德国美扣mic-o-mic 模型拼插 大火车头 拖拉机 帆船等

- 格式:docx

- 大小:1.43 MB

- 文档页数:3

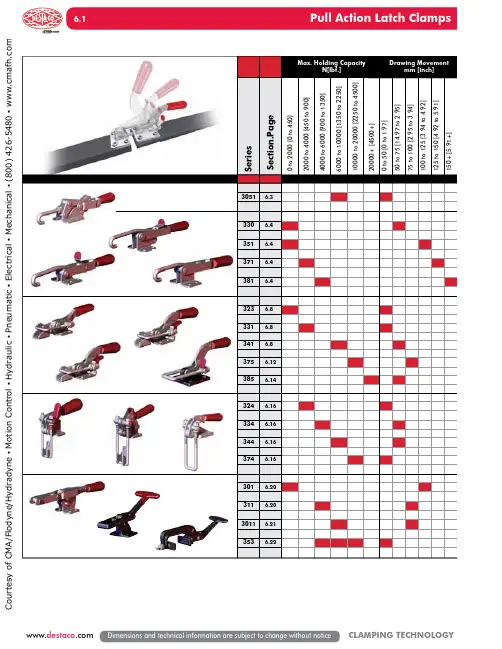

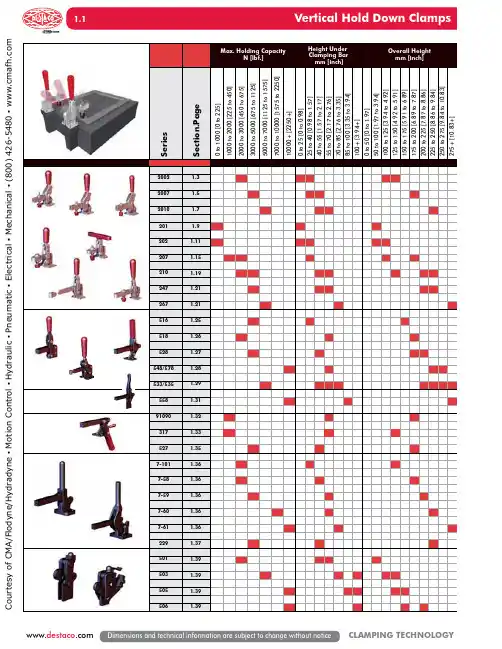

6.1 esyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com6.2Excellent/High Fair/MediumPoor/LowNot Recommendede s y of o m6.33051-R3051Series 3051Product Overview Series 3051Technical Information, Holding Capacities, Standard Clamp DimensionsFeatures:•Safe, single handed operation •Innovative controlled motion •Secure toggle locking action •Simple set-up and adjustment•Clamp hook/arm moves and stays safely out of the wayApplications:•Molding•Closures for doors, lids, covers •Assembly•Checking fixturese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.4Series 330, 351, 371, 381 Product OverviewSeries 330, 351, 371, 381Technical Information, Holding CapacitiesCovered under one year or more U.S./International PatentsFeatures:•J-hook style latch clamps are supplied withthreaded J-hooks for easy adjustment•Supplied with patented thumb control lever for one handed operation•DE-STA-CO® Toggle Lock Plus versions available •Stainless steel version available as -SS modelsApplications:•Molding•Closures for doors,lids, covers •AssemblyAlso Available:•Clamps with longer hooks available Upon Request that are 25mm, 50mm,100mm longer than standard length •To order clamp with longer hook, add -M -25, -M -50, or -M -100to the end of the model. Example: 330-M -50351351-SSwith DE-STA-CO ®Toggle Lock Plus330330-SS 351-B 351-BSS Narrow Base351-RwithDE-STA-CO ®Toggle Lock Plus371371-SS371-RwithDE-STA-CO ®Toggle Lock Plus381381-SSe s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.5Series 330, 351, 371, 381Standard Clamp Dimensions330/351/371/381/-SS/-B/-BSSC2DBA1351-SSwith DE-STA-CO ®Toggle Lock Plus330330-SSNarrow Base371371-SS381381-SSe s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6. 6Series 351-R, 371-RStandard Clamp DimensionsModel 351-R, 371-RInformation concerning the assembly and function of the clamps locking mechanismThe locking plate which is supplied with the unit must be fastened with a screw (M6 or 1/4-20) as shown in this illustration. The screw head should be flat.FunctionWhen closing the latch clamp, the locking lever engages automatically. Locking leverPressure springLocking plate [0.25]6,5351-RwithDE-STA-CO ®Toggle Lock Plus371-RwithDE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 351-R, 371-R Replacement Hook Assembly Standard Dimensions6.7e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6. 8Series 323, 331, 341 Product OverviewSeries 323, 331, 341Technical Information, Holding CapacitiesCovered under one year or more U.S./International PatentsFeatures:•U-hook style latch clamps are supplied withthreaded U-hooks for easy adjustment•Supplied with latch plate and patented thumb control lever for one handed operation•DE-STA-CO® Toggle Lock Plus versions available •Stainless steel version available as -SS modelsApplications:•Molding•Closures for doors,lids, covers •AssemblyAlso Available:•Clamps with longer hooks available Upon Request that are 25mm, 50mm,100mm longer than standard length •To order clamp with longer hook, add -M -25, -M -50, or -M -100to the end of the model. Example: 323-M -50323-R 323-RSSwith DE-STA-CO ®Toggle Lock Plus323323-SS 331331-SS 331-R 331-RSSwithDE-STA-CO ®Toggle Lock Plus341341-SS341-R 341-RSSwith DE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.9Series 323, 323-R, 331, 341Standard Clamp Dimensions 323/331/341/-SS/-R/-RSSB2323-R 323-RSSwith DE-STA-CO ®Toggle Lock Plus323323-SS331331-SS341341-SSe s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6. 10Series 331-R, 341-R Standard Clamp Dimensions-R/-RSSA4A2A5341-R 341-RSSwith DE-STA-CO ®Toggle Lock Plus331-R 331-RSSwithDE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.11Series 323, 331, 341 Replacement Hook Assembly Standard Dimensionse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6. 12Series 375Product OverviewSeries 375Technical Information, Holding CapacitiesCovered under one year or more U.S./International PatentsFeatures:•Heavy duty U-hook style latch clamps aresupplied with threaded U-hooks for easy adjustment•Supplied patented thumb control lever for one handed operation•DE-STA-CO® Toggle Lock Plus versions availableApplications:•Molding•Closures for doors,lids, covers •AssemblyAlso Available:•Clamps with longer hooks available Upon Request that are 25mm, 50mm,100mm longer than standard length •To order clamp with longer hook, add -M -25, -M -50, or -M -100to the end of the model. Example: 375-M -50375-RwithDE-STA-CO ®Toggle Lock Plus375385102Optional Latch Plate for 375, 375-R375-B Weld-on Mounting 375-BR Weld-on Mountingwith DE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 375-B, 375-BRStandard Clamp Dimensions6.13375375-BWeld-onMountingWeld-onMountingwith DE-STA-CO®Toggle Lock375-RwithDE-STA-CO®Toggle LockPlusesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com6. 14Series 385 Product OverviewSeries 385Technical Information, Holding CapacitiesCovered under one year or more U.S./International PatentsFeatures:•Heavy duty U-hook style latch clamps aresupplied with threaded U-hooks for easy adjustment•Supplied with patented thumb control lever for one handed operation•DE-STA-CO® Toggle Lock Plus versions availableApplications:•Molding•Closures for doors,lids, covers •AssemblyAlso Available:•Clamps with longer hooks available Upon Request that are 25mm, 50mm,100mm longer than standard length •To order clamp with longer hook, add -M -25, -M -50, or -M -100to the end of the model. Example: 385-M -50385-Rwith DE-STA-CO ®Toggle Lock Plus385385-LLow Profile Handle385-V2A Stainless Steel385102Optional Latch Plate for 385, 385-Re s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.15Series 385, 385-RSeries 385-L Standard Clamp Dimensions385-Rwith DE-STA-CO®Toggle LockPlus385385-LLow ProfileHandleesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com6. 16Series 324, 334, 344, 374 Product OverviewSeries 324, 334, 344, 374Technical Information, Holding CapacitiesCovered under one year or more U.S./International PatentsFeatures:•U-hook style latch clamps supplied withthreaded U-hooks for easy adjustment•Supplied with latch plate and patented thumb control lever for one handed operation•DE-STA-CO® Toggle Lock Plus versions available •Stainless steel available as -SS models.Applications:•Molding•Closures for doors,lids, covers •AssemblyAlso Available:•Clamps with longer hooks available Upon Request that are 25mm, 50mm,100mm longer than standard length •To order clamp with longer hook, add -M -25, -M -50, or -M -100to the end of the model. Example: 324-M -50324-Rwith DE-STA-CO ®Toggle Lock Plus374374107Optional Latch Plate for 374324324-SS334334-SS334-Rwith DE-STA-CO ®Toggle Lock Plus344344-SS344-Rwith DE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m334334-SS6.17Series 324, 334, 344, 374 Standard Clamp Dimensions 324/334/374/-SS324324-SS344344-SS374e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6. 18Series 324-R, 334-R, 344-R Standard Clamp Dimensions-R/-SS324-Rwith DE-STA-CO ®Toggle Lock Plus334-Rwith DE-STA-CO ®Toggle Lock Plus344-Rwith DE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m6.19Series 324, 334, 344, 374Replacement Hook Assembly Standard DimensionsC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 301, 311 Product OverviewSeries 301, 311Technical Information, Holding Capacities, Standard Clamp Dimensions311301301-SSFeatures:•Fixed stop automatically limits handle travelat various clamping positions once the clamp is installed•Model 301 available in stainless steel as 301-SSApplications:•Molding•Closures for doors,lids, covers •Assembly6. 20C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m3011-SS3011Series 3011Product Overview Series 3011Technical Information, Holding Capacities, Standard Clamp DimensionsFeatures:•Heavy duty cast steel or stainless steel construction with ergonomic handle •Replaceable stainless steel pivot pinsApplications:•Molding•Closures for doors,lids, covers •Assemblye s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 353, 359Technical Information, Holding Capacities Features:•Heavy duty cast steel clamps are designedto withstand the harshest environments•Ideally suit for parting line clamping ofrotational molds•Replaceable stainless steel pivot pins•Available in stainless steel as 359-35, 359-65Applications:•Molding•Closures for doors,lids, coversAlso Available:•Keeper plate•Papered bolt assembly359-35Stainless Steel353-35353-65359-65Stainless SteelesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmaSeries 353, 359Standard Clamp Dimensions359-35Stainless Steel353-35353-65359-65Stainless Steele s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o me s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a。

新品NEWS ACModels 出品DEFModel 出品Scibor出品ACM16010 1/16 法国伞兵 印度支那ACM35009 1/35 法国外籍军团乘员ACM75006 1/35 美国海军陆战队担架队DW35053 1/35 德国野犬2型运输车轮胎改造件(配威望)DW35054 1/35 M-ATV轮胎改造件(配熊猫)DW35056 1/35 飞毛腿导弹发射车轮胎改造件 种类1(配威龙)DW35057 1/35 飞毛腿导弹发射车轮胎改造件 种类2(配威龙)35HM0009 1/35 波兰伞兵旅史坦尼斯劳将军35HM0011 1/35 波兰童子军NEWS NEWS NEWS NEWS NEWS NEWS. All Rights Reserved.NEWSAIRES 出品MiniArt 出品牛魔王出品2192 1/32 美国A-4E天鹰攻击机细节改造件(配小号手)2193 1/32 德国Bf-109G战斗机座舱改造件(配威望)4615 1/48 英国喷火 Mk.IX战斗机机枪舱改造件(配牛魔王)4617 1/48 瑞典JAS-39C战斗机座舱改造件(配小鹰)4619 1/48 英国美洲豹攻击机GR.1 座舱改造件(配小鹰)7309 1/72 苏联米格-15bis战斗机尾喷改造件(配牛魔王)672030 1/72 AIM-7E “麻雀”导弹672029 1/72 AIM-54A “不死鸟”导弹1184 1/48 拉-5战斗机限量版84124 1/48 米格-21PFM战斗机周末版8283 1/48 喷火Mk.IXe战斗机专业版35165 1/35 二战英国军官36056 1/35 中东场景. All Rights Reserved.新品NEWS传奇出品LF1274 1/35 德国Sd.Kfz.222装甲车杂物改件LF1275 1/35 英国M8灰狗装甲车杂物改件LF1277 1/35 美国M151A1吉普车改件LF1278 1/35 南非RG-31装甲车内构改件LF1279 1/35 南非RG-31装甲车扫雷滚改件. All Rights Reserved.NEWS 伊达雷丽出品长谷川出品天力出品112 1/72 意大利CANT.Z.501水上飞机404 1/35 电线杆1349 1/72 瑞士航空DC-32735 1/48 美国ES-3A电子战飞机6518 1/35 美国M108自行火炮7071 1/35 德国15厘米火箭发射器及成员02082 1/72 美国“飞虎队”P-40E战斗机(一盒两架)02083 1/72 美国OA-4M “天鹰”战斗机(一盒两架)02085 1/72 三菱F-2A战斗机07366 1/48 日本川崎Ki-61-I“飞燕”战斗机07367 1/48 日本九州J7W2-S“震电改”截击机08235 1/32 美国BF2C-1轰炸机(第5轰炸中队式样)K48044 1/48 格鲁曼EA-6B“徘徊者”电子战飞机K48051 1/48 法国富加“教师”喷气式教练机. All Rights Reserved.新品NEWS 小号手出品田宫出品01014 1/35 俄罗斯BM-21“冰雹”自行火箭炮后期型01533 1/35 BMP-3韩国陆军型02298 1/32 德国BF109G-10战斗机02325 1/35 苏联A-19 122毫米炮02888 1/48 美国A-37A“蜻蜓”攻击机02890 1/48 韦斯特兰“旋风”战斗机03619 1/200 中国海军051C型防空导弹驱逐舰05327 1/350 美国海军印第安那波利斯重巡洋舰CA-35 1944年版05573 1/35 苏联JS-4重型坦克05575 1/35 苏联704工程自行榴弹炮35335 1/35 德国犀牛式自行反坦克炮纳粹德国发动巴巴罗萨作战入侵苏联后,原有的各类反坦克炮无法有效的击毁T-34、KV-1等重型坦克。

GSC3280开发板快速指南2013年7月北京神州龙芯集成电路设计有限公司BLX IC Design Co., Ltd1 北京神州龙芯集成电路设计有限公司版权所有第一章前言GSC3280芯片是一款主要面向工业终端类应用的SOC芯片,采用0.13um标准CMOS制造工艺,主频200~300MHZ。

GSC3280在片内集成了丰富的功能模块与外围接口,包括10/100Mbps 以太网MAC控制器、USB2.0 OTG控制器、DDR2控制器、NAND Flash控制器、SD/SDIO主控制器、LCD控制器、I2C、I2S、UART、SPI、PWM、旋转编码器鉴相器、定时器等等;丰富的片内集成设备提高了整体性能,降低了系统成本,并可以满足更多的应用需求GSC3280开发板集成了丰富的外围接口和常用的设备芯片,适用于工业终端类的产品作为参考设以及计验证版,也可以作为嵌入式的学习板供开发和研究。

GSC3280在软件上提供了开源,免费的u-boot,linux和应用示例代码,方便开发者的使用。

第二章GSC3280开发板介绍GSC3280提供了丰富的硬件接口和软件资源,主要接口:电源接口1个(DC5V/2A)电源开关1个RESET按键1个MCU BUS LCD接口1个(10*2插针座,2.0mm间距)RGB BUS LCD接口1个(20*2插针座,2.0mm间距)7英寸TFT LCM接口1个(LCD-S70,带4线电阻触摸屏,背面)PS2接口1个VGA接口1个USB HOST接口4个(2*2)USB Device接口1个RS485接口1个SD卡接口1个ISO7816接口1个(背面)串口3个,1个为全功能串口(UART6),2个为两线串口(UART0、UART1),UART6和UART0为标准DB9接口,UART1为插针接口SPI接口2个(1个为DIP8 IC座形式,1个为插针形式)3个音频接口(MIC-IN\LINE-IN\LINE-OUT各1个)2北京神州龙芯集成电路设计有限公司版权所有3北京神州龙芯集成电路设计有限公司 版权所有BOOT 设置开关1个 CAN 总线接口1个 JTAG 接口1个 RJ45以太网口1个 I2C 接口1个 旋转编码器接口1个 PWM 接口1个(6个PWM ) GPIO 接口2组(2组GPIO)软件资源:mips-linux 交叉工具链 ejtag u-boot linux-3.0.4 测试用例 QT2-embedded配件清单:设备及配件 数量 GSC3280核心板 1块 GSC3280底板1块 7寸TFT 液晶屏(带4线电阻触摸屏) 1套(标配)串口线1根 ejtag 并口下载线 1根(标配) ejtag-usb 下载线 1根(选配) DC 5v —3A 电源 1个 资源光盘1张第三章GSC3280快速体验3.1 概述本章主要介绍当拿到开发板的时候,如何快速上手使用光盘中提供的二进制文件在开发板上运行起LINUX系统。

静态模型品牌:国产小号手及支线品牌九十年代初期的时候,当上海威龙(Shanghai-Dragon,Dragon的上海分部)在模型界引起轰动的时候,小号手Trumpet的模型,不过是和正德福(ZDF)、西西利(LEE)类似的二线模型品牌,其作品如早期1/35坦克装甲车辆,早期1/700舰艇系列,被当作是玩具一样看待。

事隔十余年,这个昔日的“吴下阿蒙”,却已雄据模型界一隅,敢与港龙Dragon和田宫TAMIYA分庭抗礼了。

其产品推出速度之快,其模型题材之新颖,颇为模友们瞩目。

这里大致给大家介绍一下小号手Trumpet常见的模型种类,和购买时的一些小窍门。

小号手Trumpet的商标及产品类型可能大家很奇怪,为什么还要介绍商标类型呢?因为小号手Trumpet有好几个支线品牌,而且从很大程度上代表了其产品的相应水准,不得不解释清楚。

一、三角号手系列(Mini Hobby Models)三角号手(商标见上图),或者商标上出现“小号手”三个汉字的商标,基本上属于小号手的低端产品,价格非常低廉,但是质量比较差。

几乎没有什么仿真性可言。

只适合当作玩具来玩。

对于提高模型水平几乎没有什么帮助。

不过这些产品有些带有电动机,可玩性倒是比较强的。

这一类“玩具”模型主要包括1/35坦克,1/700或无比例战舰,1/144及1/72飞机等。

购买时要认清商标。

保留这一类产品系列,恐怕是小号手挤占低端模型市场的手段吧。

因为这一市场虽然不入流,但是由于消耗量巨大(基本上都是一次性消耗),所以也是一个不可小视的市场。

二、喇叭号手系列(TRUMPETER)喇叭号手(商标见上图)则是小号手的正规产品,它的产品类型和特点,则值得好好讲一下:(一)1/16, 1/35, 1/48,1/72,1/144坦克装甲车辆小号手Trumpet的坦克装甲车辆模型仅仅比例就达到了5种之多,可想而知其产品的丰富程度。

其中1/16的坦克模型,有全内构和遥控型两种,都是模友们非常喜爱的品种。

1.1 esyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 21.3Series 2002Technical InformationSeries 2002Product Overview2002-SFlanged Base Solid Bar 2002-UFlanged Base U-Bar 2002-UR Flanged Base U-BarwithDE-STA-CO ®Toggle Lock Plus2002-SB Straight Base Solid Bar 2002-U207Flanged Base U-BarInterchangeable with 207 Series2002-SBR Straight Base Solid BarwithDE-STA-CO ®Toggle Lock Plus2002-SR Flanged Base Solid BarwithDE-STA-CO ®Toggle Lock Plus2002-UBR Straight Base U-BarwithDE-STA-CO ®Toggle Lock Plus2002-UR207Flanged Base U-BarInterchangeable with 207 Series,DE-STA-CO ®Toggle Lock Plus2002-UB Straight Base U-BarNote:Clamps shown with included accessories. To order without spindle, add (-LS )to the end of model (Ex: 2002-U-LS )Features:•Large hand clearance for improved safety •Bolt pattern interchangeable with 202 Series •Three times the holding capacity of 202 Series •Hardened bushings at key pivot points •Near vertical clamping contactApplications:•Checking fixtures •Assembly & test •Light machining •WoodworkingAlso Available:See page 8.1 for accessoriesAccepts M6 or 1/4 spindle accessoriesCovered under one or more U.S./International Patentse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 4UFlanged Base SB Straight BaseSolid BarSeries 2002Holding Capacitiese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.5Series 2007Technical InformationSeries 2007Product Overview2007-SFlanged Base Solid Bar 2007-UFlanged Base U-Bar 2007-UR Flanged Base U-BarwithDE-STA-CO ®Toggle Lock Plus2007-SB Straight Base Solid Bar2007-SBR Straight Base Solid BarwithDE-STA-CO ®Toggle Lock Plus2007-SR Flanged Base Solid BarwithDE-STA-CO ®Toggle Lock Plus2007-UBR Straight Base U-BarwithDE-STA-CO ®Toggle Lock Plus2007-UB Straight Base U-BarNote:Clamps shown with included accessories. To order without spindle, add (-LS )to the end of model (Ex: 2007-U-LS )Features:•Large hand clearance for improved safety •Bolt pattern interchangeable with 207 Series •Over two times the holding capacity of 207 Series•Hardened bushings at key pivot points •Near vertical clamping contact Applications:•Checking fixtures •Assembly & test •Light machining •WoodworkingAlso Available:See page 8.1 for accessoriesAccepts M8 or 5/16 spindle accessoriesCovered under one or more U.S./International Patentse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 6Series 2007Holding Capacities2007-SB Straight Base Solid BarSeries 2007Standard Clamp Dimensions-U/-S/-UB/-SB/-UR/-SR/-UBR/-SBRUFlanged Base e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.7Series 2010Technical InformationSeries 2010Product Overview2010-SFlanged Base Solid Bar 2010-UFlanged Base U-Bar 2010-UR Flanged Base U-Barwith DE-STA-CO ®Toggle Lock Plus2010-SB Straight Base Solid Bar2010-SBR Straight Base Solid Barwith DE-STA-CO ®Toggle Lock Plus2010-SR Flanged Base Solid Barwith DE-STA-CO ®Toggle Lock Plus2010-UBR Straight Base U-Barwith DE-STA-CO ®Toggle Lock Plus2010-UB Straight Base U-BarNote:Clamps shown with included accessories. To order without spindle, add (-LS )to the end of model (Ex: 2010-U-LS )Covered under one or more U.S./International PatentsFeatures:•Large hand clearance for improved safety •Bolt pattern interchangeable with 210 Series •Over two times the holding capacity of 210 Series•Hardened bushings at key pivot points •Near vertical clamping contactApplications:•Checking fixtures •Assembly & test •Light machining •WoodworkingAlso Available:See page 8.1 for accessoriesAccepts M10 or 3/8 spindle accessoriese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 8Series 2010Holding Capacities2010-UFlanged Base U-Bar2010-SB Straight Base Solid BarSeries 2010Standard Clamp Dimensions-U/-S/-UB/-SB/-UR/-SR/-UBR/-SBRe s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.9Series 201Technical Information Series 201Product Overview201-UB†Straight Base201-U†Flanged BaseU-Bar201-USSFlanged BaseU-Bar, StainlessSteel201-TUStraightBase, U-Bar,T-HandleNote:Clamps shown with included accessories. †To order without spindle, add (-LS)to the end of model(Ex: 201-U-LS) Features:•Smallest series in the Vertical Handle series•Stainless steel version availableApplications:•Checking fixtures•Assembly & test•WoodworkingAlso Available:See page 8.1 for accessories812-U Pneumatic Toggle Clamp(See page 10.3)Series 201Holding CapacitiesesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 10201-UB †Straight Base201-U †Flanged Base U-BarSeries 201Standard Clamp Dimensions-U/-UB/-TU/-USS5,44,0[0.16][0.20]5,0e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.11Series 202Product Overview 202-ULFlanged Base Long U-Bar202-U †Flanged Base U-Bar 202-SSFlanged Base Solid BarStainless Steel202Flange Base Solid Bar202-TFlanged Base Solid Bar T-Handle202-TUFlanged Base U-bar, T-Handle 202-UB †Straight Base U-bar 202-BStraight Base Solid Bar202-U -L Flanged Base Open U-Bar202-USS Flanged Base U-bar, Stainless SteelNote:Clamps shown with included accessories. †To order without spindle, add (-LS )to the end of model (Ex: 202-U-LS )Features:•Two bar styles available•Low profile T-Handle version available •Available in stainless steel•Accommodates M6 or ¼” spindle accessoriesApplications:•Checking fixtures •Assembly & test •Light machining •WoodworkingAlso Available:See page 8.1 for accessories 802-U Pneumatic Toggle Clamp (See page 10.5)202-UB -L Straight Base Open U-Bare s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 12Series 202Technical Informatione s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 202Standard Clamp Dimensions 202/-U/-UL/-USS/-SS/-UB/-B/-TU/-T6,5[0.26][0.92]23,39,6[0.38]202-U †Flanged BaseU-Bar1.13Bar Style e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 14Application AreasClamping during the assembling, drilling, testing, gluing,locking of covers and much more. The vertical clamp is the most frequently used product whenever clamping products are to be integrated with a manual fixture.The essential product features•In the clamping position, the handle is vertical•Vertical clamps open at an angle between 75° and 215°•Vertical clamps are offered with U-shaped or heavy-duty solid clamping bars•Vertical clamps have a straight or flanged base. The heavy-duty vertical clamps possess a base that can be welded on without a hole patterne s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries 207Product Overview1.15Features:•Largest selection of arm and mounting options•Low profile T-Handle version available •Available in stainless steel Applications:•Checking fixtures•Assembly & test•Light machining•WoodworkingAlso Available:See page 8.1 for accessories807-U Pneumatic toggle clamp(See page 10.7)807-S Pneumatic toggle clamp(See page 10.7)Accepts M8 or 5/16 spindle accessories207-ULFlanged BaseLong U-Bar207-U†Flanged BaseU-Bar207-LFlanged BaseLong Solid Bar207-SFlanged BaseSolid Bar207-ULB†Straight BaseLong U-Bar207-UB†Straight BaseU-Bar207-LBStraight BaseLong SolidBar207-SBStraight BaseSolid Bar207-SFSolid BarDual Mount207-UFU-BarDual Mount207-UB-LStraight BaseOpen Bar207-U-LFlange BaseOpen Bar207-UR†Flanged BaseU-BarwithDE-STA-CO®Toggle LockPlus207-LBRStraight BaseLong SolidBar withDE-STA-CO®Toggle LockPlus207-TUFlanged BaseT-HandleU-Bar207-TULFlanged BaseT-HandleLong U-Bar207-LRFlanged BaseLong Solid BarwithDE-STA-CO®Toggle LockPlus207-USSStainlessFlanged BaseU-BarNote:Clamps shown withincluded accessories†To order withoutspindle, add (-LS)to the end of model(Ex: 207-UB-LS)esyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 16Series 207Technical InformationSeries 207Holding Capacitiese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.17Bar StyleThis item is available upon requestSeries 207Standard Clamp Dimensions-U/-UL/-S/-L/-TU/-TUL/-UR/-LR/-UB/-ULB/-SB-/-LB/-LBRFlanged Base 207-SBStraight Base Solid BarC o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mVertical Hold Down ClampsSeries 207Standard Clamp Dimensions - Dual Mount86,6[3.41]Ø8,4[0.33]33ADJ,[1.30]56,1[2.21]16[0.63]68,2[2.69]90°57°210,8[8.30]3,1[0.12]25,4[1.00]38,1[1.50]35,1[1.38]11,2[0.44]16[0.63]81,2[3.20]6,4[0.25]Ø8,7[0.34]3,3[0.13]35,1[1.38]38,1[1.50]25,4[1.00]16[0.63]Ø6,7[0.27]127,7[5.03]11,2[0.44]3[0.12]68,2[2.68]16[0.63]8,6[0.34]7,1[0.28]33[1.30]47,2[1.86]93,7[3.69]38,1[1.50]11,4[0.45]56°16[0.63]31,7[1.25]3,1[0.12]14357°[5.63]39,6[1.56]4,6[0.18]99°M8 OR 5/168,3[0.33]53,5[2.11]112,9[4.44]25,3[1.00]15[0.59]31,6[1.25]19,1[0.75]7,9[0.31]35,1[1.38]44,3[1.75]Ø7,1[0.28] This item is available upon requestM8 OR 5/16Model 207-SFModel 207-UF1. 18▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.19Series 210Technical InformationSeries 210Product Overview 210-USS Flanged Base U-bar, Stainless Steel210-U †Flanged Base U-Bar210-SBStraight Base,Solid Bar210-UB †Straight Base U-bar 210-UBR † Straight Base U BarwithDE-STA-CO ®Toggle Lock Plus210-TUFlanged Base U Bar, T-Handle210-UR †Flanged Base U BarwithDE-STA-CO ®Toggle Lock Plus210-SRFlanged Base Solid BarwithDE-STA-CO ®Toggle Lock Plus210-SFlanged Base Solid BarNote:Clamps shown with included accessories. †To order without spindle, add (-LS )to the end of model (Ex: 210-U-LS )Features:•DE-STA-CO ®Toggle Lock Plus versions available •Available in stainless steel•Accomodates M10 or 3/8 spindle accessoriesApplications:•Assembly & test •Light machining •Light weldingAlso Available:See page 8.1 for accessories 810-U Pneumatic Toggle Clamp (See page 10.9)810-S Pneumatic Toggle Clamp (See page 10.9)C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 2Series 210Holding CapacitiesU †Flanged Base U-BarSeries 210Standard Clamp Dimensions 210-SRFlanged Base Solid BarwithDE-STA-CO ®Toggle Lock Pluse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.21Series 247, 267Technical InformationSeries 247, 267Product Overview247-SFlanged BaseSolid Bar247-UFlanged BaseU-Bar267-UFlanged BaseU-Bar247-UBStraight BaseU-BarNote:Clamps shown with included accessories. To order without spindle, add (-LS)to the end of model(Ex: 247-U-LS) Features:•Hardened steel bushings•Large bar guides for greater lateral stability onModel 247•Series 247 accomodates M12 or1/2 spindle accessory•Series 267 accomodates M16 or5/8 spindle accessoryApplications:•Assembly & test•Light machining•WeldingAlso Available:See page 8.1 for accessories847-U Pneumatic Toggle Clamp(See page 10.15)847-S Pneumatic Toggle Clamp(See page 10.15)267-SFlanged BaseSolid BarSeries 247Holding CapacitiesesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 2210ADJUSTMENTØ 14,4[0.57]247-SFlanged Base Solid Bar247-UFlanged Base U-BarSeries 247Standard Clamp Dimensions-U/-S/-UBe s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.23Ø 16,3[0.64]48ADJUSTMENT267-UFlanged Base U-Bar267-SFlanged Base Solid BarSeries 267Standard Clamp Dimensions -U/-Se s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 24Model 210-Uused in an airframe assembly fixtureModel 210-Ushown being used in a checking fixtureapplication.Model 533-LBand 227-UB shown with black finish in a fixture for used for optical inspection.e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.25Series 516Product Overview516Weldable BaseSolid BarFeatures:•Hardened steel pins and bushings strengthand long life•Replaceable pivot pins•Large, solid clamping arm is easily modifiedto suit application requirements•Similar in size to Model 207Applications:•Light machining•Welding•Molding•Medium to heavyduty clampingapplicationsAlso Available:See page 8.1 for accessories846 Pneumatic Toggle Clamp(See page 10.11)516-BFlanged BaseSolid BarSeries 516Holding Capacities, Standard Clamp DimensionsesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 26Series 518Product Overview518Flanged Base Solid BarFeatures:•Forged clamping arm•Large clearance under the bar •Ergonomic safety handleApplications:•Assembly & test •Light machining •WeldingSeries 518Holding Capacities, Standard Clamp Dimensionse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.27Series 528Product Overview Flanged Base Solid Bar Features:•Hardened steel bushings at pivot points for long life•Solid bar may be modified to suit application requirementsApplications:•Assembly & test •Light machining •Welding•Medium to heavy duty clamping requirementsFront Mount Base Solid BarSeries 528e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 28Series 548, 578Product Overview548Straight Base Solid Bar Features:•Large bar guides for lateral stability•Hardened steel pins and bushings for long life •Replaceable pinsApplications:•Assembly & test •Light machining •Welding •Heavy duty clamping requirements578Straight Base Solid BarSeries 548, 578Holding Capacities, Standard Clamp Dimensionse s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.29Series 533, 535Technical InformationSeries 533, 535Product Overview Features:•Hardened steel bushings and pivot pins •Large bar guides for greater lateral support •Solid clamping bar may be modified to suit application requirementsApplications:•Welding •Heavy duty clamping applications533-LBStraight Base Solid Bar 533-LFlanged Base Solid Bar 535-LBStraight Base Solid Bar535-LFlanged Base Solid BarAlso Available:See page 8.1 for accessoriese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 3Series 533, 535Standard Clamp Dimensions-L/-LB B533-LFlanged Base Solid Bar535-LFlanged Base Solid Bare s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.31Series 558Product Overview 558Features:•Forged alloy steel handle and links for rugged service•Hardened steel pins and bushings•Hold down bar can be machined to suit application requirementsApplications:•Welding •Heavy duty clamping requirementsSeries 558Holding Capacities, Standard Clamp Dimensions11,1Also Available:Model 858 Pneumatic Toggle clamp See page 10.17e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 3233,4Series 91090Technical Information, Standard Clamp DimensionsSeries 91090Product Overview91090Front Flanged Base Open BarFeatures:•Front flange mount•Accepts M8 or 5/16” spindle accessory (not supplied)Applications:•Assembly & test •Checking fixtures •Light machining •WoodworkingAlso Available:See page 8.1 for accessoriese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.33Series 317Technical InformationSeries 317Product Overview 317-U U-Bar Features:•Dual mounting surfaces •Large bar opening angle •Accommodates M8 or 5/16” spindle accessoriesApplications:•Assembly & test •Checking fixtures •Light machining •Woodworking317-S Solid BarNote:Clamps shown with included accessories. To order without spindle, add (-LS )to the end of model (Ex: 317-U-LS )Also Available:See page 8.1 for accessories 817-U Pneumatic Toggle Clamp (See page 10.21)817-S Pneumatic Toggle Clamp (See page 10.21)Series 317 Holding Capacitiese s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 3425,48,6Ø 6,7[0.27]26M8 OR 5/16317-U U-Bar317-S Solid BarSeries 317Standard Clamp Dimensions-U/-Se s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.35Series 527Product Overview Features:•Hardened steel bushings at pivot points•Solid bar can be modified to suit application requirements•Thumb lever on link for easy openingApplications:•Assembly & test •Light machining •Woodworking19e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ 0) 426-5480 ▪ w w w .c m a f h .c o m1. 36C2Heavy Duty Cam Action Series Standard Clamp Dimensions - Flanged BaseHeavy Duty Cam Action Series Product Overview7-101Features:•Cam action accommodates variableworkpiece thickness•Heavy duty construction•Solid clamp arms may be modified to suit application requirementsApplications:•Light machining •Welding •Assembly7-58e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.37Series 229Product Overview Flanged BaseOpen BarFeatures:•Cam action clamp holds workpiecesof varying height•Total clamping range of 8mm[.31in.]•Accommodates M12 or ½” accessoriesApplications:•Assembly & test•Light machining•WeldingAlso Available:See page 8.1 for accessories Series 229Holding CapacitiesSeries 229Technical InformationesyofCMA/Flodyne/Hydradyne▪MotionControl▪Hydraulic▪Pneumatic▪Electrical▪Mechanical▪(8)426-548▪www.cmafh.com1. 38Series 229Standard Clamp Dimensions25,4[1.00]12,4229Flanged Base Open Bare s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1.39Series 500Product Overview Features:•Hardened pivot pins and bushings •Weldable clamping bar•LSC version with locking spring clip for securing the handle in the open position•Modular design allows you to set up the clamp to meet application requirementsApplications:•Welding •Assembly •Heavy duty, production clamping applicationsAlso Available:See page 1.42 for accessories501-LB Long Base 501-B Swivel Base 503-MBLSC Swivel Base with Locking Spring Clip503-MLB Long Base506-MB Swivel Base 506-MBLSC Swivel Base with Locking Spring Clip 506-MLB Long Base505-MLB Long Base506-MLBLSC Long Base with Locking Spring Clip505-MB Swivel Base 503-MLBLSC Long Base with Locking Spring Clip505-MBLSC Swivel Base with Locking Spring Clip 505-MLBLSC Long Base with Locking Spring Clip503-MB Swivel BaseModel 505-MLB in a robotic welding fixture This item is available upon requeste s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m1. 40Series 500Technical InformationNote:The clamping bars are made fromforged alloy steel and must be heated to 200°C(400°F) prior to welding. We recommend welding the handles,clamp arms, and mounting bases when disassembled. Welding of non pre-heated parts may only be done with the addition of welding fillers.1. Mount the clamp and place it in the closed position2. Position the bracket ➀in the leaf spring ➁ 4. In this position, weld the bracket ➀with the bar guide feature ➂at point ➃e s y of C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m。

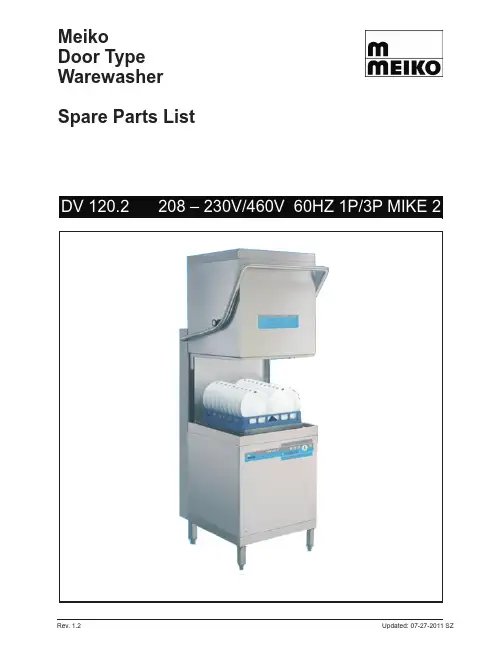

MeikoDoor Type Warewasher Spare Parts List11.37 Electronic control 208-230V 1~Contents01.18 Wash Pump 03.24 Wash system 04.25 Solenoid valve 06.07 Level control 08.37 Incorporated boiler 09.15 Tank heating 10.14 Dosing units11.38 Electronic control 208-230V 3~ 13.27 Component blocks / parts 18.10 Drain pump22.13 Booster pump 24.06 Air gapLEGEND KEY FOR PARTS* RECOMMENDED SPARE PA RTS V WEAR AND TEAR PARTWE RESERVE THE RIGHT TO CHANGEEXECUTION AND CONSTRUCTION.MEIKO USA Inc.1349 Heil Quaker Blvd. La Vergne, TN 37086T oll Free (800) 55-MEIKO (For general inquiries)FAX (615) 399-6620 *************2 4-Hour Service (800) 866-3840 or (615) 399-660011.48 Electronic control 460V 3~ 14.08 Hood Rod 11.58 Incoming Power Terminal Blocks 13.37 Wash Tank 19.01 Drain Water Tempering Kit01.18 WASH PUMP - STANDARD HOOD123456789101112136141516171801.18 WASH PUMP - STANDARD HOOD124 567 89 10 10 11123141315161918 17 POS.PART #DESCRIPTION19538681ASCENDING PIPE 29541533O-RING 46 X 339514453LOWER BEARING NECK 49541532O-RING 59538625NUT 69520931RING 79517398NUT 89517397BEARING 99604483DISK 109522439BEARING119517409KNURLED SCREW 129538645FIXING TUBE 139517391WASH ARM CPL.149547257FINAL RINSE ARM CPL.150401065O-RING 84 X 2169207851WASH / RINSE ARM BEARING KIT 179550206CLOSING CAP 188004468SPACER DISC 190401016O-RING 21 X 203.24 WASH SYSTEM04.25 SOLENOID VALVE3104POS.PART #DESCRIPTION 19207753AQUASTOP 29500321GASKET 39622932MICROSWITCH 49622935FLOAT SWITCH59250127GARDEN HOSE ADAPTER 3/4” X ½”NPT 69207228SWIVEL HOSE CONNECTOR ½”NPT 70225008Y-STRAINER BRASS 3/4”89250209REDUCER BUSHING, BRASS 3/4” X 1/2”99207230HOSE GASKET109207229Y STRAINER ASSEMBLY CPL.119207989AQUASTOP REBUILD KIT129207779FLOW RESTRICTOR 2.26 GPM - GREEN12121106.07 LEVEL CONTROL12 345 6 7 8POS.PART #DESCRIPTION 19537961PRESSURE SENSOR 29655080HOSE CLAMP 30260006HOSE, TRANSPARENT 49601265HOSE BRACKET 59655015HOSE CLAMP 69515957NUT 3/8”79515964SEAL89515955AIR TRAP08.37 INCORPORATED BOILER41223 5678 910111213141516171808.37 INCORPORATED BOILER09.15 TANK HEATING1 23POS.PART #DESCRIPTION19546105TANK HEATING ELEMENT 2 KW 208-240V20408008GASKET39548754PROTECTION AGAINST CONTACT10.14 DOSING UNITS109 128311123 345UPGRADE KIT W/O DOSING PUMPS:-DETERGENT AND RINSE AID TUBING -TUBE ADAPTERS -TUBE STIFFENERS -INSTRUCTIONS136710.14 DOSING UNITSPOS.PART #DESCRIPTION19544292DETERGENT DOSING PUMP CPL.29511675DETERGENT SQUEEZE TUBE39655015HOSE CLAMP49207252DETERGENT TUBING RED59207253RINSE AID TUBING WHITE69250135BULKHEAD PLUG79250160INJECTION FITTING89544088RINSE AID SQUEEZE TUBE99544293RINSE AID DOSING PUMP CPL.109203579YELLOW DOSING PUMP COVER119207382BLUE HOSE ADAPTER 2.5” (MADE FROM 9538712) 129207383CLEAR HOSE ADAPTER 2.5” (MADE FROM 0260007) 139207500CHEMICAL TUBING KIT10.14a CHEMICAL PICKUP TUBESFOR MACHINES SHIPPED BEFORE 4/28/2008SERIAL NUMBER < 10113866FOR MACHINES SHIPPED AFTER 2/09/2010SERIAL NUMBER ≥ 30002244FOR MACHINES SHIPPED BETWEEN 4/28/2008 - 02/09/2010SERIAL NUMBER > 10113866AND < 30002244321POS.PART #DESCRIPTION 18005393SUCTION LANCE29207327TUBE - 1/4” CPVC SCH. 8039666201SUCTION LANCE WITH LEVEL SENSOR11.37 ELECTRONIC CONTROL 208-230V 1~13891011111675171415243161811.37 ELECTRONIC CONTROL 208-230V 1~POS.PART #DESCRIPTION19207357TOUCHPAD KIT29542049DISPLAY PCB WITH HOUSING9541916DISPLAY PCB HOUSING30122106LEVER40122103MICROSWITCH59639363SUPPORT FOR TEMPERATURE SENSOR68302780MAGNETIC DOOR SWITCH0122013DOOR MAGNET79541525CPU CIRCUIT BOARD ASSEMBLY KIT89617235INPUT / OUTPUT CIRCUIT BOARD9611761FUSE 16A 20MM99521021CONTACTOR109544819CIRCUIT BREAKER 20A119544820CIRCUIT BREAKER 50A129640338WASH TANK TEMPERATURE PROBE ASSEMBLY KIT129649173WASH TANK TEMPERATURE PROBE ASSEMBLY KIT WITH WIRE NUTS 139626264POWER SUPPLY CIRCUIT BOARD149604262E-PROM - FOR UNITS SHIPPED AFTER 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 149540552E-PROM - FOR UNITS SHIPPED BEFORE 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 159615751EE-PROMNOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 169541141CPU BOARD HOUSING BOTTOM179541139CPU BOARD HOUSING TOP189635757COMMUNICATION RIBBON CABLE 1500MM9007304DV80.2 FRONT PANEL FOIL11.38 ELECTRONIC CONTROL 208-230V 3~5131812346151417716218111091911.38 ELECTRONIC CONTROL 208-230V 3~POS.PART #DESCRIPTION19207357TOUCHPAD KIT29542049DISPLAY PCB WITH HOUSING9541916DISPLAY PCB HOUSING30122106LEVER40122103MICROSWITCH59639363SUPPORT FOR TEMPERATURE SENSOR68302780MAGNETIC DOOR SWITCH0122013DOOR MAGNET79541525CPU CIRCUIT BOARD ASSEMBLY KIT89617235INPUT / OUTPUT CIRCUIT BOARD9611761FUSE 16A 20MM99542512CIRCUIT BREAKER 10A109541021CONTACTOR119542897CONTACTOR129626264POWER SUPPLY CIRCUIT BOARD139640338WASH TANK TEMPERATURE PROBE ASSEMBLY KIT139649173WASH TANK TEMPERATURE PROBE ASSEMBLY KIT WITH WIRE NUTS 149604292E-PROM - FOR UNITS SHIPPED AFTER 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 149540552E-PROM - FOR UNITS SHIPPED BEFORE 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 159615751EE-PROMNOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 169541141CPU BOARD HOUSING BOTTOM179541139CPU BOARD HOUSING TOP189635757COMMUNICATION RIBBON CABLE 1500MM9007304DV80.2 FRONT PANEL FOIL199544339MOTOR OVERLOAD 9 - 12.5A11.48 ELECTRONIC CONTROL 460V 3~512161434617197188151320910121111.48 ELECTRONIC CONTROL 460V 3~POS.PART #DESCRIPTION19207357TOUCHPAD KIT29542049DISPLAY PCB WITH HOUSING9541916DISPLAY PCB HOUSING30122106LEVER40122103MICROSWITCH59639363SUPPORT FOR TEMPERATURE SENSOR68302780MAGNETIC DOOR SWITCH0122013DOOR MAGNET79541525CPU CIRCUIT BOARD ASSEMBLY KIT89617235INPUT / OUTPUT CIRCUIT BOARD9611761FUSE 16A 20MM99542512CIRCUIT BREAKER 10A109531837MOTOR OVERLOAD FOR M2 0.35A - 0.50A119521021CONTACTOR129540601MOTOR OVERLOAD 7.0A - 10.0A139626264POWER SUPPLY CIRCUIT BOARD149640338WASH TANK TEMPERATURE PROBE ASSEMBLY KIT149649173WASH TANK TEMPERATURE PROBE ASSEMBLY KIT WITH WIRE NUTS 159545996TRANSFORMER169604262E-PROM - FOR MACHINES SHIPPED AFTER 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 169540552E-PROM - FOR MACHINES SHIPPED BEFORE 02/2010NOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 179615751EE-PROMNOTE: SERIAL NUMBER MUST BE PROVIDED WHEN ORDERING 189541141CPU BOARD HOUSING BOTTOM199541139CPU BOARD HOUSING TOP209635757COMMUNICATION RIBBON CABLE 1500MM9007304DV80.2 FRONT PANEL FOIL11.58 INCOMING POWER TERMINAL BLOCKSPOS.PART #DESCRIPTION 19545209TERMINAL BLOCK20153275TERMINAL BLOCK GROUND1213.27 COMPONENT BLOCKS/PARTS265 1243POS.PART #DESCRIPTION19651755TOP PANEL SPRING COVER 29539341SIDE PANEL39651983BACK PANEL W/ LOUVERS 49533829PLASTIC FOOT ADJUSTABLE 59547320CONTROL PANEL FRONT 9547313ADHESIVE STRIP FOR PANELS 68004126DOOR HOOD***THE FOLLOWING ITEMS ARE NOT SHOWN ON THIS PARTS BREAKDOWN***0620455SPACER FOR CLADDING 0463052HOOD ROD GUIDE LEFT 0463053HOOD ROD GUIDE RIGHT13.37 WASH TANK123POS.PART #DESCRIPTION19540851COVERING SIEVE RIGHT CPL.29540865COVERING SIEVE LEFT CPL.39546947BASKET HOLDER CPL.14.08 HOOD ROD121343981011121461556714.08 HOOD RODPOS.PART #DESCRIPTION10251103HOOD ROD20620449HOOD ROD BEARING 38004480HOOD ROLLER COVER 48000220HOOR ROLLER BOLT 50620451HOOD ROLLER60340006WASHER70337005CAP NUT M888004147TENSION NUT M898004425TENSION SCREW M8 X 760MM 100430006TENSION SPRING110620445SLIDING BEARING FOR SPRING 128004144UPPER SPRING SUSPENDER 139541450OVAL HEAD SCREW 149541531O-RING150335015HEX NUT M818.10 DRAIN PUMP123456789101112Only for 208-230VPOS.PART #DESCRIPTION19207587DOUBLE CHECK VALVE29250036CLOSE NIPPLE, BRASS 3/4” NPT 39207588TEMPERING VALVE 3/4”49207862REDUCER BUSHING, BRASS 1-1/4” NPT X 1” NPT 59207860COUPLER, 1-1/4” NPT69207861CLOSE NIPPLE, BRASS 1-1/4” NPT 79250208HOSE FITTING 1”89207863TEE, BRASS 1-1/4” NPT99207591DRAIN WATER TEMPERING KIT123456748919.01 DRAIN WATER TEMPERING KIT OPTIONAL FOR S/N: ≥ 3000169419.01 DRAIN WATER TEMPERING KITOPTIONAL FOR S/N: ≥ 30001694123453678910111211131415161718192021222324252627POS.PART #DESCRIPTION 19517067HOSE CONNECTION 29607417HOSE CLAMP 30 X 1239250208HOSE FITTING 1”49250105BRACKET 59250113TEE 1”69250102U-BOLT79250103REDUCER BUSHING 1” X 1/2”89651479CLOSE NIPPLE BRASS 1/2”99250112CHECK VALVE BRONZE 1/2”109250172HOSE BARB BRASS ½”X 3/8” 119609462HOSE CLAMP 17 X 12129207103RED HOSE 3/8”139250173HOSE BARB BRASS 3/8” X 3/8”149306463SOLENOID VALVE 3/8” 240VAC 159207079CLOSE NIPPLE 3/8”169250115REDUCER BUSHING BRASS ½”X 3/8” 179250209REDUCER BUSHING BRASS 3/4” X 1/2”189250051THREADED COUPLING BRASS 3/4”199250037NIPPLE BRASS 3/4” X 2”208660463NUT BRASS219250053ELBOW BRASS 90 3/4”229250127GARDEN HOSE ADAPTER 3/4” X 1/2”230153043TERMINAL BLOCK CLAMP 240153073END CAP250153090BRIDGE CONNECTOR 260153098FINAL ANGLE 270180314CABLE19.01 DRAIN WATER TEMPERING KIT OPTIONAL FOR S/N: ≥ 30001694345621722.13 BOOSTER PUMP24.06 AIR GAPPOS.PART #DESCRIPTION19523195AIR GAP 20650076RUBBER SEAL 30233036HOSE CLAMP49207103HOSE - FROM AQUASTOP 3/8”59207253RINSE AID TUBING - CLEAR 69605930HOSE WIRE CLAMP 79608600HOSE ½”89608607HOSE 3/8”98000609WATER GUIDE PLATE 109207382BLUE HOSE ADAPTER 119609462HOSE CLAMP 17 X 12129607418HOSE CLAMP 21 X 12129341065871112。

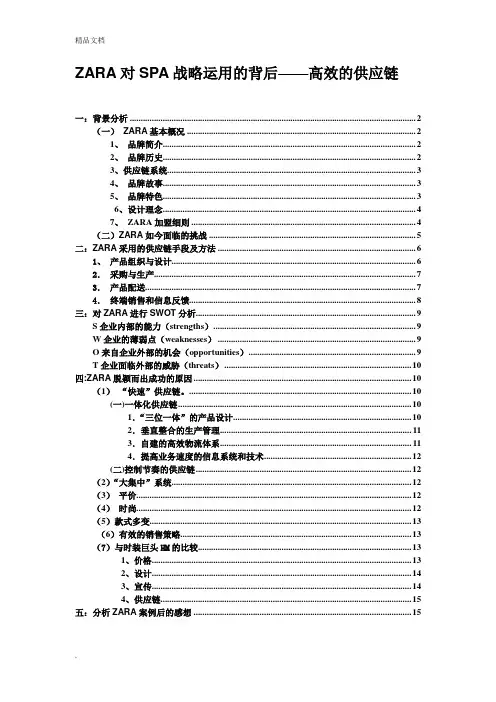

ZARA对SPA战略运用的背后——高效的供应链一:背景分析 (2)(一)ZARA基本概况 (2)1、品牌简介 (2)2、品牌历史 (2)3、供应链系统 (3)4、品牌故事 (3)5、品牌特色 (3)6、设计理念 (4)7、ZARA加盟细则 (4)(二)ZARA如今面临的挑战 (5)二:ZARA采用的供应链手段及方法 (6)1、产品组织与设计 (6)2.采购与生产 (7)3.产品配送 (7)4.终端销售和信息反馈 (8)三:对ZARA进行SWOT分析 (9)S企业内部的能力(strengths) (9)W企业的薄弱点(weaknesses) (9)O来自企业外部的机会(opportunities) (9)T企业面临外部的威胁(threats) (10)四:ZARA脱颖而出成功的原因 (10)(1)“快速”供应链。

(10)(一)一体化供应链 (10)1.“三位一体”的产品设计 (10)2.垂直整合的生产管理 (11)3.自建的高效物流体系 (11)4.提高业务速度的信息系统和技术 (12)(二)控制节奏的供应链 (12)(2)“大集中”系统 (12)(3)平价 (12)(4)时尚 (12)(5)款式多变 (13)(6)有效的销售策略 (13)(7)与时装巨头HM的比较 (13)1、价格 (13)2、设计 (14)3、宣传 (14)4、供应链 (15)五:分析ZARA案例后的感想 (15)一:背景分析(一)ZARA基本概况ZARA是西班牙Inditex集团旗下的一个子公司,它既是服装品牌,也是专营ZARA品牌服装的连锁零售品牌。

1、品牌简介品牌名称:ZARA(中文名称----飒拉)所属国家:西班牙创始时间:1975年创始人:阿曼西奥·奥尔特加所属机构:Inditex集团首席设计师:200人设计团队Inditex是西班牙排名第一,并于近年超越了美国的GAP、瑞典的H&M成为全球排名第一的服装零售集团,2005年其全球的销售额67.41亿欧元,销售数达4.29亿件,纯利润8.03亿欧元。

2013-01-305011699703-S2S3/………………………………………………………………… ENGLISH ……………………………………………………………………Thank you for choosing Delta DVP-SS2 series PLCs. DVP-SS2 series PLCs include one 12-point PLC, and two 14-point PLCs. A DVP-SS2 series PLC provides various instructions, and the size of the program memory in it is 8k steps. It is able to connect to all DVP-S series extension modules, including digital I/O (max. 480 I/O points) and analog modules (for A/D, D/A conversion and temperature measurement). 4 groups of high-speed (10kHz) pulse output satisfy all kinds of applications. DVP-SS2 is small in size, and can be install easily. Users do not have to install any batteries in DVP-SS2 series PLCs. The PLC programs and the latched data are stored in the flash memories. This instruction sheet only provides introductory information on electrical specifications, general specifications, installation and wiring. For detailed information on programming and instructions, please refer to “DVP-SS2 Operation Manual: Programming”. For information about optional peripherals, please see individual product instruction sheet enclosed with DVP-SS2.This is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity, electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key or specific tools arerequired to open the enclosure) in case danger and damage on the device may occur.DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check all the wiring again before switching on the power.Make sure the ground terminal is correctly grounded in order to preventelectromagnetic interference. DO NOT touch any terminals when the power isswitched on.1. POWER, RUN, ERROR indicator 8. Nameplate2. RUN/STOP switch 9. Extension port3. I/O port for program communication (RS-232)10. DIN rail mounting slot (35mm)4. DIN rail clip 11. Extension unit clip5. I/O terminals 12. RS-485 communication port6. I/O point indicator 13. Mounting rail for extension module7. Mounting hole for extension module 14. DC power inputconsumption approx. 10mA/point. #2: Life curvesO p e r a t i o n (X 10)Note: The layout of output terminals on DVP-SS2 is different from that on DVP-SS.Dimension & InstallationPlease install the PLC in an enclosure with sufficient space around it to allow heat dissipation, See [Figure 3]. Direct Mounting: Use M4 screw according to the dimension of the product.DIN Rail Mounting: When mounting the PLC to35mm DIN rail, be sure to use the retaining clip to stop any side-to-side movement of the PLC and reduce the chance of wires being loose. The retaining clip is at the bottom of the PLC. To secure the PLC to DIN rail, pull down the clip, place it onto the rail and gently push it up. To remove the PLC, pull the retaining clip down with a flat screwdriver and gently remove the PLC from DIN rail.WiringUse 22-16AWG (1.5mm) single or multiple core wire on I/O wiring terminals. See the figure in the right hand side for its specification. PLC terminal screws should betightened to 1.90 kg-cm (1.65 in-lbs) and please use only 60/75ºC copper conductor.1. DO NOT wire empty terminal. DO NOT place the I/O signal cable in the same wiring circuit.2. DO NOT drop tiny metallic conductor into the PLC while screwing and wiring. Tear off the sticker on the heat dissipation hole for preventing alien substances from dropping in to ensure normal heat dissipation of the PLC.✹ Power SupplyThe power input of DVP-SS2 is DC. When operating DVP-SS2, please note the following points:1. The power is connected to two terminals, 24VDC and 0V, and the range of power is20.4 ~ 28.8VDC. If the power voltage is less than 20.4VDC, the PLC will stop running, all outputs will go “Off”, and the ERROR indicator will start to blink continuously. 2. The power shutdown for less than 10ms will not affect the operation of the PLC.However, the shutdown time that is too long or the drop of power voltage will stop the operation of the PLC, and all outputs will go off. When the power returns to normal status, the PLC will automatically resume the operation. (Please take care of the latched auxiliary relays and registers inside the PLC when doing the programming).✹ Safety WiringSince DVP-SS2 is only compatible with DC power supply, Delta’s power supply modules (DVPPS01/DVPPS02) are the suitable power supplies for DVP-SS2. We suggest you install the protection circuit at the power supply terminal to protect DVPPS01 or DVPPS02. See the figure below.①AC power supply: 100 ~ 240VAC, 50/60Hz ②Breaker③Emergency stop: This button cuts off the system power supply when accidentalemergency takes place.④Power indicator ⑤AC power supply load⑥Power supply circuit protection fuse (2A) ⑦DVPPS01/DVPPS02⑧DC power supply output: 24VDC, 500mA ⑨DVP-PLC (main processing unit) ⑩Digital I/O module✹ Input Point WiringThere are 2 types of DC inputs, SINK and SOURCE. (See the example below. For detailed point configuration, please refer to the specification of each model.)DC Signal IN – SINK mode Input point loop equivalent circuit DC Signal IN – SOURCE mode Input point loop equivalent circuit✹ Output Point Wiring1. DVP-SS2 has two output modules on it, relay and transistor. Be aware of theconnection of shared terminals when wiring output terminals.2. Output terminals, Y0, Y1, and Y2, of relay models use C0 common port; Y3, Y4, andY5 use C1 common port. See [Figure 7]. When the output points are enabled, their corresponding indicators on the front panel will be on.3. The output terminals Y0~Y5 of the transistor (NPN) model are connected to thecommon terminals UP and ZP. See [Figure 8a]. The output terminals Y0~Y3 on the transistor (PNP) model are connected to the common terminals UP and ZP. Seeinside PLC and input modules.①DC power supply ②Emergency stop: Uses external switch③Fuse: Uses 5~10A fuse at the shared terminal of output contacts to protect the output circuit④Transient voltage suppressor (SB360 3A 60V): Extends the life span of contact.1. Diode suppression of DC load: Used when in smaller power [Figure 10a]2. Diode + Zener suppression of DC load: Used when in larger power and frequent On/Off[Figure 10b]⑤Incandescent light (resistive load) ⑥AC power supply⑦Manually exclusive output: For example, Y3 and Y4 control the forward running and reverserunning of the motor, forming an interlock for the external circuit, together with the PLC internal program, to ensure safe protection in case of any unexpected errors.⑧Absorber: Reduces the interference on AC load [Figure 11]① DC power supply ②Emergency stop ③Circuit protection fuse④ The output of the transistor model is “open collector”. If Y0/Y1 is set to pulse output, theoutput current has to be bigger than 0.1A to ensure normal operation of the model. 1. Diode suppression: Used when in smaller power [Figure 14a] and [Figure 15a]Diode + Zener suppression: Used when in larger power and frequent On/Off [Figure 14b]and [Figure 15b]⑤ Manually exclusive output: For example, Y2 and Y3control the forward running and reverserunning of the motor, forming an interlock for the external circuit, together with the PLC internal program, to ensure safe protection in case of any unexpected errors.DA output circuit wiring (Only for DVP-12SS211S)Please refer to figure 1 below for more information about wiring.ItemSpecificationsDA range 0~10VDC Value range 0~100 Resolution 0.1V (1~9V) Output impedance 2k Ω Minimum load1.5k Ωallel.The impedance is about 1.46 .[Figure 1]D/A conversion time<70msPlease refer to the correction formula before you use the DA output function. Set the time unit for the pulse output throughY0 to 1µs.Set the pulse cycle to 100µs. Set the duty cycle of a pulse to 50%. M1002SET M1116M0PWMD0Y0MOV K100D2MOVK50D0D2Set M0 to ON. Adjust the variable resistor so① Master node ② Slave node ③Terminal resistorresistor value of 120Ω.2. To ensure communication quality, please apply double shielded twisted pair cable (20AWG) for wiring.………………………………………………………………… 繁體中文 ………………………………………………………………………感謝您採用台達DVP系列可程式控制器。

HOLLiAS MACS -K系列模块2014年5月B版HOLLiAS MAC-K系列手册- K-PW系列电源配电板使用说明书重要信息危险图标:表示存在风险,可能会导致人身伤害或设备损坏件。

警告图标:表示存在风险,可能会导致安全隐患。

提示图标:表示操作建议,例如,如何设定你的工程或者如何使用特定的功能。

目录1.概述 (1)2.K-PW01 交流电源配电板 (2)2.1连接器定义 (2)2.2外形尺寸 (3)3.K-PW11 直流电源配电板 (4)3.1连接器定义 (4)3.2外形尺寸 (7)4.K-PW21 查询电源分配板 (8)4.1连接器定义 (8)4.2指示灯 (9)4.3外形尺寸 (9)5.技术指标 (10)5.1K-PW01 (10)5.2K-PW11 (10)5.3K-PW21 (11)K-PW系列电源配电板1.概述K-PW系列电源分配板有三个型号,分别是K-PW01、K-PW11和K-PW21。

K-PW01是交流电源配电板,K-PW11是直流电源配电板,安装在机柜背面,配合AC/DC电源模块,为整个K系列硬件提供系统电源、现场电源。

K-PW21是查询电源分配板,安装在机柜正面,为I/O模块提供24V/48VDC查询电源。

下面将分别介绍。

2.K-PW01 交流电源配电板K-PW01是K系列硬件交流分配板,实现交流电源的分配输出功能,给系统电源、现场电源、辅助电源的AC/DC电源模块提供输入配电。

有两路110V/220V交流电输入,每路输入交流电源平分成5路输出。

两组通道各带有一个PCB安装滤波器,用来给系统电源和现场电源AC/DC供电。

每路带独立的船型开关,可以接通或关断本路,开关上自带通断指示灯。

船型开关在切断对应通道电源时,该指示灯熄灭;接通对应通道电源时,该指示灯亮。

K-PW01交流配电板安装在35mm宽的标准DIN导轨上,与导轨采用卡扣的固定方式,其外观示意图如图2-1所示。

Manual LOGO 200IndexIntroductionSafety InstructionsSafety Instructions/ Tools for Assembly & RC EquipmentMain Frame - Motor Mounting / Top Bearing Block Main Frame - Top Frame Assembly Main Frame - Lower Frame Assembly Main Frame - Lower Frame Mounting Main Frame - Landing Gear Mounting Rotor Head - Bearing Installation Rotor Head - AssemblyRotor Head - Pitch Linkns / Mounting Tail Motor Mounting Tail Boom Mounting Servo Mouting Servo LinkagingVbar NEO mini - Wiring Diagram / Mounting Main Blade Mounting Tail Blade Mounting Battery Mounting Canopy Mounting Model Overview2-3 4 5 5 6 7 8 8 9 10 10 11 12 12 13 13 14 15 16-18Thank you very much for your purchase of the Mikado LOGO 200. Prior to repairs, please read and understand thismanual completely and follow all instructions exactly. If any instructions are not clear to you or if you have any questions, please contact us. You can reach Mikado on the LOGO-Forum on or contact the Mikado support hotline via email or phone. Do not under any circumstances fly this helicopter if you are unsure of setup or assembly.While this helicopter is great for beginners, it is still a high performance, dangerous and complex machine. It is expected that you have some experience in assembling and operating an RC helicopters. You are required to adhere to the safety instructions of this manual.You must secure and check all screws in all components yourself. In addition, it is necessary that you secure all other screwed connection,by which you will assemble the different components of the LOGO 200. We recommended to use securing glue Loctite 243 (blue).Please follow the recommendations of the Loctite manufacture and allow proper curing time for the Loctite prior to flying the model.RC Helicopters are not toys and must be treated with due diligence. If you do not use this helicopter responsibly it can cause severe injury and immense damage. Inappropriate use of this product can result in injury or death. Each user must have the appropriate knowledge and skill to operate any RC Helicopter.Manufacturer / reseller assumes no liability for the use or operation of this helicopter. You are responsible for any injury and damage that may be caused by this helicopter. It is recommended that your radio components be tested prior to installing in this helicopter. Improper radio installation or inadequate battery voltage can result in the loss of control of the helicopter. Proper knowledge of your radio equipment is required prior to flying this helicopter. You must check if other persons are using an RC-controlled model or device simultaneously, as this may result in interference. If the helicopter behaves in an unusual or strange way, you must land it immediately and turn off the power. Please meticuously check all of your radio gear and find/fix the problem before you continue to operate the helicopter. This is to avoid any accidents. Since one irregularity can cause other defects or problem, if the problem is not fixed first, an increased risk of failure will ensue.Additional precautions for the prevention of injury or damageBefore powering on the helicopterBefore you power on the helicopter, you must ensure that all screws and associated hardware are secured. Even just one single loose screw can cause the helicopter to become uncontrollable resulting in a crash or personnel injury. Also it is very important that you must check the model frequently and exchange any parts that show signs of deterioration or wear. Failure to complete frequent pre and post flight inspections will result in flying an unsafe model and increasing the risk of damaging the helicopter and possibly injuring yourself and/or others. Use only original Mikado parts and electronic components which are recommended by Mikado.When programing the model or testing the radio system ALWAY remove the main and tail rotor blades as the model may spool up unintentionally.Always keep a minimum of 10 yards away from a spinning rotor head. Components that run hot such as the ESC and Motor should never be touched until ample cool down time has been provided.This helicopter is primarily intended for operation outside and may only be operated in sites where operation of Radio Control models is permitted. Operate the helicopter inside closed rooms at your own discretion. Keep the helicopter at safe distance to any persons or live animals at all times. If flying around other people, before take off, inform them you will be flying and ask them to pay attention to the model. When testing / tuning, keep a minimum distance of 10 yards for safety and never operate the helicopter alone. Always take someone with you, who can help in emergency situations.The helicopter must also not be operated in the following circumstances:• when children are present or in places where people are gathering • close to houses or in park areas• in adverse weather conditions, such as rain, snow, hail or during strong winds • near trees or High Tension wiresBefore the first flight, you must check proper functioning of the motor, the ESC and the VBar. For safety reasons, these tests should be performed without mounting the main rotor blades and the tail rotor blades. It is advisable to flymoderately during the first flights. This is because you need to get used to the new size of this helicopter during the first few flights. Do not underestimate the size and power of this helicopter. Keep a safe distance from the ground to provide for ample reaction time.1.25, 1.3, 1.5, 2,2.51.1 Main Frame - Motor Mounting / Top Bearing Block3 x 2 x4 x 1 x M2.5x7M1.6 x 4M3x2.5M1.6 x 6M1.6x4M1.6x6M3x2.54x9x4 bearingM2.5x7121 x4x9x4 bearing1.2 Main Frame - Top Frame Assembly1.3 Main Frame - Lower Frame Assembly2 x 6 screwM2x4M1.6x31.6x6x2 washer1.4 Main Frame - Lower Frame Mounting1.5 Main Frame - Landing Gear Mounting4 x 2 x 8 xM1.6 x 4M1.6 x 3M2x44 xM2 sleeve M1.6X4M2x4M2x4M2 sleeveM2 sleeveM1.6x3M1.6x3M1.6X32.1 Rotor Head - Bearing Installation2.2 Rotor Head - AssemblyMount brass washer in this orientationM1.6 x 43.1x4.5x0.1 washer3x5x0.6 washerbearingM2 x 62x5x0.2 washer4 x 2 x 2 x 2 x3x6x2.5 bearing 3x4x1.4 spacer3.1x4.5x0.1washer 3x6x2.8 bearing2 x 2 x 1 x 2 xM2x6M1.6 x 43x5x0.6 washer2x5x0.2 washer2.3 Rotor Head - Pitch Links / MountingM2x10M2x102x5x2.5flange bearingATTENTION :Be sure to put head bolt through the main shaft hole2.1x3.6x0.2 washer2x3.9x2.2 spacer1 x 1 x2 x 2 x 4 x 2 xM2x10M2x10M1.6 x 42x5x2.5 flange bearing3x5x0.6 washerM2 nut3.1 Tail Motor Mounting3.2 Tail Boom MountingM2x4M2x4M1.6x4After mounting boom, tighten these bolts to lock it in placeM2x44 x 3 x1 x M1.6 x 4M2x4M2x4126 x 3 x 3 x3 x linkage ball M1.6 x 4M1.6 nut M1.6x4M1.6x4M1.6x4linkage ballM1.6 nutM1.6x4M1.6x4M1.6x4M1.6x4M1.6x4M1.6 nutlinkage ball linkage ballM1.6 nut12Make sure to center servo arm BEFORE installingelevator servo5 VBar Neo Mini - Wiring Diagram / Mounting3 x 10CH 1CH 2CH 3MAIN MOTORPOWERRPM ~ESC -+~TAIL ~T A I LM O T O RR P M~T a il~E S C -+~1mm double sided tape6.1 Main Blade Mounting6.2 Tail Prop Mounting2 x 2 x 2 x2 x 2 x4 x M2 sleeve M2 nut10x2.1x0.3washerM2x12M1.6x61.6x3.5x0.4washerM1.6x61.6x3.5x0.4washerM2x1210x2.1x0.3washer10x2.1x0.3washerM2 sleeveM2 nutDo not over tighten theblade bolts.battery platevelcro (hard)velcro (soft)velcro strap3s 650mahbatteryBatteryLockcanopy grommetsPlace rotor head perpendicular to the boom for easier canopyinstalation and removalProduct name - Rotor Head Yoke, Logo 200Part Number - 05400Product name - Main Blade Holder withBearings, Logo 200Part Number - 05401Product name - Blade Bolts with Washers,Logo 200Part Number - 05402Product name - Blade Grip Pitch Links withBearings, Logo 200Part Number - 05403Product name - Shaft Kit (Main + Spindle),Logo 200Part Number - 05404Product name - Rotor Head Refurbish Kit,Logo 200Part Number - 05405Product name - VTX 177 BladesPart Number - 05406Product name - Swashplate, Logo 200Part Number - 05407Product name - Complete Rotor HeadAssembly with Blades, Logo 200Part Number - 05408Product name - Battery Plate Set (with Velcroand Strap) x 2, Logo 200Part Number - 05409Product name - Bearing Block Set + FrameSpacers, Logo 200Part Number - 05410Product name - Canopy Holders +Canopy Grommets, Logo 200Part Number - 05411Product name - Battery / ESC Mounting Set,Logo 200Part Number - 05412Product name - Landing Gear Mounts +Canopy Support, Logo 200Part Number - 05413Product name - Carbon Landing Gear x 4,Logo 200Part Number - 05414Product name - Lower Frame Set, Logo 200Part Number - 05415Product name - Main Shaft Bearing (4x9x4)x 2, Logo 200Part Number - 05416Product name - Motor + Shaft, Logo 200Part Number - 05417Product name - Servo Arm + Linkage Set x 3,Logo 200Part Number - 05418Product name - Servo Set, Logo 200Part Number - 05419Product name - Tail Boom Mount, Logo 200Part Number - 05420Product name - Upper Frame Set, Logo 200Part Number - 05421Product name - Anti Rotation BracketReplacment Kit, Logo 200Part Number - 05422Product name - Complete Frame Set, Logo200Part Number - 05423Product name - Complete Tail Rotor Set,Logo 200Part Number - 05424Product name - Tai Boom x 2, Logo 200Part Number - 05425Product name - Tail Fin x 2, Logo 200Part Number - 05426Product name - Tail Motor Mounting Set,Logo 200Part Number - 05427Product name - Tail Motor, Logo 200Part Number - 05428Product name - Tail Prop x 2, Log 200Part Number - 05429Product name - Complete Hardware Set,Logo 200Part Number - 05433Product name - Blue/ Yellow Canopy, Logo200Part Number - 05432Product name - 3s 650mah 45C Battery (22x25x58mm), Logo 200Part Number - 05430Product name - Dual ESC Controller, Logo200Part Number - 05431Product name -Part Number -Product name -Part Number -Product name - Part Number - Product name -Part Number -Product name -Part Number -Product name -Part Number -Product name - Part Number - Product name -Part Number -Product name -Part Number -Product name -Part Number -Product name - Part Number - Product name -Part Number -Product name -Part Number -Product name -Part Number -。

Manual del usuarioModelo 461920Foto tacómetro láser461920-EU-SP V2.1V 5/072IntroducciónAgradecemos su compra del mini foto tacómetro láser modelo 461920 de Extech. Este tacómetro permite tomar medidas de RPM y cuenta de revoluciones sin contacto. El haz del puntero láser facilita apuntar con precisión a gran distancia para tomar medidas con el foto tacómetro. Este medidor se embarca probado y calibrado y con uso apropiado le proveerá muchos años de servicio confiable. Descripción del medidor1. Sensor del tacómetro y fuente láser2. Botón para MEDICIÓN3. Botón MEMORIA4. Botón MODO5. Adaptador CA6. Compartimiento de la batería (atrás)PRECAUCIÓN : Los objetos en rotación pueden serpeligrosos. Extreme sus precauciones. ADVERTENCIA: No mire directamente o apunte el puntero láser hacia los ojos. Los rayos láser visibles de baja potencia normalmente no presentan un peligro, sin embargo, pueden ser peligrosos si se ven directamente durante largos periodos de tiempo.Operación del medidor1. Aplique un trozo cuadrado de cinta reflectiva deaproximadamente (0.5”/12 mm) a la superficie del objetoa prueba.2. Apunte el medidor hacia el dispositivo a prueba a unadistancia de 50 a 500 mm (2" a 20").3. Presione el botón medición (MEAS) y alinee el haz deluz láser con la cinta reflectiva.4. Verifique que el indicador ((( ))) se vea en la LCD cuandola cinta reflectiva pasa por el haz de luz.5. Para cambiar las unidades (RPM o REV), suelte elbotón MEAS y presione el botón MODO.6. La última lectura permanece en pantalla durante 5 a 10segundos al soltar el botón para medición, antes de queel medidor se apague automáticamente.7. Con el medidor apagado, presione el botón MEM(memoria) para recuperar los valores MAX, MIN yÚLTIMA RPM o la última cuenta (REV) del últimoperiodo de medición.Notas sobre las medidas1. La luz ambiental brillante puede interferir con el haz deluz reflejado. En algunos casos puede ser necesariosombrear el objetivo.2. El área no reflectiva siempre debe ser mayor que elárea reflectiva.3. Si el eje u objeto en rotación es normalmente reflectivo,éste debe ser recubierto con cinta negra o pintura antes de aplicar la cinta reflectiva.4. Para mejorar la repetibilidad de las medidas a bajasRPM, aplique trozos adicionales de cinta reflectiva.Divida la lectura indicada en pantalla por la cantidad detrozos de cinta reflectiva para calcular las RPM reales.461920-EU-SP V2.1V 5/073461920-EU-SP V2.1V 5/074EspecificacionesBase de tiempoCristal de cuarzo PantallaPantalla LCD de 5 dígitos Fuente de luz láser Láser clase 2 potencia < 1 mW;Longitud de onda de 630 a670 nmDistancia de detección 50 a 500 mm (2 a 20")Tiempo de muestreo 0.5 seg. (sobre 120 RPM)MemoriaÚltima lectura y MIN/MAX Condiciones de operación 0 °C a 50 °C (32 °F a 122 °F);HR 80% Máx.Fuente de tensión Batería interna de 9V oadaptador externo de CA (6 a9VDC).Consumo de energía 45 mA CD aprox.Peso 151 g (5.3 oz.)Tamaño160 x 58 x 39 mm (6.3 x 2.3 x1.6")Especificaciones de escala Escala Resolución Precisión (% rdg)Foto tacómetro 2 a 99,999 RPM 0.1 rpm (<1000rpm) 1 RPM (>1000rpm)± (0.05% + 1d)Contador 1 a 99,999 REV 1 cuentaReemplazo de la bateríaEl indicador de batería débil aparece como “" en lapantalla. Para reemplazar las baterías, afloje los dostornillos cabeza Philips que aseguran la tapa posterior ylevante la tapa. Reemplace la batería de 9 V y asegure latapa.Usted, como usuario final, está legalmenteobligado (Reglamento de baterías) a regresar Array todas las baterías y acumuladores usados; ¡eldesecho en el desperdicio o basura de la casaestá prohibido! Usted puede entregar las bateríaso acumuladores usados, gratuitamente, en lospuntos de recolección de nuestras sucursales ensu comunidad o donde sea que se venden lasbaterías o acumuladores.DesechoCumpla las estipulaciones legales vigentesrespecto al desecho del dispositivo al final de suvida útil.Copyright © 2007 Extech Instruments CorporationReservados todos los derechos, incluyendo el derecho dereproducción total o parcial en cualquier medio.461920-EU-SP V2.1V 5/075。

德国美扣mic-o-mic 模型拼插大火车头拖拉机帆船等

MIC O MIC是款历史悠久的经典德国玩具品牌,它重新赋予玩具多彩、温润手感与创意兼具的意义,无限延伸大人与小孩的想像力。

所有零件都需靠自己动手组装完成,训练脑力与逻辑。

玩具本身以弹性安全无毒塑料制成,结构耐用坚固,外缘平滑,使您玩乐的同时安全无虞。

此款可爱小火车造型简单可爱,您可与大小朋友一起挑战同乐。

#母婴良品# #积木##益智玩具#。

爱乐

活玩

具。

德国美扣mic-o-mic 模型拼插

德国美扣mic-o-mic 模型拼插

爱乐活——有态度、正能量的品质生活社区。

热爱生活,乐于分享的各类达人聚在这里,分享消费攻略,激发生活灵感,发现城市最IN 的角落。

在这里,有爱,有乐,有生活。

【更多精彩内容尽在爱乐活】

文章来源:/post/23aa8de27c8a511de28061a7?from=wenku/?from=wenku。