrust Washer1 281421 Thrust Washer O1 281422 Thrust Washer1 281423 Thrust Washer1 281424 Thrust Washer Flangeless Front 1 281425 Thrust WasherWashers Included1 381319 Head Gasket Set1 381323 Head Gasket8 301138 Positive Valve Seals "Recommended"1 381318 Full Gasket Set w/Seals O1 381333 Tappet Cover Gasket1 321318 Manifold Gasket1 381335 Timing Cover Set: Except Towmotor1 381336 Timing Cover Set: Towmotor1 381322 Pan Gasket Set1 381261 Front Crank Seal1 301123 Front Wear Sleeve1 381321 Rear Crank Seal Set4 281283 Pin Bushing (Split Bushing / .915" OD)4 281286 Pin Bushing (Full Round Solid Bushing / .915" OD)4 281284 .0055 Oversize Pin Bushing (Full Round Solid / .9205" OD)4 281431 Pin Bushing, Early Rods (1.063" OD)4 281432 .010 Oversize Pin Bushing, Early Rods (1.073" OD)1 281433 Cam Bushing Set8 781195 Rod Bolt8 781196 Rod NutLETTERED ITEMS INCLUDED IN KIT DESCRIPTION QTY ITEM #Tractors: 20 Cockshutt & E2 Co-op After # 962; 20K, 22, 23 (Mustang), 82, 101 Jr, 102 Jr Massey Harris;QTY ITEM #DESCRIPTIONLETTERED ITEMSINCLUDED IN KIT1 581247 Camshaft: Tractors (Cast / Solid Nose / 3 Bolt Thrust Plate)1 581248 Camshaft (Cast / Solid Nose /2 Bolt Thrust Plate)1 581249 Camshaft (Cast / Hollow Nose /2 Bolt Thrust Plate)1 581251 Camshaft (Steel / Solid Nose /2 Bolt Thrust Plate)1 581252 Camshaft (Steel / Hollow Nose / 2 Bolt Thrust Plate)1 581253 Cam Thrust Plate (2 Bolt)1 581254 Cam Thrust Plate (3 Bolt)1 591125 Cam Key (5/32" x 5/8")1 581255 Cam Nut (3/4" NF Special)1 581256 Cam Nut (7/8")1 581257 Cam Nut (1")8 581258 STD Tappet8 581259 .001 Oversize Tappet8 581261 .002 Oversize Tappet8 581262 .003 Oversize Tappet8 581263 .005 Oversize Tappet4 481261 Exhaust Valve (Drilled Stem / 1.203" Head)4 481263 Exhaust Valve (Drilled Stem / 1.328" Head)4 481264 Exhaust Valve (Stepped 5/16" Tip / Grooved / 1.203" Head)4 481265 Exhaust Valve (Grooved Stem / 1.203" Head / Stellite)4 481267 Exhaust Valve (Taper Groove / 1.203" Head / Free Rotating)4 481268 Exhaust Valve (Taper Groove / 1.328" Head / Free Rotating)4 481262 Intake Valve (Drilled Stem / 1.520" Head)4 481266 Intake Valve (Stepped 5/16" Tip / Grooved / 1.516" Head)8 481275 Intake & Exhaust Valve Guide (.343" ID) (1)4 481276 Exhaust Valve Guide, w/Free Rotating Valves (.375" ID)8 481168 Valve Spring4 481169 Exhaust Valve Rotator8 481172 Valve Keeper, Use w/Drilled Stem (Pin Type Lock)16 481171 4812668 481278 Valve Keeper, Use w/Free-Rotating Ex Valves8 481279 Valve Retainer, w/Pin Type Lock4 481281 Intake Retainer, w/Taper Lock Keeper4 481282 Stem Cap, Free-Rotating Exhaust Valve4 401146 STD Exhaust Seat, w/1.203" Valve (1.087"x1.348"x .200")4 481212 .010 Exhaust Seat, w/1.203" Valve (1.087"x1.358"x .200")4 401132 STD Exhaust Seat, w/1.328" Valve (1.187 x 1.442" x .219")4 401161 .010 Exhaust Seat, w/1.328" Valve (1.187 x 1.452" x .219")4 401128 STD Intake Seat (1.375 x 1.630" x .219")4 401162 .010 Intake Seat (1.375 x 1.640" x .219")APPLICATION: Combines: 35 & Super 35 Massey Ferguson; Forklifts & Power Units;Tractors: 20 Cockshutt & E2 Co-op After # 962; 20K, 22, 23 (Mustang), 82, 101 Jr, 102 Jr Massey Harris;1 1 1 581264 581265 581267 Cam Gear, F400H310 (48 Tooth / 1.000" Hub Length) Cam Gear, F400H405 (Hardened / 48 Tooth / 1.000" Hub)Cam Gear, F400H227 (Hardened / 48 Tooth / 1.187" Hub)1 581268 Cam Gear, F124H302 (48 Tooth / .906" Hub w/Gov)1 581269 Cam Gear, F124H401 (Hardened / 48 T / .906" Hub w/Gov)1 581271 Crank Gear, D600H300 (24 Tooth)1 581272 Crank Gear, F400H326 (Hardened / 24 Tooth)1 581273 Idler Gear, F400H3240 (39 Tooth / Bushing Type)1 581274 Idler Gear, F209H3011 (43 Tooth)1 581275 Fan Drive Gear, F209H303 (20 Tooth)1 581277 Pump Gear, F400H321 (36 Tooth)1 581278 Pump Gear, F400H330 (29 Tooth)1 581279 Pump Gear, F400H337 (24 Tooth)1 581281 Pump Gear, F600H318 (34 Tooth)48 T Cam Gear 1 581282 Accessory Drive Gear, F162H200 (24 Tooth)1 1 1 581283 581284 581287Cam Gear, F400H403 (Hardened / 56 Tooth) Crank Gear, F226H202 (Hardened / 28 Tooth)1 581288 Crank Gear, F600H317 (Hardened / 28 Tooth)1 581289 Crank Gear, F400H334 (28 Tooth)56 T Cam Gear 1 581292 Idler Gear, F600H321 (50 Tooth / Bearing Type)1 681141 Oil Pump (Cast Gear / 7 1/8" Flg to Tip / Bypass&Full Flow)1 681142 Oil Pump (Steel Gear / 7 1/8" Flg to Tip / Bypass&Full Flow) 1 681147 Oil Pump (Cast Drive Gear / 9 1/8" Mtg Flange to Shaft Tip)1 681148 Oil Pump (Steel Drive Gear / 9 1/8" Mtg Flange to Shaft Tip)1 681155 Oil Pump Kit, OEM Pumps w/Cast Drive Gear1 681156 Oil Pump Kit, OEM Pumps w/Steel Drive Gear1 681157 Cast Drive Gear "Use w/Cast Camshafts"1 681158 Steel Drive Gear "Use w/Steel Camshafts"1 681149 Oil Pump Screen1 681159 Oil Pump Drive Shaft Support Bushing "Fits in Block"1 281294 Thrust Adjustment Shim Package (.002 & .008 Shims)1 781197 Crankshaft Thrust Plate: Engines w/Front Thrust Bearing1 781198 Expansion Plug Kit (Includes 3-Block & 1-Cam Plug)1 881156 Thermostat (180 Degree)LETTERED ITEMSINCLUDED IN KITDESCRIPTION QTY ITEM #。

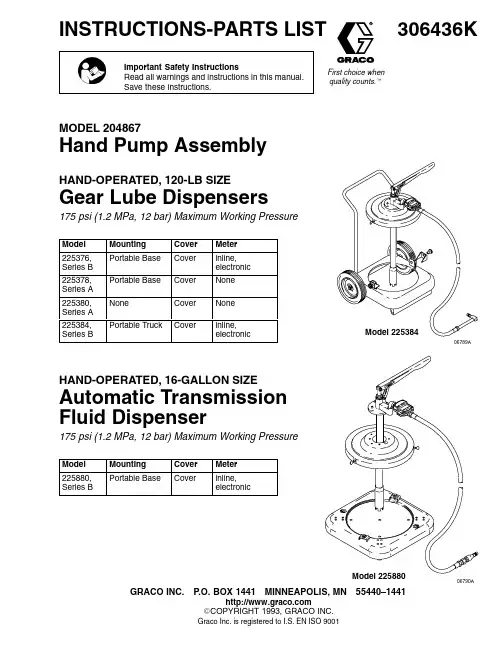

306436KFirst choice when quality counts.tINSTRUCTIONS-PARTS LISTImportant Safety InstructionsRead all warnings and instructions in this manual.Save these instructions.MODEL 204867Hand Pump AssemblyHAND-OPERATED, 120-LB SIZEGear Lube Dispensers175 psi (1.2 MPa, 12 bar) Maximum Working PressureModel Mounting Cover Meter 225376,Series B Portable Base Cover inline,electronic 225378,Series A Portable Base Cover None 225380,Series A NoneCover None 225384,Series BPortable TruckCoverinline,electronicHAND-OPERATED, 16-GALLON SIZEAutomatic Transmission Fluid Dispenser175 psi (1.2 MPa, 12 bar) Maximum Working PressureModel Mounting CoverMeter 225880,Series BPortable BaseCoverinline,electronicGRACO INC.P .O. BOX 1441MINNEAPOLIS, MN 55440–1441E COPYRIGHT 1993, GRACO INC.Graco Inc. is registered to I.S. EN ISO 900106789A06790ATable of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Operation4 Dimensions Chart 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Service6 Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hand Pump Assembly, Model 2048677. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear Lube Dispensers, Models 225378, 225376, 2253808. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gear Lube Dispenser, Model 2253849. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic Transmission Fluid Dispenser, Model 22588010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Truck Assembly, Model 20365010. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Portable Base Assembly, Model 20362211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hose and Meter Assemblies, Models 239707, 23970511 Warranty 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Graco Phone Number122306436Installation See Fig.1 or Fig. 2, depending on your model.Models with a Portable TruckInsert the truck handle (708) into the sockets in thetruck base (701).All ModelsPlace a full container of fluid on the base. Carefullyclean the container top before opening it to avoid fluid contamination. Secure the drum or shield (401) withthe hardware provided.Models with a Drum CoverInstall the drum cover (601) on the opened drum andsecure it with the thumbscrews (603).All ModelsSlide the pump extension tube (318) all the way downon the riser tube (314). Insert the riser tube into theopening in the top of the shield (401) or cover (601).Lower the pump until the outlet housing (319) rests onthe shield or cover and secure it with the four screws(309). Install the pump lever (316), clevis (311), and hose and meter assembly (2 or 5).To prime the pump, open the nozzle (502) and operate the pump until fluid flows from the nozzle. Close the nozzle and place it in the opening in the outlet housing (319).Fig. 106782A Fig. 27013306436OperationReset the meter to zero by pressing the RESETbutton.Insert the nozzle in the fill hole. Open the nozzle andoperate the pump. When finished, close the nozzleand wipe off any excess fluid. Place the nozzle in theopening in the outlet housing.If the meter fails to register, it may be due to a lowbattery. See the Service section in instruction manual308687.Models with Non-Drip Nozzle 200–348The non-drip nozzle can be set in the automatic posi-tion by turning it two or more turns counterclockwise.Dimension ChartModel No.Heightin. (mm)Widthinch (mm)Weightlb (kg)22537637 (940)19 (483)36 (16)22537837 (940)19 (483)34 (15)22538035 (889)16 (406)18 (8)22538439 (991)24 (610)49 (22)22588037 (940)19 (483)35 (16)4306436Notes30643656306436ServicePump ServiceNOTE: Clean all parts in non-flammable solvent. Dry all parts thoroughly before reassembly.1.Remove the pump from the cover or shield.2.Slide the extension (318) up the riser tube (314) toexpose the intake valve (302).3.Unscrew the intake valve (302) from the riser tube(314). Disassemble the intake valve and clean and inspect the parts. Replace worn or damaged parts.4.Unscrew the riser tube (314) from the outlethousing (319).5.Pull the riser tube down off the connecting rod(320) and piston (301).6.Unscrew the piston (301) from the connecting rod(320). Disassemble the piston and clean andinspect the parts. Replace worn or damaged parts.7.Loosen the packing nut (312).8.Disconnect the rod (320) from the pump lever(316). Pull the connecting rod down out of the outlet housing (319).9.Unscrew the packing nut (312) and remove thepackings (313). Clean and inspect the parts.Replace worn or damaged parts.10.Reassemble the pump in the reverse order,following the lubrication and sealant notes in Fig.3. Tighten the packing nut (312) just enough to stop leakage.Fig. 313421Hand Pump Assembly, Model 204–867,Series AParts Ref No. 3, Model 204867, Series AHand Pump AssemblySee Parts Drawing in Fig. 3.RefNo.Part No.Description Qty. 301200753PISTON ASSEMBLYIncludes items 301a to 301f1 301a100114.BALL, steel, 7/16 in. dia.1 301b150134.SPRING, compression1 301c150463.GLAND, male1 301d*150464.V–PACKING, leather3 301e150465.SEAT, piston1 301f152559.HOUSING, piston1 302202162INTAKE VALVE HOUSINGIncludes items 302a to 302d1 302a101021.RING, retaining1 302b156738.VALVE, poppet1 302c156739.BODY, valve1 302d156750.GUIDE, poppet1 303100133LOCKWASHER, spring, 3/8 in.1 304100184CAPSCREW, hex, 5/16–24 x 1 in.1 305100187NUT, hex, 5/16–241 306100191NUT, wing, 5/16–181 307100214LOCKWASHER, spring, 5/16 in.1RefNo.Part No.Description Qty. 308100340NUT, hex, 3/8–161 309101120SCREW, rd hd, 1/4–20 x 1–1/4 in.4 310150662SCREW, pivot1 311150726CLEVIS1 312154513PACKING NUT1 313*154514PACKING, duck and neoprene2 314156511RISER TUBE1 315156593O-RING, nitrile rubber1 316158769LEVER, pump handle1 317159487SPACER1 318159488TUBE, extension1 319159923HOUSING, outlet1 320159930CONNECTING ROD1 321159931SCREW, pivot1 322100119ELBOW, 1/2 npt 1 * Keep spare on hand to reduce down time.7306436PartsGear Lube DispenserModel 225378, Series Awithout meterIncludes items 1, 3, 6, 201Model 225376, Series Bwith meterIncludes items 1, 2, 3, 6RefNo.Part No.Description Qty 1203622PORTABLE BASE ASSEMBLYSee separate Parts List, page 111 2239705HOSE & METER ASSEMBLYSee separate Parts List, page 111 3204867HAND PUMP ASSEMBLYSee separate Parts List, page 71 6204574COVER ASSEMBLYSee manual 306–3451 201214658HOSE ASSEMBLYModel 225378 onlyIncludes items 201a to 201c; Seeseparate Parts List on page 11, underRef No. 2, Hose & Meter Assembly1Gear Lube DispenserModel 225380, Series AIncludes items 3, 6, 201RefNo.Part No.Description Qty 3204867HAND PUMP ASSEMBLYSee separate Parts List, page 71 6204574COVER ASSEMBLYSee manual 3063451 201214658HOSE ASSEMBLYModel 225378 onlyIncludes items 201a to 201c; Seeseparate parts list on page 11, underRef No. 2, Hose & Meter Assembly168306436PartsGear Lube Dispenser Array Model 225384, Series BRefNo.Part No.Description Qty2239705HOSE & METER ASSEMBLYSee separate Parts List, page 1113204867HAND PUMP ASSEMBLYSee separate Parts List, page 716204574COVER ASSEMBLYSee manual 30634517203650TRUCK ASSEMBLYSee separate Parts List, page 10106789A3064369PartsAutomatic Transmission Fluid DispenserModel 225880, Series BRefNo.Part No.Description Qty1203622PORTABLE BASE ASSEMBLYSee separate Parts List, page 1113204867HAND PUMP ASSEMBLYSee separate Parts List, page 715239707DISPENSE KIT, meteredSee separate Parts List, page 1116204574COVER ASSEMBLYSee manual 306345106790ARef No. 7, Part No. 203650, Series ATruck Assembly,RefNo.Part No.Description Qty 701203651TRUCK BASE1 702100609SCREW, rd hd, 1/4–20 x 3/8 in.2 703101242RETAINING RING2 704101251WHEEL2 705154636WASHER4 706159912THUMBNUT2 707159913HOLD DOWN CLAMP,steel drums only2 708159924TRUCK HANDLE170610306436PartsRef No. 1, Part No. 203622, Series BPortable Base AssemblyRefNo.Part No.Description Qty. 101191750BASE, drum1 102113646CASTER; polyurethane4 103102547BOLT, hex hd; 5/16 in.–18 x 1.5 in.2 104191747BRACKET2 105100214WASHER, lock2 106100132WASHER, flat2 107113660RIVET16102Ref No. 5, Part No. 239707, Series AMetered Dispense KitRefNo.Part No.Description Qty501*214657HOSE, fluid, cpld 1/2 npt(m) x1/4 npt(f); 1/2 in. ID, 5 ft long1502203469NON-DRIP NOZZLE1503158491NIPPLE, 1/2 npt1508239824METER, inline electronic1503*Keep spare on hand to reduce down time.Ref No. 2, Part No. 239705, Series AHose and Meter AssemblyIncludes items 201, 202, 203RefNo.Part No.Description Qty201214658HOSE ASSEMBLYIncludes items 201a to 201c1201a200348.NON-DRIP NOZZLE1201b*214657.HOSE, fluid, cpld 1/2 npt(m) x1/4 npt(f), 1/2 in. ID, 5 ft long1201c100200.NIPPLE, 1/4 npt, 6 in. long1202158491NIPPLE, 1/2 npt1203239824METER, inline electronic1*Keep spare on hand to reduce down time.11306436Graco Standard WarrantyGraco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or sub-stitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.FOR GRACO CANADA CUSTOMERSThe parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnais-sent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.Graco Phone NumberTO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:1–800–533–9655 Toll FreeAll written and visual data contained in this document reflects the latest product information available at the time of publication.Graco reserves the right to make changes at any time without notice.MM 306436Graco Headquarters: MinneapolisInternational Offices: Belgium, China, Japan, KoreaGRACO INC.P.O. BOX 1441MINNEAPOLIS, MN55440–1441August 1957, Revised 07/200712306436。

Thank you for using ZENOAH ENGINE.●Please read this Owner’s Manual thoroughly before operating and use theengine correctly according to this Owner’s Manual.(For safety reasons, please contact your sales dealer before operating this engine if there is something that you do not understand.)●This engine has been designed for the use of radio control car.Please use this engine in conjunction with the manual for radio control car or radio control equipment you are going to use.●Any modification of the engine or any use of other applications is prohibited.●The purchaser (user) shall bear all obligations and responsibilities stipulated by law, local ordinance and the likes.Husqvarna Zenoah Co., Ltd. shall bear no responsibility whatsoever.115 64 99-26 (402)OWNER'S MANUALModel: G320RCModel code: 9672890012CONTENTSSPECIFICATIONS (4)SAFETY PRECAUTIONS (5)FUELING SYSTEM (6)ENGINE STARTING (8)OPERATION (9)MAINTENANCE (10)SPECIAL TOOLS (15)SERVICE GUIDE (16)TROUBLE SHOOTING (20)PARTS LIST (22)WARRANTY (26)3SPECIFICATIONSEngine Type G320RCOverall Size (L x W x H)167 x 216 x 197mmWeight 2.30kgDisplacement31.8cm3Clutch Engagement6000rpm (STD Spring)Carburetor Type WT-1107Spark Plug NGK CMR7HSpark Plug Gap0.65mmRotating Direction Counter-Clockwise (View From PTO) 4●These safety precautions are to prevent you and those people in the vicinity from incurring harm or damage. Make sure to observe these precautions and constantly strive to ensure safety.●Safe use of the engine is your personal obligation and responsibility. Constantly take care to act with good judgment as you enjoy your hobbies.•The fuel is toxic. Do not let it get into your eyes or mouth. Store it in a cool place, out of the reach of infants and children.•Use of open flames around the fuel is strictly prohibited, because of danger of fire.•To prevent burns, make sure not to touch the engine while it is operating or immediately after it has stopped.•Do not run the motor in poorly ventilated places. Do not breathe the exhaust, as it is a health hazard.•Please wear clothing that facilitates your safety. Remove all scarves,5overly long sleeves, neckties and the like. Failure to do so could result in injury.•When mounting the engine to a model, make sure to follow the model’s operating manual. If necessary, reinforce the engine mounting unit and the peripheral parts.FUELING SYSTEM•Mix gasoline (octane over 95) and high grade 2 cycle engine oil (mixing use type;JASO FC grade or ISO-L-EGC grade) at mixing ratio 25:1.•The mixing ratio is according to the oil recommendation.[ NOTE ]1)Gasoline may contain maximum of 10% Ethanol (grain alcohol) or up to 15% MTBE(Methyl tertiary-butyl ether).Gasoline containing Methanol (Wood Alcohol) is NOT approved.6FUELING SYSTEM2)Gasoline is very flammable. Avoid smoking and any fires near fuel.3)To prevent all possible problems on fueling system, make sure to use the fuel filterwhich has more than 300 mesh or equivalent and gasoline proof rubber pipe or equivalent.Incorrect fuel filter may cause engine trouble like fuel passage stuffing in carburetor, or piston surface scratching etc.4)When fueling, make sure that no fuel touches the hot parts.5)Assemble the fuel line so that it does not touch the hot parts. Also, check that thereis no fuel leakage due to cracks, or hardening.6)The picture below shows the tank dimensions for use with the 1799-85400 PIPECOMP.Tank Dimensions78ENGINE STARTINGFig.1•Push the primer pump several times until overflown fuel flows out. (Fig.1)•Close the choke lever(Fig.2), and move the throttle lever 1/4~1/3 open position.•Pull the starter(knob) quickly until first firing noise.(Fig.3)•Open the choke(Fig.2), throttle idle~1/4 open •Pull the starter quickly•Operate engine for a few minutes for the warming up.•In case of engine warm condition, choking may not be necessary.•Over choking may cause starting difficulty due to wet spark plug.In this case change spark plug or dry it, and remove fuel rest in the cylinder by pulling starter.OPERATION•This engine is already tuned up to get high power and high speed, and needs correct maintenance to keep such high performance.•The details for operation may be described in the separate owners manual to be issued by car manufacturer.•Be sure to have the engine cool down for 30 seconds at idle speed after full throttle running.9MAINTENANCE1) MAINTENANCE CHARTBefore Every EveryItems Action Use25 hours100 hours NoteLeakage,Check✔Damage/CrackIdling Speed Check/Adjust✔✔✔Air-cleaner Check/Cleaning✔✔Replace if necessary Spark Plug(gap)Check/Adjust✔✔↑Cylinder(barrel)Check/Cleaning✔✔↑Piston, Ring Check/Cleaning✔✔↑Muffler & Bolt Check/Cleaning✔✔✔↑Bearings Check/Cleaning✔✔↑Crank Shaft Check/Alignment✔↑102) SPECIFICATIONS AND TECHNICAL DATAItems Unit G320RC RemarksBore x Stroke mm 38 x 28Displacementcm 331.8Effective Compression Ratio9.7Type Walbro WT Carburetor Venture(mm)ø13.5Starting Recoil StarterType TCIIgnitionTiming BTDC 30°/8000rpmStandard CMR7H NGK CR8HIXwith Terminal Nut Option(Hot Type)CMR6H↑Clutch Engagement Speedrpm 6000STD Spring No load max Speedrpm 20000Idling Speed rpm 4000Max. Net Power kW/rpm 2.40/13000Max. Net Torque N.m/rpm 2.00/9000Fuel Consumptiong/kW·h 519Carburetor H 1 7/8 ±1/4Standard settingL 1 3/8 ±1/4↑Option(For Race)Spark Plug3) MAINTENANCE SPECIFICATIONSG320RCItems Standard Limit Measuring Device RemarksBore (mm)ø38Plating damaged Eye CheckingDiameter (mm)ø37.97ø37.87Micro MeterPiston Ring1.01 1.11Thickness GaugeGroove width (mm)Piston Pin Hole (mm)ø9.01ø9.05Cylinder Gauge Clearance betweenPiston and 0.03~0.060.15Cylinder (mm)Clearance betweenGroove and 0.02~0.040.1Thickness Gauge Piston Ring (mm)End Gap (mm)0.1~0.20.5Thickness GaugeWidth (mm)0.980.93Micro Meter Piston Pin Diameter (mm)ø9ø8.98Micro Meter Connecting Rod Small end (mm)ø12ø12.05Cylinder Gauge Crankshaft Dia. at Main Bearing (mm)ø12ø11.98Micro Meter Eccentricity (mm)—0.07Dial GaugeAxial Play (mm)—0.5Thickness GaugeGritty orrMain Bearing——Feels Flat Spot At the skirt end and the right angle to the piston pin.When inserted in a new cylinder.Piston CylinderPiston RingMicro Meter Cylinder Gauge4) CARBURETORItems Standard Limit Measuring Device Remarks Metering Lever set (mm) 1.65±0.16Vanier Inlet Valve Opening Pressure (kg/cm2) 1.3~2.3Leak TesterInlet Valve Closing Pressure (kg/cm2)0.7~1.7Leak Tester5) IGNITION SYSTEMItems Standard Limit Measuring Device Remarks Spark Plug Air Gap (mm)0.6~0.70.7Thickness GaugeIgnition Coil/Flywheel Air Gap (mm)0.30.4Thickness GaugePrimary0.7—Volt Meter Secondary6100—Volt Meter Reading between primary terminal and iron core.Reading between sparking cord end and iron core.Coil Resistance(Ω)6) TIGHTENING TORQUEItems Screw Size Standard (N·m)Limit (N·m)RemarksCarburetor M5 (P=0.8) 3.4 2.9~3.9Apply Three Bond TB1342H Insulator M5 (P=0.8) 4.4 3.9~4.9(Low Strength) or equivalent Case, Clutch M5 (P=0.8) 3.4 2.9~3.9Clutch (Plate)M6 (P=1.0) 6.4 4.9~7.8Clutch (Shoe)M6 (P=1.0) 6.4 4.9~7.8Rotor M8 (P=1.0)12.79.8~14.7Cylinder M5 (P=0.8)7.9 6.9~8.8Crankcase M5 (P=0.8) 6.4 4.9~7.8Spark Plug M10 (P=1.0)10.88.8~12.8Muffler M5 (P=0.8)8.8 6.9~9.8Muffler (Stay)M4 (P=0.7) 1.7 1.5~1.9Fan Cover M5 (P=0.8) 3.4 2.9~3.9Apply Three Bond TB1342H Cylinder Cover M4 (P=0.7) 1.7 1.5~1.9(Low Strength) or equivalent Cover. TR M4 (P=0.7) 1.3 1.0~1.5Ignition Coil M4 (P=0.7) 3.2 2.5~3.9Starter Case M4 (P=0.7) 1.3 1.0~1.5Tapping Screw TP 4.3 2.4 1.9~2.9SPECIAL TOOLSPart NamePart No.External AppearanceUsage 1Puller Assy2890-96100To remove rotor.2Piston Stopper 4810-962203Rod Assy 848W10000To remove/install piston pin.4Air Gap Gauge 3330-97310To set ignition coil.5Hex Wrench 3304-976116Snap Ring Pliers 5500-96110To remove snap ring.To hold crankshaft when disassembling/assembling clutch and rotor.For socket screw of Hex.3mm, 4mm and 5mm.1) REMOVING CLUTCH SHOE1.Remove the housing and plug cap.2.Remove the spark plug and fit the stopper(4810-96220) into the plug hole.3.Remove clutch bolts(14mm Hex.).2) REMOVING ROTOR (FAN)4.Remove the rotor nut(12mm Hex.).5.Remove the rotor using the puller assy (2890-96100).Apply 8mm puller bolts.3) ASSEMBLING ROTORInsert the gauge(3330-97310) in between the rotor magnet metal and the coil.Tighten screws while pressing the coil against the rotor.Air Gap 0.3 ~ 0.4mm4) REMOVING PISTON PIN1.Remove snap rings from both sides of the piston pin.2.Engage the rod assy(848W10000) to the piston pin and gently tap with a plastic hammer to push out the pin while holding piston firmly.Hard hammering may damage the big end of the connecting rod.Plastic HammerRod AssyPiston5) INSTALLING PISTON1.Make sure to point the arrow mark on the piston to the exhaust side.2.Fit the circlip in the groove so as to face the end gap below.Deformed circlip may come off during engine operation and damage the engine.6) CARBURETOR ADJUSTMENTThe carburetor comes with a standard setting, it is for optimum performance under the barometric pressure and climatic conditions at factory, so it may be re-adjusted according to load applied.Idle rpm :4000 ±300 rpm (STD Spring)H needle : 1 7/8 ±1/4L needle : 1 3/8 ±1/4Arrow Mark CirclipEnd GapPistonCover, TRHex2.5mmArea to apply 7) APPLY LIQUID GASKETApply the liquid gasket (Three Bond TB1217F) when taking the Cover, TR on or off.Apply a thin layer. Do not let the liquid casket enterthe cylinder. This could cause damage to the engine.TROUBLE SHOOTING1) ENGINE DOES NOT STARTDescription Cause Countermeasure No spark in the spark plugSpark Plug 1. Wet spark plug electrodes Make them dry2. Carbon deposited on the electrodes Cleaning3. Insulation failure by insulator damage Exchange4. Inproper spark gap Adjust to 0.6~0.7mm5. Burn out of electrodes ExchangeMagneto 1. Ignition coil inside failure Exchange2. Damaged cable sheath or disconnected cable Exchange or repairSwitch 1. Switch is OFF ON the switch2. Switch failure Exchange3.Primary wiring earthed RepairSparks appear in the spark plugCompression & 1. Over sucking of fuel Drain excess fuelfueling is normal 2. Too rich fuel Adjust carburetor3. Overflow Carburetor adjust or exchange4. Clogging of air cleaner Wash with mixed gasoline5. Faulty fuel Change with proper fuelFueling normal but 1. Worn out cylinder, piston, or piston ring Exchangepoor compression 2. Gas leakage from cylinder and crank case gasket Apply liquid gasket and reassemble.No fuel supply 1. Choked breather air hole Cleaning2. Clogged carburetor Cleaning3. Clogged fuel filter Exchange fuel filterTROUBLE SHOOTING2) LACK OF POWER OR UNSTABLE RUNNINGDescription Cause Countermeasure Compression is normal 1. Air penetration from fuel pipe joints, etc Secure connectionand no misfire 2. Air penetration from intake tube joint orChange gasket or tightening screwscarburetor joint3. Water in fuel Change with good fuel4. Piston start to seizure Replace piston(and cylinder)5. Muffler choked with carbon CleaningOverheating 1. Fuel too lean Adjust carburetor2. Clogging of cylinder fin with dust Cleaning3. Poor fuel quality Exchange with proper fuel4. Carbon deposited in the combustion chamber Cleaning5. Spark plug electrode red hot Thoroughly clean, adjust spark gap[ 0.6~0.7(0.023~0.028in) ] Others 1. Dirty air cleaner Wash with mixed gasoline2. Over loading Reduce load3. Cover, TR leakage Apply liquid gasket2122PARTS LIST G320RC (967289001)23PARTS LISTG320RC (967289001)G320RC (967289001)2425WARRANTY TERMS1)Scope of ApplicationThis engine manufactured by Husqvarna Zenoah Co., Ltd. (herein after “Zenoah”).And sold to the user directly or through distributor/manufacturer, shall entitle to be covered by this warranty.2)Limits of WarrantyZenoah warrants that;1.The quality disclosed in the specifications.2.The engine which shall be considered defective by Zenoah, caused by material orproduction fault.3)Limits of Compensation1.Zenoah compensates such quality, material and production faults by repairing orreplacing through distributor/manufacture.2.Zenoah shall not compensate any other accompanied or benefit losses caused touser and distributor/manufacture by such faults and through repairing orreplacing.264)Term of WarrantyThree (3) months after purchased by end- user subject to 12 months from produced month.5)Exempt from WarrantyZenoah shall not warrant this engine even if the fault has been caused during the period of terms of Warranty, in case that.1.Any faults, failures caused from neglect of proper operation and maintenancedescribed in OWNER’S MANUAL.2.Any modification not approved by Zenoah.3.Normal abrasion and deterioration.4.Consuming parts.ing any parts which have not been certified by Zenoah.6.Add-on or modified use.271-9 Minamidai, Kawagoe-city, Saitama, 350-1165 Japan Phone: (+81)49-243-1117 Fax: (+81)49-243-7197。

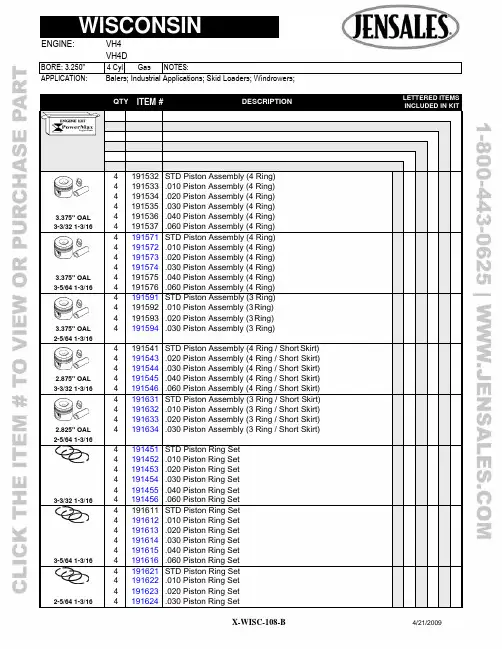

QTYITEM #DESCRIPTIONLETTERED ITEMSINCLUDED IN KIT4 4 4 191532 191533 191534 STD Piston Assembly (4 Ring) .010 Piston Assembly (4 Ring) .020 Piston Assembly (4 Ring)4 191535 .030 Piston Assembly (4 Ring)3.375" OAL 4 191536 .040 Piston Assembly (4 Ring)3-3/32 1-3/16 4 191537 .060 Piston Assembly (4 Ring)4 4 4 191571 191572 191573 STD Piston Assembly (4 Ring) .010 Piston Assembly (4 Ring) .020 Piston Assembly (4 Ring)4 191574 .030 Piston Assembly (4 Ring)3.375" OAL 4 191575 .040 Piston Assembly (4 Ring)3-5/64 1-3/16 4 191576 .060 Piston Assembly (4 Ring)3.375" OAL 4 4 4 4 191591 191592 191593 191594 STD Piston Assembly (3 Ring) .010 Piston Assembly (3 Ring) .020 Piston Assembly (3 Ring).030 Piston Assembly (3 Ring)2-5/64 1-3/164 4 4 191541 191543 191544 STD Piston Assembly (4 Ring / Short Skirt) .020 Piston Assembly (4 Ring / Short Skirt) .030 Piston Assembly (4 Ring / Short Skirt)2.875" OAL 4 191545 .040 Piston Assembly (4 Ring / Short Skirt)3-3/32 1-3/16 4 191546 .060 Piston Assembly (4 Ring / Short Skirt)2.825" OAL 4 4 4 4 191631 191632 191633 191634 STD Piston Assembly (3 Ring / Short Skirt) .010 Piston Assembly (3 Ring / Short Skirt) .020 Piston Assembly (3 Ring / Short Skirt).030 Piston Assembly (3 Ring / Short Skirt)2-5/64 1-3/164 4 191451 191452 STD Piston Ring Set .010 Piston Ring Set4 191453 .020 Piston Ring Set4 191454 .030 Piston Ring Set4 191455 .040 Piston Ring Set3-3/32 1-3/16 4 191456 .060 Piston Ring Set4 4 191611 191612 STD Piston Ring Set .010 Piston Ring Set4 191613 .020 Piston Ring Set4 191614 .030 Piston Ring Set4 191615 .040 Piston Ring Set3-5/64 1-3/16 4 191616 .060 Piston Ring Set4 4 191621 191622 STD Piston Ring Set .010 Piston Ring Set4 191623 .020 Piston Ring Set2-5/64 1-3/16 4 191624 .030 Piston Ring SetAPPLICATION: Balers; Industrial Applications; Skid Loaders; Windrowers;2 4 191566 101276Cylinder Block Assembly (Includes Valve Train)4 291521 STD Rod Bearing4 291522 .010 Rod Bearing4 291523 .020 Rod Bearing8 291456 Connecting Rod Shim, Early Babbitt Rod (.002")1 291524 Main Bearing Assembly, Exc Spec # 390568 (Flywheel End)1 291457 Main Bearing Assembly, Spec # 390568 (Flywheel End)1 291458 Outer Support Bearing Race, Spec # 390568 (Flywheel End)1 291459 Outer Support Needle Brg, Spec # 390568 (Flywheel End)1 291525 Main Bearing Assembly (PTO End)1 291526 Main Bearing Plate Shim (.006" Thick) (1)1 291527 Main Bearing Plate Shim (.013" Thick) (1)1 391456 Main Bearing Plate Gasket (.003" Thick) (1)1 391457 Main Bearing Plate Gasket (.006" Thick) (1)1 391458 Head Gasket Set2 391459 Head Gasket4 391461 Valve Cover Gasket1 391462 Manifold Gasket Set1 391463 Overhaul Gasket Set1 391464 Full Gasket Set w/Seals 1 391465 Pan Gasket Set1 391471 Flywheel Side Gear Cover Crank Seal (1.500 x 2.125 x .312)1 391472 PTO Side Crank Seal (Cork)1 391473 PTO Side Crank Seal Retainer (2)1 391474 PTO Side Crank Seal (Lip Type) (1.437 x 2.686 x .375)1 391475 PTO Seal, Clutch Output Shaft (1.563 x 2.441 x .500) (2)1 391477 PTO Seal, Reduction Output Shaft (1.750 x 2.830 x .374) (2)1 391478 PTO Seal, Shift Shaft (.750 x 1.375 x .406) (2)1 391479 PTO Seal, Shift Shaft (.750 x 1.250 x .250) (2)4 291449 Pin Bushing8 791174 Rod Bolt & Nut 8 791175 Rod Nut30 791176 Head Bolt (1.250")4 791177 Head Bolt (1.375")34 791178 Head Bolt Washer(1)Use Proper Shims & Gaskets To Give .002-.005" End Play (2)Not Included In Gasket Set LETTERED ITEMS INCLUDED IN KIT DESCRIPTION QTY ITEM #QTYITEM # DESCRIPTIONLETTERED ITEMSINCLUDED IN KIT1 591242 Camshaft 1 591243 Thrust Plunger1 591244 Thrust Plunger1 591245 Thrust Button8 591246 Tappet w/Adjusting Screw8 591247 Adjusting Screw4 491365 Exhaust Valve (Stellite / 1.250" Head)4 491366 Intake Valve (1.313" Head)8 491367 Valve Guide (1.813" OAL / .439" OD) 8 491368 Exhaust & Intake Valve Spring: VH4 (2.312" Free Length)4 491369 Ex Valve Spring w/Rotators: VH4D (1.812" Free Length)4 491368 Intake Valve Spring: VH4D (2.312" Free Length)4 491371 Ex Spring, Stellite Valves wo/Rotators (1.969" Free Length)4 491322 Exhaust Rotator: VH4D4 491372 Spring Retainer "8 Used On VH4"16 491273 Keeper Half4 491373 Exhaust Valve Seat (1.125 x 1.375 x .265) 4 491373 Intake Valve Seat (1.125 x 1.375 x .265)APPLICATION: Balers; Industrial Applications; Skid Loaders; Windrowers; 1 591248 Cam Gear, Exc Spec # 3905681 591262 Cam Gear, Spec # 390568 1 591249 Crank Gear, Exc Spec # 3905681 591259 Crank Gear, Exc Spec # 3905681 591261 Crank Gear, Spec # 3905681 591251 Cam & Crank Gear Set, Standard Application1 591252 Idler Gear, Exc Spec # 390568 (37 Tooth w/Bushing) 1 591263 Idler Gear, Spec # 3905681 591253 Idler Gear Bushing, Exc Spec # 3905681 591254 Oil Pump Drive Gear1 591255 Magneto Drive Gear1 591256 Distributor Drive Assembly Drive Gear (3)1 591257 Distributor/Governor Drive Assembly Drive Gear (4) 1 591258 Accessory Drive Assembly Drive Gear1 691185 Oil Pump 1 691186 Oil Pump1 791179 Crankshaft, Standard Direct Drive (5)1 791186 Crankshaft Nut, Flywheel Side (1 1/8-12)4 791183 Connecting Rod (Late Insert Type) (6)2 791184 Cylinder Head1 891221 Fuel Pump, Open Engine (Low Dome)1 891222 Fuel Pump, Power Unit (Rotating Dome & Fuel Inlet Conn) 1 891223 Fuel Pump Plunger Rod (2.750 OAL) "Pumps wo/Primer" 1 891224 Fuel Pump Plunger Cap1 891225 Governor Assembly, wo/Distributor Drive1 891226 Governor Assembly, w/Distributor Drive1 891227 Governor Kit (Weights, Pins, Sleeve/Brg, Seal, Spring +) (7) 1 891228 Governor Kit (Weights, Pins, Sleeve/Brg, Seal, Spring +) (8) 1 891219 Flywheel Ring Gear1 801123 Oil Filter, Thru 3408749 (2.750" x 4 Threads Per Inch) 1 801124 Oil Filter, After 3408749 (2.750" x 5.5 Threads Per Inch) 1 801122 Oil Filter, Late Style (.625" x 18 Threads Per Inch)(3) Used With TF129 Drive Assembly (Drive Housing Does Not Contain Governor)(4) Used With T113 Drive Assembly (Drive Housing Contains Governor)(5) Supply Model, Spec, Serial Number & Number Stamped In Cheek Behind PTO Side Bearing For Correct Shaft(6) Babbitt & Insert Type Rods May Be Mixed In The Same Engine (7)Used On 891225 (8)Used On 891226 LETTERED ITEMS INCLUDED IN KIT DESCRIPTION QTY ITEM #。

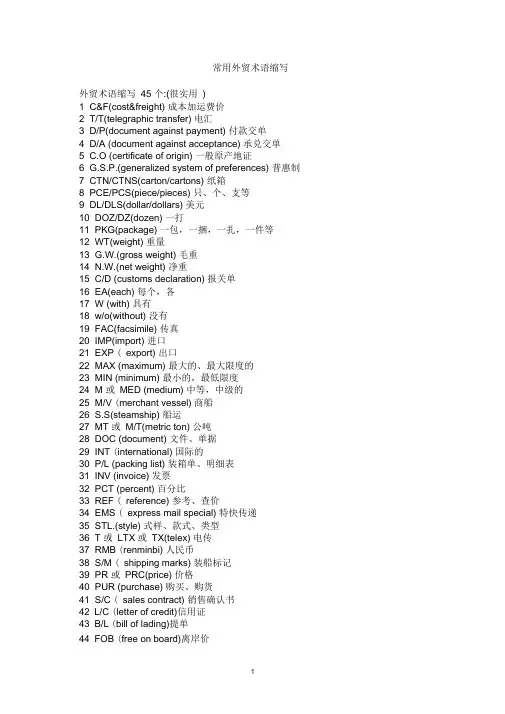

常用外贸术语缩写外贸术语缩写45 个:(很实用)1 C&F(cost&freight) 成本加运费价2 T/T(telegraphic transfer) 电汇3 D/P(document against payment) 付款交单4 D/A (document against acceptance) 承兑交单5 C.O (certificate of origin) 一般原产地证6 G.S.P.(generalized system of preferences) 普惠制7 CTN/CTNS(carton/cartons) 纸箱8 PCE/PCS(piece/pieces) 只、个、支等9 DL/DLS(dollar/dollars) 美元10 DOZ/DZ(dozen) 一打11 PKG(package) 一包,一捆,一扎,一件等12 WT(weight) 重量13 G.W.(gross weight) 毛重14 N.W.(net weight) 净重15 C/D (customs declaration) 报关单16 EA(each) 每个,各17 W (with) 具有18 w/o(without) 没有19 FAC(facsimile) 传真20 IMP(import) 进口21 EXP ( export) 出口22 MAX (maximum) 最大的、最大限度的23 MIN (minimum) 最小的,最低限度24 M 或MED (medium) 中等,中级的25 M/V (merchant vessel) 商船26 S.S(steamship) 船运27 MT 或M/T(metric ton) 公吨28 DOC (document) 文件、单据29 INT (international) 国际的30 P/L (packing list) 装箱单、明细表31 INV (invoice) 发票32 PCT (percent) 百分比33 REF ( reference) 参考、查价34 EMS ( express mail special) 特快传递35 STL.(style) 式样、款式、类型36 T 或LTX 或TX(telex) 电传37 RMB (renminbi) 人民币38 S/M ( shipping marks) 装船标记39 PR 或PRC(price) 价格40 PUR (purchase) 购买、购货41 S/C ( sales contract) 销售确认书42 L/C (letter of credit)信用证43 B/L (bill of lading)提单44 FOB (free on board)离岸价45 CIF (cost,insurance&freight )成本、保险加运费价comprehe nsive package of services 全面的一揽子服务a desig nated ma nned ship 一艘特定的配备船员的船air freight空运货物Airline cooperation 航空公司协作arrival notice 至U货通知as per按照bale or grain capacity 包装或散装容积BALTIME form 波尔的姆格式bank draft银行汇票bareboat charteri ng 光船租船BARECON form贝尔康格式bargaining strenght 讨价还价的能力bill of entry 报关单bills of lading 提单BIMCO波罗的海国际航运运协会blank bill of lading 不记名提单break bulk cargo 杂货,普通货物breakage of pack ing risks 包装破裂险bunker adjustment factor (BAF)燃油价格调整因素;燃油附加费bus in ess corresp ondence 商务通信call at a port 挂靠,停靠cargo transportation 货物运输carriage of goods by sea 海上货物运输carriage of goods by road 公路货物运输carrier承运人carrying capacity 运载能力certificate of registry 登记证书CFR (Cost and Freight) CFR (成本加运费)chargeable weight 计费重量charter party租船合同check list核查单CIF (Cost,lnsuranee and Freight)CIF ( 成本、保险费加运费)CIP (Carriage and In sura nee Paid To)CIP ( 运费、保险费付至)clash and breakage risks 碰损、破碎险class rates等级运价clean bill of lading 清洁提单clear the goods for export 办理货物出口清关手续combined transport 合并运输commissi on age nt 委托代理人com mon carrier公共承运人conference lines 班轮公会运输con sig nee收货人consolidated shipment 集运货物Constructive total loss 推定全损container cargo 集装箱货物containerization 集装箱化con tract of affreightme nt (COA) 包运合同contract of carriage 货物运输合同CPT (Carriage Paid To)CPT (运费付至)lash ing捆扎加固special cargo特殊货物报关单、核销单、提单等的英文翻译出口报关单bill of customs clearanee核销单verification sheet倒签提单antedated B/L直销direct selling传销multi-level selling,pyramid selling唛头mark正唛shipping mark ,main mark, front mark侧唛side markTHC 码头操作费FAF 燃料附加费YAS 码头附加费或者日元升值附加费EPS 是设备位置附加费EXW 工厂交货AIR WAYBILL NUMBER 包裹空运运单号B/L NO 海运的提单M B/L (Ocean Bill of Lading) 海上提单H B/L (House Bill of Lading) 仓库提单报关单英文单词和缩写一.单证( Documents) 进出口业务涉及的单证总的包括三大类:1、金融单证(信用证、汇票、支票和本票)2、商业单证(发票、装箱单、运输单据、保险单等3、用于政府管制的单证(许可证、原产地证明、商检证等)declaration form 报关单nThree steps —declaration, examination of goods andn release of goods, are taken by the Customs to exercise control over general import and export goods. 海关对进出境货物的监管一般经过申报、查验和放行三个环节。

报关单英文单词和缩写一.单证(Documents)进出口业务涉及的单证总的包括三大类:1、金融单证(信用证、汇票、支票和本票)2、商业单证(发票、装箱单、运输单据、保险单等3、用于政府管制的单证(许可证、原产地证明、商检证等)declaration form报关单νThree steps—declaration, examination of goods andν release of goods, are taken by the Customs to exercise control over general import and export goods.海关对进出境货物的监管一般经过申报、查验和放行三个环节。

the person in chargeν of the declarationinvoice发票νocean bill of lading提单νairν waybill空运提单packing list或packing specification(装箱单)νshippingν order(装货单)letter of credit(L|C)(信用证)νinsurance policy(保险单)νsalesν confirmation售货确认书contract(合同)(commodity, quantity, unit price, totalν amount, country of origin and manufacturer, packing, shipping mark, date of shipment, port of shipment, port of destination, insurance, payment, shipment, shipping advice, guarantee of quality, claims, force majeure, late delivery and penalty, arbitration)certificate(commodity inspection certificate商检证animal or plant quarantine certificate 动植物检疫证certificate of origin原产地证二.报关英语常用词汇import进口export出口importν & export corporation(Corp.)importν & export business(enterprise entitled to do import and exportbusiness)export drawback出口退税νimportν & export licenceprocessing with imported(supplied) materials进(来)料加工νbuyer买方seller卖方The buyer requests his bank to issue a letter of credit in favor of the seller. goods(import& export goods , All import and export goods shall be subject to Customs examination)cargo (bulk cargo, cargo in bulk, air cargo, sea cargo, bonded cargo,cargo-ownerWhat cargo is inside the container?The cargo is now released.Commodity(commodity inspection)merchandise泛指商品,不特指某一商品article(smuggled goods and articles, inward and outward goods and articles)luggage 行李物品postal items 邮递物品You don’t have to pay duty on personal belongings, but the other one is subject to duty.means of transport(conveyance)运输工具(vessel, aircraft, train, vehicle):All inward and outward means of transport shall be subject to Customs control on arriving in or departing from the Customs territory.ocean vessel船名packing(bag袋, bale包,bottle, coil圈,case, crate板条箱,dozen, package 件:total packages合计件数, piece, roll, set, unit辆,台,单位,drum桶,carton 纸箱, wooden cases木箱,pallet托盘,container ,in bulk)weight重量gross weight毛重net weight净重tare皮重quantity数量:The minimum quantity of an order for the goods is 500 cases. description of goods货名name and specifications of commodity品名及规格type类型mode (term)of trade贸易方式name of trading country贸易国date of importation进口日期value价值total value of the contract commercial value, duty-paying valueThe duty-paying value of an import item shall be its normal CIF price and the duty-paying value of an export item shall be its FOB price, minus the export duty.The duty-paying value of an inward or outward article shall be fixed by the Customs.price价格unit price单价total price总价total amount总价consignor发货人consignee收货人While the examination is being carried out, the consignee of the import goods or the consignor of the export goods shall be present and responsible for moving the goods, opening and restoring the packingDeclaration of import goods shall be made to the Customs by the consignee within 14 days of the declaration of the arrival of the means of transport; declaration of export goods shall be made by the consignor 24 hours prior to the loading unless otherwise approved by the Customs. 进口货物的收货人应当自运输工具申报进境之日起14日内,出口货物的发货人除海关特准的外应当在货物运抵海关监管区后装货的24小时以前,向海关申报。

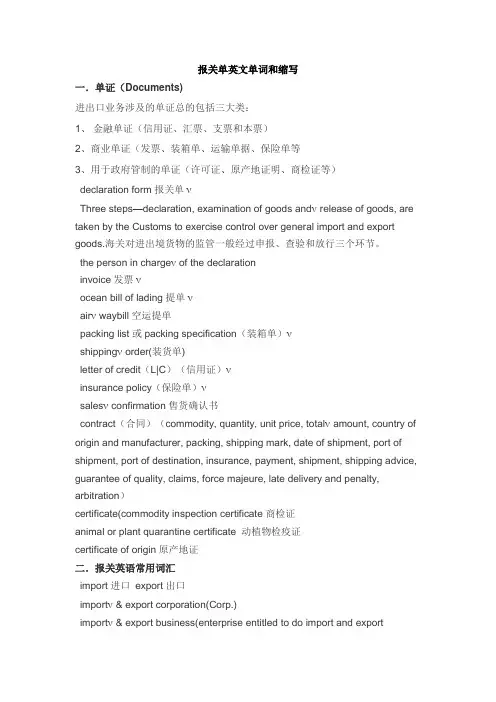

Skid Loaders: New Holland L35, L775;Trenchers: Ditch Witch;QTYITEM # DESCRIPTION LETTERED ITEMSINCLUDED IN KIT4 4 4 191581 191582 191583 STD Piston Assembly .010 Piston Assembly .020 Piston Assembly4 191584 .030 Piston Assembly4 191585 .040 Piston Assembly4 191586 .060 Piston Assembly3-3/32 1-3/164 4 191671 191672 STD Piston Ring Set .010 Piston Ring Set4 191673 .020 Piston Ring Set4 191674 .030 Piston Ring Set4 191675 .040 Piston Ring Set4 191676 .060 Piston Ring Set3-3/32 1-3/164 191577 Cylinder Barrel4 101248 Repair Sleeve (3.9405 OD / 10.250 OAL)APPLICATION: Balers: New Holland 25, 283, 286, 290, 320, 420, 425, 426, 430, 500, 505;Skid Loaders: New Holland L35, L775;Trenchers: Ditch Witch;4 291536 STD Rod Bearing4 291537 .010 Rod Bearing4 291538 .020 Rod Bearing4 291539 .030 Rod Bearing2 291519 Main Bearing Assembly (Flywheel & PTO End)1 291545 STD Center Main Bearing, After 49046561 291546 .001 Center Main Bearing, After 49046561 291547 .010 Center Main Bearing, After 49046561 291548 .020 Center Main Bearing, After 49046562 791235 Center Main Bearing Hanger Attaching Bolts (Grade 8)1 291528 Main Bearing Plate Shim (.014" Thick) (1)1 391514 Main Bearing Plate Gasket (.003" Thick) (1)1 391515 Main Bearing Plate Gasket (.006" Thick) (1)1 391516 Head Gasket Set4 391517 Head Gasket4 391518 Valve Cover Gasket1 391519 Manifold Gasket Set (14 Port Gaskets & Inserts)1 391522 Overhaul Gasket Set1 391523 Full Gasket Set w/Seals1 391487 Pan Gasket Set1 391525 Flywheel Side Gear Cover Crank Seal (2.000 x 2.996 x .375)1 391526 PTO Side Crank Seal (2.000 x 3.000 x .312)4 291469 Pin Bushing8 791221 Rod Bolt 8 791194 Rod Nut3 791222 Head Stud (8.375")1 791223 Head Stud (8.687")8 791224 Head Stud (10.000")4 791225 Head Stud (11.312")16 791226 Head Nut4 791227 Valve Cover Bail Wire(1)Use Proper Shims & Gaskets To Give .002-.005" End PlayLETTERED ITEMS INCLUDED IN KIT DESCRIPTION QTY ITEM #Skid Loaders: New Holland L35, L775;Trenchers: Ditch Witch;QTY ITEM # DESCRIPTION LETTERED ITEMSINCLUDED IN KIT1 591292 Camshaft1 591243 Thrust Plunger1 591244 Thrust Plunger Spring1 591245 Thrust Button8 591293 Tappet4 491382 Exhaust Valve4 491383 Intake Valve8 491384 Valve Guide8 491371 Valve Spring4 491385 Exhaust Rotator4 491386 Intake Spring Retainer16 491387 Keeper Half4 491373 Exhaust Valve Seat (1.125 x 1.375 x .265)4 491388 Intake Valve Seat (1.375 x 1.625 x .250)4 491389 Exhaust Rocker Arm4 491391 Intake Rocker Arm4 491392 Rocker Arm Shaft4 491393 Rocker Arm Shaft Spring4 491396 Rocker Arm Assembly, Thru 54878164 491394 Rocker Arm Assembly, After 5487816 (4)APPLICATION: Balers: New Holland 25, 283, 286, 290, 320, 420, 425, 426, 430, 500, 505;Skid Loaders: New Holland L35, L775;Trenchers: Ditch Witch;1 591295 Cam Gear, Thru 50757751 591272 Cam Gear, After 5075775 1 591296 Crank Gear, Thru 50757751 591294 Crank Gear, After 50757751 591297 Idler Gear, Thru 50757751 591275 Idler Gear, After 50757751 591253 Idler Gear Bushing1 591254 Oil Pump Drive Gear, After 50757751 591298 Governor Drive Gear, Thru 50757751 591278 Governor Drive Gear, 5075776-53568051 591277 Governor Drive Gear, After 53568051 591299 Accessory Drive Assembly Drive Gear, Thru 50757751 591281 Accessory Drive Assembly Drive Gear, After 50757758 591311 Push Rod, Thru 5487816 (10.937" Long)8 591312 Push Rod, After 5487816 (11.219' Long)8 591315 Push Rod Tube1 691191 Oil Pump1 691192 Oil Pump Screen1 691194 Pressure Relief Valve Assembly1 791232 Crankshaft, Standard After 4904656 (5)1 791233 Crankshaft Nut, Flywheel Side (1 1/2-12)4 791229 Connecting Rod, Thru 92051190 (6)4 791231 Connecting Rod, After 92051190 (6)4 791228 Cylinder Head1 891241 Fuel Pump (Low Dome)1 891242 Fuel Pump Plunger Rod1 891224 Fuel Pump Plunger Cap1 891243 Governor Kit (Weights, Pins, Sleeve/Brg, Seal, Spring +)1 891234 Flywheel Ring Gear1 801125 Oil Filter(5)Supply Model, Spec, Serial Number & Number Stamped In Cheek Behind PTO Side Bearing For Correct ShaftLETTERED ITEMS INCLUDED IN KITDESCRIPTION QTY ITEM #。

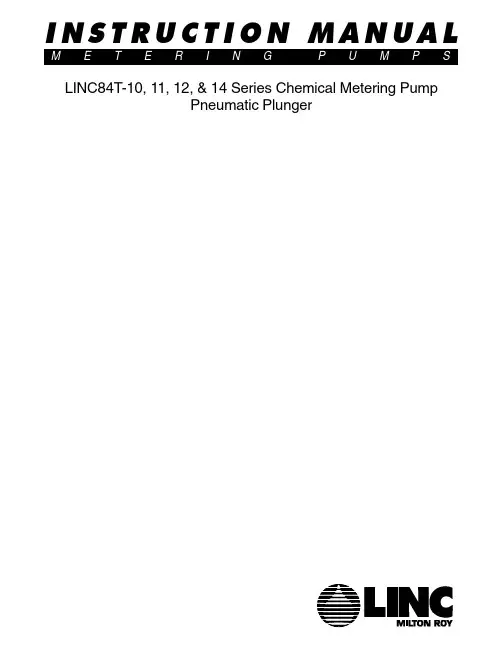

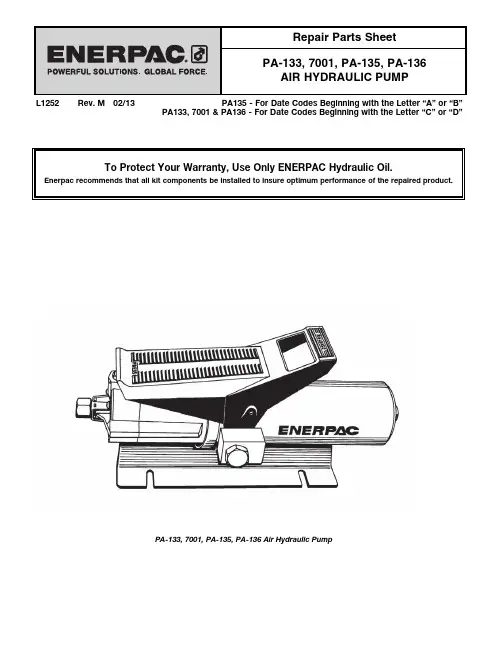

LINC84T-10, 11, 12, & 14 Series Chemical Metering PumpPneumatic PlungerTo Order, Call 800.455.LINCOr FAX your order anytime to215.293.0498For the Nearest AuthorizedRepresentative:By Telephone: 800.455.LINC forthe US & Canada, 215.293.0465 or215.441.0800 for InternationalcustomersBy Fax:215.293.0498E-mail:************************Technical SupportBy Telephone: 800.455.LINC or215.293.0498By E-mail:******************Convenient HoursOur phone lines are open Monday– Friday 8:00 AM – 4:45 PM (EST)LINC WarrantyThree year limited warranty on all ourproducts against defects in materials.LINC Technical SupportTechnical service and supportbegins with an easy toll-free call.Many times, our experiencedcustomer service reps can isolateand resolve problems over thephone or provide a referral to ourauthorized representatives nation-wide.We also offer factory repairservices with facilities in Ivyland,PA. if a warranty issue that cannotbe resolved locally.Purchase OrdersAll mail-in purchase orders mustbe signed by an authorizedperson.When ordering please list:•Quantity•Description of Items•Shipping Address•Billing Address•Purchase Order NumberRequest for Quotation – RFQ’sPlease send RFQ’s to:By Mail:Linc Milton RoyAttn: Customer Service201 Ivyland RoadIvyland, PA 18974USABy Fax:1.215.293.0498By E-mail:************************Freight ChargesAll shipments are F.O.B., Ivyland,PA, USA. Shipping and handlingare included on the invoice,prepay and add.TermsWith credit approval, net 30 days.Contents - 84T-10, 11, 12, & 14 Pump Manual.......................................................................................................Page General Specifications.. (4)Selection Chart (4)Ordering Chart (5)How to Determine Supply Pressure (6)Scope Of This Manual (7)Installation (7)Maintenance (7)Removing the Pump from Service (7)Timer (7)Suction Check Valve (8)Discharge Check Valve (8)Piston/Plunger (9)Plunger Seal (9)Reassembling The Pump (9)Assembly Drawings & Parts ListsFigure 1, 84T-10, 11, & 14 Assembly Drawing (10)Pump Assembly Parts List: 84T-10, 11, & 14 (11)Seal Materials 84T-10, 11, & 14 Parts List............................................................................................... 12 & 13F igure 2, 84T-12 Assembly Drawing (14)Pump Assembly Parts List: 84T-12 (15)Seal Materials 84T-12 Parts List (16)Figure 3, Timer (17)F igure 4, Discharge Check Valve (One Piece Body) (18)Figure 5, Discharge Check Valve (Two Piece Body) (18)Figure 6, Suction Check Valve (19)Suction Check Valve Parts List (20)LINC Chemical Pump Gas Consumption Chart (21)Notes:1.Maximum rates are based on maximum strokes per pump.2.Minimum rates are calculated as follows:3/16", 1/4" and 1/2" plunger pumps are 1/4" stroke length and a minimum of 4 strokes per minute.1" plunger pumps are 1/4" stroke length and a minimum of 4 strokes per minute.3.The timer supply pressure is 15 to 110 psi.4.When creating a Model Number using the Ordering Chart, the "X" in the Model Number column abovewill be replaced by a single digit representing the plunger seal selection. The plunger seal is shown in the Ordering Chart.5.Maximum pressure based on 100 psi supply pressure.6.Volume per stroke in shown for maximum pressure and strokes per minute. Volume per stroke increases as dischargepressure decreases.Ordering Chart: LINC 84T-10, 11, 12 & 14 Pneumatic Plunger Metering PumpSeries:84T-Pneumatic, plunger type metering pumpPlunger Diameter/Pump Control:10-3/16" plunger diameter (17-4 ss ceramic coated only), timer only11-1/4" plunger diameter, timer only12-1/2" plunger diameter, timer only14-1" plunger diameter, timer onlyPlunger Seal:1-Packing mechanical seal - Fluorocarbon, wetted o-rings - Fluorocarbon2-Packing mechanical seal - Fluoromyte, wetted o-rings - TFE3-Packing mechanical seal - Nitrile, wetted o-rings - Nitrile4-Packing mechanical seal - TFE/Graphite, wetted o-rings - TFE5-Specify your requirements6-Packing mechanical seal - Ultra High Molecular Weight Polyethylene,wetted o-rings - TFE7-O-rings packing seal - Fluorocarbon, wetted o-rings - Fluorocarbon8-O-rings packing seal - Nitrile, wetted o-rings - Nitrile9-O-rings packing seal - Kalrez, wetted o-rings - KalrezPiston Size:1- 2 1/4" piston diameter2-3" piston diameter4-4" piston diameterOther:4-Ceramic5-Specify your requirements9-All 316 ss pump/timer (when required)Option Number:( )-Factory will assign an option number based on specified requirements.Note:If no further requirements are desired, omit "other" options codesfrom the part number. Example 84T-11-41.LINC 84T- ____-_______ ( )Example: LINC 84T-11-41 Pneumatic Metering PumpScope Of This Manual:This manual describes and pro-vides instructions and parts list forthe LINC84T-10, 11, 12 & 14 Se-ries Chemical Metering Pump. Thispump is a pneumatically operatedplunger pump.1.Figure 1 of this manual is thesectional drawing and partslist for the LINC84T-10, 11 &14 Chemical Metering Pump.2.Figure 2 of this manual is thesectional drawing and partslist for the LINC84T-12Chemical Metering Pump.Installation:The LINC84T-10, 11, 12 & 14 re-quire a flooded suction and mustbe located lower than the chemicalsupply tank. Vertical installationof the piston housing is required.1.Connect the suction linethrough a filter or strainer tothe suction check valve (fig.1, item 17 or fig. 2, item 16).2.Connect the discharge line tothe desired location.Note: An in-line check valve at thepoint of injection is recommendedto prevent back flow to the pumpduring shutdown or servicing.3.Connect a supply pressureline to the timer (fig. 1, item 1or fig. 2, item 1). Air is therecommended supply; how-ever, any dry filtered gas maybe used. The supply pressureto the timer must be regu-lated between 15 psig and110 psig.4.Set the regulator to the properpressure to overcome thedischarge pressure requiredby the pump. Refer to theparagraph on "AmplicationRatio" in this manual todetermine the correct supplypressure.5.To prime the pump, loosenthe bleed screw (fig. 1, item18 or fig. 2, item 18). Allowthe liquid (chemical) to flowinto the pump chamber,venting the trapped air or gas.Tighten the bleed screw.6.Start the pump and run for aminimum of one minute.Open the bleed screw againand evacuate all the remain-ing air or gas from the pumpchamber.ing a rate gauge, set thedesired pumping rate byadjusting the timer knob andstroke adjustment screw.The timer can be set to strokethe pump from 4 strokes/minute to the maximum ratefor the particular pump beingused. See selection chart inthis section of the manual.8.The stroke length is adjustedby rotating the stroke adjust-ment screw (fig. 1, item 5 orfig. 2, item 4) on top of thepiston housing (fig. 1, item 8or fig. 2, item 6). Loosen thejam nut and adjust the strokeadjustment screw as neces-sary (fig. 1, item 4 or fig. 2,item 5). Lock down the jamnut after any adjustments aremade.Note: The minimum stroke on the84T-10, 11 & 12 is 1/8" and 1/4" onthe 84T-14.Maintenance:Refer to all sectional drawing andparts list in this manual. All repairsshould be performed in a cleanenvironment.The following steps must betaken before proceeding with anymaintenance operations:Removing the Pump from Ser-vice:1.Rotate the control knob onthe timer to the "O" position.2.Disconnect the supplypressure from the timer.3.Close the upstream anddownstream valves on thechemical lines.4.Open the bleed screw torelease the pressure in thepump.5.Disconnect the suction anddischarge lines from thecheck valves.Timer, Figure 1, item 1 or Figure2, item 1 & Figure 3:1.Disconnect the supplypressure from the timer.2.Rotate the timer counter-clockwise on the pipe nipplethat connects it to the pistonhousing until the timer isvertical with the supply pres-sure port pointing down.3.Loosen and remove the twoscrews from the timer (fig. 3,item 1).4.Separate the three timer sec-tions and discard the seal,diaphragm and the disc (fig.3, items 4, 6 & 15). Be care-ful not to lose the small discspring (fig. 3, item 16). Notethe orientation of thediaphragm as it is removed.5.Loosen the set screw on theknob (fig. 3, item 11).Remove the knob and knobspring (fig. 3, item 9).6.Unscrew the adjustmentscrew (fig. 3, item 10) fromthe front body (fig. 3, item 13).Remove and discard the o-ring (fig. 3, item 12).7.Reassemble the timer inreverse order of the abovesteps, using new rubberparts. Lubricate the adjust-ment screw threads and itso-ring. No other lubricationis required.8.After installing the adjust-ment screw, turn it in by handwithout the knob installeduntil it lightly seats. Duringthis operations do not over-tighten the adjustment screwinto its seat. Apply supplypressure to the timer andunscrew the adjustmentscrew slowly until the pumpstarts to run. Trial and errorwill be necessary to deter-mine the proper orientation ofthe knob on the adjustmentscrew. Once the properorientation is determined, re-install the knob spring andknob.Suction Check Valve,Figure 1, item 17 or Figure 2, item16 & Figure 6:1.Disconnect the piping fromthe check valve.2.Unscrew the check valvebody from the pump (fig. 6,item 1).3.Remove and discard the o-rings (fig. 6, items 3 & 4).4.Inspect the ball for damage(fig. 6, item 2). Replace ifnecessary. Reassemble thecheck valve using new o-rings.If the seat o-ring is Teflon,install it onto the checkvalve body and "peen" theball into the seat to ensureproper sealing (fig. 6, item 3).5.Install the repaired suctioncheck valve into the pumpbody. Tighten securely.Discharge Check Valve,Figure 1, item 16 or Figure 2, item15 & Figure 4:1.Disconnect the piping fromthe check valve.2.Unscrew the check valvebody from the pump (fig. 4,item 1).3.Remove and discard the o-rings (fig. 4, items 4 & 5).4.Inspect the ball and spring fordamage (fig. 4, items 2 & 3).Replace if necessary. Reas-semble the check valve usingnew o-rings. If the seato-ring is Teflon, install it intothe pump body assemblyand "peen" the ball onto theseat to ensure proper sealing.5.Install the repaired dischargecheck valve into the pumpbody. Place the ball on theo-ring seat followed by thespring (small end of thespring toward the ball) andscrew the discharge checkvalve body into the pumpbody assembly. Tighten se-curely.Discharge Check Valve,Two-Piece, Model 84T-14 only,Figure 1, item 16 & Figure 5:1.Separate the two halves ofthe check valve (fig. 5, items1 & 4).2.Replace the o-rings, ball andspring as required (fig. 5,items 2, 3, 5 & 6). The Teflono-ring may be removed,turned around and reused ifa new o-ring is not available(fig. 5, item 2). During thisprocedure extreme careshould be exercised. Theball should be "peened" onthe Teflon seat to ensureproper sealing (fig. 5, items1, 2 & 5).3.Ensure that the proper flowdirection, as marked on thevalve body is observed wheninstalling or replacing thischeck valve.Piston/Plunger:1.Secure the pump bodyassembly in a vise (fig. 1,item 19 or fig. 2, item 17).2.Remove the piston housingscrews (fig. 1, item 11 or fig.2, item 10). Grasp thepiston housing and pull up toremove (fig. 1, item 8 or fig.2, item 6).3.Grasp the piston and pullaway from the pump bodyasssembly to remove (fig. 1,item 6 or fig. 2, item 7).Inspect the plunger for wear,especially longitudinalgrooves. Replace the pistonassembly if necessary. In-spect the piston u-cup (fig. 1,item 7 or fig. 2, item 8).Replace if necessary.6.Remove the spring, lubricantseal back-up and lubricantseal from the spring cavity(fig. 1, items 9,12, & 13 or fig.2, items 9, 11 & 12).Inspect all three parts, espe-cially the lubricant seal andreplace worn or damagedparts as needed.Plunger Seal,Figure 1, item15 or Figure 2, item 14:1.With a pipe or strap wrench,separate the pump bodyassembly (fig. 1, item 19 orfig. 2, item 17).2.Remove the seal back-upand plunger seal (fig. 1,item 15 or fig. 2, item 14) fromthe lower housing of thepump body assembly. Notethat on Model 84T-12, theplunger seal and plungerseal backup are in the upperhousing of the pump bodyassembly (fig. 2, items 14).Carefully remove the sealback-up and seal. Inspect forwear or deterioration frombeing attacked by the chemi-cal the pump is pumping.3.Replace the plunger seal. Ifneeded, also replace theplunger seal back-up. Extremecare should be taken not toscratch or distort these parts.Reassemble the Pump:1.Lubricate the piston u-cupand plunger with light oil toprotect against possibledamage during assembly.2.Reassemble the piston/plunger assembly, whichincludes the lubricant seal,lubricant seal back-up andspring and install into thepump body assembly. SeeFigure 1 or Figure 2 forcorrect assembly.3.Replace the piston housingand secure with the pistonhousing screws.4.Thread the timer connectingnipple into the port at the topof the piston housing. Threadthe output port in the rearbody of the timer to thisnipple.Caution: Be sure there are noleaks at these connections. If leaksare present, the timer will not oper-ate properly.6.Install the new plunger sealand plunger seal back-upSee the procedure entitled"Plunger Seal" above.7.Screw the upper part of thepump body assembly backinto the lower part and tightensecurely.8.If the bleed screw has beenremoved, install and tightensecurely.Plunger and Plunger SealLubrication:1.Remove the plug from thepump body (fig. 1, item 14 orfig. 2, item 13).2.Add silicone base lubricant(Dow Dorning DC-7, part#10354) or equal into the portwhere the plug was removed.Approximately 0.5 cc will berequired for each refill.Replace the plug.Note: Do not use a grease gunor any metal tool to insert thelubriant into the pump to preventdamage to the plunger or plungerseal.3.Silicone lubricant should beadded every 4 - 6 weeksdepending upon operationconditions.Figure 1, LINC84T-10, 11, & 14 Series PumpLINC84T-10, 11, & 14 Series Parts ListSeries 84T-10, 11 & 14 Seal MaterialsModel 84T-11-22Item Description Part #Material15A........................................Plunger Seal.........................................................21197....................................Fluoromyte 15B........................................Plunger Seal Back-Up..........................................22571....................................Acetal16..........................................Discharge Check Assembly.................................22626....................................See Parts17..........................................Suction Check Assembly......................................24777....................................See Parts Model 84T-11-42Item Description Part #Material15A........................................Plunger Seal.........................................................11283....................................TFE/Graphite 15B........................................Plunger Seal Back-Up..........................................22581....................................Peek16..........................................Discharge Check Assembly.................................22626....................................See Parts17..........................................Suction Check Assembly......................................24777....................................See Parts Model 84T-11-62Item Description Part #Material15A........................................Plunger Seal.........................................................13007....................................UHMWPE16..........................................Discharge Check Assembly.................................22626....................................See Parts17..........................................Suction Check Assembly......................................24777....................................See Parts Model 84T-14-14Item Description Part #Material15A.........................................Plunger Seal............................................................115 8 7....................................Fludrocarbon 15B.........................................Plunger Seal Back-Up...............................................23551......................................Acetal16..........................................Discharge Check Assembly.................................24753....................................See Parts17...........................................Suction Check Assembly..........................................24165......................................See Parts Model 84T-14-44Item15A........................................Plunger Seal...........................................................11590.....................................TFE/Graphite 15B.........................................Plunger Seal Backup.................................................23551......................................Acetal16...........................................Discharge Check Assembly......................................24753......................................See Parts17...........................................Suction Check Assembly..........................................24165......................................See Parts Model 84T-14-64Item Description Part #Material15A........................................Plunger Seal...........................................................131 4 3...................................UHMWPE15B........................................Plunger Seal Back-Up..........................................23551....................................Acetal16..........................................Discharge Check Assembly.................................24753....................................See Parts17..........................................Suction Check Assembly......................................24165....................................See Parts Series 84T-10, 11 & 14 Seal MaterialsPage 14 •Figure 2, 84T-12 Series PumpLINC84T-12 Series Parts ListLINC84T-12 Series Seal MaterialsFigure 3,TimerReference fig. 1, item 1Reference fig. 2, item 1Page 18 •Figure 4, Discharge Check ValveOne Piece BodyReference fig. 1, item 16Reference fig. 2, item 15Figure 5, Discharge Check Valve Two Piece Body Reference fig. 1, item 16Model 84T-14 OnlyFigure 6,Suction Check ValveOne Piece BodyReference fig. 1, item 17Reference fig. 2, item 16For Model 84T-11 & 84-12For Model 84T-14 OnlyPage 20•LINC Chemical PumpGas Consumption T ableACTUATION PISTON DIA. (IN)>> 1.50 2.2534446810 > >SPRING SPRING SPRING SPRING SPRING GAS GAS GAS GAS CONFIGURATION RETURN RETURN RETURN RETURN RETURN RETURN RETURN RETURN RETURN > >NO RELAY NO RELAY NO RELAY NO RELAY INCLUDING INCLUDING INCLUDING INCLUDING INCLUDINGRELAY RELAY RELAY RELAY RELAY SUPPLY VOLUME DISPLACED BY PISTON FOR 1" STROKE(CUBIC FEET)PRESS.0.001022650.002300970.004090620.007272210.007272210.014544410.032724920.058177640.09090257 (PSI)THEORETICAL GAS CONSUMPTION FOR EACH 1" STROKE (SCF)00.00000.00000.00000.00000.00000.00000.00000.00000.0000100.00170.00390.00690.01220.01220.02440.05500.09780.1527200.00240.00540.00970.01720.01720.03430.07720.13730.2146300.00310.00700.01240.02210.02210.04420.09950.17690.2764400.00380.00860.01520.02710.02710.05410.12180.21650.3383500.00450.01010.01800.03200.03200.06400.14400.25610.4001600.00520.01170.02080.03700.03700.07390.16630.29560.4619700.00590.01330.02360.04190.04190.08380.18860.33520.5238800.00660.01480.02640.04680.04680.09370.21080.37480.5856900.00730.01640.02910.05180.05180.10360.23310.41440.64741000.00800.01800.03190.05670.05670.11350.25530.45390.70931100.00870.01950.03470.06170.06170.12340.27760.49350.77111200.00940.02110.03750.06660.06660.13330.29990.53310.83301300.01010.02260.04030.07160.07160.14320.32210.57270.89481400.01080.02420.04300.07650.07650.15310.34440.61230.95661500.01150.02580.04580.08150.08150.16300.36670.6518 1.0185LINC Milton Roy. represents and warrants that for a period of 3 years from receipt of the product: (1) the product will be free from defects in materials and workmanship; and (2) the product will perform substantially in accordance with product manuals, literature, or documentation. Any written or oral information or advice given by LINC Milton Roy representatives, agents, or employees will in no way increase the scope of this warranty. If the product fails to comply with the warranty set forth herein, LINC Milton Roy's entire liability and the customer's exclusive remedy will be replacement of the product(s) or, at LINC Milton Roy's option, LINC Milton Roy's reasonable effort to make the product meet the warranty set forth herein. LINC Milton Roy disclaims all other warranties, either expressed or implied, including but not limited to, implied warranties or merchantability and fitness for a particular purpose, with respect to the product. This limited warranty gives you specific legal rights. You may have others, which vary from state to state. These remedies are not available outside of the United States and Canada. In no event shall LINC Milton Roy or its suppliers be liable for any damages whatsoever (including, without limitation, damages for loss of profits, business interruption, loss of information, or other pecuniary loss) arising out of the use of or inability to use the product, even if LINC Milton Roy has been advised of the possibility of such damages. Information contained in this document is subject to change without notice and does not represent a commitment on the part of LINC Milton Roy. All prices quoted are in U.S. dollars, F.O.B. Ivyland, PA. LINC, LINC Chemical Pumps, and LINC Level & Flow Switches are trademarks of LINC Milton Roy. All other product names and/or registered trademarks are the property of their respective holders. LINC Milton Roy support services are subject to LINC Milton Roy's then-current prices, terms, and conditions, which are subject to change without notice. All prices and specifications, if published, are subject to change without notice.。