Unclejuice标准培训手册

- 格式:doc

- 大小:196.00 KB

- 文档页数:6

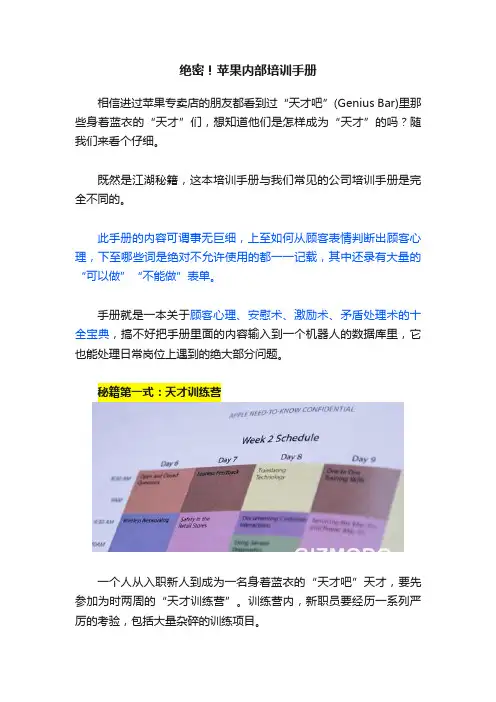

绝密!苹果内部培训手册相信进过苹果专卖店的朋友都看到过“天才吧”(Genius Bar)里那些身着蓝衣的“天才”们,想知道他们是怎样成为“天才”的吗?随我们来看个仔细。

既然是江湖秘籍,这本培训手册与我们常见的公司培训手册是完全不同的。

此手册的内容可谓事无巨细,上至如何从顾客表情判断出顾客心理,下至哪些词是绝对不允许使用的都一一记载,其中还录有大量的“可以做”“不能做”表单。

手册就是一本关于顾客心理、安慰术、激励术、矛盾处理术的十全宝典,搞不好把手册里面的内容输入到一个机器人的数据库里,它也能处理日常岗位上遇到的绝大部分问题。

秘籍第一式:天才训练营一个人从入职新人到成为一名身着蓝衣的“天才吧”天才,要先参加为时两周的“天才训练营”。

训练营内,新职员要经历一系列严厉的考验,包括大量杂碎的训练项目。

有“诊断设备的使用(Using Diagnostic Services这里有一个问题,图片中明显是Using Service Diagnostics)”、“组件绝缘(Component Isolation)”和“同理心的神奇力量(The Power of Empathy)”等等。

没错,苹果就是要在这样一个项目内为新员工搭建起自助性小组,已完成对员工的技术性与心理学教育。

在“天才培训手册”的第七页,记载着一大堆“什么是(What)”和“怎么样(How)”。

比如:问:何为“天才”的工作职责?答:教导(Educates)。

问:如何教导(顾客)呢?答:要温文尔雅、要有主人翁思想、要有同理心、要为顾客提出建议、说话要有说服力、争取让顾客点头。

总而言之,就是:与顾客产生共鸣、把产品推介出去、把交易拿下。

我们可以发现苹果在给每一个即将走进“天才吧”的员工做心理培训,这和Apple Store的环境有着紧密的联系。

与其他的零售店相比,Apple Store员工的一大工作职责就是让每一个顾客过得开心。

当然,作为一个以买卖为主的消费场所,顾客的好心情自然会转化为苹果在零售上的成功。

PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.P R I M E R B O O T H U S E A N DI N S T R U C T I O NH A N D B O O KA 04.08.08 FIRST ISSUE BELLAGAMBA BELLAGAMBA JULITTA Rev. Data Description By Checked ApprovedPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.TABLE OF CONTENTS1PRIMER BOOTH (3)1.1GENERAL DESCRIPTION (3)1.2WORKING PRINCIPLE (7)1.3REFERENCE DRAWINGS (11)2 SYSTEM CLEANING AND MAINTENANCE (12)2.1ORDINARY PREVENTIVE MAINTENANCE TABLES (12)2.2ORDINARY PREVENTIVE MAINTENANCE TABLES (14)2.3INSTRUCTIONS FOR SAFELY PERFORMING USE AND MAINTENANCE OPERATIONS FOR PAINTING BOOTHS (14)2.3.1 RISKS OF FIRE (14)2.3.2 HEALTH MEASURES AND PRECAUTIONS (15)2.3.3 ORDINARY MAINTENANCE OPERATIONS (16)2.3.4 EXTRAORDINARY MAINTENANCE AND/OR REPAIRS (16)PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.1P R I M E R S P R A Y B O O T H1.1G E N E R A L D E S C R I P T I O NThe goal of this booth is to realize an ideal working area to apply the first paint layer (called primer) on the body. This has been divided into five (5) areas:- 1° Tack-rag, 6 m long, for body tack rag and clean.- 2° Tack-rag, 6 m long, for body tack rag and clean.- Internal manual, 6 m long, where the body is painted in its internal parts with pistols manuals by operators.- External manual, 6 m long, where the body is painted in its external parts with pistols manuals by operators.- Flash-off (room temperature), 4 m long. In this zone car body is dried before entering the baking oven.This subdivision refers to 1° phase, in case you decide to move to 2 ° phase (40,000 v / h), the supply must be increased with a new AMU and a fan of extraction. The line would be longer of 12 m, the current tack rag become No. 2 positions painting Interior Manuals. In the scheme 00M00SC 01400 is well represented the difference between the 1 and 2 ° phase.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.Fig. 1.1 – Primer booth aeraulic schematicThe primer booth lies on level + 5.800 mm and develops along a total length of 28 m.It is made of an upper part, including the painting chamber and the plenum for air distribution, and a lower part made of a wet bottom incorporated in the air extraction chamber.The upper part is made of a self-supporting structure to which are fixed the plenum and the booth lateral walls made of wide glass frames.At the level of the manual spray stations there will be casings, applied to the inferior part of the booth, to arrange the painting equipments.The lighting system will be made with casings hinged to the lateral walls, with the possibility to open it from the outside for maintenance. The position of the casing outside the booths, their dimensions, the amount of neon and their internal parables guarantee a minimum lighting of 800 lux on the body inside the painting booth.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.Fig. 1.2 – Primer booth assemblyThe plenum for air distribution is divided in two sections. The upper part is used as air supply duct and it is connected to the lower part by means of dampers; the access to the plenum is granted thanks to lateral walkways and doors.The filtering ceiling is made of filtering elements that can be substituted from within the plenum. The filtering panels cover the whole width of the booth.Between the areas with different abatement speeds there will be silhouettes to divide the glasses equipped with anti-shear system.On the whole surface of the ceiling there will be a grate in stainless steel that allows walking in case of filters substitution operations. Upstream and downstream the filtering ceiling there are proper tie-ins to insert differential pressure gauges to monitor possible clogging.The floor is made of a grating level. Under the grating level there is an overspray abatement system, complete with lateral tanks with overflow regulation, water slopes and rinsing pipes.The lower part includes an over spray abatement system, made of pre-assembled booth bottom modules, one for pitch, closed within the air extraction chamber. The modules are made of gooseneck beams, to which the stainless steel panels are fixed, to form the water slopes, the lateral tanks and the rinsing pipes. The extraction chamber is modular too, and is made of a structure of carbon steel section bars, to which the stainless steel panels are fixed, for walls and bottom.The booth bottom is completed by the water-recycling duct, in stainless steel, and the supply ducts with respective connections and supports.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. There is 1 centrifugal fans for air extraction, complete with connection ducts to the booth bottom, stacks, chimney weathering and support structures.All personnel entering the booths must wear all individual protectiveequipments needed for the type of activities to be carried out, inparticular safety shoes, mask, work coat or overalls, etc.Fig. 1.3 – Primer booth sectionHIGH VELOCITY PLENUMLOW VELOCITYPLENUMCEILING FILTERS WATER DUCTAIR DUCTPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 AProject: OTV 4563 SPEC. No.1.2W O R K I N G P R I N C I P L EFig. 1.4 – Sections boothPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.Air supply is done through one (1) Air Make-up Unit (AMU for short) placed on the platform at level +17.500. The flow of air is 141,000 m³ / h.Their air is to guarantee temperature and humidity requirements both for paint application and operators wellness. The target window is 24 ± 3 °C and 70 ± 10% R.H.Following a summary chart describing main air treatment stages:STAGE NOTES1 Fresh air intake Motorized damper with anti-leaf grid.Without intake tower.2 Heating with gas burner Direct fired3 Pre-filtration with pleated filters Degree of filtration4 First filtration with pocket filters Degree of filtration G35 Cooling coil Powered with cold water6 Humidification fed with raw water Adiabatic cooling7 Post-heating coil Only provide space for future installation8 Second filtration with pocket filters Degree of filtration F59 Supply fan N° 2 to double inlet10 Silencer C onsisting of sound insulation panelsChart 1.1 – Air treatment stagesAir thermo-hygrometric regulation is managed through one (1) temperature probe and one (1) humidity probe. Both send a signal to the PLC that controls gas burner and humidification pump by mean of a VFD.In order to run the correct cycle, AMU need to know also the external air conditions. Such purpose is reached through two probe, that send both temperature and humidity value to the PLC. They are located in the fresh air intake of AMU, before any air treatment.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer: SIH IVECO – NEW CABS PAINTING SHOP 00M00DO 01009 AProject:OTV 4563SPEC. No.Fig. 1.5 – Primer booth AMU functional schemeThe regulation of the amount of air is done through dampers located in the high velocity plenum. The air, which has already been treated with three filtration stages (G3-F5) within the air make-up unit, reaches the lower part of the plenum and it passes through ceiling filters, placed on the whole length of the booth. Since ceiling filters have a lower degree of filtration (F5) compared to previous stages, they are just used to obtain the desired downdraft velocity in the booth (refer to Chart 1.2).The plain filters are the last step of filtration. Thanks to the use of differential pressure gauges, it is possible to determine the level of clogging. When the filters reach the maximum level advised of loss of load, theyFor further and more detailed information, please see the Use and Instructions Handbook of the Air Supply Houses supplier.External conditionsprobeHumidification pumpProbesGas burnerPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. The particles that do not deposit on the body are captured on a water film located under the gratings, and then conveyed to the under-booth through rinsing ducts properly dimensioned.The extraction system forces the air into a circuit that is winding on purpose, to prevent possible water drops from being conveyed to the stacks.AREA DOWNDRAFT VELOCITY1° Tack-rag 0.1 m/s2° Tack-rag 0.1 m/sInternal Manual 0.4 m/sExternal Manual 0.4 m/sFlash-off 11.000 m³/hChart 1.2 – Downdraft velocityFig. 1.6 – Wet bottom detailPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. The air extraction from the booth bottom is carried out thanks to 1 extractor, with a capacity of 141.000m3/h , placed at level + 17.500 mm. The regulation of air flow to extract is done manually by the operator using plc, that operate on the inverter of the electric motor that feed the same fan. The air is sent directly in the atmosphere through a common stack.The access to the plenum, for ceiling filters replacement and dampers regulation, is granted by maintenance doors, located on the lateral wall of the plenum, to which you can access thanks to a lateral walkway that runs the all length of the booth. Since the plenum is sectorized, to have in the different areas of the booth a different speed of the air, there will be at least an access door for the maintenance of each area of the plenum.1.3R E F E R E N C E D R A W I N G SFor an easier understanding of the primer coat spray booth please refer to the below listed schematics:DrawingDescriptionnumber00M00LA 00002Lay out00M00LA 00003Lay out - Sections00M00LA 00005Lay out – Longitudinal SectionsDAM00SC 01411 Primer Line Functional SchemeDAM02SC 01400 Primer Line – Air Make – up Unit Functional SchemePRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.2S Y S T E M C L E A N I N G A N D M A I N T E N A N C E2.1 ORDINARY PREVENTIVE MAINTENANCE TABLESBefore starting any maintenance work on the systems the following preliminary operations are necessary:-I nform the personnel concerned about the maintenance works and affix the notice “Maintenance works in progress – DO NOT TOUCH –“-Deactivate the automatic operating cycle of the system and prevent any accidental starting.-Section the electric supply of the machines and prevent any accidental starting.-Place barriers to prevent the access of unauthorized personnel to the maintenance zones.-Fix the mobile parts with temporary mechanical clamping devices, to avoid inconvenient and accidental movements.-Section the supply of fluids, compressed air, overheated water, gas, etc… making sure they are not restored accidentally.-Leave the doors or access zones open, to prevent the operator from getting accidentally locked inside parts of the system; you are advised to install notices with the words “Maintenance works in progress –DO NOT TOUCH –“PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. SymbolsOVERALLSSAFETY HELMETPROTECTIVE GLOVESPROTECTIVE GOGGLES Array SAFETY SHOESSAFETY MUFFSPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 AProject: OTV 4563 SPEC. No.2.2 ORDINARY PREVENTIVE MAINTENANCE TABLESSEE ANNEXED PREVENTIVE MAINTENANCE TABLE.REFER TO PREVENTIVE MAINTENANCE DATASHEET HIGHLIGHTING FOR EACH TYPE OF INTERVENTION, TOOLS NEEDED, SAFETY EQUIPMENTS ADVISED AND ACTION TO DO.2.3 INSTRUCTIONS FOR SAFELY PERFORMING USE ANDMAINTENANCE OPERATIONS FOR PAINTING BOOTHSThe booth must be used only for the purpose for which it was designed.For safe use remember that it is prohibited to:-Smoke in the booth and near it (it is recommended to place a notice “No Smoking”at all the entrances)-Prepare, mix, and keep paint and / or solvents in the booth.-Keep paint and / or solvent containers that are not suitable in the booth, even if empty-Keep work clothes, cloths soaked in solvent and other inflammable objects-Store paint or other inflammable products near the booth.-Use tools or equipment that may cause sparks or flames.-Spray excessive amounts of paint.-Modify or tamper with the operating cycle logic and / or safety devices provided.-Turn off or tamper with the control systems and safety devices provided by the manufacturer.-Spray paint in the booth when it is not operating or when the ventilation is not working properly.The aim of the above-mentioned prohibitions is to avoid the risks of fire, explosions and damage deriving from incorrect operating conditions.2.3.1 RISKS OF FIREIn normal operating condition the booth is safe against fire and explosion.The possible causes have been eliminated:- Avoiding concentrations of solvent by appropriately sizing the ventilation system- Preventing the immediate blocking of the spray guns if ventilation is interrupted.-Avoiding the possibility of short circuits, as the lights, electric cables and users are located outside the booth.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.- Equipping the booth with a fire-prevention system.- Informing about the risks, specifications and prohibitions to be adhered to and the maintenance operations to be carried out.Any dangerous situations can arise only in cases of faults due to negligence in checks,insufficient maintenance or serious lack of attention.In emergency situations due to failures or anything else, if there is the presence of concentrated solvent in the booth, pay attention not to cause sparks.For example, avoid accidentally rubbing two metals.In the case of fire promptly evacuate the booth and call the fire department.2.3.2 HEALTH MEASURES AND PRECAUTIONSAlthough continuous ventilation, during spraying operations, the air in the booth still contains traces of solvent.The operator is recommended to use suitable individual protective items (such asgloves, specific mask, etc.).This mask must be fitted with filters (to be replaced at routine intervals) or must be connected directly to the outside atmosphere.You are recommended to avoid direct contact with toxic products (solvents or paint), to prevent dermatitis or other forms of irritation.Therefore operators are recommended to use gloves, goggles and suitable clothing during the different operations (manual spraying, washing the guns, preparing paints, pouring or anything else).In particular if a harmful product hits the eyes, use the emergency eyewashes immediately and call the sickroom for a check.At the first symptoms of inhalation of toxic products (solvents) consult themedical staff.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No.2.3.3 ORDINARY MAINTENANCE OPERATIONSBefore entering the booth for carrying out maintenance or repair operations, always wait for the parts that have just been painted, to complete the flash-off cycle and be sent towards the oven.Once the production cycle has ended, wait for another short length of time (10 ÷15 min.) so that the solvents present are removed completely.Then stop the system and put it in safety conditions.You are also advised to place a “works in progress” notice.In many cases, for example, for cleaning work, the booth needs to be in safety conditions but with the ventilation working. In this case, start only the fans needed manually, usually the central air delivery ones and related exhausts, cutting off all the rest and taking care to signal the condition of the system.Conveyor must in any case be stopped in the safety condition.2.3.4 EXTRAORDINARY MAINTENANCE AND/OR REPAIRSBefore doing any work using electromechanical tools or tools for cutting and welding, the booth must be put in the safety conditions as described previously and it must be firstly cleaned of any deposits of paint as described in the paragraphs below.It is absolutely necessary that skilled personnel carry out these operations.The following operations are recommended:Grid cleaningThe grilled booth floor is of slip-proof type, however the paint sprayed, collecting on the grill surface, makes it slippery, causing the risk of falling.In addition heavy deposits of paint on the grills and/or underneath increase the potential risk of fire. Therefore it is necessary to regularly clean residues of paint, using special cleaning machines on the spot or removing the panels for other types of cleaning operations (solvent bath, sanding or anything else).When the grill panels are removed, always indicate the danger caused by the presence of openings in the floor.Cleaning the surface under grills and washing pipesPRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. After removing the grills, it is possible to access to the surface below.It is helpful to keep the ventilation on during cleaning operations.When cleaning is carried out using solvents, ventilation becomes absolutely necessary.You are also recommended to wear the suitable protective devices (mask, gloves and suitable clothing). Afterwards, take care to put the grilled panels correctly back in place.Cleaning exhaust ducts and booth primerHeavy paint remainders collect in these areas causing problems of functionality and danger for the spreading of possible fires.Therefore, regular removal and cleaning is necessary.Doors along the booth are provided for accessThis operation, too, is to be carried out with the system stopped in safety conditions, but with the ventilation on.Opening booth base doors is dangerous because room is in depression whileexhaust fans are running. This operation must be done only turning on exhaustfans after doors opening and its block in open position.Personnel involved is recommended to use suitable clothing, including gloves, mask, overalls, safety shoes or boots and in the specific case, a helmet.Once the operations have been ended, after making sure that all the personnel has gone out and that all the openings have been closed again, the booth can be re-started.Cleaning the wallsFor good quality painting, the environment in which one is working must be clean.You are therefore recommended to remove deposits of paint and dust from the walls.Checking and changing filtersFor satisfactory operation of the booth and to avoid the danger of a high concentration of solvents in the booth due to insufficient ventilation, it is necessary to check the condition of clogging of the filters upstream of the booth that are in the following order:Pleated and pocket filters in the Air Supply HouseCeiling filters in the boothFor pocket filter maintenance, see paragraph “Air make up unit for booths”.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 AProject: OTV 4563 SPEC. No. Ceiling filtersTo check the efficiency of the filters, special sockets are provided upstream and downstream of them to which a differential pressure gauge is applied.In general the reading is approximately 50 Pa.The filters are considered clogged when the rating rises to 150 ÷ 200 Pa.For more accurate reading, consult the supplier’s specific literature.Before replacement, check that the new filters are free of defects or transport damage such as fraying ladders or holes.Changing filtersThe filters need changing when clogging occurs.The filters of the ceiling filters are supplied as small mattresses without frame.Take care in positioning them correctly so as not to allow air between the filters.Make sure they are positioned so that the air crosses them in the correct direction; they are made with layers of meshes of variable fineness, so that they trap the largest impurities immediately and then the finer ones. This way the filter takes longer to clog. In any case, the bottom face is marked.Air make-up units for booths and heating unitIt is severely forbidden access to unauthorized personnel to this areaDuring normal working, is not foreseen any personnel presenceThe units are subdivided into stages according to the planned air treatment.Access to each stage is gained through special doors.Don't remove, tamper with or try to elude such safety devices that periodically mustbe checked for verifying its good operation. Before any type of intervention insidethe air supply houses remove tension from the electric panels of command andattend that the fan finishes completely the rotation motion. The intervention of oneof the electric safeties provokes the immediate arrest of the fan. Before restartingthe plant, verify that the zone is completely free and that there are no people insidethe air make-up units.The dangers the operator could be exposed to are mainly the following:-Shearing or crushing due to the door swinging shut owing to the effect of the vacuum exerted by the fan.-Fan rotating.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 AProject: OTV 4563 SPEC. No.-Burns due to contact with the burnersBefore entering the units, always stop the fan and put it in safety conditions.Good air conditions and efficient ventilation mainly depend on the satisfactoryworking conditions of the air supply house.Remember that efficient ventilation is a safety factor against the concentration ofsolvent in the booth.The main maintenance points of the unit are the following:-Checking and/or changing the pocket filters installed before the fan. These filters also trap the finest impurities. Their degree of clogging is controlled with a differential pressure gauge. Initially the load loss is very low (approx. 50 Pa.). The differential pressure indicator indicates clogging when the difference in pressure is approx. 200÷250 Pa. Make sure that the new filters are intact before installing them. After positioning framed filters in the housing, fasten them using the special blocks and make sure there are no gaps between the frame and housing. Specific information is given on the manufacturer’s technical sheet.-Fan maintenance following the instructions contained in the specific handbook.-Checking that the temperature and humidity probes are working properly and correctly transmitting the signal to the board.-Periodic cleaning of the unit floor, walls and ceiling.-Functional check and integrity of safety micro-switches.-Functional check and integri ty of gas train and burners (see supplier’s specific documentation).After completing the maintenance operations inside the unit, upon leaving, make sure that no objects, clothing or tools have been left inside.When closing the doors again, check that the seals are intact.PRIMER BOOTH USE AND INSTRUCTIONHANDBOOKCustomer:SIH IVECO – NEW CABS PAINTING SHOP00M00DO 01009 A Project: OTV 4563 SPEC. No. After making sure that all the maintenance personnel has left the unit and that all the doors are shut, the unit can be started again.For further information, refer to the specific component handbooks.。

精品Word文档 欢迎下载IFEInstitut de formation àl`exellence使顾客满意 使企业持久赢利 使团队成功发展人力资源培训La Formation des Ressources HumainesECOLE DESMANAGERS精品资料Word 欢迎使用精品Word文档 欢迎下载学员手册Carnet des Etudiants在本手册中所提供的全部信息属欧尚所有,应严格保密并将仅用于上海欧尚超市有限责任 公司的经营目的.在出现侵权的情况下,欧尚有权要求罚金及赔偿.”目录一.人力资源培训介绍二.欧尚人力资源管理的原则三.欢迎和融入新员工四.培训五.沟通的技术六.会议主持精品资料Word 欢迎使用精品Word文档 欢迎下载七. 八. 九. 十. 十一. 十二. 十三. 十四. 十五. 十六. 十七. 十八.面谈的技巧 员工管理的工具 中国劳动人事管理规定 欧尚的内部人事管理规定 欧尚的工资与福利制度 商场业绩奖 厂方促销人员的管理 欧尚工会及党团组织 我开始管理我的部门 现状分析 部门经理的任务 良好培训之原则精品资料Word 欢迎使用精品Word文档 欢迎下载一. 人力资源培训的介绍 人力资源部分学习的目标? 欧尚经理的基本任务?精品资料Word 欢迎使用笔记精品Word文档 欢迎下载精品资料Word 欢迎使用精品Word文档 欢迎下载二 . 欧尚人员管理的原则 激励太阳图的概念4.3. 25. 6.1.招聘 接待 融入精品资料Word 欢迎使用精品Word文档 欢迎下载 欧尚的人员管理原则包括哪几个阶段?精品资料Word 欢迎使用 请列出每个阶段的内容和目标?精品Word文档 欢迎下载精品资料Word 欢迎使用笔记精品Word文档 欢迎下载 请列举公司的一些在激励机制方面的一些例子:精品资料Word 欢迎使用笔记精品Word文档 欢迎下载精品资料Word 欢迎使用精品Word文档 欢迎下载三. 欢迎和融入新员工 如何进行第一次会谈? 介绍顺序: 新雇员的精神状态及对公司的期望新雇员的精神状态对公司的期望精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用 不成功融入集体所带来的风险对新雇员来说精品Word文档 欢迎下载*对经理来说 *对公司来说精品资料Word 欢迎使用笔记精品Word文档 欢迎下载接待的目的 接待精品资料Word 欢迎使用 融入能鼓励新员工,因为精品Word文档 欢迎下载笔记精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用四.培训精品Word文档 欢迎下载 帮助员工在其工作中取得进步的方法有: 满足所发现的需求 是与实现目标同等重要的效率 指标完成的水平代表着培训效率水平培训不仅是课堂中的一种纯粹的理论,大部分的培训 应在管理人员的辅佐下实地进行.精品资料Word 欢迎使用主要错误:精品Word文档 欢迎下载 部门经理的作用精品资料Word 欢迎使用作为培训教员,要保证三个阶段:精品Word文档 欢迎下载笔记精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用 矩形游戏精品Word文档 欢迎下载五.沟通的技巧传话游戏笔记精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用精品Word文档 欢迎下载六._会议主持部门会议: 管理手段 目标 是什么? 会 议 的 性 质: 1.提供信息2.寻求解决方法精品资料Word 欢迎使用3.总结 个人笔记精品Word文档 欢迎下载精品资料Word 欢迎使用 有关主题商业:-商业精品Word文档 欢迎下载-关于产品-广告精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用 管理: - 经营损益表- 工作安排及工作条件精品Word文档 欢迎下载 公司及商场的生活精品资料Word 欢迎使用个人笔记精品Word文档 欢迎下载精品资料Word 欢迎使用 我在会议部门中的角色1.激发培训人员的兴趣精品Word文档 欢迎下载2.使每个员工不感到拘束3.促进理解4.鼓励培训者积极参加精品资料Word 欢迎使用5.鼓励采取行动精品Word文档 欢迎下载精品资料Word 欢迎使用精品Word文档 欢迎下载标题主持人技巧 工具,设备 主持人的行为需要避免的错误信息会议寻求解决 方法会议总结会议精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用部门会议的准备*主持人应自问精品Word文档 欢迎下载*主持人应准备需要提供的资料和会议的进程*主持人应该组织会议精品资料Word 欢迎使用精品Word文档 欢迎下载个人笔记精品资料Word 欢迎使用寻求解决办法的会 议精品Word文档 欢迎下载头脑风暴法stormingBrain此种方法可以为一个给出的主题寻找到最大量的答案 拥有 4 条规则1.23.4.精品资料Word 欢迎使用精品Word文档 欢迎下载-2 有个阶段 1.2.6K 法这种方法可以协助我实施保留下来的解决方法 什么?精品资料Word 欢迎使用谁? 哪里? 什么时候? 怎么? 为什么?个人笔记精品Word文档 欢迎下载精品资料Word 欢迎使用精品Word文档 欢迎下载部门会议的规则: 1.____________________________________________ ______________________________________________ ______________________________________________ _________ 2.____________________________________________ ______________________________________________ ______________________________________________ _________ 3.____________________________________________ ______________________________________________ ______________________________________________精品资料Word 欢迎使用_________精品Word文档 欢迎下载4.____________________________________________ ______________________________________________ ______________________________________________ _________个人笔记: ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ______________________________________________ ___________________________ ______________________________________________ ___精品资料Word 欢迎使用在会议最后我应该对自己提的问题精品Word文档 欢迎下载1._________________________________________________________ ___________________________________________________________ ________ 2._________________________________________________________ ____ ___________________________________________________________ ____ 3._________________________________________________________ ____ ___________________________________________________________ ____ 4._________________________________________________________ ____ ___________________________________________________________ ____ 5._________________________________________________________ ____ ___________________________________________________________ ____ 6._________________________________________________________精品资料Word 欢迎使用精品Word文档 欢迎下载____ ___________________________________________________________ ____ 7._________________________________________________________ ____ ___________________________________________________________ ____ 8._________________________________________________________ ____ ___________________________________________________________ ____ 9._________________________________________________________ ____ ___________________________________________________________ ____ 10.________________________________________________________ ____ ___________________________________________________________ ____ 11.________________________________________________________ ____ ___________________________________________________________精品资料Word 欢迎使用精品Word文档 欢迎下载____ 12.________________________________________________________ ____ ___________________________________________________________ ____ 13.________________________________________________________ ____ ___________________________________________________________ ____ 14.________________________________________________________ ____ ___________________________________________________________ ____ 15.________________________________________________________ ____ ___________________________________________________________ ____ 16.________________________________________________________ ____ ___________________________________________________________ ____ 17.________________________________________________________精品资料Word 欢迎使用精品Word文档 欢迎下载____ ___________________________________________________________ ____ 18.________________________________________________________ ____ ___________________________________________________________ ____七. _面谈的技巧1. 二种会谈类型2.你的态度:精品资料Word 欢迎使用3. 三个步骤个人笔记精品Word文档 欢迎下载.开始精品资料Word 欢迎使用 倾听精品Word文档 欢迎下载 交流精品资料Word 欢迎使用精品Word文档 欢迎下载 精品资料Word 欢迎使用.激励精品Word文档 欢迎下载 总结精品资料Word 欢迎使用笔记精品Word文档 欢迎下载精品资料Word 欢迎使用精品Word文档 欢迎下载会谈分析得出什么结论?面谈分析 1.是否有一次真正地交流?为什么?是 不是 为什么?2.我是否注意倾听 ?3. 我是否促使他的 表达?3.1 我是否采取了一种积极的态度?3.2 是否按对方原话进行重新表达?3.3 我的表达是否清晰明确?3.4 我是否客观?3.5 我是否让对方理解我?通过交谈员 工的问题解决了吗?精品资料Word 欢迎使用4. 通过交谈员工的问题解决了吗?5. 这次面谈能促使我的合作者发 展吗?精品Word文档 欢迎下载精品资料Word 欢迎使用。

一站式稳定性测试UNcle 革命性的整合了 3 种不同的检测模式:荧光、静态光散射 SLS 和动态光散射 DLS,提供 11种特色的应用及组合。

用更少的样品,在短短几个小时内得到所需的数据。

高通量 UNcle 使得制剂配方筛选成为小菜一碟,不再为繁琐的重复劳动而困扰。

• 熔解温度 (T m) & 聚集温度 (T agg)• 采用SYPRO(DSF法)检测T m• ΔG• 等温稳定性实验• 热恢复实验• 颗粒大小 & 多分散性• 颗粒升温实验• B22• k D• 黏度独一无二的 UNi更少的样品,更多的数据。

一个 UNi 有 16 个加样孔,每孔只需要 9 µL 样品。

加样孔中的样品严密密封,避免样品交叉污染。

UNi 可耐受高温,样品无挥发;可由进行等温稳定性实验。

UNcle 每次实验可以同时测试 48 个样 本,8小时内进行 144 个样品测试,人工花费时间少于1小时。

全光谱检测蛋白在生物制剂中的表现各不相同。

使 用 UNcle, 拥有全光谱荧光 ,无需用其他仪器提前检测样品,提高实验效率。

也无需使用染料标记,通过蛋白内源性氨基酸,得到蛋白自身荧光信号。

UNcle 在 266nm 和 473nm 两个波长检 测聚集体。

无论聚集体浓度如何,都能检测到。

Intensity40302010700600500400300Wavelength (nm)Trp FluorescenceSLS266SLS473T m 、T agg 、DLS 三合一尝试新的配方或构建新的蛋白? 48 个样品筛选可在 2 小时内得到答案。

同时测试 T m 和 T agg ,全面了解并且分析蛋白在升温过程中的变性和聚集过程。

在初始和最终两点加入DLS 测试,使得聚集发生过程有了更确凿的证据。

UNcle 一天可筛选 144 个以上的样品,高通量使得配方筛选更简单更高效。

T m1 = 65.3 °C T m2 = 76.7 °C T agg = 73.8 °C 010 20 30 40 5060 Aggregation (SLS) 344 345 346347 348 349 350 351 35225 35 45 55 65 75 85 95 U n f o l d i n g (F l u o r e s c e n c e ) Temperature (°C)Hydrodynamic Diameter (nm)0.000.050.100.150.200.250.30A m p l i t u d e DLS Before DLS After 10-110-2100101102103104105106107108等温稳定性实验UNcle可在样品无挥发状态下连续数日检测,长期等温稳定性。

小学英语教师培训手册第一节使用歌曲一.理解理论1. 人们通常可以记住歌词。

事实上,这个特殊的学习过程几乎是一种下意识的行为。

我们从收音机上、电视里和CD上听到歌曲,通过听这些歌曲,我们记住了歌词。

这个过程让语言学家着迷。

好像旋律和节奏使我们可以简洁地记住歌词:我们能记住在正常状况下记不住的大量文字。

因此,学习歌曲对学生来说是一种很好的学习词汇和语言形式的方式。

2. 当不是以英语为母语的人们用英语唱歌的时候,他们的腔调通常不像说英语时那样明显。

歌曲中的语调和重音形式由于旋律和节奏而更简洁理解和仿照,而这通常会形成比拟好的发音。

歌曲是改善学生英语发音的重音和语调形式的极好方式。

3. 歌曲中为了使歌词压韵,常常会重复一句歌词中的最终几个音。

这可以成为强调相像单词发音的一种强有力的方式,而且可以通过听后练习进一步加以利用。

英语歌曲有助于改善学生的发音。

4. 在很多英语课上都强调写作和书面文字。

学生们做练习、读对话、写字母。

然而,这意味着是对那些通过看和操练书面文字来学习的学生的一种偏向。

在课堂上运用歌曲对于须要听觉输入的学生有益。

运用歌曲有助于调整课堂上学习方式的平衡,因为它可以扶植那些通过听觉来学习的学生。

5. 语言教学倾向于仅培育某些类型的智能。

基于本手册中探讨过的“多智能概念”,语言教学培育语音学、逻辑和人际交往的多方面智能。

通过运用歌曲,尤其是假如协作动作和手势运用歌曲,我们可以培育孩子的音乐和空间智能。

歌曲有助于培育学生多方面的智能。

6. 有些学生须要用语言进展活动。

这类学生会对身体反响和动作做出响应。

他们可能会因为把一个动词用行为表现出来而记住它,而不是因为这个单词被写下来或者说出来。

很多歌曲中可以参加一些手势或者相关的动作。

在课堂中学习歌曲和运用完全身体反响(TPR)之间有着密不行分的联络:两者是同时并进的。

在语言习得中运用歌曲和TPR是补充性的;它们是会让很多学生受益的互相支持的方法。

7. 年幼的学生只有短暂的留意力持续时间,大约只能维持八分钟左右。

易迪思培训手册2022 Eddic·Training BrochureBusiness Training Choose Eddic 商业培训选择易迪思Since 2003易迪思(中国)培训中心是中国领先的人才培养及管理咨询服务供应商,为企业提供项目咨询、人才测评、工作坊、内训课、公开课、在线知识付费课程等专业化高端学习服务。

目前,易迪思的核心业务板块聚焦于通用力、领导力、专业力等学习体系。

公司始创于 2003 年,商务总部设立在天津,教研中心总部设立在北京。

经过多年的快速发展,直营分支机构及代表处已经覆盖全国二十多个城市,市场及服务团队超过150人,专职兼职讲师团队超过800人。

金牌讲师均为英美管理协会会员、顶级全球 500 强企业中高层管理者、清华大学研究学者等。

易迪思结合近 20 年培训服务的经验,针对企业的管理实际不断总结,形成了独具特色的课程体系和咨询辅导系统。

通过与国内外优秀企业、机构交流合作,开展标杆学习、主题论坛、沙龙交流等特色服务,为企业管理者、学员搭建一个多样化的学习平台,累计为4000 余家企业提供定制化学习方案。

秉承“增值课程、创新服务”的理念,易迪思在培训咨询领域的出色表现获得了业界的广泛关注和一致赞誉,被众多知名企业评为“年度最佳培训供应商”,并获得“2011 年度中国企业培训行业标杆品牌”、“最受企业欢迎的专业培训机构”和“2014 中国人才-年度最佳培训机构”等称号。

未来,易迪思将不断努力,为企业提供最佳的人才培养和管理咨询解决方案,致力于成为中国最优秀的人才培养及管理咨询服务供应商。

About us关于易迪思易迪思天津培训中心创立,发展为 ORACLE 中国培训合作伙伴。

易迪思上海、广州、深圳培训中心创立,组织架构完善为2B 企业学习发展事业部、2C 个人学习发展事业部。

伴随培训行业变革,易迪思率先引进新加坡国际版权课:领导力沙盘模拟。

同时为及时满足 2B2C 学员的线上学习需要,2B2C 线上训练营产品及时迭代发布。