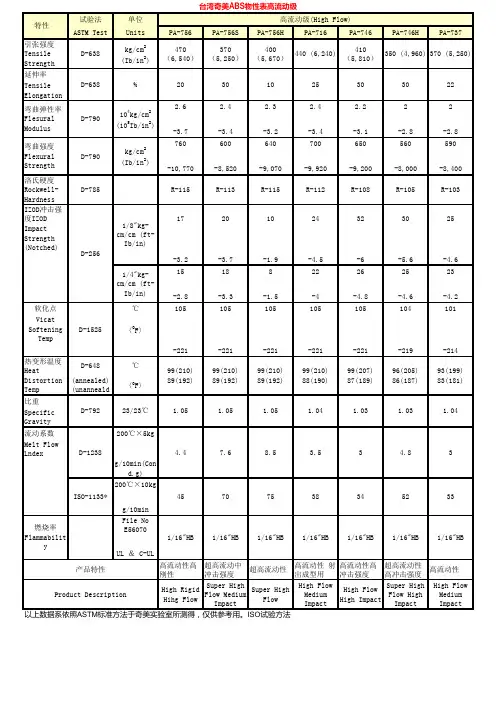

ABS台湾奇美PA-757物性表

- 格式:wps

- 大小:49.50 KB

- 文档页数:1

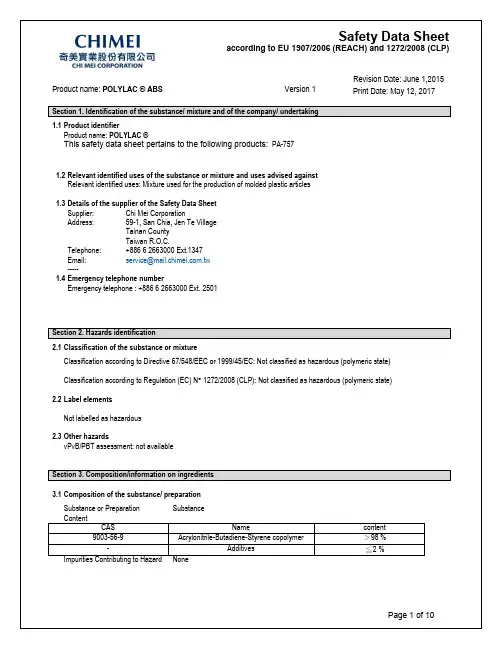

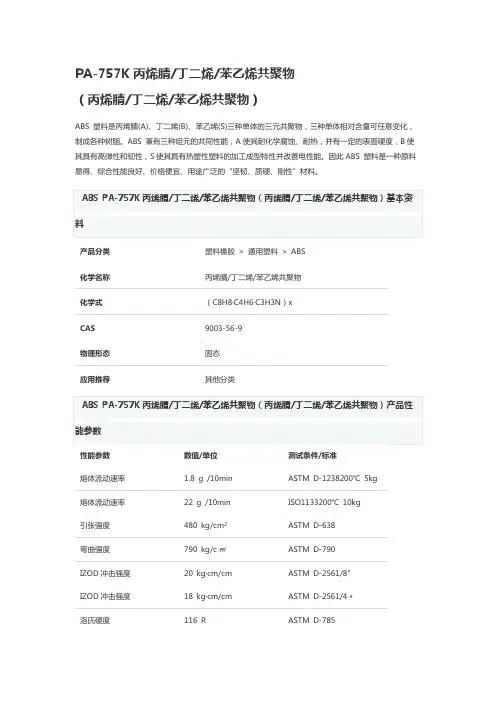

PA-757K丙烯腈/丁二烯/苯乙烯共聚物(丙烯腈/丁二烯/苯乙烯共聚物)ABS 塑料是丙烯腈(A)、丁二烯(B)、苯乙烯(S)三种单体的三元共聚物,三种单体相对含量可任意变化,制成各种树脂。

ABS 兼有三种组元的共同性能,A使其耐化学腐蚀、耐热,并有一定的表面硬度,B使其具有高弹性和韧性,S使其具有热塑性塑料的加工成型特性并改善电性能。

因此ABS 塑料是一种原料易得、综合性能良好、价格便宜、用途广泛的“坚韧、质硬、刚性”材料。

ABS PA-757K丙烯腈/丁二烯/苯乙烯共聚物(丙烯腈/丁二烯/苯乙烯共聚物)产品性能参数性能参数数值/单位测试条件/标准熔体流动速率 1.8 g /10min ASTM D-1238200℃5kg熔体流动速率22 g /10min ISO1133200℃10kg引张强度480 kg/cm2ASTM D-638弯曲强度790 kg/c㎡ASTM D-790IZOD冲击强度20 kg·cm/cm ASTM D-2561/8"IZOD冲击强度18 kg·cm/cm ASTM D-2561/4〃洛氏硬度116 R ASTM D-785伸长率20 % ASTM D-790比重 1.05 23℃/23℃ASTM D-792维卡软化点105(221) ℃(℉) ASTM D-1525热变形温度99(210) °C(°F) ASTM D-648热变形温度88(190) °C(°F) ASTM D-648弯曲弹性率 2.7 104kg/cm2ASTM D-790燃烧性1/16"HB Class File NO.E196075产品说明白色、高光泽、高刚性用途:电视机前壳/ 复印机外壳/ 电话机壳/ 化妆品盒/ 轮胎盖总体描述:材料状态流通,正常特性高光泽;高刚性用途小家电;汽车领域的应用加工方法注塑外观白色形态粒子。

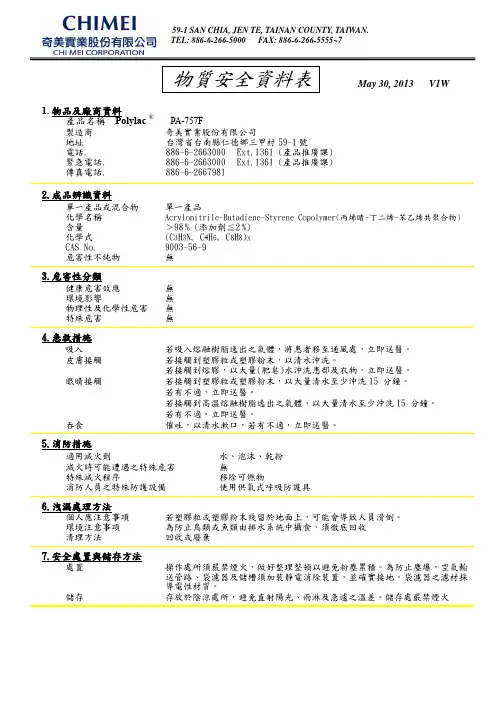

No. 59-1, SAN CHIA, JEN TE DISTRICT, TAINAN CITY, TAIWANTEL: +886-6-266-5000 FAX:+886-6-266-5555~7The above statement is based on our current level of knowledge and covers the above products directly manufactured and supplied by CHI MEI CORPORA TION at the date of issue. CHI MEI CORPORA TION makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information. Notwithstanding the foregoing, CHI MEI CORPORA TION shall in no event be held obligated or liable for any claims due to or arising from (i) any customer provided, consigned, materials and/or parts, which are incorporated or adopted in the products; (ii) any combination of the products with material not provided or authorized by our company; (iii) any modifications to the products which are made or directed by customer; (iv) our compliance with the specifications, instructions, and/or designs provided by customer; (v) any anti-trust, unfair competition and/or other unlawful actions effected by customer; or (vi) any defects, infringement, breach a nd/or violation which are arising out of customer’s faults or otherwise not solely and directly attributable to CHI MEI CORPORA TION. In no event will CHI MEI CORPORA TION be liable for any indirect, special, exemplary, punitive, or consequential damages (including lost profits) of any nature whatsoever whether arising out of the purchase, shipment, unloading, handling, or use of any product or otherwise.General ABS POLYLAC ® Characteristics PA-757April 8, 2013Notes :These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.。

ABS产品型号及物性塑料原料ABS/AG12A0/台湾化纤通用级用途:鞋跟,玩具,时钟外壳,音响外壳,手提箱,板状制品,冰箱内壳。

特性:高耐冲击性,一般成型熔体流动速率: 1.6 g/10min | 密度: 1.04 g/cm3 | 缺口冲击强度: 30 | 拉伸强度: 50 MPa | 弯曲强度:74 MpaABS/AG15A1/台湾化纤通用级用途:鞋跟,玩具,时钟外壳,音响外设,手提箱。

特性:特性:高光泽性、高耐冲击性。

熔体流动速率: 1.6 g/10min | 密度: 1.05 g/cm3 | 缺口冲击强度: 20 | 拉伸强度: 50 MPa | 弯曲强度: 84 MPa |ABS/AT5500/台湾化纤透明级用途:透明板,冰箱内抽屉及隔板,实验室容器,蓄电池外壳。

特性:特性:透明。

熔体流动速率: 2.1 g/10min | 密度: 1.07 g/cm3 | 缺口冲击强度: 15 | 拉伸强度: 44 MPa | 弯曲强度: 72 MPa |ABS/ANC120/台湾化纤阻燃级用途:防火级材料,电视外壳,电脑外壳,录影带机外壳。

特性:特性:难燃性。

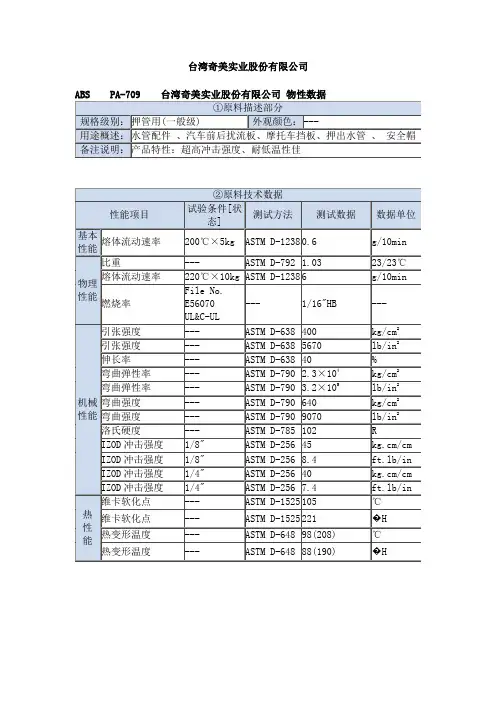

熔体流动速率: 4.5 g/10min | 密度: 1.19 g/cm3 | 缺口冲击强度: 22 | 拉伸强度: 39 MPa | 弯曲强度: 64 MPa |塑料原料ABS/AG15A1/宁波台化注塑级用途:鞋跟,玩具,时钟外壳,音响外壳,手提箱特性:特性:高光泽性,一般成型熔体流动速率: 1.6 g/10min | 密度: 1.05 g/cm3 | 缺口冲击强度: 20 | 拉伸强度: 50 MPa | 弯曲强度: 84 MPa |塑料原料ABS/ANC120/宁波台化用途:防火级材料,电视外壳,电脑外壳,录影带机外壳特性:特性:难燃性熔体流动速率: 4.5 g/10min | 密度: 1.19 g/cm3 | 缺口冲击强度: 22 | 拉伸强度: 39 MPa | 弯曲强度: 64 MPa |塑料原料ABS/PA-709/台湾奇美通用级用途:水管配件、汽车前后扰流板、摩托车挡板、押出水管、安全帽特性:产品特性:超高冲击强度、耐低温性佳台湾奇美实业股份有限公司熔体流动速率: 0.6 g/10min | 密度: 1.03 g/cm3 | 缺口冲击强度: 45 | 拉伸强度: 39 MPa | 断裂伸长率: 40 % |塑料原料ABS/PA-727/台湾奇美通用级用途:通用于一切需要电镀装饰配件按钮、音响器材面板、轮胎盖、镜框、时钟外壳及汽车部品等特性:产品特性:电镀性佳台湾奇美实业股份有限公司熔体流动速率: 1.7 g/10min | 密度: 1.04 g/cm3 | 缺口冲击强度: 26 | 拉伸强度: 47 MPa | 断裂伸长率: 20 % | 塑料原料ABS/PA-746H/台湾奇美通用级用途:性能相当于PA-747,可注射成型大面或薄肉成型品,如摩托车侧盖挡板。

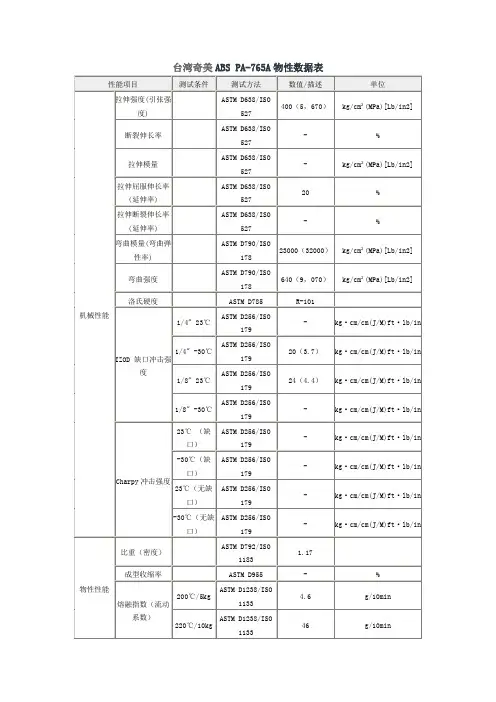

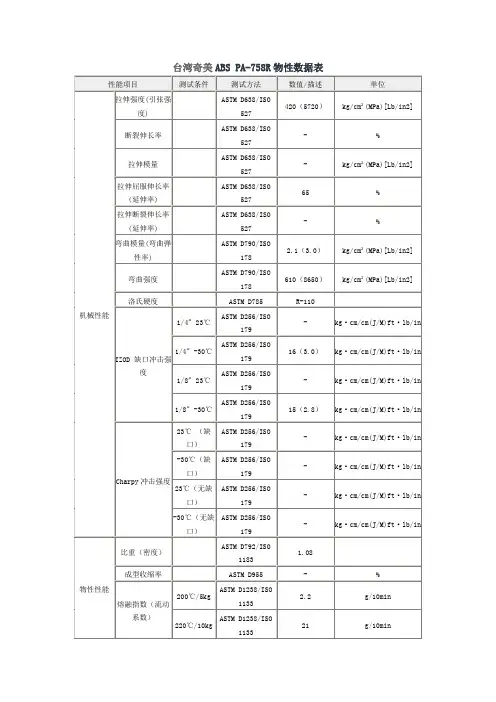

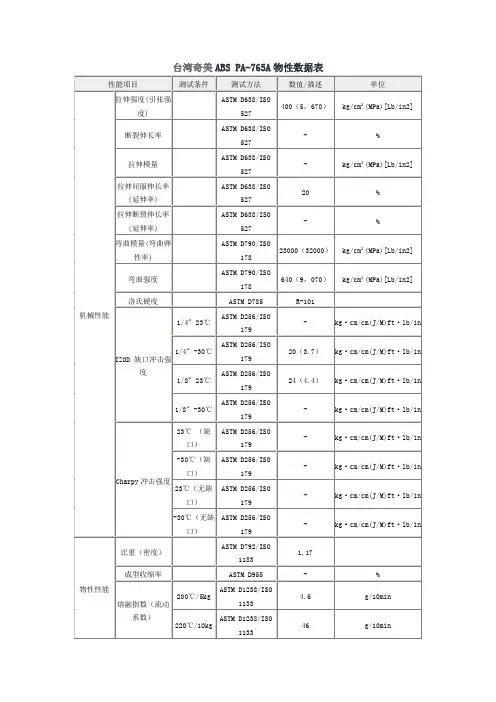

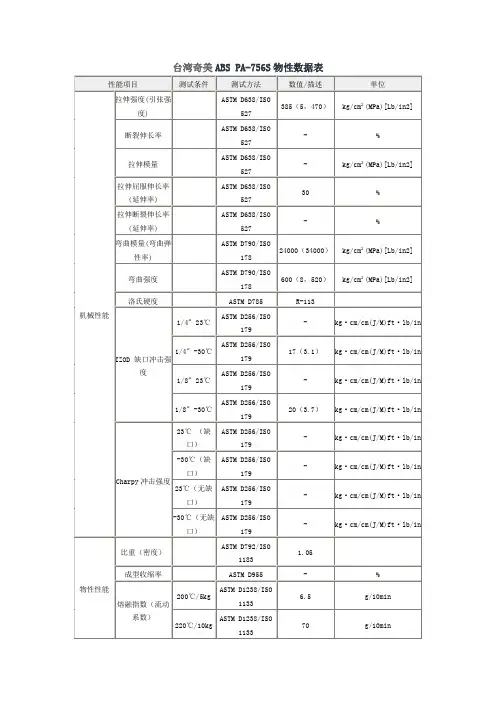

59-1 SAN CHIA, JEN TE, TAINAN COUNTY, TAIWAN.TEL: 886-6-266-5000 FAX: 886-6-266-5555~7The above statement is based on our current level of knowledge and covers the above products directly manufactured and supplied by CHI MEI CORPORA TION at the date of issue. CHI MEI CORPORA TION makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information. Notwithstanding the foregoing, CHI MEI CORPORA TION shall in no event be held obligated or liable for any claims due to or arising from (i) any customer provided, consigned, materials and/or parts, which are incorporated or adopted in the products; (ii) any combination of the products with material not provided or authorized by our company; (iii) any modifications to the products which are made or directed by customer; (iv) our compliance with the specifications, instructions, and/or designs provided by customer; (v) any anti-trust, unfair competition and/or other unlawful actions effected by customer; or (vi) any defects, infringement, breach and/or violation which are arising out of customer’s faults or otherwise not solely and directly attributable to CHI MEI CORPORA TION. In no event will CHI MEI CORPORA TION be liable for any indirect, special, exemplary, punitive, or consequential damages (including lost profits) of any nature whatsoever whether arising out of the purchase, shipment, unloading, handling, or use of any product or otherwise.Flame Retardant ABS, POLYLAC ® Characteristics September 11, 2012PropertiesISO Test Condition Unit PA-763 PA-763APA-765 PA-765APA-765B PA-764 PA-764B MVI 1133 220℃×10kgml/10min 30 28 49 46 45 30 25 Mass Density 1183 23℃g/cm 31.19 1.17 1.19 1.17 1.16 1.19 1.16 Tensile Strength 527 50mm/min, yield MPa 41 42 39 40 41 39 40 50mm/min, break MPa 32 33 34 28 30 29 30 Tensile Elongation 527 50 mm/min % 15 20 10 10 10 10 10 Flexural Strength 178 2 mm/min MPa 59 60 55 54 57 55 57 Flexural Modulus 178 2 mm/min GPa 22.1 1.8 1.7 1.8 1.7 1.8 Izod Impact Strength180/1A Notched KJ/m 2 20 22 17 19 20 13 14 Unnotched KJ/m 2 - - - - - - - Charpy Impact 179 Notched KJ/m 2 20 22 20 20 20 14 17 Unnotched KJ/m 2 - - - - - - - Vicat Softening Temp.306 50℃/hr;1kg ℃ 103 104 90 90 90 99 99 50℃/hr;5kg ℃ 96 97 78 79 79 84 85 H.D.T / A75 1.8 MPa,unanneal ℃ 86 87 74 76 77 74 83 1.8 MPa,anneal℃ 96 97 90 91 91 96 97 Ball Indentation Hardness2039-1H358/30 - 80 80 79 81827578Flammability-UL-94-1.6mm V-02.5mm 5VB2.1mm V-01.6mm V-02.5mm 5VA 2.1mm V-0 2.5mm 5VA 2.5mm V-03.2mm 5VA 1.6mm V-0 2.5mm 5VA 2.5mm V-03.2mm 5VANotes :These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests。

台南縣仁德鄉三甲村59-1號TEL: 886-6-266-3000 FAX: 886-6-266-5555~7一般級 ABS, POLYLAC ® 材料特性 January 11, 2012 V1W特性特性測試方法測試方法測試條件測試條件單位(Unit) PA-707 PA-757 PA-717C PA-727 PA-747 PA-709 Properties Test Method Test Condition 引張強度引張強度 ASTM D638 3mm, 6mm/min Kg/cm 2 490 460 430 485 385 400 Tensile Strength 延伸率延伸率 ASTM D638 3mm, 6mm/min % 20 25 30 20 30 40 Tensile Elongation 彎曲強度彎曲強度 ASTM D790 6mm, 2.8 mm/min Kg/cm 2 860 790 720 780 620 640 Flexural Strength 彎曲彈性率彎曲彈性率 ASTM D790 6mm, 2.8 mm/minKg/cm 2 29000 27000 25000 27000 22000 23000 Flexural Modulus IZOD 衝擊強度 ASTM D256 6mm, 23℃Kg-cm/cm 14 18 25 23 32 37 Izod Impact Strength(Notched) 3mm, 23℃ 16 21 29 26 41 45 流動係數流動係數 Melt Flow Index Melt Flow IndexASTM D1238 200℃, 5Kg g/10min 1.7 1.6 1.3 1.6 1.1 0.5 220℃, 10Kg23 22 14 19 13 15 硬度硬度ASTM D785 - R Scale116 116 115 110 108 102 Hardness 比重比重 ASTM D792 23℃ - 1.06 1.05 1.04 1.04 1.03 1.03 Specific Gravity 軟化點軟化點 ASTM D1525 3mm, 50℃/hr ℃ 105 105 104 105 103 105 Vicat Softening Temp. 熱變形溫度熱變形溫度 ASTM D648Annealed ℃95 95 95 95 95 95 Heat Distortion Temp.Unannealed85 85 85 85 85 85 燃燒率燃燒率 Flammability FlammabilityUL 94 --1.6mm, HB1.6mm, HB1.6mm, HB1.6mm, HB1.6mm, HB1.6mm, HB以上數據僅代表一般通用數據,並不代表每一產品的規格值若有任何疑問請洽奇美業務人員或電洽06-2663000。

No. 59-1, SAN CHIA, JEN TE DISTRICT, TAINAN CITY, TAIWANTEL: +886-6-266-5000 FAX:+886-6-266-5555~7The above statement is based on our current level of knowledge and covers the above products directly manufactured and supplied by CHI MEI CORPORA TION at the date of issue. CHI MEI CORPORA TION makes no warranties, whether express or implied, and assumes no liability in connection with any use of above information. Notwithstanding the foregoing, CHI MEI CORPORA TION shall in no event be held obligated or liable for any claims due to or arising from (i) any customer provided, consigned, materials and/or parts, which are incorporated or adopted in the products; (ii) any combination of the products with material not provided or authorized by our company; (iii) any modifications to the products which are made or directed by customer; (iv) our compliance with the specifications, instructions, and/or designs provided by customer; (v) any anti-trust, unfair competition and/or other unlawful actions effected by customer; or (vi) any defects, infringement, breach and/or violation which are arising out of customer’s faults or otherwise not solely and directly attributable to CHI MEI CORPORA TION. In no event will CHI MEI CORPORA TION be liable for any indirect, special, exemplary, punitive, or consequential damages (including lost profits) of any nature whatsoever whether arising out of the purchase, shipment, unloading, handling, or use of any product or otherwise.General ABS POLYLAC ® Characteristics PA-707May 2, 2013Notes :These are typical properties only and are not to be construed as specifications. Users should confirm results by their own tests.。