PT4115规格书

- 格式:pdf

- 大小:1015.36 KB

- 文档页数:16

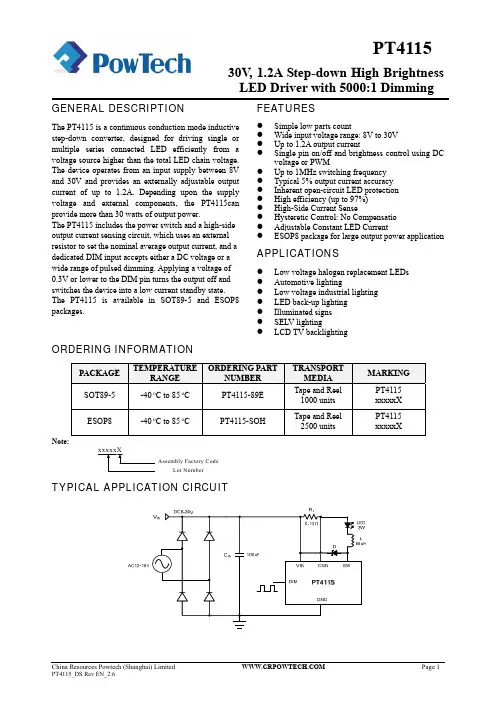

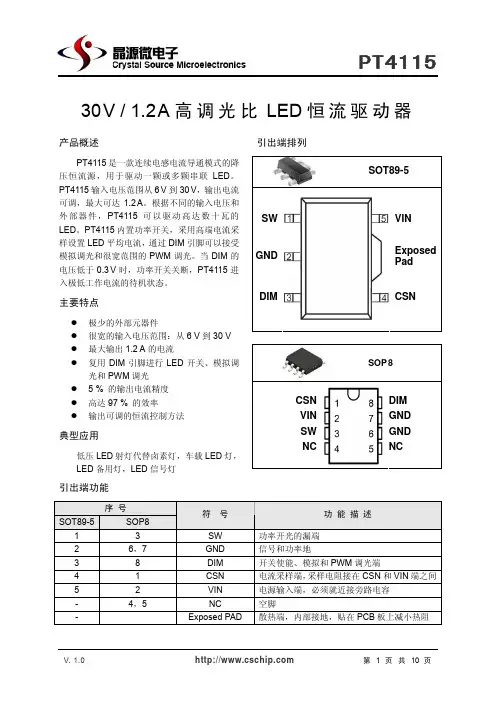

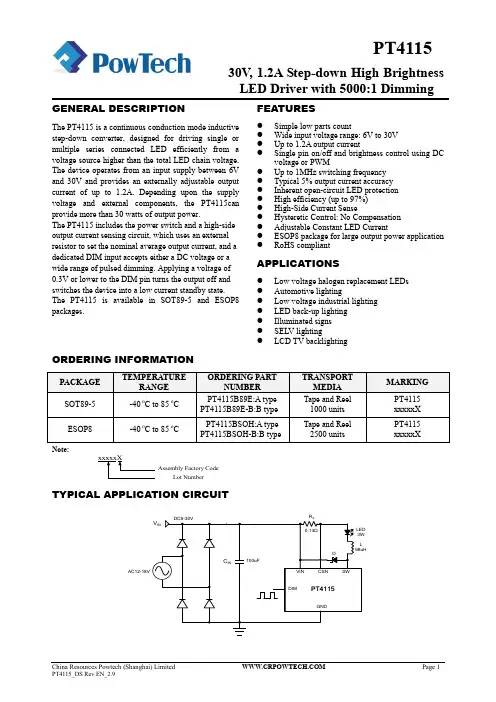

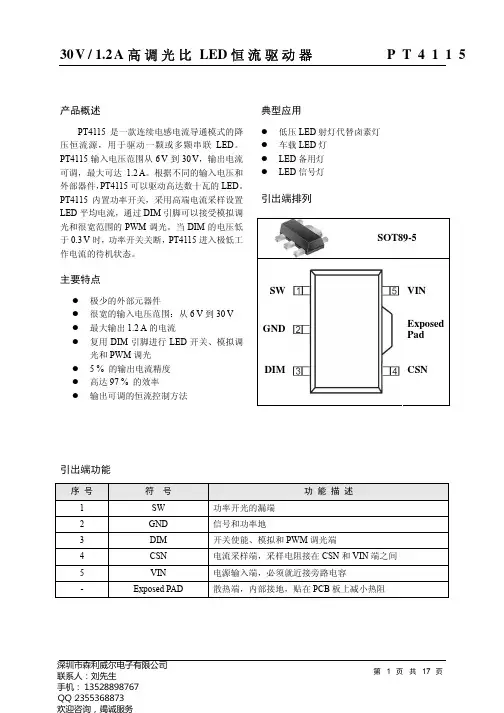

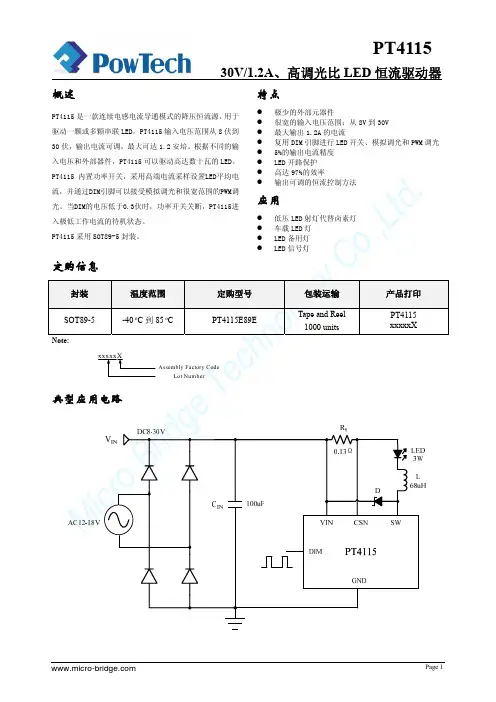

LED Driver with 5000:1 DimmingGENERAL DESCRIPTIONThe PT4115 is a continuous conduction mode inductive step-down converter, designed for driving single or multiple series connected LED efficiently from a voltage source higher than the total LED chain voltage. The device operates from an input supply between 8V and 30V and provides an externally adjustable output current of up to 1.2A. Depending upon the supply voltage and external components, the PT4115can provide more than 30 watts of output power.The PT4115 includes the power switch and a high-side output current sensing circuit, which uses an external resistor to set the nominal average output current, and a dedicated DIM input accepts either a DC voltage or a wide range of pulsed dimming. Applying a voltage of 0.3V or lower to the DIM pin turns the output off and switches the device into a low current standby state.The PT4115 is available in SOT89-5 and ESOP8 packages.FEATURESz Simple low parts countz Wide input voltage range: 8V to 30V z Up to 1.2A output currentz Single pin on/off and brightness control using DC voltage or PWMz Up to 1MHz switching frequency z Typical 5% output current accuracy z Inherent open-circuit LED protection z High efficiency (up to 97%) z High-Side Current Sensez Hysteretic Control: No Compensatio z Adjustable Constant LED CurrentzESOP8 package for large output power applicationAPPLICATIONSz Low voltage halogen replacement LEDs z Automotive lightingz Low voltage industrial lighting z LED back-up lighting z Illuminated signs z SELV lightingzLCD TV backlightingORDERING INFORMATIONPACKAGETEMPERATURERANGE ORDERING PARTNUMBERTRANSPORT MEDIA MARKING SOT89-5 -40 o C to 85 o C PT4115-89ETape and Reel1000 units PT4115 xxxxxX ESOP8 -40 o C to 85 o C PT4115-SOHTape and Reel2500 unitsPT4115 xxxxxXNote:TYPICAL APPLICATION CIRCUITAssembly Factory CodeLot NumberLED Driver with 5000:1 DimmingPIN ASSIGNMENTPIN DESCRIPTIONSPIN No. PIN NAMES DESCRIPTION1 SW Switch Output. SW is the drain of the internal N-Ch MOSFET switch. 2GNDSignal and power ground. Connect directly to ground plane.3 DIMLogic level dimming input. Drive DIM low to turn off the current regulator.Drive DIM high to enable the current regulator. 4 CSN Current sense input5 VIN Input Supply Pin. Must be locally bypassed.- Exposed PADInternally connected to GND. Mount on board for lower thermal resistance. ESOP8 4,5NCNo connectionABSOLUTE MAXIMUM RATINGS (note1)SYMBOLITEMSV ALUE UNIT V IN Supply V oltage -0.3~45V SW Drain of the internal power switch -0.3~45 V CSN Current sense input (Respect to VIN) +0.3~(-6.0) V DIM Logic level dimming input -0.3~6VI SW Switch output current 1.5 A P DMAX Power Dissipation (Note 2)1.5 W P TR Thermal Resistance, SOT89-5 θJA 45 o C /W P TR Thermal Resistance, ESOP8 θJA 40 oC /WT J Operation Junction Temperature Range-40 to 150 o C T STG Storage Temperature-55 to 150oCESD Susceptibility (Note 3)2kVCSN VIN SW NCNCDIM ESOP830V , 1.2A Step-down High BrightnessLED Driver with 5000:1 DimmingPT4115RECOMMENDED OPERATING RANGESYMBOL ITEMSV ALUE UNIT V IN V DD Supply V oltage 0 ~ 30 VT OPTOperating Temperature-40 to +85oCNote 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. RecommendedOperating Range indicates conditions for which the device is functional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which guarantee specific performance limits. This assumes that the device is within the Operating Range. Specifications are not guaranteed for parameters where no limit is given, however, the typical value is a good indication of device performance.Note 2: The maximum power dissipation must be derated at elevated temperatures and is dictated by T JMAX , θJA , and the ambient temperature T A . The maximum allowable power dissipation is P DMAX = (T JMAX - T A )/ θJA or the number given in Absolute Maximum Ratings, whichever is lower.Note 3: Human body model, 100pF discharged through a 1.5k Ω resistor.ELECTRICAL CHARACTERISTICS (Note 4, 5)The following specifications apply for V IN =12V , T A =25 o C, unless specified otherwise. SYMBOL ITEMSCONDITIONS Min. Typ. Max. UNIT V IN Input Voltage 8 30 VV UVLO Under voltage lock out V IN falling 6.8 V V UVLO, HYS UVLO hysterisisV IN rising 500 mV F SW Max. Switching Frequency1MHzCurrent SenseA type 95 98 101 mV V CSNMean current sense threshold voltage V IN -V CSNB type99 102 105 mV V CSN_hys Sense threshold hysteresis±15%I CSNCSN Pin Input Current V IN -V CSN =50mV 8 µAOperating CurrentI OFF Quiescent supply current with output off V DIM <0.3V 95 µADIM InputV DIM Internal supply voltage DIM floating 5 V V DIM_H DIM input voltage High 2.5 V V DIM_L DIM input voltage Low 0.3VV DIM_DC DC brightness control0.52.5 Vf DIMMax. DIM Frequency f OSC =500kHz 50 kHz Duty cycle range of lowfrequency dimming f DIM =100Hz 0.02% 1 D PWM_LFBrightness control range5000:1LED Driver with 5000:1 DimmingELECTRICAL CHARACTERISTICS (Continued) (Note 4, 5)SYMBOL ITEMSCONDITIONSMin.Typ.Max.UNITDIM InputDuty cycle range of highfrequency dimming f DIM =20KHz4% 1 D PWM_HFBrightness control range25:1R DIM DIM pull up resistor to Internal supply voltage200 K Ω I DIM_L DIM input leakage lowV DIM = 025uAOutput SwitchVIN =12V 0.6 R SW SW On Resistance VIN=24V0.4 Ω I SWmeanContinuous SW Current1.2AI LEAK SW Leakage Current0.5 5 µA Thermal ShutdownT SD Thermal Shutdown Threshold 160 ℃ T SD -hys Thermal Shutdown hysteresis20 ℃Note 4: Typical parameters are measured at 25˚C and represent the parametric norm.Note 5: Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.SIMPLIFIED BLOCK DIAGRAMLED Driver with 5000:1 DimmingOPERATION DESCRIPTIONThe device, in conjunction with the coil (L1) and current sense resistor (RS), forms a self oscillating continuous-mode buck converter.When input voltage VIN is first applied, the initial current in L1 and RS is zero and there is no output from the current sense circuit. Under this condition, the output of CS comparator is high. This turns on an internal switch and switches the SW pin low, causing current to flow from VIN to ground, via RS, L1 and the LED(s). The current rises at a rate determined by VIN and L1 to produce a voltage ramp (V CSN ) across RS. When (V IN -V CSN ) > 115mV, the output of CS comparator switches low and the switch turns off. The current flowing on the RS decreases at another rate. When (V IN -V CSN ) < 85mV, the switch turns on againand the mean current on the LED is determined by851152()/100/S S mV R mV R +=.The high-side current-sensing scheme and on-board current-setting circuitry minimize the number of external components while delivering LED current with ±5% accuracy, using a 1% sense resistor.The PT4115 allow dimming with a PWM signal at the DIM input. A logic level below 0.3V at DIM forces PT4115 to turn off the LED and the logic level at DIM must be at least 2.5V to turn on the full LED current. The frequency of PWM dimming ranges from 100Hz to more than 20 kHz.The DIM pin can be driven by an external DC voltage(V DIM ) to adjust the output current to a value below the nominal average value defined by RS. The DC voltage is valid from 0.5V to 2.5V. When the dc voltage is higher than 2.5V, the output current keeps constant. The LED current also can be adjusted by a resistor connected to the DIM pin. An internal pull-up resistor (typical 200K Ω) is connected to a 5V internal regulator. The voltage of DIM pin is divided by the internal and external resistor.The DIM pin is pulled up to the internal regulator (5V) by a 200K Ω resistor. It can be floated at normal working. When a voltage applied to DIM falls below the threshold (0.3V nom.), the output switch is turned off. The internal regulator and voltage reference remain powered during shutdown to provide the reference for the shutdown circuit. Quiescent supply current during shutdown is nominally 95uA and switch leakage is below 5uA.Additionally, to ensure the reliability, the PT4115 is built with a thermal shutdown (TSD) protection and a thermal pad. The TSD protests the IC from over temperature (160℃). Also the thermal pad enhances power dissipation. As a result, the PT4115 can handle a large amount of current safely.LED Driver with 5000:1 DimmingTYPICAL PERFORMANCE CHARACTERISTICS8101214161820222426283075%80%85%90%95%100%E f f i c i e n c ySupply Voltage Vin(V)01234567890123456V d i m (V )Vdim vs Supply VinVdim vs Supply Voltage510152025304.54.64.74.84.95.05.15.25.35.45.5V d i m (V )Supply Voltage Vin(V)Vdim vs Supply Voltage-40-200204060801001205.005.055.105.155.205.255.30V d i m (V )Temperature(Deg C)Vdim vs Temperature9095100105110115V s e n s e (V )Ambient TemperatureVoltage across Rcs(0.33ohm) vs TemperatureLED Driver with 5000:1 Dimming51525350.30.40.50.60.70.80.91.0R s w (o h m )Supply Voltage Vin(V)Rsw vs Supply Voltage-500501001500.30.40.50.60.70.80.91.0"o n " R e s os t e n c e (o h m )Ambient Temperature Switch "on" Resistance vs Temp510152025300102030405060708090100110120S u p p l y V o l t a g e V i n (V )Iin(uA)Shutdown Current vs Supply Voltage0510********50100150200250I i n (u A )Supply Voltage Vin(V)Supply Current vs Supply Voltage0100200300400500600O u t p u t C u r r e n t (u A )Dim Duty Cycle100200300400500600700800L E D C u r r e n t (u A )Dim Pin Voltage(V)510152025300%10%20%30%40%50%60%70%80%90%100%D u t y C y c l eSupply Voltage Vin(V)Supply Voltage Vin(V)710720730740750760770780790800O u t p u t C u r r e n t (m A )Supply Voltage Vin(V)51015202530-6%-4%-2%0%2%4%6%O u t p u t C u r r e n t D e v i a t i o nSupply Voltage(V)Output Current L=47uH Rcs=0.13ohmLED Driver with 5000:1 DimmingD u t y C y c l eDuty Cycle L=47uH Rcs=0.13ohmSwitch Frequency L=47uH Rcs=0.13ohm51015202530280285290295300305310315320325O u t p u t C u r r e n tSupply Voltage (V)Supply Voltage0%10%20%30%40%50%60%70%80%90%D u t y C y c l eSupply Voltage Vin(V)Supply Voltage Vin(V)Switch Frequency L=100uH R=0.33ohmLED Driver with 5000:1 DimmingLED Driver with 5000:1 DimmingAPPLICATION NOTESSetting nominal average output current with external resistor RSThe nominal average output current in the LED(s) is determined by the value of the external current sense resistor (RS) connected between VIN and CSN and is given by:Rs I OUT /1.0= )082.0(Ω≥RsThis equation is valid when DIM pin is float or applied with a voltage higher than 2.5V (must be less than 5V). Actually, RS sets the maximum average current which can be adjusted to a less one by dimming.Output current adjustment by external DC control voltageThe DIM pin can be driven by an external dc voltage (VDIM), as shown, to adjust the output current to avalue below the nominal average value defined by RS.The average output current is given by:RsV I DIMOUT ××=5.21.0)5.25.0(V V V DIM ≤≤Note that 100% brightness setting corresponds to:)55.2(V V V DIM ≤≤Output current adjustment by PWM controlA Pulse Width Modulated (PWM) signal with dutycycle PWM can be applied to the DIM pin, as shown below, to adjust the output current to a value below the nominal average value set by resistor RS:RsD I OUT ×=1.0)55.2%,1000(V V V D pulse <<≤≤RsD V I pulse OUT ×××=5.21.0)5.25.0%,1000(V V V D pulse <<≤≤PWM dimming provides reduced brightness by modulating the LED’s forward current between 0% and 100%. The LED brightness is controlled by adjusting the relative ratios of the on time to the off time. A 25% brightness level is achieved by turning the LED on at full current for 25% of one cycle. To ensure this switching process between on and off state is invisible by human eyes, the switching frequency must be greater than 100 Hz. Above 100 Hz, the human eyes average the on and off times, seeing only an effective brightness that is proportional to the LED’s on-time duty cycle. The advantage of PWM dimming is that the forward current is always constant, therefore the LED color does not vary with brightness as it does with analog dimming. Pulsing the current provides precise brightness control while preserving the color purity. The dimming frequency of PT4115 can be as high as 20 kHz.LED Driver with 5000:1 DimmingShutdown modeTaking the DIM pin to a voltage below 0.3V will turn off the output and the supply current will fall to a low standby level of 95μA nominal.Soft-startAn external capacitor from the DIM pin to ground will provide additional soft-start delay, by increasing the time taken for the voltage on this pin to rise to the turn-on threshold and by slowing down the rate of riseof the control voltage at the input of the comparator. Adding capacitance increases this delay by approximately 0.8ms/nF.Inherent open-circuit LED protectionIf the connection to the LED(s) is open-circuited, the coil is isolated from the SW pin of the chip, so the device and LED will not be damaged.Capacitor selectionA low ESR capacitor should be used for input decoupling, as the ESR of this capacitor appears in series with the supply source impedance and lowers overall efficiency. This capacitor has to supply the relatively high peak current to the coil and smooth the current ripple on the input supply. A minimum value of 4.7uF is acceptable if the DC input source is close to the device, but higher values will improve performanceat lower input voltages, especially when the source impedance is high. For the rectified AC input, the capacitor should be higher than 100uF and the tantalum capacitor is recommended. The input capacitor should be placed as close as possible to the IC.For maximum stability over temperature and voltage, capacitors with X7R, X5R, or better dielectric are recommended. Capacitors with Y5V dielectric are not suitable for decoupling in this application and should NOT be used.A suitable Murata capacitor would be GRM42-2X7R475K-50.The following web sites are useful when finding alternatives:Inductor selectionRecommended inductor values for the PT4115 are in the range 27uH to 100uH.Higher values of inductance are recommended at lower output current in order to minimize errors due to switching delays, which result in increased ripple and lower efficiency. Higher values of inductance also result in a smaller change in output current over the supply voltage range. (See graphs). The inductor should be mounted as close to the device as possible with low resistance connections to the SW and VIN pins.The chosen coil should have a saturation current higher than the peak output current and a continuous current rating above the required mean output current. Following table gives the guideline on inductor selection:Load current Inductor Saturation current Iout>1A27-47uH0.8A<Iout≤1A33-82uH0.4A<Iout≤0.8A47-100uHIout≤0.4A68-220uH1.3-1.5 times of loadcurrentSuitable coils for use with the PT4115 are listed in the table below:PartNo.L(uH)DCR(Ω)I SAT(A)Manufacturer MSS1038-333270.089 2.48MSS1038-333330.093 2.3MSS1038-473470.1282MSS1038-683680.213 1.6MSS1038-1041000.304 1.3CoilCraftThe inductor value should be chosen to maintain operating duty cycle and switch 'on'/'off' times within the specified limits over the supply voltage and load current range.The following equations can be used as a guide.SW Switch 'On' time)(swavgLEDINON RrLRsIVVILT++×−−Δ×=SW Switch 'Off' time)(rLRsIVVILTavgDLEDOFF+×++Δ×=Where:L is the coil inductance (H)rL is the coil resistance (Ω)R S is the current sense resistance (Ω)Iavg is the required LED current (A)LED Driver with 5000:1 DimmingΔI is the coil peak-peak ripple current (A) {Internally set to 0.3 x Iavg}V IN is the supply voltage (V)V LED is the total LED forward voltage (V) R SW is the switch resistance (Ω) {=0.6Ω nominal} V D is the diode forward voltage at the required load current (V)Diode selectionFor maximum efficiency and performance, the rectifier (D1) should be a fast low capacitance Schottky diode with low reverse leakage at the maximum operating voltage and temperature.They also provide better efficiency than silicon diodes, due to a combination of lower forward voltage and reduced recovery time.It is important to select parts with a peak current rating above the peak coil current and a continuous current rating higher than the maximum output load current. It is very important to consider the reverse leakage of the diode when operating above 85°C. Excess leakage will increase the power dissipation in the device and if close to the load may create a thermal runaway condition.The higher forward voltage and overshoot due to reverse recovery time in silicon diodes will increase the peak voltage on the SW output. If a silicon diode is used, care should be taken to ensure that the total voltage appearing on the SW pin including supply ripple, does not exceed the specified maximum value. The following web sites are useful when finding alternatives: Reducing output ripplePeak to peak ripple current in the LED(s) can be reduced, if required, by shunting a capacitor C LEDacross the LED(s) as shown below:A value of 1uF will reduce the supply ripple current by a factor three (approx.). Proportionally lower ripple can be achieved with higher capacitor values. Note that the capacitor will not affect operating frequency or efficiency, but it will increase start-up delay and reduce the frequency of dimming, by reducing the rate of rise of LED voltage.By adding this capacitor the current waveform through the LED(s) changes from a triangular ramp to a more sinusoidal version without altering the mean current value.Operation at low supply voltageThe internal regulator disables the drive to the switch until the supply has risen above the startup threshold (V UVLO ). Above this threshold, the device will start to operate. However, with the supply voltage below the specified minimum value, the switch duty cycle will be high and the device power dissipation will be at a maximum. Care should be taken to avoid operating the device under such conditions in the application, in order to minimize the risk of exceeding the maximum allowed die temperature. (See next section on thermal considerations). The drive to the switch is turned off when the supply voltage falls below the under-voltage threshold (V UVLO -0.5V).This prevents the switch working with excessive 'on' resistance under conditions where the duty cycle is high.Thermal considerationsWhen operating the device at high ambient temperatures, or when driving maximum load current, care must be taken to avoid exceeding the package power dissipation limits. The graph below gives details for power derating. This assumes the device to be mounted on a 25mm2 PCB with 1oz copper standing in still air.-40-20204060801001201402004006008001000120014001600P o w e r (m W )Ambient TemperatureMax. Power DisspationLED Driver with 5000:1 DimmingNote that the device power dissipation will most often be a maximum at minimum supply voltage. It will also increase if the efficiency of the circuit is low. This may result from the use of unsuitable coils, or excessive parasitic output capacitance on the switch output. When the application is limited by the internal power dissipation of the device, the ESOP8 package is recommended because of its enhanced power dissipation ability.Thermal compensation of output currentHigh luminance LEDs often need to be supplied with a temperature compensated current in order to maintain stable and reliable operation at all drive levels. The LEDs are usually mounted remotely from the device so,for this reason, the temperature coefficients of the internal circuits for the PT4115 have been optimized to minimize the change in output current when no compensation is employed. If output current compensation is required, it is possible to use an external temperature sensing network - normally using Negative Temperature Coefficient (NTC) thermistors and/or diodes, mounted very close to the LED(s). The output of the sensing network can be used to drive the DIM pin in order to reduce output current with increasing temperature.Thermal shutdown protectionTo ensure the reliability, the PT4115 is built with a thermal shutdown (TSD) protection function. The TSD protests the IC from over temperature (160℃). When the chip temperature decreases (140℃), the IC recovers again.Layout considerationsCareful PCB layout is critical to achieve low switching losses and stable operation. Use a multilayer board whenever possible for better noise immunity. Minimize ground noise by connecting high-current ground returns, the input bypass-capacitor ground lead, and the output-filter ground lead to a single point (star ground configuration).SW pinThe SW pin of the device is a fast switching node, so PCB tracks should be kept as short as possible. To minimize ground 'bounce', the ground pin of the device should be soldered directly to the ground plane.Coil and decoupling capacitors and current sense resistorIt is particularly important to mount the coil and the input decoupling capacitor as close to the device pins as possible to minimize parasitic resistance and inductance, which will degrade efficiency. It is also important to minimize any track resistance in series with current sense resistor RS. It’s best to connect VIN directly to one end of RS and CSN directly to the opposite end of RS with no other currents flowing in these tracks. It is important that the cathode current of the Schottky diode does not flow in a track between RS and VIN as this may give an apparent higher measure of current than is actual because of track resistance.LED Driver with 5000:1 Dimming TYPICAL APPLICATION CIRCUITFig1 :1W applicationFig 2: 3W applicationLED Driver with 5000:1 Dimming TYPICAL APPLICATION CIRCUIT (Continued)Fig 3 DEMO board for mass productionLED Driver with 5000:1 DimmingPACKAGE INFORMATIONSOT89-5 PackageMILLIMETERS INCHES SYMBOLMINMAXMINMAXA 1.400 1.600 0.055 0.063 b 0.320 0.520 0.013 0.020 b1 0.360 0.560 0.014 0.022 c 0.350 0.440 0.014 0.017 D 4.400 4.600 0.173 0.181 D1 1.400. 1.800 0.055 0.071 E 2.300 2.600 0.091 0.102 E1 3.940 4.250 0.1550.167 e1.500 TYP.0.060 TYP.e1 2.900 3.100 0.114 0.122 L 0.900 1.100 0.0350.043LED Driver with 5000:1 DimmingPACKAGE INFORMATIONESOP-8 PackageDIMENSIONS IN MILLIMETERS DIMENSIONS IN INCHESSYMBOLMIN MAX MIN MAXA 1.350 1.750 0.053 0.069A1 0.050 0.150 0.004 0.010A2 1.350 1.550 0.053 0.061b 0.330 0.510 0.0130.0200.010c 0.170 0.250 0.006D 4.700 5.100 0.185 0.200D1 3.202 3.402 0.126 0.134E 3.800 4.000 0.150 0.157E1 5.800 6.200 0.228 0.244E2 2.313 2.513 0.091 0.099e 1.270(BSC) 0.050(BSC)L 0.400 1.270 0.016 0.0508° θ0° 8° 0°。

SPECIFICATIONORDER NO.SAFETY MODEL NO.DC VOLTAGE Note.2RATED CURRENTCURRENT RANGERATED POWER(max.)RIPPLE & NOISE (max.)Note.3 OUTPUTSETUP, RISE TIME Note.7HOLD UP TIME(Typ.)VOLTAGE RANGEFREQUENCY RANGEEFFICIENCY(Typ.)AC CURRENTINPUTENVIRONMENT INRUSH CURRENT (max.) LEAKAGE CURRENT(max.)SAFETY STANDARDSSAFETY& EMC (Note. 6)WORKING TEMP. WORKING HUMIDITY STORAGE TEMP., HUMIDITY TEMP. COEFFICIENT VIBRATIONMTBFDIMENSIONOTHERSNOTE PACKINGPROTECTION5VGS60A05GS60A05-P1J GS60A07-P1J GS60A09-P1J GS60A12-P1J GS60A15-P1J GS60A18-P1J GS60A24-P1J GS60A48-P1J7.5VGS60A079VGS60A0912VGS60A1215VGS60A1518VGS60A1824VGS60A2448VGS60A48100mVp-p100mVp-p100mVp-p100mVp-p100mVp-p150mVp-p180mVp-p240mVp-p VOLTAGE TOLERANCE Note.4LINE REGULATION Note.5LOAD REGULATION5.0% 5.0% 5.0% 3.0% 3.0% 3.0% 3.0% 2.5%1.0% 1.0% 1.0% 1.0% 1.0% 1.0% 1.0% 1.0%5.0% 5.0% 5.0% 3.0% 3.0% 3.0% 3.0% 2.5%90 ~ 264VAC 135 ~ 370VDC47 ~ 63Hz81%85.5%87.5%88%88.5%88.5%90%92%1.4A/ 115VAC 1A/ 230VAC65A/ 230VAC0.75mA/ 240VACWITHSTAND VOLTAGEISOLATION RESISTANCEI/P-O/P:3KVAC I/P-FG:1.5KVAC O/P-FG:0.5KVACI/P-O/P, I/P-FG, O/P-FG/ 25/ 70% RH:100M Ohms / 500VDC711Khrs min. MIL-HDBK-217F(25)-10 ~ +50(Refer to output load derating curve)20% ~ 90% RH non-condensing-20 ~ +85, 10 ~ 95% RH0.03% /(0 ~ 50)10 ~ 500Hz, 2G 10min./1cycle, period for 60min.each along X,Y, Z axes125*50*31.5mm (L*W*H)0.305Kg; 40pcs/13.02Kg/1.05CUFTCONNECTOR PLUGCABLEStandard type for stock ther type available by customer requestedP1J: 2.1* 5.5* 11mm, tuning fork type, center positive; OSee page 2ther type available by customer requested; O1. All parameters are specified at 230VAC input, rated load, 2570% RH ambient.2. DC voltage: The output voltage set at point measure by plug terminal & 50% load.3. Ripple & noise are measured at 20MHz by using a 12" twisted pair terminated with a 0.1uf & 47uf capacitor.4. Tolerance: includes set up tolerance, line regulation, load regulation.5. Line regulation is measured from low line to high line at rated load.6. The power supply is considered as an independent unit, but the final equipment still need to re-confirm that the whole system complies with theEMC directives.7. Length of set up time is measured at first cold start. Turning ON/OFF the power supply may lead to increase of the set up time.60W AC-DC Single Output Desktop GS60seriesFeatures :Compliance to EN61000-3-2,3, GB17625.1Compliance to EN61000-4-2,3,4,5,6,8,11, light industry level, criteria AHARMONIC CURRENTEMS IMMUNITYEMI CONDUCTION & RADIATIONOVERLOADOVER VOLTAGEOVER TEMPERATURE105 ~ 150%rated output powerProtection type : Hiccup mode, recovers automatically after fault condition is removedRTH2 > 706A6A6A5A4A 3.33A 2.5A 1.25A0 ~ 6A0 ~ 6A0 ~ 6A0 ~ 4A0 ~ 3.33A0 ~ 2.5A0 ~ 1.25A30W45W54W60W0 ~ 5A60W60W60W60WProtection type : Shut down o/p voltage, re-power on to recoverProtection type : Shut down o/p voltage, re-power on to recoverUL60950-1,TUV EN60950-1, BSMI CNS14336, CCC GB4943approvedCompliance to EN55022 class B, FCC PART15 / CISPR22 class B, CNS13438 class B, GB9254 class BUniversal AC input / Full range3 pole AC inlet IEC320-C14Protections: Short circuit / Overload / Over voltage/ Over temperatureFully enclosed plastic caseApprovals: UL / CUL / TUV / BSMI / CCC / CB / FCC / CEClass power ( with earth pin)Pass LPSLED indicator for power onNo load power consumption<0.3WENERGY STAR compliantMeet EISA 2007(Energy Independence and Security Act)2 years warranty600ms, 30ms / 230VAC 600ms, 30ms / 115VAC at full load50ms / 230VAC 15ms / 115VAC at full load7.88 ~ 10.13V9.45 ~ 12.15V12.6 ~ 16.2V15.75 ~ 20.25V18.9 ~ 24.3V25.2 ~ 32.4V50.4 ~ 64.8V5.25 ~6.75V7010mm110.5mmMechanical SpecificationAMBIENT TEMPERATURE ()L O A D (%)-10201030402040508060100605070INPUT VOLTAGE (VAC) 60Hz9010095120110160140200180240220264L O A D (%)Ta=25901008070605040(HORIZONTAL)Derating CurveStatic Characteristics12531.550UL2624 16AWG UL1185 16AWG 100050mm for 12 ~ 15V 100050mm for 5 ~ 9V UL1185 18AWG 180050mm for 18 ~ 48VPlug AssignmentStandard plug: P1J (option)ID 2.1 x OD 5.5C"+"P/N OUTPUTP1JCENTER+GS60series60W AC-DC Single Output DesktopCase No. 974AUnit:mm。

华润矽威科技LED驱动新产品PT4115宽调光比的高亮度LED照明驱动PT4115PT4115#PT4115特点和应用DC-DC降压式LED转换器特点:•输入范围从8V到30V,击穿电压>45V•输出电流高达1.2A,内置大功率MOFET•效率高达97%•超低的关断电流•±5%输出电流精度•LED开路保护•模拟/PWM调光功能选择,高达5000:1的PWM调光比•内部含有抖频特性,有效地改善了EMI应用:MR16射灯、LED装饰照明、汽车的辅助照明灯##•输入电压范围:8-30V •输出电流高达1.2A •外部元器件少•调光特性好,PWM/模拟调光直流输入应用方案直流输入方案PT4115VINCSNSWDIMGNDR S L C INV IND(SS14)47uH10uFDC8-30V0.27ΩLED 1W#12-18VAC 应用方案12-18V AC 输入方案PT4115VINCSNSWDIMGNDR S L C INV IND47uH100uFAC12-18VDC8-30V0.13Ω3W LED#系统效率和输出电流8101214161820222426283075%80%85%90%95%100%E f f i c i e n c ySupply Voltage Vin(V)Efficiency1,3 and 7 LEDsL=47uH Rs=0.13ohm1LED3 LEDs7LEDs510152025307107207307407507607707807908007LEDs3LEDs5LEDs2LEDs6LEDs4LEDsO u t p u t C u r r e n t (m A )Supply Voltage Vin(V)Output Current L=47uH Rcs=0.13ohm1LED 3W LED 输出效率3W LED 输出电流#LED电流随LED个数和输入电压关系510152025301.101.121.141.161.181.201.221.247LEDs6LEDs5LEDs4LEDs3LEDs2LEDsO u t p u t C u r r e n tSupply Voltage(V)Output Current L=27uH Rcs=0.0825ohm1LED510152025302802852902953003053103153203257LEDs6LEDs5LEDs4LEDs1LED2LEDs3LEDsO u t p u t C u r r e n tSupply Voltage (V)Output Current L=100uH Rcs=0.33ohm1.2A 输出电流300mA 输出电流#PWM调光0.00.20.40.60.8 1.00100200300400500600O u t p u t C u r r e n t (u A )Dim Duty CycleOutput Current vs Dim Duty Cycle50KHz20KHz100HzPWM 调光,从0%到100%)55.2%,1000(1.0V V V D RsD I pulse OUT <<≤≤×=)5.25.0%,1000(5.21.0V V V D RsD V I pulse pulse OUT <<≤≤×××=#PWM调光比100,215000:1PWM settle PWM settlef Hz t usDim Range f t == ==´PWM 调光比#012345100200300400500600700800L E D C u r r e n t (u A )Dim Pin Voltage(V)LED Current vs VdimR=0.13ohmR=0.33ohm模拟调光)5.25.0(5.21.0V V V RsV I DIM DIM OUT≤≤××=)55.2(1.0V V V RsI DIM OUT≤≤=模拟调光动态温度调节DIM端内部是一个1兆上拉电阻(Rup)接到内部5V电源。

pt4115大功率恒流应用电路规格书引言:PT4115是一款集成了开关功率MOSFET的电流模式恒流LED驱动芯片。

它能够提供高效率和精确的LED亮度调节功能,广泛应用于室内和室外照明系统。

本文将详细介绍PT4115的规格和应用电路。

1. PT4115的特性和规格1.1 输入电压范围PT4115能够工作在8V至30V的宽输入电压范围内。

这使得它非常适合应用在各种不同类型的电源系统中。

1.2 输出电流调节范围PT4115可以通过外部器件来设置和调节输出电流。

典型的输出电流可在200mA至2A之间进行调节,因此可以满足不同功率要求的LED照明系统。

1.3 高效率和低功耗PT4115内部集成了高效率的开关功率MOSFET,具有较低的导通压降和热耗散。

在应用中,它能够以高效率转换输入电源的能量为输出电流和电压,从而减少能量损耗。

1.4 瞬态保护和过温保护PT4115具有瞬态保护和过温保护功能,能够在输入电源电压波动或工作温度过高时自动保护驱动电路,防止瞬态或长时间过载损坏。

2. PT4115应用电路设计以PT4115为核心的应用电路设计如下:(图示PT4115应用电路示意图)2.1 输入电源电容选取为了确保电路的稳定工作,建议在输入电源端并联一个适当的电容。

这可以有效减小输入电源的纹波和噪音,提供稳定的工作环境。

2.2 输出电流设置通过选择合适的电阻和电流感应器来设置输出电流。

电流感应器的选择要符合输出电流和电路要求,以保证PT4115能够正常工作。

2.3 PWM调光控制PT4115内部集成了一个可调电流比例控制器,通过PWM信号调节LED的亮度。

这可以实现精确的亮度调节和频闪控制,以满足不同应用场景的需求。

3. PT4115应用实例以室内LED照明系统为例,利用PT4115实现恒流驱动LED,具体应用实例如下:(图示PT4115应用实例电路图)3.1 输入电压接入将室内电源与PT4115的输入端相连接,注意输入电压范围应在8V 至30V之间。

PT4115是一个感应降压转换器,工作在连续模式。

当电源电压高于输出电压时,可以有效地驱动单个或多个串联的led。

该集成电路的输入电压范围为5V~24V,输出电流可外调,最大输出电流可达0.7A。

PT4115集成了功率管和高端电流检测电路,平均输出电流可通过外接电阻器设定。

此外,输出电流也可以通过外部调节引脚进行调节,使其低于设定值。

ADJ引脚可接收直流电压或PWM信号,支持线性调光或PWM调光。

如果在ADJ引脚上施加0.2V或更低的电压,输出功率管将关闭,IC将以低电流待机模式工作。

PT4115集成过热软关机功能。

当芯片内部结温升至135℃时,随着结温的不断升高,输出电流逐渐减小。

当结温达到150℃时,输出电流减小到0。

PT4115特性高效率(高达95%)软启动时间可调IC过热软关机最大0.7A输出电流PWM调光/模拟直流调光模拟直流调光范围15%~100%最小10uSPWM调光脉冲宽度(调光频率为1KHz时,调光精度可达1%)宽输入电压范围:5V~24V内置LED开路保护±3%输出电流精度SOT-89-5L套装PT4115引脚图pt4115中文数据汇总(pt4115引脚图及功能-内部结构及应用电路)pt4115,LED驱动,PWM调光PT4115工作原理参照典型的应用电路,PT4115与电感(L1)和电流感测电阻(Rs)一起构成一个工作在连续模式下的自振荡降压电路。

当应用电路第一次通电时,电感器L1和电阻器Rs的初始电流为零。

此时,VIN和ISNS之间没有电压差,ISENSE模块的输出也很低。

这个信号被传递到PWM比较器的负输入端,并且PWM比较器的输出很高。

这会使NMOS打开电源,LX引脚被拉低。

NMOS接通后,电流通过电阻器Rs、LED和电感器L1从VIN流向GND。

电流在RS 上产生一个上升的电压斜坡,上升斜率由VIN,L1和负载决定。

电阻Rs产生的电压降VRS 由ISENSE模块检测,并转换为与ISENSE模块中VRS成比例的输出电压。

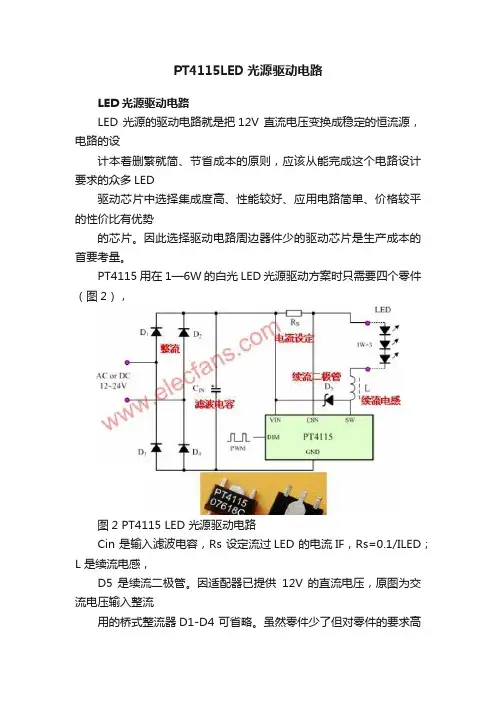

PT4115LED光源驱动电路LED光源驱动电路LED 光源的驱动电路就是把12V 直流电压变换成稳定的恒流源,电路的设计本着删繁就简、节省成本的原则,应该从能完成这个电路设计要求的众多LED驱动芯片中选择集成度高、性能较好、应用电路简单、价格较平的性价比有优势的芯片。

因此选择驱动电路周边器件少的驱动芯片是生产成本的首要考量。

PT4115 用在1—6W 的白光LED 光源驱动方案时只需要四个零件(图2),图2 PT4115 LED 光源驱动电路Cin 是输入滤波电容,Rs 设定流过LED 的电流IF,Rs=0.1/ILED;L 是续流电感,D5 是续流二极管。

因适配器已提供12V 的直流电压,原图为交流电压输入整流用的桥式整流器D1-D4 可省略。

虽然零件少了但对零件的要求高了,设计时要按表1 提示的要求选用,才能使电路进入良好的工作状态。

PT4115的开关频率采用抖频技术有效降低EMI,省略了抗EMI 电路。

表1 关键元器件的选择LED 光源驱动芯片的恒流精度对于LED 灯具生产厂家而言是至关重要的,目前LED 光源驱动IC 的恒流精度批量生产时都会有一定的离散性,LED 灯具生产厂家在批量生产调试时,同样的电源、同样的LED 光源负载、同样的恒流源电源板,因同一型号的不同驱动IC 其恒流精度的个性差异会导致恒流源电源板输出电流产生一定的公差,会使同一LED 光源负载的发光亮度有所不同,这就会增加恒流源电源板大批量生产时在线调试的时间,影响生产力。

因此,恒流源电源板生产厂家应选用恒流精度高的驱动IC,恒流精度至少要小于±3%,如是±1%更理想,但其价格会高于±3%的产品。

几点关键技术1)电感的选择以3X1W的高亮度白光LED光源的设计案例而言,三个1W的LED光源串联,其工作电流可设计为300-350mA,L的电感量应选用68uH—100uH,Q 值大于50,饱和电流大于800mA 的磁路闭合电感器。

Shenzhen LIZE Electronic Technology Co.,Ltd规格说明书PT4115C6~36V/500mA高调光比LED恒流驱动器版本V1.0励致保留在未事先通知的情况下修改此文档的权利目录1.产品概述 (4)2.主要技术参数 (4)3.应用 (4)4.典型应用电路图 (4)5.封装管脚 (5)6.管脚功能定义 (5)7.定购信息 (5)8.功能模块框图 (6)9.极限工作条件 (6)10.推荐使用条件 (6)11.电气参数 (7)12.典型工作特性曲线 (8)13.功能描述 (10)13.1工作原理描述 (10)13.2通过外部电流采样电阻RS设定LED平均电流 (10)13.3通过直流电压实现模拟调光 (10)13.4通过PWM信号实现调光 (10)13.5关断模式 (11)13.6软启动模式 (11)13.7欠压保护 (11)13.8LED开路保护 (11)13.9过热保护 (11)14元器件选择 (11)14.1电感 (11)14.2肖特基二极管D (11)15应用注意事项 (11)15.1降低输出纹波 (11)15.2低输入电压下工作 (12)15.3负载电流的热补偿 (12)15.4VIN到GND的电容,一定要靠近芯片,而且到VIN和GND端口的走线尽量短和粗。

(12)16典型应用电路 (12)17.封装信息 (13)17.1SOT23-5封装 (13)概述1.产品概述PT4115C是一款连续电感电流导通模式的降压恒流源,用于驱动一颗或者多颗串联LED。

芯片内置导通电阻为0.3Ω的功率开关,输入电压可以由6V到36V,并且根据不同外部器件,芯片可以驱动高达数十瓦的LED,最大输出电流可达0.5mA。

PT4115C具有调光功能,通过DIM引脚实现模拟调光和宽范围PWM调光。

当V DIM低于0.3V时,功率开关关断,芯片进入低功耗待机状态2.主要技术参数●输入电压范围:6V to36V●最大输出LED电流0.5A●5%的输出电流精度●高达97%的效率●极少的外部器件●复用DIM引脚进行LED开关、模拟调光和PWM调光●LED开路保护●过热保护●输出电流可调节●具有输入欠压保护功能3.应用●低压LED射灯代替卤素灯●车载LED灯●LED备用灯●LED信号灯4.典型应用电路图5.封装管脚6.管脚功能定义SOT23-51DIM开关使能、模拟调光和PWM调光2GND信号和功率地3SW功率开关的漏端4VIN电源输入端5CSN电流采样端,采样电阻接在VIN和CSN端之间7.定购信息封装温度范围定购型号包装运输产品打印SOT23-5-40℃~80℃PT4115C Tape and Reel3000pcsPT4115CXXXX8.功能模块框图9.极限工作条件◇电源电压,V IN -------------------−0.3V to 44V ◇SW 端电压,SW -------−0.3V to (VIN +0.3V)◇CSN 端电压---------------−0.3V to(VIN -6V)◇DIM 端电压------------------------−0.3V to 6V ◇结温----------------------------------------150℃◇存放温度范围----------------−55℃to 150℃◇SOP89-5,θJA ---------------------------45℃/W ◇功耗------------------------------------------1.2W ◇ESD 保护(HBM 人体模式)----------------2kV10.推荐使用条件◇电源电压,V IN --------------------6V to 36V ◇工作温度--------------------------−40℃to 85℃11.电气参数如果没有特别说明,下列性能的测试条件为V IN=12V,T A=25°C符号参数测试条件最小值典型值最大值单位VIN输入电压6-36VV UVLO欠压保护V IN下降- 5.0-V V UVLOHYS欠压保护迟滞V IN上升-450-mVF SW最大工作频率--1MHz电流采样V CSN平均采样电压V IN-V CSN95100105mV V CSNHYS采样电压迟滞-±15-%I CSN CSN管脚输入电流V IN-V CSN=50mV-16-uA 关断电流I OFF关断电流V DIM<0.3V-100-uADIM输入V DIM内部电路工作电压DIM浮空- 4.7-V V DIM_H DIM输入高电平 2.5--V V DIM_L DIM输入低电平--0.3V V DIM_DC模拟调光电压范围0.5- 2.5V F_dim最大PWM调光频率F0SC=500KHz--50kHzD PWM_LF 低频PWM调光占空比范围F DIM=100Hz0.02%-1低频PWM调光比-5000:1-D PWM_HF 高频PWM调光占空比范围F DIM=20KHz4%-1高频PWM调光比-25:1-R DIM DIM对内部电压上拉电阻-1-MΩI DIM DIM接地漏电流V DIM=0-5-uA功率开关Rsw SW导通电阻Vin=24-0.3-ΩVin=12-0.3-Isw SW连续电流--500mA I LEAK SW漏电流-0.01-uA过热保护T SD过热保护温度-160-℃T SD_HY S过热保护迟滞-20-℃12.典型工作特性曲线13.功能描述13.1工作原理描述PT4115C 和电感(L )、电流采样电阻(Rsense )形成一个自震荡连续电感电流模式的降压型恒流LED 驱动器。

LED恒流驱动PT4115PT4115是一款连续电感电流导通模式的降压恒流源,适合绿色照明LED灯的驱动电路.它具有较宽的直流8V到30V输入电压范围,击穿电压>45V,输出200~1200mA恒定直流,可满足驱动点亮1~7颗串联的大功率LED或N颗串并联的小功率LED,驱动恒流大小可按应用方案设定. PT4115采用频率抖动技术有效地改善EMI;采用从满量程向下到零的PWM调光;安全可靠;调光比可达5000:1;采用SOT89-5的封装;芯片的管芯(Die)可通过直接连通到封装外的金属板(Exposed PAD)散热;导热十分有效.PT4115内部设置了过温保护功能(TSD),以保证系统稳定可靠的工作.当IC芯片温度超出160℃,IC即会进入TSD保护状态并停止电流输出,而当温度低于140℃时,IC即会重新恢复至工作状态.PT4115可利用模拟调光的原理以及温度对LED电流的负反馈实现LED灯具动态温度控制,只要在调光端(DIM)加一热敏电阻或PN结即可.加上整流桥PT4115可应用于交流12V、24V供电的LED灯具.PT4115的应用十分简洁,周边零件仅四个. PT4115的工作效率高达97%,是真正的绿色驱动IC.PT4115广泛应用于使用LED灯的MR11、MR16、水灯、路灯等各类LED灯具. PT4115特点﹡输入电压:8~30V﹡输出电流:最大电流1.2A,﹡输出电流精度:±5%﹡高效率:最高97%﹡调光控制: 电压或脉宽调制﹡工作频率:1MHz﹡静态功耗:<60uA﹡内置LED开路保护,过温保护﹡抖频科技,能有效改善EMI﹡软启动功能﹡无铅制程﹡封装方式:SOT89-5PT4115应用﹡低压LED射灯代替卤素灯﹡车载LED灯﹡低压工业照明﹡LED备用灯﹡ILED灯饰﹡安全电压照明﹡液晶电视背光PT4115的特性• 高度集成DC/DC-Buck→Constant Current 功能.• 采用抖频技术有效降低EMI.频率抖动技术(Frequency Jitter)是一种从分散谐波干扰能量着手解决EMI问题的新方法.频率抖动技术是指开关电源的工作频率并非固定不变,而是周期性地由窄带变为宽带的方式来降低EMI,来减小电磁干扰的方法.• Vin=8-30V,击穿电压>45V ;Iout=1.2A.• 效率高达97%.• DIM调光由高向低调光,安全可靠.• 超低的关断电流.• ± 5%输出电流精度.• LED开路保护• 采用SOT89-5封装,有利于驱动芯片管芯的快速散热.• 周边应用电路简约,仅四个元器件,应用成本低.应用:MR11、MR16、水底灯、洗墙灯、泛光灯、应急灯、草坪灯、路灯、隧道灯...。

pt4115驱动10w灯珠电路一、LED主要性能指标:1)LED的颜色:目前LED的颜色主要有红色,绿色,蓝色,青色,黄色,白色,暖白,琥珀色等其它的颜色;2)LED的电流:一般小功率的LED的正向极限电流多在20mA。

但大功率LED的功率至少在1W以上,目前比较常见的有1W、3W、5W、8W和10W。

1WLED的额定电流为350mA,3WLED的750mA。

3)LED的正向电压:LED的正极接电源正极,负极接电源负极。

一般1W的大功率LED的正向电压为3.5V~3.8V。

4)LED的反向电压:所允许加的最大反向电压。

超过此值,发光二极管可能被击穿损坏LED发光强度:光源在给定方向的单位立体角中发射的光通量定义为光源在该方向的(发)光强(度),单位为坎德拉(cd)。

5)LED光通量:光源在单位时间内发射出的光量称为光源的发光通量。

单位为流明(lm)。

如1W大功率LED的光通量一般为60~80LM。

6)LED光照度:1流明的光通量均匀分布在1平方米表面上所产生的光照度。

,单位为勒克斯(lx)。

7)LED显色性:光源对物体本身颜色呈现的程度称为显色性,也就是颜色逼真的程度。

8)LED的使用寿命:LED一般可以使用50,000小时以上。

9)LED发光角度:二极管发光角度也就是其光线散射角度,主要靠二极管生产时加散射剂来控制。

二、大功率LED的驱动方式:LED驱动简单的来讲就是给LED提供正常工作条件(包括电压,电流等条件)的一种电路,也是LED能工作必不可少的条件,好的驱动电路还能随时保护LED,避免LED被损坏。

LED驱动通常分为以下三种方式:(1)镇流电阻驱动:就是简单的的在LED的回路中串接电阻,通过调节电阻的阻值,可以改变LED的驱动电流。

LED的工作电流为:所以I与镇流电阻R成反比;当电源电压U上升时,R能限制I的过量增长,使I不超出LED的允许范围。

此电路的优点是简单,成本低;缺点是电流稳定度不高;电阻发热消耗功率,导致用电效率低,仅适用于小功率LED范围,所以不选这种方案。