萨澳(SAUER DANFOSS)进口泵中文样本--15

- 格式:pdf

- 大小:722.95 KB

- 文档页数:26

11012499 July 20072结构及标题为了便于阅读此手册,相关内容以章节,主题,次主题及细节分类编排。

主题描述文字以红色字体显示。

每一页顶部的章节标题以大红字体显示。

每页最左侧的标题以粗体红色字体显示。

次主题在正文中以红色字体显示。

详述标题斜体红色字体显示。

有关章节,主题或其他文献的索引均用红色字体标识(如:见主题xyz , XX 页,在PDF 电子光碟文档中,可以通过点击这些索引来打开相关的文献页码。

本手册中的表格,图表标题位于相关表格上方并以蓝色字体显示。

补充说明信息如注意事项,说明及图纸注释以蓝色字体标识。

有关表格,图表的索引均用蓝色字体标识(如:见主题xyz , XX 页,在PDF 电子光碟文档中,可以通过点击这些索引来打开相关的文献页码。

正文中术语及缩写语以粗黑体文字标识。

正文中的需要强调的重要信息或用非常规方式标识的术语及衬托文字以细黑体标识红色及蓝色在PDF 光碟文档中为超链接(见上页)。

下一页目录中表格及图表以蓝色字体显示,在PDF 电子光碟文档中,可以通过点击这些索引来打开相关的文献页码。

表格,图表及补偿信息特殊文本格式目录© 2006 Sauer-Danfoss. Sauer-Danfoss 对目录,说明书和其他出版物中可能他存在的错误不负任何责任, Sauer-Danfoss 有权不预先通知就更改其产品。

这同时也适用于已定购产品,尽管此类更改随后没有任何已认同的说明书中认为是必要的变化。

此资料中的所有商标都归属各自公司。

Sauer-Danfoss 和 Sauer-Danfoss标志为Sauer-Danfoss 集团商标,版权所有。

BD 系列静液传动单元技术文献手册阅读须知11012499 July 2007BD 系列静液传动单元技术文献目录概况技术规格工作参数系统设计参数特征及可选项BD 系列静液传动单元 .................................................................................................................................5BD U-10 S,原理图 (6)BDU-21 L,原理图 (7)系统示意图, BDU-06/10S ............................................................................................................................8系统示意图, BDU-06/10S ............................................................................................................................8系统示意图, BDU-10L/21L/21H ................................................................................................................9系统示意图, BDU-10L/21L/21H, BDP-10L..............................................................................................9特征及可选项 . ......................................................................................................................................... ......10工作参数 ........................................................................................................................................... ..............11传动油规格 ........................................................................................................................................... .........11效率曲线 , BDU-06S,10S . ...........................................................................................................................12效率曲线 , BDU-10L/21L, 21H, BDP-10L ...............................................................................................1 概况 . ......................................................................................................................................... .........................14输入速度 ........................................................................................................................................... ..............14系统压力 ........................................................................................................................................... ..............14补油压力 ........................................................................................................................................... ..............15补油入口压力 . ......................................................................................................................................... ......15壳体压力 ........................................................................................................................................... ..............15液压油 ........................................................................................................................................... ...................15温度及粘度 ........................................................................................................................................... .........16液压油及过滤器 . (17)箱 . ......................................................................................................................................... .........................17控制轴作用力 . ......................................................................................................................................... ......17独立刹车系统 . ......................................................................................................................................... ......17主轴负载 ........................................................................................................................................... ..............18轴选项 ........................................................................................................................................... . (19)旁通阀 ........................................................................................................................................... . (21)高压溢流阀(HPRV及补油单向阀 (过压保护 (21)带阻尼孔补油单向阀 (22)可选集成油箱 . ......................................................................................................................................... (24)过滤器 ........................................................................................................................................... . (24)风扇 . ......................................................................................................................................... . (24)11012499 July 2007BD 系列静液传动单元技术文献目录4元件选型型号代码推荐安装及保养维护安装图纸最高系统压力 . ......................................................................................................................................... ......25 输入能量 ........................................................................................................................................... ..............26 元件寿命 ........................................................................................................................................... ..............27BDU 型号代码 ........................................................................................................................................... ....29 BDP 型号代码 . ......................................................................................................................................... ...... 1 壳体安装 ........................................................................................................................................... .............. 2 轴安装 ........................................................................................................................................... ................... 2 样机调试程序 . ......................................................................................................................................... ...... 2操作 . ......................................................................................................................................... ......................... 2保养维护 ........................................................................................................................................... .............. 2BDU-06S . ...................................................................................................................................... .................... BDU-10S . ...................................................................................................................................... .................... 5BDU-10L . ...................................................................................................................................... .................... 5BDU-21L . ...................................................................................................................................... .................... 9BDU-21H . ...................................................................................................................................... ................... 9BDP-10L ........................................................................................................................................ ...................4 可选风扇 ........................................................................................................................................... .. (4)11012499 July 2007BD 系列静液传动单元技术文献概况信息5BD 系列静液传动单元适应用于能量的传递及控制。

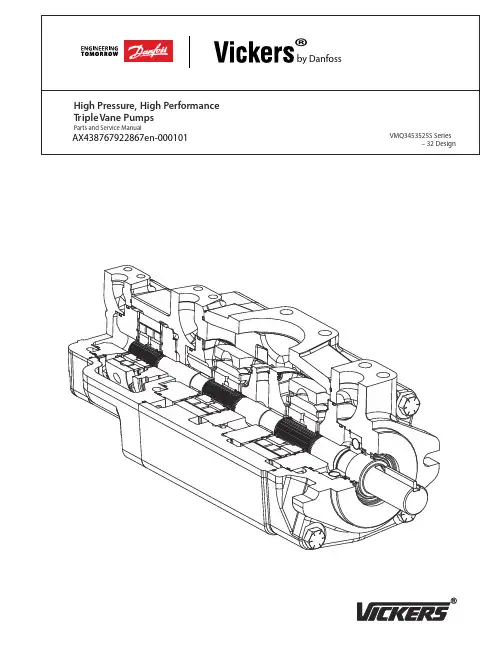

High Pressure, High Performance Triple Vane Pump VMQ3453525SS eries — 32 DesignIncluded in Single STD Seal Kit 02-346523 or Viton Seal Kit 02-346532.Included in Doublt STD Seal Kit 02-346531 or Viton Seal Kit 02-346533.*With double and triple pumps, the orientation of the kits is such that the kit rotation is a reverse of the pump rotation. See tables X1 and X2 for the correct kit rotation relative to the pump rotation.OUTLET BODYFlange Single Shaft Seal Double Shaft SealMounting Inch Port Metric Port Inch Port Metric Port Style Threads Threads Threads ThreadsSAE B998754998748998755998749ISO 100—998756—998757TABLE 1TABLE 2MODEL CODE30TH DESIGN 31ST & 32ND KEY SHAFT DESIGN SHAFT3453525VMQ–***–***–*–*–019970924993377-0019285423453525VMQ–***–***–*–*–029970804993376-001—3453525VMQ–***–***–*–*–039970934993378-0019285473453525VMQ–***–***–*–*–059970944993379-0019285433453525VMQ–***–***–*–*–069970954993380-001—3453525VMQ–***–***–*–*–099970964993381-001—Cartridge Kit Rotation for Left Hand Rotation PumpR= Right Hand RotationL=Left Hand RotationPUMP SHAFT END CENTERCOVER ENDROTATIONKIT ROTATIONKIT ROTATIONKIT ROTATIONTriple (L)(L)(R)(R)*Notes:- A left hand rotation pump has the shaft turning counterclockwisewhen viewed from the input shaft end- When ordering a left hand rotation kit, the part number will have a su x of ‘-L’TABLE X2Cartridge Kit Rotation for Right Hand Rotation PumpR= Right Hand RotationL=Left Hand RotationPUMP SHAFT END CENTER COVER ENDROTATIONKIT ROTATIONKIT ROTATIONKIT ROTATIONTriple (R)(R)(L)(L)*Notes:- A right hand rotation pump has the shaft turning clockwise whenviewed from the input shaft end- When ordering a right hand rotation kit, the part number will not have a su x.TABLE X1TABLE 3MODEL CODE*•CARTRIDGE *•CARTRIDGEENDRT I KOVC)ET I V(ONB(T I KUN)N-AVMQ3453525S***-***-01002-46557402-465569VMQ3453525S***-***-01602-46557502-465570VMQ3453525S***-***-02002-46557602-465571VMQ3453525S***-***-02502-46557802-465572VMQ3453525S***-***-03202-46557702-465573VMQ3453525S***-***-04002-34897402-348981VMQ3453525S***-***-04502-34897502-348982VMQ3453525S***-***-05002-34897602-348983VMQ3453525S***-***-06302-34897702-348984VMQ3453525S***-***-07102-34897802-348985VMQ3453525S***-***-08002-34897902-348986VMQ3453525S***-***-09002-34898002-348987TABLE 4MODEL CODE*•CARTRIDGE *•CARTRIDGECENTER SECTION KIT (BUNA-N)KIT (VITON)VMQ3453525S***-090-***02-46562102-465622VMQ3453525S***-100-***02-46562302-465624VMQ3453525S***-112-***02-46562502-465626VMQ3453525S***-125-***02-46562702-465628VMQ3453525S***-135-***02-46562902-465630VMQ3453525S***-140-***02-46563102-465632VMQ3453525S***-158-***02-46563302-465634TABLE 5MODEL CODE*•CARTRIDGE *•CARTRIDGET I KNDET FHAS)NB(NT I V(OU)N-AT I KVMQ3453525-140-***-***02-34697002-346971VMQ3453525-160-***-***02-34696802-346969VMQ3453525-180-***-***02-34696602-346967VMQ3453525-195-***-***02-34696402-346965VMQ3453525-215-***-***02-34696202-346963Model CodeVMQ3 ** ** 25 *** *** *** * ** * * * * * * * 00 * 0 321 2 3 45 67 811 12 132021 22242526272829323334 359 1014 15 1617 18 192330 31* Verify shaft torque ratings meet or exceed input torque requirementsSeries designation VMQ3 – Vane pump triple series Frame size (front section)45–140-215 cm 3/r (8.54-13.12 in3/r)Frame size(middle section)35–90-158 cm 3/r (5.49-9.64 in3/r)Frame size (rear section)25–10-90 cm 3/r (0.62-5.49 in3/r)Displacement(front section)Frame size 45140–140 cm3/r (8.54 in 3/r)160–160 cm3/r (9.76 in 3/r)180–180 cm3/r (10.98 in 3/r)195–195 cm 3/r (11.89 in 3/r)215–215 cm 3/r (13.12 in 3/r)Displacement(middle section)Frame size 35090–90 cm3/r (5.49 in 3/r)100–100 cm 3/r (6.10 in 3/r)112–112 cm 3/r (6.83 in 3/r)125–125 cm3/r (7.63 in 3/r)135–135 cm3/r (8.24 in 3/r)140–140 cm 3/r (8.54 in 3/r)158–158 cm 3/r (9.64 in3/r)Displacement(rear section)Frame size 25010–10 cm3/r (0.62 in 3/r)016–16 cm3/r (0.98 in 3/r)020–20 cm3/r (1.23 in 3/r)025–25 cm 3/r (1.58 in 3/r)032–32 cm 3/r (1.96 in 3/r)040–40 cm3/r (2.44 in 3/r)045–45 cm3/r (2.75 in 3/r)050–50 cm 3/r (3.05 in 3/r)063–63 cm 3/r (3.84 in 3/r)071–71 cm3/r (4.33 in 3/r)080–80 cm3/r (4.88 in 3/r)090–90 cm 3/r (5.49 in 3/r)Front ange mounting styleA–SAE C 2-boltSAE J744 127-2127,00 (5.000) x 12,4 (0.49) pilot17,6 (0.69) slots on 181,0 (7.13) bolt circle B –ISO 3019/2 125A2HW 2-bolt125,00 (4.921) x 9,2 (0.36) pilot18,1 (0.71) slots on 180,0 (7.09) bolt circleInput shaft type*01–SAE J744 keyed Frame size 45: 38,10 (1.500)02–SAE J744 splined Frame size 45: C-C 03–ISO 3019/2 keyed Frame size 45: 40,00 (1.575)05–SAE J744 keyed Frame size 45: 44,45 (1.750)06–SAE J744 splined Frame size 45: DPort type A–Inlet: SAE J518 4-boltangeFront outlet: SAE J518 4-bolt angeMiddle outlet: SAE J5184-bolt angeRear outlet: SAE J518 4-bolt angeB –Inlet: ISO 6162 4-bolt angeFront outlet: ISO 6162 4-bolt angeMiddle outlet: ISO 6162 4-bolt angeRear outlet: ISO 6162 4-bolt angeFront outlet port positionViewed from cover end of pumpA –Opposite inlet portB –90°CCW to inlet portC –In-line with inlet portD –90°CW to inlet portMiddle outlet port positionViewed from cover end of pumpA –Opposite inlet portB –90°CCW to inlet portC –In-line with inlet portD –90°CW to inlet portRear outlet port positionViewed from cover end of pump453525 units E –Opposite inlet port F –90°CCW to inlet port G –In-line with inlet port H –90°CW to inlet portShaft sealA–Single, primary B–Double, secondary (spring side out)Recommended for wet mount applicationsSeal typeN –Buna N V –VitonW –Buna N with Viton shaft seal(s)Shaft rotationViewed from shaft end of pumpL –Left hand (CCW)R–Right hand (CW)Special features00–NonePaint0–None A –BlueCustomer identi cation–NoneDesign code32–32 designInstallation dimensions remain unchanged for design numbers 31 to 39 inclusive.34 35333230 312928272625242321 222017 18 1914 15 1611 12 139 107 85 61 2 3 4Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and electric components. We specialize in providing state-of-the-art technology and solutions that excel in the harsh operating conditions of the mobile off-highway market as well as the marine sector. Building on our extensive applications expertise, we work closely with you to ensure exceptional performance for a broad range of applications. We help you and other customers around the world speed up system development, reduce costs and bring vehicles and vessels to market faster.Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile electrification.Go to for further product information.We offer you expert worldwide support for ensuring the best possible solutions foroutstanding performance. And with an extensive network of Global Service Partners, we also provide you with comprehensive global service for all of our components.Local address:DanfossPower Solutions GmbH & Co. OHG Krokamp 35D-24539 Neumünster, Germany Phone: +49 4321 871 0DanfossPower Solutions ApS Nordborgvej 81DK-6430 Nordborg, Denmark Phone: +45 7488 2222DanfossPower Solutions (US) Company 2800 East 13th Street Ames, IA 50010, USA Phone: +1 515 239 6000DanfossPower Solutions Trading (Shanghai) Co., Ltd.Building #22, No. 1000 Jin Hai Rd Jin Qiao, Pudong New District Shanghai, China 201206Phone: +86 21 2080 6201Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.Products we offer:•Cartridge valves •DCV directional control valves•Electric converters •Electric machines •Electric motors •Gear motors •Gear pumps •Hydraulic integrated circuits (HICs)•Hydrostatic motors •Hydrostatic pumps •Orbital motors •PLUS+1® controllers •PLUS+1® displays •PLUS+1® joysticks and pedals•PLUS+1® operator interfaces•PLUS+1® sensors •PLUS+1® software •PLUS+1® software services,support and training •Position controls and sensors•PVG proportional valves •Steering components and systems •TelematicsHydro-GearDaikin-Sauer-Danfoss。

Vickers by Danfoss®Vane PumpsService and Parts ManualAX438768395873en-00010135VTA 35VTB 35VTBP 35VTC“C” Adapter Plate (See Table)F3 SEAL KIT 92019692019802-136930920200298147 Bolt (4 Req’d)Torque 55.2 – 67.8 N.m.(40 – 50 lb. ft. )353409 “O” Ring42023 Bolt (4 Req’d)Torque 190 – 217 N.m. (140 – 160 lb. ft. )02–136717 Vane Kit(Includes12 vanes & inserts)Ring (See Table)576265 Inlet Plate S/A289475 Screw (2 Req’d)Housing (See Table)280031 Pin (2 Req’d)575478 Rotor Retaining Ring (See Table)Coupling (see Table)“A” Adapter Plate (See Table)154086 “O” Ring 351776 “O” Ring 92019592019702-136929920199MODEL SEAL KIT 435714 “O” Ring582519 Washer (4 Req’d) 298148 Bolt (4 Req’d)Torque 55.2 – 67.8 N.m.(40 – 50 lb. ft. )SPACER KITVTA VTB VTBP VTC58493658492294129694129702-136817MODEL ADAPTER PLATE ADAPTERKIT COUPLING RETAINING RING COUPLINGKIT 58183394129822317283003 (1)83003 (2)23780742677058492402-13681002-13681302-13681402-136815NOTEFOR BP MODELS AN ADAPTER KIT AND SPACER KIT IS REQUIRED.298147 Bolt (4 Req’d)Torque 55.2 – 67.8 N.m.(40 – 50 lb. ft. )588725 Spacer (See table) (BP models only)375422 “O” Ring (BP models only)427700 Washer (BP models only)205436 Screw (2 Req’d) (BP models only)Included in seal kit (See Table)Included in cartridge kit (See Table)Included in coupling kit (See Table)Included in adapter kit (See Table)Included in spacer kit (BP models only)F3 equivalent seal kit (See Table)Parts pre xed with symbols available only in kits.584940“B” Adapter Plate (See Table) 154088 “O” RingFor satisfactory service life of these components in industrial applications,use full ow ltration to provide uid which meets ISO cleanliness code 16/13 or cleaner. OFP , OFR, and OFRS series lters are recommended.NOTEModel CodeDanfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and electric components. We specialize in providing state-of-the-art technology and solutions that excel in the harsh operating conditions of the mobile off-highway market as well as the marine sector. Building on our extensive applications expertise, we work closely with you to ensure exceptional performance for a broad range of applications. We help you and other customers around the world speed up system development, reduce costs and bring vehicles and vessels to market faster.Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile electrification.Go to for further product information.We offer you expert worldwide support for ensuring the best possible solutions foroutstanding performance. And with an extensive network of Global Service Partners, we also provide you with comprehensive global service for all of our components.Local address:DanfossPower Solutions GmbH & Co. OHG Krokamp 35D-24539 Neumünster, Germany Phone: +49 4321 871 0DanfossPower Solutions ApS Nordborgvej 81DK-6430 Nordborg, Denmark Phone: +45 7488 2222DanfossPower Solutions (US) Company 2800 East 13th Street Ames, IA 50010, USA Phone: +1 515 239 6000DanfossPower Solutions Trading (Shanghai) Co., Ltd.Building #22, No. 1000 Jin Hai Rd Jin Qiao, Pudong New District Shanghai, China 201206Phone: +86 21 2080 6201Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.Products we offer:•Cartridge valves •DCV directional control valves•Electric converters •Electric machines •Electric motors •Gear motors •Gear pumps •Hydraulic integrated circuits (HICs)•Hydrostatic motors •Hydrostatic pumps •Orbital motors •PLUS+1® controllers •PLUS+1® displays •PLUS+1® joysticks and pedals•PLUS+1® operator interfaces•PLUS+1® sensors •PLUS+1® software •PLUS+1® software services,support and training •Position controls and sensors•PVG proportional valves •Steering components and systems •TelematicsHydro-GearDaikin-Sauer-Danfoss。

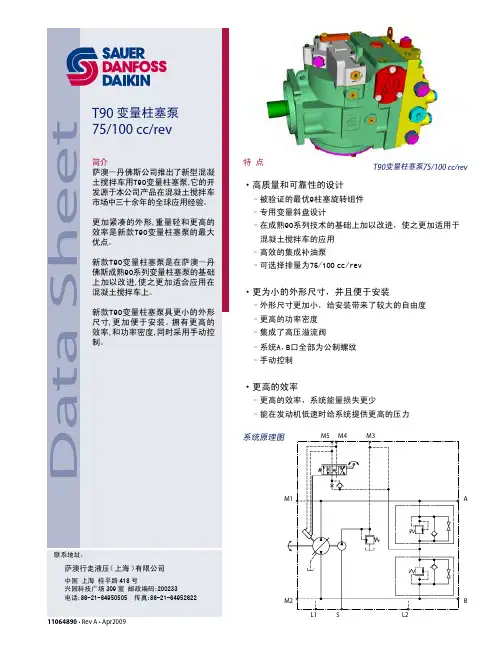

D a t a S h e e t11064890 • Rev A • Apr2009联系地址:萨澳行走液压(上海)有限公司中国 上海 桂平路418号兴园科技广场309室 邮政编码:200233电话:86-21-64950505 传真:86-21-64952622T90变量柱塞泵75/100 cc/revT90 变量柱塞泵75/100 cc/rev简介萨澳-丹佛斯公司推出了新型混凝土搅拌车用T90变量柱塞泵,它的开发源于本公司产品在混凝土搅拌车市场中三十余年的全球应用经验。

更加紧凑的外形,重量轻和更高的效率是新款T90变量柱塞泵的最大优点。

新款T90变量柱塞泵是在萨澳-丹佛斯成熟90系列变量柱塞泵的基础上加以改进,使之更加适合应用在混凝土搅拌车上。

新款T90变量柱塞泵具更小的外形尺寸,更加便于安装。

拥有更高的效率,和功率密度,同时采用手动控制。

系统原理图AB特 点·高质量和可靠性的设计–被验证的最优9柱塞旋转组件 –专用变量斜盘设计–在成熟90系列技术的基础上加以改进,使之更加适用于 混凝土搅拌车的应用 –高效的集成补油泵–可选择排量为75/100cc/rev·更为小的外形尺寸,并且便于安装–外形尺寸更加小,给安装带来了较大的自由度 –更高的功率密度 –集成了高压溢流阀 –系统A,B口全部为公制螺纹 –手动控制·更高的效率–更高的效率,系统能量损失更少 –能在发动机低速时给系统提供更高的压力© Copyright 2009, Sauer-Danfoss. All rights reserved. Contents subject to change.11064890 • Rev A • Apr2009T90 变量柱塞泵75/100 cc/rev工作参数特征技术规格T90外形图(T90 变量柱塞泵外形图(油口测压口 M2 系统压力 B 油口 L1 壳体泄油口测压口 M2 系统压力 B 油口 L1 壳体泄油口油口"Z"视图[-0.005]系统压力额定bar [psi]420 [6000]最高480 [7000]主油路最低压力10 [150]吸油口压力 (补油泵入口)最低(持续)bar (绝对压力)[in. Hg vac.]0.7 [9]最低(冷启动)0.2 [24]壳体压力持续bar [psi]3 [40]最高(冷启动)5 [75]。

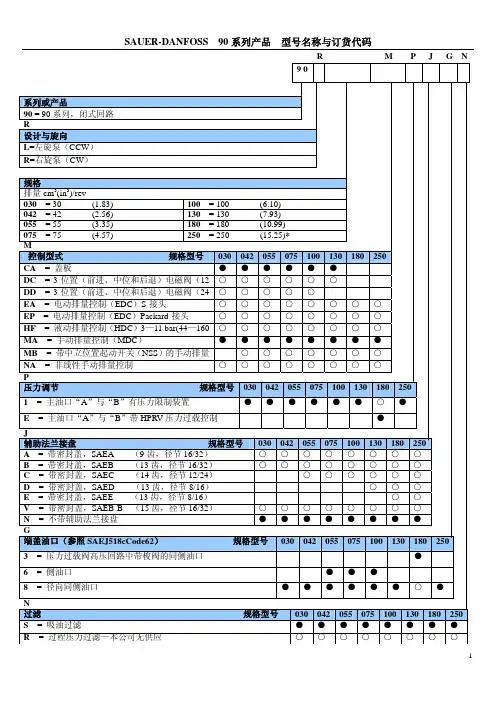

P= 外接压力过滤器—卡口式过滤器(短的)○○○○○○○○L = 外接压力过滤器—卡口式过滤器(长的)-○○○○○○○

F

●= 标准Array○= 选用

- = 无货

* = 19-95年供货

250的泵

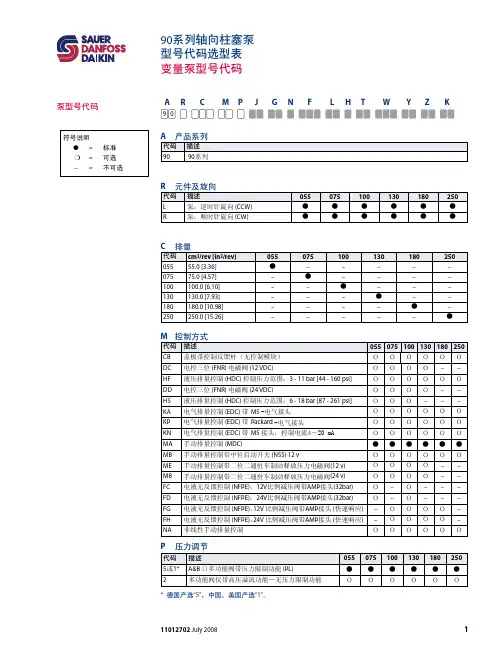

型号--90R250MA2CD80T3C05NNN262624

1—R-右旋

2—250-排量

3—MA-手控变量

4—2-只有高压溢流阀

5—CD-SAE C 14齿,带密封盖

6—T-远程液控,无滤清器

7—3-无排量限制器

8—C-14毫升补油泵

9—05-1.37毫米的节流孔

10—NNN-无特殊要求

11—26-26-“A”“B”腔的压力设定

12—24-补油压力

100的泵

型号-90R100MA1AC60L3S1E03GBA323224

90R-右旋

100—排量

MA—手控变量

13—带压力限制器

AC—SAE A 9齿 辅助安装

60—两侧油口

L—自带长压力滤清器

3—无排量限制器

S—14齿主轴

E—20毫升补油泵

03—0。

81毫米节流孔

GBA—低噪音配油盘

32—32—“A”“B”口压力设定

24—补油压力

100的马达

90M100NC0N8N0CTW00N0N000024

90M—定量马达

N(7)--轴向油口

C6—主轴21齿,C8—27齿W—带回路清洗

24—补油压力

定量马达型号名称与订贷代码

○ = 可供选用

- = 不供应 ** = 不应用

● = 标准的

○ = 可供选用 - = 不供应 ** = 不应用。

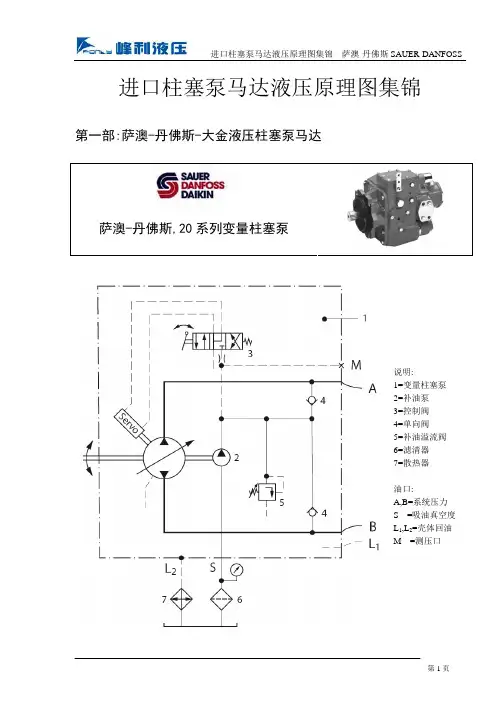

进口柱塞泵马达液压原理图集锦第一部:萨澳-丹佛斯-大金液压柱塞泵马达萨澳-丹佛斯,20系列变量柱塞泵说明:1=变量柱塞泵 2=补油泵 3=控制阀 4=单向阀 5=补油溢流阀 6=滤清器 7=散热器油口:A,B=系统压力 S =吸油真空度 L 1,L 2=壳体回油 M =测压口萨澳-丹佛斯,20系列定量柱塞马达定量马达(无阀)说明:1=定量马达油口:L 1,L 2---壳体回油口 A,B---系统压力口定量马达(带冲洗阀)说明:1=定量马达 2=低压溢流阀 3=梭形阀 4=高压溢流阀油口:L 1,L 2---壳体回油口 M A ---A 口测压口 M B ---B 口测压口 M=低压腔测压口定量马达(带冲洗阀和旁通阀)说明:1=定量马达 2=低压溢流阀 3=梭形阀 4=高压溢流阀 5=手控旁通阀 油口:L 1,L 2=壳体回油口 M A =A 口测压口 M B =B 口测压口 M=低压腔测压口萨澳-丹佛斯,20系列变量柱塞马达油口:L1,L2=壳体回油压力M A=A口测压口M B=B口测压口M=低压腔测压口萨澳-丹佛斯,40系列泵马达MPV046手动控制泵液压原理图注释:MDC---手动控制阀单元 M 1---系统压力A 口测压口M 2---系统压力B 口测压口 M 3---补油压力测压口M 4,M 5---控制压力测压口 L 1,L 2---壳体回油口 A ,B---系统压力口 S---补油泵吸油口MPV035变量柱塞泵MPV046变量柱塞泵MPV046液动控制泵液压原理图HDC---液压控制阀单元 M 4,M 5---控制压测压口 X 1,X 2---壳体回油口 A ,B---系统压力口 S---补油泵吸油口MPV046 电磁阀控制泵液压原理图FNR---通断电控阀单元 M 4,M 5---控制压测压口 A ,B---系统压力口 S---补油泵吸油口MPV046 电比例控制泵液压原理图EDC---电比例控制阀单元M4,M5---控制压测压口A,B---系统压力口S---补油泵吸油口MPV035串泵,外补油选择MPV035串泵,内补油选择M25系列定量柱塞马达液压原理图(无冲洗阀) M25定量柱塞马达M25/35/44/46系列定量柱塞马达液压原理图(有冲洗阀)M35定量柱塞马达M25/35/44系列变量柱塞马达液压原理图(有冲洗阀)M46 变量马达液压回路图注释:M1---系统压力A口测压口M2---系统压力B口测压口X1,X2---控制压力口L1,L2---壳体回油口A,B---系统压力口40系列泵马达液压系统原理图萨澳-丹佛斯,90系列变量柱塞泵注释:M 1---A 口测压口 M 2---B 口测压口M 3---补油压力测压口M 4,M 5---控制测压口L 1,L 2---壳体回油口 A ,B---系统压力口 S---补油泵吸油口FNR控制方式EDC控制方式HDC控制方式MDC控制方式萨澳-丹佛斯,90系列变量柱塞马达油口解释:A,B =高压油口,称A,B口,或A,B腔S =补油口L1,L2=壳体回油口M1,M2 =A,B腔测压口M3=补油压力测压口M4,M5 =控制压力测压口萨澳-丹佛斯,90系列定量柱塞马达解释:A,B = A,B口,系统油口L1,L2=壳体回油口M1,M2=A,B口的测压口M3 = 低压测压口萨澳-丹佛斯,90系列无反馈变量柱塞泵90系列泵马达液压系统回路图萨澳-丹佛斯,51系列马达HZ控制方式马达回路图油口解释:A,B---系统压力口L1,L2---壳体回油口M1,M2---系统压力测压口M3,M4---伺服压力测压口M5---伺服压力供油测压口M7---控制压力测压口X1---控制压力口插装式两位控制E1,E2两位控制F1,F2液压比例控制HZ, HS, K1, K2制动压力失效回路图无制动压力失效 K1,K2控制阀液压比例控制HP制动压力失效回路图无制动压力失效电/液压比例控制EP,EQ,ER,ES制动压力失效回路图无制动压力失效压力补偿控制TA,TH,T1,T2制动压力失效回路图无制动压力失效90系列泵和51系列马达液压系统回路图萨澳-丹佛斯,H1系列泵萨澳-丹佛斯,42系列泵MDC带中位启动和过载保护MDC带过载保护MDC手动变量控制阀FNR开关式电控阀—原理图外形图EDC比例电控阀—原理图剖面图NFPE液控阀液压原理图 NFPE液控阀剖面图无反馈比例液控阀剖面图无反馈比例液控阀剖面图萨澳-丹佛斯,搅拌车用变量柱塞泵带高压溢流阀无高压溢流阀萨澳-丹佛斯,搅拌车用定量柱塞马达。

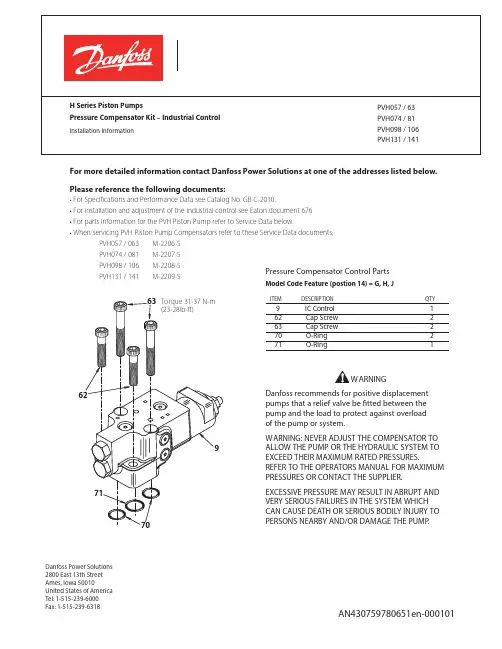

For more detailed information contact Danfoss Power Solutions at one of the addresses listed below.Please reference the following documents:• For Speci cations and Performance Data see Catalog No. GB-C-2010.• For installation and adjustment of the industrial control see Eaton document 676• For parts Information for the PVH Piston Pump refer to Service Data below.• When servicing PVH Piston Pump Compensators refer to these Service Data documents:PVH057 / 063M-2206-S PVH074 / 081M-2207-S PVH098 / 106M-2208-SPVH131 / 141M-2209-SPressure Compensator Control PartsModel Code Feature (postion 14) = G, H, JITEMDESCRIPTIONQTY91l o r t n o C C I 62Cap Screw 263Cap Screw 270O-Ring 271O-Ring 1ARNINGDanfoss recommends for positive displacement pumps that a relief valve be tted between the pump and the load to protect against overload of the pump or system.WARNING: NEVER ADJUST THE COMPENSATOR TO ALLOW THE PUMP OR THE HYDRAULIC SYSTEM TO EXCEED THEIR MAXIMUM RATED PRESSURES.REFER TO THE OPERATORS MANUAL FOR MAXIMUM PRESSURES OR CONTACT THE SUPPLIER.EXCESSIVE PRESSURE MAY RESULT IN ABRUPT AND VERY SERIOUS FAILURES IN THE SYSTEM WHICH CAN CAUSE DEATH OR SERIOUS BODILY INJURY TO PERSONS NEARBY AND/OR DAMAGE THE PUMP .Danfoss Power Solutions 2800 East 13th Street Ames, Iowa 50010United States of America Tel: 1-515-239-6000Fax: 1-515-239-6318AN430759780651en-000101Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and electric components. We specialize in providing state-of-the-art technology and solutions marine sector. Building on our extensive applications expertise, we work closely with you to ensure exceptional performance for a broad range of applications. We help you and other customers around the world speed up system development, reduce costs and bring vehicles and vessels to market faster.Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile Go to for further product information.outstanding performance. And with an extensive network of Global Service Partners, we also provide you with comprehensive global service for all of our components.Local address:DanfossPower Solutions GmbH & Co. OHG Krokamp 35D-24539 Neumünster, Germany Phone: +49 4321 871 0DanfossPower Solutions ApS Nordborgvej 81DK-6430 Nordborg, Denmark Phone: +45 7488 2222DanfossPower Solutions (US) Company 2800 East 13th Street Ames, IA 50010, USA Phone: +1 515 239 6000DanfossPower Solutions Trading (Shanghai) Co., Ltd.Building #22, No. 1000 Jin Hai Rd Jin Qiao, Pudong New District Shanghai, China 201206Phone: +86 21 2080 6201Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to productsagreed.All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.© Danfoss | September 2022•Cartridge valves •DCV directional control valves•Electric converters •Electric machines •Electric motors •Gear motors •Gear pumps •Hydraulic integrated circuits (HICs)•Hydrostatic motors •Hydrostatic pumps •Orbital motors •PLUS+1® controllers •PLUS+1® displays •PLUS+1® joysticks and pedals•PLUS+1® operator interfaces•PLUS+1® sensors •PLUS+1® software •PLUS+1® software services,support and training •Position controls and sensors•PVG proportional valves •Steering components and systems •TelematicsHydro-GearDaikin-Sauer-Danfoss。

I-3167-SRevised 10-01-89Vane Type Single Pump35VQ**A-86* - 20(L)36VQ**A-86 - 20(L)Service and Parts ManualDanfoss ®Vane PumpsAX432876936851en-000101– 3 –Model CodeViton SealsSeriesVane TypeSAE Rated CapacityPort ConnectionsMounting & Shaft SealsAssemblyShaftsPort PositionsDesignRotation(Omit if not required.)(Rating @ 1200 RPM - 100 psi)21 - 21 USgpm25 - 25 USgpm30 - 30 USgpm35 - 35 USgpm38 - 38 USgpmF - Foot (Single Shaft Seal Assy.)S - Flange (Double Shaft Seal Assy.)Omitted-Flange (Single Shaft SealAssy.)1 - Square Key4 - Splined11 - Splined86 - Square KeySee Chart BelowL - Left Hand (CCW Rotation)Omitted - Right Hand RotationFor satisfactory service life of these components, use full ow ltration to provide uid which meets ISO cleanliness code 16/13or cleaner. Selections from pressure, return, and in-line lter series are recommended.A - SAE 4-Bolt FlangePrinted in U.S.A.Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and electric components. We specialize in providing state-of-the-art technology and solutions that excel in the harsh operating conditions of the mobile off-highway market as well as the marine sector. Building on our extensive applications expertise, we work closely with you to ensure exceptional performance for a broad range of applications. We help you and other customers around the world speed up system development, reduce costs and bring vehicles and vessels to market faster.Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile electrification.Go to for further product information.We offer you expert worldwide support for ensuring the best possible solutions foroutstanding performance. And with an extensive network of Global Service Partners, we also provide you with comprehensive global service for all of our components.Local address:DanfossPower Solutions GmbH & Co. OHG Krokamp 35D-24539 Neumünster, Germany Phone: +49 4321 871 0DanfossPower Solutions ApS Nordborgvej 81DK-6430 Nordborg, Denmark Phone: +45 7488 2222DanfossPower Solutions (US) Company 2800 East 13th Street Ames, IA 50010, USA Phone: +1 515 239 6000DanfossPower Solutions Trading (Shanghai) Co., Ltd.Building #22, No. 1000 Jin Hai Rd Jin Qiao, Pudong New District Shanghai, China 201206Phone: +86 21 2080 6201Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.Products we offer:•Cartridge valves •DCV directional control valves•Electric converters •Electric machines •Electric motors •Gear motors •Gear pumps •Hydraulic integrated circuits (HICs)•Hydrostatic motors •Hydrostatic pumps •Orbital motors •PLUS+1® controllers •PLUS+1® displays •PLUS+1® joysticks and pedals•PLUS+1® operator interfaces•PLUS+1® sensors •PLUS+1® software •PLUS+1® software services,support and training •Position controls and sensors•PVG proportional valves •Steering components and systems •TelematicsHydro-GearDaikin-Sauer-Danfoss。

描述特性控制器2ASC系列电控防打滑阀技术文献概述Sauer-Danfoss 防打滑控制阀(ASC 系列阀典型应用于驱动系统中。

驱动系统中要求泵流出的液压油被均分到两个驱动马达中,确保两个马达在各种负载、压力、流量及车辆转向工况下以相同的速度转动。

这样可以防止车轮打滑并能提供最佳的车辆牵引力。

ASC 系列电控防打滑阀可广泛应用于需要流量均分的场合。

ASC 系列阀配合使用SUSMIC S1X微处理器、转向及速度传感器以及已在世界范围内得到认可的Sauer-Danfoss 静液压元件,提高了机器的操作性能。

SUSMIC S1X 微处理器提供了软件的灵活性。

由于参数易修改(在软件中,使得对不同类型的机器进行各自不同的设置成为可能。

• 行走机械应用强化设计• 两种“剩余流量”选项可用• 电源电压 12 V DC 或 24 V DC . • 便于维修• 灵活: 2 - 4 马达• 转向时一样起作用• 无需硬件(阻尼孔改变,使用软件优化/适应• 通过软件进行单独设置:- 不同转向模式选择- 车辆几何尺寸 - 履带宽度 - 轮距 - 车轮直径 - 其它• S1X-16 G2 AMP K196 S1X 控制器,非 CAN• S1X-26 G2 AMP K196C S1X 控制器, CAN11043843 Rev AA July 2008ASC系列电控防打滑阀技术文献目录概述 . ......................................................................................................................................... .........2描述 . ......................................................................................................................................... .........................................2特性 . ......................................................................................................................................... .........................................2控制器 . ......................................................................................................................................... ....................................2剖视图 ........................................................................................................................................... ....4剖视图– ASC 阀............................................................................................................................................ .................4回路示意图 ........................................................................................................................................... .........................4系统示意图 (5)回路示意图– ASC 阀和系统元件 . .........................................................................................................................5技术规格 ........................................................................................................................................... 7总体规格 ........................................................................................................................................... ..............................7规格数据 ........................................................................................................................................... ..............................7技术数据 ........................................................................................................................................... ..............................7液压油规格 ........................................................................................................................................... .........................7总体技术规格 ...................................................................................................................................8压力限制 ........................................................................................................................................... ..............................8液压油 . ......................................................................................................................................... ....................................8温度和粘度 ........................................................................................................................................... .........................9油液和过滤 ........................................................................................................................................... ......................10独立制动系统 ........................................................................................................................................... .................11油箱 . ......................................................................................................................................... ...................................... 11功能描述 (1)2总体描述 ......................................................................................................................................................................12ASC 阀功能 . ......................................................................................................................................... ........................ 12应用考虑事项 .................................................................................................................................14可选项 ........................................................................................................................................... ..15可选项 . ......................................................................................................................................... ................................. 15技术数据 (1)6外形尺寸 (1)811043843 Rev AA July 20083ASC系列电控防打滑阀技术文献剖视图剖视图– ASC 阀回路示意图411043843 Rev AA July 2008ASC系列电控防打滑阀技术文献系统示意图回路示意图– ASC 阀和系统元件P001 970油口:A, B SL, L1, L2 M1, M2 M3= 主压力油口 = 吸油口 - 补油泵 = 壳体回油 = A 和B 测压口 = 补油压力测压口M4, M5 M7, M8 X3 = 伺服压力测压口 = 控制压力测压口 = 控制压力供油口上图所示的静液压传动系统示意图,由一个90系列手动排量控制泵、两个定量马达,驻车制动及制动释放阀组成。

D a t a S h e et联系地址:萨澳行走液压(上海)有限公司中国 上海 桂平路418号兴园科技广场309室 邮政编码:200233电话:86-21-64950505 传真:86-21-64952622S20+TMM 混凝土搅拌车系统解决方案S20+TMM混凝土搅拌车驱动系统简介萨澳-丹佛斯公司已经推出混凝土搅拌车S20+TMM驱动系统,它的开发源于本公司产品在全球混凝土搅拌车市场中三十余年的应用经验。

易于操控,运行稳定,紧凑的外形尺寸是此系统的主要特点。

系统成套供应商萨澳-丹佛斯公司提供全系列的6-12m 3搅拌车滚筒驱动系统。

S20+TMM系统由S20变量柱塞泵,TMM 柱塞定量马达,TMG减速器组成。

特 点·S20变量柱塞泵–被验证了的最优的9柱塞缸体 旋转组件–更小的外形尺寸,更高的效率 –系统A,B口全部为SAE标准法兰 油口–采用高效率的圆锥滚子轴承, 使泵能承受高的径向负载 –手动控制,并具备恒速控制 和电控选项·TMM柱塞定量马达–被验证了的最优的9柱塞缸体 旋转组件–马达的排量与泵的一致 –系统A,B口全部为全部为SAE 标准法兰油口–更小的外形尺寸,更高的效率 –集成高压溢流阀和回路冲洗阀·TMG减速器–被多年使用验证了的设计 –更低的噪音–更加适用于复杂路面的工况 –有更强的抗振动和冲击的能力S20+TMM系统技术规格系统性能参数系统原理图M1 M2L1L1AMAL2L2S BB M3M2NM1Z 视图P000 022E* 最大及最小角度 α,(见视图 伺服排量控制)** 花键轴数据:渐开线花键 标准: SAE,1963,等级1 圆弧齿根,齿侧定心S2O变量柱塞泵SPV2/070外形图纸Y 视图补油泵安装位置顺时针旋转时(R )L ) "A""L2":P005 107EX 视图( SPV 2/070时)控制手柄花键轴数据:Z补油泵吸油口最大拧紧力矩 (7/8 -14 UNF - 2B) is 22 - 28 Nm [195 - 248 lbf•in]Z 视图P000 022E* 最大及最小角度 α, (见视图 伺服排量控制)** 花键轴数据:渐开线花键 标准: SAE,1963,等级1 圆弧齿根,齿侧定心S2O变量柱塞泵SPV2/089外形图纸Y 视图补油泵安装位置顺时针旋转时(R )L ) "A""L2":油口P005 107EX 视图 (SPV 2/089 时)64Z补油泵吸油口最大拧紧力矩 (7/8 -14 UNF - 2B) is 22 - 28 Nm [195 - 248 lbf•in]马达输出轴旋向E420500T 顺时针(CW)逆时针(CCW)出出入入油口A油口B P005 006E7/8-14 UNF-2B95190,3P005 007E低压口:M2低压口:M1可选项:M121,59/16-18 UNF B 系统压力油口系统压力油口可选项:M121,59/16-18 UNFA 可选项:高压流溢阀“B”可选项:高压流溢阀“A”回路冲洗阀辅助堵头M121,5深度:12.7 min.164[6,456]TMM定量马达外形图纸萨澳-丹佛斯(上海)有限公司售后服务中心中国 上海 浦东新区 金桥出口加工区 榕桥路626号邮政编码:201206电话:86-21-58345876 传真:86-21-5834 5748萨澳行走液压(上海)有限公司中国 上海 桂平路418号兴园科技广场309室邮政编码:200233电话:86-21-64950505 传真:86-21-64952622萨澳-丹佛斯全球服务网络链接/ContactUs/index.htm产品系列开式回路轴向柱塞泵及马达齿轮泵及马达风扇驱动系统闭式回路轴向柱塞泵及马达斜轴柱塞变量马达静液压传动搅拌车驱动系统静液压传动桥电液控制装置成套系统微控制器及软件PLUS+1TM GUIDE(图形化用户集成开发环境)图形显示终端操纵手柄传感器摆线马达逆变器电动力转向装置液压动力转向装置液压集成块插装阀方向阀比例阀萨澳-丹佛斯公司-全球液压传动市场的领导者萨澳-丹佛斯作为多元化的跨国公司,为全球行走机械市场提供功能完备的成套设备。