汽轮机课程设计分级计算和回热抽汽计算汇总表格

- 格式:xls

- 大小:56.50 KB

- 文档页数:2

目录第一章摘要...................... ...................... . (2)第二章汽轮机热力计算的技术条件和参数.............. ..3 第三章汽轮机低压部分介绍...................... . (4)第四章拟定汽轮机近似热力过程曲线 (5)第五章回热系统的计算 (7)第六章低压缸的压力级的级数和排汽口数的确定 (9)第七章各级详细的热力计算...................... .......... ..10 第八章参考文献...................... ....... .. (15)第九章总结 (16)第一章摘要本次课程设计主要对200MW亚临界冲动式汽轮机通流部分(低压缸)进行了详细的设计和计算。

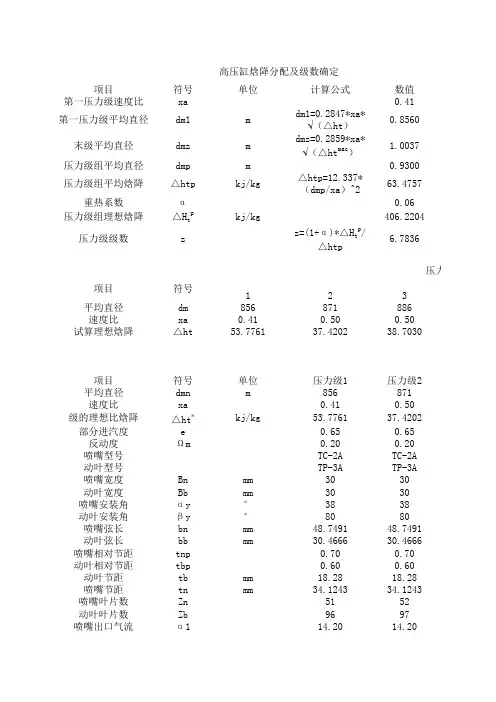

先后完成了汽轮机近似热力过程曲线的拟定、原则性回热系统的计算、低压缸进汽量的估算、低压缸级数的确定、比焓降的分配和各级详细的热力计算,初步完成了汽轮机低压缸的设计。

汽轮机是以水蒸气为工质,将热能转变为机械能的外燃高速旋转式原动机。

它具有单机功率大、效率高、运转平稳、单位功率制造成本低和使用寿命长等优点。

汽轮机是现代化国家中重要的动力机械设备。

汽轮机设备是火电厂的三大主要设备之一,汽轮机设备及系统包括汽轮机本体、调节保安油系统、辅助设备及热力系统等。

汽轮机本体是由汽轮机的转动部分(转子)和固定部分(静子)组成,调节保安油系统主要包括调节气阀、调速器、调速传动机构、主油泵、油箱、安全保护装置等;辅助设备主要包括凝汽器、抽气器、高低压加热器、除氧器、给水泵、凝结水泵、凝升泵、循环水泵等;热力系统主要指主蒸汽系统、再热蒸汽系统、旁路系统、凝汽系统、给水回热系统、给水除氧系统等。

汽轮机是以水蒸气为工质,将热能转变为机械能的外燃高速旋转式原动机。

它具有单机功率大、效率高、运转平稳、单位功率制造成本低和使用寿命长等优点。

汽轮机是现代化国家中重要的动力机械设备。

课程设计内容1.已知汽轮机机组型式及参数:机组型号: CZK300—16.67/0.4/538/538汽轮机型式:300MW 亚临界参数、一次再热、双缸双排气、双轴单调整、直接空冷、抽汽凝汽式 额定功率 : e P =300MW主蒸汽参数(主汽阀前):0P =16.67MPa ,0t =538℃;查焓熵图得0h =3398.96kJ/kg 再热蒸汽参数:冷段:rhi P =3.6869Mpa, rhi t =325.3℃, rhi h =3038.85 kJ/kg 热段(中联门前):2rh P =3.318Mpa, 2rh t =538℃, 2rh h =3539.44 kJ/kg 中联门后再热气压: 'rh p =(1-δp2)2rh P =(1-0.0143)3.318=3.2706Mpa由'rh p =3.2706Mpa,'rh h = 2rh h =3539.44kJ/kg,查水蒸气性质表,得中联门后 再热气温'rh t =537.797℃.低压缸排汽压力:c P =0.014Mpa, 排汽比焓c h =2437.4kJ/kg 计算热力系统的的有关参数: 主汽门、调门及进气管道压损 2% 中低压连通管管道压损 4.5% 再热器及管道压损 10% 中联门及管道压损 1.43%各段加热器抽气管道 1、2、3段抽气压损3%,其余5% 回热抽气级数 3高+3低+1除氧 转速 3000r/min 给水泵驱动方式 电机驱动旋转方向 顺时针方向(从汽轮机向发电机端看)额定给水温度:fw t =272.2℃。

额定工况下的电机效率:98.95%,给水泵效率:83%。

表1-1 加 热 器 端 差2.各加热器进、出水参数计算 1)首先计算高压加热器JG1加热器1P :P1(1p)P'j1=5.7215(1-0.03)=5.5499Mpa δ=-⨯式中1P ——第一抽汽口压力;1P ∆——抽汽管道相对压损;又1P =5.5499MPa ,查水蒸气性质表得 加热器饱和温度1,s t =270.545℃JG1出水温度1,w t :w ,1s ,1t t t 270.545 1.7272.245δ=-=--=()℃ 式中 t δ ——加热器上端差。

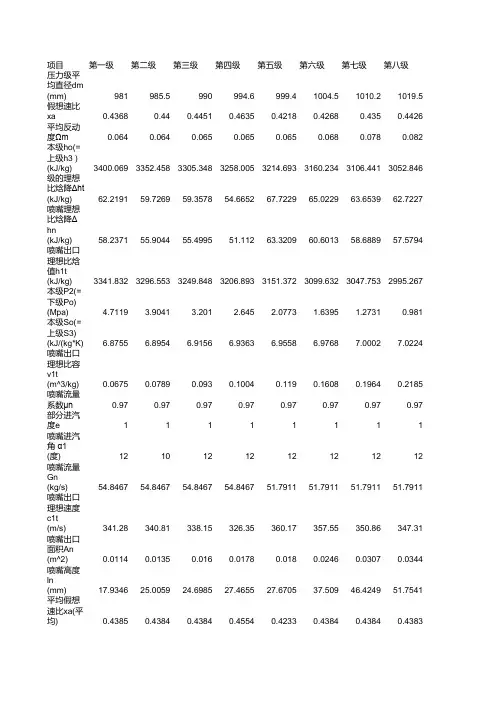

项目第一级第二级第三级第四级第五级第六级第七级第八级981985.5990994.6999.41004.51010.21019.5压力级平均直dm (mm)假想速比xa0.43680.440.44510.46350.42180.42680.4350.4426平均反动度Ωm0.0640.0640.0650.0650.0650.0680.0780.0823400.0693352.4583305.3483258.0053214.6933160.2343106.4413052.846本级ho(=上级h3 ) (kJ/kg)级的理想比焓Δht (kJ/kg)62.219159.726959.357854.665267.722965.022963.653962.722758.237155.904455.499551.11263.320960.601358.688957.5794喷嘴理想比焓Δhn (kJ/kg)3341.8323296.5533249.8483206.8933151.3723099.6323047.7532995.267喷嘴出口理想h1t (kJ/kg)本级P2(=下级Po) (Mpa)4.7119 3.9041 3.201 2.645 2.0773 1.6395 1.27310.9816.8755 6.8954 6.9156 6.9363 6.9558 6.97687.00027.0224本级So(=上级S3) (kJ/(kg*K)0.06750.07890.0930.10040.1190.16080.19640.2185喷嘴出口理想v1t (m^3/kg)喷嘴流量系数μn0.970.970.970.970.970.970.970.97部分进汽度e11111111喷嘴进汽角 α1 (度)121012121212121254.846754.846754.846754.846751.791151.791151.791151.7911喷嘴流量Gn (kg/s)喷嘴出口理想c1t (m/s)341.28340.81338.15326.35360.17357.55350.86347.310.01140.01350.0160.01780.0180.02460.03070.0344喷嘴出口面积An (m^2)17.934625.005924.698527.465527.670537.50946.424951.7541喷嘴高度ln (mm)平均假想速比xa(平均)0.43850.43840.43840.45540.42330.43840.43840.438362.25662.828563.403663.994264.613365.274566.017467.2385各级焓降h(焓降) (kJ/kg)61.759162.331662.906758.852868.760964.777665.520566.7416修正后的各级h(修正) (kJ/kg)5.6972 4.7053 3.8801 3.1788 2.6311 2.0771 1.6239 1.2604本级Po(o)(=上级P3(o)) (Mpa)62.219161.899661.031156.805169.262368.34466.517665.4555级的滞止比焓Δht(o) (kJ/kg)3337.853292.7313245.993203.343146.973095.2113042.7882990.123级的出口理想h2t' (kJ/kg)本级δhc2(=下级δhco) (kJ/kg)2.1727 1.6733 2.1399 2.19923.3211 2.8637 2.7328 3.059258.237158.077157.172853.251964.860363.922461.552660.3122喷嘴滞止比焓Δhn(o) (kJ/kg)喷嘴流量系数φ0.970.970.970.970.970.970.970.97331.04330.59328.01316.56349.36346.82340.33336.89喷嘴出口实际c1 (m/s)154.1154.8155.51156.23156.99157.79158.68160.14圆周速度u (m/s)3.4418 3.304 3.28 3.0207 3.7423 3.5815 3.4685 3.4029喷嘴损失δhn (kJ/kg)352.76351.85349.37337.06372.19369.71364.74361.82级的出口理想Ca (m/s)4.7654 3.9494 3.2418 2.978 2.4255 1.6677 1.3052 1.1569喷嘴后压力P1 (Mpa)喷嘴前后压比εn0.83640.83940.83550.93680.92190.80290.80370.9179动叶进口汽流β1 (度)22.0818.5822.4223.2221.4621.6722.1122.47183.13180.16178.85166.93198.5195.25188.03183.3动叶进口相对w1 (m/s)动叶进口相对δhw1 (kJ/kg)16.768316.228815.993713.932819.701119.061317.677616.79943345.2743299.8573253.1283209.9143155.1143103.2143051.2212998.669喷嘴出口实际h1 (kJ/kg)3.982 3.8225 3.8583 3.55324.402 4.4216 4.9655.1433动叶理想比焓Δhb (kJ/kg)20.750320.051319.85217.48624.103123.482922.642621.9427动叶滞止理想Δhb(o) (kJ/kg)203.72200.26199.26187.01219.56216.72212.8209.49动叶出口汽流w2t (m/s)动叶速度系数ψ0.930.9310.9310.9240.9210.9290.930.924189.46186.44185.51172.8202.21201.33197.9193.57动叶出口实际w2 (m/s)动叶损失δhb (kJ/kg)2.8034 2.6716 2.6451 2.55693.6579 3.2162 3.059 3.20853344.0953298.7063251.9153208.9183154.373102.0083049.3152996.735动叶出口焓值h2 (kJ/kg)0.06830.080.09430.11070.1350.16390.20180.2498动叶出口比容V2 (m^3/kg)盖度Δ 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.50.01980.02350.02790.03510.03460.04220.05280.0668动叶出口面积Ab (m^2)20.496727.568127.260630.027730.232740.07148.987154.3162动叶高度lb (mm)根部反动度Ωr0.04560.03870.04020.03760.03760.03110.0330.0325动叶出汽角β2 (度)18.7416.3919.7122.5421.942020.3723.1765.9257.8565.4266.3281.575.6873.9378.22动叶出口绝对C2 (m/s)67.4265.427387.0967.9765.4968.7176.83动叶出汽角α2 (度)53.801254.250752.966149.028358.54158.682657.257355.7849级的轮周比焓Δhu' (kJ/kg)1110.71110被下一级余速μ160.046460.226358.891255.265765.941265.480363.784865.4555级消耗的理想Eo (kJ/kg)轮周效率ηu'0.8960.90080.89940.88710.88780.89620.89770.852353.79954.122952.868648.901458.446758.482857.082955.6246单位质量蒸汽Wu (kJ/kg)轮周效率ηu"0.8960.89870.89770.88480.88630.89310.89490.8498误差(ηu'-ηu")/ηu'=Δηu00.00230.00190.00260.00170.00350.00310.00291.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6计算叶高损失a(系数)计算叶轮摩擦K(系数)1.07 1.07 1.07 1.07 1.07 1.07 1.07 1.074.919 3.5574 3.5164 2.9271 3.4691 2.5654 2.0223 1.7674叶高损失δhl (kj/kg)48.882250.693349.449746.101255.071956.117255.23554.0175轮周有效比焓Δhu (kJ/kg)轮周效率ηu0.81410.84170.83970.83420.83520.8570.8660.825355.170848.185941.823236.460830.629825.878721.619418.2838级的叶轮摩擦ΔPf (kJ)1.00590.87860.76250.66480.59140.49970.41740.353叶轮摩擦损失δhf (kJ/kg)590590590590590590590890隔板汽封齿平dp (mm)隔板汽封间隙δp (mm)0.50.50.50.50.50.50.50.51010101010101010汽封齿数zp (个)1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5叶顶轴向间隙δz (mm)0.30.30.30.30.30.30.30.3围带边厚度Δs (mm)0.30.30.30.30.30.30.30.3计算动叶顶部μ1(系数)0.9560.9560.9560.9560.9560.9560.9560.956计算动叶顶部μ2(系数)0.2160.2160.2160.2160.2160.2160.2160.216计算动叶顶部ψt(系数)0.00090.00090.00090.00090.00090.00090.00090.0014漏气面积Ap (m^2)1.2422 1.10130.90220.75410.89060.66550.52580.7117隔板漏气损失δhp (kJ/kg)考虑轮周损失Δhi' (kJ/kg)48.882250.693349.449746.101255.071956.117255.23554.01750.0750.05580.05640.05120.05080.03840.03140.0283叶顶轴向间隙δz(平均)1.1952 1.10420.90920.76950.91210.70250.56540.4984动叶顶部漏汽δht (kJ/kg)2.4374 2.2055 1.8114 1.5236 1.8027 1.368 1.0912 1.2101级的总漏汽损δhδ (kJ/kg)8.3623 6.6415 6.0903 5.1155 5.8632 4.4331 3.5309 3.3305除δhn,δhb,δhc2外级内各项损失之和Σδhi (kJ/kg)45.438947.609246.875843.912852.677854.249553.726452.4544级的有效比焓Δhi (kJ/kg)级的内效率ηi0.75670.79050.7960.79460.79890.82850.84230.8014 2492.1742611.2082570.9832408.4722728.2442809.6412782.5492716.671级的内功率Pi(s) (kW)3354.633307.0213260.1453216.2323163.5553109.3053055.5793003.124级后参数h3(o) (kJ/kg)。

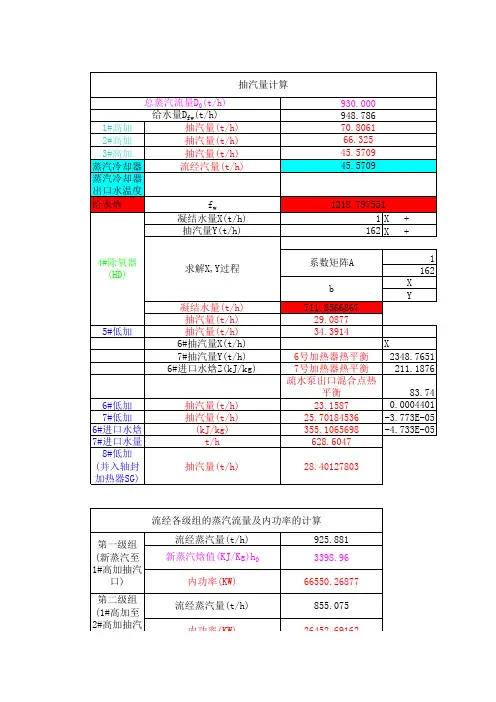

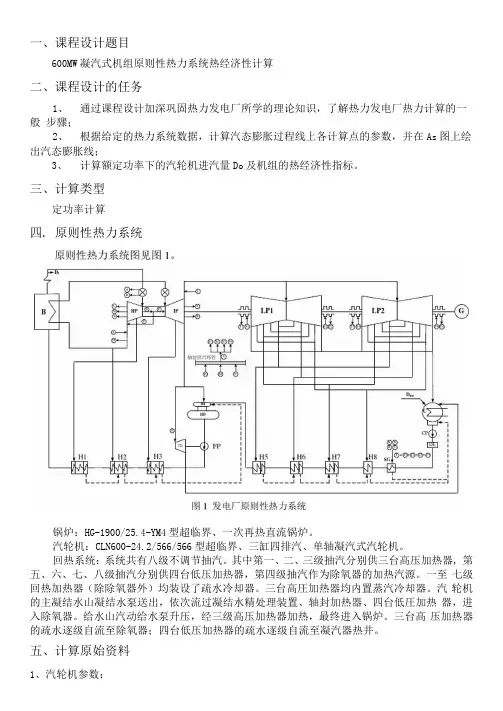

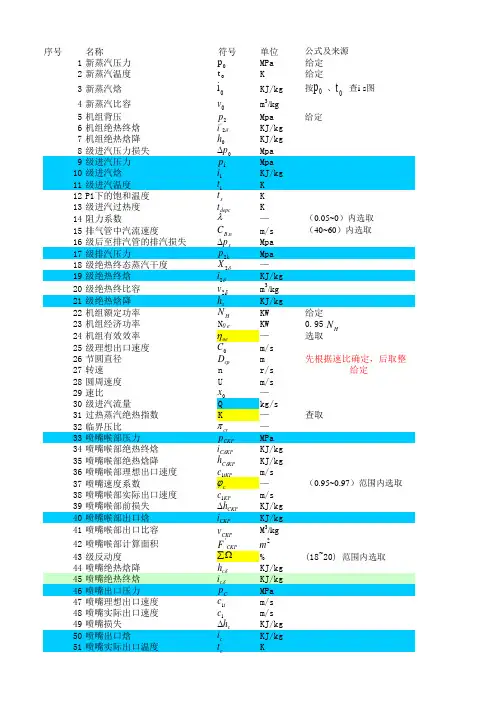

一、课程设计题目600MW凝汽式机组原则性热力系统热经济性计算二、课程设计的任务1、通过课程设计加深巩固热力发电厂所学的理论知识,了解热力发电厂热力计算的一般步骤;2、根据给定的热力系统数据,计算汽态膨胀过程线上各计算点的参数,并在As图上绘出汽态膨胀线;3、计算额定功率下的汽轮机进汽量Do及机组的热经济性指标。

三、计算类型定功率计算四. 原则性热力系统锅炉:HG-1900/25.4-YM4型超临界、一次再热直流锅炉。

汽轮机:CLN600-24.2/566/566型超临界、三缸四排汽、单轴凝汽式汽轮机。

回热系统:系统共有八级不调节抽汽。

其中第一、二、三级抽汽分别供三台高压加热器, 第五、六、七、八级抽汽分别供四台低压加热器,第四级抽汽作为除氧器的加热汽源。

一至七级回热加热器(除除氧器外)均装设了疏水冷却器。

三台高圧加热器均内置蒸汽冷却器。

汽轮机的主凝结水山凝结水泵送出,依次流过凝结水精处理装置、轴封加热器、四台低圧加热器,进入除氧器。

给水山汽动给水泵升压,经三级高压加热器加热,最终进入锅炉。

三台高压加热器的疏水逐级自流至除氧器;四台低压加热器的疏水逐级自流至凝汽器热井。

五、计算原始资料1、汽轮机参数:(1)额定功率:Pc=600MW;(2)主蒸汽参数:p()=24.2MPa, /o=566s C;(3)过热器出口蒸汽压力25.4 MPa,温度57(TC;(4)再热蒸汽参数:热段:/7rh=3.602MPa, r r h=566°C;冷段:/7rh=4.002MPa, f rh=301.9a C;(5)排汽参数:见表3中A;2、回热系统参数:(1)机组各级回热抽汽参数见表1;(2)给水泵出口压力:/7pu=29.21MPa,给水泵效率://pu=0.9;(3)除氧器至给水泵高度差:H pu=22m:(4)小汽轮机排汽压力:/7cx=7kPa,小汽轮机机械效率:;/mx=0.99,排汽干度:X cx=l;(5)凝结水泵出口压力:/7,pu=1.724Mpa;(6)高加水侧压力取给水泵岀口压力,低加水侧压力取凝结水泵岀口压力;3、锅炉参数:锅炉效率://b =93%o4、其他数据:⑴轴封加热器压力:/?sg=98kPa;(2)汽轮机组机械效率:伽=0.99,发电机效率:沪0.99六、课程设计方案选择七、计算参考事项及步骤1.整理原始数据的计算点汽水焙值根据已知数据计算或查出有关的汽水参数值;在h-s图上绘制汽轮机的汽态膨胀线;2.计算汽轮机各级回热抽汽量按照加热器山高到低的顺序依次作图计算各级抽汽份额、疏水份额、主凝结水或主给水份额;3 •汽轮机汽耗量计算根据各级抽汽份额,按定功率方法计算汽轮机汽耗量Do,并列表。

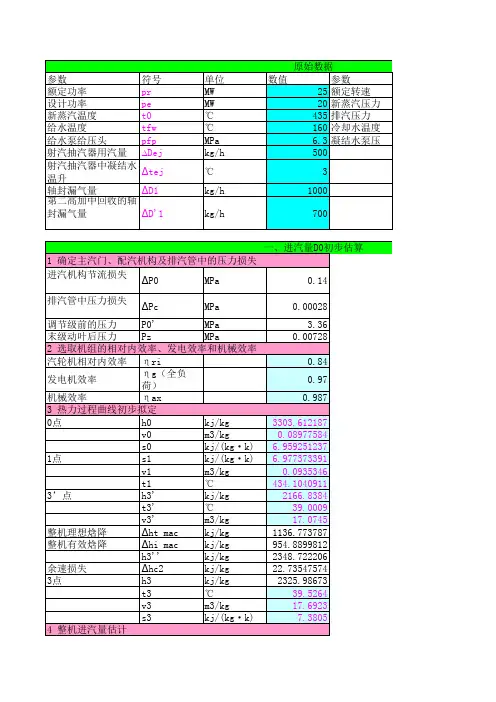

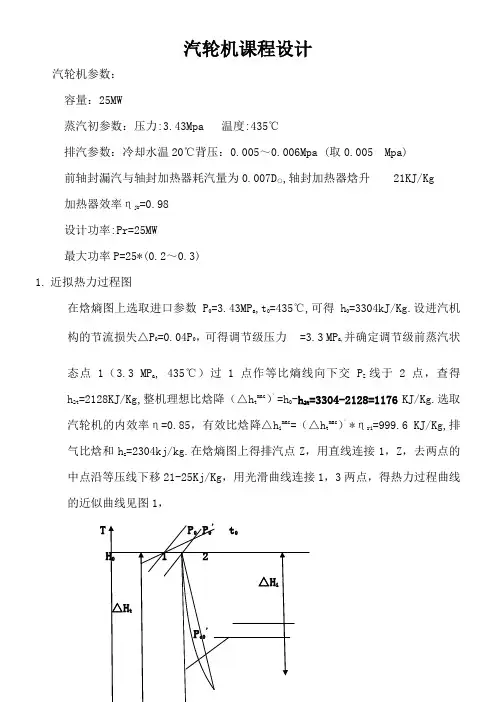

汽轮机课程设计汽轮机参数:容量:25MW蒸汽初参数:压力:3.43Mpa 温度:435℃排汽参数:冷却水温20℃背压:0.005~0.006Mpa (取0.005 Mpa)前轴封漏汽与轴封加热器耗汽量为0.007D○,轴封加热器焓升 21KJ/Kg加热器效率ηjr=0.98设计功率:Pr=25MW最大功率P=25*(0.2~0.3)1.近拟热力过程图在焓熵图上选取进口参数P0=3.43MP a,t0=435℃,可得h0=3304kJ/Kg.设进汽机构的节流损失△P0=0.04P0,可得调节级压力=3.3MP a,并确定调节级前蒸汽状态点1(3.3 MP a, 435℃)过1点作等比熵线向下交P Z线于2点,查得h2t=2128KJ/Kg,整机理想比焓降(△h t mac)’=h0-h2t=3304-2128=1176KJ/Kg.选取汽轮机的内效率η=0.85,有效比焓降△h i mac=(△h t mac)’*ηri=999.6 KJ/Kg,排气比焓和h z=2304kj/kg.在焓熵图上得排汽点Z,用直线连接1,Z,去两点的中点沿等压线下移21-25Kj/Kg,用光滑曲线连接1,3两点,得热力过程曲线的近似曲线见图1,P cS图1选取给水温度T=160℃ 回热级数:5内效率η=0.85主汽门和调节阀中节流损失△P0=(0.03~0.05)PO 排汽管中压力损失 △P C =(0.02~0.06)P C 回热抽汽管中的压力损失 △P E =(0.04~0.08)P E2.汽轮机进汽量D ○ηm =0.99 ηg =0.97 m=1.15 △D=0.03D O D 0=/ h i mac ηm ηg *m+△D=3.6*20000*1.15/(93*0.99*0.97)+0.03△D =107.19 t/h 2. 抽汽压力确定采用大气式除氧器 压力为0.118 MP A 饱和温度为104.3℃2#3. 回热抽汽流量的计算(1) H1高加给水量 △D e =0.5 △D L1=0.77 △D C =1 Dfw=D 0-△D C +△D L1+△D ej=107.19-1+0.77+0.5=107.46 t/h抽汽量△D e1(h e1-h e1’) ηjr = D fw (h W2-h w1)21'11()107.46(697.4592.04)5.01()0.98(3024730.17)fw w w el jr e e D h h D h h η--∆===--(t/h )(2)H2高加 抽汽量 21'2'22()107.46*105.2855.07()0.98(2888619.27)fw w w e e e jrD h h D h h η-∆===-- (t/h )H1疏水流入H2放热 ''1211'22760.17619.275.01*0.2452888619.27e e e ee e e h h D D h h --∆=∆==-- (t/h) 考虑前轴封漏汽'211'223098619.270.77*0.842888619.2l e l e l e e h h D D h h --∆=∆==-- (t/h) '221 5.070.2450.84 3.985e e ele l e D D D D ∆=∆-∆-∆=--= (t/h) (3) H d 除氧器(4)H3低加213'33105.4695.65* 4.54(/)()(2644402.2)*0.98w w e cw e e jr h h D D t h h h η-∆===--(5)H4低加'214'44''3433'44'443105.4695.65* 4.64(/)()(2492300.9)0.98402.2300.94.59*0.22(/)2492300.94.640.22 4.42(/)w w e cw e e jr e e e ee e e e e e e h h D D t h h h h h D D t h h h D D D t h η-∆===----∆=∆==--∆=∆-∆=-=回热系统的校验4. 流经各级组蒸汽量及其内功率调节级 0109.19(/)D t h =第一级组 10107.191106.19(/)l D D D t h =-∆=-=第二级组 211106.19 5.01101.18(/)e D D D t h =-∆=-= 第三级组 32297.175(/)e D D D t h =-∆=第四级组 4397.195 2.3594.85(/)ed D D D t h =-∆=-= 第五级组 54394.875 4.4090.335(/)e D D D t h =-∆=-= 第六级组 65490.335 4.4285.95(/)e D D D t h =-∆=-= 整机内功率5. 计算汽机装置的热经济性机械损失: (1)22189.1(10.99)269m i m P P kw η=-=-= 汽机轴端功率: 22189.122226671n i m P P P kw =-=-= 发电机功率: 26671*0.9725870e n g P P kw η=== 内功率大于25000KW,合格 汽耗率: 0(.)10001071904.13()2130825870.78kg kw h e D d P === 不抽汽估计汽耗率: 汽轮机装置的热耗率 绝对电效率 3600360033.44%10765.67el q η===25MW 凝汽式汽轮机热平衡计算数据6. 双列速度级的热力计算(1) 速度级的选择选择双列速度级(195-250KJ/Kg )选择焓降为250kj/kg.故速度级的参数为:0107.19(/)D t h = 0 3.43()P MPa = 0435t =℃1. 喷嘴热力计算 (1) 喷嘴理想焓降 (2) 喷嘴进口状态参数 (3) 喷嘴出口状态参数 由△h n 可以从H-S 图上查得: (4) 喷嘴形状的确定 前后压比: 10 1.40.420.5463..3n cr p p εε===<= 选用渐缩型喷嘴.(5) 喷嘴出口速度理想速度: 1651.9(/)t c m s === 速度系数0.97ϕ=实际速度: 110.97*627.69632.36(/)t c c m s ϕ=== 喷嘴出口汽流偏转角1δ 喷嘴出口汽流方向角115o α= (6) 轮周速度u(7) 速度级的平均直径d m (8) 喷嘴出口面积A n (9) 喷嘴出口高度l n选取部分进汽度e=0.6则叶高l n =16mm>15mm(10)喷嘴损失n h ζ∆2. 第一列动叶热力计算 (1) 动叶进口汽流的相对速度(2) 根据C 1,U 1作速度三角形,由余弦定理可得: (3) 动叶出口汽流相对速度 因为0b Ω= 则21482.03(/)t w w m s == 查图, 0.878b ϕ=复速级动叶出口汽流角21(35)o oββ=--取0220.87317.87o o β=-= (4) 动叶绝对速度 (5) 动叶进口状态参数 喷嘴出口实际状态点参数动叶比焓 113091.512.563104/t n h h h kj kg ζ=+∆=+=由H-S 图查得动叶进口密度31 6.25/kg m ρ= (5)动叶进口高度 (△r △t 由表1-1查得) (6)动叶出口面积(b μ 由图1-11查得)(7)动叶出口高度 (8)动叶损失(9)动叶出口汽流状态参数动叶出口比焓 21310426.63130.6(/)b h h h kj kg ϕ=+∆=+=查H-S 图得:出口密度32 6.28/kg m ρ=因为0bΩ=则12p p =3. 导叶热力计算(1) 导叶中汽流的理想比焓降 (2)导叶出口汽流理想状态参数由导叶进口状态( 第一列动叶出口状态)参数和△h gb 从H-S 图查得导叶出口压力 '1 1.6p MPa =导叶出口比焓 '123118/t gb h h h kj kg =-∆=导叶出口密度 '316.18/kg m ρ=(3)导叶出口汽流理想速度 导叶出口实际速度 (gb ϕ由图1-18查取) 导叶出口汽流角 (4)导叶进口高度 (6) 导叶顶部漏汽量 (7) 导叶出口面积(8) 导叶出口高度 (9) 导叶损失(10) 导叶出口汽流实际状态参数导叶出口焓 ''1131187.933125.93/t gb h h h kj kg =+∆=+= 由H-S 图查得导叶出口密度 '31 6.26/kg m ρ= 4. 第二列动叶热力计算 (1) 动叶中汽流的理想比焓降 (2) 动叶出口汽流理想状态参数由H-S 图查得动叶出口压力 '2 1.5p MPa =动叶出口密度 '32 5.56/tkg m ρ=(3) 动叶进口相对速度 (4) 动叶出口汽流相对速度 相对理想速度: 相对实际速度: ('b ϕ由图1-18查得) 动叶出口汽流相对速度角 (5) 动叶出口汽流绝对速度 (6) 动叶损失 (7) 余速损失(8) 动叶出口汽流实际状态参数动叶出口实际比焓 '''223100.93 5.13/t b h h h kj kg ζ=+=+(9) 动叶进口高度 (10) 动叶顶部漏汽量由于'b m d d =,'22b b l l =根部反动度顶部反动度(11)动叶出口面积('bμ由图1-11查得) (12)动叶出口高度5.轮周功校核1KG蒸汽所做的轮周功计算符合要求6.轮周效率7.级内损失的计算(1)叶轮摩擦损失(2)叶高损失(3)部分进汽损失鼓风损失斥汽损失(4)导叶及动叶顶部漏汽损失8.级的内功率9.级的内效率7.压力级的确定及焓降的分配1.第一压力级的平均直径1d==m=1.11m2.凝汽式汽轮机末级直径的估算3.平均理想焓降的计算各级组的直径及反动度各级的理想焓降估算级的平均理想焓降级数目的确定比焓降分配辅助表格8. 回热系统抽汽压力的重新确定(1) H1高加 给水量Dfw=D 0-△D C +△D L1+△D ej=107.19-0.75+0.58+0.5 =107.52 t/h抽汽量△D e1(h e1-h e1’) ηjr = Dfw(h W2-h w1)21'11()107.52(723622.83)4.7()0.98(3074740)fw w w el jr e e D h h D h h η--∆===--(t/h )(2) H2高加''1211'22749649.64.73*0.212904649.6e e e ee e e h h D D h h --∆=∆==--(t/h)'211'223098.1649.40.580*0.632094649.6l e l e l e e h h D D h h --∆=∆==-- (t/h) (3) H d 除氧器(4) H3低加 (5) H4低加 回热系统的校验流经各级组流量及其内功率 调节级 0107.19(/)D t h =第一级组 10107.190.75106.44(/)l D D D t h =-∆=-= 第二级组 211106.44 4.73101.73(/)e D D D t h =-∆=-= 第三级组 32298.11(/)e D D D t h =-∆=第四级组 4398.11296.11(/)ed D D D t h =-∆=-= 第五级组 54396.11 5.1390.98(/)e D D D t h =-∆=-= 第六级组 65490.98 3.0287.96(/)e D D D t h =-∆=-= 整机内功率 装置热经济性机械损失 (1)28334(10.99)283m i m P P kw η∆=-=-= 汽机轴端损失 2833428328051n i m P P P kw =-∆=-= 发电机功率 28051*0.9727209.79e n g P P kw η=== 汽耗率不抽汽估计汽耗率 汽机装置热耗率 绝对电效率9.压力级第九级第十级的详细热力计算演示 1.级内的比焓降分配 (1)焓降t h ∆= 104kj/kg初焓 0h =2500 初压 0p =0.037MP初速 092.45/c m s = 反动度 0.2m Ω=等熵滞止焓降 2*108.432000tt c h h ∆=∆+=(2) 蒸汽在动叶的理想比焓降: 2.喷管的热力计算 ⑴ 喷管前后的蒸汽参数根据o p ,o x 2c h ∆以*n h ∆由h-s 图得喷管滞止压力*o p =0.037 滞止比焓*o h ∆=2540.3 滞止密度*0ρ=0.223/kg m 喷管前比焓0h =2500喷管后压力1p =0.017MP 理想密度 1t ρ=0.1253/kg m理想比焓 1t h =2418⑵ 喷管截面积形状的确定 等熵指数 k=1.035+0.1o x =1.129 临界压比 cr ε=k 121k k ⎛⎫ ⎪-⎝⎭⎛⎫⎪+⎝⎭=0.566喷管前后压力比 n ε=0.016/0.035=0.457因为n ε≤0.457,所以汽流在喷管出口为超声速流动但是n ε>0.3~0.4 故喷管应该是渐缩型超音速斜切部分达到超音速。

300MW汽轮机热力计算数据汇总表项目符号单位调节级高压缸1高压缸2高压缸3高压缸4蒸汽流量G kg/s250.6250.82250.82250.82250.82喷嘴平均直径dn mm1155796816836856动叶平均直径do mm1155796816836856级前压力po Mpa15.836512.167411.3291910.58489.7538级前温度/干度to/x C533.62493.87485.4474.5462.5级前比焓值ho kj/kg3396.133336.3833317.583298.0543277.755圆周速度u m/s181.335124.9829128.1033131.2609134.3796理想比焓降⊿ht kj/kg8522.5923.4624.3525.24理想速度Ct m/s412.3106212.5559216.6102220.6808224.6775假想速比Xt-0.4398020.5880.59140.59480.5981反动度Ωm%847.942.948.347.9利用上级余速动能⊿hco kj/kg00 1.21 1.3 1.34喷嘴理想比焓降⊿hn kj/kg78.211.7693913.3956612.5889513.15004喷嘴滞止比焓降⊿hn*kj/kg78.211.7693913.3956612.5889513.15004喷嘴出口理想速度C1t m/s395.4744153.4235163.6805158.6755162.173喷嘴速度系数ψ-0.970.970.970.970.97喷嘴出口实际速度c1m/s383.6102148.8208158.7701153.9152157.3078喷嘴损失⊿hnζkj/kg 4.621620.6955710.7916840.7440070.777167喷嘴出口理想焓值h1t3317.933324.6133304.1843285.4653264.605熵st 6.4338 6.46 6.47 6.476749 6.483727喷嘴后压力p1Mpa12.433311.7410.9433710.14689.333897喷嘴后温度/干度t1/x C/490.347487.39479.201468.172455.962喷嘴出口理想比体积v1t m3/kg0.02530.0268740.0285280.0303950.032609喷嘴出口截面积An cm2165.2737452.9297450.6714495.3104519.943喷嘴出汽角α1(º)15.114.7814.7914.814.78喷嘴高度Ln mm2079.8129877.4173882.9951685.19964部分进汽度e-0.891111喷嘴出口焓h13322.5523325.3093304.9763286.2093265.382 p112.433311.7410.9433710.14689.333897s1 6.44084 6.46047 6.471979 6.47858 6.485347动叶进口相对速度w1m/s213.7542.4158947.8351143.0552443.86994相对于W1的比焓降⊿hw1kj/kg22.844530.899554 1.1440990.9268770.962286动叶滞止比焓降⊿h*b kj/kg29.6445311.7201611.2084412.6879313.05225动叶出口理想速度W2t m/s243.4935153.1023149.7227159.298161.5688动叶速度系数Ψ-0.9280.93550.93550.93550.9365动叶损失⊿hbζkj/kg 4.1151351.463142 1.399259 1.583958 1.605005动叶出口相对速度w2m/s225.9619143.2272140.0656149.0233151.3092动叶出口绝对速度c2m/s83.3625235.6355735.5533836.6125336.95065余速损失⊿hc2kj/kg 3.4746550.6349470.6320220.6702390.682675 h2t3315.7523314.4883294.9113274.4483253.292s1 6.44084 6.46047 6.471979 6.47858 6.485347动叶后压力p2Mpa12.167411.3291910.58489.75388.9521动叶后温度/干度t2/x2℃/489.52482.419473.951461.955449.581动叶出口比体积v2m3/kg0.0258820.027650.0293580.0314060.033667动叶出口面积Ab cm3273.3054464.777504.6194507.3747536.2627动叶出汽角β2(º)20.0318313.1375614.3584113.144313.22654动叶高度lb mm2281.8129879.4173884.9951687.19964轮周损失hu12.21141 2.79366 2.822964 2.998203 3.064848轮周有效比焓降⊿hu kj/kg72.7885919.7963420.6370421.351822.17515轮周功率pu kw18240.824965.3185176.1815355.4585561.972轮周效率ηu%85.6336487.633287.9669187.6870587.85718动叶α268.2010165.9974777.6783367.7589169.54069轮周功率(校核)72.7737119.7963420.6370421.351822.17515轮周效率(校核)85.6161387.633287.9669187.6870587.85718误差-0.02044-1.5E-13 3.23E-13-8.1E-14-4.9E-14叶高损失⊿hl kj/kg 4.3673150.2976410.3198820.3087190.312327叶轮摩擦损失v0.0255910.0272620.0289430.03090.033138⊿pf326.376647.6438650.7820753.7088356.33859⊿hf kj/kg 1.3023810000部分进气损失⊿kj/kg 2.750000湿汽损失⊿hx kj/kg00000级内有效比焓降⊿hi kj/kg64.3688919.498720.3171521.0430821.86282级相对内效率ηi%0.7572810.8631560.8660340.8641920.866197级的内功率pi kw16130.844890.6645095.9495278.0255483.634下一级ht3336.3833317.583298.0543277.7553256.669下一级st 6.46 6.47 6.476749 6.483727 6.490931 t493.87485.4474.5462.5450.2高压缸5高压缸6高压缸7高压缸8高压缸9高压缸10高压缸11高压缸12中压缸1 250.82241.12241.12241.12233.41233.3233.3227.93206.25 876896917938960981100310251079 8768969179389609811003102510798.95218.18957.4658 6.7685 6.1132 5.5058 4.9188 4.3994 3.8896450.2437.46424.4410.8396.8382.5367.6352.5336.7 3256.6693234.8273212.1923188.7193164.3813139.1573113.0523086.0343058.097 137.5319140.6701143.9758147.2661150.7183154.0052157.4763160.9328169.406326.1427.0428.0128.9830.0231.0132.0733.1343.1 228.6482232.5511236.6854240.7488245.0306249.0381253.2588257.4102293.59840.60150.60490.60830.61170.61510.61840.62180.62520.57748.548.948.749.349.750.851.452.945.91.34 1.34 1.42 1.42 1.47 1.55 1.59 1.63 1.72 13.462113.8174414.3691314.6928615.1000615.2569215.5860215.6042323.3171 13.462113.8174414.3691314.6928615.1000615.2569215.5860215.6042323.3171 164.086166.2374169.5236171.4226173.7818174.6821176.5561176.6592215.94950.970.970.970.970.970.970.970.970.97 159.1634161.2503164.4379166.28168.5684169.4416171.2594171.3594209.471 0.795610.8166110.8492160.8683480.8924140.9016840.9211340.92221 1.378041 3243.2073221.013197.8233174.0263149.2813123.93097.4663070.433034.78 6.490931 6.498026 6.504979 6.5125246.5197956.526247 6.534007 6.539 6.5464378.5567.80887.0963 6.4357 5.7971 5.2133 4.6599 4.1525 3.5847 443.454430.531417.142403.463389.291374.895359.949344.78325.136 0.0350750.0377990.0408450.0444340.0483830.052750.05810.0634540.072288 552.7379565.2104598.9254644.3308669.946726.3023791.4704844.0191711.768914.9214.8314.7814.8114.7814.8314.8914.7814.82 87.6937688.1909591.6134596.1614397.88686103.5071109.8858115.500692.28388111111111 3244.0033221.8263198.6723174.8943150.1743124.8023098.3873071.3523036.1588.5567.80887.0963 6.4357 5.7971 5.2133 4.6599 4.1525 3.5847 6.492418 6.499737 6.506982 6.5135996.5210476.527486 6.534082 6.540096 6.545338 44.0898143.9853844.5578144.5929444.7201144.4606844.7345543.9732262.97707 0.9719560.9673570.9926990.9942650.9999440.988376 1.000590.966822 1.983055 13.6498614.1899214.6335715.281415.9198816.7414617.4845718.4925921.76596 165.2262168.4632171.0764174.8222178.437182.9834187.0004192.3153208.6430.93650.93750.93750.93850.93850.93950.93950.93950.93951.678492 1.718311.772034 1.8218151.8979331.9644382.051635 2.169916 2.554012 154.7344157.9342160.3841164.0707167.4631171.9129175.6869180.6802196.0201 37.785238.2007938.5682539.1263239.7196640.5157241.2087241.8572451.77291 0.713860.729650.7437550.7654350.7888260.8207620.8490790.876014 1.340217 3231.3253208.6043185.0313160.6073135.2543109.0493081.9033053.8263016.375 6.492418 6.499737 6.506982 6.5135996.5210476.527486 6.534082 6.540096 6.5453388.18957.4658 6.7685 6.1132 5.5058 4.9188 4.3994 3.8896 3.3421 436.787423.642410.026396.025381.622366.714351.538335.743315.311 0.0362850.0392440.042530.0461390.0505330.0551430.06080.0669120.07618 565.169576.3265615.0372652.9398678.2225721.3701778.2884813.6872772.6695 13.2427613.1279613.1895313.0522413.0175212.8242712.7600912.4249813.9977 89.6937690.1909593.6134598.1614399.88686105.5071111.8858117.500694.28388 3.187963 3.264571 3.365004 3.455597 3.579172 3.686884 3.821848 3.96814 5.27227 22.9520423.7754324.64525.524426.4408327.3231228.2481529.1618637.82773 5756.835732.7315942.4016154.4446171.5546374.4836590.2946646.8637801.969 87.8042787.9268887.9864288.0759288.0773888.1106688.0827988.0225287.76736 69.734369.8865571.594571.2669971.7462770.3574770.328968.2424866.320422.9520423.7754324.64525.524426.4408327.3231228.2481529.1618637.82773 87.8042787.9268887.9864288.0759288.0773888.1106688.0827988.0225287.76736 1.29E-13 1.29E-13-8.1E-14-9.7E-14 1.61E-14-1.8E-13 6.45E-14-4.8E-14-1.5E-13 0.3140750.3235080.3228130.3185190.3241390.3167680.3084820.3029790.491887 0.035680.0385210.0416880.0452870.0494580.0539470.059450.0651830.074234 58.7462560.9127663.2106265.152766.9873668.4179669.3882570.5401680.06034000000000 000000000 000000000 22.6379623.4519224.3221825.2058826.1166927.0063527.9396728.8588837.33584 0.8660280.8673050.8683390.8697680.8699760.8708920.8712090.871080.866261 5678.0545654.7275864.5656077.6436095.8966300.5816518.3256577.8057700.518 3234.8273212.1923188.7193164.3813139.1573113.0523086.0343058.0973022.139 6.498026 6.504979 6.512524 6.5197956.5262476.534007 6.539 6.546437 6.551859437.46424.4410.8396.8382.5367.6352.5336.7318中压缸2中压缸3中压缸4中压缸5中压缸6中压缸7中压缸8中压缸922 206.25180.76180.76163.4160.2136.8116.87110.2389.18 11061133116011871214124112681296110611331160118712141241126812963.3421 2.8151 2.411 1.9863 1.7137 1.515 3.46089.9823318296.1275.6253.5232.6212.5241.9312.83022.1392984.8362946.2032906.2472864.9492822.222779.6152733.105173.7554177.8813182.1159186.3628190.604194.8407199.074203.469544.746.1947.7449.350.8652.4253.9855.63298.9983303.9408308.9984314.0064318.9357323.7901328.5727333.55660.5811250.585250.5893750.59350.5976250.601750.6058750.6145.947474749.549.550.550.51.842.14 2.3 2.263.14.19 4.98 4.9824.182724.480725.302226.12925.684326.472126.720127.5368524.182724.480725.302226.12925.684326.472126.720127.53685219.9213221.2722224.9542228.6001226.6464230.0961231.1714234.67790.970.970.970.970.970.970.970.97213.3237214.6341218.2056221.7421219.847223.1932224.2362227.63751.429198 1.446809 1.49536 1.5442241.5179421.564501 1.579158 1.6274282997.9572960.3552920.92880.1182839.2652795.7472752.8952705.5686.551859 6.561333 6.559019 6.5682286.552041 6.51949 6.095143 5.639943.0307 2.5913 2.1903 1.8214 1.6081 1.9457.965912.9548304.585284.144262.931240.839220.806212.679275.233328.0050.0813150.095350.1070640.1293240.1462890.1029340.278520.145658786.1896803.0165886.9145952.98161065.991630.90511451.622705.324714.8214.8214.9614.9614.9615.115.115.199.4444399.15232105.9842111.2887121.717369.83246157.253274.75654111111112999.3862961.8022922.3962881.6632840.7832797.3122754.4742707.1963.0307 2.5913 2.1903 1.8214 1.6081 1.9457.965912.95486.554904 6.556174 6.556534 6.5585036.5315636.364108 5.749567 5.51842163.4958662.3770963.215963.6629860.7922961.6997360.9566661.502212.015862 1.945451 1.998125 2.0264881.8478511.903428 1.857857 1.89126122.5331623.6547524.4359225.1974927.0235527.8513329.1177629.98441212.2883217.5075221.0698224.4883232.4803236.0141241.3204244.88530.93950.93950.93950.93950.93950.93950.93950.93952.644036 2.775643 2.867305 2.9566673.1709373.268068 3.41667 3.518363199.4449204.3483207.6951210.9067218.4153221.7352226.7205230.069853.3127652.8476553.8891854.5861654.4572272.7513732.403835.325771.421125 1.396437 1.452022 1.4898251.4827942.6463810.5250030.6239552978.8682940.0932899.9582858.4922815.6072771.3642727.2142679.1026.554904 6.556174 6.556534 6.5585036.5315636.364108 5.749567 5.5184212.8151 2.411 1.9863 1.7137 1.5153.46089.982313.5086294.396273.705251.601230.37209.751216.969304.302333.4740.0879860.1005230.1134850.137990.1520490.151030.1014390.072556877.0898857.1503952.08291030.5541075.043898.2095504.0552335.100914.4160313.7796714.0082914.1265313.1766418.71673 4.559553 6.15864101.4444101.1523107.9842113.2887123.717371.83246159.253276.756545.494358 5.618889 5.814687 5.9907156.1716737.47895 5.520831 5.76974639.2056440.5711141.9253143.3092844.6883344.9410548.4591749.860258086.1647333.6347578.427076.7377159.076147.9365663.4235496.09687.7083787.8352787.8200987.8484587.8653785.7326489.7724589.6283568.6495667.0749768.8971470.5615766.1023577.9656833.7938444.3231539.2056440.5711141.9253143.3092844.6883344.9410548.4591749.86025 87.7083787.8352787.8200987.8484587.8653785.7326489.7724589.62835 9.72E-14-3.2E-14-1.6E-14-3.1E-130-9.9E-14-4.7E-14-7.9E-14 0.4730960.4910160.4746970.4669940.4405780.7722660.3697920.800362 0.084650.0979360.1102750.1336570.1491690.1269820.1899790.109107 79.5949277.4633977.3880471.6433871.8362194.195270.10755136.158700000000 00000000 00000000 38.7325540.080141.4506242.8422944.2477544.1687848.0893849.059890.86650.8677220.8682580.8690120.8699910.8425940.8908740.881896 7988.5877244.8787492.6137000.437088.4896042.295620.2055407.872 2984.8362946.2032906.2472864.9492822.222779.6152733.1052685.673 6.561333 6.559019 6.568228 6.552041 6.519496.095143 5.63994 5.471054296.1275.6253.5232.6212.5241.9312.8338.2。

汽轮机课程设计汽轮机参数:容量:25MW蒸汽初参数:压力:3.43Mpa 温度:435℃排汽参数:冷却水温20℃背压:0.005~0.006Mpa (取0.005 Mpa)前轴封漏汽与轴封加热器耗汽量为0.007D○,轴封加热器焓升21KJ/Kg加热器效率ηjr=0.98设计功率:Pr=25MW最大功率P=25*(0.2~0.3)1.近拟热力过程图在焓熵图上选取进口参数P0=3.43MP a,t0=435℃,可得h0=3304kJ/Kg.设进汽机构的节流损失△P0=0.04P0,可得调节级压力=3.3 MP a,并确定调节级前蒸汽状态点1〔3.3 MP a, 435℃〕过1点作等比熵线向下交P Z线于2点,查得h2t=2128KJ/Kg,整机理想比焓降〔△h t mac〕’=h0-h2t=3304-2128=1176KJ/Kg.选取汽轮机的效率η=0.85,有效比焓降△h i mac=〔△h t mac〕’*ηri=999.6 KJ/Kg,排气比焓和h z=2304kj/kg.在焓熵图上得排汽点Z,用直线连接1,Z,去两点的中点沿等压线下移21-25Kj/Kg,用光滑曲线连接1,3两点,得热力过程曲线的近似曲线见图1,△H i△H t图1选取给水温度T=160℃回热级数:5效率η=0.85主汽门和调节阀中节流损失△P0=(0.03~0.05)PO排汽管中压力损失△P C=(0.02~0.06)P C回热抽汽管中的压力损失△P E=(0.04~0.08)P E2.汽轮机进汽量D○ηm=0.99 ηg=0.97 m=1.15 △D=0.03D OD0=/ h i macηmηg*m+△D=3.6*20000*1.15/(93*0.99*0.97)+0.03△D=107.19 t/h2.抽汽压力确定采用大气式除氧器压力为0.118 MP A饱和温度为104.3℃3.回热抽汽流量的计算(1)H1高加给水量△D e=0.5 △D L1=0.77 △D C=1Dfw=D0-△D C+△D L1+△D ej=107.19-1+0.77+0.5=107.46 t/h抽汽量△D e1(h e1-h e1’) ηjr = D fw (h W2-h w1)21'11()107.46(697.4592.04)5.01()0.98(3024730.17)fw w w el jr e e D h h D h h η--∆===--〔t/h 〕〔2〕H2高加 抽汽量21'2'22()107.46*105.2855.07()0.98(2888619.27)fw w w e e e jrD h h D h h η-∆===--〔t/h 〕H1疏水流入H2放热''1211'22760.17619.275.01*0.2452888619.27e e e ee e e h h D D h h --∆=∆==--(t/h) 考虑前轴封漏汽'211'223098619.270.77*0.842888619.2l e l e l e e h h D D h h --∆=∆==--(t/h) '221 5.070.2450.84 3.985e e ele l e D D D D ∆=∆-∆-∆=--=(t/h)(3) H d 除氧器''12121()ed ed e e l e cw w fw ed D h D D D h D h D h ∆+∆+∆+∆+=112cw l e ed e fw D D D D D D +∆+∆+∆+∆=2.35(/)ed D t h ∆=94.8(/)cw D t h =(4)H3低加213'33105.4695.65* 4.54(/)()(2644402.2)*0.98w w e cw e e jr h h D D t h h h η-∆===--(5)H4低加'214'44''3433'44'443105.4695.65* 4.64(/)()(2492300.9)0.98402.2300.94.59*0.22(/)2492300.94.640.22 4.42(/)w w e cw e e jr e e e ee e e e e e e h h D D t h h h h h D D t h h h D D D t h η-∆===----∆=∆==--∆=∆-∆=-=回热系统的校验1234123450e e ed e e D D D D D D ααααα∆+∆+∆+∆+∆++++=5.01 3.985 2.35 4.54 4.420.19342107.19++++==341094.8 4.54 4.420.8009107.19cw e e l n D D D D D α-∆-∆+∆--===1100.011nii α=-=<∑4. 流经各级组蒸汽量及其功率调节级0109.19(/)D t h =0010()6133.653.6i D h h P KW -==第一级组10107.191106.19(/)l D D D t h =-∆=-=111130983024106.1921793.6 3.6e i h h P D kw --=== 第二级组211106.19 5.01101.18(/)e D D D t h =-∆=-=230242888101.1838223.6i P kw -==第三级组32297.175(/)e D D D t h =-∆=32888276497.193347.93.6i P kw -==第四级组4397.195 2.3594.85(/)ed D D D t h =-∆=-=42764264494.84831603.6i P kw -==第五级组54394.875 4.4090.335(/)e D D D t h =-∆=-=52644349290.3353813.53.6i P kw -==第六级组65490.335 4.4285.95(/)e D D D t h =-∆=-=62492230486.534485.883.6i P kw -==整机功率606134217938223347316038144485i ij j P P ===++++++∑26941kw =5. 计算汽机装置的热经济性机械损失:(1)22189.1(10.99)269m i m P P kw η=-=-= 汽机轴端功率:22189.122226671n i m P P P kw =-=-= 发电机功率:26671*0.9725870e n g P P kw η=== 功率大于25000KW,合格 汽耗率:0(.)10001071904.13()2130825870.78kg kw h e D d P === 不抽汽估计汽耗率:'0(.)0010001071903.74()()107.19*999.62700.973.63.6kg kw h z m g D d D h h P η===-⎡⎤⎡⎤--⎢⎥⎢⎥⎣⎦⎣⎦汽轮机装置的热耗率(.)0() 4.13*(3304697.3)10765.67()kg kw h fw q d h h =-=-=绝对电效率3600360033.44%10765.67el q η=== 25MW 凝汽式汽轮机热平衡计算数据6. 双列速度级的热力计算(1) 速度级的选择选择双列速度级〔195-250KJ/Kg 〕选择焓降为250kj/kg.故速度级的参数为:0107.19(/)D t h =0 3.43()P MPa =0435t =℃ 250(/)t h kJ kg ∆=0.25a X =1. 喷嘴热力计算 (1) 喷嘴理想焓降'(1)250*0.85212.5(/)n t b gb b h h kj kg ∆=∆-Ω-Ω-Ω==(2) 喷嘴进口状态参数0 3.3P MPa =03304/h kj kg =00435t C =3010.53/kg m ρ=(3) 喷嘴出口状态参数由△h n 可以从H-S 图上查得:1 1.4p MPa =31 6.25/t kg m ρ=13091/t h kj kg =(4) 喷嘴形状确实定前后压比:10 1.40.420.5463..3n cr p p εε===<= 选用渐缩型喷嘴. (5) 喷嘴出口速度理想速度:1651.9(/)t c m s === 速度系数0.97ϕ=实际速度: 110.97*627.69632.36(/)t c c m s ϕ=== 喷嘴出口汽流偏转角1δ 喷嘴出口汽流方向角115o α=111sin()αδα+=0sin150.2716256=10.76o δ=(6) 轮周速度u10.25*632.36158.09(/)a u X c m s ===(7) 速度级的平均直径d m6060*158.091.0069()3.14*3000m u d m nπ=== (8)喷嘴出口面积A n277.51n A cm ===(9) 喷嘴出口高度l n177.51 1.6sin 0.6*3.14*100.69*sin15n n om A l cm e d πα=== 选取局部进汽度e=0.6那么叶高l n =16mm>15mm(10)喷嘴损失n h ζ∆22(1)(10.99)*250*0.8512.56(/)n n h h kj kg ζϕ=-=-=2. 第一列动叶热力计算 (1) 动叶进口汽流的相对速度(2) 根据C 1,U 1作速度三角形,由余弦定理可得:1w =482.03(/)m s ==1111111sin()608.86sin15.13sin sin463.62oc w αδβ--+==20.87o =(3) 动叶出口汽流相对速度因为0b Ω=那么21482.03(/)t w w m s == 查图,0.878b ϕ=220.878*482.03423.22(/)b t w w m s ϕ===复速级动叶出口汽流角21(35)o oββ=--取0220.87317.87o o β=-= (4) 动叶绝对速度2c =275.93(/)m s ==112222cos 423.22cos17sin sin 275.93ow c βα--==26.24o =(5) 动叶进口状态参数喷嘴出口实际状态点参数动叶比焓113091.512.563104/t n h h h kj kg ζ=+∆=+= 由H-S 图查得动叶进口密度31 6.25/kg m ρ= (5)动叶进口高度 (△r △t 由表1-1查得)'1b n n l l l r t =+∆=+∆+∆15.80.5 1.517.8mm =++=(6)动叶出口面积1071903360022106.27()0.93*482.03*6.25b b b t t G A cm w μρ===(b μ由图1-11查得) (7)动叶出口高度12106.2718sin 0.6*3.14*100.6sin17.87b b om A l mm e d πβ=== '1118.5180.5b b l mm -=-=(8)动叶损失22222482.03(1)(10.878)26.6/22000t b w h kj kg ϕϕ∆=-=-=(9)动叶出口汽流状态参数动叶出口比焓21310426.63130.6(/)b h h h kj kg ϕ=+∆=+= 查H-S 图得:出口密度32 6.28/kg m ρ= 因为0b Ω=那么12p p = 3. 导叶热力计算(1) 导叶中汽流的理想比焓降0.05*25012.5(/)gb gb t h h kj kg ∆=Ω∆==(2)导叶出口汽流理想状态参数由导叶进口状态( 第一列动叶出口状态)参数和△h gb 从H-S 图查得 导叶出口压力'1 1.6p MPa =导叶出口比焓'123118/t gb h h h kj kg =-∆= 导叶出口密度'31 6.18/kg mρ=(3)导叶出口汽流理想速度'1318.02(/)t c m s ===导叶出口实际速度''110.918*318.02291.94(/)gb t c c m s ϕ===(gb ϕ由图1-18查取) 导叶出口汽流角'12(510)26.64 5.6421o o o o o αα=--=-=(4)导叶进口高度'18.2220.2gb b b l l l r t mm =+∆=+∆+∆=+=(6) 导叶顶部漏汽量'1()gbt t gb gb t G e d e μπδ∆=+gb m d d ≈'gb gb l l ≈0.6*0.6*3.14(1.00690.021)*100.45(/)gbt G kg s -∆=+=(7) 导叶出口面积10719023600''10.45159.00.938*318.02*6.18gbgb gb t G A cmc μρ-===(8) 导叶出口高度'1158.4423sin 0.6*3.14*100.69*sin 21gb gb om A l mm e d πα=== '2320.8 2.8gb gb l l mm -=-=(9) 导叶损失'2221318.02(1)(10.918)7.93/22000t gb c h kj kg ϕ∆=-=-=(10) 导叶出口汽流实际状态参数导叶出口焓''1131187.933125.93/t gb h h h kj kg =+∆=+= 由H-S 图查得导叶出口密度'31 6.26/kg m ρ= 4. 第二列动叶热力计算 (1) 动叶中汽流的理想比焓降''0.1*25025/b b n h h kj kg ∆=Ω∆==(2) 动叶出口汽流理想状态参数'''213125.93253100.93/t b h h h kj kg =-∆=-= 由H-S 图查得动叶出口压力'2 1.5p MPa = 动叶出口密度'32 5.56/tkg m ρ= (3) 动叶进口相对速度'1w ==155(/)m s ='''1111'1sin 291.9sin 21sin 42.5155o oc w αβ-===(4) 动叶出口汽流相对速度 相对理想速度:'2272.07/t w m s === 相对实际速度:'''220.928*272.07252.48(/)b t w w m s ϕ===('b ϕ由图1-18查得) 动叶出口汽流相对速度角''21(78)42.514.528o o o o o ββ=--=-=(5) 动叶出口汽流绝对速度'2c ==135.10(/)m s ='''11222'2sin 252.48sin 28sin sin 61.3135.10oow c βα--=== (6) 动叶损失'22'222207.07(1)(10.928) 5.13/22000tb w h kj kg ζϕ∆=-=-=(7) 余速损失'22'22135.109.1/22000c c h kj kg ∆===(8) 动叶出口汽流实际状态参数动叶出口实际比焓'''223100.93 5.13/t b h h h kj kg ζ=+=+(9) 动叶进口高度'''223225b gb gb l l l t r mm =+∆=+∆+∆=+=(10) 动叶顶部漏汽量''''12()bt b b t G e d l μπδ∆=+由于'b m d d =,'22b b l l =根部反动度''''' 1.00691(1)1(10.1)0.0791.0070.025b brmb b d d l Ω=--Ω=--=--顶部反动度''''' 1.0070.0251(1)1(10.077)0.121.0070.025b b btr b b d l d l --Ω=--Ω=--=++'0.6*0.6*3.14(1.0070.025)*10bt G -∆=+0.78/kg s =(11) 动叶出口面积''107190'23600''''''2222 1.051800.943*272.07*5.56b bt bb t t b t t G G G A cm w w μρμρ-∆-====('b μ由图1-11查得) (12) 动叶出口高度'2'218029sin 0.6*3.14*100.7sin 28b b om A l mm e d πβ=== '2225.1250.1b b l l mm -=-=5. 轮周功校核1KG 蒸汽所做的轮周功1''''1111112222cos()cos cos cos 158.09632.36cos15.76275.93cos 26.64291.94cos 21135.10cos61.3188.18/u o o o oP u c c c c kj kgαδααα⎡⎤=++++⎣⎦⎡⎤=+++⎣⎦=2''12()u t n b gb b c P h h h h h h ζζζζ=∆-∆+∆+∆+∆+∆250(12.5626.67.93 5.139.6)188.54/kj kg=-++++=2111210.3%1%u u uP PP η-∆==<计算符合要求 6. 轮周效率'20()t n b gb b c u u th h h h h h h E h ζζζζη∆-∆+∆+∆+∆+∆∆==∆250(12.5626.67.93 5.139.6)75.27%250-++++==7. 级损失的计算 (1) 叶轮摩擦损失'3212()1002f u p k dρρ+∆=32158.09 6.25 6.181.2()1.00729.881002kw +== 136003600*29.881.0035/107190ff p h kj kg D ∆∆===(2) 叶高损失'''1122()/7n gb gb b b b b l l l l l l l l =++++++(1620.22317.8182525.1)/720.72()mm =++++++=2*188.1818.164(/)20.72l u a h h kj kg l ∆=∆==(3) 局部进汽损失鼓风损失31(1)2c w e a e B e X e ξ=--310.40.55*(10.6)*0.250.0028640.62=--= 0.002864*2500.7161(/)w w u h h kj kg ξ∆=∆==斥汽损失20.016**0.250.6*1.007n s ea n z c X ed ξ== 0.0135=00.0135*250 3.375/s s h E kj kg ξ∆===1.2 3.75 4.95(/)e w s h h h kj kg ∆=∆+∆=+=(4) 导叶及动叶顶部漏汽损失''gbt btt u G G h h G∆+∆∆=10719036000.450.78(118.1815) 4.26(/)kj kg +=-=8. 级的功率i i P G h =∆*''121071903600()*[250(12.5626.67.93 5.139.6 4.95 3.375 4.269.1)4957.4()t n b gb b c e c f t G h h h h h h h h h h kw ζζζζ=∆-∆-∆-∆-∆-∆-∆-∆-∆-∆=-++++++++=9. 级的效率0154.361.72%250i i h E η∆===7. 压力级确实定及焓降的分配 1. 第一压力级的平均直径1md == =1.11m2. 凝汽式汽轮机末级直径的估算1660z m d mm===4θ=3. 平均理想焓降的计算 各级组的直径及反动度各级的理想焓降估算**0020,x ,0.037c n P h h P ∆∆=根据和由焓熵图可得22 1.1512.337()87.73/0.431t h kj kg ∆== 23 1.2512.337()99.01/0.441t h kj kg ∆== 24 1.3512.337()88/0.441t h kj kg ∆== 25 1.3512.337()128.07/0.456t h kj kg ∆== 26 1.6612.337()135.84/0.50t h kj kg ∆==级的平均理想焓降123456()110.01/6t t t t t t h h h h h h h kj kg∆+∆+∆+∆+∆+∆∆==级数目确实定(1176250)(10.05)(1)/10110.1p t t Z h h α-+=∆+∆=≈比焓降分配辅助表格8.回热系统抽汽压力的重新确定(1)H1高加给水量Dfw=D0-△D C+△D L1+△D ej=107.19-0.75+0.58+0.5=107.52 t/h抽汽量△D e1(h e1-h e1’) ηjr = Dfw(h W2-h w1)21'11()107.52(723622.83)4.7()0.98(3074740)fw w w el jr e e D h h D h h η--∆===--〔t/h 〕(2) H 2高加21'2'22()107.52(622.38531)4.45(/)()0.98(2904649.6)fw w w e e e jrD h h D t h h h η--∆===--''1211'22749649.64.73*0.212904649.6e e e ee e e h h D D h h --∆=∆==--(t/h) '211'223098.1649.40.580*0.632094649.6l e l e l e e h h D D h h --∆=∆==--(t/h) '221 4.450.210.63 3.61 (t/h)e e ele l e D D D D ∆=∆-∆-∆=--=(3) H d 除氧器''12121()ed ed e e l e cw w fw edD h D D D h D h D h ∆+∆+∆+∆+=112cw l e ed e fwD D D D D D +∆+∆+∆+∆=2(/)ed D t h ∆=96.6(/)cw D t h = (4) H 3低加213'33372256.0996* 5.13(/)()(2608393.78)*0.98w w e cwe e jr h h D D t h h h η--∆===-- (5) H 4低加'214'44''3433'44'443256.09171.1796* 3.29(/)()(2470280.8)0.98393.78276.753.29*0.27(/)2500276.753.290.27 3.02(/)w w e cw e e jr e e e ee e e e e e e h h D D t h h h h h D D t h h h D D D t h η--∆===----∆=∆==--∆=∆-∆=-=回热系统的校验1234123450e e ed e e D D D D D D ααααα∆+∆+∆+∆+∆++++=4.73 3.6125.13 3.0216.04107.19++++==3410.8332cw e e l n D D D D D α-∆-∆+∆==110.00240.011nii α=-=<∑流经各级组流量及其功率 调节级0107.19(/)D t h =0010()58963.6i D h h P KW -==第一级组10107.190.75106.44(/)l D D D t h =-∆=-=111131463074106.442128.83.6 3.6e i h h P D kw --=== 第二级组211106.44 4.73101.73(/)e D D D t h =-∆=-=230742904101.7148033.6i P kw -==第三级组32298.11(/)e D D D t h =-∆=32904274898.114251.43.6i P kw -==第四级组4398.11296.11(/)ed D D D t h =-∆=-=42748260896.1137383.6i P kw -==第五级组54396.11 5.1390.98(/)e D D D t h =-∆=-=52608250090.982729.43.6i P kw -==第六级组65490.98 3.0287.96(/)e D D D t h =-∆=-=62500230487.964788.93.6i P kw -==整机功率6049442847.73065.33241.42766.52224.53126i ij j P P ===++++++∑28334kw =装置热经济性机械损失(1)28334(10.99)283m i m P P kw η∆=-=-= 汽机轴端损失2833428328051n i m P P P kw =-∆=-= 发电机功率28051*0.9727209.79e n g P P kw η=== 汽耗率0(.)10001071903.93()279209kg kw h e D d P === 不抽汽估计汽耗率'0(.)0010001071903.28()()107.19*11762830.973.63.6kg kw h z m g D d D h h P η===-⎡⎤⎡⎤--∆⎢⎥⎢⎥⎣⎦⎣⎦汽机装置热耗率(.)0() 4.26*(3304723)10995()kg kw h fw q d h h =-=-=绝对电效率3600360032.7%10995el q η===9.压力级第九级第十级的详细热力计算演示 1.级的比焓降分配(1)焓降t h ∆= 104kj/kg初焓0h =2500初压0p =0.037MP 初速092.45/c m s =反动度0.2m Ω=等熵滞止焓降2*108.432000tt c h h ∆=∆+=(2) 蒸汽在动叶的理想比焓降:**0.2*108.321.66b m t h h ∆=Ω==2.喷管的热力计算 ⑴喷管前后的蒸汽参数根据o p ,o x 2c h ∆以*n h ∆由h-s 图得喷管滞止压力*o p =0.037 滞止比焓*o h ∆=2540.3 滞止密度*0ρ=0.223/kg m 喷管前比焓0h =2500喷管后压力1p =0.017MP 理想密度 1t ρ=0.1253/kg m 理想比焓 1t h =2418 ⑵ 喷管截面积形状确实定等熵指数 k=1.035+0.1o x =1.129 临界压比 cr ε=k 121k k ⎛⎫ ⎪-⎝⎭⎛⎫⎪+⎝⎭=0.566喷管前后压力比 n ε=0.016/0.035=0.457因为n ε≤0.457,所以汽流在喷管出口为超声速流动但是n ε>0.3~0.4故喷管应该是渐缩型超音速斜切局部到达超音速。

汽轮机课程设计汽轮机参数:容量:25MW蒸汽初参数:压力:3.43Mpa 温度:435℃排汽参数:冷却水温20℃背压:0.005~0.006Mpa (取0.005 Mpa)前轴封漏汽与轴封加热器耗汽量为0.007D○,轴封加热器焓升21KJ/Kg加热器效率ηjr=0.98设计功率:Pr=25MW最大功率P=25*(0.2~0.3)1.近拟热力过程图在焓熵图上选取进口参数P0=3.43MP a,t0=435℃,可得h0=3304kJ/Kg.设进汽机构的节流损失△P0=0.04P0,可得调节级压力=3.3MP a,并确定调节级前蒸汽状态点1(3.3MP a,435℃)过1点作等比熵线向下交P Z线于2点,查得h2t=2128KJ/Kg,整机理想比焓降(△h t mac)’=h0-h2t=3304-2128=1176 KJ/Kg.选取汽轮机的内效率η=0.85,有效比焓降△h i mac=(△h t mac)’*ηri=999.6KJ/Kg,排气比焓和h z=2304kj/kg.在焓熵图上得排汽点Z,用直线连接1,Z,去两点的中点沿等压线下移21-25Kj/Kg,用光滑曲线连接1,3两点,得热力过程曲线的近似曲线见图1,图1选取给水温度T=160℃回热级数:5内效率η=0.85主汽门和调节阀中节流损失△P0=(0.03~0.05)PO排汽管中压力损失△P C=(0.02~0.06)P C回热抽汽管中的压力损失△P E=(0.04~0.08)P E2.汽轮机进汽量D○ηm=0.99 ηg=0.97 m=1.15 △D=0.03D OD0=/ h i macηmηg*m+△D=3.6*20000*1.15/(93*0.99*0.97) +0.03△D=107.19 t/h2.抽汽压力确定采用大气式除氧器压力为0.118 MP A饱和温度为104.3℃轴封加热器1# 2# 3# 4#加热器号抽汽压力Pe抽汽比焓he抽汽管压损加热器工作压力Pe’饱和水温度te’饱和水比焓he’出口端差给水出口温度tw2给水出口比焓hw2H1 0.9296 3024 8 0.8552 172.5 730.17 7 165.5 697.4 H2 0.48 2888 8 0.4416 147 619.27 7 140 592.4 Hd 0.1917 2764 8 0.1764 115.8 437.77 0 115.8 486.7 H3 0.09553 2644 8 0.08789 95.9 402.2 5 92.9 381.5 H4 0.03643 2492 8 0.03354 71.9 300.9 5 66.7 276.2CY3. 回热抽汽流量的计算(1) H1高加给水量 △D e =0.5 △D L1=0.77 △D C =1 Dfw=D 0-△D C +△D L1+△D ej=107.19-1+0.77+0.5=107.46 t/h抽汽量△D e1(h e1-h e1’) ηjr = D fw (h W2-h w1)21'11()107.46(697.4592.04)5.01()0.98(3024730.17)fw w w el jr e e D h h D h h η--∆===--(t/h )(2)H2高加 抽汽量 21'2'22()107.46*105.2855.07()0.98(2888619.27)fw w w e e e jrD h h D h h η-∆===-- (t/h )H1疏水流入H2放热 ''1211'22760.17619.275.01*0.2452888619.27e e e ee e e h h D D h h --∆=∆==-- (t/h) 考虑前轴封漏汽'211'223098619.270.77*0.842888619.2l e l e l e e h h D D h h --∆=∆==-- (t/h) '221 5.070.2450.84 3.985e e ele l e D D D D ∆=∆-∆-∆=--= (t/h) (3) H d 除氧器''12121()ed ed e e l e cw w fw ed D h D D D h D h D h ∆+∆+∆+∆+=112cw l e ed e fw D D D D D D +∆+∆+∆+∆=2.35(/)ed D t h ∆= 94.8(/)cw D t h =(4)H3低加213'33105.4695.65* 4.54(/)()(2644402.2)*0.98w w e cw e e jr h h D D t h h h η-∆===--(5)H4低加'214'44''3433'44'443105.4695.65* 4.64(/)()(2492300.9)0.98402.2300.94.59*0.22(/)2492300.94.640.22 4.42(/)w w e cw e e jr e e e ee e e e e e e h h D D t h h h h h D D t h h h D D D t h η-∆===----∆=∆==--∆=∆-∆=-=回热系统的校验1234123450e e ed e e D D D D D D ααααα∆+∆+∆+∆+∆++++=5.01 3.985 2.35 4.54 4.420.19342107.19++++==341094.8 4.54 4.420.8009107.19cw e e l n D D D D D α-∆-∆+∆--===1100.011nii α=-=<∑4. 流经各级组蒸汽量及其内功率调节级 0109.19(/)D t h =0010()6133.653.6i D h h P KW -==第一级组 10107.191106.19(/)l D D D t h =-∆=-=111130983024106.1921793.6 3.6e i h h P D kw --=== 第二级组211106.19 5.01101.18(/)e D D D t h =-∆=-=230242888101.1838223.6i P kw -==第三级组32297.175(/)e D D D t h =-∆=32888276497.193347.93.6i P kw -==第四级组 4397.195 2.3594.85(/)ed D D D t h =-∆=-=42764264494.84831603.6i P kw -==第五级组 54394.875 4.4090.335(/)e D D D t h =-∆=-=52644349290.3353813.53.6i P kw -==第六级组 65490.335 4.4285.95(/)e D D D t h =-∆=-=62492230486.534485.883.6i P kw -==整机内功率606134217938223347316038144485i ij j P P ===++++++∑26941kw =5. 计算汽机装置的热经济性机械损失: (1)22189.1(10.99)269m i m P P kw η=-=-= 汽机轴端功率: 22189.122226671n i m P P P kw =-=-= 发电机功率: 26671*0.9725870e n g P P kw η=== 内功率大于25000KW,合格 汽耗率: 0(.)10001071904.13()2130825870.78kg kw h e D d P === 不抽汽估计汽耗率:'0(.)0010001071903.74()()107.19*999.62700.973.63.6kg kw h z m g D d D h h P η===-⎡⎤⎡⎤--⎢⎥⎢⎥⎣⎦⎣⎦汽轮机装置的热耗率(.)0() 4.13*(3304697.3)10765.67()kg kw h fw q d h h =-=-=绝对电效率 3600360033.44%10765.67el q η===6. 双列速度级的热力计算(1) 速度级的选择选择双列速度级(195-250KJ/Kg )选择焓降为250kj/kg.故速度级的参数为:0107.19(/)D t h = 0 3.43()P MPa = 0435t =℃ 250(/)t h kJ kg ∆= 0.25a X =1. 喷嘴热力计算 (1) 喷嘴理想焓降'(1)250*0.85212.5(/)n t b gb b h h kj kg ∆=∆-Ω-Ω-Ω==(2) 喷嘴进口状态参数0 3.3P MPa = 03304/h kj kg = 00435t C = 3010.53/kg m ρ=(3) 喷嘴出口状态参数由△h n 可以从H-S 图上查得:1 1.4p MPa = 31 6.25/t kg m ρ= 13091/t h kj kg =(4) 喷嘴形状的确定前后压比: 10 1.40.420.5463..3n cr p p εε===<= 选用渐缩型喷嘴. (5) 喷嘴出口速度理想速度:1651.9(/)t c m s === 速度系数0.97ϕ=实际速度: 110.97*627.69632.36(/)t c c m s ϕ=== 喷嘴出口汽流偏转角1δ 喷嘴出口汽流方向角115o α=111sin()sin αδα+=0sin150.2716256=10.76o δ=(6) 轮周速度u10.25*632.36158.09(/)a u X c m s ===(7) 速度级的平均直径d m6060*158.091.0069()3.14*3000m u d m nπ=== (8)喷嘴出口面积A n277.51n A cm ===(9) 喷嘴出口高度l n177.51 1.6sin 0.6*3.14*100.69*sin15n n om A l cm e d πα=== 选取部分进汽度e=0.6则叶高l n =16mm>15mm(10) 喷嘴损失n h ζ∆22(1)(10.99)*250*0.8512.56(/)n n h h kj kg ζϕ=-=-=2. 第一列动叶热力计算 (1) 动叶进口汽流的相对速度(2) 根据C 1,U 1作速度三角形,由余弦定理可得:1w =482.03(/)m s ==1111111sin()608.86sin15.13sin sin463.62oc w αδβ--+==20.87o =(3) 动叶出口汽流相对速度因为0b Ω= 则21482.03(/)t w w m s == 查图, 0.878b ϕ=220.878*482.03423.22(/)b t w w m s ϕ===复速级动叶出口汽流角21(35)o oββ=--取0220.87317.87o o β=-= (4) 动叶绝对速度2c =275.93(/)m s ==112222cos 423.22cos17sin sin 275.93ow c βα--==26.24o =(5) 动叶进口状态参数喷嘴出口实际状态点参数动叶比焓 113091.512.563104/t n h h h kj kg ζ=+∆=+= 由H-S 图查得动叶进口密度31 6.25/kg m ρ= (5)动叶进口高度 (△r △t 由表1-1查得)'1b n n l l l r t =+∆=+∆+∆15.80.5 1.517.8mm =++=(6)动叶出口面积1071903360022106.27()0.93*482.03*6.25b b b t t G A cm w μρ===(b μ 由图1-11查得)(7)动叶出口高度 12106.2718sin 0.6*3.14*100.6sin17.87b b om A l mm e d πβ=== '1118.5180.5b b l mm -=-=(8)动叶损失22222482.03(1)(10.878)26.6/22000tb w h kj kg ϕϕ∆=-=-= (9)动叶出口汽流状态参数动叶出口比焓 21310426.63130.6(/)b h h h kj kg ϕ=+∆=+=查H-S 图得:出口密度32 6.28/kg m ρ=因为0bΩ=则12p p =3. 导叶热力计算(1) 导叶中汽流的理想比焓降0.05*25012.5(/)gb gb t h h kj kg ∆=Ω∆==(2)导叶出口汽流理想状态参数由导叶进口状态( 第一列动叶出口状态)参数和△h gb 从H-S 图查得导叶出口压力 '1 1.6p MPa =导叶出口比焓 '123118/t gb h h h kj kg =-∆=导叶出口密度'31 6.18/kg m ρ=(3)导叶出口汽流理想速度'1318.02(/)t c m s ===导叶出口实际速度''110.918*318.02291.94(/)gb t c c m s ϕ===(gb ϕ由图1-18查取) 导叶出口汽流角'12(510)26.64 5.6421o o o o o αα=--=-=(4)导叶进口高度'18.2220.2gb b b l l l r t mm =+∆=+∆+∆=+=(6) 导叶顶部漏汽量'1()gbt t gb gb t G e d e μπδ∆=+gb m d d ≈ 'gb gb l l ≈0.6*0.6*3.14(1.00690.021)*100.45(/)gbt G kg s -∆=+=(7) 导叶出口面积10719023600''10.45159.00.938*318.02*6.18gbgb gb t G A cmc μρ-===(8) 导叶出口高度'1158.4423sin 0.6*3.14*100.69*sin 21gbgb om A l mm e d πα==='2320.8 2.8gbgb l l mm -=-=(9) 导叶损失'2221318.02(1)(10.918)7.93/22000t gb c h kj kg ϕ∆=-=-=(10) 导叶出口汽流实际状态参数导叶出口焓 ''1131187.933125.93/t gb h h h kj kg =+∆=+= 由H-S 图查得导叶出口密度 '31 6.26/kg m ρ= 4. 第二列动叶热力计算 (1) 动叶中汽流的理想比焓降''0.1*25025/b b n h h kj kg ∆=Ω∆==(2) 动叶出口汽流理想状态参数'''213125.93253100.93/t b h h h kj kg =-∆=-= 由H-S 图查得动叶出口压力 '2 1.5p MPa =动叶出口密度'32 5.56/t kg m ρ=(3) 动叶进口相对速度'1w ==155(/)m s ='''1111'1sin 291.9sin 21sin 42.5155o oc w αβ-=== (4) 动叶出口汽流相对速度 相对理想速度:'2272.07/t w m s === 相对实际速度:'''220.928*272.07252.48(/)b t w w m s ϕ===('b ϕ由图1-18查得) 动叶出口汽流相对速度角''21(78)42.514.528o o o o o ββ=--=-=(5) 动叶出口汽流绝对速度'2c ==135.10(/)m s ='''11222'2sin 252.48sin 28sin sin 61.3135.10oo w c βα--=== (6) 动叶损失'22'222207.07(1)(10.928) 5.13/22000t b w h kj kg ζϕ∆=-=-=(7) 余速损失'22'22135.109.1/22000c c h kj kg ∆===(8) 动叶出口汽流实际状态参数动叶出口实际比焓 '''223100.93 5.13/t b h h h kj kg ζ=+=+(9) 动叶进口高度'''223225b gb gb l l l t r mm =+∆=+∆+∆=+=(10) 动叶顶部漏汽量''''12()bt b b t G e d l μπδ∆=+由于'b m d d =,'22b b l l =根部反动度''''' 1.00691(1)1(10.1)0.0791.0070.025b brmb b d d l Ω=--Ω=--=--顶部反动度''''' 1.0070.0251(1)1(10.077)0.121.0070.025b b btr b b d l d l --Ω=--Ω=--=++'0.6*0.6*3.14(1.0070.025)*10bt G -∆=+0.78/kg s =(11) 动叶出口面积''107190'23600''''''2222 1.051800.943*272.07*5.56b bt b b t t b t t G G G A cm w w μρμρ-∆-====('b μ由图1-11查得) (12) 动叶出口高度'2'218029sin 0.6*3.14*100.7sin 28b b om A l mm e d πβ=== '2225.1250.1b b l l mm -=-=5. 轮周功校核1KG 蒸汽所做的轮周功1''''1111112222cos()cos cos cos 158.09632.36cos15.76275.93cos 26.64291.94cos 21135.10cos 61.3188.18/u o o o oP u c c c c kj kgαδααα⎡⎤=++++⎣⎦⎡⎤=+++⎣⎦=2''12()u t n b gb b c P h h h h h h ζζζζ=∆-∆+∆+∆+∆+∆250(12.5626.67.93 5.139.6)188.54/kj kg=-++++=2111210.3%1%u u uP PP η-∆==<计算符合要求 6. 轮周效率'20()t n b gb b c u u th h h h h h h E h ζζζζη∆-∆+∆+∆+∆+∆∆==∆250(12.5626.67.93 5.139.6)75.27%250-++++==7. 级内损失的计算 (1) 叶轮摩擦损失'3212()1002f u p k dρρ+∆=32158.09 6.25 6.181.2()1.00729.881002kw +==136003600*29.881.0035/107190ff p h kj kg D ∆∆===(2) 叶高损失'''1122()/7n gb gb b b b b l l l l l l l l =++++++(1620.22317.8182525.1)/720.72()mm =++++++= 2*188.1818.164(/)20.72l u a h h kj kg l ∆=∆==(3) 部分进汽损失鼓风损失31(1)2c w e a e B e X e ξ=--310.40.55*(10.6)*0.250.0028640.62=--= 0.002864*2500.7161(/)w w u h h kj kg ξ∆=∆==斥汽损失20.016**0.250.6*1.007n s ea n z c X ed ξ==0.0135=00.0135*250 3.375/s s h E kj kg ξ∆===1.2 3.75 4.95(/)e w s h h h kj kg ∆=∆+∆=+=(4) 导叶及动叶顶部漏汽损失''gbt btt u G G h hG∆+∆∆=10719036000.450.78(118.1815) 4.26(/)kj kg +=-=8. 级的内功率i i P G h =∆*''121071903600()*[250(12.5626.67.93 5.139.6 4.95 3.375 4.269.1)4957.4()t n b gb b c e c f t G h h h h h h h h h h kw ζζζζ=∆-∆-∆-∆-∆-∆-∆-∆-∆-∆=-++++++++=9. 级的内效率0154.361.72%250i i h E η∆===7. 压力级的确定及焓降的分配 1. 第一压力级的平均直径1md == =1.11m2. 凝汽式汽轮机末级直径的估算1660z md mm===4θ=3. 平均理想焓降的计算 各级组的直径及反动度各级的理想焓降估算**0020,x ,0.037c n P h h P ∆∆=根据和由焓熵图可得22 1.1512.337()87.73/0.431t h kj kg ∆== 23 1.2512.337()99.01/0.441t h kj kg ∆==24 1.3512.337()88/0.441t h kj kg ∆== 25 1.3512.337()128.07/0.456t h kj kg ∆== 26 1.6612.337()135.84/0.50t h kj kg ∆==级的平均理想焓降123456()110.01/6t t t t t t h h h h h h h kj kg∆+∆+∆+∆+∆+∆∆==级数目的确定(1176250)(10.05)(1)/10110.1p t t Z h h α-+=∆+∆=≈比焓降分配辅助表格8. 回热系统抽汽压力的重新确定(1) H1高加 给水量Dfw=D 0-△D C +△D L1+△D ej=107.19-0.75+0.58+0.5 =107.52 t/h抽汽量△D e1(h e1-h e1’) ηjr = Dfw(h W2-h w1)21'11()107.52(723622.83)4.7()0.98(3074740)fw w w el jr e e D h h D h h η--∆===--(t/h )(2) H2高加21'2'22()107.52(622.38531)4.45(/)()0.98(2904649.6)fw w w e e e jrD h h D t h h h η--∆===--''1211'22749649.64.73*0.212904649.6e e e ee e e h h D D h h --∆=∆==--(t/h) '211'223098.1649.40.580*0.632094649.6l e l e l e e h h D D h h --∆=∆==-- (t/h) '221 4.450.210.63 3.61 (t/h)e e ele l e D D D D ∆=∆-∆-∆=--=(3) H d 除氧器''12121()ed ed e e l e cw w fw edD h D D D h D h D h ∆+∆+∆+∆+=112cw l e ed e fwD D D D D D +∆+∆+∆+∆=2(/)ed D t h ∆= 96.6(/)cw D t h =(4) H3低加213'33372256.0996* 5.13(/)()(2608393.78)*0.98w w e cwe e jr h h D D t h h h η--∆===-- (5) H4低加'214'44''3433'44'443256.09171.1796* 3.29(/)()(2470280.8)0.98393.78276.753.29*0.27(/)2500276.753.290.27 3.02(/)w w e cw e e jr e e e ee e e e e e e h h D D t h h h h h D D t h h h D D D t h η--∆===----∆=∆==--∆=∆-∆=-=回热系统的校验1234123450e e ed e e D D D D D D ααααα∆+∆+∆+∆+∆++++=4.73 3.6125.13 3.0216.04107.19++++==3410.8332cw e e l n D D D D D α-∆-∆+∆==110.00240.011nii α=-=<∑流经各级组流量及其内功率 调节级 0107.19(/)D t h =0010()58963.6i D h h PKW -== 第一级组 10107.190.75106.44(/)l D D D t h =-∆=-=111131463074106.442128.83.6 3.6e i h h P D kw --===第二级组 211106.44 4.73101.73(/)e D D D t h =-∆=-=230742904101.7148033.6i P kw -==第三级组 32298.11(/)e D D D t h =-∆=32904274898.114251.43.6i P kw -==第四级组 4398.11296.11(/)ed D D D t h =-∆=-=42748260896.1137383.6i P kw -==第五级组 54396.11 5.1390.98(/)e D D D t h =-∆=-=52608250090.982729.43.6i P kw -==第六级组 65490.98 3.0287.96(/)e D D D t h =-∆=-=62500230487.964788.93.6i P kw -==整机内功率6049442847.73065.33241.42766.52224.53126i ij j P P ===++++++∑28334kw =装置热经济性机械损失 (1)28334(10.99)283m i m P P kw η∆=-=-= 汽机轴端损失 2833428328051n i m P P P kw =-∆=-= 发电机功率 28051*0.9727209.79e n g P P kw η=== 汽耗率 0(.)10001071903.93()279209kg kw h e D d P ===不抽汽估计汽耗率 '0(.)0010001071903.28()()107.19*11762830.973.63.6kg kw h z m g D d D h h P η===-⎡⎤⎡⎤--∆⎢⎥⎢⎥⎣⎦⎣⎦汽机装置热耗率(.)0() 4.26*(3304723)10995()kg kw h fw q d h h =-=-=绝对电效率3600360032.7%10995el q η===9.压力级第九级第十级的详细热力计算演示 1.级内的比焓降分配 (1)焓降t h ∆= 104kj/kg初焓 0h =2500 初压 0p =0.037MP 初速 092.45/c m s = 反动度 0.2m Ω=等熵滞止焓降 2*108.432000tt c h h ∆=∆+=(2) 蒸汽在动叶的理想比焓降:**0.2*108.321.66b m t h h ∆=Ω==2.喷管的热力计算 ⑴ 喷管前后的蒸汽参数根据o p ,o x 2c h ∆以*n h ∆由h-s 图得喷管滞止压力*o p =0.037 滞止比焓*o h ∆=2540.3滞止密度*0ρ=0.223/kg m 喷管前比焓0h =2500喷管后压力1p =0.017MP 理想密度 1t ρ=0.1253/kg m理想比焓 1t h =2418⑵ 喷管截面积形状的确定 等熵指数 k=1.035+0.1o x =1.129 临界压比 cr ε=k 121k k ⎛⎫ ⎪-⎝⎭⎛⎫⎪+⎝⎭=0.566喷管前后压力比 n ε=0.016/0.035=0.457因为n ε≤0.457,所以汽流在喷管出口为超声速流动但是n ε>0.3~0.4 故喷管应该是渐缩型超音速斜切部分达到超音速。

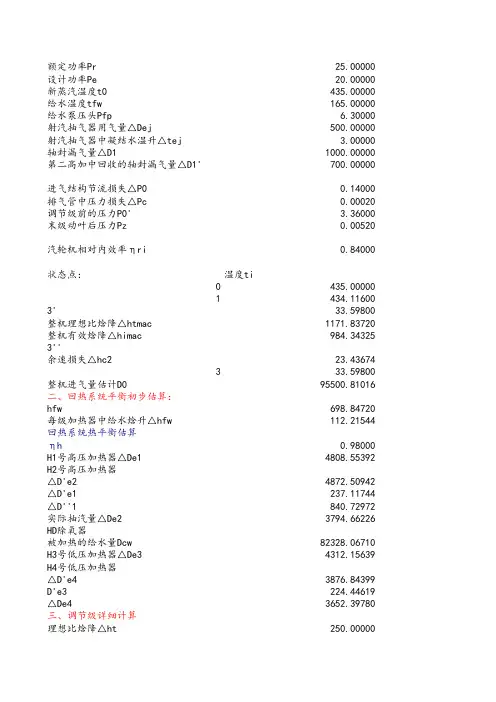

(一)汽轮机热平衡估算基本数据:额定功率Pr=10000kW,设计功率Pe=10000kW,新汽压力p0=4.9MPa,新汽温度t0=435℃,排汽压力pc=0.008MPa。

1、近似热力过程曲线的拟定在h-s图上,由p0、t0可确定汽轮机进汽状态点0并查得初比焓h0=3282.845226J/kg。

设进汽机构的节流损失△p0=0.05p0,得调节级前压力Po′=0.95p0=4.875MPa,并确定调节级前蒸汽状态点1。

设排汽损失为0.02Pc,则排汽压力pc′=0.00816MPa。

过1点作等比熵线向下交pc′线于2点,查得h3′=2121.36644kJ/kg,整机的理想比焓降(Δhtmac)′=h0-h3′=3282.845226-2121.3664=1161.478786kJ/kg。

估计汽轮机相对内效率ηri=83%,有效比焓降Δhtmac=(Δhtmac)′×ηri =1161.478786×0.83=964.0273927kJ/kg,排汽比焓hz=2121.66443kJ/kg,光滑连接1、4点,得该机设计工况下的近似热力过程曲线,见图1。

图1 近似热力过程曲线(二)设计工况下的热力计算确定机组配汽方式采用喷嘴配汽2.调节级选型采用单列级3.主要参数⑴已知设计参数Po=4.9Mpa ,to=435℃, Pc=0.008Mpa, Pe=10000KW ,n=3000rpm⑵选取设计参数①设计功率设计功率Pe=10000kW②汽轮机相对内效率ηri选取某一ηri 值,待各级详细计算后与所得ηri′进行比较,直到符合要求为止。

这里取ηri=86%③机械效率:取ηm= 98%④发电效率:取ηg= 95%4.近似热力过程线的拟定(1)进汽机构的节流损失Δpo;阀门全开时,ΔPo=(0.03~0.05)Po,取调节级喷嘴前Po′=0.95Po(2)排汽管中压力损失ΔPc :对于本机,认为Pc′=0.98Pc,即ΔPc=0.02Pc 5.汽轮机总进汽量的初步估算3.6*P elDo= —————————————*m+ΔD= 46.4443117t / h(Δht mac)′*ηriηgηmPel ——汽轮机的设计功率,kW(Δht mac)′——汽轮机通流部分的理想比焓降。

汽轮机课程设计计算表格名称符号单位初步参数新蒸汽压力p0Mpa t0℃t0kW 设计功率pe kW 排气压力pb Mpa 汽轮机转速n r/min 经济功率Pc kW相对内效率ηri 机械效率ηm 发电机效率ηg新蒸汽新蒸汽压力p0Mpa t0℃t0K新蒸汽比熵s0kJ/kg/℃新蒸汽比体积v0m^3/kg 新蒸汽焓h0kJ/kg 气阀节流压力损失△p0Mpa 调节级前压力p0'Mpa t0'℃t0'K调节级前比熵s0'kJ/kg/℃调节级前比体积v0'm^3/kg气缸出口状态排气压力pb'MPa 气缸理想出口比焓hct kJ/kg tct ℃tct K气缸理想出口比体积Vct m^3/kg 气缸理想出口干度Xct 汽轮机理想比焓降△htmac kJ/kg 汽轮机实际比焓降△himac kJ/kg 气缸实际出口比焓hc2kJ/kg tc2℃tc2K气缸实际出口比体积Vc2m^3/kg干度Xct考虑末级余速损失末级余速损失系数末级余速损失δhc2kJ/kg 考虑末级余速损失的汽轮机实际比焓降hc3kJ/kg新蒸汽温度新蒸汽温度调节级前温度气缸理想出口温度气缸实际出口温度考虑末级余速损失的气缸实际出口比体积Vc3m^3/kgtc3℃考虑末级余速损失的气缸实际出口温度tc3K汽轮机总进气量的初步估算考虑回热抽泣引起气量增大的系数m考虑前轴封漏气和门杆漏气的蒸汽余量△D t/h前轴封漏气量△D l t/h门杆漏气量△Dv t/h汽轮机总进气量D0t/hD0kg/s公式数值D0=3.6*pe/△htmac/ηri/ηg/ηm*m+△D备注机组型号:蒸汽初参数 :排汽压力:经济功率:汽轮机转速:自取背压式汽轮机取1自取,约等于D0*0.03自取?△Dl+△Dv=△D 自取?△Dl+△Dv=△D。