Power 750 PowerVM安装配置手册簿

- 格式:doc

- 大小:6.21 MB

- 文档页数:108

异地灾备中心Power 750 PowerVM安装配置手册使用火狐浏览器输入IP地址,显示如下界面:输入HMC默认用户名与密码:hscroot/abc123选中受管服务器,在下拉菜单中,选择更新密码输入HMC默认密码abc123输入ASMI默认密码admin选中受管服务器,下拉菜单>操作>开机开机选项,选择“正常”选择受管服务器,下拉菜单>属性将“关闭所有逻辑分区后关闭系统”选项去掉将受管服务器下的全分区关闭选择立即关闭选择“yes”选择“no”全分区已经关闭,如下图所示:再次选择受管服务器,下拉菜单>属性服务分区选择“未分配”选中受管服务器的全分区,将全分区删除选择“ok”选中受管服务器,下拉菜单>配置>创建分区>AIX or Linux分区名输入“test”概要文件输入“test_profile”选择专有处理器按下图配置CPU按下图配置内存将下列设备添加为“必须”(未完待续)将下列设备添加为“必须”添加后如下图所示:添加后如下图所示:一直单击下一步,直到出现如下画面,单击完成创建后的分区如下图所示:将系统诊断光盘放入光驱中,并激活test分区选择打开终端窗口,并点击高级按钮单击“ok”浏览器弹出如下窗口,选择“始终信任此发行者的内容”,单击是输入“0”后回车系统启动界面如下:服务器需要扫描新硬件,时间比较长,请耐心等待(大约50分钟左右),如下图输入“1”并回车出现如下画面,并回车如下画面,输入“3”并回车输入“vt100”并回车回车后出现如下画面:使用键盘的“向下方向键”移动到如下画面,选择“Raid Array Manager”并回车选择“IBM SAS Disk Array Manager”并回车选择“List SAS Disk Array Configuration”并回车选择“sissas0 Available 00-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车sissas0 与sissas2 两块SAS卡位HA的关系,下面共有5块300GB SAS 硬盘,如下图所示:按住ESC+3 返回,选择“sissas1 Available 01-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车Sissas1 与sissas3 两块SAS卡位HA的关系,下面共有5块300GB SAS 硬盘如下图所示:按ESC+3 返回,选择“Create an Array Candidate pdisk and Format to 528 Byte Sectors”回车选择“sissas0 Available 00-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车,如果出现如下画面按ESC+3 返回,选择与sissas0 同一组的另外一块SAS卡sissas2,如下图所示:按ESC+7 选择全部的5块硬盘回车,如下图所示:出现确认窗口后回车:回车后出现如下画面,此过程时间较长,请耐心等待格式化完成5块硬盘全部格式化完毕后,如下图所示:回车后如下图所示:回车后,选择“sissas1 Available 01-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”回车后如下图所示:按ESC+7键选择所有5块硬盘,如下图所示:出现确认对话框,回车开始格式化磁盘,格式化时间比较长,请耐心等待,如下图所示:格式化完成后如下图所示:回车后如下图所示。

Installation InstructionsOriginal InstructionsPowerFlex 750-Series Power JumpersCatalog Numbers 20F, 20G, 21GSummary of ChangesThis publication contains new and updated information as indicated in the following table.PowerFlex® 750-Series drives contain protective MOVs (metal-oxide varistors) and Common Mode Capacitors referenced to ground. T o guard against unstable operation and/or damage, the drive must be properly configured as shown in the tables on page 3.Topic Page Summary of Changes 1Precautions2Power Jumper Configuration2Jumper Installation, Removal, and Storage 4Jumper Locations and Settings5Topic Page Added voltage code B to the Jumper Locations and Settings table5, 6ATTENTION: The following information is merely a guide for proper installation. Rockwell Automation cannot assume responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this drive or associated equipment. A hazard of personal injury and/or equipment damage exists if codes are ignored.MOV and AC EMI Capacitor Phase to GroundCommon Mode Capacitor to Ground2Rockwell Automation Publication 750-IN011F-EN-P - June 2017PowerFlex 750-Series Power JumpersPrecautionsBefore proceeding, verify that all power to the drive has been removed.Qualified PersonnelPersonal SafetyProduct SafetyPower Jumper ConfigurationATTENTION: Allow only qualified personnel familiar with adjustable frequency AC drives and associated machinery to plan or implement the installation, start-up, and subsequent maintenance of the system. Failure to comply can result in personal injury and/or equipment damage.ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged completely before removing/installing jumpers. Frames 1 (7)Measure the DC bus voltage at the following points (see the PowerFlex 750-Series AC Drive Installation Instructions, publication 750-IN001 for locations):•Measure the DC bus voltage at the power terminal block by measuring between the +DC and -DC terminals or between the +DC and -DC test point sockets if equipped.•Also measure between the +DC terminal or test point and the chassis, and between the -DC terminal or test point and the chassis. The voltage must be zero for all three measurements.Frames 8 (10)Measure the DC bus voltage at the DC+ and DC- TESTPOINT sockets on the front of the power module (see Installation Instructions for location).ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies. Static control precautions are required when installing, testing, servicing or repairing this assembly. Component damage can result if ESD control procedures are not followed. If you are not familiar with static controlprocedures, reference an applicable ESD protection guide.ATTENTION: Risk of equipment damage exists. The drive power source type must be accurately determined. Jumpers PE-A, PE-A1, PE-A2, and PE-B must be configured for the power source type according to the recommendations shown in the following table.Rockwell Automation Publication 750-IN011F-EN-P - June 20173PowerFlex 750-Series Power JumpersT o connect or disconnect these devices, refer to pages 5…7.In addition, on an ungrounded distribution system where the line-to-ground voltages on any phase could exceed 125% of the nominal line-to-line voltage, install an isolation transformer. See Wiring and Grounding Guidelines for PWM AC Drives, publication DRIVES-IN001, for more information on impedance grounded and ungrounded systems.Recommended Power Jumper Configurations – Frames 1 (7)Power Source Type Jumper PE-A (1) (2)(MOV / Input Filter Caps)(1)When MOVs are disconnected, the power system must have its own transient protection to maintain known and controlled voltages.(2)Frame 5…7 Common DC Input drives do not have the PE-A jumper.Jumper PE-B(DC Bus Common Mode Caps)Benefits of Correct Configuration on Power Source TypeNon-solid Ground •AC fed ungrounded •Impedance grounded • B phase ground •DC fed from an active converterDisconnected Disconnected Helps avoid severe equipment damage when ground fault occurs.Solid Ground•AC fed solidly grounded•DC fed from passive rectifier, which has a solidly grounded AC sourceConnected ConnectedReduced electrical noise, most stable operation, EMC compliance, reduced voltage stress on components and motor bearings.Recommended Power Jumper Configurations – Frames 8 (10)Power Source TypeJumper PE-A1 (1)(MOV)(1)When MOVs are disconnected, the power system must have its own transient protection to Achieve known and controlled voltages.Jumper PE-A2(Input Filter Caps)Jumper PE-B(DC Bus Common Mode Caps)Benefits of Correct Configuration on Power Source TypeNon-solid Ground •AC fed ungrounded•Impedance grounded• B phase ground•DC fed from an active converter Disconnected Disconnected Disconnected Helps avoid severe equipment damage when ground fault occurs.Solid Ground•AC fed solidly grounded•DC fed from passive rectifier, which has a solidly grounded AC sourceConnected Connected ConnectedReduced electrical noise, most stable operation, EMC compliance, reduced voltage stress on components and motor bearings.IMPORTANTCommon mode capacitors are used to conform with the EMC Directives. Removing these devices can withdraw the associated directive.4Rockwell Automation Publication 750-IN011F-EN-P - June 2017PowerFlex 750-Series Power JumpersJumper Installation, Removal, and StorageJumper screws (Frames 2…5), wires (Frames 1, 6 & 7), or plugs (Frames 8…10) are used to complete an electrical connection when installed/connected. When power jumper screws are not used, they are stored on the left interiorWhen installing a jumper screw or wire, note the recommended torque listed.Drive IdentificationThe ‘Voltage Code’ and ‘Default Power Jumper Configuration’ are on the drive nameplate. Use this information to perform the proper procedure in the following tables.ATTENTION: Hazard of equipment damage exists if jumpers are not properly disconnected. For Frames 2…5, completely remove the jumper screw from the circuit board.Frames 1, 6 & 7, secure the disconnected jumper wire to the standoff provided.Frames 8…10 drive assemblies, secure the disconnected jumper plug in the socket that is provided and verify that all drive assemblies are identically configured.Recommended Torque ValuesFrames Recommended Torque Recommended Screwdriver/Socket 1Not ApplicableNot Applicable2...5 1.36 N•m (12.0 lb•in) 0.14 N•m (1.2 lb•in) 6.4 mm (0.25 in.) flat or T15 Hexalobular 6 (7)1.36 N•m (12.0 lb•in)7 mm socket or T20 HexalobularPowerFlex 750-Series Power JumpersJumper Locations and SettingsThe following pages show jumper locations and settings.Jumper Locations and SettingsRockwell Automation Publication 750-IN011F-EN-P - June 20175PowerFlex 750-Series Power JumpersJumper Locations and Settings (Continued)6Rockwell Automation Publication 750-IN011F-EN-P - June 2017PowerFlex 750-Series Power Jumpers Jumper Locations and Settings (Continued)Rockwell Automation Publication 750-IN011F-EN-P - June 20177Allen-Bradley, PowerFlex, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.Trademarks not belonging to Rockwell Automation are property of their respective companies.Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, T el: +90 (216) 5698400Rockwell Automation maintains current product environmental information on its website at/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.Publication 750-IN011F-EN-P - June 2017Supersedes Publication 750-IN011E-EN-P - February 2014Copyright © 2017 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.Rockwell Automation SupportUse the following resources to access support information.Documentation FeedbackY our comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the How Are W e Doing? form at /idc/groups/literature/documents/du/ra-du002_-en-e.pdf .Technical Support CenterKnowledgebase Articles, How-to Videos, FAQs, Chat, User Forums, and Product Notification Updates.https:///Local Technical Support Phone Numbers Locate the phone number for your country./global/support/get-support-now.page Direct Dial Codes Find the Direct Dial Code for your product. Use the code to route your call directly to a technical support engineer./global/support/direct-dial.page Literature LibraryInstallation Instructions, Manuals, Brochures, and Technical Data./global/literature-library/overview.page Product Compatibility and Download Center (PCDC)Get help determining how products interact, check features and capabilities, and find associated firmware./global/support/pcdc.pageAdditional ResourcesThese documents contain additional information concerning related products from Rockwell Automation.Y ou can view or download publications at /literature/. T o order paper copies of technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.ResourceDescriptionPowerFlex 750-Series AC Drive Installation Instructions, 750-IN001.Provides the basic steps that are required to install a PowerFlex 750-Series AC drive.Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives,publication DRIVES-IN001.Provides basic information to properly wire, help protect, and ground pulse-width modulated (PWM) AC drives.Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control, publication SGI-1.1.Provides general guidelines for the application, installation, and maintenance of solid-state control.Product Certifications website, .Provides declarations of conformity, certificates, and other certification details.。

Power-750--PowerVM部署手册简介本文档旨在向用户提供Power-750服务器上部署PowerVM的详细步骤和指导。

以下是部署流程的概述:1. 准备工作2. 安装PowerVM3. 配置PowerVM4. 测试PowerVM5. 故障排除和常见问题解决1. 准备工作在开始部署之前,确保您已完成以下准备工作:- 获得Power-750服务器的管理员权限。

- 确保您具备所需的PowerVM安装媒介(例如光盘或镜像文件)。

- 确定PowerVM的版本和适用于Power-750服务器的操作系统。

2. 安装PowerVM按照以下步骤安装PowerVM:1. 使用管理员权限登录Power-750服务器。

2. 插入PowerVM安装媒介或加载PowerVM镜像文件。

3. 执行安装程序,并按照安装向导的指示完成安装过程。

4. 在安装过程中,根据需要选择适当的安装选项,例如磁盘分区和网络设置。

3. 配置PowerVM安装完成后,按照以下步骤配置PowerVM:1. 使用管理员权限登录Power-750服务器。

2. 打开PowerVM管理界面。

3. 创建虚拟机,并配置虚拟机的资源(CPU、内存、存储等)。

4. 配置虚拟网络,包括网络适配器和网络连接。

4. 测试PowerVM为确保PowerVM部署成功,进行以下测试步骤:1. 启动虚拟机并验证其状态为“运行”。

2. 进行基本功能测试,例如在虚拟机上安装操作系统、运行应用程序等。

5. 故障排除和常见问题解决在部署和使用过程中,可能会遇到一些故障和常见问题。

以下是一些常见问题及其解决方法:- Q1: 安装过程中遇到错误消息"XXX",如何解决?- A1: 解决方法A。

- A2: 解决方法B。

- Q2: 虚拟机启动后无法访问网络,如何解决?- A1: 解决方法A。

- A2: 解决方法B。

结论本文档提供了Power-750服务器上部署PowerVM的指导手册。

Installation InstructionsOriginal InstructionsPowerFlex 750-Series Option ModulesCatalog Numbers 20-750 Series and 20-750 Series -XTSummary of ChangesThis publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect all changes. These instructions cover the installation of the option modules that are listed in the Compatible Ports figure and table. For wiring and jumper settings for these modules, see the PowerFlex® 750-Series I/O, Feedback, and Power Option Modules Installation Instructions, publication 750-IN111. For information on access to the drive control pod and how to install network communication and safety option modules, see the publications that are listed in Additional Resources .Option module catalog numbers that are used in this publication are for the standard protection versions. Select option modules are available with corrosive gas protection and contain an "XT" catalog number suffix.The instructions in this publication apply to both standard and XT option modules unless otherwise noted.TopicPage Summary of Changes 1Compatible Ports2Option Module Installation2Using Option Modules 20-750-S1 / 20-750-S4 with Option Modules 20-750-DENC-1 / 20-750-UFB-13Auxiliary Power Supply (20-750-APS) Installation3Option Module Installation Next to a PROFIBUS Option Module 411-Series and 22-Series I/O Module Installation4TopicPage Updated the S1 Row of the Compatible Ports table.2Added an Important statement regarding dielectric grease covers on XT option modules in the Option Module Installation section2Added an example figure to show the protective cover removal for edge connectors with dielectric grease in the Option Module Installation section3IMPORTANTOnly one safety option module can be installed at a time. Simultaneous safety option installations are not supported.2Rockwell Automation Publication 750-IN002K-MU-P - May 2021PowerFlex 750-Series Option Modules Installation InstructionsCompatible PortsOption Module InstallationT o install an option module, follow these steps1.Press the module edge connector firmly into the desired port.2.Tighten the top and bottom retaining screws.Option Module Cat. No. 20-750-PowerFlex 753 Drives PowerFlex 755 DrivesPowerFlex 755T DrivesFrame 1 Ports Frame 2…7 Ports Frame 1 Ports Frame 2…10 Ports Frame 5...15 Ports 65465465487654876541132C-2R, 1133C-1R2T,1132D-2RNoYesYesYesYesYesNoYesYesYesYesYesYesYesYesYesYesYesYes1132C-2R, 1133C-1R2T, 1132D-2Rwith 20-750-ATEX installed (1)(1)For detailed instructions on installation of 11-Series I/O with the ATEX option module, see the PowerFlex 750-Series ATEX User Manual, publication 750-UM003.No Yes Yes No Yes Yes No Yes Yes No No No Yes Yes No No No Yes Yes2262C-2R, 2263C-1R2T, 2262D-2R No Yes Yes Yes Yes Yes No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes APS See Page 3See Page 3See Page 3YesNo No No No Yes No No No No DENC-1(2)No Yes Yes Yes Yes Yes No Yes Yes No No Yes Yes Yes No No Yes Yes Yes ENC-1No Yes Yes Yes Yes Yes No Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes S Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes S1(2)(2)See Using Option Modules 20-750-S1 / 20-750-S4 with Option Modules 20-750-DENC-1 / 20-750-UFB-1.YesNoYesYesYesNoYes No Yes No No Yes Yes No No No Yes Yes Yes S3/S4(2)(3)(3)Must be installed in port 6 for integrated motion.Not Supported Yes No Yes No No Yes Yes Yes No No Yes Yes Yes UFB-1Not SupportedNoYesYesNoNoYesYesYesNoNoYesYesYesATTENTION:•Electric shock hazard. Verify that all sources of AC and DC power are de-energized and locked out or tagged out in accordance with the requirements of ANSI/NFPA 70E, Part II.•To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged before performing any work on the drive. Measure the DC bus voltage at the +DC and -DC terminals or test points. The voltage must be zero.For the location of the terminal block and test point sockets, see the manual for your drive:•PowerFlex 750-Series AC Drives Installation Instructions, publication 750-IN001.•PowerFlex 750-Series Products with TotalFORCE® Control Installation Instructions, publication 750-IN100.•PowerFlex 755TM IP00 Open Type Kits Installation Instructions, publication 750-IN101.•In Safe Torque Off mode, hazardous voltages may still be present at the motor. To avoid an electric shock hazard, disconnect power to the motor and verify that the voltage is zero before performing any work on the motor.IMPORTANTFor XT option modules, protective covers on connectors must be removed before installation. To maintain corrosion resistance, do not touch dielectric grease on circuit board connectors.For additional information on dielectric grease and protective covers, see the PowerFlex 750-Series Products with TotalFORCE Control Hardware Service Manual, publication 750-TG100, Chapter 1: Dielectric Grease Application20-750-APS20-750-S20-750-S120-750-2262C-2R 20-750-2263C-1R2T20-750-E NC-120-750-D E NC-120-750-U F B-120-750-1132C-2R 20-750-1133C-1R2T 20-750-S320-750-S4Rockwell Automation Publication 750-IN002K-MU-P - May 20213PowerFlex 750-Series Option Modules Installation Instructionsa.Recommended torque = 0.45 N•m (4.0 lb•in)b.Recommended screwdriver = T15 Hexalobular Using Option Modules 20-750-S1 / 20-750-S4 with Option Modules 20-750-DENC-1 / 20-750-UFB-1Auxiliary Power Supply (20-750-APS) InstallationA connector cable is provided with the Auxiliary Power Supply option module for use in PowerFlex 753 drives and in PowerFlex 755 Frame 1 drives. The cable is used to connect the module to the backplane when installed on the upper control pod brackets.IMPORTANTDo not overtighten the retaining screws.IMPORTANTWhen a Safe Speed Monitor option module (catalog number 20-750-S1), or a PowerFlex 755/755T Integrated Safety Functions option module (catalog number 20-750-S4), is used with a Dual Incremental Encoder option module (catalog number 20-750-DENC-1), or a Universal Feedback Encoder option module (catalog number 20-750-UFB-1), you must install both modules on the same backplane (ports 6, 5, 4).Only the 20-750-S1 and the 20-750-DENC-1 are depicted in the illustration to the right.IMPORTANTDo not use the Auxiliary Power Supply option module with PowerFlex 755 Frame 8 and larger drives. See the PowerFlex 750-Series AC Drives Installation Instructions, publication 750-IN001, for information on the connection of an external power supply to a PowerFlex 755 Frame 8 and larger drive.(Grease is Opaque - Shown Shaded for Example Only)NOTE : This figure is for illustrative purposes only. The specific4Rockwell Automation Publication 750-IN002K-MU-P - May 2021PowerFlex 750-Series Option Modules Installation InstructionsOption Module Installation Next to a PROFIBUS Option ModuleDo not allow the lower T15 Torx™ mounting screw (Detail A) on a new module to contact the metal cable connector of an installed PowerFlex 20-750-PBUS PROFIBUS option module. Electrical contact of the two metal parts can cause faulty operation. Perform these steps to help prevent contact. If a PowerFlex 20-750-PBUS PROFIBUS option module is not in that port, disregard these steps.1.Remove the lower T15 Torx mounting screw (Detail A) from the new module being installed. To remove the captive T15 Torx screw, the module must be removed to back the screw out of the mounting clip.2.Replace the larger T15 Torx screw with the smaller spare T8 Torx mounting screw that was shipped with the PowerFlex 20-750-PBUS PROFIBUS option module.11-Series and 22-Series I/O Module InstallationDetail A20-750-2262C-2R (24V DC)20-750-2263C-1R2T (24VDC)ATTENTION: When used in an Integrated Motion onEtherNet/IP™ network application for firmware revisions 12 and later, both the 11-Series and 22-Series I/O modules must be installed in port 7 only. You cannot use the ATEX option module with the 11-Series I/O module in port 7 when used in an Integrated Motion on EtherNet/IP application.20-750-1132C-2R (24V DC)20-750-1133C-1R2T (24V DC)20-750-1132D-2R (120V DC)Rockwell Automation Publication 750-IN002K-MU-P - May 20215PowerFlex 750-Series Option Modules Installation InstructionsAdditional ResourcesThese documents contain additional information concerning related products from Rockwell Automation®.Y ou can view or download publications at /global/literature-library/overview.page .ResourceDescriptionPowerFlex 750-Series I/O, Feedback, and Power Option Modules Installation Instructions, publication 750-IN111Provides drive compatibility, jumper settings, terminal designations, wiring examples for analog and digital I/O, feedback, and auxiliary power options option modules.PowerFlex 750-Series Products with TotalFORCE Control Hardware Service Manual, publication 750-TG001.Provides detailed information on:• Preventive maintenance • Component testing• Hardware replacement proceduresNetwork Communication Option Module Installation Instructions, publication 750COM-IN002Provides information on the installation of PowerFlex 750-Series Network Communication modules.PowerFlex 750-Series AC Drives Installation Instructions, publication 750-IN001Provides information on the mechanical and electrical installation of PowerFlex 750-Series drives.PowerFlex 750-Series Products with TotalFORCE Control Installation Instructions, publication 750-IN100Provides information on the mechanical and electrical installation of PowerFlex 750-Series products with TotalFORCE control.PowerFlex 755TM IP00 Open Type Kits Installation Instructions, publication 750-IN101Information on the installation of PowerFlex 755TM IP00 / Open Type kits in customer-sourced enclosures.PowerFlex 750-Series Safe Speed Monitor Option Module Safety Reference Manual, publication 750-RM001These publications provide detailed information on installation, set-up, and operation of the 750-Series safety option modules.PowerFlex 750-Series Safe Torque Off Option Module User Manual, publication 750-UM002PowerFlex 750-Series ATEX Option Module User Manual, publication 750-UM003PowerFlex 755 Integrated Safety - Safe Torque Off Option Module User Manual, publication 750-UM004PowerFlex 755/755T Integrated Safety Functions Option Module User Manual, publication 750-UM005Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1Provides general guidelines for installing a Rockwell Automation industrial system.Product Certifications website rok.auto/certificationsProvides declarations of conformity, certificates, and other certification details.Publication 750-IN002K-MU-P - May 2021 | Supersedes Publication 750-IN002J-MU-P-July 2019Copyright © 2021 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine UygundurPN-630034DIR 10006123460Allen-Bradley, expanding human possibility, FactoryTalk, and Rockwell Automation are trademarks of Rockwell Automation, Inc.Trademarks not belonging to Rockwell Automation are property of their respective companies.*PN-630034*PN-630034Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback .For technical support, visit rok.auto/support .Waste Electrical and Electronic Equipment (WEEE)Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec .At the end of life, this equipment should be collected separately from any unsorted municipal waste.Rockwell Automation SupportUse these resources to access support information.Documentation FeedbackYour comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback .Technical Support Center Find help with how-to videos, FAQs, chat, user forums, and product notification updates.rok.auto/supportKnowledgebaseAccess Knowledgebase articles.rok.auto/knowledgebase Local Technical Support Phone Numbers Locate the telephone number for your country.rok.auto/phonesupport Literature LibraryFind installation instructions, manuals, brochures, and technical data publications.rok.auto/literature Product Compatibility and Download Center (PCDC)Download firmware, associated files (such as AOP, EDS, and DTM), and access product release notes.rok.auto/pcdc。

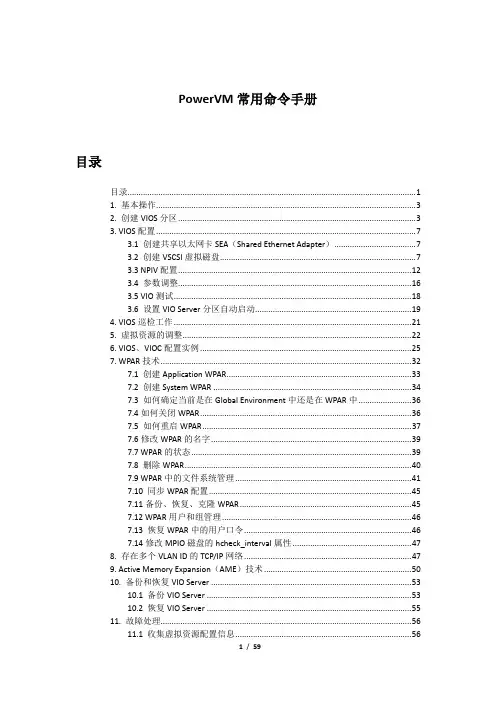

PowerVM常用命令手册目录目录 (1)1. 基本操作 (3)2. 创建VIOS分区 (3)3. VIOS配置 (7)3.1 创建共享以太网卡SEA(Shared Ethernet Adapter) (7)3.2 创建VSCSI虚拟磁盘 (7)3.3 NPIV配置 (12)3.4 参数调整 (16)3.5 VIO测试 (18)3.6 设置VIO Server分区自动启动 (19)4. VIOS巡检工作 (21)5. 虚拟资源的调整 (22)6. VIOS、VIOC配置实例 (25)7. WPAR技术 (32)7.1 创建Application WPAR (33)7.2 创建System WPAR (34)7.3 如何确定当前是在Global Environment中还是在WPAR中 (36)7.4如何关闭WPAR (36)7.5 如何重启WPAR (37)7.6修改WPAR的名字 (39)7.7 WPAR的状态 (39)7.8 删除WPAR (40)7.9 WPAR中的文件系统管理 (41)7.10 同步WPAR配置 (45)7.11备份、恢复、克隆WPAR (45)7.12 WPAR用户和组管理 (46)7.13 恢复WPAR中的用户口令 (46)7.14修改MPIO磁盘的hcheck_interval属性 (47)8. 存在多个VLAN ID的TCP/IP网络 (47)9. Active Memory Expansion(AME)技术 (50)10. 备份和恢复VIO Server (53)10.1 备份VIO Server (53)10.2 恢复VIO Server (55)11. 故障处理 (56)11.1 收集虚拟资源配置信息 (56)11.2更换VIO Server的SEA物理网卡 (56)12. topas性能监控 (58)1. 基本操作默认用户:padmin默认无密码默认用户环境为受限的Korn Shell切换到AIX root用户环境命令:oem_setup_env安装VIOS系统installios接受VIOS License文件命令:license -accept升级VIOS版本命令:updateios -commitupdateios -accept -install -dev /dev/cd0ioslevelshutdown -restart备份VIOS的配置:viosbr -backup -file /home/padmin/<backupfile_name>恢复VIOS的配置:viosbr -restore -file <backupfile_name>.tar.gz备份VIOS系统backupiosroot用户环境下输入VIOS配置命令:/usr/ios/cli/ioscli lsmap -all查看分区的CPU、内存配置lparstat -i2. 创建VIOS分区一个shared、uncapped Processor分区作为VIOS分区即可,在同一台服务器上可以部署多个VIOS分区,例如在网络IO和磁盘IO都很繁忙的应用环境,可以部署四个VIOS分区,其中两个VIOS负责处理Virtual Ethernet,另外两个VIOS负责处理Virtual Disk。

PowerVM 安装配置手册Version目录1虚拟IO服务器安装配置............................................................................................... 错误!未定义书签。

虚拟IO服务器创建............................................... 错误!未定义书签。

虚拟IO服务器分区Profile文件创建........................... 错误!未定义书签。

虚拟IO 服务器软件安装....................................... 错误!未定义书签。

安装虚拟IO服务器升级包..................................... 错误!未定义书签。

VIOS S HARED E THERNET A DATPER创建.................................... 错误!未定义书签。

VIOS VIRTUAL DISK映射 ............................................. 错误!未定义书签。

VIOS NPIV映射................................................... 错误!未定义书签。

VIOS VIRTUAL CDROM映射............................................ 错误!未定义书签。

VIOS VIRTUAL TAPE映射 ............................................. 错误!未定义书签。

2分区服务器安装配置................................................. 错误!未定义书签。

A P P E N D I X ALVD Installation Instructions For more information about LVD, see 73/23/EEC and 93/68/EEC, published by the European Economic Community (EEC).E NVIRONMENTAL C ONDITIONSPollution DegreeThe OEM750/OEM750X is designed for pollution degree 2. Installation CategoryThe OEM750/OEM750X is designed for installation category II.E LECTRICALConnecting and Disconnecting PowerThe OEM750/OEM750X's protective earth connection is provided through its heatsink. You must reliably earth the OEM750/OEM750X's protective earth connection.Attach or remove the OEM750/OEM750X's power connections only while input power is OFF.The OEM750/OEM750X's supply voltage is limited to 75 VDC. Connecting the Protective Conductor Terminal to EarthYou must provide a connection from the OEM750/OEM750X's protective conductor terminal to a reliable earth point.The protective conductor terminal is marked with a label on the product bearing the following symbol:Protective Conductor Terminal MarkingTo connect the protective conductor terminal to earth, complete these steps:➀Use a ring terminal in combination with a star washer to make good contact with the exposed metal surface surrounding one of the OEM750/OEM750X’s mounting holes. (The dimension draw-ing in Chapter 2 indicates the mounting hole that has exposedmetal.)➁Use a VDE approved green/yellow protective conductor terminal wire to reliably earth the protective conductor terminal. Wiregauge must be no thinner than the current-carrying wire in the product's mains supply.➂Resistance between the protective conductor terminal and earth must be no greater than 0.1 Ω. Use thicker gauge wire if theresistance is too high.Providing a Protective Earth Connection for MotorsYou must provide a connection from the motor to a reliable protective earth. This connection provides a protective earth for the motor contact point. The motor's protective earth connection is important for safety reasons, and must not be omitted.Compumotor’s OS Series, RS Series motors with the L10 option, and OEM83 Series motors have permanently attached cables that do not contain protective conductors (earth wires). If you use one of these motors, or any other motor without a protective conductor, make connections according to the following instructions and diagram:Motor – Earth Connection➀Use a ring terminal in combination with a star washer and mount-ing bolt to make good contact with the bare metal surface of the motor's mounting flange.➁Use a VDE approved green/yellow protective conductor terminal wire to make the connection between the motor and earth. Wire gauge must be no thinner than the current carrying wire in the motor's power cable.➂Resistance between the motor and earth must be no greater than0.1 Ω. Use thicker gauge wire if the resistance is too high. Compumotor’s RS Series motors with the C10 option have a protective conductor in the removable cable. If you use one of these motors, or any other motor with a protective conductor in its cable, connect the protective conductor to a reliable protective earth point. Follow the motor manufacturer’s installation instructions.M ECHANICALInstalling in an EnclosureThe OEM750/OEM750X must be installed within an enclosure. The enclosure’s interior must not be accessible to the operator. The enclosure should be opened only by skilled or trained service personnel.Do Not Operate the OEM750/OEM750X Without CoverThe cover provides mechanical support to the circuit assemblies inside.S ERVICING THE OEM750/OEM750XChanging FirmwareOnly skilled or trained personnel should change firmware.T HERMAL S AFETYThe Motor May Be HotThe motor may reach high temperatures during normal operations, and may remain hot after power is removed.S ONIC P RESSUREHigh Sound LevelThe sound level from some large frame step motors (NEMA 34, NEMA42, and larger) may exceed 85 dBA. Actual sound level is application dependent, and varies with motor loads and mounting conditions. Measure the sound level in your application; if it exceeds 85 dBA, install the motor in an enclosure to provide sound baffling, or provide ear protection for personnel.Table of Graphic Symbols and WarningsThe following symbols may appear in this user guide, and may be affixed to the products discussed in this user guide.Symbol DescriptionEarth TerminalProtective Conductor TerminalFrame or ChassisTerminalEquipotentialityCaution, Risk of Electric ShockCaution, Refer to Accompanying TextHot Surface。

Installation InstructionsOriginal InstructionsNetwork Communication Option ModuleCatalog Numbers 20-750-BNETIP, 20-750-DNET, 20-750-PBUS, 20-750-PNET, 20-750-PNET2P, 20-750-CNETC, 20-750-ENETR, 20-750-ENET2PProduct AdvisoriesTopic Page Product Advisories 1Install the Network Communication Option Module 2ATTENTION: Risk of injury or death exists. PowerFlex® 750-Series drives may contain high voltages that can cause injury or death. Remove power from the drive, and then verify power has been discharged before removing the drive cover.ATTENTION: Risk of equipment damage exists. The network communication option module contains electrostatic discharge (ESD) sensitive parts that can be damaged if you do not follow ESD control procedures. Static control precautions are required when handling the card. If you are unfamiliar with static control procedures, see Guarding Against Electrostatic Damage, publication 8000-4.5.2.IMPORTANT These instructions describe installing the network communication module into the drive. Depending on the type of network communication option module you are installing, additional, important procedures may also need to be performed. See the appropriate user manuals for detailed information about these procedures.Network Communication Option Module Installation InstructionsInstall the Network Communication Option Module1.Remove power from the drive.2.Remove the drive cover and lift up the drive HIM cradle (with or without the HIM installed) to its open position toaccess the drive control pod.3.into the connector.2Rockwell Automation Publication 750COM-IN003A-EN-P - January 2023Rockwell Automation Publication 750COM-IN003A-EN-P - January 20233Network Communication Option Module Installation Instructions4.Remove the lower T15 Torx mounting screw (Detail A) from the network communication module that is to the left of the PROFIBUS or PROFINET network communication module. To remove the captive T15 Torx screw, the module must be removed to back the screw out of the mounting clip.5.Replace the larger T15 Torx screw with the smaller spare T8 Torx mounting screw that was shipped with the PROFIBUS or PROFINET network communication module.6.Tighten both of the option module mounting screws to the pod mounting bracket to properly ground the module to the drive. Tighten both screws to the recommended torque shown in the following figure.IMPORTANT If you are using a PROFIBUS or PROFINET network communication module (20-750-PBUS, 20-750-PNET, or 20-750-PNET2P) with another network communication module that is positioned in the port to the left of the PROFIBUS or PROFINET module, you must replace the T15 Torx screw that holds the other network communication module to the lower mounting bracket.Replace the T15 Torx screw with a spare T8 Torx screw that is included with PROFIBUS and PROFINET modules. Due to its larger size, it is possible for the T15 Torx screw to come into contact with the PROFIBUS / PROFINET cable connector and cause faulty operation. Using the smaller T8 Torx screw helps eliminate this problem.Perform step 4 and step 5 if another network communication module is positioned in the port to the left of the PROFIBUS or PROFINET network communication module; otherwise, disregard these steps and go to step 6.Detail APublication 750COM-IN003A-EN-P - January 2023Copyright © 2023 Rockwell Automation, Inc. All rights reserved. Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeli ğine UygundurAllen-Bradley, expanding human possibility, PowerFlex, and Rockwell Automation are trademarks of Rockwell Automation,Inc.Trademarks not belonging to Rockwell Automation are property of their respective companies.Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form at rok.auto/docfeedback .For technical support, visit rok.auto/support.Waste Electrical and Electronic Equipment (WEEE)Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec.At the end of life, this equipment should be collected separately from any unsorted municipal waste.Additional ResourcesThese documents contain additional information concerning related products from Rockwell Automation.You can view or download publications at rok.auto/literature .ResourceDescription PowerFlex 20-750-BNETIP BACnet/IP Option Module User Manual, publication 750COM-UM005Provides information about using the PowerFlex 20-750-BNETIP BACnet/IP Option ModulePowerFlex 20-750-CNETC Coaxial ControlNet Option Module User Manual, publication 750COM-UM003Provides information about using the PowerFlex Coaxial ControlNet Option Module PowerFlex 20-750-DNET DeviceNet Option Module User Manual, publication 750COM-UM002Provides information about using the PowerFlex DeviceNet Option Module PowerFlex 20-750-ENETR/ENET2P Dual-port EtherNet/IP Option Module, publication 750COM-UM008Provides information about using the PowerFlex 20-750-ENETR/ENET2P Dual-port EtherNet/IP Option Module PowerFlex 20-750-PBUS Profibus DPV1 Option Module User Manual, publication 750COM-UM004Provides information about using the PowerFlex Profibus DPV1 Option Module PowerFlex PROFINET Single- and Dual-port Option Modules User Manual, publication 750COM-UM007BProvides information about using the PowerFlex PROFINET Single- and Dual-port Option Modules Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1Provides general guidelines for installing a Rockwell Automation industrial system.Product Certifications website, rok.auto/certifications .Provides declarations of conformity, certificates, and other certification details.。

PowerVM 安装配置手册Version 1.1目录1虚拟IO服务器安装配置 (3)1.1虚拟IO服务器创建 (3)1.1.1虚拟IO服务器分区Profile文件创建 (3)1.1.2虚拟IO 服务器软件安装 (12)1.1.3安装虚拟IO服务器升级包 (16)1.2VIOS S HARED E THERNET A DATPER创建 (16)1.3VIOS VIRTUAL DISK映射 (18)1.4VIOS NPIV映射 (19)1.5VIOS VIRTUAL CDROM映射 (20)1.6VIOS VIRTUAL TAPE映射 (22)2分区服务器安装配置 (23)2.1分区服务器创建 (23)2.2分区服务器虚拟光驱配置 (26)2.3分区服务器安装 (32)2.4分区服务器磁盘配置 (32)2.5分区服务器SAN存储配置 (33)2.6分区服务器网络配置 (33)3动态逻辑分区资源调整 (33)3.1分区资源调整 (33)3.2查看分区资源 (35)4在线分区迁移(LPM) (36)4.1迁移前准备 (36)4.2分区迁移验证 (36)4.3迁移分区 (38)5设备维护 (41)5.1光纤卡更换 (41)6.2网卡更换 (42)5.3ROOTVG备份与恢复 (42)6相关红皮书 (43)7常见问题排错 (43)7.1性能监控 (43)7.2常见问题 (43)1虚拟IO服务器安装配置1.1 虚拟IO 服务器创建请依照如下步骤创建VIOS分区1.1.1虚拟IO服务器分区Profile文件创建1) 如下图在HMC所管理的服务器上选择左侧server菜单下的POWER服务器建立虚拟IO 服务器分区,选择Configuration -> Create Logic Partition -> VIO Server2) 输入Partition ID 和Partition name, 完成后继续选择Next3)输入Profile name,完成后继续选择Next4)选择CPU的配置。

Power-750--PowerVM部署指南目标本文档旨在提供Power-750服务器上PowerVM的部署指南,帮助用户成功部署PowerVM虚拟化环境。

功能概述PowerVM是一种基于Power架构的虚拟化解决方案,它允许在Power-750服务器上创建和管理多个虚拟机。

在部署PowerVM 之前,需要确保服务器硬件满足最低要求,并正确配置相关组件。

部署步骤以下步骤将指导用户完成Power-750上PowerVM的部署:1. 确认服务器硬件要求:确保Power-750服务器硬件满足部署PowerVM的最低要求,包括处理器、内存和存储容量等。

2. 安装PowerVM软件:根据PowerVM软件的版本和途径,选择合适的安装方式进行安装。

用户可以通过光盘、网络或USB等方式进行安装。

3. 配置HMC(Hardware Management Console):HMC是PowerVM管理的重要组件,用户需要在部署PowerVM之前正确配置HMC,包括网络设置、用户权限等。

4. 创建虚拟机:使用HMC的管理界面,在Power-750服务器上创建所需的虚拟机。

用户需要指定虚拟机的名称、资源分配和操作系统等。

5. 分配资源:在创建虚拟机后,用户可以根据实际需求对虚拟机进行资源分配,包括CPU的核数和频率、内存容量和存储空间等。

6. 安装操作系统:根据虚拟机的需求,在虚拟机上安装合适的操作系统。

用户可以选择AIX、IBM i或Linux等操作系统。

7. 配置网络和存储:对于每个虚拟机,用户需要配置网络和存储,以便虚拟机能够正常访问网络和存储资源。

8. 测试和优化:在部署完成后,用户应该对PowerVM环境进行测试和优化,确保其正常运行和性能良好。

注意事项在部署PowerVM时,用户应注意以下事项:- 确保服务器硬件满足最低要求,以避免在部署过程中发生不必要的问题。

- 选择适合的PowerVM版本和安装方式,根据实际需求进行配置。

PowerVM 安装配置手册Version 1.1目录1虚拟IO服务器安装配置 (3)1.1 ......................................................... 虚拟IO服务器创建31.1.1........................................ 虚拟IO服务器分区Profile文件创建31.1.2.................................................. 虚拟IO 服务器软件安装121.1.3................................................. 安装虚拟IO服务器升级包161.2 ............................................... VIOS S HARED E THERNET A DATPER创建161.3 ....................................................... VIOS VIRTUAL DISK映射181.4 ............................................................ VIOS NPIV映射191.5 ...................................................... V IOS VIRTUAL CDROM映射201.6 ....................................................... VIOS VIRTUAL TAPE映射222 .......................................................... 分区服务器安装配置232.1 ............................................................ 分区服务器创建232.2 .................................................... 分区服务器虚拟光驱配置262.3 ............................................................ 分区服务器安装322.4 ........................................................ 分区服务器磁盘配置322.5 .................................................... 分区服务器SAN存储配置332.6 ........................................................ 分区服务器网络配置333 ......................................................... 动态逻辑分区资源调整333.1 .............................................................. 分区资源调整333.2 .............................................................. 查看分区资源354 ........................................................... 在线分区迁移(LPM) 364.1 ............................................................... 迁移前准备364.2 .............................................................. 分区迁移验证364.3 ................................................................. 迁移分区385 ................................................................... 设备维护415.1 ............................................................... 光纤卡更换416.2网卡更换 (42)5.3 ........................................................... R OOTVG备份与恢复426 ..................................................................相关红皮书437 ................................................................ 常见问题排错437.1 ................................................................. 性能监控437.2 ................................................................. 常见问题431虚拟IO服务器安装配置1.1虚拟IO 服务器创建请依照如下步骤创建VIOS分区1.1.1虚拟IO服务器分区Profile文件创建1) 如下图在HMC所管理的服务器上选择左侧server菜单下的POWER服务器建立虚拟IO 服务器分区,选择Configuration -> Create Logic Partition -> VIO Server2) 输入Partition ID 和Partition name, 完成后继续选择Next3)输入Profile name,完成后继续选择Next4)选择CPU的配置。

Power-750--PowerVM安装配置手册

简介

本手册旨在提供Power-750和PowerVM的安装和配置指南。

硬件要求

- Power-750服务器

- 至少8GB的内存

- 至少500GB的磁盘空间

- 支持虚拟化技术

软件要求

- PowerVM镜像文件

- IBM PowerVM软件许可证

- Power-750固件升级包

安装步骤

步骤1:固件升级

步骤2:安装操作系统

1. 将PowerVM镜像文件拷贝到一个可访问的位置。

2. 启动Power-750服务器,并按照提示进入Setup Utility界面。

3. 在Setup Utility界面中,设置启动顺序为从CD/DVD驱动器

启动。

4. 插入PowerVM镜像光盘。

5. 从光盘启动服务器,并按照提示进行操作系统安装。

步骤3:配置PowerVM

1. 安装完成后,重新启动服务器。

2. 在PowerVM Boot Wizard界面中,按照提示设置PowerVM

的网络连接和存储选项。

3. 确认配置信息无误后,等待PowerVM启动。

注意事项

- 在安装和配置过程中,务必保证服务器的稳定性和安全性。

- 请严格按照官方文档和说明进行操作,以确保安装和配置的

正确性。

- 如果遇到问题或困惑,请随时与IBM技术支持联系。

结论

本文档提供了Power-750和PowerVM的安装和配置手册,帮助用户正确地安装和配置PowerVM虚拟化软件。

异地灾备中心Power 750 PowerVM安装配置手册使用火狐浏览器输入IP地址https://10.0.0.2,显示如下界面:

输入HMC默认用户名与密码:

hscroot/abc123

选中受管服务器,在下拉菜单中,选择更新密码

输入HMC默认密码 abc123

输入ASMI默认密码admin

选中受管服务器,下拉菜单>操作>开机

开机选项,选择“正常”

选择受管服务器,下拉菜单>属性

将“关闭所有逻辑分区后关闭系统”选项去掉

将受管服务器下的全分区关闭

选择立即关闭

选择“yes”

选择“no”

全分区已经关闭,如下图所示:

再次选择受管服务器,下拉菜单>属性

服务分区选择“未分配”

选中受管服务器的全分区,将全分区删除

选择“ok”

选中受管服务器,下拉菜单>配置>创建分区>AIX or Linux

分区名输入“test”

概要文件输入“test_profile”

选择专有处理器

按下图配置CPU

按下图配置存

将下列设备添加为“必须”(未完待续)

将下列设备添加为“必须”

添加后如下图所示:

添加后如下图所示:

一直单击下一步,直到出现如下画面,单击完成

创建后的分区如下图所示:

将系统诊断光盘放入光驱中,并激活test分区

选择打开终端窗口,并点击高级按钮

单击“ok”

浏览器弹出如下窗口,选择“始终信任此发行者的容”,单击是

输入“0”后回车

系统启动界面如下:

服务器需要扫描新硬件,时间比较长,请耐心等待(大约50分钟左右),如下图

输入“1”并回车

出现如下画面,并回车

如下画面,输入“3”并回车

输入“vt100”并回车

回车后出现如下画面:

使用键盘的“向下方向键”移动到如下画面,选择“Raid Array Manager”并回车

选择“IBM SAS Disk Array Manager”并回车

选择“List SAS Disk Array Configuration”并回车

选择“sissas0 Available 00-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车

sissas0 与 sissas2 两块SAS卡位HA的关系,下面共有5块300GB SAS 硬盘,如下图所示:

按住ESC+3 返回,选择“sissas1 Available 01-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车

Sissas1 与 sissas3 两块SAS卡位HA的关系,下面共有5块300GB SAS 硬盘如下图所示:

按ESC+3 返回,选择“Create an Array Candidate pdisk and Format to 528 Byte Sectors”回车

选择“sissas0 Available 00-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”并回车,如果出现如下画面

按ESC+3 返回,选择与sissas0 同一组的另外一块SAS卡sissas2,如下图所示:

按ESC+7 选择全部的5块硬盘回车,如下图所示:

出现确认窗口后回车:

回车后出现如下画面,此过程时间较长,请耐心等待格式化完成

5块硬盘全部格式化完毕后,如下图所示:

回车后如下图所示:

回车后,选择“sissas1 Available 01-00 PCI Express x8 Ext Dual-x4 3Gb SAS Adapter”

回车后如下图所示:

按ESC+7键选择所有5块硬盘,如下图所示:

出现确认对话框,回车

开始格式化磁盘,格式化时间比较长,请耐心等待,如下图所示:

格式化完成后如下图所示:

回车后如下图所示。