非接触温度计)

- 格式:doc

- 大小:137.00 KB

- 文档页数:9

RAYMT4U RAYST80XBUS RAYMT4U.Infrared Sensorsproduct directly, instead of the oven or the dryer. This allows you to quickly adjust to process parameters to ensure top product quality. Infrared thermometers are easily integrated into existing process control systems and have the following benefits:•Non-destructive: the product is never touched or contaminated •Fast and reliable: moving objects are measured accurately and quickly•Flexible: temperature measurements can be made of a large area or a small spotSmall Size, Big FeaturesThese products may be compact, but do not compromise on features. Using advanced micro-fabrication techniques, the cost and size of these sensors remain small while retaining sophisticated features such as emissivity, signal conditioning and t-ambient processing.The wide temperature range in each model allows you to detect process variations and monitor start-up performance.Infrared ThermocouplesIf you are looking for a low-maintenance solution for infrared thermocouples, consider the MI™ or CI™. The MI™, a two-piece system with miniature sensing head and separate electronics, features adjustable emissivity and selectable peak hold, valley hold and averaging.ambient temperatures.An Affordable Solution forYour ProcessThe miniature size and low cost ofthe MI™ (shown above) make it anideal configuration for installation atmultiple points along your process.The sensor is isolated from theelectronics box which allows itto withstand ambient temperaturesup to 200°C (392°F) with coolingaccessories.Whether you choose a modular systembased on the GP™ monitor, or theMI™ or CI™, we have a compact,value-priced infrared thermometer tomeet your needs. Cooling jackets, airpurge collars and other accessoriesare available to ensure accurateperformance regardless of yourenvironment.Raytek®Service Ensures LongUseRaytek®knows infrared temperaturemeasurement. Applicationspecialists are available to helpanswer your technical questions.Each product includes a two yearwarranty. In addition, maintenance,training, calibration and othercustomized services are available toensure that you receive themaximum benefits from your Raytek®infrared, noncontact thermometer.For more information on Raytek®infrared temperature measurementsolutions, contact your Watlow salesagent or applications specialisttoday.*Must specify at time of order.Raytek®is a registered trademark of the Raytek Corporation. MiniTemp™, STProPlus™, GP™, CI™ and MI™ are trademarks of Raytek Corporation.113Infrared Sensors Raytek®Family Product Offering114115Infrared SensorsInfrared SensorsHand HeldMiniTemp™The Raytek ®MiniTemp™ is pocket-sized and easy to use—just point,shoot and read the temperature on the large backlit display. When you need a fast, easy and safe way to measure surface temperature, you need a MiniTemp™ noncontact thermometer. Use MiniTemp™ at work, at home, anywhere.Choice of ModelsChoose between MiniTemp™ MT2, no laser sighting, or MiniTemp™MT4, with laser sighting. Bothmodels are powered by a 9V battery and display temperatures in either °C or °F. An accessory packincluding a pouch and wrist strap is also available.Applications•Blown film extrusion•Cast film extrusion•Originally oriented film extrusion •Sheet extrusion •Extrusion coating•Laminating and bossing •ThermoformingOptions/Accessories Soft Pouch with Wrist StrapD:S = 8:1 at focal pointTarget Spot Sizes**U.S. only. Warranty duration may vary by country.Infrared SensorsHand HeldST Pro™20 XBChoose the ST Pro™ XB when youneed a dependable professional toolfor day-to-day applications. Youwon’t find other noncontactthermometers with the temperaturerange, ability to measure so small anarea and comparable laser sightingat this price. Simply point, shoot andread.With a wide temperature range, MAXtemperature display and choice oflaser sighting options, the ST Pro™makes temperature measurement abreeze. The ST20XB featuresrugged rubber overmolding and theability to be tripod mounted.Choose the infrared noncontactthermometer that millions ofprofessionals use worldwide. Calltoday and discover the advantage—fast, easy and safe temperaturemeasurement backed by over 40years of experience.Raytek®Infrared NoncontactThermometers are theprofessional’s choice for:•Blown film extrusion•Cast film extrusion •Originally oriented film extrusion •Sheet extrusion •Extrusion coating •Laminating and bossing •Thermoforming •Hazardous locations (ST80-IS)116Infrared Sensors*U.S. only. Warranty duration may vary by country.117Infrared Sensors Hand HeldST ProPlus™60/80 XBWhen you need more features and higher specifications, choose the ProPlus™ for your most demanding applications. Advanced infrared technology for reading higher temperatures and powerful optics for measuring smaller areas (or from farther back), make the ProPlus™the professional’s choice for noncontact temperature measure-ment. Whether you choose the ST60 or the ST80, gathering temperature data has never been easier. Simply point, shoot and read.Innovative features like extra bright laser sighting, adjustable emissivity, a wide temperature range and 12 point data logging, make any temperature measurementapplication a snap. This rugged unit with rubber overmolding also includes a jack for the optional Raytek®ST RTD temperature probe, and can be tripod mounted for hands-free operation. The ST80 is also available in a model rated “Intrinsically Safe” by Factory Mutual Research for use in hazardous locations.Raytek®Infrared NoncontactThermometers are theprofessional’s choice for:•Blown film extrusion•Cast film extrusion•Originally oriented film extrusion•Sheet extrusion•Extrusion coating•Laminating and bossing•Thermoforming•Hazardous locations (ST80-IS)Options/Accessories•RTD temperature probe•Nylon holster•NIST traceable calibrationcertificate•Factory Mutual ResearchIntrinsically Safe Rated ST80-IS,including probe (Intrinsically Safe,Class 1 Division 1 GroupsA,B,C,D Class I, Zone 0, AEx iaIIC, T4 at 50°C (122°F) when usedwith 9V alkaline battery)118Infrared Sensors*Approved by Factory Mutual Research for use in hazardous locations.**For more information on emissivity, or for unique applications visit /emissivity.htm119Infrared SensorsFixed MountRaytek®GP™SensorThe GP™ sensor is a versatile, two-piece temperature monitoring system which combines a compact, value-priced monitor with an infrared sensing head. The heart of the system is the 1⁄8DIN GP™ monitor which provides advanced infrared processing capabilities including peak and valley hold, averaging and a user-adjustable offset. The rugged GPR sensor is available with standard- or close-focus optics and provides target temperature readings with one percent accuracy. Along with its large four-digit LED display, the monitor provides a user-defined 4-20mA or thermocouple output. Two adjustable set points/ deadbands control 5V alarm outputs or optional 3A mechanical relays. The GP monitor accepts universal 110-220VÅ(ac) power and provides a 24VÎ(dc)/50mA excitation voltage for loop power to external sensors. All monitor functions are configured via the front panel, including °C/°F switching.The GP™ monitor provides adjustable emissivity when used with the GPR™ infrared sensor. This high performance, eight to 14 micron infrared sensor with detachable cable combines current loop driven signals with 35:1 optics.The GP™ monitor also works with other Raytek®infrared sensors,including the CI™ and MID™.Highlights• Temperature range from -18 to538°C (0 to 1000°F)•Compact 1⁄8DIN digital monitorwith large four-digit display•Monitor and sensor functionsconfigured on front panel•Signal processing capabilitiestypically found on much largersystems•Adjustable emissivity•Universal 110-220VÅ(ac) power•User-defined 4-20mA or thermo-couple output (J,K,E,N,R,S,T)•Adjustable dual set points anddeadband alarm outputs•Choice of sensing head to matchapplication requirements•Standard- and close-focus opticsavailable•Accessories for cooling and airpurging•Field interchangeable sensingheadsAccessories/Options:•Cooling housings for high ambientconditions•Air purge fittings for sensingheads•Adjustable mounting brackets andadapters•External isolated solid state relaysfor alarm outputs (10 Amp AC)•3A mechanical output relays120Infrared Sensors*GPR rated with adapter and compression fitting.121Infrared Sensors Fixed MountRaytek®GP™MonitorThe GP™ monitor provides a compact, easy-to-use interface and display for process instruments. This low-cost 1⁄8DIN digital panel meter comes standard with features which are optional on other panel meters in this price range. The GP™monitor accepts inputs from any0-5V sensor, 4-20mA sensor or thermocouple type J,K,E,N,R,S,T. In addition, the monitor can be used with many Raytek®noncontact, infrared temperature sensors. Along with it’s large four-digit LED display, the monitor provides a user-defined 4-20mA or thermo-couple output. Two adjustable set points/deadbands control 5V alarm outputs or optional 3A mechanicalrelays. The GP™monitor accepts 110-220VÅ(ac) power and provides a 24VÎ(dc)/50 mA excitation voltage, capable of providing loop power to external sensors.For signal processing requirements, the monitor provides peak hold, valley hold and averaging and a user adjustable offset. Best of all, there are no internal jumpers used for setup, as all monitor functions are configured via the front panel. Versatile. Compact. Value-priced. All reasons to standardize on the GP™ monitor for your process monitoring requirements.Highlights• Accepts any 0-5V or 4-20mAsensor input• Accepts Type J, K, E, N, R, S, Tthermocouple inputs•Compact 1⁄8DIN monitor•Large four-digit LED display•Universal 110/220VÅ(ac) power•Provides 24VÎ(dc) / 50mAexcitation voltage•User defined 4-20mA or thermo-couple output (J,K,E,N,R,S,T)•Adjustable dual set points anddeadband controlling alarmoutputs•Signal processing: peak hold,valley hold, averaging•User adjustable offset•External reset input122Infrared Sensors123Infrared Sensors Fixed MountRaytek®MI™Temperature Measurement SystemThe MI™ product is a two-piece infrared temperature measurement system with miniature sensing head and separate electronics. The sensor is small enough to be installed just about anywhere, yet performs as well as much larger systems. The MI™ electronics include a host of signal processing features which you won’t normally find in systems in this price range, including emissivity, peak hold, valley hold and averaging, all of which are adjustable on the five-digit LCD interface.Designed for applications where the target temperature is in the -40 to 600°C (-40 to 1112°F) range, the sensor is housed in a rugged stainless steel enclosure to ensure long term performance, even in harsh industrial environments with ambient temperatures up to 85°C (185°F) without cooling.Although the MI™ system is small in size, it still has the features you need, with one percent accuracy and 10:1 optics, with user selectable output signals. And the MI’s™response time is as fast or faster than many high-end systems.The MI’s™ system’s miniature size and low cost make it ideal for installation at multiple points along your process. Accurate. Easy to install. Affordable. With the MI™system, precision infrared temperature measurement is now aneconomical alternative.Highlights• Small sensing head fits whereother sensors cannot•Ambient operating range to 85°C(185°F) without cooling•Five-digit backlit LCD interface•Adjustable emissivity, peak hold,valley hold and averaging•One percent accuracy from -40 to600°C (-40 to 1112°F)•10:1 optics•Powered by 12-24VÎ(dc) at 100mA•Accessories for cooling and airpurging•Remote electronics box•User selectable output signals•Optional RS232 or RS485communication124125Infrared Sensorsmounting nut, 3.2 ft (1 m) of cable,die-cast housing with premounted electronics, and an operator’s manual.•Adjustable or fixed mounting bracket•Air purge jacket•Air cooling/purging system •Longer cable: 9.8 ft (3 m)*•RS232 or RS485 communication**Must be specified at time of orderEnvironmental rating NEMA-4 (IP 65)Ambient temperature range Sensing head 0 to 85°C (32 to 185°F)With air cooling -18 to 200°C (0 to 392°F)Electronics housing 0 to 65°C (32 to 150)Storage temperature -18 to 85°C (0 to 185°F)Relative humidity 10 to 95% non-condensing Construction Sensing headStainless steel Electronics housing Zinc, die-cast WeightSensing head (w/1 m cable) 1.75 oz (50 g)Electronics housing9.5 oz (270 g)General SpecificationsInfrared SensorsFixed MountRaytek®CI™SensorThe CI™ sensor provides the advantages of infrared temperature measurement in a compact, low cost integrated sensor. Designed for easy integration into a standard four-wire system, the CI™ sensor can easily replace traditional contact probes with a Type J or Type K thermocouple output, or with a 0-5 volt output if your application is susceptible to noise or requires a longer cable run.The CI™ sensor is designed to measure target temperatures ranging from 0 to 500°C (32 to 932°F). The CI’s™ onboard electronics are protected by a rugged IP 65 (NEMA-4) stainless steel housing and the sensor can function in ambient temperatures to 70°C (160°F) without cooling. With water cooling, the CI™sensor can withstand ambient temperatures to 260°C (500°F). Because the CI™ sensor has the same 50 ohm output impedance as a thermocouple, it functions accurately—without offset errors—when used in conjunction with the thermocouple break protection circuitry in most controllers, displays, and transmitters.Compact. Easy to install. Affordable. The CI™ sensor is ideal for bothOEM and end-user applications.Highlights• Type J or K, or 0-5V output•Two models cover temperatureranges from 0 to 500°C (32 to932°F)•IP 65 (NEMA-4) stainless steelelectronics housing•4:1 optics at 90 percent energy•350 mSec (95 percent) responsetime•Powered by 12-24VÎ(dc) at20mA•Accessories for cooling and airpurging126Infrared Sensors127N o t e sRAYMT4U RAYST80XBUS RAYMT4U.。

温度测量仪表的分类温度测量仪表按测温方式可分为接触式和非接触式两大类。

通常来说接触式测温仪表比较简单、可靠,测量精度较高;但受耐高温材料的限制,不能应用于很高的温度测量。

非接触式仪表测温是通过热辐射原理来测量温度的,测温元件不需与被测介质接触,测温范围广,不受测温上限的限制,也不会破坏被测物体的温度场,反应速度一般也比较快;但受到物体的发射率、测量距离、烟尘和水气等外界因素的影响,其测量误差较大。

按工作原理分为膨胀式、电阻式、热电式,辐射式。

玻璃管温度计是根据液体热膨胀原理测温,双金属温度计是根据固体热膨胀原理测温,热电阻根据热阻效应原理测温,热电偶根据热电效应原理测温,辐射高温计根据热辐射原理测温。

一、热电偶热电偶是工业上最常用的温度检测元件之一。

其优点是:①测量精度高、热惯性小。

因热电偶直接与被测对象接触,不受中间介质的影响。

②测量范围广。

常用的热电偶从-50~+1600℃均可边续测量,某些特殊热电偶最低可测到-269℃(如金铁镍铬),最高可达+2800℃(如钨-铼)。

③构造简单,使用方便。

④输出信号为电信号,便于远传。

1.热电偶测温基本原理将两种不同材料的导体或半导体A和B焊接起来,构成一个闭合回路,当导体A和B的两个执着点1和2之间存在温差时,两者之间便产生电动势,因而在回路中形成一个电流,这种现象称为热电效应。

热电偶就是利用这一效应来工S、B、E、K、R、J、T七种标准化热电偶为我国统一设计型热电偶。

工业用热电偶的测温范围见下表:在使用热电偶补偿导线时必须注意型号相配,极性不能接错,补偿导线与热电偶连接端的温度不能超过100℃,B偶不用补偿导线,用普通的屏蔽线。

2、热电偶的结构一般由热电极、绝缘套管、保护管、接线盒组成。

普通型热电偶按其安装时的固定形式可分为固定螺纹连接、固定法兰连接、活动法兰连接无固定装置等多种形式。

热电极:一般金属Φ0.5~3.2mm,昂贵金属Φ0.3~0.6mm,长度与被测物质有关,一般为300~2000mm,通常在350mm左右;绝缘管:隔离热电偶与被测物,一般在室温下要5MΩ左右;保护套管:避免受被测介质的化学腐蚀和机械损伤;接线盒:固定接线座,连接补偿导线。

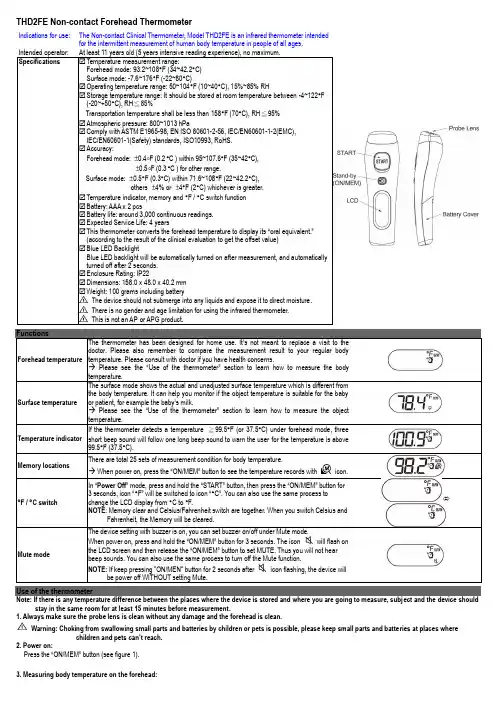

THD2FE Non-contact Forehead Thermometer⇔The device setting with buzzer is on, you can set buzzer on/off under Mute mode.beep sounds. You can also use the same process to turn off the Mute function.Use of the thermometerNote: If there is any temperature difference between the places where the device is stored and where you are going to measure, subject and the device should stay in the same room for at least 15 minutes before measurement.1. Always make sure the probe lens is clean without any damage and the forehead is clean. Warning: Choking from swallowing small parts and batteries by children or pets is possible, please keep small parts and batteries at places wherechildren and pets can’t reach.2. Power on:Press the “ON/MEM ” button (see figure 1).3. Measuring body temperature on the forehead:Indications for use: The Non-contact Clinical Thermometer, Model THD2FE is an infrared thermometer intended for the intermittent measurement of human body temperature in people of all ages.Ref No.:032020Press the “ON/MEM” button to power on the device. Forehead mode is the default mode. You can see the icon on the screenand hear two beep sounds (see figure 1). In this mode, you can hold the thermometer within 1.5 inch from the central forehead (Fig. 2) andpressthe "START" button to get the forehead measurement. The time consuming for measurement might be 1 second. After each foreheadmeasurement, wait icon stop flashing to be ready for next measurement.Figure 2 Points for attention:a. Forehead temperature is displayed in oral mode. This mode converts the forehead temperature to display its “oral-equivalent” value.b. Before the measurement, the subject should stay in a stable environment for 5 minutes and avoid exercise, bath for 30mins.c. Remember to keep the forehead area clean and away from sweat, cosmetics and scar while taking temperature.d. The “Clinical Bias” is -2.5 ~ -3.1°F (-1.4 ~ -1.7°C).e. The “Limits of Agreement” is 0.98.f. The "Repeatability" is 0.36°F (0.20°C)4. Measuring surface temperature:4.1 After power on, press and hold the “ON/MEM” button, and press the “START” button one time for “Infrared thermometer” mode to see icon on your LCDdisplay. In this mode, you can get the target surface temperature.4.2 When you press the “START” button, you will get the real time temperature immediately. If you press and hold the “START” button, the reading of measurement willbe continuously updated.4.3 Applications include temperature measurements for water, milk, cloth, skin or other objects.* Note: This mode shows the actual and unadjusted surface temperature which is different from the body temperature.5. Power off:5.1 Device will automatically shut off if left idle for more than 1 minute to extend battery life.ProblemWarranty:Warranty: 12 monthsManufacture Date: as the serial number (please open the battery cover, it is shown on the inside of the device.)Ex.SN:E512A000001, the first “E” is External, the second number “5” is the last number of manufacture year, the third and the fourth number “12” is the manufacture Note: The thermometer is calibrated at the time of manufacture. If you question calibration mode, the accuracy of temperature measurements or unexpected events at any time, please contact the dealers or nearest service address.Warning: No modification of this equipment is allowed.Please read the instructions for use BF type applied partMetris instrument east, IIcAdd: 25 Long Meadow PlaceSouth Setauket, NY USA 11720Figure 1 Figure 2 Figure 3IP220,120,23 FM c)±5 kHz deviation1 kHz sine。

非接触式温度计的工作原理非接触式温度计是一种先进的测温工具,它能够在不接触测量目标物体的情况下,准确地测量物体的温度。

这种温度计广泛应用于医疗、工业生产以及家用电器等领域。

下面将详细介绍非接触式温度计的工作原理。

1. 红外线辐射测温原理:非接触式温度计通过利用物体的红外辐射来测量物体的温度。

根据斯特藩-波尔兹曼定律,这种红外辐射的强度与物体的温度成正比。

温度计接收到物体发出的红外线辐射后,经过特定的光学组件进行聚焦和收集,并转换为电信号。

2. 光电探测器:温度计内置了一种称为光电探测器的元件,它能够接收并转化光信号为电信号。

光电探测器的主要成分是半导体材料,通过与红外辐射相互作用,产生电荷并形成电流。

3. 红外传感器:非接触式温度计通常配备了一种称为红外传感器的装置,它能够探测环境中的红外辐射。

红外传感器常常是由红外探测元件和光电探测器组成。

红外辐射被物体发出后,会被红外传感器接收到。

4. 光学系统:非接触式温度计中的光学系统是至关重要的一部分。

这个系统主要包括透镜、滤光片和反射镜等。

透镜用于集中红外辐射,使其能够在红外探测元件上产生更大的信号。

滤光片的作用是选择性地通过红外辐射,并尽量阻止其他类型的光线干扰。

反射镜可将光线反射回红外传感器,提高仪器的测量精度。

5. 信号处理和显示:非接触式温度计通过信号处理和数字显示来输出温度测量结果。

信号处理部分负责对红外辐射信号进行放大、滤波和转换等处理。

经过处理后,信号被传输到数字显示屏上,以显示出物体的温度值。

非接触式温度计的工作原理可以总结为红外辐射测温原理、光电探测器、红外传感器、光学系统和信号处理及显示。

这种温度计具有测量速度快、无损伤、操作简便等优点,广泛应用于各个行业。

在医疗领域中,非接触式温度计可用于测量体表温度,如额头或耳朵温度,适用于接触传染风险较高的场合。

在工业生产过程中,非接触式温度计可用于测量高温物体或难以接触的物体的温度,为生产过程提供实时的温度监测数据。

单点温度的测量方法

单点温度的测量方法是指在一个物体或空间中,仅对一个位置的温度进行测量的方法。

这种测量方法广泛应用于工业生产、科学实验、医疗诊断等领域。

以下是常见的单点温度测量方法:

1. 接触式温度计:该方法通过将温度计的感应部分与被测物体接触,来测量该位置的温度。

常见的接触式温度计包括温度计探针、热电偶、热敏电阻等。

2. 非接触式温度计:该方法采用红外线技术,通过测量被测物体表面的辐射能量来推算出该点的温度。

常见的非接触式温度计包括红外线温度计、激光测温仪等。

3. 热成像仪:该方法利用红外线成像技术,可以同时测量多个位置的温度。

热成像仪可以将不同温度的区域呈现为不同颜色的热图,方便用户快速了解被测物体的温度分布情况。

无论采用哪种方法,单点温度测量都需要注意以下几点:

1. 测量前应保证被测物体表面干燥、清洁、无油污等干扰因素。

2. 测量时应遵循仪器的使用说明,按照标准操作流程进行,以确保测量结果的准确性。

3. 不同的温度测量方法具有不同的适用范围和精度,应根据实际需要选择合适的方法进行测量。

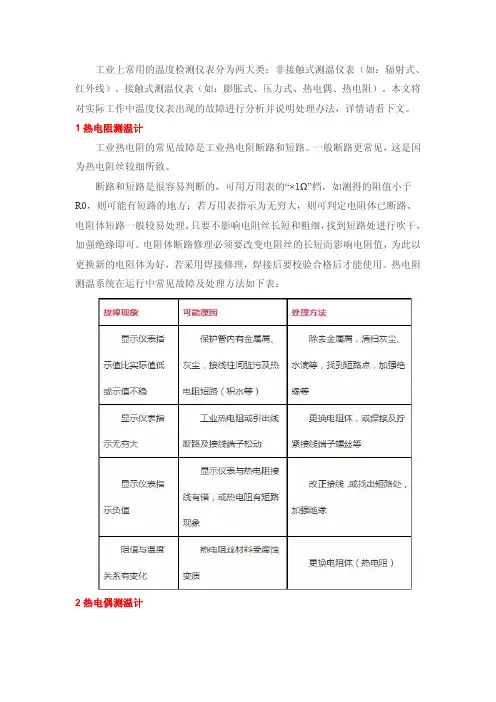

工业上常用的温度检测仪表分为两大类:非接触式测温仪表(如:辐射式、红外线)。

接触式测温仪表(如:膨胀式、压力式、热电偶、热电阻)。

本文将对实际工作中温度仪表出现的故障进行分析并说明处理办法,详情请看下文。

1热电阻测温计工业热电阻的常见故障是工业热电阻断路和短路。

一般断路更常见,这是因为热电阻丝较细所致。

断路和短路是很容易判断的,可用万用表的“×1Ω”档,如测得的阻值小于R0,则可能有短路的地方;若万用表指示为无穷大,则可判定电阻体已断路。

电阻体短路一般较易处理,只要不影响电阻丝长短和粗细,找到短路处进行吹干,加强绝缘即可。

电阻体断路修理必须要改变电阻丝的长短而影响电阻值,为此以更换新的电阻体为好,若采用焊接修理,焊接后要校验合格后才能使用。

热电阻测温系统在运行中常见故障及处理方法如下表:2热电偶测温计正确使用热电偶不但可以准确得到温度的数值,保证产品合格,而且还可节省热电偶的材料消耗,既节省资金又能保证产品质量。

除了补偿导线接反,用错及接线松动引起的常见误差外(处理方法:正确使用补偿导线,紧固接线端子),安装不正确,热导率和时间滞后等误差,它们是热电偶在使用中的主要误差。

2.1.安装不当引入的误差如热电偶安装的位置及插入深度不能反映炉膛的真实温度等,换句话说,热电偶不应装在太靠近门和加热的地方,插入的深度至少应为保护管直径的8~10倍;热电偶的保护套管与壁间的间隔未填绝热物质致使炉内热溢出或冷空气侵入,因此热电偶保护管和炉壁孔之间的空隙应用耐火泥或石棉绳等绝热物质堵塞以免冷热空气对流而影响测温的准确性;热电偶冷端太靠近炉体使温度超过100℃;热电偶的安装应尽可能避开强磁场和强电场,所以不应把热电偶和动力电缆线装在同一根导管内以免引入干扰造成误差;热电偶不能安装在被测介质很少流动的区域内,当用热电偶测量管内气体温度时,必须使热电偶逆着流速方向安装,而且充分与气体接触。

2.2.绝缘变差而引入的误差如热电偶绝缘了,保护管和拉线板污垢或盐渣过多致使热电偶极间与炉壁间绝缘不良,在高温下更为严重,这不仅会引起热电势的损耗而且还会引入干扰,由此引起的误差有时可达上百度。

本体 说明书(含EMC技术信息、保修卡) 合格证 试用电池(AAA 碱性电池(LR03) × 2)说明书含保修卡家庭用TANITA 非接触式红外体温计本仪器测量从物体表面辐射的红外线量,将其转换为温度,并以数字方式显示(温度测量模式)。

它还测量从人的额头表面发出的红外辐射量,并将其转换为舌下温度并以数字方式显示(体温测量模式)。

舌下温度通常高于腋窝温度。

本文文件说明了以下几点,以防止对用户和他人造成伤害以及财产损失。

请仔细阅读本文并正确使用本机。

此设备仅用于额头测量。

不要用它来测量其他区域的体温,可能导致无法准确测量。

自我诊断或自行解读测量结果可能会导致疾病恶化,请遵循医生指导。

请勿使用它来测量人体以外的体温,可能导致无法准确测量。

如果处理不当,电池可能会爆炸,导致受伤。

请勿充电,拆卸或着火。

放在儿童接触不到的地方。

另外,请不要让儿童单独使用它。

将电池放在儿童接触不到的地方。

有误食的危险。

如果吞下了电池,请立即就医。

用正确的 更换电池。

否则可能会导致液体泄漏,发热,破裂等,从而导致人身伤害或财产损失。

仅使用指定的电池(AAA 碱性电池)。

否则可能会导致液体泄漏,发热,破裂等,从而导致人身伤害或财产损失。

如果电池液进入您的眼睛,请立即用大量清水冲洗。

可能导致失明。

请务必立即就医。

如果电池液沾到皮肤或衣服上,请立即用大量清水清洗。

有受伤的危险。

请勿拆卸,修理或改装,可能导致无法准确测量。

请勿强行弯曲,掉落或使其受到强烈撞击。

有击穿的危险。

请勿在会产生静电或电磁波的地方(IH 电磁炉,微波炉,通讯设备等附近)使用。

存在故障或故障的风险。

请依出货说明书的储存环境温度及湿度保存本机,请勿将本机置于温度/湿度过高或阳光直接曝晒之环境下。

本产品建议每两年校正一次准确度。

请避免遮挡从被测目标发出的红外线,导致影响测量结果。

如果额头的状况与正常状况不同,则可能无法将其准确地转换为舌下温度。

·请勿用头发,汗水或化妆品遮盖额头表面。

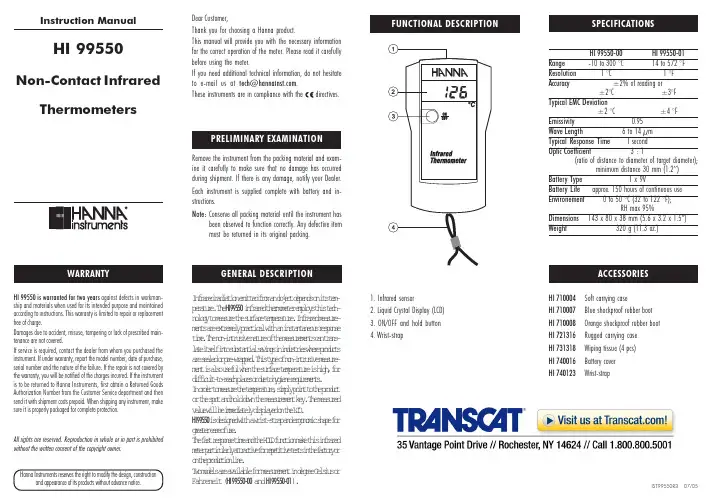

Instruction ManualHI 99550Non-Contact Infrared ThermometersHI 99550 is warranted for two years against defects in workman-ship and materials when used for its intended purpose and maintained according to instructions. This warranty is limited to repair or replacement free of charge.Damages due to accident, misuse, tampering or lack of prescribed main-tenance are not covered.If service is required, contact the dealer from whom you purchased the instrument. If under warranty, report the model number, date of purchase, serial number and the nature of the failure. If the repair is not covered by the warranty, you will be notified of the charges incurred. If the instrument is to be returned to Hanna Instruments, first obtain a Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping any instrument, make sure it is properly packaged for complete protection.All rights are reserved. Reproduction in whole or in part is prohibited without the written consent of the copyright owner.Dear Customer,Thank you for choosing a Hanna product.This manual will provide you with the necessary informationfor the correct operation of the meter. Please read it carefullybefore using the meter.If you need additional technical information, do not hesitateto e-mail us at ******************.Remove the instrument from the packing material and exam-ine it carefully to make sure that no damage has occurredduring shipment. If there is any damage, notify your Dealer.Each instrument is supplied complete with battery and in-structions.Note:Conserve all packing material until the instrument hasbeen observed to function correctly. Any defective itemmust be returned in its original packing.1. Infrared sensor2. Liquid Crystal Display (LCD)3. ON/OFF and hold button4. Wrist-strapI n f r a r e d r a d i a t i o n e m i t t e d f r o m a n o b j e c t d e p e n d s o n i t s t e m-p e r a t u r e.T h e H I 99550i n f r a r e d t h e r m o m e t e r e m p l o y s t h i s t e c h-n o l o g y t o m e a s u r e t h e s u r f a c e t e m p e r a t u r e.I n f r a r e d m e a s u r e-m e n t s a r e e x t r e m e l y p r a c t i c a l w i t h a n i n s t a n t a n e o u s r e s p o n s et i m e.T h e n o n-i n t r u s i v e n a t u r e o f t h e m e a s u r e m e n t s c a n t r a n s-l a t e i t s e l f i n t o s u b s t a n t i a l s a v i n g s i n i n d u s t r i e s w h e r e p r o d u c t sa r e s e a l e d o r p r e-w r a p p e d.T h i s t y p e o f n o n-i n t r u s i v e m e a s u r e-m e n t i s a l s o u s e f u l w h e n t h e s u r f a c e t e m p e r a t u r e i s h i g h,f o rd i f f i c u l t-t o-re a c h p l a c e s o r d u e t o h y g i e n e r e q u i r e m e n t s.I n o r d e r t o m e a s u r e t h e t e m p e r a t u r e,s i m p l y p o i n t t o t h e p r o d u c to r t h e s p o t a n d h o l d d o w n t h e m e a s u r e m e n t k e y.T h e m e a s u r e dv a l u e w i l l b e i m m e d i a t e l y d i s p l a y e d o n t h e L C D.H I 99550 i s d e s i g n e d w i t h a w r i s t-s t r a p a n d e r g o n o m i c s h a p e f o rg r e a t e r e a s e o f u s e.T h e f a s t r e s p o n s e t i m e a n d t h e H O L D f u n c t i o n m a k e t h i s i n f r a r e dm e t e r p a r t i c u l a r l y a t t r a c t i v e f o r r e p e t i t i v e t e s t s i n t h e f a c t o r y o ro n t h e p r o d u c t i o n l i n e.T w o m o d e l s a r e a v a i l a b l e f o r m e a s u r e m e n t i n d e g r e e C e l s i u s o rF a h r e n e i t(HI 99550-00a n d HI 99550-01).Hanna Instruments reserves the right to modify the design, construction and appearance of its products without advance notice.HI 99550-00HI 99550-01 Range-10 to 300 °C14 to 572 °F Resolution 1 °C 1 °F Accuracy±2% of reading or±2°C±3°F Typical EMC Deviation±2 °C±4 °F Emissivity0.95Wave Length 6 to 14 µmTypical Response Time 1 secondOptic Coefficient 3 : 1(ratio of distance to diameter of target diameter);minimum distance 30 mm (1.2’’) Battery Type 1 x 9VBattery Life approx. 150 hours of continuous use Environement0 to 50 °C (32 to 122 °F);RH max 95% Dimensions143 x 80 x 38 mm (5.6 x 3.2 x 1.5”) Weight320 g (11.3 oz.)HI 710004Soft carrying caseHI 710007Blue shockproof rubber bootHI 710008Orange shockproof rubber bootHI 721316Rugged carrying caseHI 731318Wiping tissue (4 pcs)HI 740016Battery coverHI 740123Wrist-strapIST99550R3 07/05Temperature MeasurementTo obtain the temperature ofan object, simply aim the sen-sor in the direction of theobject Keep the “ON/OFF”button pressed for a few sec-onds until the readingstabilizes.The instrument will continuereading the temperature,while the “ON/OFF” button ispressed. When released, theinstrument freezes the read-ing for a few seconds andthen switches off automati-callyReadin g DistanceThe distance between the sensor and the object is an important factor in the infrared measurement.The relation between “distance/object area” of the instrument is 3:1. This means that the diameter of the measured area is one third of the distance between the sensor and the object. For example, if the sensor is 15 cm away from the object, the instrument measures the temperature of an area with a 5 cm diameter.EmissivityThe instrument measures the temperature of objects with an emissivity of 0.95, which is the characteristic of most sub-stances such as organic material, water, plastic, fabrics, etc.BATTERY REPLACEMENT Battery replacement must only take place in a safe area andusing a 9V alkaline battery.Simply slide off the battery cover on the back of the meter, detach the battery from the terminals and attach a new 9VReplace the battery cover.。

非接触式温度传感器应用于医疗摘要——在这项研究中,我们已经开发出一种非接触式温度传感器,它使用卤化银红外光纤,用于医疗内窥镜。

我们测量的红外辐射,是通过热光纤光功率表,从热源由一银卤化物转移。

此外,一个热源和光功率测量温度之间的关系是确定的。

为了提高通过光纤银卤化物的红外辐射量和红外遥感的的一部分热光功率表,如红外线对焦镜头和光学设备准直器的使用。

热源和光功率测量温度之间的关系是确定的。

光纤温度测量范围:温度传感器采用热光功率表是从30至70摄氏度。

预计非接触式温度传感器采用红外光纤可根据本研究的结果为基础的医疗和工业应用开发。

关键词—红外光纤,光热功率计,非接触式温度传感器,红外线辐射I. 导言一般来说,非接触式温度计可以测量从一个遥远的红外辐射热源排放。

在没有明确的光纤温度传感器或一个红外光纤和红外线传感器组合许可的情况下,非接触式表面视线清楚。

这可能有助于确定了快速运动物体的表面温度,甚至在狭窄的地方和电磁场测量温度[1,2]。

作为一个红外波导,光纤的基于混合卤化银晶体,AgClxBr1 - X,被认为是为低温度下测量的最佳选择。

这些纤维的特点是灵活,不溶于水,且无毒[3]。

出于这个原因,卤化银红外光学纤维应用在红外光谱中,辐射测量和工业及医疗应用的热成像[4]。

在这项研究中,我们已经开发出一种使用卤化物红外线非接触式温度传感器,用于医疗内窥镜。

它可能会制造一个内窥镜系统,包括图像指导,光导和光纤温度传感器作为非接触式辅助通道。

通过使用热光功率表,光纤温度传感器测量的温度范围是30到70摄氏度。

II.物品和器材本次研究红外光纤选择的是卤化银红外光纤(红外900/1000,JT Ingram公司)。

这种纤维的外径为1.0毫米,包层的厚度为0.05毫米。

核心和包层的折射率是2.15和2.13,数值孔径(NA)为0.25。

银色金属卤化物的红外光学纤维是由纯氯化生产的:在一个核心包层结构的溴化银固溶体晶体。

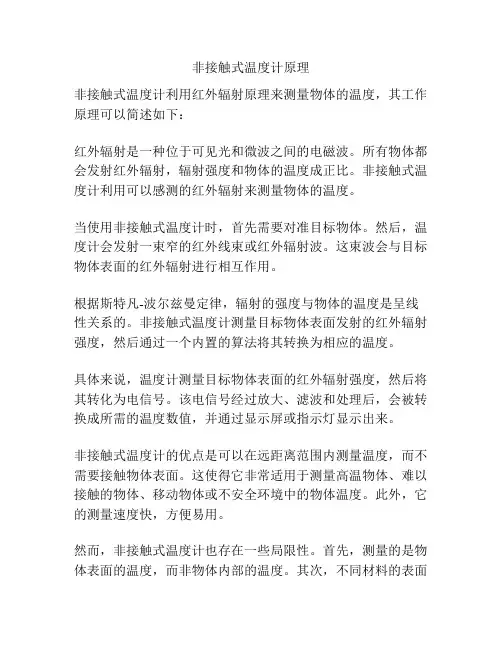

非接触式温度计原理

非接触式温度计利用红外辐射原理来测量物体的温度,其工作原理可以简述如下:

红外辐射是一种位于可见光和微波之间的电磁波。

所有物体都会发射红外辐射,辐射强度和物体的温度成正比。

非接触式温度计利用可以感测的红外辐射来测量物体的温度。

当使用非接触式温度计时,首先需要对准目标物体。

然后,温度计会发射一束窄的红外线束或红外辐射波。

这束波会与目标物体表面的红外辐射进行相互作用。

根据斯特凡-波尔兹曼定律,辐射的强度与物体的温度是呈线性关系的。

非接触式温度计测量目标物体表面发射的红外辐射强度,然后通过一个内置的算法将其转换为相应的温度。

具体来说,温度计测量目标物体表面的红外辐射强度,然后将其转化为电信号。

该电信号经过放大、滤波和处理后,会被转换成所需的温度数值,并通过显示屏或指示灯显示出来。

非接触式温度计的优点是可以在远距离范围内测量温度,而不需要接触物体表面。

这使得它非常适用于测量高温物体、难以接触的物体、移动物体或不安全环境中的物体温度。

此外,它的测量速度快,方便易用。

然而,非接触式温度计也存在一些局限性。

首先,测量的是物体表面的温度,而非物体内部的温度。

其次,不同材料的表面

特性以及环境条件可能会对测量结果产生一定的干扰。

因此,在使用非接触式温度计时,需要根据具体情况选择合适的仪器和方法,并对测量结果进行适当的修正。

HOTSPOT IRNON-CONTACT THERMOMETE RUSER MANUAL|*************************|WeAreIR™MedicalPLEASE READ THIS MANUAL BEFORE SWITCHING THE UNIT ON.IMPORTANT SAFETY INFORMATION INSIDE.ICI cameras fall under US Federal Law and Export Control.THIS DEVICE IS INTENDED FOR ADJUNCTIVE USE WITH OTHER CLINICAL DIAGNOSTIC PROCEDURES TO MEASURE HUMAN BODY TEMPERATURE VIA NON-CONTACT SKIN MEASUREMENTS VISUALIZED FROM THE HUMAN FACE . NOT MEANT FOR STANDALONE CLINICAL DIAGNOSTIC PROCEDURES OR TO TREAT OR DIAGNOSE PATIENTS .©Copyright 2021, Infrared Cameras, Inc. - All rights reserved. The contents ofthis document may not be reproduced in whole or in parts without the writtenconsent of the copyright owner.Printed in the United States of America.2105 W. Cardinal Dr.Beaumont, TX 77705(866) 861-0788Revision: 4.2021-001THE MANUFACTURER RESERVES THE RIGHT TO ALTER THE SPECIFICATIONSOF THE PRODUCT WITHOUT PRIOR NOTIFICATION. THE MANUFACTURERALLOWS HIMSELF THE RIGHT TO MODIFY WITHOUT ANY PRELIMINARYOPINION THE TECHNICAL SPECIFICATIONS OF THE PRODUCT. THIS MANUALMAY CONTAIN TECHNICAL INACCURACIES OR TYPOGRAPHICAL ERRORS.NOTICE ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THISMANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUTWARRANTY OF ANY KIND. NOTWITHSTANDING ANY OTHER WARRANTYHEREIN, ALL DOCUMENT FILES AND SOFTWARE ARE PROVIDED “AS IS” WITHALL FAULTS. ICI DISCLAIMS ALL WARRANTIES, EXPRESSED OR IMPLIED,INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESSFOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM ACOURSE OF DEALING, USAGE, OR TRADE PRACTICE.THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYINGPRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITHTHE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOUARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,CONTACT YOUR ICI REPRESENTATIVE FOR A COPY.IN NO EVENT SHALL ICI BE LIABLE FOR ANY INDIRECT, SPECIAL,CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUTLIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OFTHE USE OR INABILITY TO USE THIS MANUAL, EVEN IF ICI HAS BEEN ADVISEDOF THE POSSIBILITY OF SUCH DAMAGES.231. General Description2. Safety Information3. Features4. Intended Use5. Configuration6. Indicator7. Description of Symbols 8. Technical Specifications 9. Package Includes 10. Use11. Measuring Operations 12. Calibration Instructions 13. Advice14. Maintenance and Cleaning 15. Troubleshooting16. Conformity Standards 17.About ICIContents44567789101117192020212324THIS DEVICE IS INTENDED FOR ADJUNCTIVE USE WITH OTHER CLINICAL DIAGNOSTIC PROCEDURES TO MEASURE HUMAN BODY TEMPERATURE VIA NON-CONTACT SKIN MEASUREMENTS VISUALIZED FROM THE HUMAN FACE . NOT MEANT FOR STANDALONE CLINICAL DIAGNOSTIC PROCEDURES OR TO TREAT OR DIAGNOSE PATIENTS .41. General Description2. Safety InformationThe HotSpot IR Non-Contact Thermometer is specially designed to take the body temperature of a person regardless of room temperature. Depending on various skin types and thickness, there may be temperature difference.• Only use the device for the purposes described in this instruction manual.• Only use the device in an ambient temperature range between 10 °C and 40 °C.• Do not expose this thermometer to electric shocks.• Do not expose the thermometer to extreme temperature conditions of > 50 °C or < 0 °C.• Do not use the device in relative humidity higher than 85%.• Do not use the device near large electromagnetic fields such as found with cordless or cell phones.• Keep the device away from water and heat, including direct sunlight.• Do not drop or throw the device.• Do not use the device if it is damaged.•The accuracy of measurements may be affected when the face is covered by hair, perspiration, a cap, or a scarf (See Part 10-4).• Keep the measuring distance between 5 cm - 15 cm (2”-5.9”)(See Part 10-4).•The infrared thermometer should be left in a room 15 to 20 minutes before using.53. Features•Clean the glass with a cotton swab lightly moistened with 70% alcohol.Important:• Before taking a temperature measurement make sure to remove hair and perspiration from the forehead.•Selecting “Body” mode to measure the body temperature; Selecting “Surface” mode to measure the surface temperature of an object.• This device is not intended as a substitute for a physician’s consultation.• Should a problem occur with your device, contact your retailer. Do not attempt to repair the device yourself.•According to EMC standard, the electronic products should be maintained.• Precise non-contact measurements • User selectable ºC or ºF• Selectable Body and Surface temp • Set Alarm value• Memorization of the last 32 measurements • Automatic Data Hold & Auto power off • Display Resolution 0.1 ºC (0.1 ºF).•Back-light LCD display64. Intended UseNon-Contact IR Thermometer is designed for body surface and temperature measurement for infants and adults without coming into contact with the human body.Non-Contact IR Thermometer can also be used to measure the temperature of a baby-bottle or bath, or room temperature (by using the Surface Temp function).4-1. Normal Temperatures According to Measurement Method The temperature of the human body varies throughout the day. It can also be influenced by numerous external factors: age, sex, and thickness of skin.4-2. Normal Temperatures According to Age Measurement Method Normal Temp °C Normal Temp °F Rectal 36.6 to 3897.8 to 100.4Oral 35.5 to 37.595.9 to 99.5Axillary 34.7 to 37.394.4 to 99.1Ear35.8 to 3896.4 to 100.4Age Temp °C Temp °F 0-2 years 36.4 to 38.097.5 to 100.43-10 years 36.1 to 37.897.0 to 100.011-65 years 35.9 to 37.696.6 to 99.7>65 years35.8 to 37.596.4 to 99.575. Configuration6. Indicator1. IR Sensor2. LCD Display3. Mode Selection4. Down Button5. Up Button6. Mode Button7. Measurement Trigger 8.Battery Cover1. Surface mode Symbol2. Body mode Symbol3. Digital readout4. Battery Symbol5. The order number6. Save data readout7. Temperature Scale:°C(Celsius)/°F(Fahrenheit) 8. Buzzer symbol7. Description of Symbols89Display Resolution 0.1 °C (0.1 °F)Operating Temperature 10 °C to 40 °C (50 °F to 104 °F)Storage Temperature 0 °C to 50°C (32 °F to 122 °F)Humidity Rate < 85%Power DC 3V (2 x “AA” batteries)Size 149 mm x 77 mm x 43 mm /5.9” x 3” x 1.7” (L x W x H ± .5 mm or .1”)WeightGross 400 g / Net 172 g (14.11 oz)8-1. Normal Conditions of Use 8. Technical Specifications8-2. Measuring Range In Body Mode 32.0 °C to 42.5 °C (90 °F to 108 °F)In Surface Temp Mod 0 °C to 60°C (32 °F to 140 °F)Accuracy±0.3 °C (0.54 °F)Measuring Distance 5 cm to 15 cm (1.97” to 5.91”)Automatic Stop7 seconds 32 °C to 35.9 °C / 93.2 °F to 96.6 °F ±0.3 °C / 0.5e °F According to ASTM Standard E1965-1998 (2003)36 °C to 39 °C / 96.8 °F to 102.2 °F ±0.2 °C / 0.36 °F 39 °C to 42.5 °C / 102.2 °F to 108.5 °F±0.3 °C / 0.54 °F8-3. HotSpot IR Non-Contact Thermometer Precision SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE109. Package IncludesHotSpot IRAA Battery x2Battery Bay Screw & DriverENSURE ALL SYSTEM EQUIPMENT AND COMPONENT ITEMS ARE PRESENT BEFORE BEGINNING SCREENING1110. UseA. B.Remove screen protector from HotSpot IR thermometer.Press down and forward on thebattery bay door to open.SELECT AN APPROPRIATE AREA FREE OF IMMEDIATE AIRFLOW FROM DOORWAYS AND AIR CONDITIONING/VENTILATION SYSTEMS. THE SELECTED AREA SHOULD HAVE A STABLE AMBIENT TEMPERATURE BETWEEN 20 °C AND 24 °C (68 °F TO 75.2 °F)AND RELATIVEHUMIDITY RANGE FROM 10% TO 50%.12 C.Insert AA Batteries intoHotSpot IR battery bay.D.Close battery bay door.FOR FIRST USE OR WHEN INSERTING NEW BATTERIES,WAIT 10 MINUTES FOR THE DEVICE TO WARM-UP.E.Secure battery bay with screw.13G.Power on device by pulling trigger.Device will auto shut-off when not in use.IF THE DEVICE IS NOT USED FOR A LONG TIME, THEDEVICE WILL DELAY TURNING ON A FEW SECONDS INORDER TO FIRST TEST THE ROOM TEMPERATURE.1415H.I.Aim toward a person’s inner canthus keeping 5 to 15 cm (2” to 5.9”) distance between the thermometer and the person, press the measuring key, and the temperature will display immediately (seethe Figure 1 below for the positioning).When the room temperature is significant difference, or there is perspiration on the forehead, you can take the temperature behind the ear lobe (see the Figure 2 below for the positioning).CRITICAL INFORMATION• The technology should be used to measure only onesubject’s temperature at a time.• Measurements should not be solely, or primarily,relied upon to diagnose or exclude a diagnosis ofany disease.• Elevated body temperature should be confirmedwith secondary evaluation methods (e.g., an NCITor clinical grade contact thermometer).• Signage should instruct for the removal of glasses,headwear, and masks.• Read the current government guidance regardingthe use of telethermographic systems for skintemperature measurements. Additional informationcan be found by reading IEC 80601-2-59:2017Medical electrical equipment — Part 2-59:Particular requirements for the basic safety andessential performance of screening thermographsfor human febrile temperature screening andISO/TR 13154:2017 Medical electrical equipment- Deployment, implementation and operationalguidelines for identifying febrile humans using ascreening thermograph.CRITICAL INFORMATION1611. Measuring Operations11-1. Choosing the Temperature Unit – F1 Function1. Press MODE button for 2 seconds, screen will display: F1.2. Press ▼ for degrees Celsius, ▲ for degrees Fahrenheit.11-2. Alarm Setup – F2 Function1. Press MODE button for 2 seconds, screen will display: F1.2. Press MODE again to get to F2.3. Press ▲ to increase the threshold by 0.1 °C (0.1 °F).4. Press ▼ to reduce it by 0.1 °C (0.1 °F).THE ALARM THRESHOLD DEFAULT VALUE IS 38°C (100.4°F).11-3. Calibration – F3 FunctionTo adjust the calibration of your thermometer:1. Press MODE button for 2 seconds, screen will display: F1.2. Press MODE twice to get F3.3. Press ▲ to increase the difference by 0.1 °C (0.1 °F).4. Press ▼ to reduce the difference by 0.1 °C (0.1 °F).IN THE CASES OF SEASONAL OR ENVIRONMENTAL CHANGESA VERIFICATION AND ADJUSTMENT SHOULD BE CARRIED OUT.THIS FUNCTION IS ONLY EFFECTIVE IN BODY MODE.11-4. Buzzer ON/OFF – F4 (F3) Function1. Press MODE button for 2 seconds, screen will display: F1.2. Press three (two) times MODE button to get F4 (F3).3. Press ▲ to open the buzzer. An icon is displayed.4. Press ▼ to turn off the buzzer (icon will disappear).11-5. Exiting The Setting Mode171. Press MODE button until the screen turns off.11-6. The HotSpot IR Non-Contact Thermometer is speciallydesigned to take the body temperature of a human being. For this,use the Body mode. Measurement range for Body mode: 32 to42.5 °C (86°F to 108 °F).You can also use the thermometer to measure the temperatureof an object, a food, a liquid or a room. For this, use the Surfacemode. Measurement range for Surface mode: 0 to 60 °C (32 °Fto 140 °F)MAKE SURE TO SELECT THE BODY MODE FOR AN SKINTEMPERATURE READING AND THE SURFACE MODE FOR ANAMBIENT OR OBJECT READING.11-7. Data CollectionData collection happens automatically after taking temperaturemeasurements and will display at the right corner of LCD. Press▲ or ▼ button to display the last temperature measurement.When the device is powered off, press ▲ and ▼ button togetherfor two seconds to display the last temperature measurement.Change the order number to 0 and press MODE button to deleteall collection data.11-8. Changing The BatteriesWhen the LCD screen displays “ “, the battery needs to bereplaced. To replace batter open the lid and change the batteries,taking great care with the correct positioning.Placing the batteries into the device backwards can causedamage to the device and compromise the accuracy of yourHotSpot IR Non-Contact Thermometer. Never use rechargeablebatteries. Remove the battery from the instrument when not in usefor extended periods of time to avoid damage to the thermometer.11-9. Device LifeThe HotSpot IR Non-Contact Thermometer was conceivedfor professional use. Its longevity is guaranteed for 40000measurements.1812. Calibration InstructionsFor stable and reliable results, the thermometer provides a user-correction function.12-1. Check the Device CalibrationVerify calibration as follows:1. Take the temperature of a person using a conventionalthermometer; example: you get 37 °C (98.6 °F).2. Take the temperature of the same person using the HotSpotIR Non-Contact Thermometer keeping 5 to 15 cm (2” to5.9”) distance between the thermometer and the person.If you get 37 °C (98.6 °F), the HotSpot IR Non-ContactThermometer is properly set and ready for use.If you get a lower or higher temperature, 38.1 °C (100.6 °F) forexample, you should re-calibrate the HotSpot IR Non-ContactThermometer.12-2. Calibrate the DeviceTo calibrate the device:1. Press the MODE button for 2 seconds. The screen willdisplay F1.2. Press MODE button again until you get F3.3. Press ▲ button in order to add the difference (in ourexample, 1.1 °C – 2.2 °F).4. Repeat steps 1 - 3 until readings from conventionalthermometer and HotSpot IR Non-Contact Thermometerare the same.TAKE CARE TO REMOVE ANY OBSTACLE WHICH COULD ALTERTHE MEASUREMENT (HAIR, PERSPIRATION, ETC.)192013. Advice 14. Maintenance and Cleaning•The protective glass over the lens is the most fragile part of the thermometer. Be careful with it.• Do not attempt to recharge non-rechargeable batteries.• Do not throw the device in a fire.• Do not expose the thermometer to extreme sunlight or water.• The infrared sensor is the fragile. Be careful with it.•Clean the device with a cotton swab lightly moistened with 70% alcohol.• Do not clean the device with a corrosive detergent.• Keep the device away from water or other liquids.• Store the device in a dry environment.• Keep the device away from dust and direct sunlight.21If you happen to have problems while using your the non-contact IR thermometer refer to guide below to help resolve the issue. *****************************************************problems persist.Strange Readings when taking Skin Surface TemperaturesIf you are using Surface mode, the temperature displayed is showing the ambient temperature and not the surface skin temperature measurement.Message “HI“ The analysis is above the measurement range selected, either above 42.5 °C (108 °F) in Body mode or below 60 °C (140 °F) in Surface mode.Message “LO“The temperature analyzed is under the measuring range selected, either the measurement is less than 32 °C (90 °F) in Body mode orless than 0 °C (32 °F) in Surface mode.15. TroubleshootingMessage WarningsReasons for “LO” or “HI”messageSee TroubleshootingTemperature reading hampered by hair, perspiration…Make sure that there is no obstruction prior to taking temperature measurementsTemperature hampered by an air flux.Make sure there is no air flux as this could interfere with the infrared system.The measuring distance is too far.Be mindful the measuring distance is 5 cm - 15 cm (2” - 5.9”).From high/low temperature condition to room temperature Wait for 10 minutes after being in a room before taking body temperature measurements2216. Conformity Standards• EN12470-5 and ASTM E1965-1998• EN 980: Graphical symbols for the labeling of devices• EN 1041: Information supplied by the manufacturer• EN 60601-1: Electrical equipment Part 1: Generalrequirements for safety (IEC:60601-1:1998)• EN 60601-1-2: Electrical equipment Part 1-2: Generalrequirements for safety Collateral standard Electromagneticcompatibility Requirements and test (IEC 60601-1-2:2001)EMC StatementThis device has been tested and homologated in accordance withEN60601-1-2:2007 for EMC. This does not guarantee in anyway that the device will not be affected by electromagneticinterference. Avoid using the device in high electromagneticenvironment.The ELECTRICAL EQUIPMENT needs special precautions regardingEMC and needs to be installed and put into service according to theEMC information provided in the ACCOMPANYING DOCUMENTS.2317. About ICIInfrared Cameras, Inc.2105 W. Cardinal Dr.Beaumont, TX 77705Phone: (409) 861-0788Toll Free: (866) 861-0788International: (409) 861-0788GeneralInquiry:***************************Website: You may reach a representative by phone or email.Office Hours: Monday – Friday 8:00AM - 5:00PM CST.ICI manufactures complete systems and software. We can provide completeengineering, software, and OEM solutions. Our Fortune 500 clients rely on usfor infrared equipment and thermography training (which we offer through theInfrared Training Institute).In addition to providing custom germanium, silica, and sapphire optics, we alsobuild windows for enclosures, as well as custom pan and tilt units. We can evenprovide customizable explosion-proof systems.Our knowledge and experience stems from years of using infrared imagingand temperature measurement instruments to provide solutions to: managers,engineers, scientists, inspectors and operators in space, power companies,medical, pulp and paper, food industry, research and development, and variousprocess industries. You can see our products and services used in industrial,commercial, and government applications worldwide. Originally named TexasInfrared (still DBA), Infrared Cameras, Inc. has been in business since March,1995.Thank you for your dedicated and continued support.2425。

非接触式测温仪表的缺点随着科技的进步,越来越多的人开始使用非接触式测温仪表进行测量。

非接触式测温仪表在很多方面有着很多优点,比如可以在不接触被测物体的情况下测量它的温度,减轻了使用者的工作量,同时还有很高的测量准确度。

但是,就像任何其他技术一样,非接触式测温仪表也有其缺点,本文将对非接触式测温仪表的缺点进行分析。

1. 前提条件较严格使用非接触式测温仪表测量温度时,需要满足一定的前提条件。

首先,被测物体必须是暴露在外的,并且表面不能有污垢、水汽等外来物质。

其次,使用者需要对测量仪进行适当的校准和设置,以避免辐射源对测量结果的干扰。

如果前提条件没有得到满足,则可能会导致测量结果的不准确。

2. 无法测量内部温度由于非接触式测温仪表是通过检测热辐射来测量物体的温度,因此它不能够直接测量物体内部的温度。

尤其是对于一些复杂的结构物,非接触式测温仪表需要测量表面温度,然后通过更加复杂的计算来推断出内部的温度。

这样的方法存在一定的误差,因此在需要精确测量内部温度的情况下,非接触式测温仪表就显得力不足了。

3. 与环境因素相关使用非接触式测温仪表测量温度时,环境的影响也不能忽略。

比如气流、大气压强、湿度等因素都会对测量结果产生干扰。

而且,非接触式测温仪表也容易受到周围环境的强烈光线、热辐射等因素的干扰影响,进而影响测量结果的准确度。

4. 价格相对较高非接触式测温仪表通常拥有高精度、高灵敏度、高分辨率等优点,因此它的价格相对较高。

这也导致一些企业或消费者在购买时需要做出明智的决策,因为它们可能需要考虑成本和使用场景等因素,以避免不必要的花费。

因此,在某些使用场景下,更便宜的接触式温度计可能会更加适合。

5. 对人体安全存在风险非接触式测温仪表使用的红外线技术,它通过辐射热量来测量被测物体的温度,存在一定的放射性危险,严重时可能会对人体健康产生威胁。

另外,一些非接触式测温仪表只能在短时间内进行测量,因此如果人们在长时间内暴露在较大的辐射区域内,可能会出现放射性损伤等问题。

非接触式电子体温计说明书一、产品概述非接触式电子体温计是一种先进的医疗设备,能够通过红外线技术快速、准确地测量人体体温。

它不需要与人体接触,极大地降低了传染病的风险,同时提高了测温的便捷性和可靠性。

二、产品特点1. 非接触式测温:本体温计采用红外线技术,通过测量人体额温来获取体温数据,实现了完全的非接触式测温。

2. 快速测量:只需将温度计对准人体额头,按下测量按钮,即可在几秒钟内获得精确的体温数据。

3. 可靠准确:采用先进的红外线技术和高精度传感器,确保测量结果的准确性和可靠性。

4. 安全卫生:使用非接触式测温方式,避免了传统体温计可能带来的交叉感染风险。

5. 多功能设计:除了测量体温,本体温计还具备闹钟、日期显示、自动关机等实用功能,方便用户日常使用。

三、产品使用方法1. 观察屏幕:开机后,观察屏幕上的显示,确保指示灯正常亮起。

2. 距离调整:将体温计与被测者保持3-5厘米的距离。

3. 对准额头:使用体温计测量按钮对准被测者的额头位置。

4. 开始测量:按下测量按钮,仪器会发出连续的“嘀嘀”声,表示正在测温。

5. 测量完成:当听到一声长响,屏幕上将显示测量结果。

6. 关机:测量完成后,仪器将自动关闭。

若长时间不使用,也可手动长按开机键,关机。

四、注意事项1. 本体温计测量的是人体额温,不是口温或腋温,请确保测量位置准确。

2. 使用前请先阅读说明书,并按照说明书的要求正确操作。

3. 体温计只能用于测量人体体温,不能用于其他用途。

4. 请保持体温计的清洁卫生,避免污染及影响测量结果。

5. 本体温计不适用于测量新生儿体温,请遵循医疗专业人员的建议。

6. 在使用过程中,如遇到任何异常情况,请停止使用并及时联系售后服务。

五、维护保养1. 使用干净柔软的布进行清洁,避免使用含酒精或化学物质的溶剂。

2. 避免将体温计暴露在高温、潮湿或尘埃较多的环境中。

3. 请妥善保管体温计,避免摔落或受到外力撞击。

六、售后服务1. 本产品享受一年质保期,自购买日起计算。

AX-75101.Brief Introduction to the ProductThe instrument is a professional handheld non-contact infrared thermometer,and is featured by conve-nient use,strict design,high measurement accuracy,broad temperature measurement range,etc.It has the functions like laser aiming,backlight LCD unit,over-temperature alarm,adjustable transmission rate, and automatic shutdown.When being used,the product can measure the temperature of objects quickly and accurately only with the probing window aiming at objects.2.Basic Operating PrinciplesAll objects whose temperature are higher than absolute zero degree will transmit a certain proportion of infrared radiation energy according to their own temperature.The size and wavelength-based distri-bution of radiation energy have very close relationship with its surface temperature.According to this theory,we may obtain the accurate temperature of a measured object by accurately measuring its infrared transmission energy.3.Product Characteristics•Backlight LED digital display•Fahrenheit and Celsius modes are provided for choice•Emissivity:0.1~1.00adjustable•Built-in laser aiming device•Automatic shutdown function(saving battery consumption)•Small volume,reasonable structure,and convenient operation4.Main Technical Indexes•Normal work conditions:1.Ambient temperature:10℃~30℃2.Storage temperature:-10℃~40℃3.Relative humidity:≤90%4.Power supply:One9V battery(NEDA1604/6F22or similar model)•Basic size:97mm×43mm×160mm(L×W×H)•Weight(net weight):125g(excluding battery)•LCD resolution(precision):0.1℃/°F•Measuring range:-20℃~550℃(-4°F~1022°F)•Power consumption:≤50mW•Measuring error:±2.0℃or±2%(or±3.0℃at0℃-25℃),whichever is bigger•Measuring time:≤0.5s•Measuring distance:D:S=12:1(measuring distance is relative to object target;measuring condition: vacuum medium).•Automatic shutdown time:60s•Safety design standard:Meeting European CE safety standard.EMC/RFIIn the radio frequency electromagnetic field with strength of3V/m,the reading will possibly be affected, but the instrument won’t be affected eternally.NoteIn3V/m and350MHz~550MHz electromagnetic field,the maximum error is8℃(46.4°F).5.Application Method•Safety clauses:1.The product shall be used carefully when the laser beam is opened2.Don’t make the laser beam aim at the eyes of people or animals3.Don’t make the laser beam reflected into people’s eyes by aiming them at the surface of objects4.Don’t make the laser beam aim at any explosive gas•Measuring steps and methods:1.In order to obtain precise temperature value,the thermometer shall be used10min after mounting ofbattery;if the product is moved to a new environment(new place),it shall also be used after10min2.After the detection window is made aiming at the measured object,and the measuring key on thehandle is moved,the thermometer will be started automatically.When sending out the prompt sound “beep”,the product will display the measured resultNoteBefore measurement,the emissivity of the object to be measured shall be selected,and meanwhile,the measuring distance shall be adjusted according to the size of the object to be measured.6.Keys and LCD Signs DescriptionUp-Functional Key:Press“EMITM”key to select the setting of emissivity,with the sign“<UP>,<DOWN>”displayed simultaneously;press“up”key for upward adjustment;keep pressing the measuring key,and then press“up”key to turn on and off backlight.then press“up”and press test key to trigger“up”key for turning on and off backlight.Down-Functional Key:Press“EMITM”key to select the setting of emissivity,with the sign“<UP>,<DOW N>”displayed simultaneously;press“down”key for downward adjustment;keep pressing the measuring key,and then press“down”to turn on and off infrared laser light.Select-Functional key:Press the key circularly to select maximum value(MAX),average value(AVG), minimum value(MIN),the difference between the maximum value and minimum value(DIF),data hold (HOLD),low temperature alarm(LAL),high temperature alarm(HAL),zero offset adjustment(offset),and emissivity setting(E).EMITM-Press“EMITM”key to select the setting of emissivity,with the sign“<UP>,<DOWN>”displayed simultaneously;and trigger“up”and“down”to adjust the emissivity.Down-Press this key to select the conversion of Cels degree and Fahrenheit degree.℃-Temperature unit:Celsius degree°F-Temperature unit:Fahrenheit degree-Auditory tone cues-The appearance of the sign“”indicates over low battery voltage.-The appearance of the sign“HR”indicates over-high ambient temperature7.Storage and Cleaning•Protective lens of probe are the most easily damaged part of infrared thermometer,and so must be protected carefully•The method for cleaning the lens of probe:The lens shall be wiped gently with cotton swab or soft fabric soaked with water or alcohol•The battery shall not be charged or thrown into fire,but instead,used batteries shall be discarded at specified recycling place;using disqualified battery will possibly induce fire or explosion•Caution:The battery shall be taken out if the product is left unused for long term•The product shall not be soaked in water or exposed to direct sunshine•Do not hurtle down or impact the product heavily,or it will be damaged•Failing to use the product according to effective distance or make it aim at the central location measured will possibly induce the deviation in the measured result,and in such case,it’s suggested to measure the object once again or for more times8.List of Accessories1)One copy of manual9.Attached List:Contrast List of Emissivity of Common ObjectsMaterial name-Specification-Emissivity-Aluminum-Oxidized-0.20-0.40Aluminum-Polished-0.02-0.04Human skin--0.98Graphite-Oxidized-0.20-0.60Copper-Oxidized-0.40-0.80Copper-Polished-0.02-0.05Plastic-Transparency>0.5mm-0.95Gold--0.01-0.10Rubber--0.95Iron-Oxidized-0.60-0.90Plastic--0.85-0.95Steel-Oxidized-0.70-0.90Concrete--0.95Asbestos--0.95Cement--0.96Gyp--0.80-0.90Soil--0.90-0.98Asphalt--0.95Mortar--0.89-0.91Pottery--0.95Brick--0.93-0.96Wood--0.90-0.95Marble--0.94Charcoal Powder--0.96Textile--0.90Lacquer--0.80-0.95Lacquerware-Lack of luster-0.97Paper-Various colors-0.94Carbon cement--0.90Sand--0.90Soap bubble--0.75-0.80Clay--0.92-0.96Water0.93Grit0.95Snow0.83-0.90Glass-Tableware-0.85-0.92 Ice--0.96-0.98Textile--0.95。

电子温度计的正确使用方法随着科技的发展,电子温度计已经成为现代生活中不可或缺的工具之一。

它们准确、方便、快速地测量温度,广泛应用于医疗、食品、家居等领域。

然而,为了保证测量结果的准确性和安全性,我们需要掌握正确的使用方法。

本文将为您详细介绍电子温度计的正确使用方法。

一、选择合适的电子温度计在购买电子温度计时,我们应该根据实际需求选择合适的型号。

常见的电子温度计有接触式和非接触式两种类型。

接触式温度计需要将传感器与物体直接接触,适用于口腔、腋下等部位的测量。

而非接触式温度计则通过红外线测量物体的热量,适用于食品、水温等无法直接接触的物体。

在选择时,我们还应考虑到温度范围、显示方式和可靠性等因素。

二、准确测量温度前的准备工作在使用电子温度计前,我们需要进行一些准备工作以保证测量结果的准确性。

首先,清洁温度计的探头,确保其表面干净,无残留物。

其次,查阅电子温度计的说明书,了解其使用方法和注意事项。

如果电子温度计配备了保护套或盖子,我们应确保安装正确。

三、正确的测量方法1. 接触式电子温度计的使用方法a. 将温度计探头插入被测物体或待测区域。

b. 等待数秒,直到温度计的显示稳定。

c. 记录温度读数,并进行必要的单位换算。

2. 非接触式电子温度计的使用方法a. 确定测量距离,通常是按照电子温度计使用说明进行设定。

b. 按下测量键,对准测量目标物体。

c. 等待数秒,直到测量完成并显示出结果。

四、注意事项1. 使用过程中,不要将电子温度计探头暴露在高温或低温的环境中,以免影响其测量精度和寿命。

2. 温度计探头在使用前后需要进行清洁和消毒,避免交叉感染。

3. 遵循电子温度计的使用说明,不随意拆卸、修理或更换电池。

4. 当不使用电子温度计时,请将其存放在干燥、阴凉的地方。

总结:电子温度计的正确使用方法包括选择合适的温度计、准备工作、正确的测量方法和注意事项。

我们应根据实际需求选择适用的电子温度计型号,并在使用前仔细阅读说明书。

应用中的优点非接触式红外温度传感器的主要性能指标有光谱响应、响应时间、重复性以及发射率等。

用于玻璃和陶瓷工业、造纸和包装工业、各类窑炉测温应用以及化工行业中来测仪器仪表等的温度,从而检测仪器仪表的运行状态,保证仪器的正常运行。

时代瑞资非接触式红外温度传感器的优点:在钢铁工业:钢铁工业使用温度计是因为产品都是处于运动状态,温度都非常高。

普通的钢铁工业应用是温度是一个持续的状态熔化的钢铁开始转变成块。

用同一的温度重新加热钢铁是防止它变形的关键,红外温度传感器被用来测量回热器的内部温度。

在高温旋转轧碾机中,红外温度传感器被用来确认产品的温度是在旋转限度内。

在冷却轧碾机,红外温度传感器在钢铁冷却的过程中来监控钢铁的温度。

在玻璃工业:在玻璃工业中,要被加热到很高的温度。

红外温度传感器用来监测熔炉中的温度。

手持式的传感器通过测量外部来探测高温点。

测量溶化玻璃的温度来决定适当的熔炉口的温度。

在扁平的玻璃品中,传感器在每个加工阶段都要检测温度。

错误的温度或过快的温度变化会造成不平的膨胀或收缩。

对于瓶子和容器产品来说,熔化的玻璃会流向保持在同一温度的前炉。

红外温度传感器被用来探测前炉的玻璃的温度。

所以它在出口的地方应该是适当的状态。

在玻璃纤维制品,红外传感器被用来在加工炉中探测前炉的玻璃的温度。

红外传感器在玻璃工业中另外一个用途是用于挡风玻璃制品工艺中。

在塑料工业:在塑料工业中,红外温度传感器被用来避免产品被玷污,测量动态物体和测量高温塑料。

在吹制的薄膜喷出的过程中,温度测量来调整适应加热和冷却可以帮助保持塑料的张力的完整和它的厚度。

在抛制的薄膜喷出的过程中,传感器帮助控制温度来保证产品的厚度和同一。

在薄片压出时,传感器可以让操作员来调整熄灭的加热器和冷卷来保证产品的质量。

化学工业:在石化行业中,炼厂在常规的预防维护程序中采用温度显示系统。

这些程序包括熔炉工艺的监控及热电偶示数的确认。

在熔炉工艺检测中,红外显示器被用来检测受热面管集结碳的比例。