HP系列圆锥破碎机

- 格式:pdf

- 大小:3.08 MB

- 文档页数:12

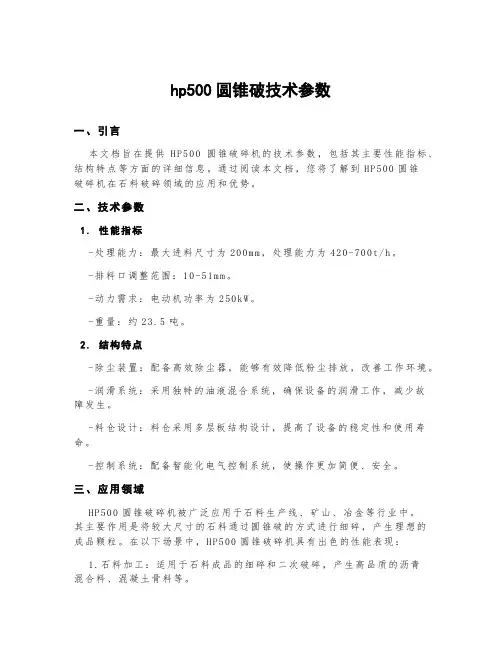

hp500圆锥破技术参数一、引言本文档旨在提供H P500圆锥破碎机的技术参数,包括其主要性能指标、结构特点等方面的详细信息。

通过阅读本文档,您将了解到HP500圆锥破碎机在石料破碎领域的应用和优势。

二、技术参数1.性能指标-处理能力:最大进料尺寸为200m m,处理能力为420-700t/h。

-排料口调整范围:10-51m m。

-动力需求:电动机功率为250kW。

-重量:约23.5吨。

2.结构特点-除尘装置:配备高效除尘器,能够有效降低粉尘排放,改善工作环境。

-润滑系统:采用独特的油液混合系统,确保设备的润滑工作,减少故障发生。

-料仓设计:料仓采用多层板结构设计,提高了设备的稳定性和使用寿命。

-控制系统:配备智能化电气控制系统,使操作更加简便、安全。

三、应用领域H P500圆锥破碎机被广泛应用于石料生产线、矿山、冶金等行业中。

其主要作用是将较大尺寸的石料通过圆锥破的方式进行细碎,产生理想的成品颗粒。

在以下场景中,H P500圆锥破碎机具有出色的性能表现:1.石料加工:适用于石料成品的细碎和二次破碎,产生高品质的沥青混合料、混凝土骨料等。

2.矿山开采:适用于矿山中石料的破碎和粉碎,如铁矿石、铜矿石等。

3.冶金工业:适用于冶金工业中对不同矿石的粉碎处理,如金属矿石、锌矿石等。

四、优势和特点H P500圆锥破碎机在市场上具有以下优势和特点:1.高处理能力:处理能力可达到700t/h,能够满足大型石料生产线的需求。

2.粒度均匀:通过优化的破碎腔设计和合理的排料口调整范围,可获得均匀的成品颗粒。

3.节能环保:采用先进的除尘装置和油液混合系统,降低了粉尘和能源的消耗。

4.操作简便:配备智能化电气控制系统,操作简单,维护方便。

5.结构稳定:料仓多层板结构设计和可靠的润滑系统,提高了设备的稳定性和寿命。

五、结论本文档详细介绍了HP500圆锥破碎机的技术参数、结构特点以及应用领域等方面的信息。

通过对其性能和优势的描述,我们可以清楚地了解到该设备在石料破碎行业中的重要地位和广泛应用。

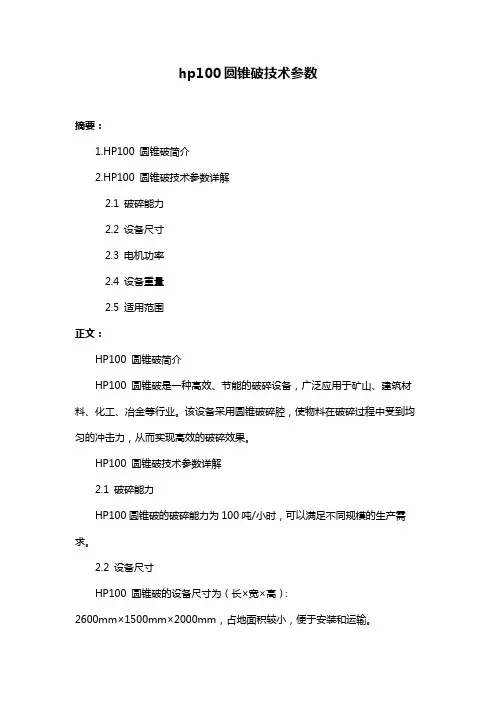

hp100圆锥破技术参数

摘要:

1.HP100 圆锥破简介

2.HP100 圆锥破技术参数详解

2.1 破碎能力

2.2 设备尺寸

2.3 电机功率

2.4 设备重量

2.5 适用范围

正文:

HP100 圆锥破简介

HP100 圆锥破是一种高效、节能的破碎设备,广泛应用于矿山、建筑材料、化工、冶金等行业。

该设备采用圆锥破碎腔,使物料在破碎过程中受到均匀的冲击力,从而实现高效的破碎效果。

HP100 圆锥破技术参数详解

2.1 破碎能力

HP100圆锥破的破碎能力为100吨/小时,可以满足不同规模的生产需求。

2.2 设备尺寸

HP100 圆锥破的设备尺寸为(长×宽×高):

2600mm×1500mm×2000mm,占地面积较小,便于安装和运输。

2.3 电机功率

HP100 圆锥破的电机功率为110kW,能在保证破碎效果的同时,实现节能降耗。

2.4 设备重量

HP100 圆锥破的设备重量约为26 吨,设备结构稳固,适应各种恶劣工况环境。

2.5 适用范围

HP100 圆锥破适用于破碎各种中硬矿石和岩石,如花岗岩、石英石、砂岩等,是矿山、建筑材料、化工、冶金等行业的理想破碎设备。

综上所述,HP100 圆锥破凭借其优异的技术参数,在破碎设备领域具有较高的应用价值。

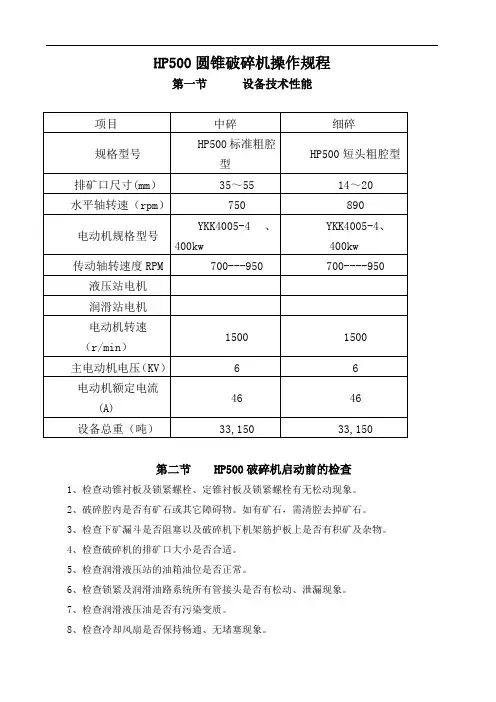

HP500圆锥破碎机操作规程第一节设备技术性能第二节 HP500破碎机启动前的检查1、检查动锥衬板及锁紧螺栓、定锥衬板及锁紧螺栓有无松动现象。

2、破碎腔内是否有矿石或其它障碍物。

如有矿石,需清腔去掉矿石。

3、检查下矿漏斗是否阻塞以及破碎机下机架筋护板上是否有积矿及杂物。

4、检查破碎机的排矿口大小是否合适。

5、检查润滑液压站的油箱油位是否正常。

6、检查锁紧及润滑油路系统所有管接头是否有松动、泄漏现象。

7、检查润滑液压油是否有污染变质。

8、检查冷却风扇是否保持畅通、无堵塞现象。

第三节 HP500破碎机开机、停机顺序1、首次开车和磨合步骤HP500圆锥破碎机首次启动以及每次安装新动锥衬套或偏心套衬套后的开车磨合步骤如下:⑴启动液压站。

开启液压站按钮箱电源开关,压力自动补偿开关拨到自动补偿位置。

检查按钮控制箱的指示灯,确认液压站液压回路压力正常,无红灯报警显示。

⑵启动润滑系统,检查回油管出口处的回油量及回油温度,回油油温必须至少达到200C。

⑶启动破碎机,并且空转2小时,检查并记录破碎机回油温度及空转电流的变化。

⑷空转2小时后,可进行50%负荷带料试车。

保持让电流达到电机额定电流50%时的给料量,连续运转至少8小时。

(注意:这里50%负荷试车是指破碎机工作电流达到主电机额定电流的50%,而不是指控制料位到破碎腔的50%,破碎机还是要挤满给矿运行,可通过放大排料口来降低破碎工作电流至主电机额定电流的50%。

)⑸完成8个小时的运转后,保持让电流达到额定电流75%时的给料量,连续运转8小时。

⑹破碎机进行满负荷运转,并做好破碎机日常运转记录。

注:停车时切要记录停车惯性时间,以观察破碎机运行状况。

2、日常开车程序⑴⑴启动液压站。

开启液压站按钮箱电源开关,压力自动补偿开关拨到自动补偿位置。

检查按钮控制箱的指示灯,确认液压站液压回路压力正常,无红灯报警显示。

⑵启动润滑系统,检查回油温度,回油油温必须至少达到200C。

产品介绍Nordberg HP系列圆锥破碎机动画片主要部件给料斗分料盘锁紧螺栓动锥球体球面瓦定锥调整环动锥上铜套锁紧缸液压调整马达定锥衬板动锥衬板动锥过铁释放缸总成偏心套推力轴承主轴大齿轮和小齿轮水平轴铜套水平轴主机架偏心套铜套动锥下铜套偏心套下推力轴承破碎机的命名•Nordberg HP xxx:-HP 的含义是高性能( HighPerformance).-xxx 的意思是驱动功率.-Nordberg HP300: 意思是驱动功率是300 HP (220 kW).•动力通过水平轴直接传递给齿轮.•齿轮带动偏心套围绕主轴旋转.•偏心套带动动锥摆动和旋转.•青铜衬套.•非接触式防尘密封(“U” 和“T”).•用定锥旋转来补偿衬板的磨损.•释放缸和排料口的调整通过液压站驱动.•液压过铁释放系统:- 6 双动液压缸+ 6 蓄能器可满足大的清腔行程.•全部从上部分解破碎机.•定锥和动锥全部得到使用.整机重量定锥,定锥衬板,调整帽,给料斗动锥,动锥衬板,分料盘最大驱动功率水平轴转速(转/分)能力Here粒度曲线能力腔形选择立方体(粒形好)•老工艺-单层破碎•新工艺-层压破碎完美的形状•HP圆锥破碎机结构紧凑适合安装在任何场合•特别适合移动式破碎厂.•使用钢底座可以方便的安装在各种基础上:-混凝土平台-混凝土基础-钢结构基础.•液压系统通过操作箱远程操作.•液压马达:-连续精确的调整排料口. -定锥转动.-维护时间短.•液压清腔系统:-可以快速简单的进行清腔-通过同一组液压缸实现可过铁释放和清腔.•全部从上部分解破碎机•一体化稀油站包括: -润滑系统.-液压系统.。

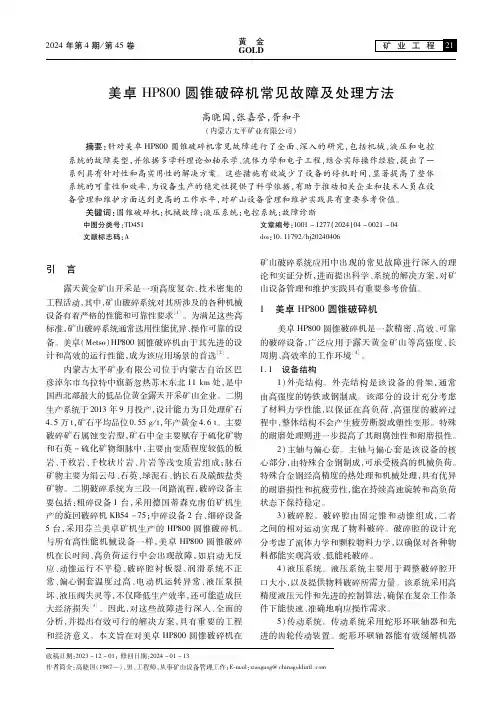

美卓HP800圆锥破碎机常见故障及处理方法收稿日期:2023-12-01;修回日期:2024-01-13作者简介:高晓国(1987—),男,工程师,从事矿山设备管理工作;E mail:xiaoguog@chinagoldintl.com高晓国,张嘉誉,胥和平(内蒙古太平矿业有限公司)摘要:针对美卓HP800圆锥破碎机常见故障进行了全面、深入的研究,包括机械、液压和电控系统的故障类型,并依据多学科理论如轴承学、流体力学和电子工程,结合实际操作经验,提出了一系列具有针对性和高实用性的解决方案。

这些措施有效减少了设备的停机时间,显著提高了整体系统的可靠性和效率,为设备生产的稳定性提供了科学依据,有助于推动相关企业和技术人员在设备管理和维护方面达到更高的工作水平,对矿山设备管理和维护实践具有重要参考价值。

关键词:圆锥破碎机;机械故障;液压系统;电控系统;故障诊断 中图分类号:TD451 文章编号:1001-1277(2024)04-0021-04文献标志码:Adoi:10.11792/hj20240406引 言露天黄金矿山开采是一项高度复杂、技术密集的工程活动,其中,矿山破碎系统对其所涉及的各种机械设备有着严格的性能和可靠性要求[1]。

为满足这些高标准,矿山破碎系统通常选用性能优异、操作可靠的设备。

美卓(Metso)HP800圆锥破碎机由于其先进的设计和高效的运行性能,成为该应用场景的首选[2]。

内蒙古太平矿业有限公司位于内蒙古自治区巴彦淖尔市乌拉特中旗新忽热苏木东北11km处,是中国西北部最大的低品位黄金露天开采矿山企业。

二期生产系统于2013年9月投产,设计能力为日处理矿石4.5万t,矿石平均品位0.55g/t,年产黄金4.6t。

主要破碎矿石属蚀变岩型,矿石中金主要赋存于硫化矿物和石英-硫化矿物细脉中,主要由变质程度较低的板岩、千枚岩、千枚状片岩、片岩等浅变质岩组成;脉石矿物主要为绢云母、石英、绿泥石、钠长石及碳酸盐类矿物。

HP500高效节能多缸液压圆锥破碎机HP500多缸液压圆锥破碎机是美卓矿机结合现代材料技术和计算机技术,在弹簧圆锥破碎机(即Symons)的基础上继承和发扬,开发的拥有独家知识产权的主轴固定式液压园锥破碎机。

与国产2200弹簧圆锥破碎机相比,主轴固定式液压HP型多缸园锥破碎机输入功率大,破碎力大,旋转速度快,破碎产品成品率高,粉矿含量高,是多碎少磨选矿工艺的最佳首选设备。

国产2200弹簧圆锥破碎机安装功率为280KW,重量84.5吨,该设备不仅笨重,而且产量低。

HP500多缸液压圆锥破碎机国产电机安装功率为400KW,进口电机安装功率为355KW,重量33.5吨,外圈直径2730毫米,内腔直径2300毫米。

该设备不仅重量轻,而且产量高。

一般而言,在同等产品粒度条件下,HP500多缸液压圆锥破碎机的处理能力是国产2200弹簧圆锥破碎机的2~4倍。

圆锥破碎机的处理能力和破碎产品粒度要求,细度分布及矿石性质密切相关,抽象比较HP500多缸液压圆锥破碎机和国产2200弹簧圆锥破碎机是没有意义的。

下面给出一个生产应用案例,以便帮助我们有一个直观的了解。

武钢集团程潮铁矿从年处理200万吨改扩建到年处理300万吨,引进和安装了美卓矿机(METSO MERALS)生产的多缸液压破碎机HP500三台,取代原流程的三台PYD,PYB 2100型圆锥破碎机,将入磨粒度从95% 小于13mm降到95% 小于8mm,在磨矿主体设备不增加的情况下,破碎和磨矿能力扩大到年300万吨(祥见武钢矿山科技,2003,第四期)。

新增加一百万吨处理能力,如果按传统方法进行破碎和磨矿扩建,须新安装三台1750圆锥破碎机和相应磨矿机及辅助设施,新增安装功率:破碎3X155KW,磨矿2500KW,其它辅助设施300KW,共计3265KW。

全年共节省电耗:[3265-3X(400-280)]KWX24小时X330天X利用系数0.8=18,406,080度全年共节省钢耗:1,000,000吨矿石X1公斤钢球/吨矿石=1000吨钢球选用三台HP500后,由于节能降耗,全年共产生的直接经济效益:18,406,080度X0.4元+1000吨钢球X5000元/吨钢球=7,362,432元+5,000,000元=12,362,432元通过上面的实例分析,投资采购三台HP500的成本半年一年不到就可以回收,HP500不仅处理能力大,而且使选矿厂能显著节能降耗。

hp500圆锥破技术参数

(实用版)

目录

1.HP500 圆锥破简介

2.HP500 圆锥破技术参数

2.1 破碎能力

2.2 功率

2.3 产量

2.4 设备尺寸

2.5 设备重量

正文

【HP500 圆锥破简介】

HP500 圆锥破是一种广泛应用于矿山、建筑材料、化工、冶金等行业的破碎设备,以其高效、节能、环保等优点受到用户的青睐。

HP500 圆锥破的型号“HP500”代表了其破碎能力为 500 吨/小时。

【HP500 圆锥破技术参数】

HP500 圆锥破的技术参数主要包括破碎能力、功率、产量、设备尺寸和设备重量。

【2.1 破碎能力】

HP500圆锥破的破碎能力为500吨/小时,这是其型号所代表的含义。

这意味着,该设备每小时能够破碎500吨的物料。

【2.2 功率】

HP500 圆锥破的功率根据不同的破碎物料和破碎程度会有所不同。

一

般来说,其功率在 110 千瓦至 200 千瓦之间。

【2.3 产量】

HP500 圆锥破的产量同样根据破碎物料和破碎程度有所不同。

在理想条件下,其产量可以达到每小时 500 吨。

【2.4 设备尺寸】

HP500 圆锥破的设备尺寸主要包括设备长度、宽度和高度。

一般来说,其设备长度在 3 米至 4 米之间,宽度在 2 米至 3 米之间,高度在 1.5 米至 2 米之间。

【2.5 设备重量】

HP500 圆锥破的设备重量在 10 吨至 15 吨之间,具体重量会根据

不同的制造材料和设计有所不同。

圆锥破碎机型号大全圆锥破碎机是一种常见的破碎设备,广泛应用于矿山、冶金、建材、化工等行业。

不同型号的圆锥破碎机具有不同的特点和适用范围,选择适合自己生产需求的机型对于提高生产效率和降低成本非常重要。

本文将为大家介绍一些常见的圆锥破碎机型号,希望能够对大家的选购提供一些参考。

1. PY系列圆锥破碎机。

PY系列圆锥破碎机是我公司引进国外先进技术研制的一种高效破碎设备。

该机型结构简单,操作方便,破碎比大,生产效率高。

适用于中等硬度及以上的矿石和岩石破碎,广泛应用于冶金、建材、水泥、化工等行业。

2. HPC系列高效液压圆锥破碎机。

HPC系列液压圆锥破碎机是一种高效的破碎设备,具有高度自动化、大破碎比、高生产效率等特点。

该机型适用于各种中等硬度矿石和岩石的破碎,特别适用于矿山、建材、冶金工业的破碎生产线。

3. HST系列液压圆锥破碎机。

HST系列液压圆锥破碎机是一种新型高效破碎设备,具有液压调整排料口和液压保护装置,操作简便,维护方便。

该机型适用于各种矿石和岩石的中、细破碎,广泛应用于矿山、冶金、水泥、化工等行业。

4. CS系列圆锥破碎机。

CS系列圆锥破碎机是一种高效的破碎设备,具有较大的进料口和较大的破碎比,适用于中等硬度及以上的矿石和岩石的破碎。

该机型广泛应用于矿山、冶金、建材、化工等行业的破碎生产线。

5. HP系列多缸液压圆锥破碎机。

HP系列多缸液压圆锥破碎机是一种高效、节能的破碎设备,具有多缸液压技术、液压调整排料口和液压保护装置等特点。

该机型适用于各种矿石和岩石的中、细破碎,广泛应用于矿山、建材、冶金、化工等行业。

总结。

以上介绍的圆锥破碎机型号是目前市场上比较常见的几种机型,每种机型都有其独特的特点和适用范围。

在选择圆锥破碎机时,需要根据自己的生产需求和实际情况进行合理的选择,以提高生产效率,降低生产成本,实现更好的经济效益。

希望本文对大家有所帮助,谢谢阅读!。

Nordberg HP series cone crushers Wear partsapplication guide Application guide2Closed side setting (CSS)The closed side setting defines the reduction ratio in HP cone crusher and has a significant effect on the product gradation, capacity and power draw.The closed side setting is measured from the bottom of the mantle to the bottom of the bowl liner at their closest point during the gyrating cycle.Feed openingThe feed opening defines the maximum feed size for a crushing cavity. The closed side feed opening is the smallest distance between the top of the mantle and bowl liner as measured when they are at their closest to one another during their gyrating cycle.The open side feed opening is the distance between the top of the mantle and bowl liner as measured when they are at their farthest from one another during their gyrating cycle.In HP standard cavities, the maximum feed size is approximately 80% of the open sidefeed opening. In HP Short head cavities, the maximum feed size is equal to the closed side feed opening.Nip angleThe nip angle is the angle between the mantle and bowl liner. T oo large a nip angle reduces the capacity and increases the wear as feed material will tend to slip back upward in the cavity rather than crush. This can be observed as bouncing or boiling of the feed material.Reduction ratioThe reduction ratio is the ratio between the size of feed and the size of the outgoing product. It is normally measured at the 80% passing point. A typical reduction ratio in the HP standard cavity is 3-5 and in the HP short head cavity it is 2-4.Wear parts application guide - Nordberg HP series cone crusherHP cone crusher and basic conceptsProduct FeedReduction ratio = F80 / P80The HP cone crusher is a compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock particles are crushed directly between the surfaces of the mantle and bowl liner. This is called single layer crushing. Smaller rock particles are crushed between other rockparticles, which is termed multi-layer crushing or inter-particle comminution. Multi-layer crushing plays a significant role in the HP cavity. This improves the end product shape and reduces wear on the wear parts.34Too big feed material Too small feed materialGood feed material levelHow to operate a HP cone crusherIn order to get optimum capacity and maximum wear life of wear parts, consider the following points:1. Check the feed arrangement:• The crusher should be choke fed so that the crushing chamber is full all the time. This is important, especially in fine crushing. Choke feeding maximizes the amount of multi-layer crushing, improves the shape of the crushing cavity as it wears and improves thecrushing efficiency. => Choke feed level for an HP cone crusher is 300 mm or more above the feed plate.• The feed must be distributed evenly 360º around the crushing chamber. Uneven feed distribution may cause power and force cycles through each gyration cycle. Evenly distributed feed will result in a more steady power and crushing force.• Feed should not be segregated (for example finer material on one side of the cavity and coarser material on the other side of the cavity).• Flow of the feed should be stable and continuous.• Closed circuit crushing (where the crusher product goes to ascreen and the oversize material returns to the crusher) is needed when producing high quality products.2. Check the feed size and gradation:• Oversize feed material decreases capacity and can cause abnormal wear of the liners• Too small a feed size for the cavity increases the wear at the bottom part of the liners and may cause poor utilization of the wear parts• Fines (0-4 mm) should be screened out before the material is fed to the crusher as the fines may cause packing which can be seen as adjustment ring movement which is a force overload.• Feed should be well graded with no gaps in the size distribution.3. Check the power draw. Crusher should operate with a steady power draw and as close to full rated power as practical, depending the circuit design and the ability to control system.Note: Feed material characteristics such as gradation, bulk density, moisture, clay content and crushability have significant impact on crusher capacity.54. Check the closed side setting. The setting should be close to the required product. The setting is too small if the adjustment ring is moving on the main frame (ring bounce).• Larger setting -> Product size increases • Larger setting -> Capacity increases • Larger setting -> Power draw decreases5. Check the crusher operating speed.Generally, a higher speed creates a finer product gradation curve and better product shape, which is important when producing the end product in most construction applications. While operating the HP cone crusher at the lower end of its speed range will increase the cavity volumetric throughput and the product gradation curve can be altered to produce fewer fines. The allowed speed limits can be found in the Nordberg HP cone crusher instruction manual. Before changing the speed of the crusher, consult product support for further information.6. Check the cavity in use. • Based on feed size• Based on required end product size which determines the required setting range• Check the crushing reduction ratio7. Check the wear profile of the liners: a distorted wear profile may decrease capacity, increase the liner wear rate and increase the crushing force.Example of abnormal wear. Cupping hasoccurred.Example of normal wear. Obtained with correct feed arrangements, feed gradationand parameters for the cavity.6HP cone crusher cavity selectionStandard liners are typically used in secondary applications. Secondary applications don’tnecessarily need to be operated in closed circuit, but preferably choke fed.Short head liners are used in tertiary orquaternary stage applications for fine crushing. Fine crushing requires choke feeding and closed circuit operation with oversize returning to the crusher.1. The minimum setting is that at which the crusher will operate without causing ring bounce. Depending on the crusher characteristics of the rock, this setting can change.2. Feed opening “B“ is at a minimum setting “A“.3. Maximum feed size vary from 80 to 100% of “B“ depending on the machine size and material.Each HP cone crusher has several cavity options with different feed openings and setting ranges. The correct cavity can be selected based on the feed size, setting and application.7● Can be used ●● Good choice ●●● Recommended C - Contact Outotec representative for more informationDefinitions for different rock types are presented inWear and materials application guide, page 4.Examples of standard (left) and short head liners (right).8HP3, HP4 and HP6 cone crushercavity selection●●● RecommendedDefinitions for different rock types are presented in Wear and materials application guide, page 4.1. Feed opening “B“ is at a minimum setting “A“.2. Maximum feed size vary from 80 to 100% of “B“ depending on the machine size and material.HP3, HP4 and HP6 cone crushers have several cavity options with different feed openings and setting ranges. The correct cavity can be selected based on the feed size and setting. Liners are manufactured from XT710 material.9EC MFEFCExtra coarse MediumFineExtra fineCoarse10See the following instructions1. On the initial set of new liners, place a mark on the adjustment cap driver ring where the pinion tooth makes contact with a driver ring tooth when the target crusher setting has been achieved.2. Keep an accurate record of the number of teeth used to compensate for liner wear on this set of liners.3. After the initial set of liners have worn out, but before moving the bowl, record the total number of teeth the driver ring has moved and also paint a horizontal liner on the side of the dust shell just below the bottom of the adjustment cap. This will be the baseline for determining how close the next liner sets are to being worn out.4. When a new liner set has been installed, keep a record of the number of teeth the driver ring has moved and compare this number to the total number from the initial set of liners. This will give an estimation of the liner wear. The horizontal mark painted on the dust shell will also indicated when the liners are approaching the wear limit. The approximate minimum heights of the adjustment cap (A-dimension) with worn liners are listed in the attached tables.When changing liners and determining liner wear, follow the instructions in the related Nordberg HP cone crusher instruction manual.Production considerations may sometimes favor changing of wear parts before they are fully utilized. Hourly capacity or product quality may decrease toward the end of the liner wear life and it may bemore economical to change before the end of the liner wear life.Typically, distorted wear profiles can cause a reduction in capacity. Other symptoms of poorly worn liners are high power draw and ring bounce. Also, the wear life can be reduced because the wear is sometimes concentrated in a small zone rather than spread along the full cavity and the cavity may have to be replaced before they are fully worn. This results in poor utilization and a higher operatingwear costs.When to change linersIn order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through. In normal conditions, approximately 50% of the liner weight is consumed when liners are worn out. It is important to keep a record of liner wear in order to assess the degree of liner wear without the need to stop the crusher operation.Caution: A is given for a good wear. Meaning similar mantle and concave wear, without distorted wear profile = correct application according to cavity selected.11Efficient crusher maintenanceSpecially designed, fit-for-purpose tools makes wear part change-outs faster and more efficient. By using OEM parts, risk of damaging equipment is avoided. As a result, maintenance times are shortened and crusher downtime is reduced.Improved safety and qualityT o succeed in today’s competitive environment, aggregate producers often seek to optimize their crusher maintenance. Using parts that last longer and make crusher maintenance easier and safer can make the big difference. Metso Outotec’s specialty tools are developed with qualitysuppliers ensuring that high standards and tolerances are met.Our crusher wear part lifting tools are designed with OEM expertise, making them the best choice to remove mantles from your Metso Outotec crushers.Mantle lifting toolsTOOLS APPLICATIONS LOAD LIMITRead more at:/CrusherPartsBenefits• OEM design and assurance• Improved safety and maintenance• Reduced downtime with more efficient changeoutsC o p y r i g h t © 2021 M e t s o O u t o t e c . B r o c h u r e n o : 2602-10-21-E N -C N S . A l l r i g h t s r e s e r v e d . P i n t a /L i b r i s , H e l s i n k i , F i n l a n d .Metso Outotec, Töölönlahdenkatu 2, FI-00100, Helsinki, Finland.tel. +358 20 484 100, fax +358 20 484 Metso Outotec is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. By improving our customers’ energy and water efficiency, increasing their productivity, and reducing environmental risks with our product and process expertise, we are the partner for positive change.。

Nordberg HP900 圆锥破碎机安全操作规程一、开机前检查1. 对破碎机进行全面的检查,确认破碎机上没有工器具或机械障碍物,所有连接件与紧固件都已紧固,没有明显松动现象。

2.检查润滑系统和液压系统温度和压力是否正常,各连接管道是否通畅,接头有无渗漏现象,冷却系统运行是否正常。

3. 传动皮带是否良好,张紧程度合适,发现皮带有破损现象应及时更换,当皮带过松或过紧应及时调整,皮带轮上有油污时,应用干净抹布将其擦净;4.各种防护装置是否齐全完好,如发现防护装置有不安全的现象,应及时处理;5. 确保破碎机的破碎腔是空的,检査破碎机排料口是否通畅。

6. 检查破碎机所有接线是否正常,各种检测信号显示是否正常。

7. 在启动破碎机之前,确保破碎机附近没有人。

绕破碎机走一圈,确保没有人在破碎机上面、旁边或下面。

二、试运行1.启动润滑油泵启动前,检査储油箱温度是否至少为32°C,温度过低应使用加热器将润滑油加热至32°C方可启动润滑泵,回油温度保持最低15°C的连续运行温度。

检查储油箱内的回油管,确信润滑油循环流动。

在正常操作条件下,经由回油管的回油量应达到油管的 1/2液位。

2.缓慢转动破碎机人工顺时针转动传动轴,使破碎线系统油路充分润滑,检查动锥衬板未碰撞到定锥衬板,且无任何机械缺陷。

3.起动破碎机空载试车开始2小时空载磨合运行之前,不要安装定锥总成、料斗、调整帽或分料盘。

这样,有利于在必要时拆卸动锥。

安装动锥时,使用夹紧环,使动锥处于中央位置。

应特别注意,下放动锥时,不要损坏动锥衬套或球面瓦。

起动破碎机前,将动锥提离球面瓦 6mm-10mm,然后运行润滑系统至少两小时。

为保证破碎机轴承的充分润滑,起动破碎机前,回油温度必须至少为15°C,如有必要,应使用浸没式加热器加热润滑油。

起动破碎机驱动电机,空载运行破碎机2小时(无给料物料)。

监测主电机电流消耗,如果电流下降和不稳定,但爬升5 安培或以上,应立即关闭破碎机。