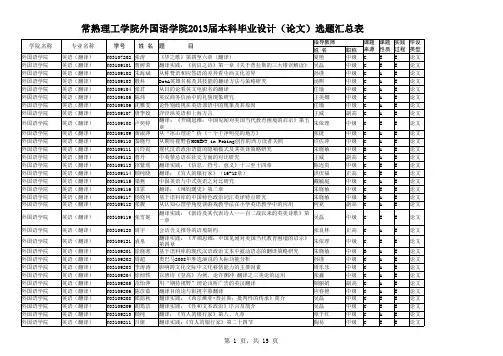

(完整版)常熟理工学院本科_毕业设计(论文)外文翻译_

- 格式:doc

- 大小:40.00 KB

- 文档页数:3

大连东软信息学院

毕业设计(论文)外文资料及译文

系所:

专业:

班级:

姓名:

学号:

大连东软信息学院

Dalian Neusoft University of Information

外文资料和译文格式要求

一、装订要求

1、外文资料原文(复印或打印)在前、译文在后、最后为指导教师评定成绩。

2、译文必须采用计算机输入、打印。

3、A4幅面打印,于左侧装订。

二、撰写要求

1、外文文献内容与所选课题相关。

2、本科学生译文汉字字数不少于4000字,高职学生译文汉字字数不少于2000字。

三、格式要求

1、译文字号:中文小四号宋体,英文小四号“Times New Roman”字型,全文统一,首行缩进2个中文字符,1.5倍行距。

2、译文页码:页码用阿拉伯数字连续编页,字体采用“Times New Roman”字体,字号小五,页底居中。

3、译文页眉:眉体使用单线,页眉说明五号宋体,居中“大连东软信息学院本科毕业设计(论文)译文”。

本科生毕业设计(论文)外文翻译外文原文题目:Real-time interactive optical micromanipulation of a mixture of high- and low-index particles中文翻译题目:高低折射率微粒混合物的实时交互式光学微操作毕业设计(论文)题目:阵列光镊软件控制系统设计姓名:任有健学院:生命学院班级:06210501指导教师:李勤高低折射率微粒混合物的实时交互式光学微操作Peter John Rodrigo Vincent Ricardo Daria Jesper Glückstad丹麦罗斯基勒DK-4000号,Risø国家实验室光学和等离子研究系jesper.gluckstad@risoe.dkhttp://www.risoe.dk/ofd/competence/ppo.htm摘要:本文论证一种对于胶体的实时交互式光学微操作的方法,胶体中包含两种折射率的微粒,与悬浮介质(0n )相比,分别低于(0L n n <)、高于(0H n n >)悬浮介质的折射率。

球形的高低折射率微粒在横平板上被一批捕获激光束生成的约束光势能捕获,捕获激光束的横剖面可以分为“礼帽形”和“圆环形”两种光强剖面。

这种应用方法在光学捕获的空间分布和个体几何学方面提供了广泛的可重构性。

我们以实验为基础证实了同时捕获又独立操作悬浮于水(0 1.33n =)中不同尺寸的球形碳酸钠微壳( 1.2L n ≈)和聚苯乙烯微珠( 1.57H n =)的独特性质。

©2004 美国光学学会光学分类与标引体系编码:(140.7010)捕获、(170.4520)光学限制与操作和(230.6120)空间光调制器。

1 引言光带有动量和角动量。

伴随于光与物质相互作用的动量转移为我们提供了在介观量级捕获和操作微粒的方法。

过去数十年中的巨大发展已经导致了在生物和物理领域常规光学捕获的各种应用以及下一代光学微操作体系的出现[1-5]。

本科毕业设计外文翻译题目:德黑兰城市发展学院: 城市建设学院专业: 建筑学学号:学生姓名:指导教师:日期: 二零一一年六月First Chapter:Development of the city of TehranAli MadanipourTehran :the making of a metropolis,First Chapter:Development New York John Wiley,1998,page five to page eleven。

第一章:德黑兰市的发展阿里.马丹妮普尔德黑兰:一个大都市的建造,第一章:德黑兰市的发展,阿1998,第五页到第十一页。

德黑兰市的发展全市已长成了一定的规模性和复杂性,以这样的程度,空间管理需要另外的手段来处理城市组织和不断发展的复杂性,并为城市总体规划做准备。

第二次世界大战后,在盟军占领国家的期间,有一个时期的民主化,在冷战时开始的政治紧张局势之后,它们互相斗争对石油的控制权。

这个时期已经结束于1953年,结果是由政变产生了伊朗王,那个后来担任了25年的行政君主的人。

随着高出生率和农村向城市迁移,德黑兰和其他大城市增长加剧甚至比以前更快地。

到1956年,德黑兰的人口上升到150万,到了1966至300万, 1976至450万,其规模也从1934年46平方公里到1976年的250平方公里。

从石油行业的收入增长创造的盈余资源,需要流通和经济的吸收。

50年代中期,特别是在工业化的驱动下德黑兰许多大城市有了新工作。

20世纪60年代的土地改革释放了大量来自农业的农村人口,这是不能吸收的指数人口增长。

这种新的劳动力被吸引到城市:到新的产业,到似乎始终蓬勃发展建筑界,去服务不断增长公共部门和官僚机构。

德黑兰的角色是国家的行政,经济,文化中心,它坚定而巩固地通往外面的世界。

德黑兰战后的城市扩张,是在管制、私营部门的推动,投机性的发展下进行的。

房屋一直供不应求,并有大量可用的富余劳动力和资本,因此在德黑兰建筑行业蓬勃发展,土地和财产的价格不断上涨。

毕业设计(论文)外文资料翻译附件1 :外文资料翻译译文双闭环直流调速系统的说明一、系统分析与综合1. 系统分析(1)在转速、电流双闭环调速系统中,若要改变电动机的转速,应调节什么参数?改变转速调节器的放大倍数Kn行不行?改变电力电子变换器的放大系数Ks 行不行?改变转速反馈系数行不行?若要改变电动机的堵转电流,应调节系统中的什么参数?答:若要改变电动机的转速,改变转速调节器的放大倍数Kn 和电力电子变换器的放大系数Ks 都不行,稳定时n=Un=Un*,所以只有改变给定值Un*和反馈系数才行。

若要改变电动机的堵转电流,同样只须改变给定值Uim*和反馈系数,因为,稳定时,Uim* = Idm, 从式中可得出。

(2)转速、电流双闭环调速系统稳态运行时,两个调节器的输入偏差电压和输出电压各是多少?答:转速、电流双闭环调速系统稳态运行时,两个调节器的输入偏差电压均是零,由式子n=Un=Un*,n=n0 ; Uim* = Idm, Idm=Idl 。

(3)在转速、电流双闭环调速系统中,两个调节器均采用PI 调节器。

当系统带额定负载运行时,转速反馈线突然断线,系统重新进入稳态后,电流调节器的输入偏差电压Ui 是否为零?为什么?答:当系统带额定负载运行时,转速反馈线突然断线,则Un=0,Un =Un*-Un=Un*, 使Ui 迅速达到Uim ,Ui 0 ,速度n 上升,当系统重新进入稳态后,即Id=Idl ,那么,Ui = Uim*- Idl 0,Ui 也不再变化,转速n也不再变化,但,此时的转速n 比反馈线断线时的转速要大。

(4)为什么用积分控制的调速系统是无静差的?答:在积分调节器的调速系统中,能实现无静差,是由于积分调节器控制特点,即积分的记忆和积累作用。

(5)双环调速系统(PI),负载变化,Idl>Idm, 问双环调速系统ACR和ASR 怎么调节,结果如何?答:当负载变化时,Idl>Idm, 转速迅速下降,电流Id 很快增加到Idm,而达限幅值,速度ASR迅速饱和,ACR一直在限流状态下,形成堵转现象,长时间运行会损坏系统。

常熟理工学院毕业设计(论文)有关文件及管理规定1、常熟理工学院毕业设计(论文)工作条例(修订稿)2、常熟理工学院本科生毕业设计(论文)评分标准3、常熟理工学院毕业设计(论文)管理规定4、常熟理工学院校外做毕业设计(论文)的管理规定(试行)5、常熟理工学院校外做毕业设计(论文)申请表6、常熟理工学院校外做毕业设计(论文)情况汇总表7、常熟理工学院本科生团队毕业设计(论文)工作规范(试行)8、常熟理工学院毕业设计(论文)答辩工作规程9、常熟理工学院本科毕业设计(论文)撰写规范常熟理工学院毕业设计(论文)工作条例(修订稿)为了进一步规范我校的毕业设计(论文)工作,切实保证我校本科生毕业设计(论文)的教学质量,我们在以往有关文件规定的基础上,修订了《常熟理工学院毕业设计(论文)工作规程》。

各二级学院应以此文件为指导,做好毕业设计(论文)工作。

第一章总则第一条毕业设计(论文)是学生在校期间最重要的综合性实践教学环节,是学生在校所学知识的综合应用,是检验学校培养质量的重要依据,也是学生毕业及学位资格认定的重要依据之一。

为进一步规范毕业设计(论文)工作,保证毕业设计(论文)及人才培养质量,特制定本规程。

第二条毕业设计(论文)工作的目的是培养学生综合运用所学基础理论、专业知识和基本技能来分析、解决实际问题的能力。

因此,毕业设计(论文)工作应注重学生独立工作和研究能力的锻炼,重视学生创新精神和创造能力的培养。

第三条本规程适用于常熟理工学院各本科专业。

第二章组织与管理工作第四条毕业设计(论文)工作实行在学校主管教学校长的统一领导下,由“教务处—学院—系三级管理。

学校教务处统一协调与管理,各学院和系具体组织落实。

各学院主管教学的院长应对本院毕业设计(论文)工作的组织管理和教学质量全面负责。

具体任务为:教务处负责毕业设计(论文)工作的宏观管理和指导,协调教学资源的配置,评价毕业设计(论文)工作,组织毕业设计(论文)教学研究和优秀毕业设计(论文)评选;学院主管教学院长是毕业设计(论文)工作的直接领导者和责任人,全面负责本学院各专业的毕业设计(论文)工作;系(教研室)在学院的领导下具体负责毕业设计(论文)的组织及实施工作。

Computer networking summarizeNetworking can be defined as the linking of people, resources and ideas. Networking occurs via casual encounters, meetings, telephone conversation, and the printed words. Now the computer networking provide beings with new networking capabilities. Computer network are important for services because service tasks are information intensive. During the is transmitted between clients, coworkers, management, funding sources, and policy makers. Tools with rapidly speed up communication will dramatically affect services.Computer network growing explosively. Two decades ago, few people essential part of our infrastructure. Networking is used in every aspect of business, including advertising, production, shipping, planning, bulling, and accounting. Consequently, most corporations in on-line libraries around the world. Federal, state, and local government offices use networks, as do military organizations. In short, computer networks are everywhere.The growth in networking economic impact as well. An entire industry jobs for people with more networking expertise. Companies need workers to plan, acquire, install, operate, and manage the addition computer programming is no longer restricted to individual computers; programmers are expected to design and implement application software that can communicate with software on other computers.Computer networks link computers by communication lines and software protocols, allowing data to be exchanged rapidly and reliably. Traditionally, they split between wide area networks (WANs) and local area networks (LANs). A WAN is a network connected over long-distance telephone lines, and a LAN is a localized network usually in one building or a group of buildings close together. The distinction, computers. Today networks carry e-mail, provide access to public databases, and are beginning to be used for distributed systems. Networks also allow users in one locality to share expensive resources, such as printers and disk-systems.Distributed computer systems are built using networked computers that cooperate to perform tasks. In this environment, each part of the networked system does what it is best at. The of a personal computer or workstation provides a good user interface. The mainframe, on the other the results to the users. In a distributed environment, a user might use in a special language (e. g. Structured Query Language-SQL), to the mainframe, which then parrrses the query, returning the user only the data requested. The user might then use the data. By passing back the user’s PC only the specific information requested, network traffic is reduced. If the whole file were transmitted, the PC would then of one network to access the resources on a different type of network. For example, a gateway could be used to connect a local area network of personal computers to a mainframe computer network. For example, if a company this example, using a bridge makes more sense than joining all thepersonal computers together in one large network because the individual departments only occasionally need to access information on the other network.Computer networking technology can be divided into four major aspects.The first is the data transmission. It explains that at the lowest level electrical signals traveling across wires are used to carry information, and shows be encoded using electrical signals.The second focuses on packet transmission. It explains why computer network use packets, and shows . LANs and WANs discussed above are two basic network.The third covers internetworking—the important idea that allows system, and TCPIP, the protocol technology used in global internet.The fourth explains networking applications. It focuses on , and programs provide services such as electronic mail and Web browsing.Continued growth of the global Internet is one of most interesting and exciting phenomena in networking. A decade ago, the Internet was a research project that involved a few dozen sites. Today, the Internet into a production communication system that reaches millions of people in almost all countries on all continents around the world. In the United States, the Internet connects most corporations, colleges and universities, as well as federal, state, and local government offices. It will soon reach most elementary,junior, and senior addition, many private residences can reach the Internet through a dialup telephone connection. Evidence of the Internet’s impact on society can be seen in advertisements, in magazines and on television, which often contain a reference to an Internet Web site that provide additional information about the advertiser’s products and services.A large organization with diverse networking requirements needs multiple physical networks. More important, if the organization chooses the type network that is best for each task, the organization will network can only communicate with other computers attached to same network. The problem became evident in the 1970s as large organizations began to acquire multiple networks. Each network in the organizations formed an island. In many early installations, each computer attached to a single network and employees employees was given access to multiple svreens and keyboards, and the employee was forced to move form one computer to another to send a massage across the appropriate network. Users are neither satisfied nor productive when they must use a separate computer. Consequently, most modern computer communication syetem allow communication between any two computers analogous to the way a telephone system provides communication between any two telephones. Known as universal service, the concept is a fundamental part of networking. With universal service, a user on any computer in any part of an organization can send messages or data to any other users. Furthermore, a user does not need to change computer systems whenchanging tasks—all information is available to all computers. As a result, users are more productive.The basic component used to commect organization to choose network technologies appropriate for each need, and to use routers to connect all networks into a single internet.The goal of internetworking is universal service across an internet, routers must agree to forward information from a source on one network to a specified destination on another. The task is complex because frame formats and addressing schemes used by underlying networks can differ. As s resulrt, protocol software is needed on computers and routers make universal service possible. Internet protocols overcome differences in frame formats and physical addresses to make communication pissible among networks that use different technologies.In general, internet software provides the appeatrance of a single, seamless communication system to which many computers attach. The syetem offers universal service :each computer is assigned an address, and any computer can send a packet to any other computer. Furthermore, internet protocol software —neither users nor application programs are a ware of the underlying physical networks or the routers that connect them.We say that an internet is a virtual network system because the communication system is an abstraction. That is, although a combination of of a uniform network syetem, no such network exists.Research on internetworking modern networking. In fact,internet techmology . Most large organizations already use internetworking as primary computer communication mechanism. Smaller organizations and individuals are beginning to do so as well. More inportant, the TCPIP technology computers in schools, commercial organications, government, military sites and individuals in almost all countries around the world.电脑网络简述网络可被定义为人、资源和思想的联接。

南京理工大学紫金学院毕业设计(论文)外文资料翻译系:机械系专业:车辆工程专业姓名:宋磊春学号:070102234外文出处:EDU_E_CAT_VBA_FF_V5R9(用外文写)附件:1。

外文资料翻译译文;2.外文原文.附件1:外文资料翻译译文CATIA V5 的自动化CATIA V5的自动化和脚本:在NT 和Unix上:脚本允许你用宏指令以非常简单的方式计划CATIA。

CATIA 使用在MS –VBScript中(V5.x中在NT和UNIX3。

0 )的共用部分来使得在两个平台上运行相同的宏。

在NT 平台上:自动化允许CATIA像Word/Excel或者Visual Basic程序那样与其他外用分享目标。

ATIA 能使用Word/Excel对象就像Word/Excel能使用CATIA 对象。

在Unix 平台上:CATIA将来的版本将允许从Java分享它的对象。

这将提供在Unix 和NT 之间的一个完美兼容。

CATIA V5 自动化:介绍(仅限NT)自动化允许在几个进程之间的联系:CATIA V5 在NT 上:接口COM:Visual Basic 脚本(对宏来说),Visual Basic 为应用(适合前:Word/Excel ),Visual Basic。

COM(零部件目标模型)是“微软“标准于几个应用程序之间的共享对象。

Automation 是一种“微软“技术,它使用一种解释环境中的COM对象。

ActiveX 组成部分是“微软“标准于几个应用程序之间的共享对象,即使在解释环境里。

OLE(对象的链接与嵌入)意思是资料可以在一个其他应用OLE的资料里连结并且可以被编辑的方法(在适当的位置编辑).在VBScript,VBA和Visual Basic之间的差别:Visual Basic(VB)是全部的版本。

它能产生独立的计划,它也能建立ActiveX 和服务器。

它可以被编辑。

VB中提供了一个补充文件名为“在线丛书“(VB的5。

Library of C the CNC industrialdeveloped tens of thousands and educational field, he hasNUMERICAL CONTROLNumerical Control technology as it is known today, emerged in the mid 20th century. It can be traced to the year of 1952, the U.S. Air Force, and the names of John Parsons and the Massachusetts Institute of Technology in Cam-bridge, MA, USA. It was not applied in production manu-facturing until the early 1960's. The real boom came in the form of CNC, around the year of 1972, and a decade later with the introduction of affordable micro computers. The history and development of this fascinating technology has been well documented in many publications.In the manufacturing field, and particularly in the area of metal working, Numerical Control technology has caused something of a revolution. Even in the days before comput-ers became standard fixtures in every company and in many homes, the2machine tools equipped with Numerical Control system found their special place in the machine shops. The recent evolution of micro electronics and the never ceasing computer development, including its impact on Numerical Control, has brought significant changes to the manufacturing sector in general and metalworking in-dustry in particular.DEFINITION OF NUMERICAL CONTROLIn various publications and articles, many descriptions have been used during the years, to define what Numerical Control is. It would be pointless to try to find yet another definition, just for the purpose of this handbook. Many of these definitions share the same idea, same basic concept, just use different wording.The majority of all the known definitions can be summed up into a relatively simple statement:Numerical Control can be defined as an operation of machine tools by the means of specifically coded instructions to the machine control systemThe instructions are combinations of the letters of alpha-bet, digits and selected symbols, for example, a decimal point, the percent sign or the parenthesis symbols. All in-structions are written in a logical order and a predetermined form. The collectionNUMERICAL CONTROLof all instructions necessary to ma-chine a part is called an NC Program, CNC Program, or a Part Program. Such a program can be stored for a future use and used repeatedly to achieve identical machining re-sults at any time.♦ NC and CNC TechnologyIn strict adherence to the terminology, there is a differ-ence in the meaning of the abbreviations NC and CNC. The NC stands for the older and original Numerical Control technology, whereby the abbreviation CNC stands for the newer Computerized Numerical Control technology, a modem spin-off of its older relative. However, in practice, CNC is the preferred abbreviation. To clarify the proper us-age of each term, look at the major differences between the NC and the CNC systems.Both systems perform the same tasks, namely manipula-tion of data for the purpose of machining a part. In both cases, the internal design of the control system contains the logical instructions that process the data. At this point the similarity ends. The NC system (as opposed to the CNC system) uses a fixed logical functions, those that are built-in and perma-nently wired within the control unit. These functions can-not be changed by the programmer or the machine opera-tor. Because of the fixed4wiring of the control logic, the NC control system is synonymous with the term 'hardwired'. The system can interpret a part program, but it does not al-low any changes to the program, using the control features. All required changes must be made away from the control, typically in an office environment. Also, the NC system re-quires the compulsory use of punched tapes for input of the program information.The modem CNC system, but not the old NC system, uses an internal micro processor (i.e., a computer). This computer contains memory registers storing a variety of routines that are capable of manipulating logical functions. That means the part programmer or the machine operator can change the program on the control itself (at the ma-chine), with instantaneous results. This flexibility is the greatest advantage of the CNC systems and probably the key element that contributed to such a wide use of the tech-nology in modern manufacturing. The CNC programs and the logical functions are stored on special computer chips, as software instructions, rather than used by the hardware connections, such as wires, that control the logical func-tions. In contrast to the NC system, the CNC system is syn-onymous with the term 'softwired'.NUMERICAL CONTROLWhen describing a particular subject that relates to the numerical control technology, it is customary to use either the term NC or CNC. Keep in mind that NC can also mean CNC in everyday talk, but CNC can never refer to the older technology, described in this handbook under the abbrevia-tion ofNC. The letter 'C 'stands for Computerized, and it is not applicable to the hardwired system. All control systems manufactured today are of the CNC design. Abbreviations such as C&C or C'n 'C are not correct and reflect poorly on anybody that uses them.CONVENTIONAL AMD CNC MACHININGWhat makes the CNC machining superior to the conven-tional methods? Is it superior at all? Where are the main benefits? If the CNC and the conventional machining pro-cesses are compared, a common general approach to ma-chining a part will emerge: Obtain and study the drawingSelect the most suitable machining methodDecide on the setup method (work holding)Select the cutting toolsEstablish speeds and feedsMachine the part6This basic approach is the same for both types of machin-ing. The major difference is in the way how various data are input. A feedrate of 10 inches per minute (10 in/min) is the same in manual or CNC applications, but the method of applying it is not. The same can be said about a coolant - it can be activated by turning a knob, pushing a switch or programming a special code. All these actions will result in a coolant rushing out of a nozzle. In both kinds of machin-ing, a certain amount of knowledge on the part of the user is required. After all, metal working, particularly metal cut-ting, is mainly a skill, but it is also, to a great degree, an art and a profession of large number of people. So is theappli-cation of Computerized Numerical Control. Like any skill or art or profession, mastering it to the last detail is neces-sary to be successful. It takes more than technical knowl-edge to be a CNC machinist or a CNC programmer. Work experience and intuition, and what is sometimes called a 'gut-feel', is a much needed supplement to any skill.In a conventional machining, the machine operator sets up the machine and moves each cutting tool, using one or both hands, to produce the required part. The design of a manual machine tool offers many features that help the process of machining a part -NUMERICAL CONTROLlevers, handles, gears and di-als, to name just a few. The same body motions are re-peated by the operator for every part in the batch. However, the word 'same 'in this context really means'similar 'rather than 'identical'. Humans are not capable to repeat every process exactly the same at all times - that is the job ofma-chines. People cannot work at the same performance level all the time, without a rest. All of us have some good andsome bad moments. The results of these moments, when*applied to machining a part, are difficult to predict. There will be some differences and inconsistencies within each batch of parts. The parts will not always be exactly the same. Maintaining dimensional tolerances and surface fin-ish quality are the most typical problems in conventional machining. Individual machinists may have their own time 'proven' methods, different from those of their fellow col-leagues. Combination of these and other factors create a great amount of mconsistency.The machining under numerical control does away with the majority of inconsistencies. It does not require the same physical involvement as manual machining. Numerically controlled machining does not need any levers or dials or handles, at least8not in the same sense as conventional ma-chining does. Once the part program has been proven, it can be used any number of times over, always returning consistent results. That does not mean there are no limiting factors. The cutting tools do wear out, the material blank in one batch is not identical to the material blank in another batch, the setups may vary, etc. These factors should be considered and compensated for, whenever necessary.The emergence of the numerical control technology does not mean an instant, or even a long term, demise of all man-ual machines. There are times when a traditional machin-ing method is preferable to a computerized method. For ex-ample, a simple one time job may be done more efficiently on a manual machine than a CNC machine. Certain types of machining jobs will benefit from manual or semiauto-matic machining, rather than numerically controlled ma-chining. The CNC machine tools are not meant to replace every manual machine, only to supplement them.In many instances, the decision whether certain machin-ing will be done on a CNC machine or not is based on the number of required parts and nothing else. Although the volume of partsNUMERICAL CONTROLmachined as a batch is always an important criteria, it should never be the only factor. Consideration should also be given to the part complexity, its tolerances, the required quality of surface finish, etc. Often, a single complex part will benefit from CNC machining, while fifty relatively simple parts will not.Keep in mind that numerical control has never machined a single part by itself. Numerical control is only a process or a method that enables a machine tool to be used in a pro-ductive, accurate and consistent way.NUMERICAL CONTROL ADVANTAGESWhat are the main advantages of numerical control?It is important to know which areas of machining will benefit from it and which are better done the conventional way. It is absurd to think that a two horse power CNC mill will win over jobs that are currently done on a twenty times more powerful manual mill. Equally unreasonable are ex-pectations of great improvements in cutting speeds and feedrates over a conventional machine. If the machining and tooling conditions are the same, the cutting time will be very close in both cases.Some of the major areas where the CNC user can and should expect improvement:10Setup time reductionLead time reductionAccuracy and repeatabilityContouring of complex shapesSimplified tooling and work holdingConsistent cutting timeGeneral productivity increaseEach area offers only a potential improvement. Individ-ual users will experience different levels of actual improve-ment, depending on the product manufactured on-site, the CNC machine used, the setup methods, complexity of fixturing, quality of cutting tools, management philosophy and engineering design, experience level of the workforce, individual attitudes, etc.Setup Time ReductionIn many cases, the setup time for a CNC machine can be reduced, sometimes quite dramatically. It is important to realize that setup is a manual operation, greatly dependent on the performance of CNC operator, the type of fixturing and general practices of the machine shop. Setup time is unproductive, but necessary - it is a part of the overhead costs of doing business. To keep the setupNUMERICAL CONTROLtime to a mini-mum should be one of the primary considerations of any machine shop supervisor, programmer and operator. Because of the design of CNC machines, the setup time should not be a major problem. Modular fixturing, standard tooling, fixed locators, automatic tool changing, pallets and other advanced features, make the setup time more efficient than a comparable setup of a conventional machine. With a good knowledge of modern manufacturing, productivity can be increased significantly.The number of parts machined under one setup is also important, in order to assess the cost of a setup time. If a great number of parts is machined in one setup, the setup cost per part can be very insignificant. A very similar re-duction can be achieved by grouping several different oper-ations into a single setup. Even if the setup time is longer, it may be justified when compared to the time required to setup several conventional machines.Lead Time ReductionOnce a part program is written and proven, it is ready to be Bsed again in the future, even at a short notice. Although the lead time for the first run is usually longer, it is virtually nil for any subsequent run. Even if an engineering change of the part design12requires the program to be modi tied, it can be done usually quickly, reducing the lead time.Long lead time, required to design and manufacture sev-eral special fixtures for conventional machines, can often be reduced by preparing a part program and the use of sim-plified fixturing. Accuracy and RepeatabilityThe high degree of accuracy and repeatability of modern CNC machines has been the single major benefit to many users. Whether the part program is stored on a disk or in the computer memory, or even on a tape (the original method), it always remains the same. Any program can be changed at will, but once proven, no changes are usually required any more. A given program can be reused as many times as needed, without losing a single bit of data it contains. True, program has to allow for such changeable factors as tool wear and operating temperatures, it has to be stored safely, but generally very little interference from the CNC pro-grammer or operator will be required. The high accuracy of CNC machines and their repeatability allows high quality parts to be produced consistently time after time. Contouring of Complex ShapesNUMERICAL CONTROLCNC lathes and machining centers are capable of con-touring a variety of shapes. Many CNC users acquired their machines only to be able to handle complex parts. A good examples are CNC applications in the aircraft and automo-tive industries. The use of some form of computerized pro-gramming is virtually mandatory for any three dimensional tool path generation.Complex shapes, such as molds, can be manufactured without the additional expense of making a model for trac-ing. Mirrored parts can be achieved literally at the switch of a button. Storage of programs is a lot simpler than storage of patterns, templates, wooden models, and other pattern making tools.Simplified Tooling and Work HoldingNonstandard and 'homemade' tooling that clutters the benches and drawers around a conventional machine can be eliminated by using standard tooling, specially designed for numerical control applications. Multi-step tools such as pilot drills, step drills, combination tools, counter borers and others are replaced with several individual standard tools. These tools are often cheaper and easier to replace than special and nonstandard tools.Cost-cutting measures have forced many tool suppliers to keep a low or even a nonexistent inventory, increasing the delivery lime14to the customer. Standard, off-the-shelf tooling can usually beob-tained faster then nonstandard tooling.Fixturing and work holding for CNC machines have only one major purpose - to hold the part rigidly and in the same position for all parts within a batch. Fixtures designed for CNC work do not normally require jigs, pilot holes and other hole locating aids.♦ Cutting Time and Productivity IncreaseThe cutting time on the CNC machine is commonly known as the cycle time - and is always consistent. Unlike a conventional machining, where the operator's skill, experi-ence and personal fatigue are subject to changes, the CNC machining is under the control of a computer. The small amount of manual work is restricted to the setup andload-ing and unloading the part. For large batch runs, the high cost of the unproductive time is spread among many parts, making it less significant. The main benefit of a consistent cutting time is for repetitive jobs, where the production scheduling and work allocation to individual machine tools can be done very accurately.The main reason companies often purchase CNCma-chines is strictly economic - it is a serious investment. Also, having a competitive edge is always on the mind of every plant manager. The numerical control teclmology offers excellent means to achieve a significant improvement in the manufacturing productivity and increasing the overall quality of the manufactured parts. Like any means, it has to be used wisely and knowledgeably. When more and more companies use the CNCtechnology, just having a CNC machine does not offer the extra edge anymore. Thecom-panies that get forward are those who know how to use the technology efficiently and practice it to be competitive in the global economy.To reach the goal of a major increase in productivity, it is essential that users understand the fundamental principles on which CNC technology is based. These principles take many forms, for example, understanding the electronic cir-cuitry, complex ladder diagrams, computer logic, metrol-ogy, machine design, machining principles and practices and many others. Each one has to be studied and mastered by the person in charge. In this handbook, the emphasis is on the topics that relate directly to the CNC programming and understanding the most common CNC machine tools, the Machining Centers and the lathes (sometimes also called the Turning Centers). The part quality consideration should be very important to every programmer and ma-chine tool operator and this goal is also reflected in the handbook approach as well as in the numerous examples.TYPES OF CNC MACHINE TOOLSDifferent kinds of CNCmachines cover an extremelylarge variety. Their numbersare rapidly increasing, as thetechnology developmentadvances. It is impossible toiden-tify all the applications,they would make a long list.Here is a brief list of some ofthe groups CNC machines canbe part of: *Mills and Machining centersLathes and Turning CentersDrilling machines CNC machining centers andlathes dominate the number ofinstallations in industry. Thesetwo groups share the marketjust about equally. Someindustries may have a higherneed for one group ofmachines, depending on their □ Boring mills and Profilers □ EDM machines □ Punch presses and Shears □ Flame cutting machines □ Routers □ Water jet and Laser profilers □ Cylindrical grinders □ Welding machines □ Benders, Winding and Spinning machines, etc.needs. One must remember that there are many different kinds of ladies and equally many different kinds ofma-chining centers. However, the programming process for a vertical machine is similar to the one for a horizontalma-chine or a simple CNC mill. Even between differentma-chine groups, there is a great amount of general applica-tions and the programming process is generally the same. For example, a contour milled with an end mill has a lot in common with a contour cut with a wire.♦ Mills and Machining Centers Standard number of axes on a milling machine is three - the X, Y and Z axes. The part set on a milling system is al-ways stationary, mounted on a moving machine table. The cutting tool rotates, it can move up and down (or in and out), but it does not physically follow the tool path.CNC mills - sometimes called CNC milling machines - are usually small, simple machines, without a tool changer or other automatic features. Their power rating is often quite low. In industry, they are used for toolroom work, maintenance purposes, or small part production. They are usuallydesigned for contouring, unlike CNC drills.CNC machining centers are far more popular and effi-cient than drills and mills, mainly for their flexibility. The main benefit the user gets out of a CNC machining center is the ability to group several diverse operations into a single setup. For example, drilling, boring, counter boring, tap-ping, spot facing and contour milling can be incorporated into a single CNC program. In addition, the flexibility is enhanced by automatic tool changing, using pallets to minimize idle time, indexing to a different side of the part, using a rotary movement of additional axes, and a number of other features. CNC machining centers can be equipped with special software that controls the speeds and feeds, the life of the cutting tool, automatic in-process gauging and offset adjustment and other production enhancing and time saving devices.There are two basic designs of a typical CNC machining center. They are the vertical and the horizontal machining centers. The major difference between the two types is the nature of work that can be done on them efficiently. For a vertical CNC machining center, the most suitable type of work are flat parts, either mounted to the fixture on the ta-ble, or held in a vise or a chuck. The work that requires ma-chining on two or more faces m a single setup is more de-sirable to be done on a CNC horizontal machining center. An good example is a pump housing and other cubic-like shapes. Some multi-face machining of small parts can also be done on a CNC vertical machining center equipped with a rotary table.The programming process is the same for both designs, but an additional axis (usually a B axis) is added to the hori-zontal design. This axis is either a simple positioning axis (indexing axis) for the table, or a fully rotary axis for simul-taneous contouring. This handbook concentrates on the CNC vertical ma-chining centers applications, with a special section dealing with the horizontal setup and machining. The program-ming methods are also applicable to the small CNC mills or drilling and/or tapping machines, but the programmer has to consider their restrictions.♦ Lathes and Turning CentersA CNC lathe is usually a machine tool with two axes, the vertical X axis and the horizontal Z axis. The main feature of a lathe that distinguishes it from a mill is that the part is rotating about the machine center line. In addition, the cut-ting tool is normally stationary, mounted in a sliding turret. The cutting tool follows the contour of the programmed tool path. For the CNC lathes with a milling attachment, so called live tooling, the milling tool has its own motor and rotates while the spindle is stationary.The modem lathe design can be horizontal or vertical. Horizontal type is far more common than the vertical type, but both designs have their purpose in manufacturing. Sev-eral different designs exist for either group. For example, a typical CNC lathe of the horizontal group can be designed with a flat bed or a slant bed, as a bar type, chucker type or a universal type. Added to these combinations are many ac-cessories that make a CNC lathe an extremely flexible ma-chine tool. Typically, accessories such as a tailstock, steady rests or follow-up rests, part catchers,pullout-fingers and even a third axis milling attachment are popular compo-nents of the CNC lathe. ?CNC lathe can be veiy versatile - so versatile in fact, that it is often called a CNC TurningCenter. All text and program examples in this handbook use the more traditional term CNC lathe, yet still recogniz-ing all its modern functions.中文翻译:数控正如我们现在所知,数控技术出现于20世纪中叶。

Optimum blank design of an automobile sub-frameJong-Yop Kim a ,Naksoo Kim a,*,Man-Sung Huh baDepartment of Mechanical Engineering,Sogang University,Shinsu-dong 1,Mapo-ku,Seoul 121-742,South KoreabHwa-shin Corporation,Young-chun,Kyung-buk,770-140,South KoreaReceived 17July 1998AbstractA roll-back method is proposed to predict the optimum initial blank shape in the sheet metal forming process.The method takes the difference between the ®nal deformed shape and the target contour shape into account.Based on the method,a computer program composed of a blank design module,an FE-analysis program and a mesh generation module is developed.The roll-back method is applied to the drawing of a square cup with the ¯ange of uniform size around its periphery,to con®rm its validity.Good agreement is recognized between the numerical results and the published results for initial blank shape and thickness strain distribution.The optimum blank shapes for two parts of an automobile sub-frame are designed.Both the thickness distribution and the level of punch load are improved with the designed blank.Also,the method is applied to design the weld line in a tailor-welded blank.It is concluded that the roll-back method is an effective and convenient method for an optimum blank shape design.#2000Elsevier Science S.A.All rights reserved.Keywords:Blank design;Sheet metal forming;Finite element method;Roll-back method1.IntroductionIt is important to determine the optimum blank shape of a sheet metal part.However,because its deformation during the forming process is very complicated,it is not easy to design the optimum blank shape even by the skilled labor based on the experience of many years.Recently,computa-tional analysis for a complex automobile part has been able to be carried out easily due to improved computer perfor-mance and the numerical analysis technique.In the analysis process,all kinds of variables that affect the deformation should be considered.The optimum blank shape leads to the prevention of tearing,uniform thickness distribution and to the reduction of the press load during drawing.If the blank shape is designed optimally,the formability will be increased and the ®nal product will require the least amount of trimming at the end of the process.Therefore,it is desirable to design the blank shape with a uniform ¯ange of its periphery after deep drawing.Several numerical solutions for the deep drawing process of non-circular components have been reported.Hasek and Lange [1]gave an analytical solution to this problem usingthe slip-line ®eld-method with the assumption of plane-strain ¯ange deformation.Also,Jimma [2]and Karima [3]used the same method.V ogel and Lee [4]and Chen and Sowerby [5]developed ideal blank shapes by the method of plane-stress characteristics.Sowerby et al.[6]developed a geometric mapping method providing a trans-formation between a ¯at sheet and the ®nal surface.Majlessi and Lee [7,8]developed a multi-stage sheet metal forming analysis method.Chung and Richmond [9±12]determined ideal con®gurations for both the initial and the intermediate stages that are required to form a speci®ed ®nal shape using the ideal forming theory.Lee and Huh [13]introduced a three-dimensional multi-step inverse method for the optimum design of blank shapes.Toh and Kobayashi [14]developed a rigid±plastic ®nite-element method for the drawing of general shapes based on membrane theory and ®nite-strain formulations.Zhaotao [15]used the boundary element method for a 2D potential problem to design optimum blank shapes.This paper presents an optimum design method of blank shapes for the square cup drawing process considering process variables.An optimum blank shape of square cup drawing was obtained using the proposed method.Also,it was applied to the deep drawing of an automobile sub-frame,and an optimum blank shape with a uniform ¯ange at its periphery weredetermined.Journal of Materials Processing Technology 101(2000)31±43*Corresponding author.Tel.: 82-2-705-8635;fax: 82-2-712-0799.E-mail address :nskim@ccs.sogang.ac.kr (Naksoo Kim)0924-0136/00/$±see front matter #2000Elsevier Science S.A.All rights reserved.PII:S 0924-0136(99)00436-72.Design of optimum blank shapeThe de®nition of the optimum blank shape is the mini-mization of the difference between the outer contour of the deformed blank and the target contour that indicates the residual ¯ange of uniform size around the periphery of the product.The target contour is generated from the outer contour of the product and determines an optimum blank shape using the results of ®nite-element simulation with the roll-back method.In the process of blank design the simula-tion is performed using an explicit ®nite-element software PAM-STAMP and the interface program is developed for con-necting the blank design module,the remeshing module,the post-processor module and the FE-analysis package.2.1.Roll-back method`The roll-back method starts by de®ning the target con-tour.After determining the length of the ¯ange that remains around the periphery of the product,the pro®le of the target contour is created by offsetting an equal distance from the outer contour of the product and its mesh system is gener-ated by beam elements.The process of blank design is illustrated in Fig.1.The mesh system of the prepared square blank for initial analysis is shown in Fig.1(a).After an analysis,the mesh system of the deformed blank and the target contour are shown in Fig.1(b).At the ¯ange of the deformed blank,a distinction is made between the interior ¯ange within the target contour and the exterior ¯ange out ofthe target contour.The ¯ange out of the target contour is the part that will be trimmed and the ¯ange within the target contour is the part which does not keep shape is due to the incompletion of the blank shape.Thus the modi®ed blank shape should be designed to take the shape of the outer contour of the product completely.The contour of the modi®ed blank shape using the roll-back method and the initial blank shape is shown in Fig.1(c).The mesh system of the modi®ed blank shape for FE-analysis is shown in Fig.1(d).The blank design method will be introduced in detail.The quarter of the deformed blank and the target contour are shown in Fig.2(a).According to the previous explanation,the remained ¯ange can be divided into the interior and the exterior ¯ange.The design process of region A is shown in Fig.2(b).In the mesh of the deformed blank a square grid IJKL on the target contour will be considered,and then the internal dividing point Q in will be calculated at the ratio of m tonFig.1.Illustrating the process of ®nding the optimum blank:(a)initial blank shape;(b)deformed blank and target contour;(c)roll-back blank and contour;(d)modi®ed blankshape.Fig.2.The roll-back process of a mesh located on the surface of the ¯ange:(a)a mesh located on the surface of the ¯ange;(b)region A:residual drawing part out of target contour;(c)region B:residual drawing part inside the target contour.32J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43between the node J and K.This point is mapped back into the mesh system of the initial blank.The internal dividing point Q H in is calculated at the ratio of m to n between the same node J H and K H.The following process is performed on the element of the deformed blank on the target contour.The describing point of the outer contour of the modi®ed blank shape can be calculated.If the coordinates of the nodes J and K are J(x1,y1),K(x2,y2)and the coordinates of the nodes J H and K H are J H x H1Y y H1 Y K H x H2Y y H2 ,the ratio of m to n ism X n JQJKX QKJK(1)The coordinate of the internal dividing point Q H in can be expressed asQ H inmx H2 nx H1m nYmy H2 ny H1m n(2)The design process of region B is shown in Fig.2(c).In the mesh of the deformed blank a square grid MNOP of which the outward edge crosses the target contour should be considered,and then the external dividing point Q out can be calculated at the ratio of m to n between nodes O and P.This point is mapped back into the mesh system of the initial blank.The external dividing point Q H out can be calculated at the ratio of m to n between the same nodes Q H and P H.If the coordinates of the nodes O and P are O(x1,y1),P(x2,y2)and the coordinates of the O H and P H are O H x H1Y y H1 Y P H x H2Y y H2 ,the ratio of m to n ism X n OQOPX QPOP(3)The coordinate of the external dividing point Q H out can be expressed asQ H outmx H2Ànx H1Ymy H2Àny H1(4)The following process is performed on all the element of the deformed blank related on the target contour.The points describing the outer contour of modi®ed blank shape can be calculated.When all points of two cases are connected by the spline,the outer contour of modi®ed blank can be described.This process is shown in Fig.3.2.2.The development of the optimum blank design programTo optimize the initial blank shape,a design program was developed following the prescribing method and procedures. This program consists of the blank shaper design module, the mesh generation module and the post-processor module. The whole procedure is illustrated in Fig.4.To perform the design process of a blank shape,an interface module is needed.This module is developed to read the output®le of ®nite-element analysis and design the optimum blank shape and generate the input®le.3.Designs of blank shape and application3.1.Blank design of a square cupTo verify the validity of the roll-back method,it is applied to the process of square cup deep drawing.Several numerical solutions of the deep drawing process for non-circular components have been reported recently.The pub-lished blank shapes by Lee and coworkers[16±18]are compared with the resultusing the roll-back method.The Fig.3.Flowchart of the blank design module.Fig.4.Flow chart of the main program.J.-Y.Kim et al./Journal of Materials Processing Technology101(2000)31±4333dimensions of the die and punch set for an analysis are shown in Fig.5.The material of the sheet metal is cold-rolled steel for an automobile part.The following are the material propertiesand process variables.Stress±strain relation:"s58X 78Â 0X 00003 "e0X 274 kgf a mm 2 ;Lankford value:"R 1X 679;initial blank size:160mm Â160mm square blank;initial thickness:t 0.69mm;friction coef®cient:m 0.123;and blank-holding force:4000kgf (1kgf 9.81N).The deformed shapes of the square cup obtained from the initial blank and the optimum blank are shown in Fig.6.Inthe present work the optimum blank shape for a square cup that is of 40mm height and 5mm width of ¯ange will be determined.Each modi®ed blank shape after the application of the roll-back method is illustrated in Fig.7.When an 160mm Â160mm square blank is used for an initial blank the outer contour of deformed blank is shown in Fig.7(a).A ®rst modi®ed blank shape can be calculated with the result of the initial square blank.An analysis result is shown in Fig.7(b).The difference between the deformed shape and the target contour is signi®cant.If the blank design process is repeated several times the difference decreases and con-verges to zero.Hence a square cup with a uniform ¯ange at its periphery can be made.The comparison between the ®nal result and a published result is shown in Fig.8.In the transverse direction the optimum blank shape using the roll-back method is larger than the published result.The load±displacement curves in square cup drawing process with various initial blank shapes are shown in Fig.9.As the modi®cation is repeated,the gap of the load±displacement curves before and after iteration decreases.Thus after the third modi®cation the maximum value of the load becomes the mean value between that of the ®rst and second modi®cation.After three modi®cations the optimum blank shape is determined,then the result with the optimum blank shape is compared with results in the literature.The thickness strain distribution in the diagonal direction is shown in Fig.10(a),whilst the thickness strain distribution in the transverse direction is shown in Fig.10(b).In the thickness strain distribution the result using the roll-back method is slightly different from the published result,but the overall strain distributions are quite similar.It is thus veri®ed that the roll-back method is a useful approach in the design of optimum blank shapes.3.2.Blank design of the left member of a front sub-frameAn analysis for members of a box-type front sub-frame is performed.The left member is selected as one of the subjects for analysis because its shape is shallow but complex.Fig.11shows the manufacturing set-up as modeled for the numer-ical simulation.The left member requires a uniform ¯ange for the spot welding between the upper and the lower parts besides the improvement of formability.It is recommended that the length of uniform ¯ange is 30mm.The target contour is de®ned at the position which is 30mm from the outer contour of product and is shown in Fig.12.Its mesh system is generated by beam elements.The material of the sheet metal is SAPH38P,a hot-rolled steel for automobile parts.The following are the material properties and process variables.Stress±strain relationship:"s 629Â"e 0X 274(MPa);Lankford value:"R1X 030;initial thickness:t 2.3mm;friction coef®cient:m 0.1;blank holding pressure:1MPa.Fig.5.Geometrical description of the tooling for the deep drawing of a square cup (dimensions:mm).Fig.6.The deformed shape of square cups with FE-mesh geometry where the cup height is 40mm:(a)deformed shape of the square cup obtained from the initial blank;(b)deformed shape of the square cup obtained from the optimum blank.34J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43A hexagonal blank is used as the initial blank.After three modi®cations the optimum blank shape is determined.For this case,the load±displacement curves with various blank shapes are shown in Fig.13.The comparison of the initial ¯ange and the deformed ¯ange with various blank shapes is shown in Fig.14.As the modi®cation is repeated,the maximum punch load is reduced and the outer contour may be drawn to the target contour at the same time.The thickness distribution is improved step by step;the thickness distribution with various blank shapes being shown in Fig.15.The comparison between the optimum blank shape designed by the roll-back method and the blank shape for mass production is illustrated in Fig.16.The optimum blank shape shows curvature because the outer contour of the product and the ¯ow rate of the sheet metal are considered.However,the blank shape for mass production is simple and straight because the convenience of cutting is considered.To verify the result an initial blank cut by a laser-cutting machine was prepared.The ®nal shape drawn with the initial blank in the press shop isshownparison of the initial ¯ange shapes and the deformed ¯ange shapes:(a)initial square blank;(b)®rst modi®ed blank;(c)second modi®ed blank;(d)third modi®edblank.parison of the initial blank contour between the roll-back method and Huh's method.J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±4335in Fig.17.It had a ¯ange of uniform size around its periphery.The thickness distribution at the position of four sections in the longitudinal direction of the left member was mea-sured.Fig.18shows a comparison of thickness between the computed results and the experimental results in each sec-tion.In section A,the thickness distribution has some error at the end of the ¯ange,whilst in sections B and C,the computed results are compatible with the experimentalresults.In section D,the computed results predicted that a split might happen,but the experimental cup did notsplit.Fig.9.Load±displacement curves in the square cup drawing process with various initial blankshapes.Fig.10.Thickness strain distribution in a square cup:(a)diagonal direction;(b)transversedirection.Fig.11.FE-model for a sub-frame left member.36J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43If the initial blank shape,the ®nal shape and thickness distribution are considered,the results predicted by the roll-back method has a good agreement with the experimental values.Therefore,as well as the roll-back method being applicable to a simple shape,it can be applied to a complex and large shape.3.3.Blank design of No.2member of front sub-frame An analysis of No.2member is performed,with its deep and complex shape.Its optimum blank shape is designed using the roll-back method.Fig.19shows the manufacturing set-up as modeled for the numerical simulation.Because its drawing depth is very deep,eccentricity may occur due to the blank initial position or shape.Thus the target contour is de®ned at the position that is 40mm from the outer contour of product and it is shown in Fig.20.A square blank is used as the initial blank.After three modi®cations the optimum blank shape isdetermined.Fig.12.Target contour for the leftmember.Fig.13.Load±displacement curves in the left member drawing process with various blankshapes.parison of the initial ¯ange shapes and the deformed ¯ange shapes:(a)initial blank;(b)®rst modi®ed blank;(c)second modi®ed blank;(d)third modi®ed blank.J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±4337Fig.15.Thickness distribution with various blank shapes (unit:mm):(a)initial blank;(b)®rst modi®ed blank;(c)second modi®ed blank;(d)third modi®edblank.parison of the initial blank shapes predicted by the roll-back method and those designed by skilled labor.38J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43For this case,load±displacement curves for various blank shapes are shown in Fig.21,whilst a comparison of the initial ¯ange and the deformed ¯ange with various blank shapes in shown in Fig.22.The thickness distribution with the initial shape is shown in Fig.23,whilst the thickness distribution with the optimum blank shape is shown in Fig.24.The thickness distribution of the side-wall and of the ®llet connecting the side-wall to the top isimproved.Fig.17.Left member drawn in the press shop with the initial blank predicted by the roll-backmethod.Fig.18.(a)Sections for measuring the thickness distribution.(b±e)Thickness distributions at sections A±D,respectively.J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43393.4.Design of the welding line with TWB analysis of No.2memberAfter designing the optimum blank shape of No.2member,a tailor-welded blank is applied to this member.To reduce the weight of the sub-frame,structural analysis is performed.On the area where the stress intensity level is low,it is proposed to reduce the thickness locally.Therefore,it is required to design a tailor-welded blank that makes a speci®ed shape after deformation.When two sheet metals of different thickness are welded together,their metal ¯ow is different from that of sheet metal of the same thickness.Thus it is dif®cult to design the location of the weld line.In this simulation the weld line is designed by the use of the roll-back method and the welding line should be located at the speci®ed position after deformation:the speci®ed position is 120mm on both sides of the centerline.Thus the target line is de®ned and meshed by beam elements.The outer contour of TWB and the welding line are shown in Fig.25,and the results are shown in Figs.26and 27.The welding lines can be reached to the target line but,on the top of the blank that has the lower thickness,fracture may occur.This is the same as the result that in the deep drawing of a tailor-welded blank with different thickness,failure occurred at the ¯at bottom of the punch parallel to the weld line.This is due to the deformation not beingdis-Fig.19.FE-model for the sub-frame leftmember.Fig.20.Target contour for the No.2member.Fig.21.Load±displacement curves in the No.2member drawing process with various blank shapes.40J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43parison of the initial¯ange shapes and the deformed¯ange shapes:(a)initial blank;(b)®rst modi®ed blank;(c)second modi®ed blank;(d)third modi®edblank.Fig.23.Thickness distribution with the initial blank shape(unit:mm):(a)front view;(b)rearview.Fig.24.Thickness distribution with the optimum blank shape(unit:mm):(a)front view;(b)rearview.parison of the weld line between the initial blank shape andthe deformed blank shape.J.-Y.Kim et al./Journal of Materials Processing Technology101(2000)31±4341tributed uniformly,most of the stretching being concentrated on the side of the blank with lower strength.The process condition without fracture should be determined for the combination of the drawing depth and the two different thickness as shown in Fig.28.4.ConclusionsIn this paper the roll-back method that designs an opti-mum blank shape is proposed.Based on the method,a computer program composed of a blank design module,an FE-analysis program and a mesh generation module is developed and it is applied to the deep drawing of a front sub-frame.The results of the present paper are summarized as follows:1.To verify the validity of the proposed method it is applied to the deep drawing of a square cup.The outer contour may be drawn to the target contour.2.The roll-back method is applied to the optimum blank design of a left member of an automobile sub-frame.The thickness distribution and the load level are improved.When the initial blank shape,the ®nal shape and thickness distribution are compared,the results predicted by the roll-back method have a good agreement with the experimental results.It is concluded that this method can be applied to the deep drawing of the complex automobile parts.3.The analysis of No.2member with a tailor-welded blank is performed.The position of welding lines on the initial blank is designed.The roll-back method can be applied to the design of the welding line position.4.In most cases,the edge of blank takes the shape of the target contour within a few iterations,which shows that the roll-back method is an effective and convenient method for an optimum blank shape design.References[1]V .V .Hasek,nge,Use of slip line ®eld method in deep drawingof large irregular shaped components,Proceedings of the Seventh NAMRC,Ann Arbor,MI,1979,pp.65±71.[2]T.Jimma,Deep drawing convex polygon shell researches on the deepdrawing of sheet metal by the slip line theory.First report,Jpn.Soc.Tech.Plasticity 11(116)(1970)653±670.[3]M.Karima,Blank development and tooling design for drawn partsusing a modi®ed slip line ®eld based approach,ASME Trans.11(1989)345±350.[4]J.H.V ogel,D.Lee,An analysis method for deep drawing processdesign,Int.J.Mech.Sci.32(1990)891.[5]X.Chen,R.Sowerby,The development of ideas blank shapes by themethod of plane stress characteristics,Int.J.Mech.Sci.34(2)(1992)159±166.[6]R.Sowerby,J.L.Duncan,E.Chu,The modelling of sheet metalstamping,Int.J.Mech.Sci.28(7)(1986)415±430.[7]S.A.Majlessi,D.Lee,Further development of sheet metal forminganalysis method,ASME Trans.109(1987)330±337.[8]S.A.Majlessi,D.Lee,Development of multistage sheet metalforming analysis method,J.Mater.Shap.Technol.6(1)(1988)41±54.[9]K.Chung,O.Richmond,Ideal forming-I.Homogeneous deformationwith minimum plastic work,Int.J.Mech.Sci.34(7)(1992)575±591.[10]K.Chung,O.Richmond,Ideal forming-II.Sheet forming withoptimum deformation,Int.J.Mech.Sci.34(8)(1992)617±633.Fig.26.Deformed shape of No.2member with the tailor-weldedblank.Fig.27.Deformed shape of No.2member with the tailor-welded blank:(a)front view;(b)rearview.Fig.28.Thickness distribution with the tailor-welded blank (unit:mm):(a)front view;(b)rear view.42J.-Y.Kim et al./Journal of Materials Processing Technology 101(2000)31±43[11]K.Chung,O.Richmond,Sheet forming process design based onideal forming theory,Proceedings of the Fourth International Conference on NUMIFORM,1992,pp.455±460.[12]K.Chung,O.Richmond,The mechanics of ideal forming,ASMETrans.61(1994)176±181.[13]C.H.Lee,H.Huh,Blank design and strain prediction of automobilestamping parts by and inverse®nite element approach,J.Mater.Process.Technol.63(1997)645±650.[14]C.H.Toh,S.Kobayashi,Deformation analysis and blank design insquare cup drawing,Int.J.Mech.Tool Des.Res.25(1)(1985)15±32.[15]Z.Zhatao,L.Bingwen,Determination of blank shapes for drawingirregular cups using and electrical analogue methods,Int.J.Mech.Sci.28(8)(1986)499±503.[16]H.Huh,S.S.Han,Analysis of square cup deep drawing from twotypes of blanks with a modi®ed membrane®nite element method, Trans.KSME18(10)(1994)2653±2663.[17]C.H.Lee,H.Huh,Blank design and strain prediction in sheet metalforming process,Trans.KSME A20(6)(1996)1810±1818. [18]C.H.Lee,H.Huh,Three-dimensional multi-step inverse analysis foroptimum design of initial blank in sheet metal forming,Trans.KSME A21(12)(1997)2055±2067.J.-Y.Kim et al./Journal of Materials Processing Technology101(2000)31±4343。