Powermax45

- 格式:ppt

- 大小:252.00 KB

- 文档页数:5

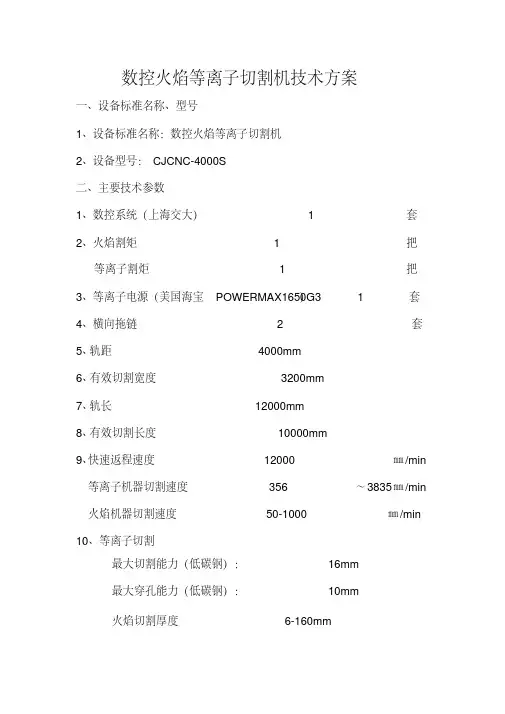

数控火焰等离子切割机技术方案一、设备标准名称、型号1、设备标准名称:数控火焰等离子切割机2、设备型号:CJCNC-4000S二、主要技术参数1、数控系统(上海交大) 1套2、火焰割矩 1把等离子割炬 1把) 1套3、等离子电源(美国海宝POWERMAX1650G34、横向拖链 2套5、轨距 4000mm6、有效切割宽度 3200mm7、轨长 12000mm8、有效切割长度 10000mm9、快速返程速度 12000㎜/min 等离子机器切割速度 356~3835㎜/min 火焰机器切割速度 50-1000㎜/min 10、等离子切割最大切割能力(低碳钢): 16mm最大穿孔能力(低碳钢): 10mm火焰切割厚度 6-160mm11、割炬升降距离≤150mm12、直线定位精度±0.2mm/10m重复精度±0.2mm/10m13、环境温度 -5-45℃14、相对湿度<95%无冷凝15、周边环境通风,无较大冲击16、电源、电压 220V±10%17、电源频率 50HZ18、驱动方式双驱三、设备组成1、纵向导轨(12米)纵向导轨采用铁路用轨(38KG),表面经磨削处理,因此具有很高的精度及耐磨性。

驱动齿条由专业厂家进行加工,从而保证了精度要求,同时在导轨两端装有防撞保护装置。

2、大车架(4米)本部件包括钢带箱、主副滑车。

大车架为数控切割机运动的主要执行单元,整机为龙门式结构,具有很高的刚度,在端梁安装有刮削装置,以随时清掉导轨上的杂质。

3、割炬升降挂架(火焰升降挂架1套)割炬升降挂架用于实现割炬升降。

采用直流电机,经齿轮箱减速再由丝杆驱动实现升降。

保证割枪与水平面的垂直度,从而保证了切割的精度。

4、气路系统(1套)气路系统包括气体调节控制盘,气路分配系统等,为保证产品质量及安全性。

调节阀、压力表、割枪、回火防止器、电磁阀等均采用专业厂家的配套产品。

5、操作柜及控制柜(1套)操作柜面板设有割炬预选、急停、电源指示灯、自动/手动升降、电源开关等各种所需功能操作按钮;控制柜则具有防尘功能。

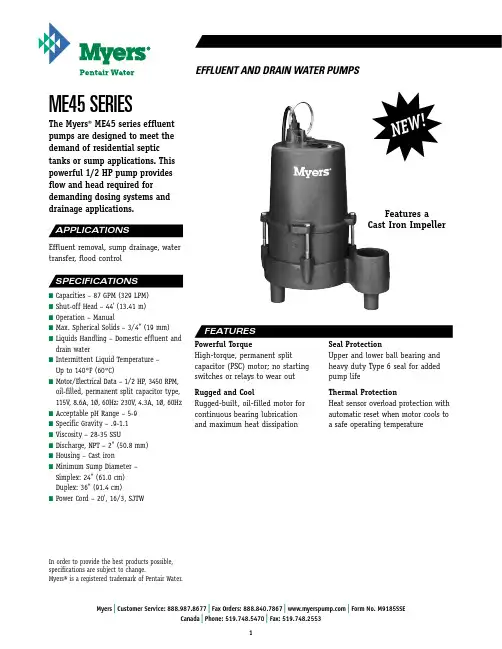

ME45 sEriEsPowerful TorqueHigh-torque, permanent splitcapacitor (PSC) motor; no starting switches or relays to wear out Rugged and CoolRugged-built, oil-filled motor for continuous bearing lubrication and maximum heat dissipationSeal ProtectionUpper and lower ball bearing and heavy duty Type 6 seal for added pump lifeThermal ProtectionHeat sensor overload protection with automatic reset when motor cools to a safe operating temperatureThe Myers ® ME45 series effluent pumps are designed to meet the demand of residential septic tanks or sump applications. This powerful 1/2 HP pump provides flow and head required for demanding dosing systems and drainage applications.Effluent removal, sump drainage, water transfer, flood control n C apacities – 87 GPM (329 LPM)n S hut-off Head – 44' (13.41 m)n O peration – Manualn M ax. Spherical Solids – 3/4" (19 mm)n L iquids Handling – Domestic effluent anddrain water n I ntermittent Liquid Temperature – Up to 140°F (60°C)n M otor/Electrical Data – 1/2 HP , 3450 RPM, oil-filled, permanent split capacitor type, 115V , 8.6A, 1Ø, 60Hz; 230V , 4.3A, 1Ø, 60Hz n A cceptable pH Range – 5-9n S pecific Gravity – .9-1.1n V iscosity – 28-35 SSU n D ischarge, NPT – 2" (50.8 mm)n H ousing – Cast iron n M inimum Sump Diameter – Simplex: 24" (61.0 cm) Duplex: 36" (91.4 cm)n P ower Cord – 20', 16/3, SJTWNE W !In order to provide the best products possible, specifications are subject to change.Myers® is a registered trademark of Pentair Water.Features aCast Iron ImpellerCatalog Phase/ Discharge Switch Cord Approx. Wt. Number HP Volts Cycles Amps Size Type Length Lbs.ME45MC-11 1/2 115 1/60 8.6 2" Manual 20' 58ME45MC-21 1/2 230 1/60 4.3 2" Manual 20' 58EFFLUENT PUMPS – Pump(s) shall be F. E. Myers ME45 Series effluent pump selected in accordance with the following design criteria:Number of Pumps: _____________________Primary Design Flow: _____________________Primary Design Head: _____________________Minimum Shut-off Head: 44'Motor Horsepower: 1/2Motor Speed: 3450 RPMElectrical: 115 Volts, 1Ø, 60 Hz or230 Volts, 1Ø, 60 HzPUMP – The pump shall be designed to handle septic tank effluent and be capable of passing 3/4 inch spherical solids. The pump shall be capable of handling liquids with temperatures to 140°F intermittent.MOTOR – The pump motor shall be of the submersible type rated 1/2 hp at 3450 RPM and shall be for _____115 volts or _____230 volts single phase, 60 cycles. Single phase motor shall be PSC motor with no relays or starting switches. Stator winding shall be of the open type with Class B insulation rated for 130°C maximum operating temperature. The winding housing shall be filled with clean dielectric oil to lubricate bearings and seals, and transfer heat from the windings to the outer shell.The motor shall be capable of operating over the full range of the performance curve without overloading the motor and causing any objectionable noise or vibration. The motor shall have two bearings to support the rotor; an upper sleeve bearing to accommodate radial loads and a lower sleeve bearing with thrust pad to take thrust and radial loads.A heat sensor thermostat and overload shall be attached to the top end of the motor windings and shall be wired in series with the windings to stop the motor if the motor winding reaches 200°C. The overload thermostat shall reset automatically when the motor cools to a safe operating temperature.POWER CORD – The motor power cord shall be 20 feet SJTW type. The power and switch cords shall be of the positive sealing type. The power and switch cable connections shall be sealed at the motor entrance by means of a compression nut which serves to make a positive electrical connection and prevent water from entering the cable jacket and motor housing.SHAFT SEAL – The motor shall be protected by a rotating mechanical shaft seal. The seals shall have carbon and ceramic seal faces lapped to a tolerance of 1 -3 light band. Metal parts and springs for seals shall be 18 - 8 series stainless steel. PUMP IMPELLER – The pump impeller shall be of the two vane semi-open type. The impeller shall be constructed of cast iron.MOTOR HOUSING – The motor housing castings shall be of high tensile strength Class 30 gray cast iron. Castings shall be painted with a high quality, 1/8" thick (per UL778) baked epoxy spray for corrosion protection.PUMP CASE – The pump case shall be a high efficiency volute design capable of passing 3/4 inch spherical solids. The pump volute shall be constructed of cast iron.FASTENERS – All exposed fasteners shall be of 300 series stainless steel.EFFLUENT AND DRAIN WATER PUMPS。

国外光伏逆变器知名品牌一览德国SMASMASolarTechnologyAG艾思玛太阳能技术股份公司是全球领先的专业逆变器生产供应商,成立于1981年,总部位于德国卡塞尔市的Niestetal。

SMA是光伏逆变器的全球市场领导者,产品应用遍及全球,已经在全球四大洲的十三个国家,包括美国、中国、意大利、西班牙、法国、澳大利亚、希腊、捷克等设立了分支机构。

经过32年的创新发展,SMA目前拥有员工人数超过4000人。

于32年建成占地18500平方米的全球最大光伏逆变器生产基地,能够将SMA的年生产能力提高至约5GW,并继续扩大,可以满足全球光伏市场快速发展的需求。

2008年6月27日,SMA在德国法兰克福股票交易所上市(s92),并在2008年9月22日列入TecSMA.在过去的数年中,SMA公司本身,以及其创新生产的众多产品,创造了更多成绩,也获得了多项殊荣。

SMA的主要业务领域是开发和生产各种型号的光伏逆变器,功率从1kW 到1.25MW不等,能够满足不同类型光伏组件、所有电站规模和不同电网类型的需要。

SMA研发生产的光伏系列设备主要包括并网逆变器Sunny Boy/Sunny Mini Central/Sunny Tripower/ Sunny Central、双向独立运行逆变器SunnyIsland、风力并网逆变器WindyBoy、并网备用发电设备Sunny Backup、燃料电池逆变器Hydro Boy,以及用于电站全面监测及控制的通讯设备。

其中光伏并网和双向独立运行逆变器为其主要产品。

SMA推出的光伏逆变器系列相关产品达到近百种,是名副其实的全球光伏逆变器第一大生产供应商。

美国Power-OnePower-One是全球最大的电能转换和电能管理解决方案提供商。

其产品范围足以支持将民用交流电转化成不同电压的直流电的各个环节,用以驱动高电能需求的工作场所、系统和不同半导体层面上的基础设施系统。

其也是全世界规模第二的光伏逆变器生产商,在过去的几年中,可再生能源解决方案领域增长迅速。

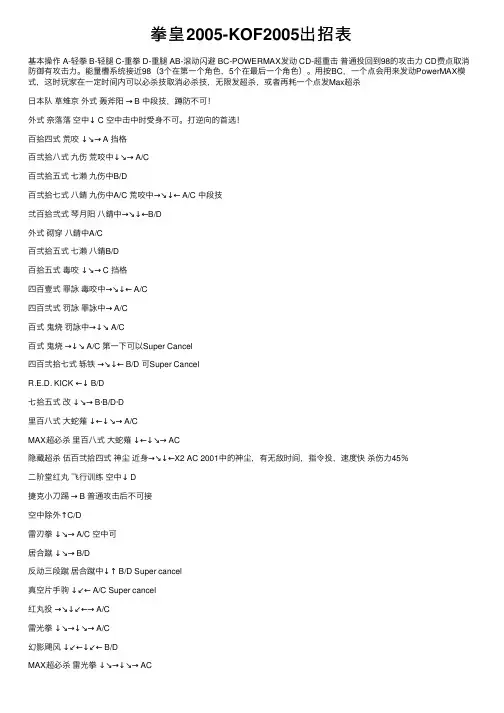

拳皇2005-KOF2005出招表基本操作 A-轻拳 B-轻腿 C-重拳 D-重腿 AB-滚动闪避 BC-POWERMAX发动 CD-超重击普通投回到98的攻击⼒ CD费点取消防御有攻击⼒。

能量槽系统接近98(3个在第⼀个⾓⾊,5个在最后⼀个⾓⾊)。

⽤按BC,⼀个点会⽤来发动PowerMAX模式,这时玩家在⼀定时间内可以必杀技取消必杀技,⽆限发超杀,或者再耗⼀个点发Max超杀⽇本队草雉京外式轰斧阳→ B 中段技,蹲防不可!外式奈落落空中↓ C 空中击中时受⾝不可。

打逆向的⾸选!百拾四式荒咬↓↘→ A 挡格百弐拾⼋式九伤荒咬中↓↘→ A/C 百弐拾五式七濑九伤中B/D 百弐拾七式⼋錆九伤中A/C 荒咬中→↘↓← A/C 中段技弐百拾弐式琴⽉阳⼋錆中→↘↓←B/D 外式砌穿⼋錆中A/C 百弐拾五式七濑⼋錆B/D 百拾五式毒咬↓↘→ C 挡格四百壹式罪詠毒咬中→↘↓← A/C 四百弐式罚詠罪詠中→ A/C 百式⿁烧罚詠中→↓↘ A/C 百式⿁烧→↓↘ A/C 第⼀下可以Super Cancel四百弐拾七式轹铁→↘↓← B/D 可Super CancelR.E.D. KICK ←↓ B/D 七拾五式改↓↘→ B·B/D·D ⾥百⼋式⼤蛇薙↓←↓↘→ A/C MAX超必杀⾥百⼋式⼤蛇薙↓←↓↘→ AC 隐藏超杀伍百弐拾四式神尘近⾝→↘↓←X2 AC 2001中的神尘,有⽆敌时间,指令投,速度快杀伤⼒45%⼆阶堂红丸飞⾏训练空中↓ D 捷克⼩⼑踢→ B 普通攻击后不可接空中除外↑C/D 雷刃拳↓↘→ A/C 空中可居合蹴↓↘→ B/D 反动三段蹴居合蹴中↓↑ B/D Super cancel真空⽚⼿驹↓↙← A/C Super cancel红丸投→↘↓↙←→ A/C 雷光拳↓↘→↓↘→ A/C 幻影飓风↓↙←↓↙← B/D MAX超必杀雷光拳↓↘→↓↘→ AC 隐藏超杀 →↙↘←→任意键 按A键:雷电出现在头的前⽅ 按B键:雷电出现在脚的前⽅ 按C键:雷电出现在头的后⽅ 按D键:雷电出现在脚的后⽅ 雷是不可防御的!⼤门五郎投技⼗字缚(⾮常近)4or6 C 叩击(近)4or6 C 送⾜拂4or6 D特殊技⽟溃6 A 头上拂3 C必杀技地雷震623 AorC 天地返(接近)632146 AorC 超⼤外刈(接近)623 BorD 超受⾝ 214 BorD 云⾥投 236 A 切株返 236 C ⾥投 632146 BorD 根返 236 BorD 超必杀技 地狱极乐落 (近⾝)6321463214 AorC 岚之⼭根拔 (接近)4123641236*2 BorD ┗续?切株返 426 BorD ┗根拔?⾥投 623 BorDMAX超必杀技 地狱极乐落 (近⾝)6321463214 AC 岚之⼭根拔 (接近)4123641236*2 BD ┗续?切株返 426 BorD ┗根拔?⾥投 623 BorD龙虎拳队坂崎良投技 ⾕落 4or6 C 巴投 4or6 D特殊技 冰柱割 6 A 上段受 6 B 下段受 3 B必杀技 虎煌拳 236 A 虎咆 623 AorC 飞燕疾风脚 41236 BorD 暂烈拳 646 AorC 猛虎雷神刹 236 BorD超必杀技 霸王翔吼拳 641236 AorC 龙虎乱舞 2363214 AorCMAX超必杀技 龙虎乱舞 236 C?A◎招式变化 不明罗伯特投技 龙跳脚 4or6 C ⾸切投 4or6 D特殊技 勾龙降脚蹴 6 A ⾥拳 4 A 龙翻蹴 6 B必杀技 龙击拳 236 AorC 龙⽛ 623 AorC 幻影脚 646 BorD 飞燕龙神脚 (空中)214 BorD 极限流连舞脚 (接近)41236 BorD 超必杀技 霸王翔吼拳 641236 AorC 龙虎乱舞 2363214 AorC 背⽛龙 236236 AorCMAX超必杀技 龙虎乱舞 2363214 AC◎招式变化 极限流连舞脚动作变化,不可追击。

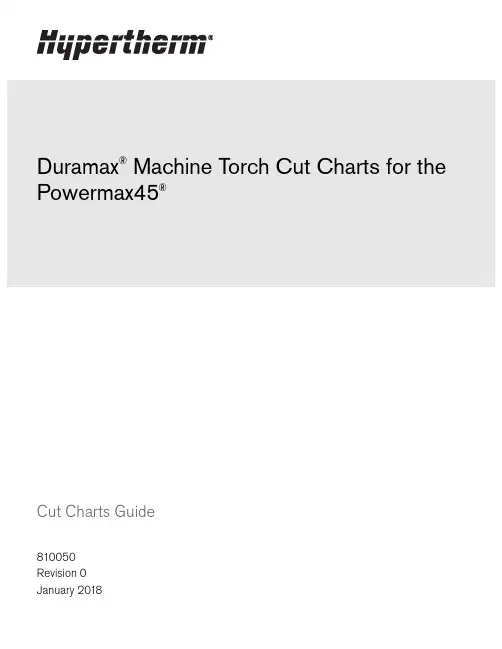

Duramax® Machine Torch Cut Charts for the Powermax45®Cut Charts Guide810050Revision0January2018Hypertherm Inc.Etna Road, P.O. Box 5010Hanover, NH 03755 USA603-643-3441 Tel (Main Office)603-643-5352 Fax (All Departments)*******************(MainOfficeEmail)800-643-9878 Tel (Technical Service)********************************(TechnicalServiceEmail)800-737-2978 Tel (Customer Service)*******************************(CustomerServiceEmail)866-643-7711 Tel (Return Materials Authorization)877-371-2876 Fax (Return Materials Authorization)*******************************(RMAemail)Hypertherm México, S.A. de C.V.Avenida Toluca No. 444, Anexo 1,Colonia Olivar de los Padres Delegación Álvaro Obregón México, D.F. C.P. 0178052 55 5681 8109 Tel 52 55 5683 2127 Fax******************************(TechnicalServiceEmail)Hypertherm Plasmatechnik GmbHSophie-Scholl-Platz 563452 Hanau Germany00 800 33 24 97 37 Tel 00 800 49 73 73 29 Fax31 (0) 165 596900 Tel (Technical Service)00 800 4973 7843 Tel (Technical Service)************************************(TechnicalServiceEmail)Hypertherm (Singapore) Pte Ltd.82 Genting Lane Media CentreAnnexe Block #A01-01Singapore 349567, Republic of Singapore 65 6841 2489 Tel 65 6841 2490 Fax*****************************(MarketingEmail)******************************(TechnicalServiceEmail)Hypertherm Japan Ltd.Level 9, Edobori Center Building 2-1-1 Edobori, Nishi-ku Osaka 550-0002 Japan 81 6 6225 1183 Tel 81 6 6225 1184 Fax***************************(MainOfficeEmail)******************************(TechnicalServiceEmail)Hypertherm Europe B.V.Vaartveld 9, 4704 SE Roosendaal, Nederland 31 165 596907 Tel 31 165 596901 Fax31 165 596908 Tel (Marketing)31 (0) 165 596900 Tel (Technical Service)00 800 4973 7843 Tel (Technical Service)************************************(Technical Service Email)Hypertherm (Shanghai) Trading Co., Ltd.B301, 495 ShangZhong Road Shanghai, 200231PR China86-21-80231122 Tel 86-21-80231120 Fax86-21-80231128 Tel (Technical Service)********************************(Technical Service Email)South America & Central America: Hypertherm Brasil Ltda.Rua Bras Cubas, 231 – Jardim Maia Guarulhos, SP – Brasil CEP 07115-03055 11 2409 2636 Tel*************************(TechnicalServiceEmail)Hypertherm Korea Branch#3904. APEC-ro 17. Heaundae-gu. Busan.Korea 4806082 (0)51 747 0358 Tel 82 (0)51 701 0358 Fax******************************(MarketingEmail)******************************(Technical Service Email)Hypertherm Pty LimitedGPO Box 4836Sydney NSW 2001, Australia 61 (0) 437 606 995 Tel 61 7 3219 9010 Fax***********************(MainOfficeEmail)******************************(Technical Service Email)Hypertherm (India) Thermal Cutting Pvt. LtdA-18 / B-1 Extension,Mohan Co-Operative Industrial Estate,Mathura Road, New Delhi 110044, India 91-11-40521201/ 2/ 3 Tel 91-11 40521204 Fax***************************(MainOfficeEmail)******************************(Technical Service Email)1/28/16© 2018 Hypertherm Inc. All rights reserved.Powermax, Duramax, FineCut, and Hypertherm are trademarks of Hypertherm Inc. and may be registered in the United States and/or other countries. All other trademarks are the property of their respective holders.Environmental stewardship is one of Hypertherm’s core values, and it is critical to our success and our customers’ success. We are striving to reduce the environmental impact of everything we do. For more information: /environment.Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide 8100503Using the cut chartsUse the cut charts in this document:⏹Only for Duramax ® machine torches on the Powermax45⏹As a starting pointAdjust the variables in the cut charts as needed to achieve optimal results for your cutting equipment and environment.The cut charts are based on the latest process development from the Powermax45XP and provide a wider range of material thicknesses than previous 45A cut charts for Duramax torches.If you are using a T45m torch with the Powermax45, use the cut charts in the Powermax45 Operator Manual (805780). For Powermax45XP cut charts, refer to the Powermax45XP Operator Manual (809240). Download the manuals at /docs .Cut charts are provided for each set of mechanized cutting consumables. A consumable diagram with part numbers precedes each cut chart.Cut charts are included for:⏹Cutting mild steel, stainless steel, and aluminum at 45A with air using shielded consumables⏹Cutting mild steel and stainless steel with air using FineCut consumables ⏹Cutting stainless steel at 45A with F5gas using shielded consumablesEach cut chart may contain the following information:⏹Amperage setting –The amperage setting at the top of the page applies to all the settings given on that page. In FineCut ® charts, the amperage setting for each thickness is included in the cut chart.⏹Material Thickness –Thickness of the workpiece (metal plate being cut).⏹Torch-to-Work Distance –For shielded consumables, the distance between the shield and the workpiece during cutting. For unshielded consumables, the distance between the nozzle and the workpiece during cutting. This is also known as cut height.⏹Initial Pierce Height –Distance between the shield (shielded) or the nozzle (unshielded) and the workpiece when the torch is fired, prior to descending to the cut height.⏹Pierce Delay Time –Length of time the triggered torch remains stationary at the pierce height before the torch starts the cutting motion.⏹Best Quality Settings (cut speed and voltage)–Settings that provide the starting point for finding the best cut quality (best angle, least dross, best cut-surface finish). Adjust the speed for your application and table to obtain the desired result.Duramax Machine Torch Cut Charts for the Powermax454810050Cut Charts Guide Powermax45⏹Production Settings (cut speed and voltage)–70% to 80% of the maximum speedratings. These speeds result in the greatest number of cut parts, but not necessarily the best possible cut quality.The arc voltage increases as the consumables wear, so the voltage setting may need to be increased to maintain the correct torch-to-work distance. Some CNCs monitor the arc voltage and adjust the torch lifter automatically.⏹Kerf Width –Width of material removed by the cutting process. The kerf widths were obtained with the “Best Quality” settings and are for reference only. Differences between installations and material composition may cause actual results to vary from those shown.Each cut chart lists hot and cold gas flow rates.⏹Hot flow rate –Plasma is on, the system is operating at running current, and the system is in a steady state at the default system pressure (cutflow, or automatic mode).⏹Cold flow rate –Plasma is off and the system is in a steady state with gas flowing through the torch at the default system pressure (postflow).Hypertherm collected the cut chart data under laboratory test conditions using new consumables.Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide8100505Duramax Machine Torch Cut Charts for the Powermax456810050Cut Charts Guide Powermax45Mild Steel – 45A – Air – ShieldedMetricMaterial Thickness Torch-to-Work DistanceInitial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage mmmmmm%secondsmm/min voltsmm/min voltsmm21.53.82500.255601287910125 1.433960128559012840.428001283960128 1.560.614301302110127810201331385130 1.7100.8780136920134 1.8121540140690138 1.916Edge Start310146400141 2.120170152240147 2.3251101571451543EnglishMaterial Thickness Torch-to-Work Distance Initial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage inchesinchesinches%secondsin/min voltsin/min voltsinches16GA0.060.152500.12491283201250.05314GA 0.22251283201250.05410GA 0.41291281811280.0573/160.5851291221270.0591/40.648130721270.0613/80.833136381330.0691/21181********.0775/8Edge Start131********.0823/47151101450.0867/8615471510.1031415761540.119Gas flow rate –slpm /scfh151/320Hot (cutflow)184/390Cold (postflow)220817220854(220953 for ohmic sensing)220941220857220842Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide 8100507Stainless Steel – 45A – Air – ShieldedMetricMaterial Thickness Torch-to-Work DistanceInitial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage mmmmmm%secondsmm/min voltsmm/min voltsmm21.53.82500.1562012678301290.630.2328512947251280.940.419951302960129 1.160.611451311695131 1.288301341100134 1.4100.8605137870137 1.612 4.6300 1.2380141540139 1.816Edge Start240145320142 2.420160149205146 3.1EnglishMaterial Thickness Torch-to-Work Distance Initial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage inchesinchesinches%secondsin/min voltsin/min voltsinches16GA0.060.152500.12371253201280.01714GA 0.22301263201290.02210GA 0.4901301341280.0413/160.563131931300.0441/40.640131591310.0473/80.826137291360.0611/20.18300 1.212142191400.0755/8Edge Start10145131420.0963/4714891450.1167/8515161490.137Gas flow rate –slpm /scfh151/320Hot (cutflow)184/390Cold (postflow)220817220854(220953 for ohmic sensing)220941220857220842Duramax Machine Torch Cut Charts for the Powermax458810050Cut Charts Guide Powermax45Aluminum – 45A – Air – ShieldedMetricMaterial Thickness Torch-to-Work DistanceInitial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage mmmmmm%secondsmm/min voltsmm/min voltsmm21.53.82500.178901219585134 1.330.248501307120129 1.540.43670133565012960.520601393095132 1.680.613301391830136 1.7100.78601421015140 1.912Edge Start6201447451422163601523401482.5EnglishMaterial Thickness Torch-to-Work Distance Initial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage inchesinchesinches%secondsin/min voltsin/min voltsinches1/100.060.152500.22401263201310.0561/80.41701312631280.0603/161201341841300.0611/40.5701371041320.0633/80.736141421390.0731/2Edge Start21145261430.0825/815152141480.1003/4815891530.117Gas flow rate –slpm /scfh151/320Hot (cutflow)184/390Cold (postflow)220817220854(220953 for ohmic sensing)220941220857220842Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide 8100509Mild Steel – FineCut – Air – Shielded and UnshieldedMetricMaterial ThicknessCurrent Torch-to-Work DistanceInitial Pierce Height Pierce Delay TimeRecommended Kerf Width Cut Speed Voltage mmAmmmm%secondsmm/min voltsmm0.5401.53.82500.08250780.70.68250780.80.18250780.61450.28250780.71.50.4640078 1.22480078 1.330.525007840.6190078EnglishMaterial ThicknessCurrent Torch-to-Work Distance Initial Pierce Height Pierce Delay TimeBest Quality Settings Kerf Width Cut Speed Voltage inchesAinchesinches%secondsin/min voltsinches26GA400.060.152500.0325780.02524GA 325780.02922GA 0.1325780.02420GA 325780.02018GA 450.2325780.04316GA 0.4250780.04614GA 200780.04912GA 0.5120780.05210GA95780.051Gas flow rate –slpm /scfh155/330Hot (cutflow)215/460Cold (postflow)220955 (deflector)220948 (shield)220854220953 (ohmic)220930220947220842Duramax Machine Torch Cut Charts for the Powermax4510810050Cut Charts Guide Powermax45Stainless Steel – FineCut – Air – Shielded and UnshieldedMetricMaterial ThicknessCurrent Torch-to-Work DistanceInitial Pierce Height Pierce Delay TimeRecommended Kerf Width Cut Speed Voltage mmAmmmm%secondsmm/min voltsmm0.5400.52.04000.08250680.60.68250680.50.80.18250681450.28250680.61.50.4615070 1.024*******.5255080 1.440.61050841.5EnglishMaterial ThicknessCurrent Torch-to-Work Distance Initial Pierce Height Pierce Delay TimeBest Quality Settings Kerf Width Cut Speed Voltage inchesAinchesinches%secondsin/min voltsinches26GA400.020.084000.0325680.02424GA 325680.02122GA 0.1325680.01820GA 325680.01718GA 450.2325680.03616GA 0.4240700.03914GA 200700.04012GA 0.5120800.04910GA0.675800.055Gas flow rate –slpm /scfh155/330Hot (cutflow)215/460Cold (postflow)220955 (deflector)220948 (shield)220854220953 (ohmic)220930220947220842Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide 81005011Mild Steel – FineCut Low Speed – Air – Shielded and UnshieldedMetricMaterial ThicknessCurrent Torch-to-Work DistanceInitial Pierce Height Pierce Delay TimeRecommended Kerf Width Cut Speed Voltage mmAmmmm%secondsmm/min voltsmm0.5301.5 3.82500.03800690.60.63800680.80.13800701*400.23800720.81.5*0.43800752453700760.730.5275078 1.340.61900781.5EnglishMaterial ThicknessCurrent Torch-to-Work Distance Initial Pierce Height Pierce Delay TimeBest Quality Settings Kerf Width Cut Speed Voltage inchesAinchesinches%secondsin/min voltsinches26GA300.060.152500.0150700.02624GA 150680.02422GA 0.1150700.02520GA 1507118GA 400.2150730.03116GA*0.4150750.02914GA*45150760.02712GA 0.5120780.05210GA95780.051Gas flow rate –slpm /scfh155/330Hot (cutflow)215/460Cold (postflow)*Not a dross-free cut.220955 (deflector)220948 (shield)220854220953 (ohmic)220930220947220842Duramax Machine Torch Cut Charts for the Powermax4512810050Cut Charts Guide Powermax45Stainless Steel – FineCut Low Speed – Air – Shielded and UnshieldedMetricMaterial ThicknessCurrent Torch-to-Work DistanceInitial Pierce Height Pierce Delay TimeRecommended Kerf Width Cut Speed Voltage mmAmmmm%secondsmm/min voltsmm0.5300.5 2.04000.03800690.70.63800690.80.13800691400.23800690.61.50.42900690.52275069 1.33450.5255080 1.440.61050801.5EnglishMaterial ThicknessCurrent Torch-to-Work Distance Initial Pierce Height Pierce Delay TimeBest Quality Settings Kerf Width Cut Speed Voltage inchesAinchesinches%secondsin/min voltsinches26GA300.020.084000.0150690.02824GA 1506922GA 0.1150690.02520GA 150690.02318GA 400.21456916GA 0.4115690.02214GA 110690.02112GA 450.5120800.04910GA0.675800.055Gas flow rate –slpm /scfh155/330Hot (cutflow)215/460Cold (postflow)220955 (deflector)220948 (shield)220854220953 (ohmic)220930220947220842Duramax Machine Torch Cut Charts for the Powermax45Powermax45Cut Charts Guide 81005013Stainless Steel – 45A – F5 – ShieldedWhen used with a Powermax system, F5 should be used only to cut stainless steel.For more information on cutting with F5, download the Use F5 to Cut Stainless Steel (809060) Application Note at /docs .F5 is not recommended for thicknesses less than 7mm or 1/4inch or for use with FineCut consumables.MetricMaterial Thickness Torch-to-Work DistanceInitial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage mmmmmm%secondsmm/min voltsmm/min voltsmm81.53.82500.8630150860144 2.110435153525147 2.312Edge Start340156440150 2.5EnglishMaterial Thickness Torch-to-Work Distance Initial Pierce Height Pierce Delay Time Best Quality Settings Production SettingsKerf Width Cut Speed Voltage Cut Speed Voltage inchesinchesinches%secondsin/min voltsin/min voltsinches1/40.060.152500.632147471410.0753/80.8181********.0881/2Edge Start12157161510.101Gas flow rate –slpm /scfh149/315Hot (cutflow)184/390Cold (postflow)220817220854(220953 for ohmic sensing)220941220857220842。

DE3591 1NEXT ®MCW无线 PowerCode 数字红外探测器安装说明书1. NEXT MCW 是一个微处理控制的无线数字红外探测器,它可以轻松安装,无需纵向调节。

它具有一个有独特探测灵敏度的柱型镜头 最大到12米的探测距离.(40 英尺),还具有防死角爬墙功能。

. NEXT 是卫视公司的注册商标。

先进的True Motion Recognition ™ (真实动作识别系统)运算法 (专利)可以让NEXT MCW 将真实报警事件和其他引起误报的干扰事件加以区别一个内置的动做事件跳线可以决定一个还是两个连续事件可以触发报警。

NEXT MCW 具有以下特点:• 包含一个完全监控的 PowerCode 传输器• 获专利的精细动作分析运算法系统- 真实动作识别 (TMR ™) • 精细的频率范围数字信号处理 • 不需要纵向调节.• 可编程动态事件记数器• 探测后,探头自动撤防进入节电模式. 探头在之后的两分钟后没有收到继续的探测信号则会自动重新布防.选装版提供更好的附和DD243系统要求的保护.在最初的探测时候, 探头还可以在五分钟的时间内有七次额外的探测. 在接下去的两分钟要是没有动作,会接着探测. 五分钟内没有动静探头会恢复到初始状态极低的电流消耗量• 微处理控制的温度补偿系统. • 密封外壳保护光学元件 • 前盖防拆功能 • 后盖防拆(选装) • 白光保护 • 幽雅外观,结实外壳UL 安装: 探头只兼容 UL 制定的 控制单元 PowerMax+.2.光学探测类别: 双元素低噪音 热电感应器镜头数据 慕廉数: 9 + 5最大覆盖范围 12 x 12 米/90° 电子:内部电池: 3V 锂电, CR-123A. UL 安装时候建议使用Panasonic 或 Sanyo 。

额定电池容量: 1450 mA/h.待机电流: 大约 0.025 mA. 转换电流强度: 20 mA (包含LED 灯)电池寿命 (LED 灯亮): 一般大于三年。

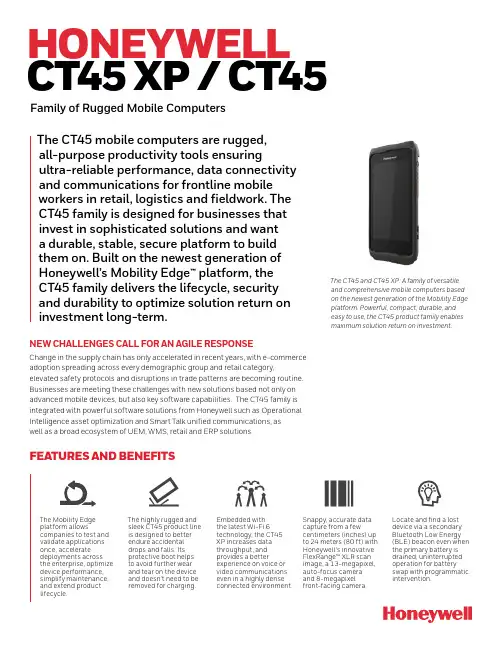

The CT45 and CT45 XP: A family of versatileand comprehensive mobile computers basedon the newest generation of the Mobility Edgeplatform. Powerful, compact, durable, andeasy to use, the CT45 product family enablesmaximum solution return on investment. FEATURES AND BENEFITSThe Mobility Edge platform allows companies to test and validate applications once, accelerate deployments across the enterprise, optimize device performance, simplify maintenance, and extend product lifecycle. The highly rugged andsleek CT45 product lineis designed to betterendure accidentaldrops and falls. Itsprotective boot helpsto avoid further wearand tear on the deviceand doesn’t need to beremoved for charging.Embedded withthe latest Wi-Fi 6technology, the CT45XP increases datathroughput, andprovides a betterexperience on voice orvideo communicationseven in a highly denseconnected environment.Snappy, accurate datacapture from a fewcentimeters (inches) upto 24 meters (80 ft) withHoneywell’s innovativeFlexRange™ XLR scanimage, a 13-megapixel,auto-focus cameraand 8-megapixelfront-facing camera.Locate and find a lostdevice via a secondaryBluetooth Low Energy(BLE) beacon even whenthe primary battery isdrained, uninterruptedoperation for batteryswap with programmaticintervention.HONEYWELL CT45 XP / CT45 Family of Rugged Mobile ComputersThe CT45 mobile computers are rugged,all-purpose productivity tools ensuringultra-reliable performance, data connectivity and communications for frontline mobile workers in retail, logistics and fieldwork. TheCT45 family is designed for businesses that invest in sophisticated solutions and wanta durable, stable, secure platform to buildthem on. Built on the newest generation of Honeywell’s Mobility Edge™ platform, theCT45 family delivers the lifecycle, securityand durability to optimize solution return on investment long-term.NEW CHALLENGES CALL FOR AN AGILE RESPONSEChange in the supply chain has only accelerated in recent years, with e-commerce adoption spreading across every demographic group and retail category,elevated safety protocols and disruptions in trade patterns are becoming routine. Businesses are meeting these challenges with new solutions based not only on advanced mobile devices, but also key software capabilities. The CT45 family is integrated with powerful software solutions from Honeywell such as Operational Intelligence asset optimization and Smart Talk unified communications, aswell as a broad ecosystem of UEM, WMS, retail and ERP solutions.1. CT45 product family passes (6 ft) drops toconcrete at -20°C to +50°C (-4°F to +122°F)per MIL-STD-810H; multiple 2.4 m (8 ft) dropsto concrete with protective boot at -20°C to+50°C (-4°F to +122°F) per MIL-STD-810HHASSLE FREE CONNECTIVITY INSIDE AND OUTSIDE OF THE FOUR WALLSMobile workers often struggle to get up-to-date information in a timely manner to boost efficiency. In response, the CT45 XP leverages the latest Wi-Fi 6 technology to facilitate access to essential information with low latency, even in a highly dense connected environment. Delivery workers can now efficiently access the network outside of the four walls using 4G-LTE advanced technology, keeping mobile frontline workers always connected to crucial information to place orders, check stock, look up order status, or scan items anywhere and anytime.SURVIVES TOUGH ENVIRONMENTSOperation downtime results in revenue loss. The CT45 product family enables mobile workers to work while on the road, in the rain, or in a dusty warehouse. Designed to withstand challenging environments with no adverse damage or compromise to device integrity or sacrifice to ergonomic benefits. Built on a sleek design with enhancement on superior ruggedness, the CT45 product family delivers a compact device that mobile workers can carry comfortably throughout the shift and which also can endure accidental drops and falls.IMPROVED PRODUCTIVITY AND EASE OF USEThe CT45 product family extends the usability of an enterprise class device by offering a converged solution for cycle counting, on-demand delivery and asset management. It is integrated with the Honeywell Operational Intelligence solution and is available with FlexRange and 7th Generation scan options, an 8-megapixel front-facing camera, and a full suite of accessories. The full high-definition display (1920*1080p) makes it easy to use and supports modern high definition software. PROTECT INVESTMENT OF OWNERSHIPStolen, misplaced or lost assets increase critical information and asset leakage risks. Featuring “Device Finder” capability, CT45 XP can easily locate lostdevices even when the batteries are drained after a certain period of time. This helps to prevent permanent device loss and protect your investment.BUILT ON THE MOBILITY EDGE PLATFORMBuilt on the newest generation of Honeywell’s Mobility Edge platform, a durable, stable, secure foundation for effective, long lasting solutions, the CT45 family delivers the lifecycle, security and durability required by serious businesses. The CT45 leverages the latest processor and memory technology for high performance with planned support through Android 14 and Android 15, subject to feasibility.MECHANICALDimensions: 163 mm x 79 mm x 19.2 mm Weight: 282 g (9.9oz) with battery pack Display Size: 12.7 cm (5.0 in) Resolution: Full High Definition (1920 x 1080) (CT45XP); High-Definition (1280 x720) (CT45)Backlight: LEDTouch Panel: Rugged multi-touch capacitive touch panel, optically-bonded for extra durability. Glove, stylus and rain modes supported (CT45 XP). Water droplet rejection with screen protector mode. Covered with Gorilla Glass 5 for increased resistance to drops.Hard Keys: Volume up/down key, left/right scan, power button, Push to Talk button. Soft Key: On-screen scan button, reprogrammable into an application quick-launch key.Audio: 3.5 mm jack**, PTT, VoIP ready, speaker, HAC-compliant.Three microphones with noise cancellationI/O Ports: Durable, flat IO connector, USB Type C connector.USB OTG supported via I/O portsUSB 3.0 is supported via USB Type C Universal Dock Platform: Compatible ENVIRONMENTALOperating Temperature: -20°C to +50°C (-4°F to +122°F)Storage Temperature: -30°C to +70°C (-22°F to +158°F)Humidity: 5% to 95% (non-condensing) Drop: Multiple 1.8 m (6 ft) drops to concrete at -20°C to +50°C (-4°F to+122°F) per MIL-STD-810H; multiple 2.4m (8 ft) drops to concrete with protective boot at -20°C to +50°C (-4°F to +122°F) per MIL-STD-810HTumble: Exceeds 1,500 times at 1m (3.28 ft) per IEC 60068-2-32 specification ESD: ±8 kV direct; ±15 kV air Environmental Sealing: Independently certified to meet IP68 and IP65 standards for moisture and particle intrusion Thermal Shock: -30°C to +70°CSYSTEM ARCHITECTUREProcessor: Qualcomm QCS4290/QCM4290 octa-core, 2.0GHzOperating System: Each Android version planned from Android 11 to Android 14 and planned support for Android 15, pending feasibilityMemory: 6 GB DDR4x RAM, 64 GB UFS Flash (CT45XP); 4 GB DDR4x RAM, 64 GB UFS Flash (CT45)Camera: 13-megapixel rear camera;8-megapixel front-facing camera.Sensors: Ambient light sensor, proximitysensor, accelerometer, gyroscope,magnetometer, barometer (Modeldependent), eCompass (Model dependent),hall sensor, high gravity sensorSIM:CT45 XP: Available with configurations ofeSIM and Nano SIM or configurations of2 Nano SIMsCT45: Available with configurations of 2Nano SIMsStorage Expansion: User-accessiblemicroSD card up to 512 GB (SDXC/SDHC/SDIO-compliant)Battery: Li-Ion, 3.85 V, 4020 mAh; smartbattery with integrated diagnostic toolsBattery warm swap: Available on CT45 XPCharging: Quick Charge 3.0 compliant;Less than 3 hours to be fully charged.Decode Capabilities: Honeywell FlexRangeS0803 XLR (available on CT45XP),FlexRange Standard, and Honeywell S0703Application Software: Honeywell MobilityEdge Utilities and DemosWARRANTYOne-year factory warrantyWIRELESS CONNECTIVITYWWAN: WWAN Radio (ATT/VZW/SPRINT/TMO/NA/EU)AT&T FirstNet CompliantLTE Advanced SupportUp to 390 Mbps CAT13 LTE downlinkUp to 75 Mbps CAT5 LTE uplinkLTE – Bands 1, 2, 3, 4, 5, 7, 8, 12, 13,14, 17, 19, 20, 25, 26, 28, 29, 30, 38,39, 40, 41, 66, 71UMTS/HSPA+ (3G) – Bands 1, 2, 4,5, 6, 8, 9, 19GSM: 850, 900, 1800, 1900 (Quad Bands)WLAN: Wi-Fi certifiedCT45P-X0N: IEEE 802.11 a/b/g/n/ac/axand 2*2 MU-MIMOCT45P-L1N, CT45-L1N, CT45-L0N: IEEE802.11 a/b/g/n/acAll SKUs: 802.11 d/e/h/i/k/r/v/u/w/mcWLAN Security: OPEN, WEP, WPA/WPA2/WPA3(Personal and Enterprise)Supported EAP: TLS, PEAP, TTLS, PWD,LEAP, CCX compliant (except CT45XPWLAN)Bluetooth®: V5.1 Bluetooth and BLE2nd BLE: Available on CT45 XPBluetooth Profiles: HFP, PBAP, A2DP,AVRCP, OPP, SPP, GATTNFC: Integrated NFC reader, compliantwith ISO/IEC 14443 A, ISO/IEC 14443 B,ISO/IEC 15693 (ICode), MIFARE 1K / 4K,MIFARE DESFire, Sony FeliCa, ISO/IEC18092 (Type F)VPN: IPSec V4/L2TP, PPTPPush to Talk (PTT): SupportedGPS Supported Protocols: SimultaneousGNSS Receiver Support for GPS, GLONASS,Galileo, and Beidou, Assisted GPS* Specifications are subject to changewithout notice.** 3.5mm jack is available on Wi-Fiversion only.CT45 XP / CT45 Technical SpecificationsFor a complete listing of all complianceapprovals and certifications, please visit/compliance.For a complete listing of all supportedbarcode symbologies, please visit www./symbologies.Android, Bluetooth, Gorilla Glass andQualcomm are trademarks or registeredtrademarks of their respective owners.For more informationHoneywell Safety andProductivity Solutions855 S Mint Street,Charlotte, NC 28202800-582-4263CT45 XP / CT45 Datasheet LTR | Rev D | 12/23。

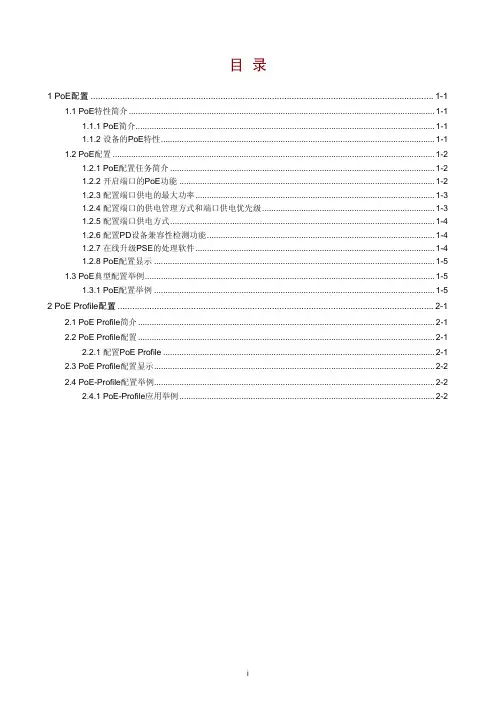

目录1 PoE配置............................................................................................................................................1-11.1 PoE特性简介.....................................................................................................................................1-11.1.1 PoE简介..................................................................................................................................1-11.1.2 设备的PoE特性.......................................................................................................................1-11.2 PoE配置............................................................................................................................................1-21.2.1 PoE配置任务简介...................................................................................................................1-21.2.2 开启端口的PoE功能...............................................................................................................1-21.2.3 配置端口供电的最大功率........................................................................................................1-31.2.4 配置端口的供电管理方式和端口供电优先级...........................................................................1-31.2.5 配置端口供电方式...................................................................................................................1-41.2.6 配置PD设备兼容性检测功能...................................................................................................1-41.2.7 在线升级PSE的处理软件........................................................................................................1-41.2.8 PoE配置显示..........................................................................................................................1-51.3 PoE典型配置举例..............................................................................................................................1-51.3.1 PoE配置举例..........................................................................................................................1-52 PoE Profile配置.................................................................................................................................2-12.1 PoE Profile简介.................................................................................................................................2-12.2 PoE Profile配置.................................................................................................................................2-12.2.1 配置PoE Profile......................................................................................................................2-12.3 PoE Profile配置显示..........................................................................................................................2-22.4 PoE-Profile配置举例..........................................................................................................................2-22.4.1 PoE-Profile应用举例...............................................................................................................2-21 PoE配置本章所指的交换机和以太网交换机代表了一般意义下的交换设备,以及WX3000系列有线无线一体化交换机的交换引擎。

KOF2002 基本BC连续技有关的操作前冲快速前前并按住前遥杆疾退快速后后,注意,疾退中不可防御紧急回避前或后+AB同时按(防御中或普通攻击中也可,防御中或普通攻击中使用将耗费一个能量珠)击倒攻击C、D同时按(防御中也可,防御中使用将耗费一个能量珠),有攻击力拆解投技对手普通投时前或后+与对手使用的相同的按键受身倒地前A、B同时按破防一定时间内连续攻击,快要被破防前血槽边上会闪动红色大跳跃先轻点一个下方向再用普通跳跃法小跳跃出普通跳时摇杆轻点后快速回中中跳跃先轻点一个下方向再用小跳跃法PowerMax发动B、C同时按,发动后会出现时间槽,不断减少。

允许再用一个点使用MAX超杀。

)。

用超杀会PoweMax的剩余时间消失。

另外发动中可以使用的全部特殊技巧有:1.防御紧急回避(消耗部分时间)2.防御击倒攻击(消耗部分时间)3.超必杀技(消耗尽所有剩下的时间)5.SC超必杀(再多消耗一颗能量珠)6 .MAX超必杀技(再多消耗一颗能量珠)7.SC MAX超必杀技(再多消耗两颗能量珠)8.隐藏超杀(再多消耗一颗能量珠,且自己体力1/3以下)9.超级取消(每次取消后PowerMax的剩余时间会消失大约是满槽的1/4)日本队草剃京Kyo:上跳D)C)BC)跑近C)正半圈C)正半圈A×2)正半圈D D)反半圈B)正半圈A 如果有4个必杀正半圈C)正半圈A)正半圈C)再连超杀。

破隐上跳二阶堂红丸Benimaru:D)BC)跑近D)反半圈C)正半圈B下上B)反半圈C)正半圈B下上B )反半圈C)反反B。

或下B)正半圈B)反反B 破隐重要的是脚上的必杀不好抵,如果对方发了你就后退,上跳D或发招让他抵一下就没了大门五郎Daimon:D)BC)跑近C)反反AC 破隐上跳下蹲饿狼传说队特瑞Terry:D)BC)D)反正AC 破隐死抵前滚安迪·伯加得Andy :C)BC)跑近C)正半圈C )正半圈B空中)正半圈B)正半圈A)正半圈BD 。

Powermax45 XP®Professional-grade plasma system for cutting 16 mm thick metal, gouging, and marking.Easy-to-use with versatile design• Small size and light weight provides exceptional portability for a 16 mm rated cutting system.• Handheld and mechanized usage with CNC interface and FastConnect ™ torch connection.• Patented drag-cutting technology makes it easy to use – even for first-time operators.• Tackle different jobs with multiple, easy-to-use torch styles.• No need to change the air pressure. Smart Sense ™ technology ensures that it is always correctly set.• Mark, score and make precision gouges with new low amp process.Maximum productivity• Finish jobs faster with cut speeds one and a half times greater than oxyfuel on 6 mm mild steel.• Spend less time on grinding and edge preparation due to superior cut and gouge quality.• Fast change out of consumables using the new torch disable switch feature.Rugged and reliable• Duramax ® Lock torches are designed for high-impact and heat resistance.• S pringS tart ™ technology ensures consistent starting and a more reliable torch.• Hypertherm Certified ™ reliability ensures performance in the most demanding environment.ew Duramax Lock 15° hand torchDuramax Lock machine torchDuramax Lock 75° hand torchOrdering informationBelow are common system configurations which include a power supply, torch, and work cable. Additional configurations are available or a custom configuration can be made. See the next page for details.Common applicationsProperty/plant maintenance, HVAC and mechanical contracting, general fabrication, plus:Agricultural and farm equipment maintenanceConstructionMaintenance and repairCustom configurations(select power supply, torch, consumable kit, work cable, and other components) Power supply optionsStarter kit consumable optionsTorch optionsCable optionsTorch consumable partsNozzles and electrodes are available in various quantities. Contact your distributor for more information.12O hmic retaining capRecommended Hypertherm genuine accessoriesFace shieldClear face shield with flip-up shade for cutting and grinding. Safety shield included. ANSI Z87.1, CSA Z94.3, CE 127239 Face shield shade 6 127103Face shield shade 8Circle cutting guidesQuick and easy set up for accurate circles up to 70 cm diameter.For optional use as a stand-off guide for straight and bevel cuts.127102Basic kit – 38 cm arm,wheels and pivot pin 027668 Deluxe kit – 28 cm arm,wheels, pivot pin, anchor baseand plastic case Air filtration kitA ready-to-install kit with a 1-micronfilter and an auto drain moistureseparator protects againstcontaminated air.128647 Eliminizer filterRolling tool bagThis rugged bag transports thePowermax45 XP with extra room fortorches, consumables, accessories,and other gear. 50 cm x 44 cm x 32 cm017060 Rolling tool bagEssential consumable kitEssential kits provide an assortment ofstandard consumables in a convenientcase for organizing and reordering.851510 Powermax45 XP kitLeather torch sheathingAvailable in 7,6 m sections, this optionprovides additional protection fortorch leads against burn-throughand abrasion.024548 Brown leather024877 Black leather withHypertherm logosSystem dust coversMade from a flame-retardant vinyl,a dust cover will protect yourPowermax® system for years.127219 Cover, Powermax45and 45 XPISO 9001:2008Environmental stewardship is a core value of Hypertherm. Our Powermax products are engineered to meet and exceed global environmental regulations including the RoHS directive.Hypertherm, Powermax, FastConnect, Smart Sense, Duramax, SpringStart, Powercool, and FineCut are trademarks of Hypertherm Inc. and may be registered in the United States and/or other countries. All other trademarks are the properties of their respective owners.©7/2016 Hypertherm Inc. Revision 086071D。