专业英语阅读与翻译基础知识共53页文档

- 格式:ppt

- 大小:5.34 MB

- 文档页数:53

C o m m e n c e m e n t o f t h e Commercial Operation of 600M W U n i t , "H i ro n o N o. 5Thermal Power Station of The Tokyo Electric Power Co., Inc."Commercial operation of The Tokyo Electric Power Co., Inc. Hirono No. 5 Thermal Power Station commenced in July 2004. This plant is a 600 MW coal-fired supercritical power plant. The main line-up of the plant, which features a steam turbine and a boiler, are supplied by Mitsubishi Heavy Industries, Ltd. (MHI). MHI set up this plant with a range of such key equipment along with ancillary facilities such as control systems, a flue gas treatment system, a wastewater treatment system, and stacks. This report gives a brief overview of the advanced technologies applied to the steam turbine and boiler of this plant supplied by MHI.1. IntroductionThe Hirono No. 5 Thermal Power Station began com-mercial operation in July 2004. It is a 600 MW coal-fired,supercritical power plant that operates under the high-est global standards for steam conditions (24.5MPa x 600/600o C).The steam turbine has various advanced MHI tech-nologies, including the first 600 MW class two-casing turbine, high- and intermediate-pressure combined cas-ing developed by utilizing high temperature materials and cooling structures to cope with the ultra supercritical steam condition, 48 inch steel integral shroud blade (ISB), a new type of condenser, and a single shell deaerator cum storage tank.The boiler adopted in this plant has MHI's advanced technologies. They are reduced emission of NOx and unburned carbon with the A-PM burner and MRS pul-verizer. In addition, the vertical waterwall furnace that uses high temperature compatible materials and rifled tubes are adopted.Further, the plant is very much streamlined through the use of such simple systems and equipment as de-scribed below:(1) unification of air duct and flue gas duct into a single line through the adoption of a maximum capacity class fan,(2) unification of all feed water heaters into a single line,(3) unification of circulating water pumps into a single line, and(4) adoption of a plant starting system that does not rely on the boiler circulating pump.Since the plant is located in a narrow site adjacent to existing units operated using oil and gas, the overall arrangement of the plant has been improved by consult-ing with the Owner and is arranged in a more compact manner.Advanced MHI technologies have also been adopted in ancillary facilities. This includes the use of a dry se-lective catalytic NOx removal system, a high performance flue gas treatment system based on the harmonious de-sign of a double contact flow scrubber type flue gas desulfurization system with a low-low temperature dry electrostatic precipitator, an overall waste water treat-ment system, and self-supporting group stacks. In this way, MHI has drawn upon all of its competencies in es-tablishing this plant.2. Steam turbineFigure 1Figure 1 shows an external view of the Hirono No. 5steam turbine.Fig. 1 View of the 600 MW Hirono No.5 steam turbineHIROMASA MOMMA*1TAKAYUKI SUTO*1RYUJI IWAMOTO*3JUNICHI ISHIGURO*1TOSHIHIRO MIYAWAKI*2TSUYOSHI NAKAHARA*4T able 1able 1 shows the major specifications of the turbine.The turbine is of a two-casing type consisting of a com-bined casing made up of a high-pressure turbine and an intermediate pressure turbine and a single low-pressure turbine casing. It has the world's largest capacity as two-casing structure.Usually, in the 600 MW class turbines, two low-pres-sure turbine casings (quadruple exhaust flows) were required in order to secure last stage exhaust area meet-ing the requirements for steam flow. Since 48 inches,the longest last stage steel blades in the world for the 3000 rpm machine were adopted in this turbine, it be-came possible to unify the low-pressure turbine into a single casing (double exhaust flows), thereby realizing a compact design.In addition, the high- and intermediate-pressure tur-bines are combined into one casing, and both main steam and reheat steam with a temperature of 600o C are led into it. MHI has developed a high performance and highly reliable frame drawing on the company's high tempera-ture technologies cultivated by the development of the 1000 MW -600o C class turbines (1) and the track record of the 700 MW class large capacity high- and intermedi-ate-pressure combined turbines (2).2.1 Design featuresHigh temperature materials and cooling structures with good track records for 600o C steam conditions have been adopted in the high- and intermediate-pressure turbines.Since ultra supercritical steam condition requires additional number of blade rows and the space for them due to the increase of heat drop in the turbine, perfor-mance of the blade rows and overall size of the frame were optimized in the design of the high- and intermedi-ate-pressure combined frame in order to secure the performance and reliability of shaft dynamics.As for the low-pressure turbine, various high perfor-mance and highly reliable technologies such as 48 inch last stage steel blades, a high performance exhaust hood,and a bearing base structure directly supported by foun-dation have been adopted.2.1.1 High temperature materialsThe new 12Cr forged steel is used for the high- and intermediate-pressure turbine rotor, while 12Cr cast steel is used for the inner casing, and 9Cr steel is used for the turbine inlet valves and the interconnecting pip-ing between the valves and the casing.2.1.2 Structure for high temperatureThe longitudinal center section of the rotor as well as blade grooves at intermediate-pressure inlet section are cooled by the leaking steam from the control stage outlet to the intermediate-pressure turbine side along the rotor.In addition, a thermal shield is installed so that the inner surface of the outer casing at the intermediate-pressure inlet section is not directly exposed to the reheat steam of 600o C, and cooling steam from the high-pres-sure turbine exhaust is led into a space between the thermal shield and the outer casing.2.1.3 48 inch ISB low-pressure last stage steel blades Until the late 1990s, the length of the steel blades for 3000 rpm machines was limited to the 40 inch class. In 1998, ahead of the industry, MHI completed the devel-opment of a 3000 rpm 48 inch blade, which was the largest steel blade of its type in the world, along with a 3600 rpm 40 inch blade, which was the scaled design blade of the 3000 rpm 48 inch blade (3).A highly reliable ISB structure has been adopted for the blades, which were developed by latest vibration analysis technology. Three-dimensional multi-stage vis-cous flow analysis based on advanced computational fluid dynamics (CFD) technology was used in the aerodynamic design. Moreover, the rotating vibratory test using a full-size blade, and the verification tests for performance and vibratory strength using the model turbine on-load test facility in MHI are performed before the blades are ap-plied to an actual machine.Though the 48 inch blade is first applied in this unit,the 3600 rpm 40 inch blades, which are scaled design blade,has already been used in many number of units and are in operation since 2000. Use of these blades has made it pos-sible to obtain excellent operating results in terms ofperformance and reliability. Figure 2Figure 2 shows the appear-ances of the 48 inch ISB and the low-pressure turbine rotor.600000kW24.5MPa 600oC 600o C 3000 rpm -962.6 hPa 48 inches8Table 1 Major specifications of steam turbineItemSpecificationsTypeOutput (rated)Steam conditions Main steam pressure Main steam temperature Reheat steam temperature Rotational speed VacuumLast stage blade length Number of feed water heatersTandem compound, double exhaust,reheat condensing typeFig. 2 48 inch steel ISB and Hirono No.5 low-pressure rotor2.2 Operating experience and verification resultsVarious operational parameters were monitored, in-cluding shaft vibration, which showed sufficiently lower values than the allowable values. Namely, stable opera-tion was achieved and the reliability of the turbine was confirmed.2.2.1 High- and intermediate-pressure combinedcasingIn order to verify the reliability of the 600o C class high-and intermediate-pressure combined casing, approxi-mately fifty thermocouples were fitted onto the outer surface of the outer casing, and the distribution of metal temperatures was measured. As a result, the tempera-ture distribution was found to be as predicted, and the temperature gradient in the axial direction was suffi-ciently small. In this way, the effect of the casing cooling structure was confirmed.2.2.2 48 inch ISBAs the 48 inch last stage blades are first applied in this unit, a final confirmation test was performed for this unit. Strain gauges were attached to the last stage rotating blades, and signals from the rotating part were transmitted to the stationary side via a telemeter sys-tem to measure the vibration stress on the blades.As a result, the generated stress was very small in all operating ranges starting from the no-load to the rated load, and it was equivalent to stress levels measured during model turbine tests. Hence, it could be confirmed that the 48 inch blades have a sufficient reliability.2.2.3 PerformanceThe high efficiency technologies applied in this unit include a fully three-dimensional design reaction blade, high efficiency 48 inch last stage blades, and an opti-mized geometry for low-pressure exhaust hood.As a result of these improvements, it was verified through performance tests that the turbine efficiency surpasses the design values in all loads, as shown in FigFig..3, thereby providing a highly efficient unit.3. Boiler3.1 Major featuresThe major specifications of the boiler are shown in T able 2able 2, and a side view of the boiler is shown in FigFigFig..4.1770000kg/h25.40MPa604o C602o CTable 2 Major specifications of boilerBoiler typeRadiant reheat type sliding pressure operationonce-through vertical waterwall furnace boiler (Indoor type)At maximumcontinuousload(BMCR)Main steam flow rateSteam pressure atsuperheater outletSteam temperatureat superheater outletSteam temperatureat reheater outletFuel Coal, light oil (30% ECR capacity)Combustion system Circular firing withA-PM burner and A-MACT method Pulverizing system Unit direct pressurizing system Type of drafting system Balanced draftSteamtemperaturecontrol methodMain steam Fuel/Feed water ratio, sprayReheat steamGas biasing damper for back passSpray (transient) Fig. 3 Turbine performance test resultsFig. 4 Side view of boilerA vertical waterwall furnace system using rifled tubes has more advantages than spiral waterwall furnace sys-tems. The major advantages of this system are described below.(1) Since the mass velocity is low in the vertical waterwall tubes, pressure loss in the furnace system is less thereby making it possible to save auxiliary power consumption.(2) Since the boiler is formed with a simple structure in which the furnace wall tubes are placed in the vertical direction, the furnace can be supported eas-ily and the number of attached fittings for supporting is less. Hence, the reliability, ease of installation,and maintainability of the system are increased (Fig Fig Fig..5).(3) In the coal-fired unit, the adhesion of ash to the waterwall tubes cannot be avoided over time, how-ever, the natural fall of slag is facilitated and the amount of ash that adheres to the furnace waterwall is reduced.(4) The amount of friction loss of the heated waterwall tubes is small compared with total pressure loss, and variations in flow when the amount of heat absorp-tion of the waterwall is varied, are also small.MHI is a world's sole manufacturer of sliding pres-sure operation once-through boilers that adopt the vertical waterwall furnace system, which has such a large number of advantages as mentioned above. MHI has an extensive track record of delivery of these types of boilers.This boiler is rationally designed in which a forced draft fan, primary air fan, air preheater, and induced draft fan are integrated into a single line system with-out installation of a gas re-circulation fan and a boiler circulating pump for heat recovery during start-up.MHI's equipment with its exclusive technologies has also been adopted for the major boiler auxiliary equipment,such as regenerative air preheater, forced draft fan, in-duced draft fan, and primary air fan.During commissioning, excellent steam temperature characteristics, load variation characteristics, and start-up time that completely met design requirements were confirmed.3.2 Efforts to reduce NOxIn order for this boiler to satisfy strict environmen-tal requirements, it employs a low NOx combustion system formed by combining an A-PM (Advanced-Pollution Minimum) burner, an in-furnace DeNOx system (A-MACT), a high fineness MRS (Mitsubishi Rotary Separator) pulverizer, and Selective Catalytic NOx Removal System (SCR) with MHI circular fir-ing system.(1) A-PM burnerFurther reductions in NOx emissions have been achieved through the adoption of conc. and weak com-bustion, which is a basic MHI technology first applied in the original PM burners. In addition, an advanced A-PM burner realizes superior maintainability, reli-ability, and durability is adopted by reducing the number of wind box dampers and improving accessi-bility to the burner section (Fig Fig Fig..6).Fig. 5 Comparison of furnace structuresItem Vertical waterwall furnace systemSpiral waterwall furnace systemSupport plateSimpleBaseFurnace structureSupport lugFig. 6 A-PM burner(2) In-furnace DeNOx system (A-MACT)The in-furnace DeNOx system (A-MACT) has been adopted, and additional air (AA) is injected in order to complete the combustion of any unburned fuel re-maining after NOx reduction, while sufficiently ensuring a NOx reduction region for in-furnace DeNOx of the upper surface of the main burner.(3) MRS pulverizerThis unit adopts an MRS pulverizer capable of sta-bly realizing excellent fine particle characteristics and high fine particle operation that has a signifi-cant effect on low NOx and low unburned carbon combustion.(4) Selective Catalytic NOx Removal System (SCR)A Selective Catalytic NOx removal system with an extensive track record has been adopted to further reduce the NOx to acceptable level in the combustion gas emitted from the furnace. As a result, excellent performance was confirmed across all loads.3.3 Boiler performanceThe efficiency of the boiler was verified by the perfor-mance tests, and the results are shown in Fig. 7Fig. 7Fig. 7. As aresult of the adoption of a high performance A-PM burner plus A-MACT and MRS pulverizer, the actual efficiency of the boiler surpassed the design values, and it was con-firmed that these devices contribute greatly to the highly efficient operation of the plant.3.4 Reduction in construction time at siteIn order to reduce the length of construction time at the site, the installation of flat-blocked steel frames and large-sized parts (main pipes, ducts) were performed in parallel. The method used to construct pressure parts consists of lifting the pressure parts together with the ceiling girder (SBS construction method: Steel Structure Boiler Simultaneous Construction).4. ConclusionMHI is confident that, technologies that allow im-proved efficiency, and high reliability through the adoption of advanced technologies, especially suited to high steam conditions, are co-exist with each other could be established with the completion of the Hirono No. 5Thermal Power Station. Such technologies are expected to contribute greatly in the development of forthcoming plants in the future.MHI will make every effort possible to further achieve the successful development and commercialization of the technologies demanded by society to advance the dreams of an ever better future.Lastly, MHI wishes to express its sincere apprecia-tion to everyone of the Tokyo Electric Power Co., Inc.who guided us on the operation and design of this plant and to all others concerned for their support and encour-agement.References(1) Murayama et al., Design and Operating Experience of theTachibana-wan No.2 1050 MW Steam Turbine of the Elec-tric Power Development Co., Ltd., The Thermal And Nuclear Power Vol.54 No.566 (2003) p.40(2) Nakamura et al., Design for Kobe Power Station No.1,Mitsubishi Juko Giho Vol.40 No.4 (2003) p.208(3) Yamamoto et al., Development of 3000 rpm 48 Inch Low Pres-sure End Blade, Mitsubishi Juko Giho Vol.35 No.1 (1998) p.6Fig. 7 Results of boiler performance testsToshihiro Miyawaki Ryuji Iwamoto Tsuyoshi NakaharaHiromasa Momma Junichi Ishiguro T akayuki Suto。

英语阅读理解英译汉翻译技巧翻译过程包括两个阶段:正确理解和充分表达。

理解是表达的前提,而表达是理解的目的和结果,二者缺一不可,因此,考生在做英译汉部分试题时:(1)切记不可急躁,一定要先通读全文,把握全文的主旨、内容,把握画线部分的语境。

(2)在着重理解画线部分时,首先要在语义上弄清全句的整体意思和每个单词的意思;其次要分析清楚句子结构,理出句群,找出各分句之间的关系。

(3)可考虑先打一份翻译草稿,再根据文章意义和汉语结构进行调整。

(一)词的译法1.词义的选择由于英语中一词多义的现象十分普遍,且英汉词典中给出的汉语解释未必全面,未必与英文的意思完全对等,这就给我们带来两方面的问题:其一,我们需要根据该多义词在其语言环境中的词类、搭配关系甚至是单复数形式来确定其基本意思(即“忠实”);其二,在“忠实”的原则下,如果词典上的释义显得不“通顺”,那么为了“忠实”与“通顺”的统一,我们必须立足于原意,对其加以适当的引申。

选择词义的时候,要根据词在句中的词类及上下文的搭配关系来确定。

如:The target is wrong, for in attacking the tests, critics divert attention from the fault that lies with ill?informed or incompetent users. (1995年真题) [译文]把标准化测试作为抨击的目标是错误的。

因为在抨击这类测试时,批评者没有意识到弊病来自人们对这种测试的不甚了解或使用不当。

[分析]attack的基本意思是“进攻,攻击”,但在这里的搭配是attacking the tests,显然这是指“口诛”、“笔伐”,译为“抨击”或“批评”才算准确。

divert attentionfrom 的意思是“将注意力从……移开”,但文中的批评者坚持认为错在考试形式,并不是已经注意到什么而又有意转移视线。

第二章汉英翻译基础知识-汉英翻译与文化根据《现汉》,“文化”有三个定义:1.人类在社会历史发展过程中所创造的物质财富和精神财富的总和,特指精神财富,如文学、艺术、教育、科学等;2.考古学用语,指同一历史时期的不依分布地点为转移的遗迹、遗物的综合体。

同样的工具、用具,同样的制造技术等,是同一种文化的特征,如仰韶文化、龙山文化;3.指运用文字的能力及一般知识,学习~/~水平。

而在 OALED 中, culture 的定义是①:1 [U] (a) refined understanding and appreciation of art, literature,etc. (对于文艺等的深刻的了解和鉴赏) (b) (often derog. 常作贬义) art, literature, etc. collectively 文化(文学、艺术等的总称)2 [U] state of intellectual development of a society 文化(一个社会智力发展的状况)3 [U, C] particular form of intellectual expression, e. g. in art and literature 文化(智力表现的形式,如体现于文艺方面)4 [U, C] customs, arts, social institutions, etc. of a particular group or people 文化(某群体或民族的风俗、人文现象、社会惯例等)5 [U] development through training, exercise, treatment, etc. 锻炼、训练、修养6 [U] growing of plants or rearing of certain types of animals (e. g. bees, silkworms, etc.) to obtain a crop or improve the species (植物的)栽培;(动物,如蜂、蚕等,良种的)培育7 [C] (biology 生) group of bacteria grown for medical or scientific study 培养的细菌。

英语入门翻译知识点总结Translation is the process of conveying the meaning of text from one language to another. It is a complex and challenging task that requires not only a good understanding of both the source and target languages, but also a deep knowledge of the culture and context of the texts being translated. In this article, we will provide an introduction to some basic knowledge points about translation, including the principles of translation, translation techniques, and the importance of cultural competence in translation.Principles of Translation1. EquivalenceEquivalence is a fundamental principle in translation, referring to the idea that the translation should convey the same meaning as the original text. This means that the translator needs to find the most appropriate words and expressions in the target language to accurately represent the meaning of the source text.2. Communicative FunctionAnother important principle of translation is to maintain the communicative function of the original text. This involves not only conveying the literal meaning of the words, but also considering the intended purpose and effect of the text in the target language.3. Textual CohesionTextual cohesion is the principle that a translated text should maintain the coherence and flow of the original text. This includes the use of consistent terminology, maintaining the logical structure of the text, and ensuring that the translation reads smoothly and naturally.4. Cultural ContextCultural context is a crucial consideration in translation, as it influences the meaning and interpretation of the text. Translators need to be aware of cultural nuances, idiomatic expressions, and social conventions in both the source and target languages to ensure an accurate and culturally appropriate translation.Translation Techniques1. Literal TranslationLiteral translation involves translating the words and phrases of the source text directly into the target language, without taking into account the nuances, idiomatic expressions, or cultural differences. While this approach can sometimes result in a word-for-word translation, it often fails to capture the true meaning of the original text.2. Dynamic EquivalenceDynamic equivalence, also known as functional equivalence, is a translation technique that focuses on conveying the meaning and communicative function of the original text, rather than a literal rendering of the words. This approach allows for greater flexibility in the translation process, as it prioritizes the overall meaning and impact of the text in the target language.3. TranscreationTranscreation is a technique used for creative and highly expressive texts, such as marketing materials, slogans, and literary works. It involves adapting the original text in such a way that the same impact, emotion, and intent are conveyed in the target language, rather than a direct translation of the words.4. LocalizationLocalization is a technique that involves adapting a translation to suit the cultural and linguistic conventions of a specific region or target audience. This may include adapting dates, currencies, measurements, and cultural references to make the translation more relevant and accessible to the target audience.Importance of Cultural Competence in TranslationCultural competence is a critical skill for translators, as it enables them to accurately convey the nuances and cultural references of the source text in the target language. It involves not only an understanding of the language itself, but also the customs, traditions, and social norms of the cultures involved. Without cultural competence, translations may miss important nuances, appear unnatural, or even cause offense to the target audience.In conclusion, translation is a complex and multifaceted process that requires a deep understanding of both the source and target languages, as well as the cultural and contextual factors involved. By applying the principles of equivalence, maintaining communicative function, ensuring textual cohesion, and considering cultural context, translators can create accurate, meaningful, and culturally appropriate translations. Developing cultural competence and mastering various translation techniques are essential for producing high-quality translations that effectively convey the meaning and impact of the original text in the target language.。

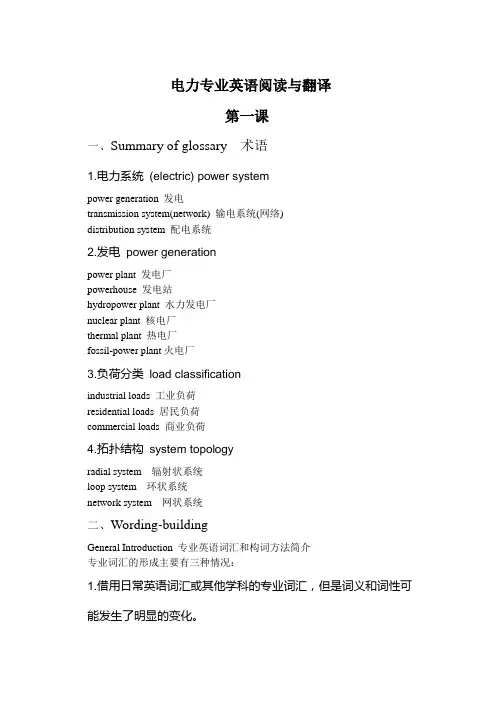

电力专业英语阅读与翻译第一课一、Summary of glossary 术语1.电力系统(electric) power systempower generation 发电transmission system(network) 输电系统(网络)distribution system 配电系统2.发电power generationpower plant 发电厂powerhouse 发电站hydropower plant 水力发电厂nuclear plant 核电厂thermal plant 热电厂fossil-power plant火电厂3.负荷分类load classificationindustrial loads 工业负荷residential loads 居民负荷commercial loads 商业负荷4.拓扑结构system topologyradial system 辐射状系统loop system 环状系统network system 网状系统二、Wording-buildingGeneral Introduction 专业英语词汇和构词方法简介专业词汇的形成主要有三种情况:1.借用日常英语词汇或其他学科的专业词汇,但是词义和词性可能发生了明显的变化。

例如:在日常英语中表示“力量、权力”和在机械专业表示“动力”的power,数学上表示“幂”,在电力专业领域可以仍作为名词,表示“电力、功率、电能”;也可以作为动词,表示“供以电能”。

在日常英语中表示“植物”的plant,在电力专业领域中用来表示“电厂”等。

2.由日常英语词汇或其他学科的专业词汇,直接合成新的词汇。

例如:over和head组合成overhead,表示“架空(输电线)”;super和conductor 合成superconductor,表示“超导体”等。

3.由基本词根和前缀或后缀组成新的词汇。

大部分专业词汇属于这种情况。

翻译的基础知识“翻译是一项对语言进行操作的工作,即用一种语言文本来替代另一种语言文本的过程。

”“翻译是把一种语言的言语产物在保持内容方面,也就是意义不变的情况下,改变为另一种语言的言语产物的过程。

”“翻译是在接受语中寻找和原语信息尽可能按近、自然的对等话语,首先是意义上的对等,其次才是风格上的对等。

”“翻译乃是与语言行为抉择密切相关的一种语际信息传递的特殊方式。

”“翻译是一种跨文化的信息交流与交换的活动,其本质是传播。

”翻译在西方历史在欧洲,翻译实践有长远的历史。

有人甚至认为,欧洲文明源于翻译,上至罗马帝国,下至今天的欧洲共同市场,都要靠翻译来进行国际贸易。

有人说,用古希伯来语写的《圣经》和用阿拉伯写的《福音》,如果没有先译为希腊文和拉丁文,后来又译为中世纪和近代诸语言的话,2000年来的犹太基督教文化就不会产生,因而欧洲文化也不会出现。

自翻译《圣经》起,将近2000年来,欧洲的翻译活动一直没有停止过。

《圣经》的翻译是一件大事,它帮助许多国家的语言奠定了基础。

在古代希腊、拉丁文学方面,荷马的史诗、希腊悲剧、喜剧和抒情诗,忒奥克里托斯、卡图卢斯、普卢塔克的作品等等也多次被译1 / 8 成欧洲许多国家的语言。

在保存古希腊文艺方面,阿拉伯译者作出了巨大的贡献。

至于欧洲各国古代和近代的其他大作家,如维吉尔、但丁、莎士比亚、歌德、塞万提斯、安徒生、易卜生、托尔斯泰、陀思妥耶夫斯基、莫里哀等等的作品,也都多次被译成其他国家的语言。

在东方文学方面,阿拉伯的《一千零一夜》、日本的能剧、中国的小说诗歌、印度的《故事海》、《薄迦梵歌》、《沙恭达罗》等等都译成了欧洲语言。

特别值得一提的是印度的《五卷书》,它通过中古波斯文和阿拉伯文译本,反反复复地被译成了多种欧洲语言,产生了巨大的影响。

实践产生理论,欧美许多国家的翻译理论是五花八门的。

从大的方面来看,可以分为两大派:一派是翻译可能论,一派是翻译不可能论。

其实,完完全全百分之百的可能是没有的,完完全全百分之百的不可能也是没有的。

英语阅读与翻译(复习资料)一、名词解释(要求掌握英文):1、大众传播(mass communication):由新闻传播机构通过报纸、杂志、书籍等印刷品或广播、电视、电影等电子技术手段,反映社会信息变化,用语言、文字、图像等符号,传达给大众的过程叫大众传播(mass communication)。

2、“大众传播”(mass communication)一词最早出现于二十世纪三十年代的美国,后来迅速传播到欧洲和世界各地。

八十年代以后,随着科学技术的发展,对大众传播的研究有了很大的进步。

3、新闻媒介(news media):指那些主要用于传播新闻和信息的媒介。

以文字及图片的方式传播新闻的媒介主要有报纸和杂志,以电子方式传播新闻的媒介有电台和电视广播。

但今天的文字新闻媒介已经基本上电子化了。

4、“普利策新闻奖”:是美国一年一度颁发给新闻、文学、戏剧和音乐方面的优秀作品的最高奖励。

5、通讯社(news agency)(也叫新闻社):是以收集和传播信息为主的机构,它专门收集和供应新闻稿件、图片与资料。

通讯社又称“消息总汇”,是报纸、电台广播、电视的主要新闻来源之一。

6、头版(the front page):是一份报纸最重要的一个版面,因为它最能引起读者的注意。

头版一般都刊登有一则“头条消息”(lead story),并用较大字号做标题。

二、简答题(要求掌握英文):1、新闻学的定义(the definition of journalism):新闻学是研究新闻现象和新闻活动规律的科学。

它的内容,从狭义上说,是专指新闻理论,即理论新闻学。

广义的新闻学包括理论新闻学(新闻学概论、新闻学原理等)、应用新文学(对新闻时间和新闻业务的研究)和历史新闻学(中外新闻事业史、新闻学术发展史、著名新闻界人物等)三个部分。

(注:我国于1918年开始研究新闻学。

)2、新闻的五大要素:新闻通常包含五个要素,对于当前发生的时间的报道,一般来说,必须告诉读者有关事件的内容、人物、事件发生的原因、方式、地点、时间、过程和结果等,让读者对它有一个基本的了解。