tesa 胶带基础知识

- 格式:ppt

- 大小:1.69 MB

- 文档页数:15

tesa双面胶粘接力的测试方法tesa 测试方法tesa 标准测试方法tesa 标准测试方法总览1. 180o剥离力测试2. 90o剥离力测试3. 静态剪切力4. 初粘力—初粘力—滚球测试方法5. 耐温测试6. 抗增塑剂测试7. 雾化测试3–3 4–4 5–5 6–6 7–7 8–8 9–9tesa Test Method - Standard Test Method/2011033021. 180o剥离力测试剥离力是指将一条附有加强膜的胶带从标准测试板上以指定速度剥离所需要的力。

标准测试条件粘接时间:立即或14天温度和湿度:23 ± 1°C, 50 ± 5 % rel. hum. 滚压:加强膜: 4 kg; 5 runs; 10 m/min 乙烯膜(40 μm)胶带样品宽度:2 cm 剥离速度:测试单位:300 mm/min N/cm测试方法依据: JOPMA00232. 90o剥离力测试剥离力是指将一条附有加强膜的胶带从标准测试板上以指定速度剥离所需要的力。

标准测试条件粘接时间:立即或14天温度和湿度:23 ± 1°C, 50 ± 5 % rel. hum. 滚压:加强膜: 4 kg; 5 runs; 10 m/min 乙烯膜(40 μm)胶带样品宽度:2 cm 剥离速度:测试单位:300 mm/min N/cm测试方法依据:JOPMA00243. 静态剪切力静态剪切力是指以平行于胶带粘接面方向将胶带与被粘物分开所需的力。

标准测试条件粘接面积:13 mm x 20 mm = 260 mm2 滚压:负重: 4 kg; 5 runs; 10 m/min 0.5/1/2 kg温度及湿度:? 23 ± 1°C, 50 ± 5 % rel. hum. ? 低温 (如,5°C) ? 高温 (如,40/70°C) 加强膜:铝箔(50 μm)测试单位:min测试方法依据:JOPME00254. 初粘力 - 滚球测试初粘力是指胶对另外一种材料表面在没有压力的条件下,短暂接触后形成粘结的一种能力。

遮蔽系列-纸基材tesa4304 tesa4309 tesa4314 tesa4315 tesa4316 tesa4317 tesa4322 tesa4330 tesa4331 tesa4432tesa4438 tesa4349 tesa51300tesa51432tesa53123tesa53131tesa4104tesa4164 tesa4169 tesa4174tesa4244tesa50501tesa50530tesa50550tesa50589tesa51108tesa62993tesa51408tesa46 13 tesa4651tesa4653 tesa4657 tesa4660 tesa4661遮蔽胶带-泡棉基材tesa476系列 tesa477系列 tesa5195系列 tesa600系列 tesa602系列tesa604系列 tesa6110系列tesa6111系列 tesa749系列遮蔽胶带-PVC基材tesa4963 tesa4968 tesa4970 tesa4917 tesa51960 tesa51970 tesa51990 tesa4971 tesa4985tesa4900 tesa68105tesa4952 tesa4967 tesa4977 tesa4978双面胶带系列tesa4940 tesa4959 tesa4962 tesa60975 tesa60980 tesa4928 tesa4965tesa4967 tesa4982tesa4983 tesa4964 tesa4987 tesa4989无纺布胶带tesa68623 tesa68634 tesa68645 tesa68646其它PVC和SPVC系列tesa4172 tesa4252 tesa4253 tesa4840包装胶带tesa4224 tesa4287 tesa4288 tesa4289 tesa64007 tesa64284 tesa4574tesa4579 tesa53314撕口胶带系列tesa4235 tesa4236 tesa51235 tesa51236 tesa7496拼接系列-磁带拼接tesa4231 tesa4232 tesa52450拼接系列-瓦楞纸箱拼接tesa4962 tesa7158 tesa50607柔印贴板胶带系列-薄膜基材tesa52307 tesa52310 tesa52315 tesa52320 tesa52325 tesa52330 tesa52332 tesa52338tesa52345 tesa52350其它贴面胶带、封面胶带、辊轮防滑胶带tesa4204 tesa4206 tesa4563 tesa4863 tesa51108 tesa52916柔印贴板胶带系列-泡棉基材tesa52015 tesa52016 tesa52017 tesa52020 tesa52021 tesa52060 tesa52380 tesa52382tesa52502 tesa52506tesa常用型号系列tesa50503 tesa50504 tesa50525 tesa50575 tesa51150 tesa51467 tesa51445 tesa51446tesa51913 tesa51914 tesa51006 tesa51608 tesa51616 tesa51618 tesa51965 tesa51967tesa51968 tesa51972 tesa51980 tesa51982 tesa5456 tesa54994 tesa60943 tesa60976tesa4128 tesa4215 tesa4334 tesa4359 tesa4378 tesa4428 tesa4576 tesa4688 tesa64250 tesa8401 tesa8402 tesa4204 tesa4204 tesa4330 tesa4252 tesa4863德国著名胶带品牌,产品销往100多个国家和地区,被广泛应用于汽车、电子、电气、智能卡、造纸、印刷、包装、装饰等诸多行业。

Tesa7475剥离力标准范围剥离力标准是在工业生产和质量控制中非常重要的一项指标,特别是对于胶带和粘性制品来说。

Tesa7475剥离力标准范围提供了一系列的指标来评估这种胶带的剥离力能力,以确保其在不同应用场景下的性能表现。

1. 引言Tesa7475胶带是一种广泛应用于工业生产中的高性能胶带,具有优异的剥离力能力。

为了确保其质量和性能的可靠性,制定了一系列的剥离力标准范围来对其进行测试和评估。

2. Tesa7475剥离力测试方法Tesa7475剥离力测试方法基于国际通用的标准测试程序,主要包括以下几个方面:•基底材料的选择:根据使用场景和需求,选择适当的基底材料,如不锈钢片或特定的塑料板,以确保测试的准确性和可靠性。

•测试样本的制备:将Tesa7475胶带贴合在基底材料上,确保其与基底材料之间的接触良好,并消除气泡和杂质。

•测试设备的选择:使用专业的剥离力测试设备,例如万能试验机(Universal Testing Machine),以保证测试的准确性和可重复性。

•剥离力测试过程:在一定的速度下,以一定的角度和力量剥离Tesa7475胶带,记录产生的剥离力数值。

3. Tesa7475剥离力标准范围根据测试结果和相关要求,制定了Tesa7475剥离力标准范围。

这些标准范围通常包括以下几个方面的指标:•平均剥离力值:根据多次测试的结果,计算出Tesa7475胶带的平均剥离力值。

这个值反映了胶带在剥离过程中需要施加的平均力量。

•最小剥离力值:通过多次测试,确定Tesa7475胶带的最小剥离力值。

这个值用于加工过程中的设计和可靠性验证,确保胶带在正常使用条件下不会意外剥离。

•剥离力的一致性:通过对多个样本进行测试,评估Tesa7475胶带的剥离力的一致性。

这个指标表明了胶带的产品稳定性和可靠性。

•耐温性能:对不同温度下的剥离力值进行测试,评估Tesa7475胶带在不同工作温度下的剥离性能。

这个指标对于特殊环境下的应用非常重要。

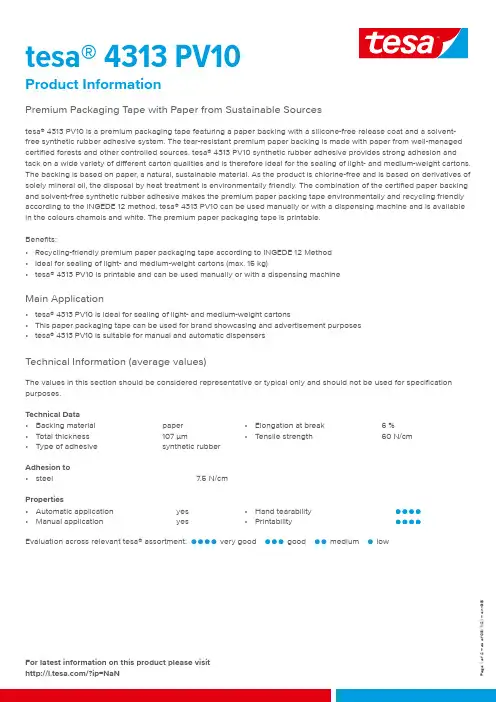

Product InformationPremium Packaging Tape with Paper from Sustainable Sourcestesa® 4313 PV10 is a premium packaging tape featuring a paper backing with a silicone-free release coat and a solvent-free synthetic rubber adhesive system. The tear-resistant premium paper backing is made with paper from well-managed certified forests and other controlled sources. tesa® 4313 PV10 synthetic rubber adhesive provides strong adhesion and tack on a wide variety of different carton qualities and is therefore ideal for the sealing of light- and medium-weight cartons.The backing is based on paper, a natural, sustainable material. As the product is chlorine-free and is based on derivatives of solely mineral oil, the disposal by heat treatment is environmentally friendly. The combination of the certified paper backing and solvent-free synthetic rubber adhesive makes the premium paper packing tape environmentally and recycling friendly according to the INGEDE 12 method. tesa® 4313 PV10 can be used manually or with a dispensing machine and is available in the colours chamois and white. The premium paper packaging tape is printable.Benefits:•Recycling-friendly premium paper packaging tape according to INGEDE 12 Method •Ideal for sealing of light- and medium-weight cartons (max. 15 kg)•tesa® 4313 PV10 is printable and can be used manually or with a dispensing machineMain Application•tesa® 4313 PV10 is ideal for sealing of light- and medium-weight cartons•This paper packaging tape can be used for brand showcasing and advertisement purposes •tesa® 4313 PV10 is suitable for manual and automatic dispensersTechnical Information (average values)The values in this section should be considered representative or typical only and should not be used for specification purposes.Technical Data •Backing material paper •Total thickness 107 µm•Type of adhesive synthetic rubber•Elongation at break 6 %•Tensile strength 60 N/cmAdhesion to •steel7.5 N/cm Properties•Automatic application yes •Manual applicationyes•Hand tearability •PrintabilityEvaluation across relevant tesa® assortment:very goodgoodmedium lowP a g e 1 o f 2 – a s o f 05/11/21 – e n -G BFor latest information on this product please visit /?ip=NaNProduct InformationDisclaimertesa® products prove their impressive quality day in, day out in demanding conditions and are regularly subjected to strict controls. All information and recommendations are provided to the best of our knowledge on the basis of our practical experience. Nevertheless tesa SE can make no warranties, express or implied, including, but not limited to any implied warranty of merchantability or fitness for a particular purpose. Therefore, the user is responsible for determining whether the tesa® product is fit for a particular purpose and suitable for the user’s method of application. If you are in any doubt, our technical support staff will be glad to support you.P a g e 2 o f 2 – a s o f 05/11/21 – e n -G BFor latest information on this product please visit /?ip=NaN。