海尔洗衣机说明书

- 格式:pdf

- 大小:40.70 MB

- 文档页数:2

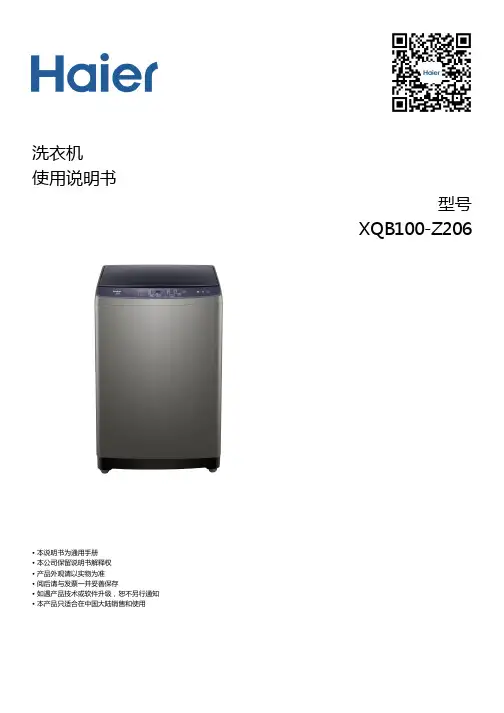

洗衣机使用说明书型号XQB100-Z206• 本说明书为通用手册• 本公司保留说明书解释权• 产品外观请以实物为准• 阅后请与发票一并妥善保存• 如遇产品技术或软件升级,恕不另行通知• 本产品只适合在中国大陆销售和使用1. 产品介绍1 1.1. 产品部件1 1.1.1. 部件介绍1 1.2. 技术规格21.2.1. 参数介绍22. 使用说明4 2.1. 安全注意事项4 2.1.1. 图示说明4 2.1.2. 警告类4 2.1.3. 注意类4 2.2. 洗衣机的安装5 2.2.1. 拆除包装5 2.2.2. 洗衣机的放置6 2.2.3. 洗衣机的调平6 2.2.4. 排水管7 2.2.5. 进水管8 2.3. 洗涤注意事项12 2.3.1. 不可洗涤衣物12 2.3.2. 检查衣物12 2.3.3. 衣物分类洗涤16 2.3.4. 重污衣物预处理17 2.3.5. 衣物放入方法19 2.3.6. 衣物洗涤重量参考20 2.4. 洗衣操作20 2.4.1. 洗衣步骤20 2.4.2. 操控界面21 2.4.3. 开机21 2.4.4. 程序22 2.4.5. 参数23 2.4.6. 洗涤剂投放28 2.5. 清洁保养28 2.5.1. 线屑过滤器28 2.5.2. 进水阀过滤网302.5.3. 箱体和内桶333. 售后服务35 3.1. 疑问解答35 3.1.1. 问题解答35 3.1.2. 显示代码及处理方法373.2. 有害物质37 3.2.1. 有害物质名称与含量37 3.3. 保修说明38 3.3.1. 洗衣机保修说明381. 产品介绍1.1. 产品部件1.1.1. 部件介绍本电子说明书使用的配图均为示意图,由于产品改进及系列化扩展,您所得到的产品外观、颜色及功能部件可能与此图片不一致,请以实际产品为准。

附件1.2. 技术规格1.2.1. 参数介绍技术数据注:本产品技术数据如有变更,恕不另行通知,请以产品实物为准。

窗帘

轻触“烘干”按键可设定是否

选择烘干功能,程序不同,

窗帘

超柔

超柔

6

781026

78206

7

8

10

2

功能可选择不同,有些程序不能选择烘干。

3

用户使用的洗涤程序。

和漂洗时进水量。

,无操作,12小时后脱水。

排水阀内掉入硬币、发卡等异物导致阀塞不封水而边进边排(清除异物)

70-HBX12266 SN

窗帘窗帘

由

下可打开机门;若水位高于观察窗下沿,

拉住拉环向下轻拉,听到轻微的响声后,可打开机门并添加衣物或取出衣物,之后将底部小门复位。

则需要打开洗衣机底部小门,将一个盛水容器放于流尽管处,拔掉管堵将水排出,待水位低于观察窗下沿可打开机门。

开机门时,需要向下拉动底部小盒内的拉杆,排水阀

75

异常报警

异常报警

是否过高(应小于5cm)

(放平排水管,清除异物)

超柔。

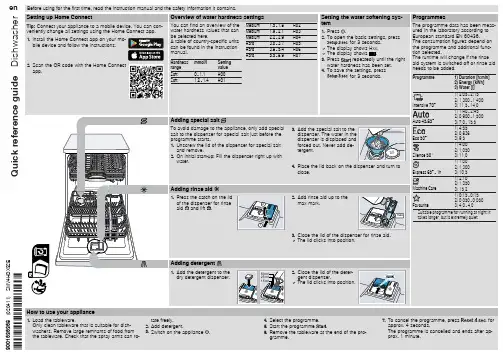

滚筒洗衣机滚筒洗衣干衣机使用说明书微信服务二维码目录快速入门使用说明服务指南控制面板介绍 ...........................................洗涤剂盒介绍............................................程序/功能介绍 ..........................................智能配网介绍 ...........................................清洁保养..................................................故障现象及处理方法...................................售后服务..................................................包修卡.....................................................快速入门..................................................安全警示安全警示 . (2)355101011131515执行标准:GB/T4288 GB4706.1 GB4706.24 GB4343.1 GB17625.1 GB19606 GB12021.4 GB4706.20安装说明详见包装纸箱内摇盖或扫描机身二维码查看电子说明书。

本说明书适应多个机型,对应机型详细内容请查阅所购机型电子说明书!快速入门安全警示使用说明服务指南快速入门注意:.在您使用本机器前,请确保机器已经按照安装说明正确安装好。

2.首次使用,建议您在没有衣物的情况下完成一次“筒自洁”或其他高温程序洗涤。

3.1如需加长排水管,联系售后服务热线。

二.开始洗衣三.洗衣结束注意:1.只有机器带预洗功能选择了该功能后洗涤剂盒中加入洗涤剂2,,才需要向预洗;.请使用随机附带的进水管部件,旧软管部件不可重复利用。

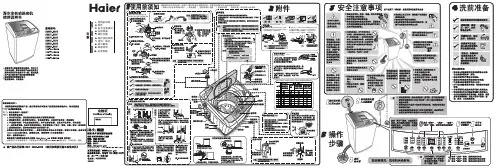

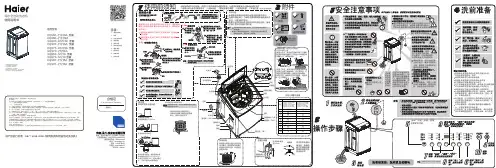

海尔全自动洗衣机使用说明书

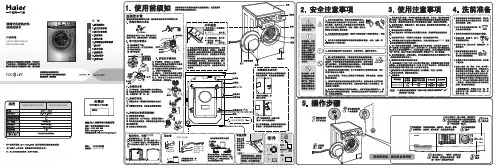

适用型号

XQS60-Z1236A 至爱XQS60-Z1226M

XQB60-KS1236 至爱XQB75-KS1236 至爱XQS70-Z1226A XQB60-S1218 至爱XQB70-S1218 至爱XQS70-Z1236A 至爱XQS60-Z1216A 至爱XQS70-Z1216A 至爱

此图示以XQS60-Z1236A 至爱为例

·使用前请仔细阅读本说明书·本公司保留说明书解释权·产品外观请以实物为准·阅后请与发票一并妥善保存

·如遇产品技术或软件升级,恕不另行通知·本产品只适合在中国大陆销售和使用

扫描二维码 智享科技魅力

版次:2014年 第1版专用号:0030509870G

厂家代码:V98497

地址:青岛市高科技工业园海尔工业园内在线报修地址:

售后服务热线:4006 999 999

网址:

该产品执行标准:GB/T 4288-2008《家用和类似用途电动洗衣机》

一、使用前须知

二、附件 三、安全注意事项

四、洗前准备

五、操作步骤

六、操作按钮说明 七、清洁/维护 八、疑问解答 目录:九、保修说明 十、技术数据 。

使用前请仔细阅读说明书请妥善保存,以备参阅

本产品只适合在中国大陆销售和使用

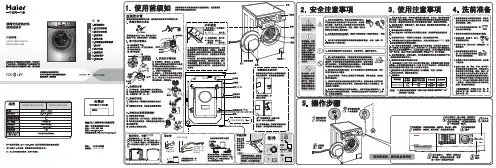

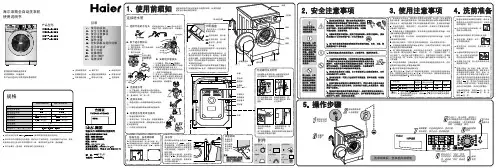

海尔滚筒全自动洗衣机使用说明书

● 该产品执行标准:GB/T 4288-2008 《家用和类似用途电动洗衣机》

● 本产品属于I 类电器,请您使用时注意用电安全!

规格

电源

额定洗涤容量额定脱水容量洗涤噪声脱水噪声外形尺寸(高×深能效等级甩干转速0020505574

2009年第1版● 本说明书中的图形均为示意图,同时由于产品的改进,您所得到的产品外观、颜色及其配件可能与本说明书中的图示不一致,请以实际产品为准,谨此致歉。

进水水压。

海尔洗衣机说明书篇一:海尔波轮全自动洗衣机操作使用说明海尔波轮全自动洗衣机操作使用说明一.洗前准备1. 确认衣物有无特殊洗涤要求,不易吸水的衣物请用手按入水中。

2. 清理衣袋,将硬币、砂子、发夹等物品取出3. 将长带打结、纽扣扣好、拉链拉好4. 洗涤物不应过量,投入前衣物展开抖松5. 洗衣机运转时,衣物的纽扣可能会发出声音,为慎重起见,将带有纽扣的衣物放在衣物当中二.洗涤剂的使用1. 洗衣粉a 模糊程序(标准)及预约洗涤时,建议将洗衣粉直接投入洗衣粉盒使用b 在洗衣机内直接融化(不适用于模糊程序(标准)及预约洗涤):注入少量水(选择最低水位)→放入洗衣粉,运转约30秒钟,使之充分溶化后按动“启动/暂停”→放入洗涤物,选择合适水位,再次按动“启动/暂停”c 准备约30℃的温水和容器→边搅拌边放入洗衣粉,使之充分溶化→将溶解液倒入洗衣机d洗衣粉用量参考洗衣粉说明,建议不要使用高泡洗衣粉2. 漂白剂注水至规定水位后,将漂白剂用容器稀释后,慢慢倒入液体洗涤剂注入口。

3. 液体洗涤剂将液体洗涤剂倒入液体洗涤剂注入口。

三.投放洗涤物一次洗涤以放入适量洗涤物,洗涤过程中洗涤物能正常翻转为宜。

1.0kg以下的布量不要选择高水位,以防水滴飞溅。

四.洗涤程序操作操作流程:电源/暂停→程序→水量→启动/暂停流程说明:1.按动“电源开/关”按钮,开启电源2.按动“程序”按钮,选择合适的全自动程序,默认为“大物”3.按动“水量”按钮:选择适合衣物洗涤的用水量,注意“快速”程序和“脱水”程序均无法选择水量。

4.按动“启动/暂停”按钮五.关闭上盖在脱水过程中,如打开上盖,洗衣机会停止运行并报警。

六.洗衣结束洗衣过程结束后,洗衣机蜂鸣报警,然后自动断电。

★注意事项:1. 不要洗涤雨衣、自行车罩等防水性衣物,以免异常振动或损坏衣物。

2. 不要将如何热的、重的物品、湿的衣物放在洗衣机上,尤其是程序操作面板上。

3. 不要使用50℃以上的热水洗衣物。

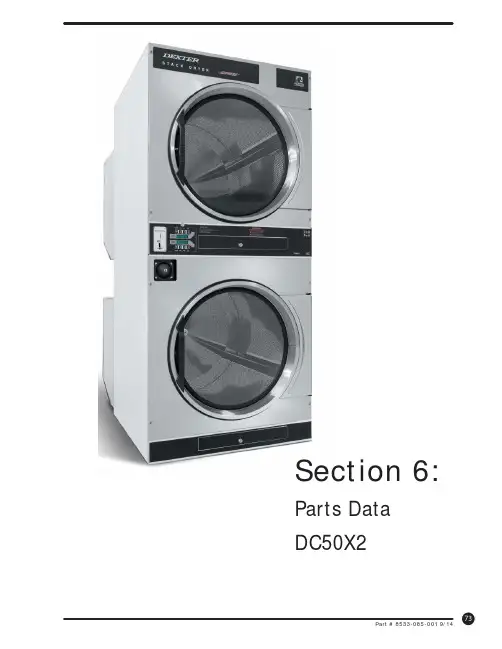

Section 6: Parts DataDC50X264310131211216547Cabinet GroupKey Part Number Description Quantity * 9960-285-008Door Assy., Loading Complete-Wht (2)* 9960-285-011Door Assy., Loading Complete-SS (2)* 9960-285-007Door Assy., Loading Complete-Chrome/BLK/SS (2)1 9960-284-002Door Assy., Loading-SS(ring only) (2)1 9960-284-004Door Assy., Loading-Chrome(ring only) (2)2 9982-353-002Plate Assy., Hinge (Wht) No Pin (2)2 9982-353-001Plate Assy., Hinge (SS) No Pin (2)* 9545-012-015Screw, Hinge to Door (8)* 8640-413-002Nut, Hinge to Door (8)3 9212-002-004Glass, Door (2)4 9206-413-002Gasket, Glass Black (2)* 9548-117-000Support, Door Glass (2)5 9206-420-005Gasket, Outer Rim Black (2)6 9244-082-001Handle, Loading Door (2)* 9545-018-017Screw, Handle 1/4-20 x 3/8 (4)* 9531-033-003Stud, Door Catch (2)* 8640-413-001Nut, Hex (2)* 8640-413-003Nut, Acorn (2)* 9086-015-002Catch, Loading Door (2)* 8638-190-009Pop Rivet for mtg. catch (4)* 8641-582-006Lockwasher (4)* 8640-399-001Spring Nut (6)7 9989-521-003Panel Assy., Front- Lower (Wht) (1)7 9989-521-001Panel Assy., Front- Lower (SS) (1)8 9989-517-003Panel Assy., Front- Upper (Wht) (1)8 9989-517-001Panel Assy., Front- Upper (SS) (1)* 9277-054-001Insulation Front Panel, half moon (top) (2)* 9277-054-002Insulation Front Panel, half moon (bottom) (2)9 9545-008-014Screw, FLHDCR, 10B x 1 (14) (6)* 8641-585-001 Lockwasher* 8640-399-001Nut, Spring (12)10 9544-069-002Strap, Hinge (Wht) (2)10 9544-069-005Strap, Hinge (SS/Black) (2)* 9545-012-028Screw, Hinge to Panel (8)11 9545-052-001Screw, Door to Hinge Strap (Special Black Type) (2)12 8641-436-003Washer, Fiber (2)13 9021-041-001Acceptor, Coin (1)* 9486-149-001Retainer, Coin Acceptor (2)14 9545-053-002Screw (4)* 9801-099-001Switch, Optical (1)Cabinet Group ContinuedKey Part Number Description Quantity15 9994-032-001Escutcheon, Upper (1)16 9435-039-002Trim, Overlay-Upper Blue (1)16 9435-039-001 Trim, Overlay-Upper Black (1)17 9994-033-001Escutcheon, Lower (1)18 9435-023-001Trim, Overlay-Lower Blue (1)18 9435-031-001Trim, Overlay-Lower Black (1)* 9545-020-009Screw (20)19 9412-167-002Nameplate Stack Dryer Express Blue (1)19 9412-167-001Nameplate Stack Dryer Express Black (1)20 9866-005-001Lint Drawer Assembly Blue (2)20 9866-005-004Lint Drawer Assembly Black (2)21 9435-024-001Overlay Trim, Lint Drwr-Blue (1)21 9435-032-001Overlay Trim, Lint Drwr-Black (1)* 9532-074-003Felt Seal ( back of lint screen assembly ) (2)* 9805-033-002Lint Screen Assembly ONLY (no front) (2)* 9555-057-008Replaceable Lint Screen Only (2)22 8650-012-004Lock and Key, Lint Drawer (2)* 6292-006-010Key 6101 only (2)* 9095-043-001Cam, Lock (2)* 9545-008-001Lint Screen Strap Hold Down Screws 10Bx 1/4 (32)23 9857-198-001Controls Assy, Blue (1)23 9857-198-003Controls Assy, Black (1)* 9627-869-001Harness, Electronic Control (1)24 8650-012-003Lock and Key, Control (1)* 9095-041-001Cam, Lock (1)* 6292-006-007Key only 6324 (1)* 9627-855-003Harness, Heat Sensor (1)* 8640-276-002Wire Nut Connector Grey (4)25 9501-004-003Sensor Temp Control (2)26 9501-008-001Bracket for Heat Sensor Mounting (Under Basket) w/ sensor..2* 9545-045-005Screw, Round Head (Mounts sensor; phillips head) (2)* 9209-037-002Gromm.et, 3/16 ID (2)* 8544-006-001Leg, Leveling 1/2” (4)* 9074-320-001 Cover, Cabinet (Top) (1)* 9277-041-017 Insulation Cabinet Cover (1)* 9732-276-001Kit for Dryers without Neutral and using 208-240 volt (1)* 9732-102-013LP Kit for 50Lb Stk Dryers (1)* 9732-243-001Stack Dryer Trunion Puller (1)* 9544-041-002 Strap - Bead Tie (1)27 9942-038-005 Vault, Coin Box (1)* 9545-008-024 Screws, Mounting-Coin Vault (2)28 9897-099-002 Coin Box Assy, Large Blue (1)28 9807-099-004 Coin Box Assy, Large Black (1)191526252792531089Control Parts GroupKey Part Number Description Quantity * 9857-198-001Controls Assy, Electronic Mounted With Membrane Switch, BLU (1)* 9857-198-003Controls Assy, Electronic Mounted With Membrane Switch, BLK (1)1 9826-008-001 Trough Assembly (1)2 9032-062-002 Button-Push, Control, Blue (2)2 9032-062-001 Button-Push, Control, Black (2)3 9538-166-011Spacer-Metal, 4mm (4)4 9486-158-001 Retainer-Push Button (2)5 8640-424-002Nut-Hex, Elastic stop, #4-40 (4)6 8652-130-038Terminal-Grounding clip (1)7 9534-365-001Spring-Flat, Control (1)8 9545-008-001Screw-Hex, #10B x 1/4 (2)9 9545-044-010 Screw-Hex, #10B x 1/4 (10)9 8641-582-005Washer-External tooth, #6 (10)10 9435-038-001Overlay-Control, Coin, Black (1)10 9435-038-002Overlay-Control, Coin, Blue (1)11 9021-041-001Acceptor-Coin, Optical (1)* 9486-149-001Retainer, Coin Acceptor (1)12 9545-053-002Screw (4)* 9801-099-001 Optical Sensor, Replacement (1)Note: Jumpers required if using 1.5 Control on Older Machines (P9 Connection)* 8220-155-001 Wire Assy, Jumper, 30Lb Stack Coin (1)* 8220-155-002 Wire Assy, Jumper, 50Lb Stack Coin (1)Door Switch GroupPart NumberDescription Quantity9539-487-001Door Switches (2)Hinge Plate Cover1 9074-340-002 Cover-Hinge, Black .....................................................................22 8636-008-010 Screw-TRHDCR, 10B x 3/8, Black.. (4)12Bearing Housing GroupKey Part Number Description Quantity J1 9241-189-002 Housing, Bearing (2)J2 9036-159-003Bearing, Ball Rear..................................................................... .2 * 9538-183-001 Spacer, Bearing (2)* 9036-159-001Bearing, Ball Front .................................................................... .2 J5 9545-017-017Bolt, 1/2 x 3/4 . (8)J7 8640-417-002Nut, 1/2 (8)* 9803-201-001Bearing Housing Complete Ass’y (includes bearings,spacer) (2)J4 9545-017-018Screw 1/2 x 1 1/2 (4)Burner Housing GroupKey Part Number Description Quantity * 9803-207-001 Housing Assembly, Burner (2)1a 9452-730-001Service Burner Plate Front... (2)1 9452-729-001 Service Plate baffl e Recirculation Chamber Clean Out (2)* 9545-008-006Screws (8)2 9545-008-001Screw (16)18 9003-220-001Angle, Burner Support (2)* 9545-008-006Screw (4)17 9048-020-002Burner, Main (4)* 9545-008-006Screw 10AB x 3/8” (4)* 9454-824-001 Panel, Back Burner Housing (2)4 9545-008-001Screw 10B x1/4” (8)5 9875-002-003Electrode Assy, Ignition (2)19 9545-045-001Screw, Electrode Mtg 8B x 1/4” (4)7 9379-186-001Valve, Gas Shut Off (1)8 9857-134-001Control Assy, Gas (2)9 9381-012-001Manifold, Assy (2)* 9425-069-021Orifi ce, Burner-Natural #27 (4)* 9425-069-022Orifi ce, Burner-LP #44 (4)10 9029-175-001Bracket, Manifold (2)22 8615-104-038Pipe Plug in end of Burner Manifold (2)* 9545-008-006Screw (4)12 9576-203-002Thermostat, Hi-Limit (2)* 9538-142-001Spacer, Hi-Limit (4)* 9545-045-007 Screw 8B x 3/4” (4)13 9074-329-001Cover, Hi-Limit Stat Ignitor (2)* 9545-008-006Screw (6)* 9576-207-008Thermostat, Safety Shutoff (2)* 9545-008-006Screw (4)15 9825-062-001Cover, Safety Stat (2)* 9545-008-024Screw (6)16 9857-116-003Control, Ignition Fenwall (3 trybox) (2)* 9732-102-013Kit, LP Conversion 50Lb Stack Kit (2)* 9838-018-003Welded One Piece Gas Pipe Assembly (1)Part # 8533-085-001 9/14Burner Housing Group Photos10221092221851A141594851613Rear ViewKey Part Number Description Quantity * 9627-861-001Wire Harness Overtemperature Switch/Air Switch (2)* 9801-098-001Switch Assy, Air Flow (2)1 9539-461-009Switch, Air Flow (2)2 9029-200-001 Bracket, Switch- Air Flow (2)3 9008-007-001Actuator, Switch (2)4 9451-169-002Pin, Cotter (2)5 9545-020-001Screw 4-40 x 5/8” (4)* 8640-401-001Nut, Special Twin .#4-40 (2)* 9550-169-003Shield, Switch (2)6 9376-322-001Motor, Drive (2)7 9452-770-001Plate, Motor Mounting (1)* 9545-029-008Bolt 3/8” - 16 x 3/4” (8)* 8641-582-003Lockwash Spring 3/8 (8)8 9545-018-019Screw, Motor Plate to Back Assy. 1/4-20x 2 1/2 (8)* 8641-582-007Lockwasher 1/4 (8)9 9538-163-006Spacr (8)* 8641-581-017Flat Washer 1/4 x 7/8 (24)* 9209-086-002Rubber Grommet (8)* 9538-166-006Grommet Spacers (8)* 9545-028-013Screw, Set (4)10 9962-018-002Back Assy, Blower Hsg (2)11 9991-053-001Support Assy, Intermed. Pulley (2)12 9545-029-010Bolt, Rd Hd 3/8-16 x 1 1/4 (6)12 8640-415-004Nut Flange Wizlock 3/8” - 16 (6)12 8641-581-035Washer, Flat (6)13 9545-029-003Bolt, 3/8-16 x 1 1/2 (2)14 9861-022-001Arm Assy-Tension, Complete (2)* 9487-200-003Ring-Retaining (6)15 9908-048-003Pulley Assy, Intermediate with bronze fl ange bearing (2)* 9036-145-002Bronze Flange Bearing (4)16 9908-047-002Pulley Driven Tumbler (2)17 9040-076-009Belt, Drive Motor (2)18 9040-073-011Belt, Driven Intermediate to Tumbler (2)19 9534-151-000Spring, Tension (2)20 9099-012-005Chain, Tension (2)21 9248-022-002Hook, Tension (2)* 9451-146-001Pin, Damper Hinge (2)* 9074-334-001 Cover Duct Upper (1)22 9973-032-001 Heat Recirculation Assembly Duct (2)* 9453-169-013Motor Pulley - Driver (1)* 9545-028-013Set Screws (2) (2)* 9278-043-001Impeller23 8641-581-026Washer, Flat 1/2” for Tumbler Pulley (2)24 9545-017-009Bolt, 1/2”-13 x 1 1/4 (2)25 8641-582-016Washer, Star 1/2” for Tumbler Pulley (2)* 9545-008-001Screw 10 Bx 1/4” (6)* 9545-014-004Bolt, 5/16-18 x 5/8” (8) (8)5/16-18* 8640-400-003Nut,* 9538-184-001Spacer, Shaft (2)* 9487-234-005Ring Tolerance (2)* 9125-007-001Damper Inside Duct Exhaust (2)* 9125-007-002Damper Inside Duct Exhaust (1)* 8520-141-000Nut, Spring (4)* 9074-335-001Cover Duct Lower (1)* 9545-008-024Screw 10ABx 3/8” (72)* 9029-173-001Bracket for Wire Harness Under Burner Housing (2)Part # 8533-085-001 9/14Part # 8533-085-001 9/14Rear View Photos1264722Rear Panel & Cover GroupKey Part Number Description Quantity19208-090-001Rear Guard Side Panel 1 (2)4 9545-008-024Screws 10 AB x 3/8 (30)5 8502-649-001Label - Connection Electrical (1)8 9208-089-001Rear Guard Back Panel (2)10 8502-600-001Label Warning & Notice (1)11 8502-645-001Label - Instructions (1)12 9109-113-001Transition Assembly Outlet (1)13 9074-320-001 Top Cover Dryer Panel (1)14 9550-188-001 Top Burner Housing Heat Shield Inlet (1)15 9074-321-001 Top Panel Burner Housing Cover (1)Part # 8533-085-001 9/141851113121514Tumbler GroupKey Part Number Description Quantity 9848-131-001Tumbler Assembly Galvanized w/spider (2)G2 9568-013-001Spider Assembly (2)G3 9497-226-002Rod, Tumbler (6)G4 8640-417-005Nut, 1/2 - 13 (6)G6 8641-590-002Washer, Special (6).............................................................................AR G7 9552-013-000Shim* 9848-130-002Tumbler Assembly Stainless Steel (2)G1 9848-130-001Tumber Assembly Galvanized (2)Part # 8533-085-001 9/14Control Assembly GroupKey Part Number DescriptionQuantity* 9857-189-001 Control Assmbly Complete (all below included) .............................1* 9108-117-001 Control Box Cover ..................................................................... 1* 8220-001-478 Wire Assembly Green 7” ............................................................ 1* 8639-621-007 Screw #10-32 x 12 Green ............................................................1* 8641-582-006 Lockwasher Ext Tooth #10 ..........................................................13 9897-026-002 Terminal Block Main Power Middle ...............................................14 9897-026-001 Terminal Block ............................................................................2* 9545-045-012 Screw #8 ABx 1/2 for terminal block ............................................6 5 8711-011-001 Transformer Ignition ...................................................................2* 9545-008-024 Screws 10AB x 3/8” ...................................................................46 9982-348-001 Plate Assembly MTG Ignition Control............................................2* 9545-008-024 Screws 10B x 1/4” MTG Above Plate and Others ...........................47 9857-116-003 Ignition Control ..........................................................................2* 8640-411-003 #6-32 Nuts ................................................................................48 9631-403-009 Wire Assembly High Voltage Upper ..............................................19 9627-860-001 Wire Harness Ignition Control Upper ............................................110 9627-860-002 Wire Harness Ignition Control Lower ............................................1* 9053-067-002 Bushing Wire 7/8” .......................................................................413 9200-001-002 Fuseholder Assembly ..................................................................314 8636-018-001 Fuse 1.5 Amp .............................................................................315 5192-299-001 Relay Power ...............................................................................216 9897-035-001 Terminal Block Assembly Main Power Inlet ...................................1* 9545-008-024 Screw #8 AB x 1/2” ....................................................................2* 8220-062-036 Wire Assembly Red/Black 14” ......................................................1* 8220-062-037 Wire Assembly Red/White 14” .....................................................1* 8220-062-038 Wire Assembly White 14” ............................................................221 9627-864-004 Wire Harness Motor Extension .....................................................2* 9527-007-001 Stand Off - Wire Saddle / Arrowhead ..........................................13* 9545-031-005 Screw 6 B x 3/8” ........................................................................422 9558-029-003 Strip Terminal Marker (Behind Input Power) ..................................124 9627-863-001 Wire Harness Main Extension Access Under Burner Housing .........123 9631-403-008 Wire Ass’y - High Voltage Lower ..................................................125 9627-859-001 Wire Harness - Main Power (1)Part # 8533-085-001 9/14Control Assembly GroupPart # 8533-085-001 9/1416252223245Coin AccecptorKey Part Number Description Quantity1 9021-041-001Coin Accecptor, Optical (1)Replacement (1)2 9801-099-001Sensor-Optical,3 9545-039-002Screw, Heighth Bar, 3mm (2)* 9486-136-001 Retainer, Coin Acceptor (1)* 9545-053-002 Screw (4)Part # 8533-085-001 9/14NotesPart # 8533-085-001 9/14NotesPart # 8533-085-001 9/14Section 7: VoltageConversionPart # 8533-085-001 9/14Part # 8533-085-001 9/14Instructions - Convert a Dual Voltage Stack Dryer from 120V to 208-240V with Neutral Wire Only1. Remove incoming power from the dryer. Use a known working voltmeter to check power.2. Remove the cover of both the upper and lower control box assemblies from the dryer using a 5/16” wrench.3. Move the black/blue wire from the N position of the main power terminal block to the L2 position of the mainpower terminal block in the upper control box assembly. See Figure 6 below.4. Move the white wire of the upper motor harness to an upper inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.5. Move the orange wire of the upper motor harness to an upper inner left terminal in the middle terminal block inthe lower control box assembly. See Figure 6 below.6. Move the white wire of the lower motor harness to a lower inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.7. Move the orange wire of the lower motor harness to a lower inner left terminal in the middle terminal block in thelower control box assembly. See Figure 6 below.8. Reconnect power to the dryer and test to ensure proper operation; one line voltage to L1, one line voltage to L2,the neutral to N, and the earth ground to E.9. Reinstall the cover of both the upper and lower control box assemblies from the dryer using a 5/16” wrench.Part # 8533-085-001 9/14NotesPart # 8533-085-001 9/14Section 9: MaintenancePart # 8533-085-001 9/14MaintenanceDaily1. Clean lint screen by unlocking and sliding out in their tracks for access. Use soft brush ifnecessary. Failure to do so will slow drying and increase gas usage and temperatures through out the dryer.2. Check lint screen for tears. Replace if necessary.Monthly1. Remove lint accumulation from end bells of motor.2. Clean lint from lint screen compartment.3. Remove lint and dirt accumulation from top of the dryer and all areas above, and around theburners and burner housing. Failure to keep this portion of the dryer clean can lead to a buildup of lint creating a fi re hazard.4. Inspect Recirculation burner housing for excessive buildup.5. Place a few drops of light oil on top and bottom pivots of the clothes door hinge.6. Grease bearings and shaft of intermediate drive pulley.Quarterly1. Check belts for looseness, wear or fraying.2. Inspect gasket of door glass for excessive wear.3. Check tightness of all fasteners holding parts to support channel.4. Check tightness of tumbler shaft retaining nut. MUST MAINTAIN 150 FOOT LBS.5. Remove lint accumulation from primary air ports in burners.6. Grease pivot pins and tension arms where in contact with each other.Semiannually1. Remove and clean main burners.2. Remove all orifi ces and examine for dirt and hole obstruction.3. Remove all lint accumulation. Remove front panel, lint screen housing and remove lintaccumulation.Annually1. Check intermediate pulley bearings for wear.2. Check and remove any lint accumulation from exhaust system.NOTE: DRYER MUST NOT BE OPERATED WITHOUT LINT SCREEN IN PLACE。

“预约”程序根据需要,可选择洗涤温度、甩干速度 、选择所需的程序

使用前请仔细阅读说明书请妥善保存,以备参阅

本产品只适合在中国大陆销售和使用

海尔滚筒全自动洗衣机使用说明书

XQG50-B12866

XQG50-B10866XQG50-B9866XQG50-B8866XQG50-12866XQG50-10866XQG50-9866XQG50-8866XQG50-8866A XQG56-12866XQG56-10866XQG56-9866XQG56-8866

产品型号:

使用前须知安全注意事项使用注意事项洗前准备操作步骤

控制面板及程序说明显示屏说明其它功能故障排除清洁/维护保修说明

1.2.3.4.5.6.7.8.9.10.11.● 该产品执行标准:GB/T 4288-2008 《家用和类似用途电动洗衣机》

● 本产品属于I 类电器,请您使用时注意用电安全!

规格

电源

额定洗涤容量额定脱水容量洗涤噪声脱水噪声外形尺寸(高×深能效等级

甩干转速0020505501

2009年第1版6

9

● 本说明书中的图形均为示意图,同时由于产品的改进,您所得到的产品外观、颜色及其配件可能与本说明书中的图示不一致,请以实际产品为准,谨此致歉。

●●●●电源

预洗

棉麻

化纤

羊毛

内衣

快洗

启动/暂停

单甩

单洗

单漂

XQG50-B12866

S-D 芯变频

目录

自动档技术变频驱动技术断电记忆技术变频系列非变频系列

LED 显示

●断电记忆技术

●自选档技术。

海尔洗衣机eb90b30mate1使用说明书

一、准备工作

购买安装完毕后,插上电源插头,再打开自来水龙头,其次是放下或者接好排水管,排水管一定要放置妥当,排水管的水一定要排的出,不然脱水程序会受阻碍。

二、放入洗涤剂

对于xx洗衣机来说,它有三个可以放置洗涤剂的槽,这三个槽是专门用来放置不同洗涤剂的。

按照次序从左至右分别为主洗剂、柔顺剂和预洗剂。

1、主洗剂一般是指洗衣粉,假如洗羊毛制品,可以在这里放入专用洗剂。

2、柔顺剂应投入中间的槽内,洗衣机会在适当的时候将其释放入桶内。

3、预洗剂我们平时用得不太多,主要是指正式洗涤前的浸泡剂,例如衣物上浆剂和染色剂等。

所有的洗涤剂必须在洗衣程序开始之前投放好。

程序开始后,从进水管接入的自来水会先被导入料盒,再从料盒导入滚桶内,这样水流就把稀释后的洗衣粉冲入滚桶中了。

三、洗衣程序

洗衣的程序分为泡浸、洗涤、漂洗、脱水,按次序分别进行,也可以择其一、其二、其三进行洗衣。

但是也要考虑到洗涤衣物的材质进行选择,例如洗涤棉织物时,水温可以设定为90度,这样高的温度比较适合洗涤非凡脏的牛仔裤、沾有大量油渍的工作服等等;洗涤羊毛衣物时,只能将水温加热至30度,这个温度下洗衣粉中酶更具有活力,而且不会伤及衣物,即使在洗涤强度不太大的情况下仍可达到较好的去污效果。

选择模糊程序及预约洗涤时,建议将洗衣粉直接投入洗衣粉盒。

建议不要使用高泡洗衣粉,以免影响洗衣效果或出现泡沫溢出桶外,滴落到地上的现象。

注打开上盖部件,观察水平仪内的液体空气球是否在水平仪的红圈内,如果在,说明注洗衣机放置水平,如果不在,请调节调整脚使洗衣机水平。

软化剂投入口选择漂洗次数不是两次时,请不要使用软化注标准程序为节水程序,建议不要使用软化剂,以免软化剂过早投入而影响使用效果;剂,以免影响使用效果。

0030509169A1.使用前须知2.附件3.安全注意事项4.洗前准备5.操作步骤6.操作按钮说明7.清洁/ 维护8.疑问解答9.保修说明10.技术数据按动“程序”按钮可以选择以下程序:常用标准强力羊绒轻柔毛毯操作按钮说明指示灯显示指示灯显示状态如下:指示灯闪烁:“程序”正在运行指示灯亮起:待机或选择模式“风干”按钮按动“风干”按钮,可选择风干时间,30分、60分、120分本机最多可风干化纤衣物1.5kg(风干后适合熨烫),其他衣物风干程度随布质的不同可能不同。

使用风干功能前,请将衣物抖散传感过程中,显示“- -”预约过程中,显示预约剩余时间,程序运行中,显示剩余总时间(分钟)出现异常符号时,显示异常现象符号(请参阅本册中“疑问解答”)童锁:为了保护儿童安全及防止儿童改变洗衣过程特设定 本功能启动:在关机状态下,同时按住“程序”和“顽垢”按钮,并按动 “电源”按钮听到“嘀、嘀、嘀”3声蜂鸣,数码管显示“CL”,然后选择其他需要的程序,在洗衣程序全部设定 完毕后,按 下“启动/暂停”按钮后,童锁功能开启,所有按钮进入锁定状态,不可选择,其余型号除补进水操作外,所有按钮进入锁定状态,不可选择;解除:同时 按住“程序”和“顽垢”按钮,持续三秒以上,听到“嘀”的蜂鸣音,童锁解除记忆注意:在童锁状态下打开上盖,数码管会显示“E2”报警,需解除童锁后合上上盖才可取消,否则机器会在10s后排水。