IAEA 50-C/SG-Q《总体介绍和术语》

- 格式:doc

- 大小:31.50 KB

- 文档页数:4

核电站安全质量保证法规

国际原子能机构参考美国的经验,于1978年颁布了核电站安全质量保证法规IAEA50-C-QA ,并得到世界上先进工业国的认可。

50-C-QA包含如下13项条款(通常称13条):引言;质量保证大纲;组织机构;文件管理;设计控制;采购控制;材料管理;工艺及工艺过程控制;检测、试验控制;不符合项处理;纠正措施;记录;质量监察(audit:核工业系统译为监察,全面质量管理工作者译为审核)。

国际原子能机构为了使生产厂能更好地理解和贯彻执行完全法规,还陆续制订了安全法规的实施导则50-SG-QA系列,对法规的主要条款作了进一步展开。

已制订了10个导则:

50-SG-QA1:核电站质量保证大纲的编制;

50-SG-QA2:核电站质量保证的记录制度;

50-SG-QA3:核电站物项和服务采购工作的质量保证;

50-SG-QA4:核电站施工期间的质量保证;

50-SG-QA5:核电站运行期间的质量保证;

50-SG-QA6:核电站设计的质量保证;

50-SG-QA7:核电站质量保证的组织机构;

50-SG-QA8:核电站物项制造的质量保证;

50-SG-QA10:核电站质量保证的监察;

50-SG-QA11:核燃料组件采购、设计和制造中的质量保证。

50-C-QA 和50-SG-QA系列吸取了世界各主要核电国家质量保证的经验,已得到世界众多国家的承认。

此文件在国际原子能机构成员国范围内推荐使用,我国也在1986年制订了相应的法规《核电厂质量保证安全规定》及其支持性文件《安全导则》系列。

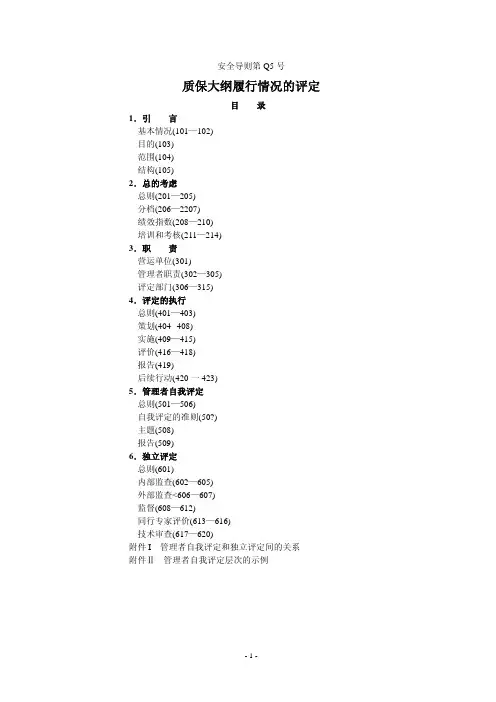

安全导则第Q5号质保大纲履行情况的评定目录1.引言基本情况(101—102)目的(103)范围(104)结构(105)2.总的考虑总则(201—205)分档(206—2207)绩效指数(208—210)培训和考核(211—214)3.职责营运单位(301)管理者职责(302—305)评定部门(306—315)4.评定的执行总则(401—403)策划(404--408)实施(409—415)评价(416—418)报告(419)后续行动(420一423)5.管理者自我评定总则(501—506)自我评定的准则(50?)主题(508)报告(509)6.独立评定总则(601)内部监查(602—605)外部监查<606—607)监督(608—612)同行专家评价(613—616)技术审查(617—620)附件I 管理者自我评定和独立评定间的关系附件Ⅱ管理者自我评定层次的示例1.引言基本情况101.本安全导则是国际原子能机构(1AEA)核安全标准(NUSS)规划的组成部分。

它提出了有关实现《核电厂和其他核设施安全的质量保证》法规(下文中简称“法规”)中的基本要求的建议。

102.若采用本安全导则列出者之外的实现法规基本要求的方法和解决方案也是可以接受的,条件是它们至少能促成相同的核安全水平。

目的103.本安全导则提供了如何实现法规中关于管理者自我评定和独立评定的基本要求的建议。

范围104.本安全导则适用于营运单位(即刘’核电厂负有全面责任的单位)的质量保证大纲,也适用于核电工程每一阶段的各别质保大纲,涉及到影响核安全的物项、服务和过程。

经过相应调整,也可以有效地适用于核电厂以外的核设施。

结构105.本安全导则由6节和两个附件组成:第2节描述了有关管理者自我评定和独立评定以及培训和资格考核要求的总的考虑。

第3节描述了营运单位,管理者和评定部门的职责。

第4节提供了有关如何执行评定的指南。

第5节提出了有关管理者自我评定的指南。

β/α ratemeter β/α比值仪132KV electrical power system 132KV电气系统220KV electrical power system 220KV电气系统220KV & 132KV indoor switchgear building HVAC system220KV和132KV室内配电装置HVAC系统220V AC important instrumentation power system220V交流重要仪表电源系统380KV AC distribution and control system 380V交流配电和控制系统6KV normal auxiliary power system 6KV厂用电源系统220V AC computer power supply system 220V交流计算机电源系统CEAS-WMS 部分术语Active work order 处理中的工单Calendar Plan 日历计划Central equipment administration system (CEAS)Event Plan 事件计划Fault report 缺陷报告Historical work order 历史工单Industrial & Financial Systems (IFS)Maintenance engineer 维修工程师Operation engineer 运行工程师Preventive Maintenance 预防性维修Recovery safety instruction 恢复安措Refuel outage work order 换料大修工单Route PM Action 路线预防性维修Safety instruction 安措Separate PM Action 单项预防性维修Work leader 工作负责人Work order 工单Work permission Management System (WMS)P3E/C词汇Analyst 分析员Business intelligence 商业信息Change control 变更控制Collaboration 协作Communication 交流Cost management 费用管理Cost Manager 费用经理Earned value 赢得值Executive 高级管理人员Governance 管理Issue management 问题管理Planner/Scheduler 规划/调试人员Planning & scheduling 计划&进度计划PMO 项目管理办公室Portfolio analysis 组合分析Procurment payments 采购支付Program Manager 项目经理Project Manager 项目经理Project control 项目管理Quality management 质量管理Resource management 资源管理Resource Manager 资源经理Risk containment 风险控制Team Member/Collaborator 团队成员/合作者International Standardization Organization (ISO) 国际标准化组织Business Process Reengineering (BPR) 商业重组过程Total Quality Management (TQM) 全面质量管理Nuclear Regulatory Commission (NRC)国际机构Atomic Energy of Canada Ltd. (AECL) 加拿大原子能有限公司China National Nuclear Corp. (CNNC) 中核总Framatome 法马通公司General Electric Co. (GE) 通用电气公司Initial inspection 初始视察Internation Atomic Energy Agency (IAEA) 国际原子能机构International nuclear trade 国际核贸易Multiple package contract 零散分包合同Nuclear safeguards 国际核保障监督Routine inspection 例行视察Special inspection 专门视察Split contract 大块分包合同the Pakistan Atomic Energy Commission (PAEC) 巴基斯坦原子能委员会Turnkey contract 交钥匙承包合同Unannounced inspection 不通知视察Westing-house Electric Corporation (WH) 西屋电气公司Any question,feel free to contact with me! Thanks!Eearth leakage protection接地保护earth return大地回馈earthing resistance接地电阻earthing system接地系统earthing接地earthquake subsidence震陷earthquake地震editor编辑程序effective delayed neutron fraction缓发中子份额effective dose equivalent有效剂量当量effective flow rate有效流量effective full power days等效满功率天effluent radiation monitoring system排出流辐射监测系统egg crate grid蛋篓型格架ejector喷射器ejector抽气器elastic scattering弹性散射electret microphone驻极体传声器electric building cooler system电气厂房循环冷风机组系统electric building smoker exhaust system电气厂房排烟系统electric building ventilation system电气厂房通风系统electric building water supply and drainage system电气厂房给排水系统electric building电气厂房electric dispatch network电力调度网electric furnace电炉electric heater电加热器electric horn电喇叭electric monorail hoist单轨电动葫芦electrical conduit引出线管electrical panel配电屏electrical penetration电气贯穿件electric-hydraulic actuating brake电磁液压制动器electroacoustic component电声元件electromagnetic braker电磁制动器electromagnetic flowmeter电磁流量计electronic pocket dosimeter电子式袖珍剂量计electro-slag remelting电渣重熔electro-sound telephone system检修电话系统electrotechnical box电气箱elevation立面ellipsoidal head椭圆形封头embedded part预埋件emergency announcement紧急通知emergency boration紧急硼化emergency control room system应急控制室emergency core cooling应急堆芯冷却emergency diesel generation system应急柴油发电机系统emergency diesel generator building water supply and drainage system 应急柴油发电机给排水系统emergency diesel generator room ventilation system应急柴油发电机通风系统emergency disk brake应急盘式制动器emergency drain应急疏水emergency exposure应急照射emergency feedwater tank应急给水箱emergency oil pump应急油泵emergency outlet事故排出口emergency power source(or supply)应急电源emergency power应急电源emergency shutdown紧急停堆emergency telephone system应急自动电话系统emergency transfer equipment应急电源转换设备emergency trip time紧急停堆时间enclosed motor封闭式电机,防水电动机end of cycle循环末end of life(EOL)寿期末end plug端塞end truck端梁end-of erection state report安装完工报告end-of travel limit switch行程终端限位开关end-window counter钟罩形计数管energization通电energy group能群energy level能级energy resolution能量分辨率energy response能量响应energy spectrum能谱engineer station工程师站engineering company工程公司engineering enthalpy rise factor工程焓升因子engineering factor工程因子engineering heat flux hot channel factor工程热通量热管因子engineering heat flux hot spot factor工程热通量热点因子engineering manual工程手册enriched fuel富集燃料enriched uranium reactor浓缩铀反应堆enriched uranium浓缩铀enriched浓缩的enrichment浓缩度,富集度enthalpy rise factor焓升因子enthalpy rise uncertainty factor焓升不确定因子enthapy rise engineering hot channel factor焓升工程热管因子entrainment夹带environment monitoring vehicle环境监测车environment qualification环境鉴定environmental assessment(EA)环境评价environmental monitoring环境监测environmental quality(EQ)环境质量epicenter震中epithermal neutron超热中子equilibrium enrichment平衡富集度equilibrium poisoning平衡中毒equipment hatch设备闸门equipment list设备明细表equipotential connection等电压连接equivalent core diameter堆芯等效直径equivalent diameter当量直径erosion corrosion磨损腐蚀escape rate coefficient逃脱率系数escape泄漏,逃逸essential chilled water system重要冷冻水系统essential service water intake filteration system重要厂用水取水过滤系统essential service water pumping station system重要厂用水泵房系统essential service water pump重要厂用水泵essential service water yard pipe network重要厂用水厂区管路系统evaporative air cooling(EAV) unit蒸发式空气冷却机组evaporator蒸发器event事件examination检验excess letdown heat exchanger过剩下泄热交换器excess letdown过剩下泄excess power超功率excess reactivity过剩反应性excitation励磁exclusion area boundary禁区边界ex-core instrumentation堆外测量exhaust cleanup unit(ECU)排风净化机组exhaust fan排风机exhaust hole排气孔exhausting smoke fan排烟风机expansion joint膨胀结合,伸缩缝expansion ring膨胀环expansion tank膨胀水箱expert's opinion专家意见expert's report专家报告external contamination外污染external exposure外照射external interface外部接口external load外负荷external pressure外压Fface of weld焊缝正面face plate面板failed fuel assembly location detecting system破损燃料定位检测系统failed fuel fraction破损燃料份额failure detector module故障检测元件failure失效,故障,损坏fan风机fast connector快拆接头fast fission factor快裂变因子fast neutron fluence快中子通量fast neutron flux快中子通量fault故障,事故feasibility study可行性研究feed water heater给水加热器feed water pump给水泵feed water storage tank给水箱feed water给水feeder ring给水环管feeder馈电线feedwater inlet nozzle给水进口管嘴fiberglass玻璃纤维field change现场修改field inspection巡回检查field字段file文件filing归档filler metal填充金属fillet welding角焊fill充注film badge胶片剂量计film boiling膜态沸腾filter滤池filter过滤器final acceptance report最终验收报告final acceptance最终验收final safety analysis report(FSAR)最终安全分析报告final storage of document文件最终储存fine sand细砂fin散热片fire alarm失火报警fire annihilation protecting equipment熄火保护装置fire break防火墙fire damper防火阀fire extinction agent灭火剂(器)fire extinction pump消防泵fire extinction灭火fire fighting foam system泡沫消防系统fire hose消防水龙带fire hydrant消火栓fire proof installation防火设施fire protection water system消防水系统fire protection消防fire rating耐火等级fire resistant耐火的fire stopping wall挡火墙fire stop阻火件fire-fighting water消防水first collision probability首次碰撞几率first core第一堆芯first out alarm首发报警fissile nucleus易裂变核fission and corrosion product activity裂变和腐蚀产物活度fission chain裂变链fission chamber(miniature)裂变室(微型)fission cross section裂变截面fission energy裂变能fission fragment裂变碎片fission gas裂变气体fission neutron裂变中子fission product裂变产物fission rate裂变率fission source裂变源fission spectrum裂变谱fission yield裂变产额fissionable可裂变的fitting配件fixed point固定点fixed radio station无线固定台fixed tube固定套管flame arrester阻火器flame resistant耐火焰的flammable易燃的flange welding卷边焊flanged connection法兰连接flare groove welding喇叭型坡口焊flare test(传热管)扩口试验flashing alarm闪光报警flashing闪蒸flask ,cask屏蔽容器flat head平封头fleatation气浮池flexible connection柔性连接flexible cord柔线flexible coupling挠性联轴器,挠性接头float charge浮充电float type flowmeter浮子流量计floating point浮点flood light泛光灯,探照灯flooding淹没floor contamination monitor地面污染监测仪floor drain tank楼面疏水箱floor drain楼面疏水floppy disk软盘flow coastdown惯性流量下降flow diagram(工艺)流程图flow distribution plate流量分配板flow distribution流量分配flow induced vibration流致振动flow instability流动不稳定性flow lift force流动升力flow restrictor限流器flow transmitter流量变送器flow-head cure流量-扬程曲线fluorescent lamp荧光灯flush pump冲洗泵flushing water冲洗水flush-mounted镶嵌,暗装flux density通量密度flux distribution通量分布flux flattening通量展平flux gradient通量梯度flux instrumentation guide tube通量测量导向管flux map通量分布图flux通量follow-up action后续行动food chain事物链forced circulation强迫循环foreground前台foreign material杂质forged parts锻制件forging锻造format格式化former辐板(堆芯围板的径向支撑板)fouling coefficient污垢系数foundation ring基础环fracture mechanics断裂力学framework框架,构架frame框架free-standing cladding自立式包壳frequency analysis频谱分析frequency meter频率计,周波表fresh water淡水fretting corrosion激振腐蚀fretting wear微振磨损friction coefficient摩擦系数friction loss摩擦损失front computer前置计算机front panel前面板fuel assembly sipping device燃料组件啜吸装置fuel assembly visual inspection equipment燃料组件目视检查装置fuel assembly燃料组件fuel basket燃料篮fuel building bridge燃料厂房桥架fuel building crane燃料厂房起重机fuel building ventilation system燃料厂房通风系统fuel building water supply and drainage system燃料厂房给排水系统fuel building燃料厂房fuel burnup燃料燃耗fuel cluster燃料棒束fuel column燃料柱fuel cycle lifetime燃料循环寿期fuel cycle燃料循环fuel element failure accident燃料元件破碎事故fuel element燃料元件fuel handling system燃料装卸系统fuel inventory燃料装量fuel loading and unloading装料与卸料fuel management燃料管理fuel mispositioning accident错装料事故fuel pellet燃料芯块fuel pool bridge燃料抓取机(燃料池桥架)fuel rod燃料棒fuel shipping container rig燃料运输容器吊具fuel storage、transportation and inspection system燃料储运和检验系统fuel swelling燃料肿胀fuel transfer shielding燃料运输屏蔽fuel transfer system燃料运输系统fuel transfer tube燃料运输通道fuel tube燃料包壳管fuel燃料组件full penetration welding全透焊逢full penetration weld全穿透焊full power满功率full-load torque满载能力function key功能键function test功能试验functional assignment职责分工fuse isolator熔断器闸刀fuse switch熔断器开关fuse熔断器fusion welding熔焊Ggantry crane龙门吊gantry龙门架gap conductance间隙导热gas accumulated flowmeter气体累计流量计gas chromatograph气体色谱gas cooler气体冷却器gas heater气体加热器gas insulated switchgear(GIS)气体绝缘开关装置gas stripper脱气塔gas stripping unit脱气装置gas stripping脱气gaseous sample 气体取样gaseous space气空间gaseous waste treatment system气体废物处理系统gasket垫片gate valve闸阀gear coupling齿轮联轴器gear reducer齿轮减速器Geiger-Muller counter盖革/弥勒管general arrangement(厂房总布置图)general corrosion全面腐蚀general scientillation counter通用闪烁计数器general standard通用标准generation生成generator& main transformer system发电机和主变压器系统genetic effect遗传效应geography地理girder主梁girth welding环缝焊接gland packing压盖填料glass dosimeter玻璃剂量计globe valve截止阀glove box手套箱go pulse启动脉冲governor valve调节阀grab sampling手选取样grain-size晶粒度graphic display图形显示graphic package图形软件包graphic printer图形打印机graphic screen图形显示屏gravelly sand砾砂Gray code shaper葛莱码整形器Gray code葛莱码Gray/Gy戈瑞grid cell定位格架栅元grid spring定位格架grid telephone network电网通话网络grid电网,栅栏gripper抓具groove angle坡口角度groove welding坡口焊groove(焊接)坡口ground fault接地不良ground water地下水grounded electrode接地电极grounding conductor接地导体grounding resistance接地电阻grounding wire接地线groundwater level地下水位group display成组显示group selector组选择器guide cylinder导流筒guide rail导向轨道guide tube support plate压紧顶帽guide tube导向管guide vane导向管guide导则Hhabitability area(可)居留区hand and foot monitor手足监测仪hand hole手孔handling opening吊装孔handrail扶手hands-free speaking telephone set免提扬声电话hanger支吊架hard copy printer硬拷贝打印机hardware硬件harmful effect有害影响hazardous atmosphere危险环境head block assembly定滑轮组head dome insulation顶盖球冠保温层head flange insulation顶盖法兰保温层head loss水头损失heading标题headset头戴式送受话器head封头health physics program保健物理大纲health physics system保健物理系统hear exchanger热交换器heat affected zone热影响区heat balance热平衡heat capacity热容heat conductivity热导率heat diffusion热扩散heat flow rate热流量heat flux热通量heat generation释热heat load热负荷heat sink热井heat tracing(electric)加热保温(电)heat transfer coefficient热交换系数heat treatment热处理heat(or ladle) analysis熔炼分析heater加热器heating coil加热盘管heating ventilation and air conditioning采暖通风及空调heavy oil重油helical-wrap drive cable螺旋形驱动电缆helium leak check氦气检漏hemispherical半球形封头hexadecimal十六进制的high efficiency particulate and air filter高效过滤器high efficient filter高效过滤器high energy pipe高能管道high neutron flux trip中子高通量紧急停堆high range gamma radiation monitor for accident事故用高量程γ辐射监测仪high range ionization chamber area gamma monitor高量程电离室区域γ监测high voltage power supply高压电源high-level noble gas gamma monitor高放惰性气体γ监测仪high-pressure ionization chamber高压电离室high-purity germanium高纯锗hoist speed提升速度hold down spring压紧弹簧环hold point停工待检点hold-down support assembly压紧支撑结构hold-up tank暂存箱hood通风柜hook吊钩horizontal acceleration水平加速度horizontal guide wheel水平导向轨horizontal pipe横管horizontal position welding横焊horn loudspeaker号筒扬声器hot cell热室hot channel factor热管因子hot channel热通道hot laundry ventilation system洗衣房通风系统hot leg热段hot performance test热态性能试验hot point factor热点因子hot shutdown热停堆hot sink热井hot spot factor热点因子hot standby热备用hot startup热启动hot test热态试验hot water production and distribution system热水生产与分配系统hot water system热水系统hourly variation coefficient时变化系数house load operation, service power operation带厂用电运行housekeeping场地管理HP sampling cooler高压取样冷却器HP-heater & LP heater drain system高-低压加热器疏水系统humidifier加湿器hunting抖动hydraulic drag水力阻力hydraulic equivalent diameter水力等效直径hydraulic press水压机hydraulic resistance水力阻力hydrazine联氧hydrogen analyzer氢分析仪hydrogen embrittlement氢脆hydrogen induced cracking氢致开裂hydrogen measuring device氢气测量装置hydrogen pickup吸氢hydrogen recombiner消氢器hydrogen system氢气系统Iidentification识别,标记ignition 点燃,触发illuminated pushbutton带灯按钮illuminated switch带灯开关illumination照明impedance voltage(transformer)短路电压,阻抗电压(变压器)impedance阻抗impurity杂质inaccessible equipment不可接近的设备incandescent lamp白炽灯incident of moderate frequency中等频率事故inclined positioning welding倾斜焊inclusion夹杂物incoming breaker进线开关Inconel 718 alloy因科镍718合金Inconel alloy因科镍合金in-core instrumentation room堆芯仪表室in-core instrumentation thimble堆芯测量管in-core instrumentation堆芯测量in-core neutron flux monitoring system堆芯中子通量测量系统in-core neutron flux monitoring system堆芯中子通量测量系统in-core temperature monitoring system堆芯温度测量系统in-core堆芯independence from cost and schedule不受经费和进度的约束independent review独立检查index file索引文件indicating lamp, indicator lamp(indicator)指示灯,指示仪indication of inspection status检查状态标识individual dosimetry and management device个人剂量监测和管理装置induced radioactivity感生放射性inductance电感,感应industrial wastewater工业废水inelastic scattering非弹性散射infinite lattice无限栅格infinite medium multiplication factor无限介质增殖因子infrequent incident稀有事故initial power初始功率inlet nozzle insulation进口接管保温层inlet temperature进口温度inner strap(格架内)条带in-pile densification堆内密实in-plate area radiation monitoring system区域辐射监测系统input device输入设备input isolator module输入隔离组件input/output(I/O)输入/输出insertion of reactivity反应性引入in-service inspection在役检查in-site controlled area environment radiation monitoring system 厂区环境辐射监测系统inspection at delivery point交接检查inspection of work工作检查inspection plan检查计划inspection program检查大纲inspection record检查记录inspection检查inspector检查员installation安装instantaneous relay瞬时继电器instruction sheet指令单instruction说明(书),细则instrument room仪表室instrumental joint仪表接头instrumentation (stop) valve仪表(截止)阀instrumentation metering valve仪表计量阀instrumentation tube测量管insulation level绝缘强度insulator隔热片(块)intact loop完好环路intake structure取水构筑物intake取水口,摄入量integrated flux积分通量integrated worth积分价值intelligent智能intensity of back washing返洗强度interaction交互作用interactive mode交互方式interbedding互层intercept valve再热调节阀intercom network内部通信网intercom system调度电话系统interface drawing接口图interface接口intergranular corrosion晶间腐蚀intergranular stress corrosion cracking晶间应力腐蚀开裂interlock联锁intermediate range中间量程intermittent welding断续焊internal contamination内污染internal exposure内照射internal interface内部接口internal pressure内压internals lifting support stand堆内构件存放台International Atomic Energy Agency(IAEA)国际原子能机构International Electrotechnical Commission国际电工委员会International Organization for Standardization(ISO)国际标准化组织International Standardization Association(ISO)国际标准化协会interpass temperature层间温度interpreter解释程序interrupting capacity遮断容量interrupt中断intervention level干预水平intrinsically safe equipment固有安全设备inverter逆变装置investigating level调查水平iodine cartridge碘吸附盒iodine removal efficiency除碘效率iodine-131 monitor碘-131监测仪ion chromatograph离子色谱ion exchange resin离子交换树脂ion exchange离子交换器ionization chamber电离室irradiated fuel已辐照燃料irradiation damage辐照损伤irradiation embrittlement辐照脆化irradiation induced growth辐照感生生长irradiation surveillance capsule辐照监督管irradiation辐照isokinetic sampling nozzle for stack烟囱等速取样头isolating amplifier隔离放大器isolating switch隔离开关isolating valve隔离阀isolation damper隔离(风)阀isolator绝缘子,绝缘体,隔离器isoseismic等震线isoseisms等震线isotopic abundance同位素丰度isotopic stripping fraction同位素萃取份额item important to safety安全重要物项item物项Jjib crane悬臂式起重机jumper打接线junction接管,接头,接点Kkeeper保管员Kerma比释功能key plan索引图keyboard键盘key-locked switch带钥匙开关key键,销knife corrosion刀口腐蚀knob-and--tube wiring穿墙布线knob旋钮knot节(测量航海速度的单位- 1。

IAEA-TECDOC-1182Quality assurance standards: comparison between IAEA 50-C/SG-Qand ISO 9001:1994November 2000The originating Section of this publication in the IAEA was:Nuclear Power Engineering SectionInternational Atomic Energy AgencyWagramer Strasse 5P.O. Box 100A-1400 Vienna, AustriaQUALITY ASSURANCE STANDARDS: COMPARISON BETWEEN IAEA 50-C/SG-Q AND ISO 9001:1994IAEA, VIENNA, 2000IAEA-TECDOC-1182ISSN 1011–4289© IAEA, 2000Printed by the IAEA in AustriaNovember 2000FOREWORDThe International Atomic Energy Agency (IAEA) and the International Organization for Standardization (ISO) agreement regarding the scope and coverage of documents published by both organizations points out that the standards of safety developed by the IAEA are recommendations for use by its Member States in the framework of national regulations for the safe utilization of nuclear energy. Such standards should be considered as nuclear safety regulatory documents. The standards developed by the ISO are complementary technical documents emphasizing industrial application and contractual aspects. Regarding the quality assurance topic, the IAEA standards 50-C/SG-Q are mostly used directly or indirectly to establish the nuclear safety requirements at the utility–regulatory interface. The industrial ISO 9001 standards have progressively been used to implement the quality assurance requirements at the interface utility–supplier.The relationship between both standards is growing in significance owing to the impact upon the owners/operators of nuclear facilities and their contractors/suppliers. The relationship between the IAEA and ISO standards is considered critical, in particular regarding suppliers with a small range of nuclear supplies. These organizations are not always willing to prepare special quality assurance programmes based on nuclear safety standards. On the other hand, these organizations may be qualified on the basis of the ISO quality assurance standards. In any case, for delivering nuclear items and services the quality assurance programme must comply with the requirements established in the nuclear safety regulatory standards. This implies that the utility–supplier will have to demonstrate that the acceptable degree of quality assurance in relation to nuclear safety is accomplished. This may be achieved by imposing additional requirements on the supplier over and above those contained within the ISO.In order to provide a description of the differences between the IAEA and ISO standards when applied in nuclear installations, and to support the practical way of fulfilling nuclear safety, the IAEA established a project for producing a guidance report. Valuable contributions from the European Atomic Forum (FORATOM) were committed and contractual arrangements made, with the target of finalizing the report in the shortest feasible timeframe commensurable with available resources.The issue as to which ISO 9001 standard should be used for the comparison, i.e. the current version 1994 or future version 2000, was discussed quite extensively by the members of the initial consultants meeting held in Vienna in January 1999. The consultants recommended proceeding with the use of ISO 9001 version 1994 on the grounds that some time would still be needed before the next version 2000 is adopted and effectively implemented. In the meantime guidance based upon the ISO 9001 version 1994 was considered to be applicable and the efforts expended in the preparation of the guidance report worthwhile. The report will subsequently be updated to include the new ISO 9001 version 2000 standard.In thanking the contributors to this report, the IAEA wishes to acknowledge the efforts and assistance provided by FORATOM and by the participants at the preparatory and review meetings, who are listed at the end of the report. Special acknowledgement is due to K.-P. Kleinert (Germany), E. Glauser (Switzerland), M. Hille (Germany) and N. Redman (United Kingdom) for their contributions. The IAEA officer responsible for this work was N. Pieroni of the Division of Nuclear Power.EDITORIAL NOTEThe use of particul ar designations of countries or territories does not impl y any judgement by the publ isher, the IAEA, as to the l egal status of such countries or territories, of their authorities and institutions or of the delimitation of their boundaries.The mention of names of specific companies or products (whether or not indicated as registered) does not imply any intention to infringe proprietary rights, nor should it be construed as an endorsement or recommendation on the part of the IAEA.CONTENTS1. INTRODUCTION (1)1.1. Background (1)1.2. Objective (1)1.3. Scope (1)2. STANDARDS USED IN THE COMPARISON (1)2.1. IAEA Code and Safety Guides on Quality Assurance 50-C/SG-Q (1)2.2. Quality System Standard ISO 9001:1994 (3)3. MAJOR DIFFERENCES AND LINKAGES (4)3.1. IAEA Code 50-C-Q basic requirements and IAEA Safety Guides50-SG-Q1 to Q14 (4)3.2. IAEA Code 50-C-Q basic requirements and clauses of ISO 9001:1994 (4)3.2.1. Underlying approaches (4)3.2.2. Identification of the customer (4)3.2.3. Additional requirements (5)3.3. Linkages between the IAEA Safety Guides 50-SG-Q1 to Q14 andclauses of ISO 9001:1994 (7)4. GUIDANCE WHEN USING ISO 9001:1994 (8)4.1. Additional requirements of the IAEA Code 50-C-Q (8)4.2. Additional guidance of the IAEA Safety Guides (11)APPENDIX: CORRELATION MATRICES (21)Matrix 1: IAEA Code 50-C-Q basic requirements coverage in the IAEASafety Guides 50-SG-Q1 to Q14 (21)Matrix 2: Correlation between the clauses of ISO 9001:1994 and the IAEA Code50-C-Q basic requirements (22)Matrix 3: Correlation between the clauses of ISO 9001:1994 and the IAEA SafetyGuides 50-SG-Q1 to Q14 (23)REFERENCES (24)CONTRIBUTORS TO DRAFTING AND REVIEW (25)IAEA PUBLICATIONS ON QUALITY ASSURANCE/QUALITY MANAGEMENT (27).1. INTRO DUCTIO N1.1. BackgroundThe International Atomic Energy Agency (IAEA) Code and Safety Guides contained in the Safety Series No. 50-C/SG-Q [1] define basic quality assurance requirements, which must be considered to ensure safety, and provides recommendations on how to fulfil these basic requirements. The IAEA 50-C/SG-Q standard reflects the performance based approach to quality assurance covering all aspects of plant safety, economics and efficiency. The IAEA requirements and recommendations are generally used at the nuclear utility–regulator interface.The International Organization for Standardization (ISO) International Standard ISO 9001:1994 [2] specifies quality system requirements for use where any supplier’s capability to design and supply a conforming product needs to be demonstrated. The requirements specified are aimed primarily at achieving customer satisfaction by preventing non-conformity at all stages from design through to servicing. The ISO 9001:1994 standard is sometimes used at the nuclear utility–supplier interface.1.2. O bjectiveThe objective of this report is to compare the requirements of IAEA 50-C/SG-Q (1996) [1] with ISO 9001:1994 [2] in order to identify the main differences and additional requirements contained within [1]. The report also provides information and guidance, which may be considered when ISO 9001:1994 is utilized by the nuclear industry.1.3. ScopeThe comparison is made with the following publications:IAEA Safety Series No. 50-C/SG-Q (1996), Quality Assurance for Safety in Nuclear Power Plants and other Nuclear Installations, Code and Safety Guides Q1–Q14 [1].ISO 9001:1994, Quality Systems — Model for Quality Assurance in Design, Development, Production, Installation and Servicing [2].ISO 9002:1994, Quality Systems — Model for Quality Assurance in Production, Installation and Servicing [3].ISO 9003:1994, Quality Systems — Model for Quality Assurance in Final Inspection and Test [4].Throughout this report, the comparison discussed is the comparison against ISO 9001:1994 only, as it contains all the requirements contained in ISO 9002:1994 and ISO 9003:1994. Suppliers, utilities, regulatory bodies, as well as research and development organizations could use this report when considering using ISO 9001:1994 to procure items and services for use in the nuclear industry.2. STANDARDS USED IN THE COMPARISON2.1. IAEA Code and Safety Guides on Quality Assurance 50-C/SG-QThe IAEA Safety Series includes one Code 50-C-Q on quality assurance and 14 related Safety Guides 50-SG-Q1 to Q14 [1].The quality assurance Code 50-C-Q establishes the basic requirements that must be met to ensure adequate safety of nuclear power plants and other nuclear installations.The Code consists of 10 basic requirements (BR) to be adopted by the responsible organization as the foundation for establishing and implementing a comprehensive quality assurance programme related to the safety of nuclear power plants. The basic requirements are presented in three functional categories:I. ManagementBR 1: Quality Assurance ProgrammeBR 2: Training and QualificationBR 3: Non-Conformance Control and Corrective ActionsBR 4: Document Control and RecordsII. PerformanceBR 5: WorkBR 6: DesignBR 7: ProcurementBR 8: Inspection and Testing for AcceptanceIII. AssessmentBR 9: Management Self-AssessmentBR 10: Independent AssessmentThe Code includes an annex, which provides guidance to aid the understanding and implementation of the basic requirements. The content of this annex is included in this comparison.The Safety Guides describe acceptable methods of implementing particular parts of the Code. The Safety Guides 50-SG-Q1 to Q14 are one of two types:· Basic requirement related Safety GuidesThese Safety Guides provide recommendations and guidance on how to fulfil the basic requirements of the Code that are relevant in all of the life-cycle stages of nuclear power plants and other nuclear installations.The BR related guides are:Safety Guide Q1: Establishing and Implementing a Quality Assurance ProgrammeSafety Guide Q2: Non-conformance Control and Corrective ActionsSafety Guide Q3: Document Control and RecordsSafety Guide Q4: Inspection and Testing for AcceptanceSafety Guide Q5: Assessment of the Implementation of the Quality Assurance Programme Safety Guide Q6: Quality Assurance in Procurement of Items and ServicesSafety Guide Q7: Quality Assurance in Manufacturing· Stage related Safety GuidesThese Safety Guides provide specific recommendations and guidance on how to implement the Code during the different life-cycle stages of nuclear power plants and other nuclear installations.The Stage related guides are:Safety Guide Q8: Quality Assurance in Research and DevelopmentSafety Guide Q9: Quality Assurance in SitingSafety Guide Q10: Quality Assurance in Design (this specific guide may also be used as a BR related Guide when the design activities are carried out in any stage). Safety Guide Q11: Quality Assurance in ConstructionSafety Guide Q12: Quality Assurance in CommissioningSafety Guide Q13: Quality Assurance in OperationSafety Guide Q14: Quality Assurance in Decommissioning2.2. Quality System Standard ISO 9001:1994The ISO 9001:1994 standard defines the requirements for a quality management system in clauses 4.1 to 4.20. The clauses are sequentially numbered to reflect the sequence of events and activities supporting production, from developing the quality policy to the after sales service.The clauses of ISO 9001:1994 are:4.1 Management Responsibility4.2 Quality System4.3 Contract Review4.4 Design Control4.5 Document and Data Control4.6 Purchasing4.7 Control of Customer-Supplied Product4.8 Product Identification and Traceability4.9 Process Control4.10 Inspection and Testing4.11 Control of Inspection, Measuring and Test Equipment4.12 Inspection and Test Status4.13 Control of Nonconforming Product4.14 Corrective and Preventive Action4.15 Handling, Storage, Packaging, Preservation and Delivery4.16 Control of Quality Records4.17 Internal Quality Audits4.18 Training4.19 Servicing4.20 Statistical TechniquesThese 20 clauses have a relationship with and are comparable to the 10 basic requirements of the IAEA Code 50-C-Q. The ISO 9001:1994 standard, however, does not give any guidance or recommendations on how the defined requirements can be implemented.3. MAJOR DIFFERENCES AND LINKAGES3.1. IAEA Code 50-C-Q basic requirements and IAEA Safety Guides 50-SG-Q1 to Q14While the IAEA Code 50-C-Q specifies the ten basic requirements for quality assurance in nuclear power plants and other nuclear installations, the Safety Guides provide recommendations relative to the fulfilment of these basic requirements for different topics and life-cycle stages. An overview showing how each Safety Guide addresses the basic requirements is given in the Appendix: Matrix 1.3.2. IAEA Code 50-C-Q basic requirements and clauses of ISO 9001:1994The linkages between the ten basic requirements of the IAEA Code 50-C-Q and the 20 clauses of ISO 9001:1994 are provided in the Appendix: Matrix 2. In general the basic requirements of the IAEA Code 50-C-Q are addressed by one or more clauses of ISO 9001:1994. However the IAEA Safety Guides provide more detailed and comprehensive guidance and recommendations on how to implement the basic requirements of the IAEA Code.Each basic requirement of the IAEA Code 50-C-Q addresses one or more of the clauses of ISO 9001:1994. However there are some significant differences in the approaches, identification of the customer and additional requirements.3.2.1. Underlying approachesThe IAEA Code 50-C-Q provides the basic requirements to be adopted for establishing and implementing quality assurance programmes related to the safety of nuclear power plants and other nuclear installations. These basic requirements apply to the overall quality assurance programme of the responsible organization, i.e. the organization having overall responsibility for the nuclear power plant, as well as to any other separate quality assurance programmes in each stage of the life of a nuclear power plant.The objective of the IAEA Code is to establish basic requirements for quality assurance in order to enhance nuclear safety by continuously improving the methods employed to achieve quality. The Code recognizes that all work is a process that can be planned, performed, assessed and improved.The quality assurance model set out in ISO 9001:1994 provides the framework for the quality assurance programme of a supplier, which enables the supplier to demonstrate the capability to produce a quality product and provides a vehicle for assessment by external parties. The requirements specified are aimed primarily at achieving customer satisfaction by preventing non-conformity at all stages from design to servicing. They are generic and independent of any specific industry sector.The comparison suggests that the IAEA Code 50-C-Q is a top-down approach focused on meeting the overall safety requirements for the plant, personnel and the society in general whilst ISO 9001:1994 is a bottom-up approach focusing on satisfying the specific requirements of the immediate customer.3.2.2. Identification of the customerThe nuclear utility in meeting national regulatory requirements satisfies the safety requirements of its customer: society at large. The regulator, representing the customer in thiscase, utilizes the IAEA Code 50-C-Q to define the requirements for the quality assurance programme of its supplier, the nuclear utility. The nuclear utility also fulfils the role of the customer utilizing, where appropriate, ISO 9001:1994 plus any additional requirements to define the quality assurance programme of its suppliers of items and services. The supplier satisfies the nuclear utility (the customer) by supplying a quality product. (See Figure 1)_______ Requirement path............... Satisfaction pathFig. 1: Application of IAEA Code 50-C-Q and ISO 9001:1994.3.2.3. Additional requirements 3.2.3.1. Management self-assessmentThe IAEA Code 50-C-Q defines specific requirements for “Management self-assessment”, an activity not required by ISO 9001:1994.“Manag ement at all levels shall reg ularly assess the processes for which it is responsible. Manag ement shall determine its effectiveness in establishing , promoting and achieving nuclear safety objectives. Management process weaknesses and barriers that hinder the achievement of the nuclear safety objectives shall be identified and corrected.” (Section 401)Regulator (Customer) Supplier (Items or Services)This statement in the Code is further clarified in the Annex:“The thrust of manag ement self-assessment is to identify, correct and prevent management problems that hinder the achievement of the organization's objectives. This Code establishes the requirement for a routine and continuing assessment of the management system by the organization's managers.This self-assessment methodology is in addition to the traditional audit/appraisal that determines the adequacy and extent of the QA programme development, documentation and implementation in accordance with specified requirements. This basic requirement improves on the standard stipulation in many QA prog rammes, which requires that management regularly assess the adequacy of the portion of the programme for which it is responsible and ensure its effective implementation. This standard requirement is typically achieved, on an annual basis, by an independent consultant or g roup of consultants on behalf of management, and it addresses compliance issues rather than broad categ ories of manag ement issues. Manag ement self-assessment g oes beyond such matters as conformance to regulations, item standards or established procedures.An effective management self-assessment evaluates issues such as:— mission of the organization— whether employees understand the mission— what is expected of the organization— whether the expectations are being met— opportunities for improving quality and enhancement safety— how to make better use of human resources.The results of the management self-assessment are documented. Decisions and related actions resulting from the recommendations are promptly followed up to evaluate their effectiveness.The assessment process involves all levels of manag ement, but senior manag ement retains the overall responsibility for manag ement self-assessments. It is essential that senior management directly participate in this process.”3.2.3.2. GradingThe IAEA QA Code 50-C-Q recommends a graded approach for the application of quality assurance during the various stages of a nuclear power plant life cycle.All items, services and processes have various controls built in to ensure they perform correctly. The grading process is a means of determining what types and extent of controls are applied to specific items, services and processes.Applying controls costs money, therefore they should be applied and focused where necessary and not applied or applied to a lesser degree for less important activities. Errors in more significant activities can potentially cost huge amounts of money, could shut down a plant or production line and could cause a threat to the staff and the environment. Additional controls that may reduce or eliminate such errors are therefore a good investment.“Nuclear safety shall be the fundamental consideration in the identification of the items, services and processes to which the quality assurance prog ramme applies. A g raded approach based on the relative importance to nuclear safety of each item, service orprocess shall be used. The g raded approach shall reflect a planned and recog nized difference in the applications of specific quality assurance requirements.In g eneral, the hig hest g rade should require the most string ent application of the quality assurance requirements; the lowest grade the least stringent.The following are examples of topic areas where grading should be applied:— Type and content of training— Amount of detail and degree of review and approval of instructions— Need for and detail of inspection plans,— Degree of in-process reviews and controls,— Requirements for material traceability— Type of assessment,— Records to be generated and retained. (Section 210).When items, processes or services are modified, the assigned grade of quality assurance requirements could become more string ent or less string ent depending on whether a change in nuclear safety significance has occurred.” (Section 211)Safety Guide 50-SG-Q1 explains what the “graded approach” in relation to nuclear safety means:“Whilst the quality assurance principles remain the same, the extent to which the quality assurance requirements are to be applied shall be consistent with the importance to nuclear safety of the item, service or process. A graded approach which can satisfy the necessary requirements and ensure the required quality and safety shall be used.” (Section 209)ISO 9001:1994 does not specify or define a graded approach for applying the controls specified in the quality system.3.2.3.3. Independence of inspection and testing personnelThe IAEA Code 50-C-Q requires that inspection and testing of specified items, services and processes shall be conducted using established acceptance and performance criteria. The level of inspection and testing and the degree of independence of personnel shall be established.ISO 9001:1994 does not specifically cover the independence of inspection and testing personnel.3.3. Linkages between the IAEA Safety Guides 50-SG-Q1 to Q14 and clauses of ISO9001:1994The linkages between the content of the IAEA Safety Guides and the ISO clauses are presented in the Appendix: Matrix 3.Matrix 3 supports the following observations:· The IAEA Safety Guides do not directly consider the customer-related requirements of ISO 9001 defined in Clauses 4.3 Contract Review, 4.7 Control of Customer-Supplied Product and 4.19 Servicing.· Similar requirements defined under the clauses ‘management responsibility’ and ‘quality system’ in ISO 9001 can be found in all of the Safety Guides.· Stage related Safety Guides in general address the majority of subjects in the ISO clauses.4. GUIDANCE WHEN USING ISO 9001:1994A detailed comparison of the IAEA Code 50-C-Q and BR related Safety Guides with ISO 9001:1994 to identify all additional requirements and guidance was carried out. In this comparison the annexes of the IAEA publications 50-C/SG-Q have not been considered as they contain examples illustrative of how the guidance could be implemented. The stage related Safety Guides, with exception of the Safety Guide “Quality Assurance in Design” (50-SG-Q10), were not included in this comparison as they provide specific recommendations for the content of the quality systems at each of the life-cycle stages. The Safety Guide 50-SG-Q10 was included as it provides guidance that may be relevant to the design activity of all stages.The detailed results of the comparison are included in Sections 4.1 and 4.2. These sections identify additional requirements or guidance found in the IAEA publications 50-C/SG-Q that are not found in ISO 9001:1994. Where the additional requirement or guidance is not self-explanatory some additional notes on application to suppliers are provided.The application of additional requirements or guidance from the IAEA Code and Safety Guides 50-C/SG-Q should be considered by the nuclear utility from two points of view:— Should the nuclear power plant/utility address this difference within its own quality assurance programme?— Should the nuclear power plant/utility require its suppliers to address the difference as an additional requirement in the procurement documents?The consideration should also take into account the regulatory requirements of each Member State.4.1. Additional requirements of the IAEA Code 50-C-QThe following table identifies additional or more detailed requirements in the IAEA Code 50-C-Q that are not contained within ISO 9001:1994.Section Additional Requirement Notes to aid application101 to 108 Introduction104 The responsible organization has to demonstrate the effective fulfilment of the quality assurancerequirements to the satisfaction of the regulatorybody… The utility should demonstrate that its quality programme takes account of and incorporates any requirements from the regulatory body. The utility should require its suppliers to apply any of these specific requirements where necessary.201 to 205 BR 1: Quality Assurance Programme204 Nuclear safety shall be the fundamentalconsideration in the identification of the items,services and processes to which the qualityassurance programme applies. A gradedapproach based on the relative importance tonuclear safety of each item, service or processshall be used. The graded approach shall reflecta planned and recognized difference in theapplications of specific quality assurancerequirements. The graded approach for activities and items, including procurement, should be described within the utility quality programme. The application of grading to supplier activities should be clarified. The utility should consider whether its supplier should adopt complimentary grading and provide guidance.Section Additional Requirement Notes to aid application 206 BR 2: Training and Qualification206 Personnel shall be trained and qualified so thatthey are competent to perform their assignedwork and understand the safety consequences oftheir activities. The utility should identify personnel involved with safety matters and provide the related training and qualification programme. The utility should notify its suppliers when their personnel are involved with safety matters and ensure they are trained appropriately.206 to 208 BR 3: Non-Conformance Control andCorrective Actions Non-conformance (as per IAEA Code 50-C-Q) covers non-conforming product, system and process non-conformity as per the ISO standard.304 to 305 BR 6: Design305 The adequacy of design, including design tools and design inputs and outputs shall be verifiedor validated by individuals or groups other thanthose who originally performed the work.Verification, validation and approval shall becompleted before implementation of the design. The utility quality programme addressing design should specify that persons in charge of safety related design verification and validation should be different from those performing the work. The utility should notify the relevant requirements to suppliers when they perform safety related design activities. Any design verification and approval should be performed before implementation of design. Generally design validation is performed through commissioning under defined operating conditions and specific dispositions should be applied for accidental conditions.Annex …Design inputs include all requirements for thedesign, such as the technical bases for thedesign (design basis), performancerequirements, reliability requirements, andsafety and security requirements. …... Computer programs used in design arevalidated through testing or simulation prior touse if not proven through previous use.—306 to 308 BR 7: Procurement Suppliers in IAEA terms are equivalent tosubcontractors.308 Requirements for reporting deviations fromprocurement requirements shall be specified inthe procurement documents. The option contained within ISO 9001:1994 for reporting deviations (non-conforming product) should be identified as being necessary.309 to 310 BR 8: Inspection and Testing for Acceptance309 Inspection and testing of specified items,services and processes shall be conducted usingestablished acceptance and performance criteria.The level of inspection and testing and thedegree of independence of personnel shall beestablished. It is recommended that utilities request suppliers to include this requirement in their quality programme, when appropriate.401 BR 9: Management Self-Assessment Management Self-Assessment is more complexand detailed than the ISO Management-Review.Management Self-Assessment focuses on theachievement of the nuclear safety objectives.Although ISO 9001:1994 covers themanagement review and internal audit processesit does not cover management self-assessment.(It is therefore recommended that suppliersproviding items and services to ISO Standardalso include management self-assessment intheir quality assurance programme.)。

核电站安全质量保证法规

国际原子能机构参考美国的经验,于1978年颁布了核电站安全质量保证法规IAEA50-C-QA ,并得到世界上先进工业国的认可。

50-C-QA包含如下13项条款(通常称13条):引言;质量保证大纲;组织机构;文件管理;设计控制;采购控制;材料管理;工艺及工艺过程控制;检测、试验控制;不符合项处理;纠正措施;记录;质量监察(audit:核工业系统译为监察,全面质量管理工作者译为审核)。

国际原子能机构为了使生产厂能更好地理解和贯彻执行完全法规,还陆续制订了安全法规的实施导则50-SG-QA系列,对法规的主要条款作了进一步展开。

已制订了10个导则:

50-SG-QA1:核电站质量保证大纲的编制;

50-SG-QA2:核电站质量保证的记录制度;

50-SG-QA3:核电站物项和服务采购工作的质量保证;

50-SG-QA4:核电站施工期间的质量保证;

50-SG-QA5:核电站运行期间的质量保证;

50-SG-QA6:核电站设计的质量保证;

50-SG-QA7:核电站质量保证的组织机构;

50-SG-QA8:核电站物项制造的质量保证;

50-SG-QA10:核电站质量保证的监察;

50-SG-QA11:核燃料组件采购、设计和制造中的质量保证。

50-C-QA 和50-SG-QA系列吸取了世界各主要核电国家质量保证的经验,已得到世界众多国家的承认。

此文件在国际原子能机构成员国范围内推荐使用,我国也在1986年制订了相应的法规《核电厂质量保证安全规定》及其支持性文件《安全导则》系列。

安全导则 Q11 建造的质量保证目录1. 引言基本情况(101-102)目的(103)范围(104-105)结构(106)2. 管理质量保证大纲(201-204)分档(205-206)组织(207-208)接口(209-210)职责的交接和转移(211)培训和考核(212-213)策划(214-218)不符合性控制和纠正措施(219)文件控制和记录(220-222)工业安全(223-226)人因(227-228)3. 执行总则(301)采购(302-303)启动会议(304)供方文件的审查(305)设计资料的控制(306-308)分供方的批准(309)施工和安装期间的场地管理(310-311)物项控制(312-319)测量和试验设备(320)建造工作的验证(321-323)4. 评定管理者自我评定(401)独立评定(402)附录:可能要求制定程序的建造活动的例子。

1. 引言基本情况101 本安全导则是国际原子能机构(IAEA)核安全标准(NUSS)规划的一部分。

它给出了有关实现《核电厂和其它核设施安全的质量保证》法规(以下简称法规)基本要求的一些建议。

102 不同于安全导则所提出的、实现法规基本要求的一些方法和解决方案是可以接受的,条件是至少能促成同样的核安全水平。

目的103 本安全导则就怎样实现法规中有关核电厂建造阶段的要求提供建议。

范围104 本安全导则适用于营运单位(即对核电厂负全面责任的单位)的质量保证大纲,也适用于核电厂工程项目建造阶段或也要执行建造活动的其它某个阶段的各别质保大纲,它涉及影响核安全的物项、服务和过程。

经过适当的调整,它也可有益地适用于核电厂以外的核设施。

105 本安全导则关系到核电厂的建造阶段。

建造阶段与核电厂其它阶段,如设计和调试,有所重叠。

营运单位可为这些阶段单立组织,或者将它们组合成一个单位。

不论作出何种组织安排,必须明确界定职责和接口,并让人了解,而且电厂状态必须始终给以确定。

Safety seriesNo.50-C-QAIAEA SAFETY STANDARDSQuality Assurancefor Safety in Nuclear Power PlantsA Code of PracticeCONTENTS FOREWORDSTATEMENT1.INTRODUCTION1.1General1.2. Scope1.3. Responsibility2. QUALITY ASSURANCE PROGRAMMES2.1. General2.2.Procedures, instructions and drawings2.3.Management reviewANIZATION3.1. Responsibility, authority and communicationsanizational interfaces3.3. Staffing and training4. DOCUMENT CONTROL4.1 Document preparation, review and approval4.2 Document release and distribution4.3Document change control5. DESIGN CONTROL5.1 General5.2Design interface control5.3Design verification5.4Design changes6 PROCUREMENT CONTROL6.1. General6.2Supplier evaluation and selection6.3Control of purchased items and services7 MATERIAL CONTROL7.1 Identification and control of materials, parts and components7.2Handling, storage and shipping8 PROCESS CONTROL9 INSPECTION AND TEST CONTROL9.1.Programme of inspection9.2.Test programme9.3.Calibration and control of measuring and test equipment9.4.Indication of inspection, test and operating status10.NON-CONFORMANCE CONTROL10.1.General10.2.Non-conformance review and disposition11.CORRECTIVE ACTIONS12.RECORDS12.1.Preparation of quality assurance records12.2.Collection, storage and preservation of quality assurance records13.AUDITS13.1.General13.2.SchedulingFOREWORDby the Director GeneralThe demand for energy is continually growing, both in the developed and the developing countries. Traditional sources of energy such as oil and gas will probably be exhausted within a few decades, and present world-wide energy demands are already overstraining present capacity. Of the new sources nuclear energy, with its proven technology, is the most significant single reliable source available for closing the energy gap that is Iikely, according to the experts, to be Upon us by the turn of the century.During the past 25 years, 19 countries have constructed nuclear power plants. more than 200 power reactors are now in operation, a further 150 are planned, and, in the longer term, nuclear energy is expected to play an increasingly important role in the development of energy programmes throughout the world.Since its inception the nuclear energy industry has maintained a safety record second to none. Recognizing the importance of this as aspect of nuclear power and wishing to ensure the continuation of this record, the International Atomic Energy Agency established a wide-ranging programme to provide the Member States with guidance on the many aspects of safety associated with thermal neutron nuclear power reactors. The programme, at present involvingPreparation and publication of about 50 books in the form of Codes of Practice and Safety Guides, has become known as the NUSS programme (the letters being an acronym for Nuclear Safety Standards). The publications are being produced in the Agency’s Safety Series and each one will be made available in separate English, French, Russian and Spanish versions. They will be revised as necessary in the light of experience to keep their contents up to date.The task envisaged in this programme is a considerable and taxing one, entailing, and numerous meetings for drafting, reviewing, amending, consolidating and approving the documents. The Agency wishes to thank all those Member States that have so generously provided experts and material, and those many individuals, named in the published Lists of Participants, who have given their time and efforts to help in implementing the programme. Sincere gratitude is also expressed to the International organizations that have participated in the work.The Codes of Practice and Safety Guides are recommendations issued by the Agency for use by Member States in the context of their own nuclear safety requirements. A Member State wishing to enter into an agreement with the Agency for the Agency’s assistance in connection with the siting, construction, commissioning, operation or decommissioning of a nuclear power plant will be required to follow those parts of the Codes of Practice and Safety Guides thatPertain to the activities covered by the agreement. However, it is recognized thatthe final decisions and legal responsibilities in any licensing procedures always restwith the Member State.The NUSS publications presuppose a single national framework within which the various parties, such as the regulatory body, the applicant/licensee and the supplier or manufacturer, perform their tasks. Where more than one Member State is involved, however, it is understood that certain modifications to the procedures described may be necessary in accordance with national practice and with the relevant agreements concluded between the States and between the various organizations concerned.The Codes and Guides are written in such a form as would enable a MemberState, should it so decide, to make the contents of such documents directly applicable to activitiesunder its jurisdiction. Therefore, consistent with acceptedPractice for codes and guides, and in accordance with a proposal of the seniorAdvisory Group, “shall” and “should” are used to distinguish for the potential user between a firm requirement and a desirable option.The task of ensuring an adequate and safe supply of energy for coming generations, and thereby contributing to their well-being and standard of Iife, is amatter of concern to us all. It is hoped that the publication presented here, together with the others being produced under the aegis of the NUSS programme, will be of use in this task.STATEMENTBy the Senior Advisory GroupThe Agency’s plans for establishing Codes of Practice and Safety Guides for Nuclear power plants have been set out in IAEA document GC(XVIII)/526/Mod.l.The programme, referred to as the NUSS programme, deals with radiological safety and is at present limited to land-based stationary plants with thermal neutron reactors designed for the production of power. The present publication is brought out within this framework.A Senior Advisory Group (SAG), set up by the Director General in September 1974 to implement the programme, selected five topics to be covered by Codes of practice and drew up a provisional list of subjects for Safety Guides supporting the five Codes. The SAG was entrusted with the task of supervising, reviewing and advising on the project at all stages and approving draft documents for onward transrnission to the Director General. One Technical Review Committee (TRC), composed of experts from Member States, was created for each of the topics covered by the Codes of Practice.In accordance with the procedure outlined in the above-mentioned IAEA document, the Codes of Practice and Safety Guides, which are based on documentation and experience from various national systems and practices, are firstdrafted by expert working groups consisting of two or three experts from MemberStates together with Agency staff members. They are then reviewed and revised by the appropriate TRC. In this undertaking use is made of both published and unpublished material, such as answers to questionnaires, submitted by Member States.The draft documents, as revised by the TRCs, are placed before the SAG. After acceptance by the SAG, English, French, Russian and Spanish versions are sent to Member States for comments. When changes and additions have been made by the TRCs in the light of these comments, and after further review by the SAG, the drafts are transmitted to the Director General, who submits them, as and when appropriate, to the Board of Governors for approval before final publication.The five Codes of Practice cover the following topics:Governmental organization for the regulation of nuclear power plantsSafety in nuclear power plant sitingDesign for safety of nuclear power plantsSafety in nuclear power plant operationQuality assurance for safety in nuclear power plants.These five Codes establish the objectives and minimum requirements that should be fulfilled to provide adequate safety in the operation of nuclear power plants.The Safety Guides are issued to describe and make available to Member States acceptable methods of implementing specific parts of the relevant Codes of Practice. Methods and solutions varying from those set out in these Guides may be acceptable, if they provide at least comparable assurance that nuclear power plants can be operated without undue risk to the health and safety of the general public and site personnel. Although these Codes of Practice and Safety Guides establish an essential basis for safety, they may not be sufficient or entirely applicable. Other safety documents published by the Agency should be consulted as necessary.In some cases, in response to particular circumstances, additional requirements may need to be met. Moreover, there will be special aspects which have to be assessed by experts on a case-by-case basis.Physical security of rissile and radioactive materials and of a nuclear power plant as a whole is mentioned where appropriate but is not treated in detail.Non-radiological aspects of industrial safety and environmental protection are not explicitly considered.When an appendix is included it is considered to be an integral part of the document and to have the same status as that assigned to the main text of the document.On the other hand annexes, footnotes, lists of participants and bibliographies are only included to provide information or practical examples that might be helpful to the user. Lists of additional bibliographical material may in some cases be available at the Agency.A list of relevant definitions appears in each book,These publications are intended for use, as appropriate, by regulatory bodies and others concerned in Member States. To fully comprehend their contents, it is essential that the other relevant Codes of Practice and Safety Guides be taken into account.1.INTRODUCTION1.1GeneralThis Code of Practice provides the principles and objectives to be adopted as regards safety when establishing both a satisfactory overall quality assurance programme for a nuclear power plant and also separate quality assurance programmes for each of the constituent areas of activity (e.g. design, manufacturing, Construction, commissioning, operation). The principles to be followed in each Case, for each type of programme, are the same.The establishment and implementation of a quality assurance programme for a nuclear power plant are essential. However, it shall always be recognized that the basic responsibility for achieving quality in performing a particular task (e.g. in design, in manufacturing, in commissioning, in operation) rests with those assigned the task and not with those seeking to ensure by means of verification that it has been achieved.Quality assurance is an essential aspect of“good management”. Good management contributes to the achievement of quality through thorough analysis of the tasks to be performed, identification of the skills required, the selection and training of appropriate personnel, the use of appropriate equipment, the creation of a satisfactory environment in which activity can be performed and, as already noted, a recognition of the responsibility of the individual who is to perform the task. Briefly stated, then, a quality assurance programme shall provide for a disciplined approach to all activities affecting quality, including, where appropriate, verification that each task has been satisfactorily performed and that necessary corrective actions have been implemented. It shall also provide for production of documentary evidence to demonstrate that the required quality has been achieved.The manner in which the principles described in this document are implemented, both at the overall plant level and at the constituent activity levels, will vary from country to country and variations will be due to such considerations as regulatory requirements, the general organization of industry, and the degree of sophistication and experience of the technical organizations involved in providing and operating the nuclear power plant. In any event, the basic intent of the principles shall be kept in mind at all times and the detailed implementation procedures shall be arranged accordingly.The Code of Practice forms part of the Agency’s programme, referred to as the NUSS programme, for establishing Codes of Practice and Safety Guides relating to land-based stationary thermal neutron power plants, The Guides listed in Section 5 0f the Provisional List of NUSS Programme Titles, printed at the end of this publication, will be of assistance in implementing the present Code.1.2. ScopeThe document provides the principles and objectives for the establishment and implementation of a quality assurance programme during design, manufacture, construction, commissioning and operation of structures, systems and components important to safety. They apply to activities affecting quality of items, such as designing, purchasing, fabricating, manufacturing, handling, shipping, storing, cleaning, erecting, installing, testing, commissioning, operating, inspecting, maintaining, repairing, refueling, modifying and decommissioning. They are applicable by all those responsible for the power plant, by plant designers, suppliers, architect engineers, plant constructors, plant operators and other organizations participating in activitiesaffecting quality.1.3. ResponsibilityIn its responsibility for ensuring the health and safety of the public, the Government of the IAEA Member State should have established a general, legal framework (see the Agency’s Safety Series No.50-C-G,“Governmental Organization for the Regulation of Nuclear Power Plants: A Code of Practice”), Within this framework should be the requirement that an effective, overall quality assurance pogramme be established.The organization having overall responsibility for a nuclear power plant shall also be responsible for the establishment and implementation of the overall quality assurance programme for the complete plant. This organization may delegate to assurance programme for the complete plant. This organization may delegate to other organizations the work of establishing and implementing all, or a part, of the programme but shall retain responsibility for the effectiveness of the overall programme, without prejudice to the contractors’ obligations and/or legal responsibilities.2. QUALITY ASSURANCE PROGRAMMES2.1. GeneralAn overall quality assurance programme shall be established consistent with the requirements contained in this Code of Practice as an integral part of the nuclear power plant project. The overall programme shall provide for control of the constituent activities associated with a nuclear power plant, such as design, construction, manufacturing, commissioning and operation. The control of each constituent activity shall also be consistent with this Code of Practice.Management in the overall and constituent areas of activity shall provide for effective implementation of the quality assurance programmes consistent with the time schedules for accomplishing project activities, including the procurement of materials for long-delivery items.All programmes shall define the organizational structure within which the quality assurance activities are to be planned and implemented and shall clearly delineate the responsibility and authority of the various personnel and organizations involved.The establishment of the programmes shall include consideration of the technical aspects of the activities to be performed. The programmes shall contain provisions to ensure identification of, and compliance with, requirements of appropriate recognized engineering codes, standards, specifications and practices.Items, services and processes to which the quality assurance programmes will apply shall be identified. Appropriate methods or levels of control and verification shall be assigned to those items, services and processes. All programmes shall provide control and verification over activities affecting the quality of the identified items to an extent consistent with their importance to safety.All programmes shall provide suitably controlled conditions for the accomplishment of activities affecting quality. This includes appropriate environmental conditions, appropriate equipment and skills to attain the required quality.All programmes shall provide for training of personnel performing activities affecting quality.All programmes shall be subject to regular evaluation and updating.All programmes shall state the languages used for documentation. Measures shall be established to ensure that persons performing the quality assurance function have adequate knowledge of the language in which the documentation is written. Translations of the documentation shall be reviewed by competent persons. Verification of conformance to the original is necessary.2.2Procedures, instructions and drawingsAll programmes shall provide that the activities affecting quality are accomplished in accordance with written in procedures, instruction or drawings of a type appropriate to the circumstances. Instructions, procedures and drawings shall include appropriate quantitative and/or qualitative acceptance criteria for determining that important activities have been satisfactorily accomplished.Procedures for implementing the quality assurance programmes on a planned and systematic basis for different phases of the nuclear power project shall be developed and documented by the organization performing the constituent activities. The procedures shall be periodically reviewed and updated as necessary to ensure adequate coverage of those activities.2.3Management reviewAll programmes shall provide for the review at appropriate intervals by management of organizations participating in the programme, of the status and adequacy of the part of the quality assurance programme for which they have designated responsibility. Corrective action shall be taken when programme deficiencies are discovered.3. ORGANIZATION3.1. Responsibility, authority and communicationsA documented organizational structure, with clearly defined functional responsibilities, levels of authority and lines of internal and external communication for management, direction, and execution of the quality assurance programme shall be established. The organizational structure and functional assignments shall recognize that execution of a quality assurance programme involves both performers and verifiers and is not the sole domain of a single group. The organization’s structure and the functional assignments shall be such that:(a)attainment of quality objectives is accomplished by those who have been assigned responsibility for performing the work; This may include examination, checks and inspections of the work by the individuals performing the work(b) When verification of conformance to established requirements is necessary it is carried out by those who do not have direct responsibility for performing the work.The authority and duties of persons and organizations responsible for quality assurance performance and verification shall be delineated in writing. The persons and organizations performing the quality assurance functions of(a) Ensuring that an appropriate quality assurance programme is established and effectively executed, and(b) Verifying that activities have been correctly performedshall have sufficient authority and organizational freedom to identify quality problems: to initiate, recommend or provide solutions; and, where necessary, to initiate actions to control further processing, delivery or installation of an item which is non-conforming, deficient or unsatisfactory, until proper disposition has been achieved.Such persons and organizations performing quality assurance functions shall report to a management of high enough level to ensure that this required authority and organizational freedom, including sufficient independence from cost and schedule considerations, are provided. Because of the many variables involved, such as the number of personnel, the type of activity being performed, and the location or locations where activities are performed, the organizational structure for executing the quality assurance programme may take various forms, provided that the persons and organizations assigned the quality assurance functions have this required authority and organizational freedom. Irrespective of the organizational structure, the individual or individuals assigned the responsibility for ensuring effective execution of any portion of the quality assurance programme at any location where activities affecting quality are being performed shall have direct access to such levels of management as may be necessary to achieve effective implementation of the quality assurance programme.3.2Organizational interfacesWhere multiple organizational arrangements exist, the responsibility of each organization shall be clearly established and interfaces and co-ordination among organizations ensured by appropriate measures. Provision shall be made for communication among organizations and organizational groups participating in activities affecting quality. The communication of essential! Information shall be by means of appropriate documentation. The type of documents shall be identified and a distribution list should be provided.3.3. Staffing and trainingPlans shall be developed for selecting staff and training personnel to perform activities affecting quality. Plans shall reflect the schedule of activity so as to allow adequate time for assigning or selecting, and training, required personnel.All personnel responsible for performing activities affecting quality shall be qualified on the basis of general education, experience and proficiency required for performing the specific assigned tasks. Training programmes and procedures shall be established to ensure that suitable proficiency is achieved and maintained.As appropriate, the accomplishment and maintenance of proficiency shall be marked by the issue of a written statement, such as a certificate.4. DOCUMENT CONTROL4.1 Document preparation, review and approvalThe preparation, review, approval and issue of documents essential to the performance and verification of the work, such as instructions, procedures and drawings, shall be subject to control.The control measures shall include the identification of all individuals or organizations responsible for preparing, reviewing, approving and issuing documents related to activities affecting quality. The reviewing and approving organization or individuals shall have access to pertinent background information upon which to base the review or approval.4.2 Document release and distributionA document release and distribution system hall be established, utilizing Up-to-date distribution lists. Measures shall be provided for ensuring that those participating in an activity are aware of and use appropriate and correct documents for performing the activity.4.4Document change controlChanges to documents shall be subject to review and approval in accordance with documented procedure. The reviewing organizations shall have access to pertinent background in formation upon which to base their approval and shall have an adequate understanding of the requirements and intent of the original document. Changes to documents shall be reviewed and approved either by the same organizations that performed the original review and approval or by other organizations that have been specifically designated. Timely information on document revision and its actual status shall be promptly relayed to all affected persons and organizations to preclude the use of outdated and inappropriate documents.5. DESIGN CONTROL5.1 GeneralControl measures shall be established and documented to ensure that applicable specified design requirements, such as regulatory requirements, design bases, codes and standards are correctly translated into specifications, drawings, procedures or instructions. They shall include provisions to ensure that applicable quality standards are specified and stated in design documents. Changes and deviations from specified design requirements and quality standards shall be controlled. Measures shall also be established for the selection, and for the review for suitability of application, of any materials, parts, equipment and processes that are essential to the function of the structure, system or component.Design control measures shall be applied to items such as the following:radiation protection; physics and stress analysis; thermal, hydraulic, seismic and accident analysis;*compatibility of materials; accessibility for in-service inspection, maintenance and repair; and delineation of acceptance criteria for inspection and tests.Design activities shall be documented to permit adequate evaluation by technical personnel other than those performing the original design.5.2Design interface controlExternal and internal interfaces between organizations and organizational units performing the designs shall be identified in writing. Responsibility for each organization and organizational unit shall be defined in sufficient detail to cover the preparation, review, approval, release, distribution and revision of documents involving interfaces. Methods shall be established for communicating design information, including changes, across the design interfaces. The information communication shall be documented and controlled.5.3 Design verificationDesign control measures shall provide for verifying the adequacy of design, such as by the performance of design reviews, by the use of alternative calculation methods, or by the performance of a suitable testing programme. Design verification shall be performed by individuals or groups other than those who performed the original design. Verification methods to be applied shall be identified by a responsible organization and design verification results shall be documented to the extent specified.Where a test programme is used to verify the adequacy of a specific design feature in lieu of other verifying or checking processes, it shall include suitable qualification testing of a prototype unit under the most adverse conditions for the specific design features being verified. Where testing cannot be carried out under the most adverse design conditions, testing is permissible under other conditions if the results can be extrapolated to the most adverse design conditions and if they can verify the adequacy of a specific design feature5.4Design changesDocumented procedure shall be provided for effecting design changes, including field changes. The technical impact of changes shall be carefully considered and required actions documented. The changes shall be subject to the same design control measures as those applied to the original design.Change documents shall be reviewed and approved by the same groups or organizations responsible for review and approval of the original design documents, unless other organizations are specifically designated. This designation of alternative organizations shall be conditional on their having access to pertinent background information, on their demonstrating competence in the specific design area of concern, and on their having an adequate understanding of the original design requirements and intent. Information concerning the changes shall be transmitted to all affected persons and organizations.6PROCUREMENT CONTROL6.1. GeneralMeasures shall be established and documented to ensure that applicable regulatory requirements, design bases, standards, specifications and other requirements necessary to assure adequate quality are included or referenced in the documents for procurement of items and services.Procurement requirements for assuring quality shall include, but need not be limited to, the following, as applicable:(a)A statement of the scope of the work to be performed by the supplier(b)Technical requirements specified by reference to documents such as codes, standards, regulations, procedures, instructions and specifications, including revisions thereto that describe the items or services to be performed(c) Test, inspection and acceptance requirements, and any special instructions and requirements related to these。

安全丛书号:50-C/SG-Q核电厂和其它核设施安全的质量保证法规和安全导则Q1—Q14国际原子能机构,维也纳,1996前言总干事核动力得到了充分的确认并且可预期它将成为许多国家能源规划中更为重要的部分,条件是能确保核动力的安全使用以及能预见到这样的安全使用正在确保着。

认识到工业安全的重要性以及希望促进提高安全记录,国际原子能机构(以下简称IAEA)於1974年制定了一个规划,就核动力堆安全的各个方面给成员国以指导。

在这核安全标准(NUSS)规划下,於1978到1995年间,本安全丛书出版了60多本针对辐射安全的法规和安全导则,NUSS规划至今为止限於为产生动力而设计的具备热中子反应堆的陆基固定电厂。

法规和安全导则表现的形式是这样的,如果某成员国愿意,就能把法规和安全导则的内容直接应用于该成员国管辖范围内的活动。

所以为与法规和导则的实践一致,分别使用“必须(Shall)”和“应(Should)”来区分严格的要求和希望的选择。

五个法规针对下列专题:—政府组织;—选址;—设计;—运行;—质量保证。

这五个法规,制定了核电厂业务中为确保充分安全而一定要满足的基本要求。

发布的安全导则,描述了成员国执行有关法规特定部分的可接受方法;采用导则列出以外的方法和解决方案是可以接受的,条件是它们至少能给出导则列出方法相当的把握,即核电厂运行使公众和厂址工作人员的健康与安全不遭到过分的风险。

虽然这些法规和安全导则建立了必不可少的安全基础,但它们可能需要按国家的实际情况结合进更为详细的要求。

再者,将还有一些需要专家按具体情况逐例评定的特殊方面。

这些出版物,打算供成员国核安全管理部门和其它有关部门根据情况使用。

为了充分理解这些出版物中任一法规和导则的内容,关键的是要计及其它有关的法规和导则。

必要时,应查阅IAEA的其它安全出版物。

相应场合提到了裂变和放射性材料、以及核电厂整体的实体保卫,但未作详细的处理。

工业安全和环境保护的非放射性方面,也未给以明显的考虑。

1802019.7MEC 对策建议MODERNENTERPRISECULTURE一、HAF003修订的必要性 (一)HAF003出台具有历史局限性改革初期,核电事业开始发展的时候,HAF003形成了,由于当时条件的限制,使得当时的管理水平和技术,和发达国家相比,相差甚远,关于安全法规方面,也是没有相关条例。

出于种种原因,才使用了IAEA 的50-C-QA,但是IAEA 的发展也不是很完善,存在一些问题,所以HAF003也会有相应的问题,大致有以下四个方面的问题:(1)关于管理者职责界定不清晰,质量保证也不突出,HAF003中只有小部分有提到管理者职责,即“参与实施大纲的单位的管理部门要对其负责的那部分质量保证大纲的状况和适用性定期进行审查 ”但是部门和级别没有详细说明,从实际情况来看,质量管理有无效果,质量保证大纲能否行之有效,都是管理部门领导决定的,因此,不明确管理者质量保证职责是不行的。

(2)工艺过程控制章节随意拓展,50-C-QA 来源于10CFR50App.B,这一章节简单粗暴的把特殊工艺拓展到全部工艺过程,虽然要注意控制不能完成、或者难以进行工艺检查的过程,但是简单复制到全部工艺,这明显违背了质量管理,也没有逻辑性可言。

(3)关于不符合控制的这一章节有缺陷,该章节只是描述了不符合性出现在物项、过程、体系上,这些不符过于局限,缩小了范围,有失偏颇。

(4)规定模糊,实际执行困难,例如虽然规定了质量保证人和部门报告的对象是足够高的管理部门,那么问题来了,足够高的标准是什么?如何来界定,再比如纠正措施中提到的关于质量严重损毁的,严重的程度该如何确定,执行的标准困难。

(二)HAF003在实践中,已显现出一些问题虽然已经按照HAF003的标准执行了几十年,遇到的情况也大大小小,在此过程中积累了相关经验,确保了核电工程能安全稳步运行,但是HAF003依旧是不完美的,还存在一些问题。

首先,HAF003对于管理者和执行者的职责权限规定较为笼统,只是大范围确定了职责,但是细小的情节没有落实,这样就会造成为了保证质量,拖延进度和提高成本的可能,如果发生质量问题时,各部门会发生互相推卸责任的情况。

安全丛书号:50-C/SG-Q

核电厂和其它核设施安全的

质量保证

法规和安全导则Q1—Q14

国际原子能机构,维也纳,1996

前言

总干事

核动力得到了充分的确认并且可预期它将成为许多国家能源规划中更为重要的部分,条件是能确保核动力的安全使用以及能预见到这样的安全使用正在确保着。

认识到工业安全的重要性以及希望促进提高安全记录,国际原子能机构(以下简称IAEA)於1974年制定了一个规划,就核动力堆安全的各个方面给成员国以指导。

在这核安全标准(NUSS)规划下,於1978到1995年间,本安全丛书出版了60多本针对辐射安全的法规和安全导则,NUSS规划至今为止限於为产生动力而设计的具备热中子反应堆的陆基固定电厂。

法规和安全导则表现的形式是这样的,如果某成员国愿意,就能把法规和安全导则的内容直接应用于该成员国管辖范围内的活动。

所以为与法规和导则的实践一致,分别使用“必须(Shall)”和“应(Should)”来区分严格的要求和希望的选择。

五个法规针对下列专题:

—政府组织;

—选址;

—设计;

—运行;

—质量保证。

这五个法规,制定了核电厂业务中为确保充分安全而一定要满足的基本要求。

发布的安全导则,描述了成员国执行有关法规特定部分的可接受方法;采用导则列出以外的方法和解决方案是可以接受的,条件是它们至少能给出导则列出方法相当的把握,即核电厂运行使公众和厂址工作人员的健康与安全不遭到过分的风险。

虽然这些法规和安全导则建立了必不可少的安全基础,但它们可能需要按国家的实际情况结合进更为详细的要求。

再者,将还有一些需要专家按具体情况逐例评定的特殊方面。

这些出版物,打算供成员国核安全管理部门和其它有关部门根据情况使用。

为了充分理解这些出版物中任一法规和导则的内容,关键的是要计及其它有关的法规和导则。

必要时,应查阅IAEA的其它安全出版物。

相应场合提到了裂变和放射性材料、以及核电厂整体的实体保卫,但未作详细的处理。

工业安全和环境保护的非放射性方面,也未给以明显的考虑。

老电厂可能不会完全满足NUSS出版物定出的要求和建议,这些厂是否实施这些要求和建议,一定要根据国家状况逐例地做出决策。

法规和导则的修订,如质量保证法规和安全导则的修订,考虑了早先出版物发布以来得到的经验教训。

这些出版物在原先制定期间以及在修订过程中,注意到确保所有具备进展中核电规划的成员国都提出他们的意见。

法规和安全导则的草案经过各方的审查,其中包括由核安全标准顾问团(NUSSAG)对最终草案的审查。

修订了的法规由理事会批准。

修订过程中,根据国际上多数意见结合进了分析技艺和方法发展的新情况。

希望这修订的法规将有实用价值;并希望成员国在其国家法律和核安全管理框架范围内为核动力堆制定安全要求方面,将考虑这些修订的法规。

有关某核电厂选址、设计、建造、调试、运行或退役方面,希望得到IAEA帮助而与IAEA 签订协议的任何成员国,将要求他们遵循法规和安全导则中与协议规定活动相关的那些部

分。

但是,应认识到在许可证审批程序中,最终决策和法律责任由该成员国承担。

目录

术语

法规

核电厂和其它核设施安全的质量保证

安全导则

Q1: 质保大纲的制定和履行

Q2: 不符合性控制和纠正措施

Q3: 文件控制和记录

Q4: 针对验收的检查和试验

Q5: 质保大纲履行情况的评定

Q6: 物项和服务采购的质量保证

Q7: 制造的质量保证

Q8: 科研开发的质量保证

Q9: 选址的质量保证

Q10:设计的质量保证

Q11:建造的质量保证

Q12:调试的质量保证

Q13:运行的质量保证

Q14:退役的质量保证

术语