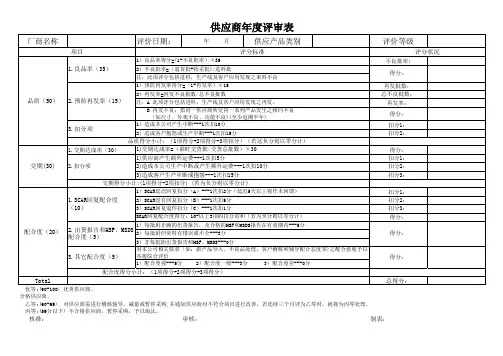

供应商年度审核报告表

- 格式:xls

- 大小:59.50 KB

- 文档页数:1

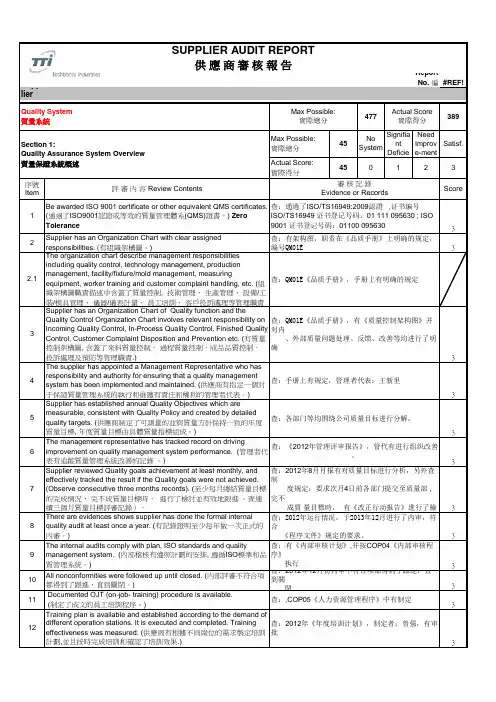

ReportNo. 編#REF!Supp lier477389Max Possible:實際總分45No System Signifia nt Deficie Need Improv e-ment Satisf.Actual Score:實際得分45123序號Item 評 審 內 容 Review ContentsScore1Be awarded ISO 9001 certificate or other equivalent QMS certificates.(通過了ISO9001認證或等效的質量管理體系(QMS)證書。

) ZeroTolerance 32Supplier has an Organization Chart with clear assigned responsibilities. (有組織架構圖。

)32.1The organization chart describe management responsibilities including quality control, technology management, production management, facility/fixture/mold management, measuringequipment, worker training and customer complaint handling, etc. (組織架構圖職責描述中含蓋了質量控制, 技術管理、 生產管理、 設備/工裝/模具管理、 儀器/儀表計量、 員工培訓、 客戶投訴處理等管理職責3Supplier has an Organization Chart of Quality function and theQuality Control Organization Chart involves relevant responsibility on Incoming Quality Control, In-Process Quality Control, Finished Quality Control, Customer Complaint Disposition and Prevention etc. (有質量控制架構圖, 含蓋了來料質量控制、 過程質量控制、成品品質控制、投訴處理及預防等管理職責.)34The supplier has appointed a Management Representative who has responsibility and authority for ensuring that a quality management system has been implemented and maintained. (供應商有指定一個对于保證質量管理系統的執行和維護有責任和權利的管理者代表。

OEM供应商评审报告

供应商名称:

报告日期:

一、企业信息

工厂名称:审核日期:

工厂地址:审核类型:□首次审核

□年度监督审核

工厂电话:□整改后审核传真:

厂房面积: M2

企业性质:□ 外资□ 合资□ 国营□私营□ 集体□ 民营□ 个体

二、审核项目

1、来料管控

3、成品管控

4、产品监视和测量

5、不合格品控制

6、仓储管理

7、采购管理

9、开发管理

8、生产管理

11、实验室管理

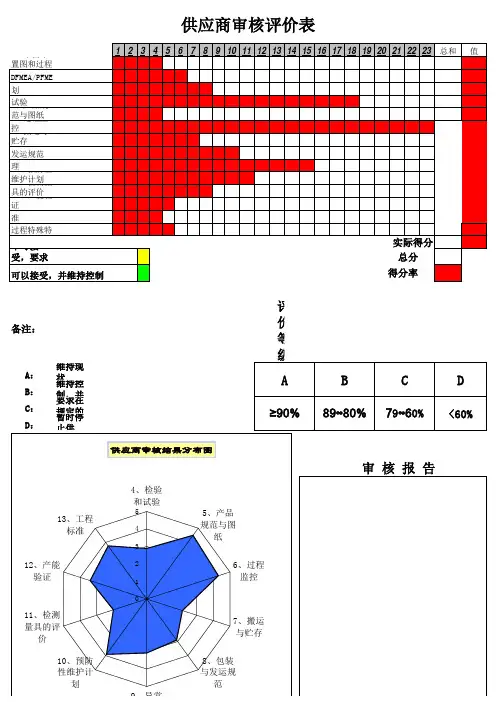

三、审核得分三、审核得分

说明:审核得分=实际得分总计/满分总计*100

审核结果:

□A、86-100分---通过,可作为合格供应商引入;

□B、70-85分---整改通过,在规定期限内提交整改资料,验证有效后可正常引入;

□C、60-69分---待定,待整改后另行安排时间现场评审(整改时间限定一个月内,超期不得引入);

□D、60以下---不合格,不能作为供应商引入。

审核记录描述工厂必须根据以下问题点,采取纠正预防措施,并确保工厂将持续改善。

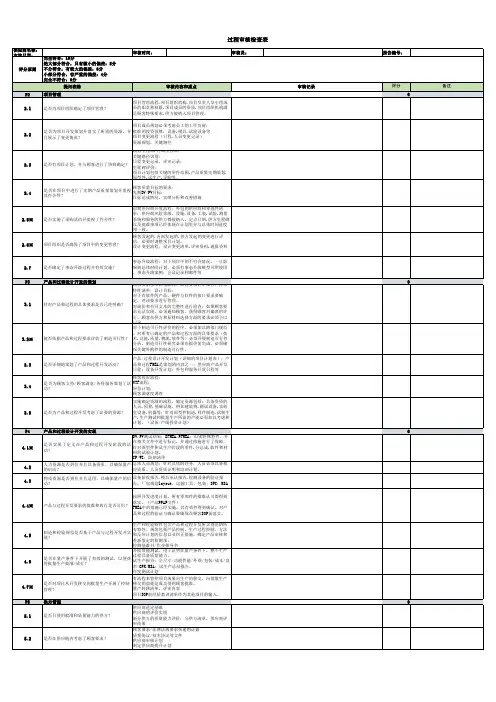

Supplier Quality System Audit项次No项目 Item单项最高分Highest Score实际得分Real Score评鉴合格率Qualified Rate单项目标Target%质量系统Quality System Requirement设计管理Design Control文件管理与品质记录Document Control & Quality Record 供应商管理Supplier Managemant产品识别与追朔Product Identification and Lot Traceability 检验与测量Inspection and Test仪器校验Equipment Calibration制程控制Process Control不合格品控制Nonconforming Product Control仓库管理Warehouse Management生产排程管理Production Schedule合同评审Contract Review采购 PurchasingRoHS管理 RoHS management缺失的分布Defect Distribution Chart综合品分 Total评分标准 Standard有文件且执行良好Document and implementation are well-done有文件,绝大部份确实执行,少部份未执行Document ok but implementation with small part有文件,少部份执行,绝大部份未执行Document ok but implementation with most part无文件,亦无执行NO document and no implementation质量系统Quality System设计管理Design Control文件管理与品质记录Document Control & Quality Record供应商管理Supplier Managemant产品识别与追朔Product Identification and Lot Traceability检验与测量Inspection and Test仪器校验Equipment Calibration制程控制Process Control不合格品控制Nonconforming Product Control仓库管理Warehouse Management生产排程管理Production Schedule合同评审Contract Review采购Purchasing评鉴合格率Qualified Rate确保质量政策让组织内所有阶层了解并展开为各部门目标,从而实施推行Assuring the quality policy be understood by every member of the orgnization and work together to realize the target.客户满意度与质量目标之间,具有相关的客观资讯予以证实There is relative objective information to testify customer satisfaction and quality tare.从事质量管理、执行、验证人员,均需明文定义其责任、授权与相互关系Personal responsibility, authorization, inter-relationship should be explicitly identified a mong thosemembers responsible for quality management, policy carrying out and quality testing.指派管理代表之其中一员,完全授权推展质量系统运作并不受其它职务责任影响,并定期向管理阶层报告以供审查Appoint one member and fully qualify him to carry out quality system and report to supe rvisors periodically.质量手册应定义各项书面程序以符合质量系统与质量政策需求,并对于文件架构予以概要说明The quality handbook should include a written process document so as to conform to th e quality system and policy, and give a general instruction to the document frame.先期产品的管制计划应包括原型样品、试产、量产三个阶段(QC工程图)Procduct control plans should include three process: sample run, pilot Run and mass p roduction(QCflow chart).订定管制计划检讨、更新与确认程序,同时可依照程序提供客户产品管制状况。

表格编号form code:A-PQEO-15/1-5/03Page页: 2Supplier/供应商: Date日期: QM audit/体系审核a = Requirements are fully satisfied/完全满意*) Please enclose copy附上复印件b = Requirements are satisfied with deviations/基本满意,但稍有偏差c = Requirements are not satisfied/不满意n.a. = Not applicable/不适用a = Requirements are fully satisfied/完全满意*) Please enclose copy附上复印件b = Requirements are satisfied with deviations/基本满意, 但稍有偏差c = Requirements are not satisfied/不满意n. a. = Not applicable/不适用a = Requirements are fully satisfied/完全满意*) Please enclose copy附上复印件b = Requirements are satisfied with deviations/基本满意,但稍有偏差c = Requirements are not satisfied/不满意n. a. = Not applicable/不适用Page页: 3Supplier供应商: Date日期:表格编号form code:A-PQEO-15/1-5/03a = Requirements are fully satisfied完全满意b = Requirements are satisfied with deviations/基本满意,但稍有偏差c = Requirements are not satisfied/不满意n.a. = Not applicable/不适用b = Requirements are satisfied with deviations/基本满意, 但稍有偏差c = Requirements are not satisfied/不满意n. a. = Not applicable/不适用b = Requirements are satisfied with deviations/基本满意,但稍有偏差c = Requirements are not satisfied/不满意n. a. = Not applicable/不适用Page页: 5Supplier/供应商: Date日期:EHS audit/环境健康安全审核表格编号form code:A-PQEO-15/1-5/03a = Requirements are fully satisfied/完全满意*) Please enclose copy附上复印件b = Requirements are satisfied with deviations/基本满意, 但稍有偏差c = Requirements are not satisfied/不满意n.a. = Not applicable/不适用Action plan Enclosure for audit conducted on:Signature Supplier (corrective actions started): ___________________表格编号form code:A-PQEO-15/1-5/03。