佐志 空调产品介绍

- 格式:pdf

- 大小:1.16 MB

- 文档页数:11

立体的索伊空调的说明书

1、按功能模式键,看遥控器显示屏图标:太阳-制暖、雪花-制冷、三角-自动(机器按设定温度自动制冷和制暖,一般不用。

)水滴-除湿(下雨天降低室内湿度用)风扇-通风(压缩机不工作,电风扇的作用)。

2、选好以上功能后,按上下箭头键,就是设定你需要的温度。

3、按启动键,空调就运行了,室温到达你设定的温度压缩机就会自动停机,离开设定温度,压缩机又自动启动。

4、注意不要将设定温度调的与环境温度相差过大,否则会非常耗电,一般室内温度达到26度左右就可以了。

雪花标志是制冷,太阳标志是制热,水滴标志是除湿,风扇标志是送风,三角形标志是自动。

一般制冷适用温度范围是16-43度,制热是-3度-30度可以开启空调,遥控器可设定温度范围在16-30度,遥控器或显示屏上设定的温度低或高并不代表空调的制冷或制热效果就好,一般普通空调只要压缩机工作了,无论你设置多少度,其效果都一样,但变频空调除外,设定温度只代表你想要房间能达到的温度,至于能

不能达到则要看房间环境及空调功率是否和房间相匹配。

OWNER’S MANUALAIR CONDITIONER (SPLIT TYPE)For general public useIndoor unit42TVG010, 013, 016, 018-703Outdoor unit38TVG010, 013, 016, 018-7031118350207ESPAÑOLENGLISHภาษาไทย1● Do not move the louver manually by others.● The louver may automation positioning by some operation mode.AUTOMATIC OPERATION5To automatically select cooling or fan only operation: Select AUTO, LOW , LOW+ , MEDMED+, or HIGH .Cooling: Min. 17°C, Fan Only: No temperature indication : Select AUTO, LOW , LOW+ , MEDMED+, or HIGH .DRY OPERATION7For dehumidi fication, a moderate cooling performance is controlled : Select Dry.Hi-POWER OPERATION8To automatically control room temperature and air flow for faster cooling (except in DRY and FAN ONLY mode)1Infrared signal emitter 2Start/Stop button 3456789!"#Check button (CHECK)PRECAUTIONS FOR SAFETYREMOTE CONTROL4 PREPARATION BEFORE USE2Preparing Filters1. Open the air inlet grille and remove the air fi2. Attach the fi1. Remove the slide cover.and (–) positions.Remote Control Reset 1. Remove the batteries.3. Insert the batteries.ECO OPERATION9To automatically control room to save energy (except in DRY and FAN ONLY mode)Note: Cooling operation; the set temperature will increase automatically 1degree/hour for 2 hours (maximum 2 degrees increase).Set the timer when the air conditioner is operating.TIMER OPERATION10AUTO RESTART OPERATIONDISPLAY LAMP BRIGHTNESS ADJUSTMENT1311To automatically restart the air conditioner after the power failure (Power of the unit must be on.)Setting1. Press and hold the RESET button on the indoor unit for 3 seconds to set the operation. (3 beep sound and OPERATION lamp blink 5 time/sec for 5 seconds)2. Press and hold the RESET button on the indoor unit for 3 seconds to cancel the operation. (3 beep sound but OPERATION lamp does not blink)• In case of ON timer or OFF timer are set, AUTO RESTART OPERATION does not activate.To decrease the display lamp brightness or turn it off.1. Press and holdfor 3 seconds until brightness level (, , oror● In the examples of and , the lamp illuminates for 5 seconds beforegoing off.OPERATION AND PERFORMANCE161. Three-minute protection feature: To prevent the unit from being activated for 3 minutes when suddenly restarted or switched to ON.2. Some minor cracking sound may occur when unit operating. This is normal because the cracking sound may be caused by expansion/contraction of plastic.Air conditioner operating conditionsREMOTE CONTROL A-B SELECTION18To separate using of remote control for each indoor unit in case of 2 air conditioner are installed nearly.Remote Control B Setup.1. Press RESET button on the indoor unit to turn the air conditioner ON.2.3. 1)Remote Control B is memorized. (Picture 2)Note: 1. Repeat above step to reset Remote Control to be A. 2. Remote Control A has not “A” display.3. Default setting of Remote Control from factory is A.Indoor Unit and Remote Control● Clean the indoor unit and the remote control with a wet cloth when needed.● No benzine, thinner, polishing powder or chemically-treated duster.Air filtersClean every 2 weeks.1. Open the air inlet grille.2. Remove the air filters.3. Vacuum or wash and then dry them.4. Reinstall the air filters and close the air inlet grille.SELF CLEANING OPERATION141. If 30 seconds.EN1118350207。

规格书一、产品概述1.1 产品名称:ac7811qbge1.2 产品型号:ac7811qbge1.3 产品功能:ac7811qbge是一款用于家庭和办公环境的智能空调系统。

它具有节能、智能控制、空气净化等多种功能,能够提供舒适的室内环境。

二、产品特性2.1 节能功能ac7811qbge采用先进的节能技术,能够根据室内室外温度和人员活动情况实时调节空调的运行模式,最大限度地降低能耗,实现节能环保的目的。

2.2 智能控制ac7811qbge配备了智能控制系统,用户可以通过手机App或者语音控制模式对空调进行远程控制,实现精准的温度调节和定时开关等功能。

2.3 空气净化ac7811qbge内置空气净化器,能够对室内空气中的细菌、病毒等有害物质进行有效净化,为用户提供清新的室内空气环境。

2.4 多种模式选择ac7811qbge具有制冷、制热、除湿、送风等多种模式选择,满足用户在不同季节和环境下的需求。

三、产品参数3.1 制冷制热能力:根据不同型号和规格,制冷能力可达到XBTU,制热能力可达到XBTU。

3.2 能效等级: ac7811qbge符合国家X级能效等级标准。

3.3 噪音: ac7811qbge在运行时的噪音水平低于X分贝。

3.4 外形尺寸:ac7811qbge的外形尺寸为X*Y*Z mm(长*宽*高)。

四、安全性能4.1 防火防爆设计:ac7811qbge采用防火防爆设计,确保产品在使用过程中的安全可靠性。

4.2 过载保护:ac7811qbge内置过载保护装置,一旦出现过载情况会立即停机,保护设备和用户的安全。

五、使用说明5.1 安装要求:用户在安装ac7811qbge时,需确保空调外部通风良好,避免遮挡空调散热口。

5.2 维护保养:定期清洁空调滤网、室内外风道,保持空调系统的清洁,可有效延长产品使用寿命。

六、售后服务6.1 保修期:ac7811qbge提供X年质保期,质保期内出现故障可享受免费维修或更换服务。

匠智空调遥控器说明书篇一:匠智空调遥控器说明书标题:匠智空调遥控器说明书正文:匠智空调遥控器是一款集控制空调、调节温度、定时开关等功能于一体的智能遥控器。

以下是使用匠智空调遥控器的详细步骤:1. 打开匠智空调的电源并按下遥控器上的“开”或“关”按钮,让空调开始工作。

2. 使用遥控器的“设置”或“模式”键,选择要调节的温度和模式。

例如,可以选择“26°C”、“睡眠模式”等。

3. 使用遥控器的“定时”键,设置空调的开启和关闭时间。

例如,可以选择“每天清晨08:00”或“每周六16:00”等。

4. 使用遥控器的“风速”键,调节空调的风速。

可以根据实际需要选择不同风速,例如“静音”、“中速”、“高速”等。

5. 使用遥控器的“返回”键,返回主菜单,以便查看当前的设置和下次的定时器。

6. 在使用匠智空调遥控器时,请确保遥控器电池充足,并且不要将遥控器放入高温或潮湿的环境中。

7. 如果长时间不使用匠智空调遥控器,建议先关闭电源,并将遥控器放入干燥的信封中保存。

拓展:匠智空调遥控器还支持语音控制,可以通过语音指令控制空调的温度、模式和定时器。

具体操作步骤如下:1. 打开匠智空调的电源并按下遥控器上的“开”或“关”按钮,让空调开始工作。

2. 按住遥控器上的“语音”键,然后说出要控制的指令,例如“设置温度26°C”或“开启睡眠模式”。

3. 遥控器会按照指令进行操作,并在屏幕上显示完成提示。

使用匠智空调遥控器可以更加方便快捷地控制空调,提高生活质量。

篇二:匠智空调遥控器说明书尊敬的用户,匠智空调遥控器是一款功能强大、易于使用的智能空调遥控器。

以下是使用说明:1. 操作说明使用匠智空调遥控器前,请先仔细阅读操作说明。

遥控器上有各种功能图标,通过按下这些图标来执行各种操作。

- 开启空调- 调节温度- 调节湿度- 静音- 睡眠模式- 定时开关空调2. 使用方式- 将遥控器与空调匹配。

匠智空调遥控器支持多种空调品牌和型号,需要确认遥控器上的品牌和型号信息,并确保遥控器与相匹配的空调匹配。

优控yk307温控器说明书摘要:一、产品简介二、产品特点三、产品功能四、产品安装与使用五、产品维护与保养六、注意事项正文:一、产品简介优控YK307温控器是一款高性能的温度控制器,适用于家庭、商业及工业领域的加热、制冷和通风系统。

该产品具有出色的控温性能和稳定的输出特性,能够满足各种场合的需求。

二、产品特点1.精准控温:优控YK307温控器采用先进的传感器技术,实现精确的温度控制,让您的环境保持在舒适的范围内。

2.智能化:该产品具备自动调节功能,可根据实际需求自动调整输出功率,实现节能降耗。

3.操作简便:温控器采用大屏幕液晶显示,实时显示当前温度和设定温度,便于用户观察和调整。

4.抗干扰能力强:优控YK307温控器采用屏蔽技术,有效抵抗电磁干扰,确保设备稳定运行。

5.兼容性强:该产品支持多种通信协议,可与各类智能系统无缝对接。

三、产品功能1.温度设定:用户可根据需求设定温度,实现个性化温控需求。

2.模式选择:温控器提供多种工作模式,如制冷、制热、通风等,满足不同季节和环境的需求。

3.定时功能:可设置定时开关机,节省能源,提高使用便捷性。

4.故障诊断:温控器具备故障诊断功能,便于用户及时发现和解决问题。

四、产品安装与使用1.安装:请遵循产品安装说明书进行安装,确保安装牢固、接线正确。

2.使用:在使用过程中,请根据实际需求设置温度和模式,如遇问题,可参考产品说明书或联系售后服务。

五、产品维护与保养1.定期清洁:为确保温控器灵敏度和稳定性,建议每半年对产品进行一次清洁。

2.检查线路:定期检查温控器接线,确保连接牢固、无损伤。

3.避免潮湿:请将温控器安装在干燥、通风的环境中,避免进水损坏。

六、注意事项1.在安装和使用过程中,请务必遵循产品说明书和相关法律法规。

2.请勿将温控器暴露在高温、潮湿、腐蚀等恶劣环境中。

3.温控器在使用过程中如有异常声音、气味或故障现象,请立即切断电源,并联系售后服务。

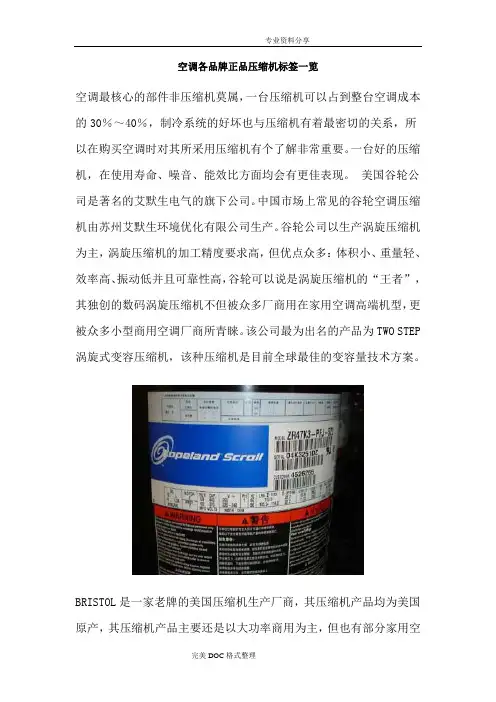

空调各品牌正品压缩机标签一览空调最核心的部件非压缩机莫属,一台压缩机可以占到整台空调成本的30%~40%,制冷系统的好坏也与压缩机有着最密切的关系,所以在购买空调时对其所采用压缩机有个了解非常重要。

一台好的压缩机,在使用寿命、噪音、能效比方面均会有更佳表现。

美国谷轮公司是著名的艾默生电气的旗下公司。

中国市场上常见的谷轮空调压缩机由苏州艾默生环境优化有限公司生产。

谷轮公司以生产涡旋压缩机为主,涡旋压缩机的加工精度要求高,但优点众多:体积小、重量轻、效率高、振动低并且可靠性高,谷轮可以说是涡旋压缩机的“王者”,其独创的数码涡旋压缩机不但被众多厂商用在家用空调高端机型,更被众多小型商用空调厂商所青睐。

该公司最为出名的产品为TWO STEP 涡旋式变容压缩机,该种压缩机是目前全球最佳的变容量技术方案。

BRISTOL是一家老牌的美国压缩机生产厂商,其压缩机产品均为美国原产,其压缩机产品主要还是以大功率商用为主,但也有部分家用空调采用BRISTOL压缩机。

该公司最为著名的为其BENCHMARK系列压缩机和TS系列压缩机。

其中BENCHMARK系列压缩机采用交互式涡旋技术,在高能效以及低噪音方面有着非凡表现;而TS系列压缩机所采用的技术称为“TWIN-SINGLE”,即“独立双缸变容量技术”,这是除谷轮“TWO STEP”技术以外全球仅有的第二种变容量技术方案。

日本大金无论是在商用制冷还是家用制冷领域,都以可靠的品质和先进的技术赢得了崇高声誉。

大金压缩机以低噪和高效技术见长。

目前中国市场上的大金压缩机均为西安大金庆安压缩机有限公司生产,目前大金庆安公司共有四个系列的产品:G系列高效能涡旋式压缩机、D系列高能效涡旋式压缩机、B系列高能效涡旋压缩机、变频系列高能效涡旋压缩机。

其中D系列高能效涡旋式压缩机为世界上首次采用非对称涡旋技术的压缩机,该技术显著的提高了能效比。

西安庆安制冷设备股份有限公司的成员包括庆安集团及江苏春兰制冷股份有限等。

PUNP ELECTRONICDM500A 柜机柜机((多I /O 板)机组控制器厂家使用说明书在安装使用控制器之前,请详细阅读该使用说明书!邦普电脑技术开发有限公司20020066/0/044/2/266软件功能码:软件功能码:DM500A-TY-F02M DM500A-TY-F02M V1.V1.01A01A 版权所有,翻版必究版权所有,翻版必究!!如需帮助请发邮件到:如需帮助请发邮件到:caocool@caocool@目录一、概述 (1) (11)二、控制器操作框架...........................................................................................................................三、安装说明 (1)1、DM500B外观图 (1)2、DM500A外观图 (2)3、外形安装尺寸图 (3)4、I/O板的设置说明 (5)5、DM500B电源通讯连接示意图 (6)6、DM500A电源通讯连接示意图 (7) (88)四、界面及操作说明...........................................................................................................................1、用户操作 (8)(1)开机显示 (8)(2)用户主界面显示 (8)(3)用户查询操作 (9)(4)用户设置 (10)(5)参数设置 (12)2、控制逻辑 (16)(1)开机操作 (16)(2)停机操作 (16)(3)能量调节 (16)(4)工作逻辑 (17)(5)故障制约关系 (18)(6)运行指示 (18)(7)报警指示 (18)(8)线控开停 (18)3、故障处理 (18)19 (19)五、运行参数设置.............................................................................................................................24 (24)六、相关逻辑....................................................................................................................................1、冬季防冻逻辑 (24)2、除霜逻辑 (24)3、外循环水泵控制逻辑 (25)4、水源热泵控制逻辑 (26)5、送风机型说明 (27)6、自动模式控制逻辑 (28)附录1:水冷送水电气连接示意图 (29)附录2:风冷送水电气连接示意图 (35)附录3:外循环泵电气连接示意图 (41)附录4:版本更改说明 (42)一、概述控制器采用先进的、高集成度的一体化单片机,极大的提高了系统的抗干扰能力。

A、东芝开利株式会社公司介绍日本东芝株式会社成立于1875年,是一家集电子、化工、现代工业设备为一体的跨国集团公司,是日本最有实力的集团公司之一,2003年世界500强排名第44位,在日本家电行业排名第一。

东芝开利株式会社(前身是日本东芝公司—空调部门),创立于东芝公司(世界五百强第44位)空调事业的蓬勃发展时期,是与美国开利公司(世界空调设备最大供应商)的合资公司,业务范围遍及世界各地。

东芝开利株式会社在空调行业中一直处于领先地位,并致力于尖端技术创新、高新产品开发和制造。

强强联合,优势互补。

东芝开利株式会社集中了东芝公司在电子技术及中小型变频空调方面和开利公司在大型中央空调设备及冷冻机方面的优势,进一步提高了合资公司在产品研发、制造等方面的世界领先地位。

为用户带来更加安全、可靠、节能、舒适的空调产品。

东芝开利株式会社在全球拥有四大生产基地,分别位于日本、泰国、英国和中国;由东芝开利日本海外营业本部下属的海外营销机构更是遍布世界的主要国家和地区。

东芝富士工厂位于日本国富士市,注册资金115亿日元,拥有高级工程师500名。

下图为座落于日本著名的富士山脚下的富士市,图中框内标出的即为东芝空调富士工厂。

东芝空调富士工厂SMMS系列空调产品年产量30000套。

东芝集团上年工业总产值达5,655,778百万日元,实现利润115,542百万日元。

作为东芝空调在全球最大的空调生产工厂,其主要生产家用空调,轻型商用空调,通风系统,冷冻产品,轨道交通用空调等。

东芝空调富士工厂共有近10座厂房,分别生产东芝家用型空调,轻型商用空调,通风系统,冷冻产品,轨道交通用空调、零部件中心、研修中心等。

其中用于生产本次投标产品SMMS空调系统的厂房,分别为压缩机生产厂房、其它部件生产厂房、整装车间用厂房。

在这些厂房中,配备了数十条全电脑控制高性能的产品流水线,保证了东芝空调产品杰出的性能。

作为一家专业的空调产品制造厂家,东芝公司斥巨资建造了日本独一无二的“东芝塔”。

WK无水节能机柜空调产品介绍佐志温控技术(上海)有限公司

WK无水节能机柜空调产品介绍内容

•空调吹水的现象和佐志解

决方案

•内置冷凝水蒸发器彻底解

决冷凝水排放的问题

•外置的温度传感器使空调

更节能和控制精度更高

•超大的外循环通风面积

•与威图空调安装尺寸相同

用户拍的电影

空调吹水的现象和佐志解决方案•机柜空调向机柜内吹水是生产商的恶梦

空调吹水的现象和佐志解决方案

•创新来自积累和突破:上出风

空调吹水的现象和佐志解决方案

•创新来自积

累和突破:上

出风

WK无水节能机柜空调产品介绍

内置冷凝水蒸发器彻底解决冷凝水排放的问题•功率大:800瓦,每天可以蒸发15升水

•蒸汽被冷凝风机排到空气中

外置的温度传感器使空调更节能和控制精度更高•温度传感器在机柜内,可以控制机柜内任何位置的温度•温度传感器在机柜内,可以降低内风机的能耗

超大的外循环通风面积

•通风面积小,压缩机的负荷大,寿命短•增加的3层结构,通风面积增加6倍•过滤网的脏污程度可以目视

其它品牌

与威图空调安装尺寸相同

•与威图空调安装尺寸相同

小于1KW

1到2 KW

2 KW 以上

WK无水节能机柜空调产品介绍

2013年5月

谢谢。

志高移动空调单制冷2匹说明书摘要:一、志高移动空调概述二、志高移动空调的优点三、志高移动空调的使用说明四、用户评价及注意事项正文:一、志高移动空调概述志高移动空调是一款便携式、单制冷2 匹的空调设备,具有无需专业安装、使用方便、小功率、局部控制等优点。

其整体式设计,将压缩机、蒸发器和冷凝器全部集成在一起,无需外机,插电即可使用。

志高移动空调采用万象脚轮,可以随心移动,适用于多个房间,节省采购成本。

二、志高移动空调的优点1.使用方便:志高移动空调采用整体式设计,无需外机,插电即可使用,无需专业安装。

2.便携性强:装有万象脚轮,可以随心移动,适用于多个房间,节省采购成本。

3.小功率、局部控制:在面积较大的环境或者是中央空调局域网内,志高移动空调可以进行局部制冷,降低能耗。

三、志高移动空调的使用说明1.开机方法:轻轻扳起面板下部的两侧端,朝外向上翻起面板,即可打开面板。

然后按下开关键,空调器启动运行。

2.功能选择:遥控器对准空调,按下功能选择键,选择所需的模式(智能制冷、除湿、制热或通风)。

3.温度设定:按下温度按键,设定到所需的温度(温度调节范围为16-32C)。

4.风速设定:按下风速键,设定适当的风速(自动风、高风、中风或低风)。

5.风向设定:按下风向或摆风键,调节上下送风方向。

四、用户评价及注意事项1.用户评价:志高移动空调制冷效果良好,降温迅速,使用方便,节能环保,备受用户好评。

2.注意事项:请不要用手直接调节导风条,以免引起零部件损坏;遥控器电池使用寿命约为6-12 个月,电池耗尽时需更换新电池。

总之,志高移动空调凭借其便携性、易用性和制冷效果,在市场上获得了良好的口碑。

日翼移动空调说明书一、产品概述日翼移动空调是一款便携式空调设备,适用于各种场合,如家庭、办公室、露营等。

它采用先进的移动技术,可以随时随地提供舒适的室内温度。

二、产品特点1. 便携性:日翼移动空调采用轻巧的设计,方便携带,可以随时随地使用。

2. 多功能:除了空调功能外,日翼移动空调还具备除湿、通风等多种功能,满足不同季节和使用需求。

3. 低噪音:日翼移动空调采用静音技术,运行时噪音较低,不会影响您的休息或工作。

4. 节能环保:日翼移动空调采用节能设计,使用能效高,对环境友好。

三、使用方法1. 首次使用前,请仔细阅读本说明书,并确保所有配件齐全。

2. 将日翼移动空调放置在需要调节温度的房间中,确保空调通风口畅通。

3. 连接电源并打开开关,日翼移动空调将开始运行。

4. 使用遥控器或面板上的按键来调节空调的温度、风速等参数。

5. 使用完毕后,请关闭电源并拔掉插头。

四、注意事项1. 使用时请确保插头和插座连接牢固,以免发生电器故障。

2. 在清洁日翼移动空调之前,请先关闭电源并拔掉插头。

3. 清洁时请使用柔软的布料擦拭,不要使用含有酸性或碱性物质的清洁剂。

4. 如果长时间不使用日翼移动空调,请将其存放在干燥通风的地方,避免积尘和潮湿。

5. 请勿将日翼移动空调放置在高温或潮湿的环境中,以免损坏设备。

6. 如果发现日翼移动空调有任何异常情况,如漏水、异味等,请立即停用并联系售后服务。

五、常见问题解答1. 问:日翼移动空调的最佳使用环境是什么?答:最佳使用环境是在室内温度适宜的情况下使用,避免过高或过低的温度环境。

2. 问:如何调节日翼移动空调的风速?答:您可以使用遥控器或面板上的按键来调节空调的风速,通常有低、中、高三档可选。

3. 问:日翼移动空调是否需要定期清洁?答:是的,为了保持空调的正常运行和使用效果,请定期清洁空调,避免灰尘堆积。

六、售后服务如果您在使用日翼移动空调时遇到任何问题,或需要购买备件和配件,可以联系我们的售后服务团队,我们将竭诚为您提供帮助。

Product DataThis unit has been designed utilizing R-410A refrigerant. The environmentally sound refrigerant allows you to make a responsible decision in the protection of the earth’s ozone layer.NOTE: Ratings contained in this document are subject to change at any time. Always refer to the AHRI directory () for the most up-to-date ratings information.Industry leading Features / BenefitsEfficiency •Up to 17.0 SEER2 (18 SEER)/ Up to 13.5 EER2 (14.5 EER)•Indoor air quality accessories available Sound•Sound level as low as 71 dBAComfort•System supports Thermidistat or standard 2-stage thermostat controlsReliability•R-410A refrigerant - environmentally sound, won’t deplete the ozone layer and low lifetime service cost.•Front-seating service valves •2-stage scroll compressor •Internal pressure relief valve •Internal thermal overload •Filter drier•Balanced refrigeration system for maximum reliabilityDurability•Protection Package:Solid, Durable sheet metal construction •Pre-painted cabinet finish over galvanized steelApplications•Long-line - up to 250 feet (76.2 m) total equivalent length, up to 200feet (60.96 m) condenser above evaporator, or up to 80 ft. (24.38 m)evaporator above condenser (See Longline Guide for more information.)•Low ambient cooling (down to 0°F / -17.8°C ) with approved low ambient accessory kits.X = Standard O = Accessory * With approved combinationsPA7T2-Stage Air Conditioner with R-410A Refrigerant 2 To 5 TonsSTANDARD FEATURESFEATURESUnit Size24364860R-410A RefrigerantXXXXMaximum SEER2 (SEER) Rating*17.0 (18.0)17.0 (18.0)16.5 (17.0)16.0 (16.5)2-Stage Scroll CompressorX X X X Low Ambient Cooling Capability with Approved Kits X X X X Crankcase Heater w/Temperature Switch O X X O Field Installed Filter Drier X X X X Front Seating Service Valves X X X X Internal Pressure Relief Valve X X X X Internal Thermal Overload X X X X Long Line capability X X X X Low Pressure Switch X X X X High Pressure SwitchXXXXAHRI RATINGSFor AHRI ratings certificates, please refer to the AHRI directory Additional ratings and system combinations can be accessed via the Ratings Database here: Payne database here: MyPayneRatingsMODEL NUMBER NOMENCLATURE12345678, 9101112P A 7T A N 42400W BrandingOD TypeSEER2OD Design TypeMajor SeriesVoltageRefrigerantNominal Capacity FeatureSpecial FeatureRegion P = Generic A = AC7 = 17 SEER2T =2-Stage A-Z = Major Iteration N = 208-230-1or 208/230-1P = 208-230-3or 208/230-3E = 460-34 = R410A24 = 24,000 BTUH (2 Tons)36 = 36,000 BTUH (3 Tons)48 = 48,000 BTUH (4 Tons)60 = 50,000 BTUH (5 Tons)0 = Standard 0 =StandardW = Standard SouthwestACCATALOG ORDERING NUMBERSSize Model Ordering Number24PA7TAN42400W 36PA7TAN43600W 48PA7TAN44800W 60PA7TAN46000WPHYSICAL DATAUNIT SIZE24364860Compressor Type Scroll REFRIGERANT R-410AControlTXV (R-410A Hard Shutoff) Charge lb (kg) 6.03 (2.74)10.3 (4.67)12.22 (5.54)9.27 (4.20)COND FAN Propeller Type, Direct DriveAir Discharge VerticalAir Qty (CFM)2640283047794779 Motor HP 1/121/121/41/4 Motor RPM 800800800800COND COILFace Area (Sq ft)19.320.125.125.1 Fins per In.25202020 Rows 1222 Circuits5877VALVE CONNECT. (In. ID) Vapor 3/47/87/87/8Liquid3/8"REFRIGERANT TUBES* (In. OD) Rated Vapor(0-80 Ft Tube Length)3/47/81 1/81 1/8Liquid (0-80 Ft Tube Length)3/8"REFRIGERANT PIPING LENGTH LIMITATIONSLiquid Line Sizing and Maximum Total Equivalent Lengths† for Cooling Only Systems with R-410A Refrigerant:The maximum allowable length of a residential split system depends on the liquid line diameter and vertical separation between indoor and outdoor units.See Table below for liquid line sizing and maximum lengths :Table 1 – Maximum Total Equivalent LengthOutdoor Unit BELOW Indoor Unit* Maximum actual length not to exceed 200 ft (61 m)†Total equivalent length accounts for losses due to elbows or fitting. See the Long Line Guideline for details. -- = outside acceptable range* Maximum actual length not to exceed 200 ft (61 m)†Total equivalent length accounts for losses due to elbows or fitting. See the Long Line Guideline for details.Units are factory charged for 15 ft (4.6 m) of 3/8” liquid line. The factory charge for 3/8” lineset 9 oz.(266.16 g). When using other length or diameter liquid lines, charge adjustments are required per the chart above.Charging Formula:[(Lineset oz/ft x total length) – (factory charge for lineset)] = charge adjustmentExample 1: System has 15 ft of line set using existing 1/4“ liquid line. What charge adjustment is required? Formula:(.27 oz/ft x 15ft) – (9 oz) = (-4.95) oz.Net result is to remove 4.95 oz of refrigerant from the systemExample 2: System has 45 ft of existing 5/16” liquid line. What is the charge adjustment?Formula:(.40 oz/ft. x 45ft) – (9 oz.) = 9 oz.Net result is to add 9 oz of refrigerant to the systemNOTE: Conditions must be favorable for charging by subcooling method. Indoor temperature must be 70°F to 80°F (21.1°C to 26.7°C), and outdoor temperature must be 70°F to 100°F (21.1°C to 37.8°C). If outside these conditions, adjust charge for long line sets by weigh-in method.SizeLiquid Line ConnectionLiquid Line Diam.w/TXV AC with R-410A Refrigerant Maximum Total Equivalent Length†: Outdoor unit BELOW IndoorVertical Separation ft (m)0-5(0-1.5)6-10(1.8-3.0)11-20(3.4-6.1)21-30(6.4-9.1)31-40(9.4-12.2)41-50(12.5-15.2) 51-60(15.5-18.3)61-70(18.6-21.3)71-80(21.6-24.4)24 3/81/4 7575755050--------5/16250*250*250*250*250*225*1751251003/8250*250*250*250*250*250*250*250*250*36 3/85/1617515015010010010075----3//8250*250*250*250*250*250*250*250*250*483/83/8250*250*250*250*250*250*230160--603/83/8250*250*250*225*190150110----Table 2 – Maximum Total Equivalent LengthOutdoor Unit ABOVE Indoor UnitSizeLiquid LineConnectionLiquid LineDiam.w/TXVAC with R-410A Refrigerant Maximum Total Equivalent Length †:Outdoor unit ABOVE Indoor Vertical Separation ft (m)25(7.6)26-50(7.9-15.2)51-75(15.5-22.9)76-100(23.2-30.5)101-125(30.8-38.1)126-150(38.4-45.7)151-175(46.0-53.3)176-200(53.6-61.0)243/81/4100125175200225*250*250*250*5/16250*250*250*250*250*250*250*250*3/8250*250*250*250*250*250*250*250*363/85/16225*250*250*250*250*250*250*250*3/8250*250*250*250*250*250*250*250*483/83/8250*250*250*250*250*250*250*250*603/83/8250*250*250*250*250*250*250*250*Table 3 – Refrigerant Charge AdjustmentsLiquid Line SizeR-410A Charge oz/ft (g/m)3/80.60 (17.74)(Factory charge for lineset = 9 oz / 266.16 g)5/160.40 (11.83)1/40.27 (7.98)LONG LINE APPLICATIONSAn application is considered Long Line, when the refrigerant level in the system requires the use of accessories to maintain acceptable refrigerant management for systems reliability. See Accessory Usage Guideline table for required accessories. Defining a system as long line depends on the liquid line diameter, actual length of the tubing, and vertical separation between the indoor and outdoor units. For Air Conditioner systems, the chart below shows when an application is considered Long Line.NOTE: See Residential Piping and Long Line Guideline for detailsVAPOR LINE SIZING AND COOLING CAPACITY LOSSAcceptable vapor line diameters provide adequate oil return to the compressor while avoiding excessive capacity loss. The suction line diameters shown in the chart below are acceptable for AC systems with R-410A refrigerant:* Units are rated with 25 ft (7.6 m) of lineset length. See Vapor Line Sizing and Cooling Capacity Loss table when using other sizes and lengths of lineset.Table 4 – AC with R-410A Refrigerant Long Line Description ft (m) Beyond these lengths, a TXV is requiredTotal LengthOutdoor Unit Above or Below Indoor UnitTXV required beyond 50 ft. (15.2 m)TXV required beyond 20 ft. (6.1 m)Table 5 – AC with R-410A Refrigerant Long Line Description ft (m) (Beyond these lengths, long line accessories are required)Liquid Line Size Units On Same LevelOutdoor Below Indoor Outdoor Above Indoor1/4 + TXV No accessories needed within allowedlengths No accessories needed withinallowed lengths175 (53.3) 5/16 + TXV 120 (36.6)50 (15.2) vertical or 120 (36.6) total 120 (36.6) 3/8 + TXV80 (24.4)35 (10.7) vertical or 80 (24.4) total80 (24.4)Table 6 – Vapor Line Sizing and Cooling Capacity Losses — R-410A Refrigerant 2-Stage Air Conditioner ApplicationsUnit Nominal Size (Btuh)Maximum Liquid Line Diameters (In. OD)Vapor Line Diameters(In.) ODCooling Capacity Loss (%)Total Equivalent Line Length ft. (m)26-50 (7.9-15.2)51-80 (15.5-24.4)81-100(24.7-30.5)101-125 (30.8-38.1)126-150 (38.4-45.7)151-175 (46.0-50.3)176-200 (53.6-60.0)201-225 (61.3-68.6)226-250(68.9-76.2)243/85/80112334453/4000011111363/85/8124567910113/40011223347/8000011112483/83/41223456777/80112223331-1/800———————603/83/4124567910117/80122344551-1/8000111111Applications in this area may be long line and may have height restrictions. See the Residential Piping and Long Line Guideline.— Applications in this area are not recommended due to insufficient oil return* Permissible limits of the voltage range at which the unit will operate satisfactorily † Time-Delay fuse.FLA - Full Load Amps LRA - Locked Rotor Amps MCA - Minimum Circuit Amps RLA - Rated Load AmpsNOTE : Control circuit is 24-V on all units and requires external power source. Copper wire must be used from service disconnect to unit.All motors/compressors contain internal overload protection.Complies with 2010 requirements of ASHRAE Standards 90.1NOTE : Tested in compliance with AHRI 270 but not listed with AHRI.Electrical DataUNIT SIZEV/PHOPER VOLTS*COMPR FAN MCA MAX FUSE†orCKT BRK AMPSMAXMINLRA RLA FLA 24208-230/125319761.010.90.4314.0203692.015.40.5019.83548126.519.9 1.2026.14060158.025.61.2033.250A-WEIGHTED Sound SOUND POWER LEVEL (dBA) w/o ACCESSORY SOUND SHIELDUNIT SIZESTANDARD RATINGTYPICAL OCTAVE BAND SPECTRUM (without tone adjustment)12525050010002000400080002473 - High Stage 63.463.465.466.562.158.654.473 - Low Stage 62.062.862.864.059.958.151.53674 - High Stage 74.269.464.963.961.259.755.974 - Low Stage 73.371.065.663.761.259.957.04875 - High Stage 67.566.068.969.663.459.755.574 - Low Stage 68.368.968.469.262.658.853.56075 - High Stage 66.367.767.969.363.361.559.474 - Low Stage68.565.367.667.763.960.556.0A-WEIGHTED Sound SOUND POWER LEVEL (dBA) WITH ACCESSORY SOUND SHIELDUNIT SIZESTANDARD RATINGTYPICAL OCTAVE BAND SPECTRUM (without tone adjustment)12525050010002000400080002472- High Stage 62.962.162.562.158.252.947.672 - Low Stage 62.162.862.862.258.355.248.43672 - High Stage 74.068.965.662.860.859.154.972 - Low Stage 73.471.165.562.660.659.155.54872 - High Stage 68.765.567.368.161.857.652.071 - Low Stage 68.866.667.266.862.458.352.16074 - High Stage 67.566.767.668.461.258.054.172 - Low Stage68.566.166.765.762.558.653.7Charging Subcooling (TXV-Type Expansion Device)UNIT SIZEREQUIRED SUBCOOLING °F (°C)249 (5.0)3611 (6.1)4811 (6.1)609 (5.0)X = Accessory* For tubing line sets between 80 and 200 ft. (24.38 and 60.96 m) and/or 20 ft. (6 m) vertical differential, refer to Residential Piping and Longline Guideline.Accessory Description and Usage (Listed Alphabetically)1. Crankcase HeaterAn electric resistance heater which mounts to the base of the compressor to keep the lubricant warm during off cycles. Improves compressor lubrication on restart and minimizes the chance of liquid age Guideline:Required in low ambient cooling applications.Required in long line applications.Suggested in all commercial applications.2. Evaporator Freeze ThermostatAn SPST temperature-actuated switch that stops unit operation when evaporator reaches freeze-up age Guideline:Required when low ambient kit has been added.3. Liquid-Line Solenoid Valve (LLS)An electrically operated shutoff valve which stops and starts refrigerant liquid flow in response to compressor operation. It is to be installed at the outdoor unit to control refrigerant off cycle migration in the heating mode.Usage Guideline:An LLS is required in all long line heat pump applications to control refrigerant off cycle migration inthe heating mode. See Long Line Guideline.Suggested for all commercial applications.4. Low-Ambient Pressure SwitchA long life pressure switch which is mounted to outdoor unit service valve. It is designed to cycle the outdoor fan motor in order to maintain head pressure within normal operating limits. The control will maintain working head pressure at low-ambient temperatures down to 0°F (-17.8°C) when properly installed.Usage Guideline:A Low-Ambient Pressure Switch must be used when cooling operation is used at outdoor temperatures below 55°F (12.8°C). 5. Thermostatic Expansion Valve (TXV)A modulating flow-control valve which meters refrigerant liquid flow rate into the evaporator in response to the superheat of the refrigerant gas leaving the evaporator.Kit includes valve, adapter tubes, and external equalizer tube. Hard shut off types are available.NOTE: When using a hard shut off TXV with single phase reciprocating compressors, a Compressor Start Assist Capacitor and Relay is required. Usage Guideline:Required to achieve AHRI ratings in certain equipment combinations.Refer to combination ratings.Hard shut off TXV or LLS required in air conditioner long line applications.6. Winter Start ControlThis control is designed to alleviate nuisance opening of the low-pressure switch by bypassing it for the first 3 minutes of operation.AccessoriesKIT NUMBER KIT NAME24364860KSAFT0101AAA Evaporator Freeze Stat X X X X KAATD0101TDR Time Delay Relay X X X X KSALA0301410Low Ambient X X X X KSALA1001AAA MotorMaster X X X X KSAHS2501AAA Hard Start X X KSAHS2801AAA Hard StartX X KSACY0101AAA Cycle Protection X X X X KSASF0201AAA Support Feet X X X X KAALS0201LLS Solenoid Valve X X X X KAAWS0101AAA Winter StartX X X X KAACH1701AAA Crankcase Heater X SKAACH1601AAA Crankcase HeaterSXKSATX0201PUR TXV KIT (for use with copper coils)XKSATX0301PUR TXV KIT (for use with copper coils)XKSATX0401PUR TXV KIT (for use with copper coils)XXKSBTX0201PUR TXV KIT (for use with aluminum coils)XKSBTX0301PUR TXV KIT (for use with aluminum coils)XKSBTX0401PUR TXV KIT (for use with aluminum coils)XX KSASH2301COP Sound Blanket X X KSASH2401COP Sound BlanketX X KAALP0401PUR Pressure Switch Low X X X X KAAHI0501PURPressure Switch HighXXXX ACCESSORY USAGE GUIDELINEAccessoryRequired for Low Ambient Cooling Applications (Below 55°F / 12.8°C)Required for Long Line Applications*Required for Sea Coast Applications(within 2 miles/3.2 km)Ball Bearing Fan Motor StandardStandardStandard Crankcase HeaterYes (standard on some units)Yes (standard on some units)No Evaporator Freeze Thermostat YesNoNoHard Shutoff TXV Yes(standard w/factory approvedindoor unit)Yes(standard w/factory approvedindoor unit)Yes(standard w/factory approvedindoor unit)Liquid Line Solenoid Valve No See Residential Piping and Long Line GuidelineNo Low-Ambient Control Yes No No Winter Start ControlYesNoNoPA7T: Product DataManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.13Condenser Only Ratings*SST °F (°C)CONDENSER ENTERING AIR TEMPERATURES °F (°C)55.0 (12.8)65.0 (18.3)75.0 (23.9)85.0 (29.4)95.0 (35.0)105.0 (40.6)115.0 (46.1)30.0 (-1.1)TCG 20.0919.1018.0716.9915.8614.7113.52SDT 67.0276.6386.2195.77105.31114.76124.12KW 0.93 1.08 1.23 1.40 1.57 1.77 2.0035.0 (1.7)TCG 22.1821.1119.9918.8217.6016.3315.03SDT 68.0277.6087.1596.67106.17115.64124.96KW 0.92 1.08 1.23 1.40 1.58 1.78 2.0140.0 (4.4)TCG 24.4123.2622.0720.8019.4818.0916.65SDT 69.1378.6788.1497.65107.06116.46125.85KW 0.91 1.07 1.23 1.40 1.58 1.79 2.0245.0 (7.2)TCG 26.8125.5924.2822.9121.4919.9918.46SDT 70.3479.7689.2398.67108.01117.36126.44KW 0.90 1.06 1.23 1.40 1.59 1.80 2.0250.0 (10.0)TCG 29.4028.0826.6825.1823.6122.0220.31SDT 71.4580.8890.2899.72109.15118.25127.57KW 0.88 1.05 1.22 1.40 1.60 1.80 2.0455.0 (12.8)TCG 32.1630.7329.2227.6125.9224.1622.32SDT 72.7382.1291.44100.80110.10119.35128.53KW 0.86 1.04 1.22 1.40 1.60 1.822.0630.0 (-1.1)TCG 13.6913.1912.5911.8610.999.998.86SDT 63.5273.3283.0792.75102.36111.87121.33KW 0.680.790.91 1.04 1.19 1.36 1.5535.0 (1.7)TCG 15.3314.7314.0413.2412.3111.2910.10SDT 64.3174.0683.7793.42103.08112.47121.97KW 0.650.770.89 1.03 1.18 1.35 1.5440.0 (4.4)TCG 17.1016.3915.6114.7313.7212.6411.43SDT 65.1674.8584.5194.13103.76113.19122.60KW 0.630.740.87 1.01 1.16 1.33 1.5245.0 (7.2)TCG 19.0018.1817.2916.3215.2514.1012.85SDT 66.1175.6985.3094.88104.47113.87123.21KW 0.600.720.850.99 1.14 1.31 1.5050.0 (10.0)TCG 21.0420.0919.0918.0316.8715.6514.31SDT 67.0676.5786.1395.66105.22114.58123.99KW 0.570.690.820.97 1.12 1.29 1.4855.0 (12.8)TCG 23.2422.1321.0219.8518.6217.3115.89SDT 68.0077.5687.0096.48105.93115.32124.68KW 0.540.670.800.95 1.10 1.271.4630.0 (-1.1)TCG 31.0729.3927.7626.1224.4422.6820.83SDT 67.8577.2786.7296.16105.59114.99124.35KW 1.47 1.67 1.87 2.09 2.33 2.62 2.9535.0 (1.7)TCG 34.2232.4330.6628.8827.0325.1323.10SDT 69.0778.4487.8397.23106.60115.94125.22KW 1.49 1.69 1.89 2.10 2.35 2.63 2.9640.0 (4.4)TCG 37.6135.6933.7831.8429.8427.7525.46SDT 70.3879.7089.0498.38107.68116.94126.14KW 1.52 1.70 1.90 2.12 2.36 2.65 2.9845.0 (7.2)TCG 41.2539.1937.1335.0232.8430.5528.13SDT 71.8081.0690.3499.61108.80118.02127.16KW 1.54 1.72 1.92 2.13 2.38 2.66 2.9950.0 (10.0)TCG 45.1542.9440.7138.4236.0433.5230.90SDT 73.3282.5291.73100.92110.04119.17128.21KW 1.56 1.74 1.94 2.15 2.39 2.68 3.0155.0 (12.8)TCG 49.3246.9344.5242.0339.2436.6933.82SDT 74.9584.0893.22102.33111.29120.39129.34KW1.591.77 1.962.17 2.41 2.693.02PA7T: Product DataManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.1430.0 (-1.1)TCG 20.1019.4518.6517.6816.5215.1513.59SDT 63.4773.2382.9492.57102.14111.65121.08KW 0.99 1.14 1.32 1.51 1.73 1.98 2.2735.0 (1.7)TCG 22.5221.7120.7819.7118.4617.0615.46SDT 64.3974.0883.7393.32102.88112.35121.77KW 0.95 1.11 1.29 1.48 1.70 1.95 2.2440.0 (4.4)TCG 25.1524.1623.0921.9020.5519.0817.42SDT 65.3874.9984.5994.13103.64113.09122.48KW 0.91 1.08 1.26 1.46 1.68 1.93 2.2145.0 (7.2)TCG 28.0126.8125.5724.2522.7821.2319.48SDT 66.4775.9885.5195.00104.46113.87123.23KW 0.87 1.05 1.23 1.43 1.65 1.90 2.1850.0 (10.0)TCG 31.0629.6628.2326.7525.1623.4921.65SDT 67.6377.0686.5195.93105.34114.69124.00KW 0.83 1.02 1.21 1.41 1.63 1.88 2.1555.0 (12.8)TCG 34.3132.7031.0629.4027.6725.8623.90SDT 68.8778.2287.5796.93106.26115.56124.81KW 0.800.99 1.19 1.39 1.62 1.862.1330.0 (-1.1)TCG 42.8640.4438.1735.9633.7231.4028.92SDT 67.0076.2785.6395.07104.51113.94123.37KW 2.07 2.33 2.59 2.88 3.19 3.55 3.9635.0 (1.7)TCG 47.1244.5842.1639.7737.3234.7932.08SDT 68.1377.3586.6696.04105.41114.80124.17KW 2.10 2.36 2.62 2.91 3.22 3.58 3.9940.0 (4.4)TCG 51.7249.0346.4543.8841.2138.4535.47SDT 69.3878.5287.7797.08106.41115.74125.04KW 2.14 2.39 2.66 2.94 3.25 3.61 4.0245.0 (7.2)TCG 56.7253.8351.0748.2945.4042.3939.15SDT 70.8279.7988.9998.24107.49116.75125.97KW 2.20 2.43 2.69 2.97 3.29 3.64 4.0650.0 (10.0)TCG 61.9559.0456.0353.0449.8946.6243.10SDT 72.1381.2690.3199.50108.66117.84126.97KW 2.23 2.49 2.73 3.01 3.32 3.68 4.0955.0 (12.8)TCG 67.7364.5761.3858.0954.7051.1447.29SDT 73.9282.7891.79100.82109.92119.00128.00KW 2.32 2.54 2.78 3.05 3.36 3.714.1330.0 (-1.1)TCG 26.6826.1925.0323.3621.3319.0616.67SDT 62.3672.2281.9191.51101.04110.51119.96KW 1.43 1.67 1.90 2.13 2.37 2.64 2.9335.0 (1.7)TCG 29.8229.2728.0126.2324.0621.6519.08SDT 63.1572.9782.6492.20101.69111.13120.54KW 1.37 1.62 1.85 2.09 2.33 2.60 2.8940.0 (4.4)TCG 33.1832.5831.2329.2927.0224.4521.69SDT 63.9973.7883.4292.97102.40111.80121.16KW 1.31 1.57 1.81 2.05 2.30 2.56 2.8545.0 (7.2)TCG 36.8336.1334.6932.6330.2227.4624.52SDT 64.9074.6684.2793.77103.17112.51121.83KW 1.26 1.53 1.77 2.01 2.26 2.53 2.8150.0 (10.0)TCG 40.8639.9438.3936.2433.5830.7127.57SDT 65.9275.6185.1894.63104.00113.28122.55KW 1.22 1.49 1.74 1.99 2.24 2.50 2.7855.0 (12.8)TCG 44.9644.0442.3540.0537.2634.1930.85SDT 66.9876.6686.1695.56104.88114.11123.33KW1.141.47 1.72 1.972.22 2.482.76Condenser Only Ratings* (Continued)SST °F (°C)CONDENSER ENTERING AIR TEMPERATURES °F (°C)55.0 (12.8)65.0 (18.3)75.0 (23.9)85.0 (29.4)95.0 (35.0)105.0 (40.6)115.0 (46.1)PA7T: Product DataManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.15* AHRI listing applies only to systems shown in Combination Ratings table.KW - Outdoor Unit Kilowatts Only.SDT -Saturated Temperature Leaving Compressor (°F)SST -Saturated Temperature Entering Compressor (°F/°C)TCG -Gross Cooling Capacity (1000 Btuh)30.0 (-1.1)TCG 50.2847.6845.0342.3239.5436.5933.50SDT 69.1778.4787.6496.85106.13115.37124.61KW 2.52 2.85 3.18 3.55 3.97 4.44 4.9835.0 (1.7)TCG 55.3452.5149.6746.7743.7040.4837.08SDT 70.5679.7588.8998.07107.23116.39125.54KW 2.55 2.88 3.21 3.59 4.00 4.48 5.0240.0 (4.4)TCG 60.9857.7854.7151.5348.1744.6240.90SDT 72.6681.2390.2899.36108.43117.49126.53KW 2.65 2.91 3.25 3.62 4.04 4.52 5.0745.0 (7.2)TCG 66.7763.5260.1356.6352.9649.0944.94SDT 73.9282.9191.79100.75109.71118.67127.57KW 2.65 2.96 3.29 3.66 4.08 4.56 5.1150.0 (10.0)TCG 73.0669.5865.8962.0758.0553.8049.25SDT 75.6384.6193.40102.23111.07119.90128.70KW 2.69 3.01 3.33 3.70 4.12 4.61 5.1655.0 (12.8)TCG 79.8276.0672.0567.8763.4558.7553.78SDT 77.5386.5095.10103.79112.51121.21129.87KW 2.72 3.07 3.38 3.75 4.17 4.665.2230.0 (-1.1)TCG 33.5831.4329.3527.2325.0322.5919.94SDT 64.1073.5182.9592.41101.86111.29120.67KW 1.73 1.99 2.26 2.53 2.83 3.15 3.5035.0 (1.7)TCG 37.1734.9632.7830.5328.1525.5622.71SDT 65.0274.4083.7993.23102.62112.01121.34KW 1.67 1.94 2.21 2.50 2.80 3.12 3.4840.0 (4.4)TCG 41.0738.7536.4734.0631.4828.7725.71SDT 66.0275.3484.7394.10103.45112.79122.07KW 1.62 1.89 2.17 2.46 2.76 3.09 3.4545.0 (7.2)TCG 45.2842.9040.4737.9335.2032.2328.96SDT 67.0476.4185.7295.06104.38113.64122.86KW 1.56 1.85 2.13 2.42 2.73 3.06 3.4250.0 (10.0)TCG 49.8947.4244.8142.1239.1635.9232.45SDT 68.2277.5986.8196.11105.35114.55123.72KW 1.51 1.80 2.09 2.38 2.70 3.03 3.3955.0 (12.8)TCG 55.0952.3049.5746.6743.4839.9736.20SDT 69.9678.8288.0397.26106.44115.56124.64KW1.511.762.05 2.35 2.673.003.36Condenser Only Ratings* (Continued)SST °F (°C)CONDENSER ENTERING AIR TEMPERATURES °F (°C)55.0 (12.8)65.0 (18.3)75.0 (23.9)85.0 (29.4)95.0 (35.0)105.0 (40.6)115.0 (46.1)PA7T: Product DataManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.16Guide Specifications GENERALSystem DescriptionOutdoor-mounted, air-cooled, split-system air conditioner unit suitable for ground or rooftop installation. Unit consists of a hermetic compressor, an air-cooled coil, propeller-type condenser fan, and a control box. Unit will discharge supply air upward as shown on contract drawings. Unit will be used in a refrigeration circuit to match up to a packaged fan coil or coil unit.Quality Assurance–Unit will be rated in accordance with the latest edition of AHRI Standard 210.–Unit will be certified for capacity and efficiency, and listed in the latest AHRI directory.–Unit construction will comply with latest edition of ANSI/ASHRAE and with NEC.–Unit will be constructed in accordance with UL standards and will carry the UL label of approval. Unit will have c-UL approval.–Unit cabinet will be capable of withstanding Federal TestMethod Standard No. 141 (Method 6061) 500-hr salt spray test.–Air-cooled condenser coils will be leak tested and pressure tested.–Unit constructed in ISO9001 approved facility.Delivery, Storage, and Handling–Unit will be shipped as single package only and is stored and handled per unit manufacturer’s recommendations.Warranty (for inclusion by specifying engineer)–U.S. and Canada only.PRODUCTSEquipment–Factory assembled, single piece, air-cooled air conditioner unit.Contained within the unit enclosure is all factory wiring, piping,controls, compressor, refrigerant charge R-410A, and special features required prior to field start-up.Unit Cabinet –Unit cabinet will be constructed of galvanized steel, bonderized,and coated with pre-paint.FansCondenser fan will be direct-drive propeller type, discharging air upward.–Condenser fan motors will be totally enclosed, 1-phase type with class B insulation and permanently lubricated bearings. Shafts will be corrosion resistant.–Fan blades will be statically and dynamically balanced.–Condenser fan openings will be equipped with coated steel wire safety guards.Air-cooled, split-system air conditionerPA7T2 to 5 nominal tonsCompressor–Compressor will be hermetically sealed.–Compressor will be mounted on rubber vibration isolators.Condenser Coil–Condenser coil will be air cooled.–Coil will be constructed of aluminum fins mechanically bonded to copper or aluminum tubes which are then cleaned, dehydrated, and sealed. Refrigeration Components–Refrigeration circuit components will include liquid-line shutoff valve with sweat connections, vapor-line shutoff valve with sweat connections, system charge of R-410A, refrigerant, and compressor oil.–Unit will be shipped with filter drier for R-410A, refrigerant.Operating Characteristics–The capacity of the unit will meet or exceed _____ Btuh at a suction temperature of _____ _F/_C. The power consumption at full load will not exceed _____ kW.–Combination of the unit and the evaporator or fan coil unit will have a total net cooling capacity of _____ Btuh or greater at conditions of _____ CFM entering air temperature at the evaporator at _____ _F/_C wet bulb and _____ _F/_C dry bulb, and air entering the unit at _____ _F/_C.–The system will have a SEER of _____ Btuh/watt or greater at DOE conditions.Electrical Requirements–Nominal unit electrical characteristics will be _____ v, single phase, 60 hz. The unit will be capable of satisfactory operation within voltage limits of _____ v to _____ v.–Unit electrical power will be single point connection.–Control circuit will be 24v.Special Features–Refer to section of this literature identifying accessories and descriptions for specific features and available enhancements.PA7T: Product DataManufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.17System Design Summary1.Intended for outdoor installation with free air inlet and outlet. Outdoor fan external static pressure available is less than 0.01-in. wc.2.Minimum outdoor operating air temperature without low-ambient operation accessory is 55_F (12.8_C).3.The maximum outdoor operating ambient in cooling mode is 125_F (51.67_C) when operating voltage is 230v.4.For reliable operation, unit should be level in all horizontal planes.5.For interconnecting refrigerant tube lengths greater than 80 ft (23.4 m) and/or elevation differences between indoor and outdoor units greater than 20 ft (6.1 m), consult Residential Piping and Longline Guideline and Service Manual available from equipment distributor.6.If any refrigerant tubing is buried, provide a 6 in. (152.4 mm) vertical rise to the valve connections at the unit. Refrigerant tubing lengths up to 36in. (914.4 mm) may be buried without further consideration. Do not bury refrigerant lines longer than 36 in. (914.4 mm).e only copper wire for electric connection at unit. Aluminum and clad aluminum are not acceptable for the type of connector provided.8.Do not apply capillary tube indoor coils to these units.9.Factory-supplied filter drier must be installed.。

智冷空调扇的工作原理智冷空调扇是一种能够同时提供空调和风扇功能的电器设备。

它具有智能控制、节能环保等特点,广泛应用于家庭、办公室和商业场所。

智冷空调扇的工作原理主要包括制冷循环和风扇循环两部分。

首先是制冷循环部分。

智冷空调扇内部装有压缩机、冷凝器、膨胀阀和蒸发器等核心组件。

首先,压缩机将低温低压的制冷剂吸入,通过压缩将其转化为高温高压的气体。

然后,气体通过冷凝器进行散热,将高温气体冷却成高压液体。

接下来,高压液体通过膨胀阀进入蒸发器,膨胀阀使液体制冷剂压力骤降,此时液体制冷剂变成低温低压的蒸汽。

最后,蒸发器中外界空气通过风扇循环,与低温蒸汽进行热交换,吸收空气中的热量,同时空气中的湿气也会凝结成水滴,实现降温和湿度调节效果。

制冷循环反复进行,从而实现持续的空调功能。

其次是风扇循环部分。

智冷空调扇内部有一个独立的风扇系统,用于驱动空气循环。

风扇通过电机带动叶片旋转,产生强大的气流。

风扇通常采用不同档位的控制,可以调节风速。

风扇系统会将空气吸入机内,经过蒸发器内的水滴,再通过出风口排出,形成流动的凉爽空气。

智冷空调扇通过制冷循环和风扇循环相结合,实现空调和风扇功能的集成。

具体工作流程如下:当用户开启智冷空调扇时,电源将提供能量给压缩机和风扇电机,压缩机开始工作,并且风扇也开始旋转。

随着压缩机的工作,制冷循环开始运行,将热量从机内排出,空气中的湿气也会凝结成水滴从水箱中流出。

同时,风扇通过叶片旋转产生气流,将冷却后的空气吹出,使室内温度降低,空气质量得到改善。

在智能控制方面,智冷空调扇通常配备有智能温度感应器和湿度感应器,可以根据周围环境的温度和湿度变化自动调节制冷和风扇运行状态,从而提供更好的舒适度。

与传统空调相比,智冷空调扇具有更低的能耗、更环保的制冷剂,并且具有更高的移动性和便捷性,可以轻松搬运和安装在不同的房间中。

总结起来,智冷空调扇的工作原理是利用制冷循环和风扇循环相结合,通过压缩机、冷凝器、膨胀阀和蒸发器等组件实现制冷效果,再通过风扇产生气流进行空气循环,达到降温、降湿和改善空气质量的目的。

专利名称:天花板悬挂式空调机专利类型:实用新型专利

发明人:我科贤二

申请号:CN200820137073.5申请日:20080905

公开号:CN201448933U

公开日:

20100505

专利内容由知识产权出版社提供

摘要:本实用新型提供一种廉价的、装配时不会产生垃圾的而且安装操作性良好的天花板悬挂式空调机。

在该天花板悬挂式空调机中,天花板上安装的吊环螺栓贯通在壳体上设置的吊件的安装孔,上下两枚垫圈和螺合在上述吊环螺栓上的上下两个螺母夹着吊件,壳体被固定在天花板上,上侧垫圈上在偏离重心的位置设置有用于使上述吊环螺栓贯通的螺栓贯通孔。

申请人:东芝开利株式会社

地址:日本东京都

国籍:JP

代理机构:永新专利商标代理有限公司

更多信息请下载全文后查看。

WK无水节能机柜空调产品介绍佐志温控技术(上海)有限公司

WK无水节能机柜空调产品介绍内容

•空调吹水的现象和佐志解

决方案

•内置冷凝水蒸发器彻底解

决冷凝水排放的问题

•外置的温度传感器使空调

更节能和控制精度更高

•超大的外循环通风面积

•与威图空调安装尺寸相同

用户拍的电影

空调吹水的现象和佐志解决方案•机柜空调向机柜内吹水是生产商的恶梦

空调吹水的现象和佐志解决方案

•创新来自积累和突破:上出风

空调吹水的现象和佐志解决方案

•创新来自积

累和突破:上

出风

WK无水节能机柜空调产品介绍

内置冷凝水蒸发器彻底解决冷凝水排放的问题•功率大:800瓦,每天可以蒸发15升水

•蒸汽被冷凝风机排到空气中

外置的温度传感器使空调更节能和控制精度更高•温度传感器在机柜内,可以控制机柜内任何位置的温度•温度传感器在机柜内,可以降低内风机的能耗

超大的外循环通风面积

•通风面积小,压缩机的负荷大,寿命短•增加的3层结构,通风面积增加6倍•过滤网的脏污程度可以目视

其它品牌

与威图空调安装尺寸相同

•与威图空调安装尺寸相同

小于1KW

1到2 KW

2 KW 以上

WK无水节能机柜空调产品介绍

2013年5月

谢谢。