三星SM421作业指导书 详细

- 格式:pdf

- 大小:127.10 KB

- 文档页数:7

三星盘式飞达使用作业指导书一、产品介绍三星盘式飞达是一款高效、便捷的办公设备,适用于各种办公场所。

它具有快速打印速度、高质量的打印效果和易于操作的特点,能够满足用户的各种打印需求。

二、使用前的准备1. 确保盘式飞达已经连接到电源,并且电源线已经插入到电源插座。

2. 检查打印纸的质量和尺寸是否符合要求,并将其放入打印纸托盘中。

3. 确保打印机的墨盒已经安装好,并且墨盒的墨水充足。

三、打印操作步骤1. 打开盘式飞达的盖子,将打印纸托盘拉出。

2. 将打印纸放入打印纸托盘中,并根据纸张的尺寸调整托盘的宽度。

3. 关闭打印纸托盘,并确保纸张能够顺利通过打印机。

4. 打开电源开关,等待打印机自检完成。

5. 在电脑上选择需要打印的文件,并点击打印按钮。

6. 在打印对话框中选择三星盘式飞达作为打印机,并设置打印参数。

7. 点击“打印”按钮,开始打印。

四、注意事项1. 在打印过程中,不要随意打开打印机的盖子,以免影响打印效果。

2. 如果打印纸卡住或者打印质量不佳,可以尝试重新安装打印纸或者更换墨盒。

3. 打印机长时间不使用时,应该关闭电源开关,以节省能源并延长设备寿命。

4. 定期清洁打印机的内部和外部,以保持打印质量和设备的正常运行。

五、故障排除1. 如果打印机无法正常启动,可以检查电源线是否插紧,或者尝试更换电源插座。

2. 如果打印纸卡住,可以打开打印机的盖子,轻轻拉出卡纸,并重新安装打印纸。

3. 如果打印质量不佳,可以尝试清洁墨盒或者调整打印参数。

六、总结三星盘式飞达是一款高效、便捷的办公设备,通过本指导书的介绍和操作步骤,相信用户能够轻松上手并正确使用该设备。

在使用过程中,用户应该注意一些注意事项,以保证打印质量和设备的正常运行。

如果遇到故障,用户可以根据故障排除的方法进行处理。

希望本指导书能够帮助用户更好地使用三星盘式飞达,提高工作效率。

目:在一台电脑安装SM411,421程序的方法发信:三星泰科深圳技术中心

因代理商要求同时在一台电脑安装SM411和SM421MMI,特整理了方法进行说明.

若对此资料有任何疑问请联系三星泰科深圳技术中心.(TEL.755-2733-0313)

SM411和SM421适用共同软件,所有都应安装在C:\SmartSM\文件夹.

有SM411和SM421设备的客户应安装两种程序,但若安装就会在同一个文件夹构成,导致之前的内容被删除.因此在这里简约说明SM400系列MMI的安装方法。

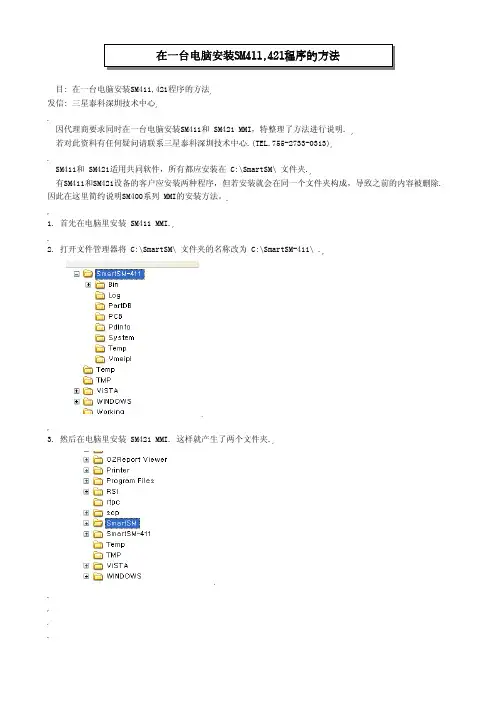

1.首先在电脑里安装SM411MMI.

2.打开文件管理器将

C:\SmartSM\

文件夹的名称改为C:\SmartSM-411\.

3.

然后在电脑里安装SM421

MMI.

这样就产生了两个文件夹.

4.打开C:\SmartSM-411\Bin\文件夹的SmartSM.ini FILE.

5.在SmartSM.ini FILE将以下用红色线标示的部分如同图片进行变更.

6.将C:\SmartSM-411\Bin\文件夹里的执行文件快捷方式到桌面,将名称改为SM411.

7.最后将桌面的SmartSM.EXE变更为SM421.

8.执行.

以上.。

关于用户指南本用户指南提供设置您的机器所需的信息。

它还提供了有关将机器用作打印机、扫描仪和复印机的全部详细说明,以及有关机器维护和故障排除等信息。

本指南第二部分软件用户指南提供了有关安装随附软件及使用其功能所需的信息。

本手册仅供参考。

手册中的信息如有变更,恕不另行通知。

Samsung Electronics 对因本手册的使用引起的或与本手册的使用相关的变更不负任何责任(无论是直接的还是间接的)。

© 2005 Samsung Electronics Co., Ltd. 保留所有权利。

• SCX-4321 和 SCX-4521F 是 Samsung Electronics Co., Ltd. 的型号名称。

• SAMSUNG 和 Samsung 徽标是 Samsung Electronics Co., Ltd. 的商标。

• Apple、AppleT alk、TrueType、Laser Writer 和 Macintosh 均为 Apple Computer, Inc. 的商标。

• Microsoft、Windows、Windows 98、Windows Me、Windows 2000、Windows NT 4.0 和 Windows XP 是 Microsoft Corporation 的注册商标。

• 所有其它品牌或产品名称均属其各自公司或组织的商标。

Contact SAMSUNG WORLD WIDE If you have any comments or questions regarding Samsung products,contact the SAMSUNG customer care center.Country Customer Care Center Web Site CANADA1-800-SAMSUNG (7267864)/ca MEXICO01-800-SAMSUNG(7267864)/mxU.S.A1-800-SAMSUNG (7267864)/ar /br CHILE800-726-7864 (SAMSUNG)/cl COSTA /latin /latin EL /latin /latin /latin /latin PUERTO /latin REP.DOMINICA/latinTRINIDAD &TOBAGO/latin /latin BELGIUM02 201 /beCZECHREPUBLIC844 000 /cz DENMARK38 322 /dk FINLAND09 693 79 /fiFRANCE08 25 08 65 65(€ 0,15/min)/frGERMANY01805 - 121213(€ 0,12/min)www.samsung.de HUNGARY06 40 985 /hu ITALIA199 153 /it LUXEMBURG02 261 03 710www.samsung.luNETHERLANDS0900 20 200 88(€ 0,10/min)/nl NORWAY231 627 /no POLAND0 801 801 /pl PORTUGAL80 8 200 /pt SLOVAKIA0850 123 /sk SPAIN902 10 11 /es SWEDEN08 585 367 /se U.K0870 242 /uk RUSSIA8-800-200-0400www.samsung.ru /ur AUSTRALIA1300 362 /au CHINA800-810-5858010- 6475 1880 HONG KONG2862 /hk INDIA3030 82821600 1100 11/in /id /jp /myPHILIPPINES1800-10-SAMSUNG(7267864)/ph SINGAPORE1800-SAMSUNG (7267864)/sg THAILAND1800-29-323202-689-3232/th /tw VIETNAM 1 800 588 /vn SOUTH AFRICA0860 7267864 (SAMSUNG)/za U.A.E800SAMSUNG (7267864)/mea Country Customer Care Center Web Site目录1. 介绍特殊功能 ........................................................................................................................ 1.1了解组件位置 ................................................................................................................... 1.2正视图 ...................................................................................................................... 1.2后视图 ...................................................................................................................... 1.2控制面板功能 .............................................................................................................. 1.32. 入门开箱 .............................................................................................................................. 2.1选择安装位置 .............................................................................................................. 2.2安装墨粉盒 ...................................................................................................................... 2.2装纸 .............................................................................................................................. 2.3建立连接 ........................................................................................................................ 2.4开机 .............................................................................................................................. 2.5安装打印机软件 ................................................................................................................ 2.6系统要求 ................................................................................................................... 2.6打印机驱动程序功能 ...................................................................................................... 2.6更改显示语言和国家 ........................................................................................................... 2.7设置语言 ................................................................................................................... 2.7设置国家 ................................................................................................................... 2.7设置机器 ID(仅限SCX-4521F) ............................................................................. 2.7使用数字键盘输入字符 ................................................................................................... 2.7设置日期和时间(仅限SCX-4521F) .......................................................................... 2.8更改时钟模式 .............................................................................................................. 2.8设置纸张尺寸和类型 ........................................................................................................... 2.9设置声音(仅限SCX-4521F) ................................................................................. 2.9扬声器、振铃、按钮音和警告音 ........................................................................................ 2.9扬声器音量 ................................................................................................................. 2.9使用节省模式 ................................................................................................................... 2.9省墨模式 ................................................................................................................... 2.9节能模式 ................................................................................................................... 2.9设置拨号模式(仅限SCX-4521F) .......................................................................... 2.103. 纸张处理选择打印介质 ................................................................................................................... 3.1纸张类型、进纸源及容量 ................................................................................................ 3.1纸张与特殊介质使用原则 ................................................................................................ 3.2装纸 .............................................................................................................................. 3.3使用纸盘 ................................................................................................................... 3.3使用手动纸盘 .............................................................................................................. 3.3验证输出位置 ................................................................................................................... 3.34. 复印为复印装纸 ...................................................................................................................... 4.1准备文档 ........................................................................................................................ 4.1在文档扫描玻璃板上复印 ..................................................................................................... 4.2从自动进纸器复印 ............................................................................................................. 4.2设置复印选项 ................................................................................................................... 4.3明暗度 ...................................................................................................................... 4.3原稿类型 ................................................................................................................... 4.3缩小/放大复印 ........................................................................................................... 4.3份数 ......................................................................................................................... 4.3使用特殊复印功能 ............................................................................................................. 4.4复制复印 ................................................................................................................... 4.4逐份复印 ................................................................................................................... 4.4自动调整复印 .............................................................................................................. 4.4身份证复印 ................................................................................................................. 4.5更改默认设置 ................................................................................................................... 4.6设置超时选项 ................................................................................................................... 4.6设置偏好复印选项 ............................................................................................................. 4.6 5. 基本打印打印文档 ........................................................................................................................ 5.1取消打印作业 ................................................................................................................... 5.1 6. 扫描扫描基础 ........................................................................................................................ 6.1从控制面板扫描到应用程序 .................................................................................................. 6.1 7. 传真(仅限SCX-4521F)设置传真系统更改传真设置选项 ............................................................................................................. 7.1可用的传真设置选项 ........................................................................................................... 7.1发送传真装入文档 ........................................................................................................................ 7.2调整文档分辨率 ................................................................................................................ 7.3自动发送传真 ................................................................................................................... 7.4手动发送传真 ................................................................................................................... 7.4重拨前一号码 ................................................................................................................... 7.4确认发送 ........................................................................................................................ 7.4自动重拨 ........................................................................................................................ 7.4接收传真关于接收模式 ................................................................................................................... 7.5为接收传真装入纸张 ........................................................................................................... 7.5在传真模式中自动接收 ........................................................................................................ 7.5在电话模式中手动接收 ........................................................................................................ 7.5在应答/传真模式下自动接收 ................................................................................................ 7.5使用分机电话手动接收 ........................................................................................................ 7.6使用 DRPD 模式接收传真 .................................................................................................... 7.6把传真接收到内存中 ........................................................................................................... 7.6自动拨号速拨 .............................................................................................................................. 7.7存储速拨号码 .............................................................................................................. 7.7使用速拨号码发送传真 ................................................................................................... 7.7组拨 .............................................................................................................................. 7.7设置组拨号码 .............................................................................................................. 7.7编辑组拨号码 .............................................................................................................. 7.7使用组拨号发送传真(多地址发送) .................................................................................. 7.8搜索内存中的号码 ............................................................................................................. 7.8连续搜索内存 .............................................................................................................. 7.8用特定首字母搜索 ........................................................................................................ 7.8打印电话簿列表 ................................................................................................................ 7.8其它传真方式发送广播传真 ................................................................................................................... 7.9发送延迟传真 ................................................................................................................... 7.9发送优先传真 .................................................................................................................7.10在预定传真中添加文档 ......................................................................................................7.10取消预定传真 .................................................................................................................7.10其它功能使用安全接收模式 ...........................................................................................................7.11打印报告 ......................................................................................................................7.11使用高级传真设置 ...........................................................................................................7.128. 维护清除内存 ........................................................................................................................ 8.1将机器设置为通过电话检查(仅限 SCX-4521F) ...........................................................................................8.2清洁机器 ........................................................................................................................ 8.2清洁机器外部 .............................................................................................................. 8.2清洁机器内部 .............................................................................................................. 8.2清洁扫描装置 .............................................................................................................. 8.3维护墨粉盒 ...................................................................................................................... 8.3摇匀墨粉 ................................................................................................................... 8.4更换墨粉盒 ................................................................................................................. 8.4设置墨粉通知选项(仅限 SCX-4521F) ......................................................................................8.4清洁硒鼓 ................................................................................................................... 8.5忽略墨粉用尽信息(仅限 SCX-4521F) .................................................................8.5耗材与可更换部件 ............................................................................................................. 8.5更换 ADF 橡胶垫 .............................................................................................................. 8.6 9. 故障排除清除文档卡纸 ................................................................................................................... 9.1进纸故障 ................................................................................................................... 9.1出纸故障 ................................................................................................................... 9.2清除卡纸 ........................................................................................................................ 9.2在纸盘中 ................................................................................................................... 9.2在手动纸盘中 .............................................................................................................. 9.2热熔区中或墨粉盒附近 ................................................................................................... 9.3出纸区中 ................................................................................................................... 9.3避免卡纸的提示 ........................................................................................................... 9.4清除 LCD 错误消息 ........................................................................................................... 9.4解决其它问题 ................................................................................................................... 9.6进纸故障 ................................................................................................................... 9.6打印故障 ................................................................................................................... 9.6打印质量问题 .............................................................................................................. 9.7复印故障 ................................................................................................................... 9.9扫描问题 ................................................................................................................... 9.9传真问题(仅限SCX-4521F) .............................................................................9.9常见 Linux 问题 .............................................................................................................9.10常见Macintosh问题 .......................................................................................................9.11打印机设置实用程序问题 ..............................................................................................9.1110. 规格一般规格 ......................................................................................................................10.1扫描和复印规格 ..............................................................................................................10.2打印机规格 .................................................................................................................... 10.2传真规格(仅限SCX-4521F)................................................................................................... 10.3纸张规格 ......................................................................................................................10.3概述 ....................................................................................................................... 10.3支持的纸张尺寸 .........................................................................................................10.4纸张使用原则 ............................................................................................................ 10.4纸张规格 .................................................................................................................10.5出纸容量 .................................................................................................................10.5纸张存放环境 ............................................................................................................ 10.5重要预防措施和安全信息使用本机器时,请务必遵循下列基本安全预防措施,以减少火灾、电击和人身伤害等危险:1阅读并了解所有说明。

SMT检验作业指导书一、引言SMT(表面贴装技术)是一种常用的电子元器件组装技术,广泛应用于电子产品创造过程中。

为确保SMT贴装工艺的质量,提高产品的可靠性和稳定性,需要进行SMT检验。

本作业指导书旨在为SMT检验提供详细的操作步骤和标准,确保检验工作的准确性和一致性。

二、检验前准备1. 确认检验设备的完好性:检查检验设备(如显微镜、检测仪器等)是否正常工作,如有损坏或者异常,需及时修复或者更换。

2. 准备检验样品:根据检验要求,准备待检样品,并确保样品的数量和质量符合要求。

3. 确认检验环境条件:检验环境应满足相应的温度、湿度和静电要求,确保检验过程的稳定性和准确性。

三、检验流程1. 外观检验外观检验是SMT检验的第一步,主要用于检查元器件的外观是否符合要求。

具体操作步骤如下:(1)使用显微镜对待检元器件进行观察,检查是否存在外观缺陷(如划痕、变形、氧化等)。

(2)根据产品规格要求,对外观缺陷进行分类和记录。

(3)判断外观缺陷的严重程度,根据标准进行评定和判定。

2. 尺寸检验尺寸检验是对SMT元器件的尺寸进行检测,以确保其尺寸是否符合设计要求。

具体操作步骤如下:(1)使用测量仪器(如卡尺、显微镜等)对待检元器件的尺寸进行测量。

(2)将测量结果与产品规格进行比对,判断尺寸是否在允许范围内。

(3)记录测量结果并进行评估,根据标准判定是否合格。

3. 电性能检验电性能检验是对SMT元器件的电性能进行测试,以验证其电气特性是否符合要求。

具体操作步骤如下:(1)连接待检元器件与测试设备,确保电路连接正确。

(2)进行电性能测试,如电流、电压、阻抗等参数的测量。

(3)将测试结果与产品规格进行比对,判断电性能是否满足要求。

(4)记录测试结果并进行评估,根据标准判定是否合格。

四、检验记录与评估1. 检验记录在每次检验过程中,需要详细记录检验的相关信息,包括待检样品的编号、检验日期、检验人员、检验结果等。

记录的目的是为了后续的分析和评估提供依据。

SM421详细说明介绍(三星官网介绍)Advanced Flexible MounterUsing the vision system which is upgraded from theSM421 vision system, the SM421 can be applied toparts from 0603 microchip to ∴22mm IC partthrough On-The-Fly recognition.It also allows recognition of parts with fine pitchsuch as ∴55mm with 0.4mm pitch by adopting amega pixel vision system for the Stage camera.It allows IC parts to be placed with high accuracy of30 microns.It also easily registers parts of complicated shapeby supporting the polygon recognition algorithm.1.1............................................................................................................... Features1.2..............................................................................................................Throughput 1.3.............................................................................................................. Modularity 1.4.............................................................................................................. Simple & Easy1.5.............................................................................................................. Software2.1............................................................................................................. Specification➢Features➢ThroughputThe unique On-The-Fly image recognition technology of Samsung Techwinown that allows part recognition without stopping after part pickup, minimizingthe time of movement between pickup position and placement position andmaximizing the placement speed by zeroing the recognition time.• Placement Speed:42,000 CPH (IPC9850),51,000 CPH (Optimal Condition)By adopting a dual work conveyor and shuttle inlet conveyor of first-in-firstout type, the PCB feeding type wasminimized and gantry efficiency is maximized due to elimination of a common work area, thus maximizing theactual productivity. Each gantry can work at full speed independently without risk of interrupting the opposinggantry. In addition, it supports various placement modes according to production characteristics and board size.The twin servo system applied to each axis of the gantry structure allows high speed placement bystrong accelerating force.• Equipped with self motion controller• Reinforced rigidity of driving system• Implementation of high acceleration and low vibration• Reduced setting time• Reinforced absolute accuracy and repetition accuracyChip ±50㎛(Cpk≥1.0),IC±30㎛(Cpk≥1.0)The newly upgraded placement accuracy calibration system automatically checks and calibrates the pickup point offset, head offset, C/V offset, etc. to allow reliable part placement.•Absolute Accuracy : ±50㎛(Cpk≥1)➢ModularityIt has an enhanced part registration library to allow quick part registration as well as stable part recognition and placement, and supports the polygon recognition related to unregistered part to allow the parts of complicated shape to be registered easily.The mega pixel camera allows the placement of parts from 0603(01005) micro chips. The SM400 series machine also allows recognition of larger parts with fine pitch or balls using 45mm camera such as □42mm with 0.4mm pitch by adopting a me ga pixel vision system for the Stage camera.The SM Series dual-lane conveyor system accommodates PCBs up to 250mm, increasing the overall placement speed. The system can also accommodate PCBs up to 460mm on a single-lane conveyor.The highest productivity compared to the area of machine : 11,700 CPH/m2➢Simple & EasyThe height of the machine was lowered through ergonomic redesign and the operation panel and keyboard position were optimized for convenient operationTwo operating consoles allow access to system controls from both the front and rear sides of themachine.All utility connections are installed inside the machine to provide aclean and safe environment.For the grease injection that is periodically performed during maintenance, the position of the nipple was considered for convenient grease injection.Samsung’s optional IT Feeder System assures correct feeder positioning because it checks the replaced feeder locations every time a component is loaded. The machine does not enter production mode when feeders are loaded incorrectly. It alerts the operator and provides easyto- follow instructions for corrective action.IT Feeder FeaturesBuilt-in CPU Board / Use of Device Net / Maintenance Record / Storage of Component No., Component Inventory, etc. / Component Shortage Warning LED / Feeder Recognition / ConfirmationFeeder Placement VerificationPerforms a changeover setup verification each time a feeder is reinserted. This feature saves valuable time and avoids costly rework due to incorrect feeder positioning.Remaining Component Quantity AlarmHelps to ensure continuous system operations. This basic function of the IT Feeder System alerts the operator that a component supply needs to be replenished, based on the remaining quantity.Production Information Tracking / Recording FunctionAutomatically tracks and generates a record of production information, such as operation hours, program developer, operated equipment, worked on components, etc.A machine checking software that automatically warns the time required for maintenance of the machine.Creates automatic placement routines on any number of machines in a production line, to configure the most productiveline balance for any environment or series of products.The SM Series features built-in optimizer software to ensure exceptionally efficient machine operation. Itautomatically configures the optimum feeder set-up and most efficient program sequence according touser-defined priority conditions. This function minimizes changeover while maximizing machine runtime.Top-quality accessories, such as non-stop tape feeders and non-stop tray feeders, increase overall system reliability and help significantly reduce amount of machine downtime.Non-Stop Tape FeederThe new SM tape feeder employs an endless-discharge method of nonstop operation in delivering reliable,repeatable, and efficient component pickups. Components supplied on tape can be reloaded easily while themachine is running, ensuring smooth continuous system operation(SM Tape Feeder).Non-Stop Tray FeederJEDEC tray cassettes are separated into upper and lower portions and can operate independently. Traycomponents also can be reloaded while the machine is running, enabling consistent non-stop operation.Side Tray FeederEntire JEDEC trays can be presented to the machine without any impact on PCB process width or availablefeeder slot locations, allowing for direct pick-up from tray and maximum efficiency of feeder space.Non-Stop Tape SplicingProvide a continuous, steady supply of available components quickly and easily using a component tape connecting splicer.Automatic Pickup Position AdjustmentSM Series systems perform real-time recognition of a component as it is picked up from the component feeder.This feature provides the ability to automatically adjust the pickup position, ensuring that components are pickedup consistently at the center, regardless of tape variations.Improved Accuracy• High feeder base stability• New mounting mechanism• Two position-control pins at the front side• Newly designed sprocketStable Indexing• Built-in cylinder• Optimized pressure control within the cylinder• Increased pick-up speeds with the index sensor• Tape guide automatically compensates for changes in tape thickness• Variable tape support (for feeders accommodating tape widths of 12mm and higher) Easy to Use• Swing-type reel hanger (splicing/verification)• Easy feeder identification by applying a different color for eachclamp (01005, 0201, 2p, 4p, 4E, general feeder)• Ergonomic handle design• Manual index switch (IT option)• Power supply indication lamp illuminates when fixed by the clamp• Tape guide lift prevention through the use of the control pinSamsung’s Docking Feeder Cart System is the key to rapid changeo ver. A Docking Feeder Cart can be loaded offline, and then quickly rolled up to the machine where it is pneumatically clamped to the feeder base. Both the front and rear sides of the SM Series machines are designed to accommodate the Docking Feeder Cart System.• Significantly reduce changeover time• Replace carts without halting production• Accommodates up to 56 8mm feeders per cart• Automatically connects to feeder power and air supply• Easily set the cart height using adjustable feetRegister up to 120 8mm feeders on one machine simultaneously. Concurrent optimizer support for 1 to 5programs allows for multiple models to be arranged at the same time. The sliding-type feeder systempermits the user to remove and replace feeders during operation without interrupting the overall system.The SM series can automatically generate a Job Change Order Sheet (feeder changeover report) while running productionin order to minimize setup time. This report identifies only the feeders that need to be changed, eliminating the need tocompletely reload the machine.The board transport system automatically adjusts to the precise board width in order to furtherfacilitate quick changeover.SM Series systems use nozzles that are common to other Samsung SMT assembly systems, allowing for interchangeability and optimal line balancing. With the increase in popularity of more delicate micro components, SM series systems have incorporated features to handle the demands of such products, specifically using nozzles with compliant mechanisms in order to prevent component damage.• Ceramic Nozzle • Bare Component Soft PAD Nozzle (Optional)Feeder Types/Sizes Feeder Pitch(mm)8mm (1005/0603) 8mm12mm16mm24mm32mm44mm56mm72mm88mm 244, 8, 124, 8, 128, 12, 16, 208, 12, 16, 20, 24, 32 8, 12, 16, 20, 24, 32, 40 8, 12, 16, 20, 24, 32, 40 8, 12, 16, 20, 24, 32, 40 8, 12, 16, 20, 24, 32, 40• Adjustable frequency control• 24 VDC, 0.8A 0.8• Maximum of four lanes• Applicable components - SOP, SOJ, QFP, PLCC, connector, etc.• Dual level magazine racks allow the component trays to be loaded while the machine is runni ng • Large capacity tray feeder for various odd-shaped components• 20 Tray (1 Tray / 1 Pallet)• 40 Tray (2 Tray / 1 Pallet)•One-touch mounting allows the tray to be easily inserted and removed from feeder base.• Flat tray installation surface enables high speed pickup.• M ultiple orientations, based on tray dimensions• Applicable Trays : 2", 4", 136 x 316mm, 200 x 316mm, 272 x 316mm• Type : Single-layer tray feeders (136 x 316mm) with 2 traysSingle-layer tray feeders (136 x 316mm) with 4 traysSignificantly reduce changeover time using the SM Series Docking Feeder Cart System. The system allows for replacing a complete feeder configuration in just minutes.Basic Set Configuration• Docking Feeder Base• Docking Cart• Minimize the space required to store unused or staged SMfeeders• SM feeder storage rack with 100 slots provides storage capacity for up to 100 SMfeeders (based on 8mm feeder)• SM feeder storage rack with 20 slots and the Feeder E xchange JIG providesstorage capacity for up to 20 SMfeeders (based on 8mm feeder)• Allows the user to replace tape reels in front of the machine, thus preventingfeeder damage and improving work efficiencyProvide a continuous, steady supply of available components to increase productivity and reduce machine downtime.• Manual Tape Splicing Tool• Portable Tape Splicing Tool• Performs the tape connecting function that guarantees high quality by moving the tool in front of the machine.Verify and adjust the feeder tape pocket position with the SM Series Feeder Calibration JIG as part of a scheduled system maintenance program to ensure reliable component pickups.Use the tape cutter to automatically cut used paper and plastic tape.• Non-Docking • Docking Cart➢SoftwareTo prevent inaccurate component placements, the SM Series systems verify that the expected component feedersare indeed in the required locations. The verification is performed using barcode information that is obtained fromthe feeder and component when they are installed on the system. The operator is notified of any incorrectlymounted feeder or component before production begins.• Stops operation after an error occurs if incorrect placement happens.• Al erts the operator when corrective action is required.Monitor real-time component inventory with barcode labels attached to the supply reels. Stock levels can bemonitored once the reel is assigned to a SM IT Feeder. Monitoring component consumption using the commondatabase allows the operator to replenish the system before the stock becomes depleted.Automatic RecognitionEach feeder has a unique identifier (ID) used to provide information about the feeder and component. Simply pressing a button automatically causes the feeder information to be registered with the control system.Advanced SM Series IT Feeder FunctionsEach SM IT feeder has a built-in CPU and memory that are used to store component information and maintenance history. Multicolor LEDs indicators provide the feeder status for easy identification of the feeder condition, allowing operators to easily monitor production progress at a glance.Shared DatabaseA common database stores information concerning the feeders, components, machines, and information on each job in real-time.The component shortage warning feature prevent component shortages in real-time during machine operation. Thisfeature minimizes machine downtime by permitting the operator to replenish components in advance so as to notimpact production.• Monitor remaining quantity for each component tape reel• Alert the user that a component shortage is imminentLoad components onto the SM IT feeders using offline stations that are connected to the shared database. Assign components to specific feeders to reduce changeover time, and further ensure accuracy using the built-in barcode system.• Minimize setup time using the Docking Feeder Cart• Verify feeder and component setup prior to operation using OLP changeover reportsLot Tracking, which is one of the options of IT Feeder System, traces and manages the history of the parts that wereused when producing boards. It minimizes the range of recall by using the LOT Tracking history file if an externalerror occurs, and it helps to easily cope with an error that occurs while the machine is running. Lot Tracking dataalso can be integrated with the modules of TUIC Co., to manage the history in SMD IN-LINE.The CAD data, ASCII data, and the placement information on the program of the machine made by other companies can be changed accurately and easily and they can be verified using Gerber file. In addition, the work program can be easily changed in the line by readjusting the actual line balance results of existing job files. Furthermore, it is possible to check the improvement result.It is possible to manage one integrated DB for each line through the network and perform work program management by line. Using the EasyOLP exclusively used for the line, the work program can be downloaded to each machine and the data and job files can be managed by automatically uploading the modified work program information, allowing reduction of work preparation time and easy work change.It is possible to monitor various production indexes and work status as well as detail information of themachine and improve the operation rate and the defect rate of the line by providing the function that tracks anerror when it occurs.It is possible to perform management of each user through registration of each line, equipment and users, and provide support to achieve quick production by outputting various reports. In addition, it is possible to create a program to allow multi-board and multi-work and predict actual working hours.➢Specification。

关于用户指南本用户指南提供设置您的机器所需的信息。

它还提供了有关将机器用作打印机、扫描仪和复印机的全部详细说明,以及有关机器维护和故障排除等信息。

本指南第二部分软件用户指南提供了有关安装随附软件及使用其功能所需的信息。

本手册仅供参考。

手册中的信息如有变更,恕不另行通知。

Samsung Electronics 对因本手册的使用引起的或与本手册的使用相关的变更不负任何责任(无论是直接的还是间接的)。

© 2005 Samsung Electronics Co., Ltd. 保留所有权利。

• SCX-4321 和 SCX-4521F 是 Samsung Electronics Co., Ltd. 的型号名称。

• SAMSUNG 和 Samsung 徽标是 Samsung Electronics Co., Ltd. 的商标。

• Apple、AppleT alk、TrueType、Laser Writer 和 Macintosh 均为 Apple Computer, Inc. 的商标。

• Microsoft、 Windows、 Windows Vista、 Windows 7 和 Windows 2008 Server R2 是 Microsoft Corporation 的注册商标或商标。

• 所有其它品牌或产品名称均属其各自公司或组织的商标。

• 请参阅所提供 CD-ROM 中的“LICENSE.txt”文件,以取得有关开放源代码的许可信息。

目录1. 介绍特殊功能 ........................................................................................................................ 1.1了解组件位置 ................................................................................................................... 1.2正视图 ...................................................................................................................... 1.2后视图 ...................................................................................................................... 1.2控制面板功能 .............................................................................................................. 1.32. 入门开箱 .............................................................................................................................. 2.1选择安装位置 .............................................................................................................. 2.2安装墨粉盒 ...................................................................................................................... 2.2装纸 .............................................................................................................................. 2.3建立连接 ........................................................................................................................ 2.4开机 .............................................................................................................................. 2.5安装打印机软件 ................................................................................................................ 2.6系统要求 ........................................................................................................................ 2.6打印机驱动程序功能 ...................................................................................................... 2.7更改显示语言和国家 ........................................................................................................... 2.8设置语言 ................................................................................................................... 2.8设置国家 ................................................................................................................... 2.8设置机器 ID(仅限SCX-4521F) ............................................................................. 2.8使用数字键盘输入字符 ................................................................................................... 2.8设置日期和时间(仅限SCX-4521F) .......................................................................... 2.9更改时钟模式 .............................................................................................................. 2.9设置纸张尺寸和类型 ......................................................................................................... 2.10设置声音(仅限SCX-4521F) ............................................................................... 2.10扬声器、振铃、按钮音和警告音 ...................................................................................... 2.10扬声器音量 ............................................................................................................... 2.10使用节省模式 ................................................................................................................. 2.10省墨模式 ................................................................................................................. 2.10节能模式 ................................................................................................................. 2.10设置拨号模式(仅限SCX-4521F) .......................................................................... 2.113. 纸张处理选择打印介质 ................................................................................................................... 3.1纸张类型、进纸源及容量 ................................................................................................ 3.1纸张与特殊介质使用原则 ................................................................................................ 3.2装纸 .............................................................................................................................. 3.3使用纸盘 ................................................................................................................... 3.3使用手动纸盘 .............................................................................................................. 3.3验证输出位置 ................................................................................................................... 3.34. 复印为复印装纸 ...................................................................................................................... 4.1准备文档 ........................................................................................................................ 4.1在文档扫描玻璃板上复印 ..................................................................................................... 4.2从自动进纸器复印 ............................................................................................................. 4.2设置复印选项 ................................................................................................................... 4.3明暗度 ...................................................................................................................... 4.3原稿类型 ................................................................................................................... 4.3缩小/放大复印 ........................................................................................................... 4.3份数 ......................................................................................................................... 4.3使用特殊复印功能 ............................................................................................................. 4.4复制复印 ................................................................................................................... 4.4逐份复印 ................................................................................................................... 4.4自动调整复印 .............................................................................................................. 4.4身份证复印 ................................................................................................................. 4.5更改默认设置 ................................................................................................................... 4.6设置超时选项 ................................................................................................................... 4.6设置偏好复印选项 ............................................................................................................. 4.6 5. 基本打印打印文档 ........................................................................................................................ 5.1取消打印作业 ................................................................................................................... 5.1 6. 扫描扫描基础 ........................................................................................................................ 6.1从控制面板扫描到应用程序 .................................................................................................. 6.1 7. 传真(仅限SCX-4521F)设置传真系统更改传真设置选项 ............................................................................................................. 7.1可用的传真设置选项 ........................................................................................................... 7.1发送传真装入文档 ........................................................................................................................ 7.2调整文档分辨率 ................................................................................................................ 7.3自动发送传真 ................................................................................................................... 7.4手动发送传真 ................................................................................................................... 7.4重拨前一号码 ................................................................................................................... 7.4确认发送 ........................................................................................................................ 7.4自动重拨 ........................................................................................................................ 7.4接收传真关于接收模式 ................................................................................................................... 7.5为接收传真装入纸张 ........................................................................................................... 7.5在传真模式中自动接收 ........................................................................................................ 7.5在电话模式中手动接收 ........................................................................................................ 7.5在应答/传真模式下自动接收 ................................................................................................ 7.5使用分机电话手动接收 ........................................................................................................ 7.6使用 DRPD 模式接收传真 .................................................................................................... 7.6把传真接收到内存中 ........................................................................................................... 7.6自动拨号速拨 .............................................................................................................................. 7.7存储速拨号码 .............................................................................................................. 7.7使用速拨号码发送传真 ................................................................................................... 7.7组拨 .............................................................................................................................. 7.7设置组拨号码 .............................................................................................................. 7.7编辑组拨号码 .............................................................................................................. 7.7使用组拨号发送传真(多地址发送) .................................................................................. 7.8搜索内存中的号码 ............................................................................................................. 7.8连续搜索内存 .............................................................................................................. 7.8用特定首字母搜索 ........................................................................................................ 7.8打印电话簿列表 ................................................................................................................ 7.8其它传真方式发送广播传真 ................................................................................................................... 7.9发送延迟传真 ................................................................................................................... 7.9发送优先传真 .................................................................................................................7.10在预定传真中添加文档 ......................................................................................................7.10取消预定传真 .................................................................................................................7.10其它功能使用安全接收模式 ...........................................................................................................7.11打印报告 ......................................................................................................................7.11使用高级传真设置 ...........................................................................................................7.128. 维护清除内存 ........................................................................................................................ 8.1将机器设置为通过电话检查(仅限 SCX-4521F) ...........................................................................................8.2清洁机器 ........................................................................................................................ 8.2清洁机器外部 .............................................................................................................. 8.2清洁机器内部 .............................................................................................................. 8.2清洁扫描装置 .............................................................................................................. 8.3维护墨粉盒 ...................................................................................................................... 8.3摇匀墨粉 ................................................................................................................... 8.4更换墨粉盒 ................................................................................................................. 8.4设置墨粉通知选项(仅限 SCX-4521F) ......................................................................................8.4清洁硒鼓 ................................................................................................................... 8.5忽略墨粉用尽信息(仅限 SCX-4521F) .................................................................8.5耗材与可更换部件 ............................................................................................................. 8.5更换 ADF 橡胶垫 .............................................................................................................. 8.6 9. 故障排除清除文档卡纸 ................................................................................................................... 9.1进纸故障 ................................................................................................................... 9.1出纸故障 ................................................................................................................... 9.2清除卡纸 ........................................................................................................................ 9.2在纸盘中 ................................................................................................................... 9.2在手动纸盘中 .............................................................................................................. 9.2热熔区中或墨粉盒附近 ................................................................................................... 9.3出纸区中 ................................................................................................................... 9.3避免卡纸的提示 ........................................................................................................... 9.4清除 LCD 错误消息 ........................................................................................................... 9.4解决其它问题 ................................................................................................................... 9.6进纸故障 ................................................................................................................... 9.6打印故障 ................................................................................................................... 9.6打印质量问题 .............................................................................................................. 9.7复印故障 ................................................................................................................... 9.9扫描问题 ................................................................................................................... 9.9传真问题(仅限SCX-4521F) .............................................................................9.9常见 Linux 问题 .............................................................................................................9.10常见Macintosh问题 .......................................................................................................9.11打印机设置实用程序问题 ..............................................................................................9.1110. 规格一般规格 ......................................................................................................................10.1扫描和复印规格 ..............................................................................................................10.2打印机规格 .................................................................................................................... 10.2传真规格(仅限SCX-4521F)................................................................................................... 10.3纸张规格 ......................................................................................................................10.3概述 ....................................................................................................................... 10.3支持的纸张尺寸 .........................................................................................................10.4纸张使用原则 ............................................................................................................ 10.4纸张规格 .................................................................................................................10.5出纸容量 .................................................................................................................10.5纸张存放环境 ............................................................................................................ 10.5重要预防措施和安全信息使用本机器时,请务必遵循下列基本安全预防措施,以减少火灾、电击和人身伤害等危险:1阅读并了解所有说明。

三星SM贴片机技术说明第一:三星贴片机SM4111、产品图片:2、产品介绍:SM411采用实现中速机的最快速贴装的三星专利On The Fly识别方式,以及双悬臂结构,从而达到芯片元器件42,000 CPH、SOP元器件30,000 CPH(IPC9850标准)在同类产品中拥有世界最快速的贴片速度。

并且,其在高速中也能实行50微米的高精度贴片,从而从最小0402芯片到最大□14mmIC元器件为止,皆可以实行贴片.产品基本特性:对中方式飞行视觉轴的数量6轴*2台架贴装速度飞行视觉Chip 1608 42,000 CPH(IPC9850) SOP 30,000CPH(IPC9850)贴装精度Chip±50um@3ó/Chip(使用标准元器件样品)窄间距贴装0.1mm(0603)/0.15mm(1005)元器件范围范围0603~□14mm Chip,QFP,BGA(0402选件) 最小引脚间距(QFP)最小球间距(BGA) 0.5mm(QFP)/0.65mm(BGA)最大高度H=12mmBoard尺寸(mm) 最小50(L)*40(W)最大510(L)*460(W)(单导轨模式)510(L)*250(W)(双导轨模式)610(L)*460(W)(选件)PCB厚度0.38-4.2供料器数量120ea/112ea(供料器交换车)能耗耗电量AC200/208/220/240/380/415V(50/60Hz,3Phase) MAX.5.0kVA耗气量5~7kg/m2 300Ne/min重量1,820kg外形尺寸(mm) 1,650(L)*1,690(D)*1,535(H)3、优点:平行双轨, 搬运PCB时间0秒极低的物料损耗率:万分之二三星独有的飞行对中识别系统(Fly Vision)供料器元件位置自动识别功能先进的扁平线结构防静电ESD吸嘴新型不停机送料器PM Manager管理功能第二、三星贴片机SM4211、产品图片:2、产品介绍:SM421采用实现中速机的最快速贴装的三星专利On The Fly识别也能对应从0603微小芯片到22mm IC元器件。

SMT检验作业指导书引言概述:SMT(表面贴装技术)是现代电子制造中广泛使用的一种技术,它通过将电子元件直接贴装在印刷电路板上,提高了生产效率和产品质量。

然而,SMT检验是确保产品质量的关键环节。

本文将介绍SMT检验的作业指导书,以帮助操作人员准确进行检验工作。

一、检验前准备1.1 确认检验标准:在进行SMT检验之前,操作人员应仔细阅读并熟悉所使用的检验标准。

这些标准包括IPC-A-610(电子组装可接受性标准)等,它们规定了电子元件的可接受程度和质量要求。

1.2 准备检验设备:操作人员需要准备适当的检验设备,如显微镜、X射线检测仪、红外热成像仪等。

这些设备能够帮助检测元件的焊接质量、引脚连接等问题。

1.3 准备检验记录表:为了记录检验结果并进行后续分析,操作人员应准备检验记录表。

这些记录表应包括产品信息、检验日期、检验项目、检验结果等。

二、外观检验2.1 检查元件的正确安装:操作人员应仔细检查元件的安装位置和方向是否正确。

他们应确保元件没有倾斜、错位或者翘起等问题。

2.2 检查焊接质量:操作人员需要检查焊接是否均匀、充分,焊点是否有裂纹或者气泡等问题。

他们还应检查焊盘是否有过度焊接或者不足焊接的情况。

2.3 检查引脚连接:操作人员应仔细检查引脚的连接情况。

他们应确保引脚与印刷电路板的焊盘之间有良好的接触,并且没有松动或者断裂的情况。

三、功能性检验3.1 进行电气测试:操作人员需要使用适当的测试设备对电子元件进行电气测试。

他们应检查元件的电压、电流等参数是否符合规定范围,并确保元件能够正常工作。

3.2 进行信号测试:操作人员应使用信号发生器等设备对电路板上的信号进行测试。

他们应确保信号传输正常,没有干扰或者失真的情况。

3.3 进行功能性测试:操作人员需要根据产品的功能要求进行相应的功能性测试。

他们应确保产品能够按照设计要求完成各项功能,并且没有故障或者异常情况。

四、记录和分析4.1 记录检验结果:操作人员应准确记录每项检验的结果,包括通过和不通过的情况。

SMT作业指导书一、背景介绍自动贴片技术(SMT)是电子元器件表面贴装技术的一种主要方式,广泛应用于电子制造领域。

为了提高学生对SMT工艺的认识和应用能力,特编写本作业指导书,引导学生完成相关SMT作业。

二、实验目的通过本次实验,旨在帮助学生:1.了解SMT的基本原理和工艺流程;2.学习掌握SMT工艺中的关键技术;3.提高学生的动手实践能力和故障排除能力。

三、实验材料1.电路板:提供给学生的实验电路板;2.贴片元件:提供给学生的SMT贴片元件;3.工具:焊锡台、烙铁、喷嘴、焊锡丝、镊子等。

四、实验步骤以下是本次SMT作业的具体步骤:1.准备工作- 清洁工作区域,确保工作环境干净整洁;- 检查实验材料,确认电路板和贴片元件齐全。

2.贴片元件的安装- 根据电路板上的元件安装图,仔细查看元件型号和位置;- 使用镊子将贴片元件从包装中取出;- 将元件按照图纸上的位置正确安装在电路板上;- 注意对极性元件的方向,并避免元件之间的短路。

3.焊接贴片元件- 准备好焊锡台、烙铁和焊锡丝;- 将焊锡台加热至适宜的温度;- 将焊锡丝融化,涂抹在贴片元件与电路板焊盘之间;- 通过烙铁进行焊接,确保焊点牢固可靠。

4.质量检查与故障排除- 检查焊点是否完整,没有冷焊、虚焊等现象;- 使用万用表或测试仪器检测电路的连通性;- 如果发现问题,根据焊接技术要求进行修复或替换。

5.完成实验报告- 撰写实验报告,详细记录实验过程和结果;- 总结实验中遇到的问题和解决方法;- 分析实验结果,并提出改进建议。

五、注意事项1.操作时要注意安全,避免烫伤和其他意外事故;2.仔细阅读工艺流程和元件安装图纸,确保操作正确无误;3.注意焊点的质量,确保焊接牢固且没有短路或冷焊等问题;4.遵守实验室的规章制度,保持实验环境整洁有序。

六、实验评分标准学生将根据以下标准进行评分:1.实验报告的完整性和准确性;2.贴片元件的正确安装和焊接质量;3.故障排除能力和问题解决的效果;4.实验操作的安全性和规范性。

SM421设备系统安装详解

1.在安装系统时请先备份C:\ SmartSM\SYSTEM\,将这三个文件备份在自己电脑中(因为系统安装好之后要使用);或直接备份整个SmartSM或SYSTEM都可以!

2.按照上图操作进行安装XP系统(系统光盘随机配有,光盘标有windows XP SM XXX),安装系统时如果设备提示输入密码(密码:admin),如果不提示输入就不用!

3.安装上图操作时请注意硬盘的格式方式,HDD表示将格式化整个硬盘,OS表示只格式化C盘,可以根据自己的需要选择,建议在安装系统时请选择OS这项,只格式化C盘就可以了!

4.将XP系统安装完后进行安装MMI操作软件,用MMI软件光盘直接插入CD-ROM,双击进行安装MMI,安装完之后将之前我们备份的C:\

SmartSM\SYSTEM\进行覆盖掉在进行关机重新启动就可以

了!。

三星贴片机作业指导书及操作规范三星cp40贴片机作业指导书及操Array作规范1.目的使机器正常、有效地运行。

2.适用范围适用于公司SMT车间三星Cpl40贴片机。

3.职责3.1技术员,机种之切换,ECN导入和机器的调试与周、月保养以及异常处理。

3.2操作员,日常之保养和生产中的操作。

3.3 IPQC,上料之核对和首件的确认。

4.基本作业4.1开机前准备:4.1.1认机器内无杂物,轨道上无PCB。

4.1.2确认左右Z轴Table上的料架有无上好。

4.1.3确认气压是否在0.5-0.55MPa。

4.1.4检查输入电压是否为单相220伏特交流电。

4.1.5检查面对机台右下方的开关是否在”ON”的位置。

4.1.6检查位于前方及后方的急紧开关(Emergency Stop)是否为解除。

4.1.74.2开机:4.2.1将顺时针方向打开。

4.2.2相隔5~10秒后,按下位在的Start(绿色按钮)。

(切记万好不要在打开后,直接按下Start,以免伤及硬件。

4.3.3进入主程序后,按下位在Operation Panel上的。

4.4.4拿起Teaching Box,设定Mode = Home之后,按下( ▼向下的方键),此时,机台所有的轴X、Y、Z、R以及Swing Mirror,除了轨道宽度以外,皆会做原点复归的动作,如果要做轨道复归动作,必需在Teaching Box上,选择Axis= W/Cv,按下,即可。

4.5.5暖机三到五分钟。

选择Utility Warm-Up,按下选择”START”。

4.5.6暖机完成后,按下钮来结束暖机。

4.3上料4.3.1操作员按排位表上料。

4.3.2操作员根据排料表领取所需物料。

4.3.3把物料挂在飞达尾部挂钩上。

4.3.4揭开飞达遮蔽器,将料带孔对准前进齿轮的齿上。

4.3.5从飞达胶带开口处拉出胶带,放下遮蔽器,压紧料带。

4.3.6将胶带按下、上、下的顺序套在胶带滑轮上,再将未端绕于卷带轮卷紧胶带4.3.7确认元件是否在吸嘴吸料位置,否则按下飞达压杆使其到位。

三星feeder管制作业指导书1. 引言在电子制造业中,feeder是一种用于供给元器件的装置。

三星作为全球领先的电子制造公司,其feeder管制作业对于生产线的高效运作至关重要。

本指导书旨在提供关于三星feeder管制作业的详细指导,以确保生产线的顺利运行。

2. 三星feeder管制作业流程三星feeder管制作业涉及多个环节,包括feeder管理、feeder检查、feeder上料等。

以下是三星feeder管制作业的流程图:2.1 Feeder管理在feeder管理环节,需要进行以下操作: 1. 新建feeder档案:记录新购入的feeder信息,包括型号、规格、状态等。

2. 编辑feeder档案:对已有的feeder 进行信息更新,如更换feeder的状态、维修记录等。

3. 删除feeder档案:当feeder不再使用或报废时,需要将其从档案中删除。

2.2 Feeder检查在feeder检查环节,需要进行以下操作: 1. 检查feeder外观:检查feeder外壳是否完好,是否有损坏或变形。

2. 检查feeder连接器:确保feeder连接器与设备连接良好,没有松动或脱落。

3. 检查feeder供料机构:检查feeder供料机构是否正常运转,是否有卡料或堵塞现象。

4. 检查feeder传感器:测试feeder传感器是否灵敏,能够准确识别元器件的供给情况。

2.3 Feeder上料在feeder上料环节,需要进行以下操作: 1. 准备上料元器件:根据生产计划,准备好需要上料的元器件,确保元器件的品质和数量符合要求。

2. 安装feeder:将准备好的feeder正确安装到设备上,并确保连接器牢固。

3. 校准feeder:根据设备要求,对feeder进行校准,确保元器件的供给准确无误。

4. 开始上料:通过设备控制界面,设置feeder的上料参数,并启动上料过程。

3. 三星feeder管制作业的注意事项在进行三星feeder管制作业时,需要注意以下事项:3.1 安全操作1.在进行feeder检查和上料操作时,必须戴上防静电手套和防静电衣物,以防止静电对元器件的损坏。