设备制造质量检验规程(Storage-Tanks-Shop-Fabrication)

- 格式:pdf

- 大小:61.97 KB

- 文档页数:8

金越昇重型机械有限公司产品检验规程一、产品检验依据用户技术条件、生产工艺图纸、国家标准、企业标准二、钢锭入场检验1、依据供应货产品质量保证书及相应国家标准。

2、钢锭进场,仓库人员进行过磅,数量清点、钢种、炉号及尺寸验收。

3、质检部负责对钢锭质量检验,检验标准按照《钢锭检验规定》执行,合金成分含量标准执行国家标准验收。

4、验收合格后开具合格单仓库入库。

三、下料检验1、钢锭或坯进入车间,锯切工自检验外观质量,根据下料单或下料工艺卡片核对钢号、炉号、规格、产品编号等。

2、锯切工记录坯料的工艺要求重量及实际下料重量,锯切后及时标识。

标识内容:实际下料重量、炉号、钢种、产品编号。

3、坯料按钢号、炉号、编号分类堆放。

4、质检人员对坯料工艺重量及实际重量进行抽查,每周至少抽查两次,做好相应的原始记录。

四、成品检验1、质检人员根据工艺卡片对成品锻件进行百分之百检验,不得采取抽查方式,并做好原始记录,若发现有问题或不合格的及时填写不合格品通知单转生产部。

2、主要根据工艺卡片检验产品的几何形状、表面是否有缺陷,如裂纹、折叠、压痕等。

3、根据客户技术条件要求及订单的特殊要求对产品的标识进行检查或直接按照用户的标识要求进行标识。

4、根据用户基数条件要求及订单要求,分别对粗车及毛坯锻件进行机械性能检验及其他的理化检验,并做好原始记录,。

5、所有产品均需要进行超声波检验,并做好原始记录,若发现不合格的及时填写不合格品通知单转生产部。

6、所有经过返修的产品均按照产品检验流程重新检验,并做好原始记录。

五、开具质保书1、根据产品表面检验及标识原始记录和探伤原始记录进行核对好后开具质保书。

2、根据客户提供的技术条件及特殊要求或国家标准开具质保书。

3、性能及理化检验数据要根据原始记录如实填写。

设备制造与施工过程质量控制规范1范围本标准规定了乘用车工厂设备类工程制造、施工过程质量管理的规范。

本标准适用于乘用车工厂建设设备类项目过程质量管理,是项目管理中与质量相关的部分。

2规范性引用文件下列文件对于本文件的应用是必不可少的。

凡是注日期的引用文件,仅注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

Q/CAW-195-2015乘用车工厂工艺设备验收通用技术规范3术语下列术语和定义适用于本文件。

3.1设备技术要求《设备技术要求》是由采购方提出的,提交给采购、招标的技术文件。

该文件对项目的主要技术特性,如设备数量、结构、配置、工艺要求、设备品质、双方义务等进行约定,是供应商投标的依据。

参见附录A o3.2设备技术协议是确定设备中标供应商后,与中标供应商签定的项目技术文件,作为技术合同的一部分。

它来自于《设备技术要求》及对中标供应商的差异性要求,对项目的指标一般应不低于《设备技术要求》。

参见附录B o3.3预验收供应商承制的设备制造完成后,发运前由采购方就设备与《设备技术协议》的符合性进行认定的过程。

只有通过预验收的设备才能发运。

3.4终验收是设备在采购方现场安装、调试完成,供应商确认达到采购方《设备技术协议》的基本要求后,申请并由采购方确认的过程。

只有通过终验收的设备才能正式接收,并做为商务付款的依据。

4通则4.1工厂建设的设备工程项目需按生产准备过程的不同时期设置相关控制节点,按不同阶段特征进行区别管理。

4.2各节点需按本标准定义的输出解释,确认相关输出条件达成情况。

4.4本标准设定节点为一般性设备工程的典型过程,标准设备质量管理过程可以参考本标准适当简化,非标设备质量过程管理应参照执行。

4.5采购方使用、设备维修、安全、消防、质保等相关部门的人员在各节点应就与本部门相关的内容进行确认。

4.6各节点确认应输出书面文件,并由相关人员签字。

5方案设计5.1设备技术要求5.1.1采购方采购前组织编制《设备技术要求》,文件应包括但不限于如下相关要素:a)供货范围,工期;b)设计条件,即甲方现场和设计相关的基本条件;c)供应商资质及证明文件的要求;d)双方责任;e)设备制造、安装相关的通用技术规范或标准,或引用国际、国家相关标准;f)针对设备特殊工艺状态、使用条件或结构等提出的针对性要求;g)确保工艺性能的工序能力指标;h)保证人身及设备安全的安全性要求;i)对使用者作业轻便,符合人机工程学的适用性要求;j)方便维修的可维修性要求;k)影响使用寿命(不小于10年)的重要结构、零部件可靠性设计要求;I)针对零部件选型的要求;m)随机备件、专用工具要求;n)资料要求;o)培训要求;P)供应商服务:陪产、售后服务要求。

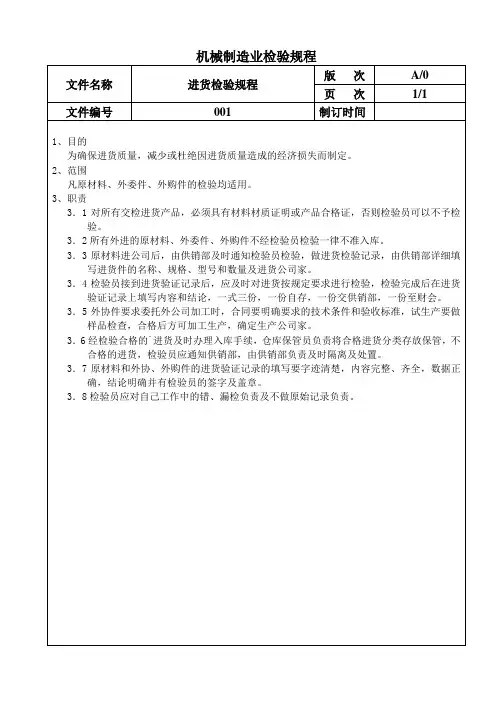

一、原材料入库检验规程1. 钢板检验规程1.1 检验程序1.1.1 检验合格入库1.1.1.1 钢板进公司,由进货人员分项填写《原材料和零部件报验单》并通知检验员按本规范规定项目逐项检验,结果记录于《原材料和零部件报验单》上。

1.1.1.2 检验合格后,质检员在《原材料和零部件报验单》上签字,库管员凭质检员签字后的《原材料和零部件报验单》验数入库,并在《入库单》上签字。

1.1.1.3 《原材料和零部件报验单》、入库单存于销售部、质管部处各1份。

1.1.2 不合格处理质检员检验不合格,立即将签字后的《原材料和零部件报验单》、《不合格品通知单》交给进货人员,由进货人负责与供方联系处理事宜。

1.2 检验规则1.2.1 检验方式:抽检。

1.2.2 抽检办法:批数量在5张及以下时全检,批数量大于5张时抽检5张。

1.2.3 接收质量限:不允许有不合格。

3 检验项目及要求1.3.1 报检资料检验:钢板报检时必须提交符合标准要求及订货合同的质量证明书。

1.3.2 外观检验(全检):1.3.2.1 不得有肉眼可见的气泡、裂纹、结疤、折叠及夹杂,不得有分层;1.3.2.2 表面允许有深度和高度不大于厚度公差之半的折印、麻点、划伤、小拉痕、压痕以及氧化铁皮脱落所造成的表面粗糙的局部缺陷;1.3.2.3 表面的局部缺陷允许用修磨方法清除,但清除深度不得大于钢板和钢带厚度公差之半;1.3.2.4 钢板允许带缺陷交货,但缺陷部分不得超过总长度的8%。

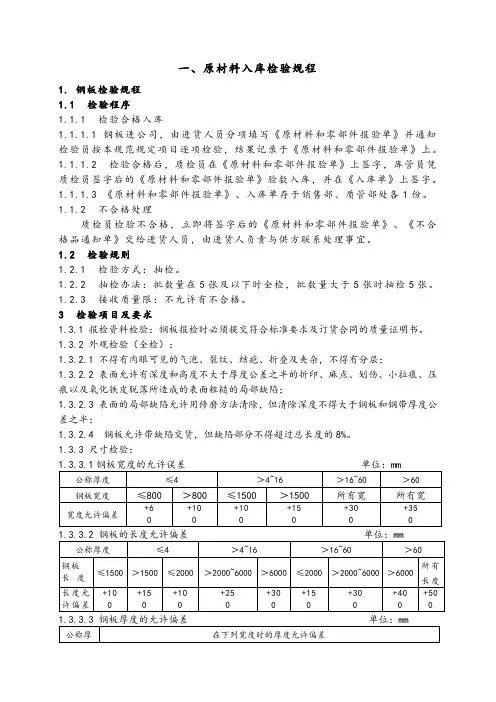

1.3.3 尺寸检验:1.3.3.1钢板宽度的允许误差单位:mm公称厚度≤4 >4~16 >16~60 >60 钢板宽度≤800>800≤1500>1500所有宽所有宽宽度允许偏差+6+10+10+15+30+351.3.3.2 钢板的长度允许偏差单位:mm公称厚度≤4 >4~16 >16~60 >60钢板长度≤1500 >1500 ≤2000 >2000~6000 >6000 ≤2000 >2000~6000 >6000所有长度长度允许偏差+10+15+10+25+30+15+30+40+501.3.3.3 钢板厚度的允许偏差单位:mm 公称厚在下列宽度时的厚度允许偏差度mm 600-750 750-1000 1000-1500 1500-2000 2000-2300 2300-2700 2700-3000 ≤1 ±0.10 ±0.10 —————>1-2 ±0.15 ±0.17 ±0.18 ±0.20 ———>2-3 ±0.18 ±0.20 ±0.21 ±0.22 ±0.25 ——>3-4 ±0.23 ±0.26 ±0.28 ±0.28 ±0.30 ——>3-4 +0.2-0.4+0.3-0.4+0.3-0.5+0.4-0.5+0.45-0.5——>4-5 +0.2-0.5+0.2-0.6+0.25-0.6+0.4-0.6+0.45-0.6——>5-6 +0.2-0.8+0.2-0.8+0.3-0.8+0.35-0.8+0.45-0.8+0.6-0.8—>6-7 +0.2-0.8+0.2-0.8+0.3-0.8+0.40-0.8+0.50-0.8+0.7-0.8+1.0-0.8公称厚度mm 负偏差mm下列宽度时的厚度允许正偏差1000-12001200-1500 1500-1800 1800-2000 2000-2500 >2500>7-8 0.8 0.2 0.2 0.4 0.6 0.8 1.0 >8-9 0.9 0.2 0.2 0.4 0.6 0.9 1.1>9-10 1.0 0.2 0.3 0.4 0.6 0.9 1.2>10-11 1.1 0.3 0.4 0.6 0.7 1.0 1.3>11-12 1.2 0.4 0.5 0.7 0.8 1.1 1.4>12-13 1.3 0.6 0.7 0.9 1.0 1.1 1.3>13-14 1.8 —— 1.0 1.0 1.1 1.3>14-15 2.0 —— 1.2 1.2 1.3 1.5 1.3.3.4钢板平面度公差单位:mm测量单位长度1000公称厚度≤1.5 >1.5~4 >4~10 >10~25 >25平面度公差15 12 10 8 7 注:表中规定的不平度只适用于屈服点下限值不超过460N/mm²的钢板,屈服点超过的以及进行调质的钢板,其不平度的最大值为表内规定的1.5倍。

INSPECTION GUIDELINES UNFIRED PRESSURE VESSELSOFWELDED CONSTRUCTION0For Approval03/03/2004J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved DateCONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7VESSEL DATA DOSIER8INSPECTION CHECK LIST1.0PURPOSEThis instruction covers the inspection, test and verification activities required to validate the supply, manufacture and test of all welded unfired pressure vessels.2.0SCOPEThis instruction covers all necessary stages in the production of the pressure vessels from the examination of certification from procurement sources to the final inspection, preservation and packing to despatch to site.Although the methodology in compiling this instruction is to systematically progress through the construction of a typical pressure vessel. Experienced, inspectors may interpret the intent of the instruction to accommodate local or novel practices or to utilise the instruction for a one-off, or alternative design of pressure vessels, the design having been approved by the client. Any such variations should be noted on the inspector's report.3.0PROCEDURE3.1GENERALT his instruction together with its associated check sheet may be used on any order or contract.It is intended to act as a guide to the inspector in the course of the inspection programme. Any part of the document may be invoked and the sections to be used and the level of inspection required will be specified on the check list.All tests and inspections will be carried out against the approved drawings, purchase order specifications, purchasers or company standards, and within the practices and rules of the country, state or province and any government decrees, laws, ordinance or regulation as may apply.If any conflict or contradictions should be apparent in any of the above then the more onerous requirement will apply unless the purchaser or client directs otherwise in writing.3.2REFERENCE DOCUMENTSApplicable codes and specifications.•Design code (to be stated on inspection report)•Purchase order specification• Purchaser'sstandardsdrawings• Approved•SGS company standardsApplicable codes and standards (sample only)•EN 13445 : 2002•ASME VIII Division 1 or 2•ASME V, ASME IX1210• AS•BS EN 287, 2884.0DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONInspection Test Plan [ITP]Data sheetApproved drawings, [arrangements]Sub-assembly drawingsMaterial test certificatesWeld procedures and Procedure Qualification RecordList of qualified welders or welding operatorsWelders' qualificationsNDE procedures, (appropriate to material of construction)List of qualified NDE operators/inspectorsNDE /inspectors' qualificationsHeat treatment procedureCalibration certificates for test equipmentHydrostatic testing procedure, water quality documentPreparation and painting procedurePreservation, packing and shipping procedureSpares/operating manualsSupply list (packing list)5.0INSPECTION PROCESS5.1MATERIAL5.1.1REVIEW OF CERTIFICATIONOriginal or authenticated copies of mill certificates shall be available at manufacturer's premises.These should be examined for compliance with specifications and where appropriate, drawings.The review will include checks on:-•Maker's name and location.• CertificateNoSpecification.• Material•Heat or cast No.•Makers No or Plate No.composition.• Chemicalproperties.• Mechanicalcondition.• Heat-treated•NDE applied and results.finish.• Surface•Structural observations, notable defects.5.1.2VISUAL AND DIMENSIONAL VERIFICATIONMaterial identification on certificates against product markings.Material supplied against vessel drawing data sheet, material list and specification as appropriate.Transfer identification to cut off components, (Cast No transfer), as specified.Visual and dimensional compliance with specification.5.1.3ADDITIONAL/SPECIAL REQUIREMENTSMay apply on special components, e.g. thick components, dished heads, clad or dissimilar materials, alloy steels or non-ferrous alloys.These components may require formal acceptance of tests before further preparation can continue. Check to ensure that specification/contract requirements have been met. Witness NDE examinations as necessary.5.1.4REPORTINGReporting on material checks should include:-•Confirmation of satisfactory document review•Record of the endorsement of certification reviewed/witnessed•Record of all non-conformities•Record of any tests witnessed and the result5.2PRESSURE VESSEL FABRICATIONAfter clearance of above points to satisfaction of the inspector, then the fabricator will proceed with the manufacture of sub-assemblies and components of the pressure vessel.Inspectors will review the following points on a basis to be outlined in the purchaser's documentation, quality plan, test and inspection plan, or other document, as notified to the inspector.5.2.1PREPARATION FOR WELDINGCarry out visual and dimensional check to ensure compliance with WPS and specification. Where specified, weld bevels will be examined by required code method after grinding/machining. Edges and weld bevels will be clean, dry and free from surface defects, laminations, cracks, voids, notches, etc. These will be a cause for rejection unless suitable/satisfactory remedial action can be taken. Weld repairs must be carried out in accordance with the code requirements and approved by the client before welding proceeds. Serious or excessive defects must be reported.5.2.2WELD INSPECTION5.2.2.1EDGE PREPARATIONVisual and dimensional check will be performed in accordance with WPS and specifications MT or PT shall be carried out in the cut edges as required. Edges must be free from laminations, cracks, notches etc.5.2.2.2FIT-UP INSPECTIONShapes, alignment and dimensions will be checked in accordance with the approved WPS and drawing.5.2.2.3VISUAL CHECK AND NON-DESTRUCTIVE EXAMINATIONThe prepared groove and adjacent area will be clean and free from foreign materials, oil, paint, water and rust. The prepared edge will be re-examined to ensure no defects have been exposed during final preparation.Tack welds will be produced using the applicable WPS conditions and will be visual free from defects.Non destructive examination will be performed in accordance with the code requirement.5.2.2.4MONITORING OF WELD CONDITIONSPreheat heat temperature and method. Interpass temperatures weld material control, welder and process qualifications will be checked for conformity to code requirements.5.2.2.5 BACK GOUGING INSPECTIONThe shape and dimensions of the back gouged groove will be checked for conformity to the WPS requirements. The visual appearance must be clean and free from defects.NDE examination will be in accordance with the code /client requirements5.2.2.6POST WELD INSPECTIONAfter completion of all welding and grinding operations a visual examination will confirm there are no harmful defects such as cracks, lack of fusion, surface porosity or exposed slag inclusions, incomplete penetration, incorrect profile of the weld, lack of leg length and overlap.Temporary attachments will be removed, ground smooth, and the areas checked for defects by MP or PT for defects.5.2.2.7NON DESTRUCTIVE EXAMINATIONNDE will be performed by qualified personnel to approved techniques. The techniques available are dependent on vessel classification and the materials used. Check that the correct method has been used and verify the approved status of both the technique and the personnel.5.2.2.8WELD REPAIRWeld repairs will be completed using an approved WPS method and retested accordingly. All repairs will be approved before any post weld heat treatment is carried out.5.2.2.9POST WELD HEAT TREATMENTThe post weld heat treatment record of temperature and time should be reviewed in accordance with the approved code/procedure. Similarly the results of hardness tests should be reviewed in accordance with the code requirements.5.2.2.10 DIMENSIONAL MEASUREMENT AND VISUAL EXAMINATIONA dimensional check covering all major dimensions and the position/orientation of attachments will be carried out in accordance with the code and drawing requirements .In addition a full visual examination of both inside (where practicable) and outside surfaces of the vessel will be completed. Particular attention should be paid to the cleanliness of the interior of the vessel, the condition/appearance of welds and associated areas, the condition of sealing faces.5.2.3PNEUMATIC TESTNozzle reinforcing pads, support saddles or other attachments shall be examined when specified by an approved low pressure pneumatic test procedure using soapy water as the indicating medium.A minimum of 2 gauges with correct working ranges as described by the code shall be used.5.2.4HYDRAULIC TESTINGCheck all previous items have been accepted by authorised bodies. Code requirements which specify testing will be witnessed.The following items will be verified.Calibration status and correct working ranges of gauges. A minimum of 2 pressure gauges will be attached to item under test.Adequate provision for venting of high points and draining will be provided.Test pressure shall be applied as directed by procedure or code until test limiting pressure is reached. During hold period, a methodical check for leaks will be conducted.Test pressures, metal and water temperatures will be recorded.Water quality will be as specified.Special requirements of the purchaser's specification for deflection or strain gauges orpressure/time/temperature recordings will be examined by the inspector and records verified. 5.2.5POST HYDRAULIC TESTINGAfter depressurisation, pressure vessel components will be drained and dried to meet specified requirements.Stamping of Inspection authority stamps, will be carried out in approved area, as required by client/code.Stamps used shall be low stress type.Application of desiccant/preservative will be as directed in client's specification and checked by the inspection.5.2.6FINAL INSPECTIONAfter hydraulic testing, the vessel will be thoroughly drained and dried out by approved methods. All internal fittings, attachments, coatings or other requirements will be completed. Specified post hydraulic test NDE will be completed and the vessel closed.All pressure vessels shall be checked for cleanliness and dryness by an approved method. Recheck nozzle, saddle and bracket locations and orientations against assembly drawings.5.3MARKINGMatch marks, identification marks shall be checked and low stress type stamp shall be used on all pressure parts.5.4NAME PLATEThe contents of the marking will be checked in accordance with approved drawing and specifications and authority stamped as required.5.5PAINTING/COATING INSPECTIONSurface preparation for painting shall be checked for the following points, according to specification.•Cleaning method (Blast or scraping and wire brushing)grades• Preparation•Freedom from weld spatter, blow-holes and other defects[a] Humidity and Steel Temperatures will be checked prior to painting[b] Paint Manufacture, type and colour to be checked to clients specification[c] Dry film thickness to be checked according to specification[d] Surface condition to be free from pin-holes, runs damage and other discontinuity.[e] Painting Reports to be reviewed5.6SPARES AND ACCESSORIESSpares, tools and accessories shall be checked visually and for dimensions, materials,workmanship and quantity according to purchase order specification and supply list.Marking and/or Tag shall be checked for identification.5.7REPORT AND RELEASE5.7.1REPORTINGA final report summarising the activities carried out during the vessel production will be issued inaccordance with the contract requirements and circulated within the time limits specified in the contract. The report will be in the format required by the client and must clearly indicate final acceptance or rejection of the pressure vessel.5.7.2RELEASE NOTEWhen required by the contract a release document will be issued and issued to the Manufacture when the unfired pressure vessel has been finally accepted.6.0SHIPPING6.1PREPARATION AND PACKINGThe following points shall be checked.•Cleanliness and dryness of pressure vessels•Rust prevention for all machined surfaces•Protection for cover for all opening and protruding parts•Packing style and suitably for overseas transportation•Shipping marks and other markings and notification of welding prohibited, etc.•Where nitrogen purge is specified the gas pressure will be checked and the presence of warning notices checked.7.0VESSEL DATA DOSSIER7.1FABRICATION DOSSIERThe following final documents will be reviewed and endorsed as necessary.Manufactures Certificate of ConformityAs built, drawings if requiredManufacturer's data reportsMaterial certificate or certified mill test reports for all pressure partsMaterial list or mapWelder record for each seam or mapHeat treatment records (Temperature-time record chart during PWHT)Dimensional recordNDE recordsProduction test record/mock test recordAlloy verification records, (if required)Hydrostatic test recordPneumatic test recordHardness test recordPost weld heat treatment NDE, if specifiedRubbing-off name plate or other marksPacking listSpare parts and tool listThird Party Inspection Certificate8.0INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesInspection & Test Plan (ITP)Data SheetApproved Drawings (Arrangements)Sub-Assembly DrawingsWeld Procedures Specification (WPS) &Procedure Qualification Records (PQR)Welder Qualification RecordsNDT Personnel and ProceduresIn-Process Inspection & Testing RequirementsMaterial Test Certificates & IdentificationWeld Edge PreparationFit Up InspectionMonitoring Weld ConditionsWeld Back Gouging InspectionPost Weld InspectionNDE ExaminationWeld RepairsPost Weld Heat TreatmentVisual & Dimensional ExaminationPneumatic TestHydraulic TestingPost Hydraulic Testing/InspectionReview Calibration CertificatesFinal Inspection & Testing RequirementsVisual & Dimensional CheckNameplate StampingMarkingPainting/Coating InspectionSpares & AccessoriesReview of Vessel Data DossierAdditional/Supplementary RequirementsPreparation & Packing。

机械产品质量检验规范一、引言机械产品在各个行业中起着重要的作用,其质量对于生产效率和产品安全至关重要。

为了确保机械产品质量达到标准要求,规范的质量检验流程至关重要。

本文将从产品检验、工艺检验和环境检验三个方面,探讨机械产品质量检验规范。

二、产品检验产品检验是机械产品质量检验的核心环节。

在产品检验中,我们将关注以下几个方面:1. 外观检验:包括产品表面的平整度、光洁度、涂层质量等。

对于外观有要求的机械产品,可以使用目视等方法进行检验。

2. 尺寸检验:对于涉及尺寸的机械产品,尺寸的准确性是保证产品质量的重要指标。

通过使用测量工具进行尺寸检验,如卡尺、量规等。

3. 功能检验:机械产品的功能是指产品的使用目的和性能。

对于功能型机械产品,需要进行相应的功能检验,以确保其按照预定要求正常工作。

4. 耐久性检验:机械产品在使用过程中需要经受各种条件和环境的考验,耐久性检验可以评估产品在长期使用中的可靠性和稳定性。

5. 安全性检验:机械产品对操作人员的安全至关重要。

安全性检验包括产品的防护装置、安全控制系统等的检验,以确保产品在使用过程中不会对人身安全造成威胁。

三、工艺检验除了产品本身的质量,还需要对机械产品的生产过程进行工艺检验。

工艺检验是评估制造过程中是否符合标准要求的关键环节。

1. 原材料检验:机械产品所使用的原材料对产品质量有着直接影响。

常见的原材料检验项目包括材料的成分分析、机械性能测试等。

2. 制造工艺检验:制造工艺检验旨在检验制造过程中是否符合标准要求。

比如焊接接头是否符合强度要求,机械加工的尺寸是否满足要求等。

3. 装配工艺检验:机械产品的装配质量对于产品的使用效果和寿命都有着重大影响。

装配工艺检验包括装配过程中的操作规范、装配质量的评估等。

四、环境检验机械产品在使用过程中需要适应各种环境条件,因此还需要进行环境检验,以评估产品是否符合环境要求。

1. 温度适应性检验:机械产品需要在不同的温度条件下正常工作。

(SHOP APPLIED)Date:07/04/04 INSPECTION GUIDELINESCOATING OF LINE PIPE(SHOP APPLIED)0For Approval07/04/04J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved Date(SHOP APPLIED)Date:07/04/04CONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7LINE PIPE COATING DATA DOSSIER8INSPECTION CHECK LIST(SHOP APPLIED)Date:07/04/04 1.0PURPOSEThis inspection instruction covers the inspection, test and verification activities required tovalidate the coating and testing of Line Pipe external coating shop applied.2.0SCOPEThis instruction covers all necessary stages in the external coating of Line Pipe from theexamination of certification from procurement sources to the final inspection, preservation andpacking for despatch to site.Although the methodology in compiling this instruction is to systematically progress through theshop applied cycle for the external coating of a typical length of line pipe. Experienced,inspectors may interpret the intent of the instruction to accommodate local or novel practices.Any variations should be noted on the inspector's report. This instruction is based on the mostregularly used specification.3.0PROCEDURE3.1GENERALThis instruction together with its associated check sheet may be used on any order or contract.It is intended to act as a guide to the inspector during the course of the inspection programme.Any part of the document may be invoked and the sections to be used with the level ofinspection required will be specified on the check sheet.All tests and inspections will be carried out against approved purchase order specifications,procedures, purchasers or company standards, and within the practices and rules of thecountry, state or province and any government decrees, laws, ordinance or regulation as mayapply.If any conflict or contradictions should be apparent in any of the above then the more onerousrequirement will apply unless the purchaser or client directs otherwise in writing.3.2REFERENCE DOCUMENTSApplicable codes and specifications.•Design code•Purchase order specification•Purchaser's standards•Coating Procedures•SGS Company standards4.0DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONPurchase order/contractPipe Inspection and Test Plan [ITP]Material Test Certificates [if applicable]Coating SpecificationsCoating Material Storage ConditionsCoating ProceduresShipping procedure(SHOP APPLIED)Date:07/04/045.0INSPECTION PROCESS5.1MATERIAL5.1.1REVIEW OF CERTIFICATION [IF APPLICABLE]Original or authenticated copies of mill certificates will be available at the coatingmanufacturer’s premises. These should be examined for compliance with specifications.The review will include:•Maker's name and location•Certificate number•Material Specification•Heat or cast number•Chemical composition•Mechanical properties•Heat treated condition•NDE applied [if required]5.1.2VISUAL AND DIMENSIONAL VERIFICATIONMaterial identification on certificates.Material supplied in accordance with specification.Visual and dimensional compliance with specification.5.1.3REPORTING [IF APPLICABLE]Reporting on the material checks must include:Confirmation of satisfactory document review.Record of the endorsement of certificates reviewed/witnessed.Record of all non-conformities.Record of any tests witnessed and the result.5.2COATING INSPECTIONAfter clearance of the above points to the satisfaction of the inspector, the manufacturer willproceed with the production of coating the Line Pipe.Inspectors will review the following points on a basis to be outlined in the, applicable NationalStandard, purchaser's documentation, test and inspection plan, or other document, as notified tothe inspector.5.2.1SURFACE PREPARATIONCheck following prior to blastingAbrasive Type, performance, shape, dryness and cleanliness of Blast MaterialTemperature & Dew Point ReadingsCompressed Air Supply Blotter TestCheck following after Blasting(SHOP APPLIED)Date:07/04/04 Surface ProfileVisual inspection for Scabs, Silvers, Gouges, Laminations, flash rusting, dust and surface debris5.2.2 COATINGS INSPECTIONCheck following prior to and during coatingPaint Manufacture, type and colour against clients requirementsAtmospheric Conditions and Substrate TemperatureSubstrate Surface InspectionWet and Dry Film Coatings Thickness ReadingsTemperature of Pipe SurfacesAdhesion Test5.2.3FINAL INSPECTIONVisual Inspection of finished coatingsHoliday Detection TestingDry film final coating thickness reading5.3MARKINGMarking of pipes in accordance with clients requirements will be checked.5.4 REPORT AND RELEASE5.4.1. REPORTINGA final report summarising the activities carried out will be issued in accordance with thecontract requirements and circulated within the time limits laid down.The report will be in a format approved by the client and must clearly indicate the finalacceptance or rejection of Line Pipes coating5.4.2RELEASE NOTEWhen required by the contract a release document will be issued to the manufacture whenthe Line Pipes coating have been finally accepted6.0SHIPPINGCheck pipe protection on each end of pipesCheck shipping marks or marking instructions and recordCheck handling marksVerify that the packing conforms to clients specification for mode of transport7.0LINE PIPE DATA DOSSIERThe following final documents will be reviewed and endorsed as necessaryManufacture Data ReportsMaterial Certification [If applicable]Painting ReportsCoating test Results(SHOP APPLIED)Date:07/04/04(SHOP APPLIED)Date:07/04/048.0 INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesPurchase Order RequirementsInspection & Test Plan (ITP)Material CertificatesCoating ProcedureCoating Material Storage ConditionsIn-Process Inspection & Testing RequirementsCheck abrasive type, performance, shape,dryness and cleanliness of blast material &processBlast abrasive chemical analysisSurface preparation prior to blasting & afterblastingTemperature & dew point readingsCompressed air supply blotter testCleaning; Spent abrasive removalVisual inspection for Scabs, Silvers Gouges etc.Surface profile and surface finishCoating applications check for:Atmospheric conditions & substratetemperatureSubstrate surface inspectionWet & dry film coating thickness readingsTemperature of pipe surfaceAdhesion testsFinal Inspection & Testing RequirementsHoliday detection testVisual inspection of finished coatingMarkingPipe handling & storageCoating Reports reportAdditional/Supplementary RequirementsPreparation & Packing。

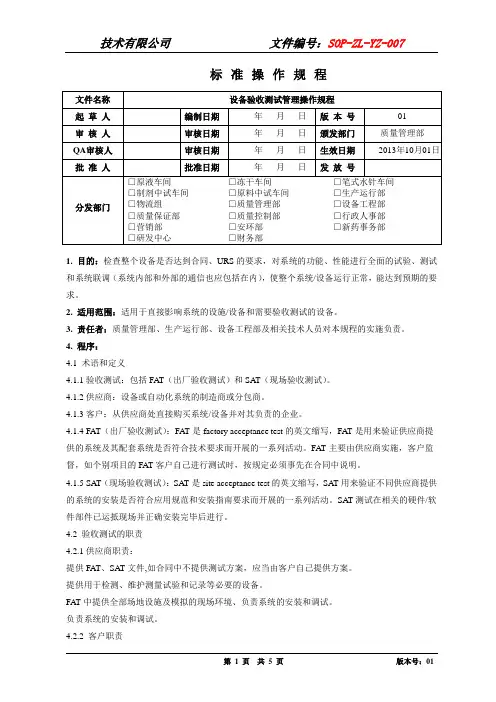

技术有限公司文件编号:SOP-ZL-YZ-007标准操作规程1. 目的:检查整个设备是否达到合同、URS的要求,对系统的功能、性能进行全面的试验、测试和系统联调(系统内部和外部的通信也应包括在内),使整个系统/设备运行正常,能达到预期的要求。

2. 适用范围:适用于直接影响系统的设施/设备和需要验收测试的设备。

3. 责任者:质量管理部、生产运行部、设备工程部及相关技术人员对本规程的实施负责。

4. 程序:4.1 术语和定义4.1.1验收测试:包括FAT(出厂验收测试)和SAT(现场验收测试)。

4.1.2供应商:设备或自动化系统的制造商或分包商。

4.1.3客户:从供应商处直接购买系统/设备并对其负责的企业。

4.1.4 FAT(出厂验收测试):FAT是factory acceptance test的英文缩写,FAT是用来验证供应商提供的系统及其配套系统是否符合技术要求而开展的一系列活动。

FAT主要由供应商实施,客户监督,如个别项目的FAT客户自己进行测试时,按规定必须事先在合同中说明。

4.1.5 SA T(现场验收测试):SAT是site acceptance test的英文缩写,SAT用来验证不同供应商提供的系统的安装是否符合应用规范和安装指南要求而开展的一系列活动。

SAT测试在相关的硬件/软件部件已运抵现场并正确安装完毕后进行。

4.2 验收测试的职责4.2.1供应商职责:提供FAT、SAT文件,如合同中不提供测试方案,应当由客户自己提供方案。

提供用于检测、维护测量试验和记录等必要的设备。

FAT中提供全部场地设施及模拟的现场环境、负责系统的安装和调试。

负责系统的安装和调试。

4.2.2 客户职责提供测试方案(如合同中制造商不提供测试方案)。

审核批准验收测试方案。

有经验的工程师参与FAT。

SAT中提供设备使用现场环境,参与系统的安装和调试。

4.3系统/设备验收测试流程:URS→设计确认→ FAT →启动与调试→现场测试验收→安装确认→运行确认→性能确认工厂测试验收是IQ的基础,现场测试验收是OQ的基础。

GENERAL SERVICE Date:17/03/04INSPECTION GUIDELINESCENTRIFUGAL PUMPSFORGENERAL SERVICE0For Approval17/03/2004J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved DateGENERAL SERVICE Date:17/03/04CONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7CENTRIFUGAL PUMPS DATA DOSSIER8INSPECTION CHECK LISTGENERAL SERVICE Date:17/03/041.0 PURPOSEThis instruction covers the inspection, test and verification activities required to validate thesupply, manufacture and test of a centrifugal pump for general use it includes horizontal,vertical and in-line pumps.2.0 SCOPEThis instruction covers all necessary stages in the production of the Centrifugal Pump forgeneral use from the examination of certification from procurement sources to the finalinspection, preservation and packing to despatch to site.Although the methodology in compiling this instruction is to systematically progress throughthe construction of a typical Centrifugal Pump. Experienced, inspectors may interpret theintent of the instruction to accommodate local or novel practices or to utilise the instruction fora one-off or alternative design of Centrifugal Pump. The design having been approved by theclient. Any such variations should be noted on the inspector's report.3.0 PROCEDURE3.1 GENERALThis instruction together with the associated check sheet may be used on any contract ororder. It is intended to act as a guide to the inspector in the course of the inspectionprogramme. Any part of the document may be invoked and the sections to be used and thelevel of inspection required will be as specified on the check list.All tests and inspections will be carried out against the approved drawings, purchase orderspecifications, purchasers or company standards, and within the practices and rules of thecountry, state or province and any government decrees, laws, ordinance or regulation as mayapply.If any conflict or contradictions should be apparent in any of the above then the more onerousrequirement will apply unless the purchaser or client directs otherwise in writing.The range of pump types, materials, sizes and pressure ratings included in standardmanufacturers catalogues is large and varied and excludes the possibility of producing anoverall instruction, which defines precisely to what extent inspection is required by thePurchase Order documentation or project instructions.3.2 REFERENCE DOCUMENTSApplicable codes and specifications.•Design code (to be stated on inspection report)•Purchase order specification•Purchaser's standards•Approved drawings•SGS company standardsApplicable codes and standards (sample only)•API 610•BSS 7784•BS EN 5199•BS EN 9905•BS EN 9908GENERAL SERVICE Date:17/03/04•BS EN 137094.0 DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONPurchase Order or ContractInspection and Test PlanData sheetSub-assembly drawingsMaterial test certificatesWeld procedures and Procedure Qualification RecordsList of qualified welders or welding operatorsWelders' qualificationsCalibration of measuring and test equipmentNDE procedures, (appropriate to material of construction)List of qualified NDE operators/inspectorsNDE /inspectors' qualificationsHeat treatment procedureHydrostatic testing procedureWater quality documentImpeller inspection procedurePerformance Test procedurePreparation and painting procedurePreservation, packing and shipping procedureSupply list (packing list)5.0 INSPECTION PROCESS5.1 MATERIAL5.1.1 REVIEW OF CERTIFICATIONOriginal or authenticated copies of certificates should be available at the manufacturer'spremises. These should be examined for compliance with specifications and whereappropriate, drawings:The review will include checks on:-•Manufacturer's name and location•Certificate No•Material Specification•Heat or cast No•Makers No or Plate No•Chemical composition•Mechanical properties•Heat treated condition•NDE applied and results•Surface finish5.1.2VISUAL AND DIMENSIONAL VERIFICATIONMaterial identification on certificates against product markings.Material supplied against drawing, material list and specification as appropriate.Visual and dimensional compliance with specification.GENERAL SERVICE Date:17/03/04 5.1.3ADDITIONAL/SPECIAL REQUIREMENTSMay apply on special components, e.g. thick components, alloy steels or non ferrous materials. Check to ensure specification contract requirements have been met.Witness NDE examinations as necessary.5.1.4REPORTINGReporting on the material checks should include•Conformation of satisfactory document review•Record of endorsement of certification reviewed/witnessed•Record of all non-conformities•Record of any tests witnessed and the result5.2CENTRIFUGAL PUMP MANUFACTUREAfter clearance of the above points to the satisfaction of the inspector, the fabricator willproceed with the manufacture of the sub-assemblies and components for a Centrifugal Pump.5.2.1PUMP CASING INSPECTIONFollowing the completion of machining pump casings will be checked as follows:•Visual inspection for damage•Dimensional check to drawing requirements•Witness or review hydrostatic test•Witness or review NDE examination•Application of test marks•Visual examination of welded on connections•Review weld qualification and weld procedure records5.2.2IMPELLER INSPECTIONAfter completion of manufacture the pump impeller will be inspected/witnessed as follows:•Witness or review Run Out test•Witness or review Dynamic Balance test•Review NDE examination results5.2.3PERFORMANCE TESTAfter complete assembly the pump will be submitted to a performance test. The test will be conducted within the contract and code requirements.The inspector will witness as follows:•Collection of test data•Preparation of test curves•Rated speed•Check bearings for overheating•Noise test•Vibration testGENERAL SERVICE Date:17/03/04 5.2.4NPSH TESTWhere required by the contract or specification the inspection will witness andapprove the results.The inspection will check the following points:•Test method is as required by the contract is used•Confirmation of results5.2.5MECHANICAL RUNNING TESTWhen required by the contract or specification each pump will be run for a pre-determinedtime depending on type, the pump and it's driver will be as complete as possible.The inspector will check as required:•Flow requirement•Excessive vibration•Excessive noise•Bearing temperatures5.2.6DISMANTLING INSPECTIONPumps with three or more stages will be inspected by dismantling after test. Other types maybe inspected when required by the contract. The inspector will check as necessary to ensurethat no damage has occurred during tests and the necessary care taken during re-assembly, including rust prevention procedures where necessary.5.2.7CLEARANCE CHECKINGThe establishment of running clearances is determined by giving consideration to variablessuch as pumping temperature, suction condition, fluid characteristics, thermal expansion orgalling characteristics of the materials etc. The final clearances being the manufacturers standard. Where required the inspector will confirm the standards have been met.5.2.8FINAL VISUAL AND DIMENSIONAL INSPECTIONAfter completion of all manufacture and test the inspector will carry out a final inspection of the pump.Paying particular attention to:•Main dimensions to drawing requirements•Base plate dimensions•Size rating and position of flanged connections•Size and type of threaded connection•Inspection for workmanship, defects and damage•Check on installed condition of parts, assemblies5.3NAME PLATEContents to be checked in accordance with the approved drawings and specifications andstamped in accordance with the code requirements.5.4PAINTING/COATING INSPECTIONSurface preparation for painting will be checked for the following points according to specification:GENERAL SERVICE Date:17/03/04 Cleaning method (Blast or scraping and wire brushing)Preparation gradeFreedom from weld spatter, blow holes and other defectsHumidity and Steel temperature checks prior to paintingPaint Manufacture, type and colour to be checked to clients specificationDry film paint thickness to be checked according to specificationPainted surface condition to be free from pin-holes, runs, damage and otherdiscontinuity5.5SPARE PARTS, LOOSE ITEMS AND ACCESSORIESSpare parts, loose items and accessories will be checked visually and for dimensions,materials, workmanship and quantity according to purchase order specification test marks andtags will be checked for correct identification.5.6REPORT AND RELEASE5.6.1REPORTINGA final report summarising the activities carried out will be issued in accordance with thecontract requirements and circulated within the time limits laid down in the contract. Thereport will be in a format approved by the client and must clearly indicate the final acceptanceor rejection of the pump.5.6.2RELEASE NOTEWhen required by the contract a release document will be issued to the manufacturer whenthe pumps have been finally accepted.6.0SHIPPING6.1PREPARATION AND PACKINGThe following points will be checked.•All exterior machined surfaces must be coated with rust preventative•All internal surfaces which are susceptible to corrosion must be coated withrust preventative•All flanged openings should be fitted with metal protectors in accordance withthe specification•All threaded connections must be provided with steel plugs•Exposed shafts and shaft couplings to be covered with waterproof materialand sealed•Check manuals and instructions are included as the specificationrequirements•Packing style and suitability for overseas shipment•Shipping marks are correct•Pre-assembled systems are marked as required by the specificationGENERAL SERVICE Date:17/03/04 7.0Centrifugal Pumps Data DossierThe following final documents will be reviewed and endorsed as necessary:Manufacturers data reportMaterial certificationDimensional recordNDE reportsHydrostatic test reportsPerformance test requirementsNPSH reportsRun-test reportsStrip down reportsFinal inspection reportMarkingsPacking testSpare partsGENERAL SERVICE Date:17/03/048.0INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesPurchase Order RequirementsInspection & Test Plan (ITP)Weld Procedures Specification (WPS) &Procedure Qualification Records (PQR)Welder Qualification RecordsNDT Personnel Records and ProceduresPump Performance ProceduresPump Data SheetsIn-Process Inspection & Testing RequirementsMaterial Test Certificates & IdentificationPump Casing Inspection & Hydraulic TestsImpeller Inspection & BalancingPerformance Test & Sound Level ChecksPerformance TestNPSH TestMechanical Running TestStrip Down Inspection after Running TestClearance Inspection ChecksNDE Records (if applicable)Nameplate IdentityReview Calibration CertificatesPainting Coating InspectionSparesWeld Conditions and Fit Ups (if applicable)Final Inspection & Testing RequirementsVisual & Dimensional CheckMarkingShippingReview of Data Documentation PackageAdditional/Supplementary RequirementsPreparation & Packing。

GENERAL SERVICES Date:18/03/04INSPECTION GUIDELINES RECIPROCATING COMPRESSORSFORGENERAL SERVICES0For Approval18/03/2004J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved DateGENERAL SERVICES Date:18/03/04CONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7RECIPROCATING COMPRESSORS DATA DOSSIER8INSPECTION CHECK LISTGENERAL SERVICES Date:18/03/041.0 PURPOSEThis instruction covers the inspection, test and verification activities required to validate thesupply, manufacture and test of a Reciprocating Compressor for general use.2.0 SCOPEThis instruction covers all necessary stages in the production of the Reciprocating Compressorfrom the examination of certification from procurement sources to the final inspection,preservation and packing to despatch to site.Although the methodology in compiling this instruction is to systematically progress through theconstruction of a typical Reciprocating Compressor. Experienced, inspectors may interpret theintent of the instruction to accommodate local or novel practices or to utilise the instruction for aone-off, or alternative design of compressor. The design having been approved by the client.Any such variations should be noted on the inspector's report.3.0 PROCEDURE3.1 GENERALThis instruction together with the associated check sheet may be used on any contract or order.It is intended to act as a guide to the inspector in the course of the inspection programme. Anypart of the document may be invoked and the sections to be used and the level of inspectionrequired will be as specified on the check list.All tests and inspections will be carried out against the approved drawings, purchase orderspecifications, purchasers or company standards, and within the practices and rules of thecountry, state or province and any government decrees, laws, ordinance or regulation as mayapply.If any conflict or contradictions should be apparent in any of the above then the more onerousrequirement will apply unless the purchaser or client directs otherwise in writing.3.2 REFERENCE DOCUMENTSApplicable codes and specifications.•Design code (to be stated on inspection report)•Purchase order specification•Purchaser's standards•Approved drawings•SGS company standardsApplicable codes and standards (sample only)•API 618•JIS B83414.0 DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONPurchase Order or ContractInspection and Test plansData sheetSub-assembly drawingsGENERAL SERVICES Date:18/03/04 Material test certificatesWeld procedures and Procedure Qualification RecordsList of qualified welders or welding operatorsWelders' qualificationsCalibration of measuring and test equipmentNDE procedures, (appropriate to material of construction)List of qualified NDE operators/inspectorsNDE /inspectors' qualificationsHydrostatic testing procedurePreparation and painting procedurePreservation, packing and shipping procedureSupply list (packing list)5.0 INSPECTION PROCESS5.1 MATERIAL5.1.1 REVIEW OF CERTIFICATIONOriginal or authenticated copies of certificates should be available at the manufacturer'spremises. These should be examined for compliance with specifications and where appropriate,drawings:The review will include checks on:-•Manufacturer's name and location•Certificate No•Material Specification•Heat or cast No•Makers No or Plate No•Chemical composition•Mechanical properties•Heat treated condition•NDE applied and results•Surface finish5.1.2 VISUAL AND DIMENSIONAL VERIFICATIONMaterial identification on certificates against product markings.Material supplied against drawing, material list and specification as appropriate.Visual and dimensional compliance with specification.5.1.3ADDITIONAL/SPECIAL REQUIREMENTSMay apply on special components. Check to ensure specification contract requirements havebeen met. Witness NDE examinations as necessary.5.1.4 REPORTINGReporting on the material checks should include:•Conformation of satisfactory document review•Record of endorsement of certification reviewed/witnessed•Record of all non-conformities•Record of any tests witnessed and the resultGENERAL SERVICES Date:18/03/045.2RECIPROCATING COMPRESSOR MANUFACTUREAfter clearance of the above points to the satisfaction of the inspector, the fabricator will proceedwith the manufacture of the sub assemblies and components for a reciprocating compressor.5.2.1FABRICATION INSPECTIONFollowing the completion of welding and machining operations the compressor parts will be inspected as required by the specification or contract.The inspection will consist of:•Visual inspection for damage•Dimensional check to drawing requirement•Inspection of parts, particularly cast in passages and piping for cleanliness•Visual examination of welded on connections•Review of welder qualifications•Review of weld procedure record•Confirmation of satisfactory NDE5.2.2HYDROSTATIC TESTSThe compressor and other pressure containing parts will be hydrostatically tested.The main items being:•Cylinder•Cooling Jackets•Piping•Pressure vessels•Filters•CoolersThe inspector must verify that the correct test pressure has been applied to the relevant parts depending on specification requirements.5.2.3PRESSURE TESTIn addition to the hydrostatic test it may be necessary to carry out a pressure test using heliumas the test medium.The inspector will:•Witness pressure test as required•Review test method to ensure it is acceptable to the code/specification requirement.5.2.4ASSEMBLY INSPECTIONDuring compressor assembly and when required by the Purchase order or contract inspectionwill be carried out paying particular attention to the following items:Piston end clearanceCrankshaft deflectionRun-out checkProper match markingProtection of machined surfacesGENERAL SERVICES Date:18/03/045.2.5MECHANICAL RUNNING TESTCertain types of compressor may be subjected to a mechanical running test. This particularly applies to skid mounted units. Where required by the purchase order the inspector will check forthe following attributes during the test period.•Lubricating oil - temperature, pressure flow rate•Cooling water - temperature, pressure flow rate•Critical speed•Bearing temperatures•Vibration•Gasket condition/leakage•Proper operation of pressure relief valves speed governors and overspeed shutdown devices5.2.6DISMANTLING INSPECTIONSome purchasers may require a strip down inspection after testing. Where there is an inspection the following points will be checked as a minimum:•Visual condition of cylinder liner•Surface condition of cross head guide piston rods and bearings•Valve plates•Valve springs•Pistons5.2.7FINAL VISUAL AND DIMENSIONAL INSPECTIONAfter completion of all manufacture and test the inspector will undertake final inspection of the compressor paying particular attention to:•Main dimensions to drawing requirements•Skid dimensions•Match marks for re-assembly•Position of outside connection points•Inspection of workmanship•Direction of rotation marked correctly5.3NAME PLATEContents to be checked in accordance with the approved drawings and specifications and stamped/marked in accordance to clients requirements.5.4PAINTING/COATING INSPECTIONSurface preparation for painting will be checked for the following attributes according to the specification:•Cleaning method•Preparation grade•Freedom from weld spatter, blow holes and other defects.•Humidity and Steel Temperature checks prior to painting•Paint manufacture, type and colour of paint to clients specification•Dry film paint thickness to be checked according to specification.GENERAL SERVICES Date:18/03/04•Painted surface condition to be free from pin-holes, runs, damage or otherdiscontinuity5.5SPARE PARTS, LOOSE ITEMS AND ACCESSORIESSpare parts, loose items and accessories will be checked visually and for dimensions materials,workmanship and quantity according to purchase order specification test marks and tags will bechecked for correct identification.5.6REPORT AND RELEASE5.6.1REPORTINGA final report summarising the activities carried out will be issued in accordance with the contractrequirements and circulated within the time limits laid down in the contract. The report will be ina format approved by the client and must clearly indicate the final acceptance or rejection of thepump.5.6.2RELEASE NOTEWhere required by the contract a release document will be issued to the manufacturer when thepumps have been finally accepted.6.0SHIPPING6.1PREPARATION AND PACKINGThe following points must be checked:•All exterior machined surfaces must be coated with rust preventative•All internal surfaces which are susceptible to corrosion must be coated with rustpreventative•All flanged openings should be fitted with metal protectors in accordance withthe specification•All threaded connections must be provided with steel plugs•Check manuals and instructions are included are included as the specificationrequirements•Packing style and suitability for overseas shipment•Shipping marks are correct•Pre-assembled systems are marked as required by the specification7.0RECIPROCATING COMPRESSORS DATA DOSSIERThe following final documents will be reviewed and endorsed as necessary.Manufacturer's data reportsMaterial certificationDimensional recordNDE reportsHydrostatic test reportsPerformance test requirementsNPSH reportsRun-test reportsStrip down reportsFinal inspection reportMarkingsPacking listSpare partsGENERAL SERVICES Date:18/03/048.0INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesPurchase Order RequirementsInspection & Test Plan (ITP)Approved DrawingsP.W.H.T ProceduresWeld Procedures Specification (WPS) &Procedure Qualification Records (PQR)Welder Qualification RecordsNDT Personnel Records and ProceduresCompressor Performance ProceduresIn-Process Inspection & Testing RequirementsMaterial Test Certificates & IdentificationCompressor Casing Inspection & Hydro TestComponents Inspection Prior to AssemblyHydrostatic – Pressure TestsAssembly Inspection (Piping & Electrical)Mechanical Running TestDismantling Inspection (if specified by client)Visual & Dimensional InspectionElectric MotorSteam Turbine Drivers (if applicable)Diesel Engine (if applicable)InstrumentationFinal Inspection & Testing RequirementsVisual & Dimensional CheckNameplate & Identification MarkingPainting/Coating InspectionSpare Parts, Loose Items & AccessoriesShippingDocumentation PackageAdditional/Supplementary RequirementsPreparation & Packing。

制造过程检验制度本制度对压力容器制造主要过程的工序检验的内容、方法、要求及检验记录和签字作出了规定,以保证压力容器的产品质量。

1 范围本制度适用于本厂产品制造的各工序检验要求。

2 检验的依据和原则2.1检验的依据:a.产品图纸和工艺文件;b.有关法规、标准和规范,主要是:《压力容器安全技术监察规程》、GB150-1998《钢制压力容器》、GB151-1999《管壳式换热器》等及相关标准;c.质量体系文件包括质保手册、有关管理制度或程序文件等。

2.2检验的原则是:不合格的原材料不投料,不合格的零部件不转下道工序,不合格的产品不出厂。

3 工序检验的一般要求3.1工序检验应坚持“三检制”,即自检、互检和专检相结合。

操作者完成工序的工作后应首先进行自检和互检,合格后交专职检查员检验,合格后签署,转下道工序。

3.2主要受压元件制造应编制制造卡,检验应编制检验卡。

主要工序完成后,操作者应签字,并交专职检查员检查,检查合格并签字后转下道工序。

3.3检查员应按有关图纸、工艺文件和标准及检验指导书的规定,使用规定的适宜的计量器具和测量方法,对规定的检验项目进行测量和检验,认真填写检验记录。

3.4检验中发现不合格时,按《不合格品管理制度》的规定处理。

4 工序检验的内容、方法及要求4.1材料检验4.1.1应按《采购材料验收管理制度》的规定对进厂材料的质证书进行审查,对材料实物的标识、几何尺寸及表面质量进行检查,需要复验的进行复验,合格后给出材料本厂代号并进行标记移植。

4.1.2按《外购件、外协件、配套件管理制度》的规定对外购件外协件、安全附件等进行检查验收,审查质证书、按有关标准进行检定、校验和检验。

4.1.3经验收合格的材料及外购外协件,应办理验收入库手续,经材料责任师审核确认后入库。

4.2下料及坡口加工检验4.2.1检查员应检查所领材料的牌号、规格及有关附加技术要求是否符合图样及工艺文件的规定,材料标识是否齐全,材料的表面质量是否合格。

机械设备质检部工作流程英文回答:Inspection Process for Mechanical Equipment.The inspection process for mechanical equipment involves a series of steps designed to verify that the equipment meets the required specifications and standards. It is essential to ensure the proper functioning, safety, and reliability of the equipment.The following steps outline a typical mechanical equipment inspection process:1. Preparation:Gather necessary documentation, drawings, and specifications.Prepare the equipment for inspection, includingcleaning and disassembly if required.2. Visual Inspection:Examine the equipment's exterior surfaces for defects, damage, or corrosion.Check for proper assembly and alignment.3. Dimensional Inspection:Use measuring instruments to verify dimensions, tolerances, and clearances as per specified drawings.4. Material Inspection:Conduct material testing, such as hardness testing or chemical analysis, to ensure compliance with material specifications.5. Functional Testing:Test the equipment under operating conditions to assess its performance, functionality, and safety features.6. Non-Destructive Testing:Utilize non-destructive testing methods, such as ultrasonic testing or magnetic particle inspection, to detect internal defects or flaws.7. Reporting and Documentation:Record the inspection findings and observations in a detailed report.Provide recommendations for corrective actions or repairs if necessary.8. Acceptance or Rejection:Based on the inspection results, the equipment is either accepted or rejected for use.Rejected equipment may require further evaluation or repairs before being accepted.中文回答:机械设备质检流程。

机械设备技术检验制度第四十五条机械设备技术检验的基本规定(一)凡机械设备大修理(包括长期停用后恢复及转移到新工地安装使用的新旧设备),均须按本规定进行技术检验及试运转。

(二)设备大修理后的技术检验,是一次全面系统的质量鉴定,是保证机械交付使用后有良好的动力性能、经济性能、安全可靠性及操作性能的重要环节,必须由集团公司安全生产部的技术人员参加验收。

(三)交付检验的机械,除最后一次喷漆外,必须完成全部工序。

(四)机械竣工交验之前,承修单位应及时通知安全生产部和送修单位参加验收。

送修单位在接到通知后未及时派出代表,可由安全生产部和承修单位进行验收。

(五)竣工验收应以安全生产部为主,承修方的质检和技术部门负责组织,送修单位代表参加验收。

验收合格后承修单位填制竣工交验记录,经安全生产部及有关技术人员签认后方可作为验收凭证,并同有关修理资料一起送交安全生产部,存档保管,财务部门根据验收单负责结算。

(六)各种机械试运转验收一般分为:试前试验,空载运转,负荷运转及试后检查四个步骤。

检查内容及要求见附录。

(七)机械出厂时,规定的附属装置必须齐全,保障使用。

(八)对验收中发现的缺陷或故障,必须修复改善后方可出厂使用。

第四十六条机械设备技术检验(一)发动机1.起动方便.用起动机或手柄起动的汽油机,在环境温度不低于-5℃,柴油机不低于5℃时,不用任何预温方法能迅速起动,用小发动机起动的柴油机,在环境温度不低于0℃时,在10分钟内能起动二次。

2.发动机起动后,不论在低速、中速或高速,均应运转平衡。

突然加速或减速时,不应有停顿、放炮、熄火等现象,排气不应有时浓时淡或冒黑烟现象。

柴油机允许冒淡色蓝烟。

3.最高和最低运转应达到原厂规定,其允许误差最高转速不应超过±5%,最低速度不应高于规定的5%。

并保持平衡。

4.水温在75~85℃急速运转,机油压力应不低于0.1MPa,中速运转,机油压力应为0.2~0.4MPa,气缸压力应符合原厂规定。

Date:13/04/04 INSPECTION GUIDELINESPIPE FITTING BUTT WELDINGGRADE WPB WROUGHTCARBON STEEL & HIGHSTRENGTH FITTINGSSEAMLESS OR WELDED0For Approval13/04/04J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved DateDate:13/04/04CONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7PIPE FITTINGS BUTT WELDED DATA DOSSIER8INSPECTION CHECK LISTDate:13/04/04 1.0PURPOSEThis inspection instruction covers the inspection, test and verification activities required tovalidate the supply manufacture and test of pipe fittings butt welding [Grade WPB wroughtCarbon steel & High strength fittings seamless or welded]2.0SCOPEThis instruction covers all the necessary stages in the shop manufacture of pipe fittings from theexamination of certification from procurement sources to the final inspection, preservation andpacking for dispatch to site.Although, the methodology in compiling this instruction is to systematically progress through theprocess cycle for the manufacture of a typical item of pipe fittings. Experienced inspectors mayinterpret the intent of this instruction to accommodate local or novel practices or the use theprocedure for a one off type of manufacture. Any variations should be noted on the inspectorsreport. Most pipe fittings are manufactured to well known specifications.3.0PROCEDURE3.1GENERALThe instructions together with its associated check sheet may be used on any order or contract.It is intended to act as a guide to the inspector during the course of the inspector programme.Any part of the document may be invoked and the sections to be used with the level ofinspection required will be specified on the check sheet.All tests and inspections will be carried out against approved drawings, purchase orderspecifications, purchasers and company standards and within the practices and rules of thecountry state or province and any government decrees law, ordinance or regulation as mayapply.If any conflict or contradiction should be apparent in any of the above the more onerousrequirement will apply unless the purchaser or client directs otherwise in writing.3.2REFERENCE DOCUMENTSApplicable codes and specifications•Design code•Purchase order specification•Purchasers standards•Approved drawings•SGS company standardsApplicable codes and standards (sample only)•ANSI B31.14.0DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONPurchase order/contractPipe Fittings Inspection and Test Plan [ITP]Material test certificatesHeat treatment proceduresNDE Procedures & Personnel RecordsApproved Drawings/Data SheetsDate:13/04/04 Weld Procedures Specification [WPS]Procedure Qualification Records [PQR]Welder Qualification Records5.0INSPECTION PROCESS5.1MATERIAL5.1.1REVIEW OF CERTIFICATIONOriginal or authenticated copies of mill certificates will be available at the manufacturerspremises. These should be examined for compliance with specifications/code.The review will include:•Makers name and location•Certificate number•Material Specification•Heat or cast number•Chemical composition•Mechanical properties•Heat treated condition•NDE applied and results•Hydrostatic pressure5.2.VISUAL AND DIMENSION EXAMINATIONIn accordance with the referencing code requirements pipe fittings will be subjected to a visualand dimensional examination checking following;Correct type of fittingSize and wall thicknessEnds diameters and prepWelded or seamlessThe pipe fittings should also be free from dents, scrapes and handling damage.5.3 MECHANICAL TESTINGInspector to witness additional test[a] Charpy Impact Tests[b] Production Hardness testing5.4HEAT TREATMENTInspector to check Heat Treatment after forming & welding5.5MARKINGFull identification marks in accordance with clients requirements and code will be checkedDate:13/04/045.6REPORT AND RELEASE5.6.1 REPORTINGA final report summarising the activities carried out will be issued in accordance with the contractrequirements and circulated within the time limits laid downThe report will be in a format approved by the client and must clearly indicate the finalacceptance or rejection of pipe fittings5.6.2RELEASE NOTEWhen required by the contract a release document will be issued to the manufacture when pipefittings have been finally accepted6.0SHIPPINGCheck pipe fittings ends are fitted with protection against damage, abrasion and other damageCheck shipping marks to marking instructions and recordVerify that packing conforms to specification for the mode of transport7.0PIPE FITTING DATA DOSSIERThe following final documents will be reviewed and endorsed as necessary.Manufacture Data ReportsMaterial CertificationNDE Reports and operators QualificationsHeat Treatment Charts [if applicable]Weld Procedures Specification & Procedure Qualification RecordsWeld & NDE MapDate:13/04/048.0 INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesPurchase Order RequirementsInspection & Test Plan (ITP)Approved Drawings/Data SheetNDE Procedures & PersonnelWeld Procedures Specification (WPS) &Procedure Qualification Records (PQR)Welder Qualification RecordsIn-Process Inspection & Testing RequirementsMaterial Test Certificates & IdentificationMechanical Testing including Charpy Impacts &Production Hardness TestsNDE Tests (MPI, UT & Radiography)Heat Treatment after Forming & WeldingFinal Inspection & Testing RequirementsVisual & Dimensional CheckProduct MarkingReview of Data DossierWeld End Coating & ProtectionShipping Marks & ShippingAdditional/Supplementary RequirementsPreparation & Packing。

源通和公司作业指导书产品检验规范文件编号文件版本制定日期 2014-11-12 生效日期※※封面※※产品检验规范制定:审核:批准:文件分发明细副本:□总经理□管理者代表□ 财务部□仓库□市场部□采购部□研发部□工程部□生产部□品管部□行政人事部□计划物控部正本:文控中心副本编号:制修订记录文件版本修订日期制修订页次制修订摘要A.0 1-8 第一版页版本目录页次1 2 3 4 5 6 7 8版本 A.0 A.0 A.0A.0A.0A.0A.0A.01. 目的:建立一套本公司通用之成品检验标准、以适合品管部在执行标准时有章可依;完善公司质量作业标准,规范产品检验方式,确保产品质量满足客户质量要求。

2. 范围:公司所有充电器产品均适合本标准。

3. 权责:品管部:负责公司产品外观、电性等各类检验工作。

4. 定义:4.1 致命不合格(CR :可能影响产品的安全使用或导致产品主要性能失效的不合格; 4.2 严重不合格(MA :可能影响产品性能失效或降低性能或影响产品形象的不合格; 4.3 轻微不合格(MI :任何不符合规定要求又不严重影响产品外观或性能的不合格; 4.4 自检:由 QA 根据现有设备自行检验;4.5 外检:由产线测试或第三方检测机构进行测试; 4.6 实验室:由公司实验室做可靠性测试;5.支持文件:采用 GB2828.1-2012(Ⅲ级正常检验单次抽样计划进行随机抽样 , 依下表选定其 AQL 值, 列表如下:5.1《成品检验作业指导书》 QWPG-003 5.2《抽样计划作业指导书》 QWPG-0046. 检验内容:各类产品检验规范如下:如客户有特殊的检验要求按照客户要求的标准执行。

附件 1:步步高旅充检验标准附件 2:联想旅充检验标准类别外观电气性能AQL 0 0 MAJ0.65 0.4 MIN1.50.65成品检验规范(旅行充电器检验项目检验方法 /条件质量要求检验设备 /工具缺陷等级 CRI MAJ MIN1. 外观在光源为 40W日光灯的照明下,以非透光方式,眼睛与待测物距离 30cm,目检方向与待测物成 90度.检验时每面不超过 5s,以目视扫描进行⒈表面应无划伤、流痕、毛刺、裂痕、无明显缩痕、脱花等成型缺陷及其他机械损伤,皮纹应均匀一致。

设备生产制作及检验流程集团生产004字【2013】002号一、产品生产环节示意图折弯焊接喷塑壳体装配元件装配成品检验成品入库物流运输二、主要生产设备简介1,德国通快系列数控加工中心全球主要生产技术及工业激光制造商德国通快提供的TRUMATIC6000机床,整合了冲裁与激光切割技术的优点,可用于制造各种零件,对于各种板材的三维冲裁和处理不规则外形有着卓越的质量保证和更强的加工能力。

2、德国通快数控折弯机采用电液伺服系统控制双缸同步,配合国际水准的光栅尺,形成全闭环控制,同步控制精度高,折弯精度、重复定位精度也达到很高的水准。

数控油缸挠度自动补偿系统,克服工作过程中滑块变形对工件质量造成的影响,保证了加工工件良好的直线度和折弯角度。

补偿由数控系统自动调整,补偿方便、精确。

功能齐全的后挡料机构,最多可扩展为六轴。

工件折弯“随心所欲”。

参数名称参数指标公称压力5000KN可折板宽6000mm立柱间距离5600mm开启高度700mm喉口深度500mm滑块行程300mm行程调节量200mm工作台高度1200mm主电机功率45kw快下70 mm/s工作速度工程7 mm/s返程35 mm/s机床外形尺寸mm(L×W×H)6100mm×2350mm×3880mm 3、立体仓库南京六维自动立体化仓库多功能的立体料库,将原材料、半成品统一管理,成为一个物流的中转站,所有生产数据有中心服务器管理,生产全过程控制数字化,可放置最大尺寸3000×1500mm的板材。

参数名称参数指标动力设备电源要求电压AC380V±10%频率50Hz±1%相数三相五线管理系统电源要求电压AC220V±10%频率50Hz±1%相数单相温度立体库区域0℃-40℃中央控制室18℃-40℃湿度(自动化仓储物流系统区域)<85%Rh 仓库地面平整度允许偏差±10mm库区地面高差±5mm 立体库空间(长*宽*高)102000mm*9940mm*7000mm储存量单元承重Max.360Kg托盘货位4排×59列×7层-8=1644个货位料箱1644×6=9864个料箱4、焊接设备德国库卡焊接机器人工作站参数名称参数指标尺寸(长x高x厚):330x260x35mm 机器人系统德国库卡焊接机器人KR16L6焊接系统福尼斯TPS5000激光焊缝跟踪系统加拿大SERVO-ROBOT电控系统西门子PLC 315-2DP安全系统红外线光栅德国库卡焊接机器人编程控制器 KCP福尼斯焊接系统TPS5000参数名称参数指标参数名称参数指标尺寸(长x高x厚):330x260x35mm主电压±15% 50/60Hz 3*400V 保护等级:IP54焊接电流范围MIG/MAG 3—500A 显示屏:640x480,256色LCD彩显,VGA模式,TIG 3—500AMMA 10—500A 工作模式6D空间鼠标,使示教动作容易操作4种工作模式切换旋钮,方便操作与安全焊接周期40%暂载率,500A100%暂载率,360A尺寸(L×W×H)625/290/475mm德国库卡焊接机器人 KR16L/6德国库卡机器人控制器KRC2参数名称参数指标参数名称参数指标负载6Kg处理器库卡(工业)计算机运动轴数6操作系统微软WINDOWS XP重复精度小于±0.1mm编程及控制库卡VKCP控制器KRC2设计生产标准DIN EN 292, DIN EN 418, DINEN 614-1, DIN EN 775,自重240公斤保护等级IP54每个轴的运动参数运动范围工作环境温度0°~50°(无需外加空调系统)轴1+/-185°控制轴数8-11个轴2+35°/-155°自重178公斤轴3+154°/ -130°输入电源3x400V-10%∽3x415V+10% ,49-轴4+/-350°负载功率4KVA(最大8KVA)32A, 3只(慢熔型)轴5+/-130°保护熔断器Ether Net, CAN BUS 轴6+/-350°(Interbus, profibus 作为最大工作半径1911mm与外围设备通讯接口Ether Net, CAN BUS空间最大旋转角度±185º至机器人电缆总成15米安装面积3011mm x 3238mm噪音等级(根据DIN 45635-1) 67dB 螺柱焊机逆变式直流脉冲TIG焊机(氩弧焊机)参数名称参数指标参数名称参数指标输出800A/30V20A/10.8V~400A/26VX60%100% U o70V I2400A315A X5%U226V22.6V I2800A20A/20.8V~315A/32.6VX60%100% U230V I2315A250A 频率3~50/60Hz U232.6V30V U1400V U1380VI1max31A I1max27.8AI1eff22A I1eff22AIP23IP21S绝缘等级FCOSΦ0.8(400A)冷却方式风冷5、加工设备多工位数控冲床VIPROS 358 KING液压母排加工机SJW303参数名称参数指标参数名称参数指标产品规格VIPROS 358 KING折弯工位公称压力300KN冲压能力ton(U.S.ton) 30(33)电机功率 5.5KW最大行程mm(in.)2000 x 1270油泵31.5MPa-10ml/r板材最大尺寸mm(in.)270 x 4000(含换一次夹)剪断工位公称压力300KN最大板厚 mm(in.)3.2电机功率3KW板材最大重量kg(lb)50油泵31.5MPa-5ml/r每分钟冲程数s.p.m1200(2mm st.1mm间距)冲孔工位公称压力300KN最大冲孔速度h.p.m(2mmincrement)1200电机功率3KW最大进料速度m/min(in./min.)80油泵31.5MPa-5ml/r转塔速度(r.p.m)30最大平弯尺寸160*12mm 工位58(2 auto index)最大立弯尺寸120*12mm 冲压精度mm+/- 0.1最大剪断尺寸160*8mm控制系统AMADAN 04P.C +新PHNC冲孔尺寸园孔模φ9、φ11、φ13、φ17控制轴四轴向同时控制腰孔模9X14 11X16 13X18 17X22供给空压(kg/c㎡) 5.7模芯电机功率120W 程序代码ISO/EIA外形尺寸(长*宽*高)2688mm*1372mm*1263mm制造厂商AMADA设备重量2200Kg数控母排冲孔机MC-40数控母排折弯机 MZ-40参数名称参数指标参数名称参数指标公称力4000KV公称力400KN定位速度40m/min折弯精度±0.3°X轴最大行程1000mm最大折弯角度95°Y轴最大行程1000mm快进速度13mm/sZ轴最大行程200mm工作进度0~13mm/s冲孔频率50hpm最大液压力270Bar模位数6pcs折弯最大行程200mm冲孔精度±{0.2+(L/4000)}mm返回行程0~200mm加工最大板材尺寸6000*200mm总功率7Kw60mm 最大板料厚度铜板15mm钢板10mm U形折弯内宽最小普通立弯最大15*160mm 液压缸行程26mm尺寸总功率25KW平弯最大尺寸12*100mm制造厂商江苏金方圆外形尺寸4325mm*1560mm*1860mm总重量1950Kg数控铣床 XKA5032平面磨床 MGBA1420A参数名称参数名称参数名称参数指标工作台面积(宽*长)320*1325mm可磨外径φ8-200(φ0.3-8)mm 工作台最大纵/横向行程680mm/230mm可磨孔径φ18-80(φ0.7-3)mm工作台最大升降行程320mm最大磨外园长度500(200)mmT型槽数3个最大磨孔长度125(5)mmT型槽宽度/间距离18mm/70mm工作台最大移动量600(24)mm主轴锥度7:24工作台移动速度范围0.01-4(0.0004-157)mm 主轴孔径29mm工作台最大转动角度±7°主轴轴向移动距离85mm手轮转一转的移动量1(0.04)mm立铣头最大回转角度±45℃微调捏手每格的移动量0.001(0.00004)mm主轴端面到工作台间距离45~380mm最大砂轮直径400(16)mm床身垂直导轨到工作台中央T形槽中心距离215~470mm最大砂轮直径时的砂轮线速度(二档)35175m/s工作台进给量范围(X轴、Y轴、Z轴)6~3500mm/3500mm/1200mm主轴转度(线速度)80-300r/min主传动电动机功率7.5KW主轴锥孔的莫氏锥度(无极)NO.4Morse 主传动电动机转速1440r/min顶尖套筒最大移动量30(12)mm 纵向、横向进给电动机扭矩10N·m顶尖套锥孔的莫氏锥度NO.3Morse 垂向进给电动机扭矩15N·m主轴转速13300r/min 冷却泵电动机功率0.129KW外形尺寸2200*1405*1500(86*57*59)mm 冷却泵电动机转数2790r/min电机容量 4.4KW机床外形尺寸(长*宽*高)2272mm*1970mm*2094m机床重量2800Kg烘箱 WG-12-20机械压力机 J21S-400KV参数名称参数指标参数名称参数指标平衡调温调湿控制系统(BTHC)P·I·D方式控制SSR公称压力160KN 温度范围RT+10℃~+220℃滑块行程60mm升温时间(+40℃~+220℃)≤40min滑块行程次数120次/M 温度均匀度≤±5.0℃(空载)最大封闭高度190mm温度波动度≤±5.0℃(空载)滑块调节量40mm内箱材料进口SUS304镜面不锈钢工作台尺寸(前后*左右)180mm*455mm 外箱材料优质彩钢板工作台下料孔尺寸(直径)φ130mm 加热系统镍铬合金电热丝式加热器机身两立柱间距离160mm保温材料超细玻璃保温纤维模柄尺寸(直径*深度)φ35mm*60mm 送风循环系统低噪音多翼离心见机2只机身最大可倾角度30度加长轴心工作台至导轨距离250mm翼式扇叶(SIROCCOFAN)工作台垫板厚度45mm 箱门拉扣式拨手电机功率 1.5KW控制器韩国进口TEMP880控制仪外形尺寸(长*宽*高)1050mm*700mm*1750mm 安全保证装置短路及漏电保护一只周围环境10~35摄氏度,40~75%RH三点式母线折弯机 WYC-15电火花线切割机 DK7732参数名称参数指标参数名称参数指标折弯力30-300KN工作台面行程320mm*400mm300mm(可调)平弯最大尺寸160*12mm切割工件最大厚度立弯最大尺寸120*12mm切割工件最大锥6°(100mm内可达)度平口120*12mm最大切割效率>160m㎡/min(Cr12 80mm厚时)剪断最大尺寸尖口130*12mm最大切割电流6A 电机功率 5.5KW粗糙度加工40mm厚的Cr12粗糙度Ra≤1.2μm加工精度0.012mm 外形尺寸1100*460*1160mm加工直径Φ10mm 机器重量1200Kg机床消耗功率 1.5kw专利号ZL99231082.2电极丝直径Φ0.10~Φ0.18mm走丝速度4~11m/s(变频器控制)环氧浇注设备 LXZ空压机 WS3710参数名称参数指标参数名称参数指标规格φ1800*2500mm排气量M3/min 5.8加热功率40.5Kw额定排气压力bar10.0真空度-0.095Mpa.最大排气压力 bar10.5真空泵功率7.5Kw马达(HP)/(KW)50/37占地面积20㎡外形尺寸(mm)L*W*H1574*875*1562三、主要生产制造工艺流程1、壳体生产、装配(1)计算机结构化设计及图纸的下发:通过设计软件,以准确、快捷的方式直接从设计阶段转为生产阶段,并确保性能稳定性;(2)原材料的选用和控制:所需原材料必须经过专门测试设备检测;(3)钣金加工:对钣金件加工所产生的误差范围,切割边的光滑程度及边角料的利用提出了具体要求,先进的德国通块激光切割机保证加工精度;(4)壳体喷塑:将冷轧钢板表面喷涂塑粉,保护壳体、美观;(5)壳体装配:低压柜壳体板材制作完成后,需组装拼接;2、一次装配(1)元件安装:对元器件安装有具体要求,严格按照电气行业相关标准执行,保证一、二次回路主要元器件准确、可靠的安装;(2)铜排制作、安装:根据公司技术部门提供的电气一次系统图及一系列先进的铜排制作、加工设备,保证了合理的选用和制作铜排,并可靠的安装在相关元器件上,并需套四色(黄、绿、红、蓝)热缩套管;(3)一次导线制作和安装:根据元器件额定电流大小,选取适当截面积的电缆导线,下料、套色套、压线鼻子等工艺;3、二次接线(1)制作二次端子排:选用端子排首先为了使元件与元件之间线路可靠有效的连接在一起,其次使得接线美观,维护方便,在远距离线之间的联接时主要是牢靠,施工和维护方便;(2)放二次线、二次接线:根据元件安装位置,合理的选择、量取二次软导线,并套上号码管;然后根据技术部门提供的二次原理图纸,准确、美观的将二次导线接在相应的端子及元器件上。

MANUFACTURERS WORKS Date:11/03/04INSPECTION GUIDELINESSTORAGE TANKSPREFABRICATION INMANUFACTURERS WORKS0For Approval11/03/2004J. C. Brotton B. Tremain B. Tremain June 2004 Rev.Description Date Prepared Checked Approved DateMANUFACTURERS WORKS Date:11/03/04CONTENTS1PURPOSE2SCOPE3PROCEDURE4DOCUMENTS5INSPECTION PROCESS6SHIPPING7STORAGE TANK DATA DOSSIER8INSPECTION CHECK LISTMANUFACTURERS WORKS Date:11/03/041.0 PURPOSEThis instruction covers the inspection, test and verification activities required to validate thesupply, manufacture and test of storage tanks for general use in refineries and chemical plants.This instruction is primarily for mill and prefabrication stages at fabricators works2.0 SCOPEThis instruction covers all necessary stages in the production of the storage tank from theexamination of certification from procurement sources to the final inspection, preservation andpacking to despatch to site.Although the methodology in compiling this instruction is to systematically progress through theconstruction of a typical storage tank. Experienced, inspectors may interpret the intent of theinstruction to accommodate local or novel practices or to utilise the instruction for a one-offdesign of storage tank, the design having been approved by the client. Any such variationsshould be noted on the inspector's report.3.0 PROCEDURE3.1 GENERALThis instruction together with its associated check sheet may be used on any order or contract.It is intended to act as a guide to the inspector in the course of the inspection programme. Anypart of the document may be invoked and the sections to be used and the level of inspectionrequired will be specified on the check list.All tests and inspections will be carried out against the approved drawings, purchase orderspecifications, purchasers or company standards, and within the practices and rules of thecountry, state or province and any government decrees, laws, ordinance or regulation as mayapply.If any conflict or contradictions should be apparent in any of the above then the more onerousrequirement will apply unless the purchaser or client directs otherwise in writing.3.2 REFERENCE DOCUMENTSApplicable codes and specifications.•Design code (to be stated on inspection report)•Purchase order specification•Purchaser's standards•Approved drawings•SGS company standardsApplicable codes and standards (sample only)•BS 2654•BS 2594•BS 7777•API 620•API 650•API 653•EEMUA 159MANUFACTURERS WORKS Date:11/03/044.0 DOCUMENTS TO BE RECEIVED/AVAILABLE AT INSPECTIONPurchase Order or ContractInspection and Test Plan [ITP]Data sheetApproved drawings, [arrangements]Sub-assembly drawingsMaterial test certificatesWeld procedures and Procedure Qualification RecordsList of qualified welders or welding operatorsWelders' qualificationsInspection and test planCalibration of measuring and test equipmentNDE procedures, (appropriate to material of construction)List of qualified NDE operators/inspectorsNDE /inspectors' qualificationsHeat treatment procedurePreparation and painting procedurePreservation, packing and shipping procedureSupply list (packing list]5.0 INSPECTION PROCESS5.1 MATERIAL5.1.1 REVIEW OF CERTIFICATIONOriginal or authenticated copies of certificates should be available at the manufacturer'spremises. These should be examined for compliance with specifications and where appropriate,drawings:The review will include checks on:-•Manufacturer's name•Certificate No•Material Specification•Heat or cast No•Makers No or Plate No•Chemical composition•Mechanical properties•Heat treated condition•NDE applied and results•Surface finish•Structural observations, notable defects.5.1.2 VISUAL AND DIMENSIONAL VERIFICATION•Material identification on certificates against product markings.•Material supplied against drawing, material list and specification as appropriate.•Transfer identification to cut off components, (Cast No transfer), as specified.•Visual and dimensional compliance with specification.MANUFACTURERS WORKS Date:11/03/04 5.1.3 ADDITIONAL/SPECIAL REQUIREMENTSMay apply on special components, e.g. thick components.Check to ensure specification contract requirements have been met.Witness NDE examinations as necessary.5.1.4 REPORTINGReporting on the material checks should include•Conformation of satisfactory document review•Record of endorsement of certification "Reviewed"•Record of any non-conformities•Record of any tests witnessed and the result5.2 STORAGE TANK FABRICATIONAfter clearance of above points to satisfaction of the inspector, then the fabricator will proceedwith the manufacture of sub-assemblies and components of the storage tank.Inspectors will pay attention to the following points on a basis to be outlined in the purchaser's documentation, inspection and test plan, or other document, as notified to the inspector.5.2.1 PLATE PREPARATIONCarry out visual and dimensional check to ensure compliance with WPS and specification. Where specified, weld bevels shall be examined by MT or PT after grinding/machining. Edgesand weld bevels will be clean, dry and free from surface defects, laminations, cracks, voids, notches, etc. These shall be a cause for rejection unless suitable/satisfactory remedial actioncan be taken. Welding repairs to bevels are not permitted, without approval from the engineer/inspector. Inspectors must report excessive or serious defects.Plates subject to forming, rolling or dishing may require additional heat treatment, NDE to meetcode requirements.5.2.2 SHELL COURSES OR BASE PLATES, CONTAINING WELDED SEAMSThis stage inspection will be carried out when plates have been tacked using welding consumables and parameters from an approved WPS.Inspectors shall check and report on:-Cleanliness and fit up accuracy of weld preparation.Flatness of plates, methods of preventing distortion, e.g sequenced welding, strongbacks, backstep, etc.Application of preheat.Storage and handling of welding consumables.Interpass condition where welding is in progress.Cleaning of welds.Completion of test coupons, (where specified)NDE. Results shall meet specifications or code requirements.Hardness tests - when specified.Impact tests - when specified.MANUFACTURERS WORKS Date:11/03/045.2.3 REPAIR WELDSRepair welds may be permitted in accordance with the code requirements and must be carriedout only after investigation of the probable cause and in accordance with approved WPS documents. All weld repairs should be reported to the client.5.2.4 POST WELD HEAT TREATMENT OF HOT FORMED COMPONENTSCarry out dimensional check and review furnace record chart to ensure heat treatment was carried out as specified. Hardness measurement may be used to establish condition of material,heat affected zone or welds, as may be specified. Check dimensions, curvature, etc., after PWHT.INSPECTION5.3 ASSEMBLYStorage tanks may sometimes be assembled prior to despatch, this should be witnessed andthe results of any filling test recorded.The number and thickness of the plates should be checked if no trial assembly has been possible. Plates with access holes, manways and valve openings must be visually and dimensionally checked.5.3.1 MARKINGMatch marks, identification marks will be checked to the drawing requirement. Name plates if attached should be in accordance with the approved drawing.5.4 PAINTING INSPECTION5.4.1SURFACE PREPARATIONSurface preparation for painting will be checked for the following points, according to specification.•Cleaning method (Blast or scraping and wire brushing)•Preparation grades•Freedom from weld spatter, blow-holes and other defectsHumidity and steel temperature to be checked prior to paintingPaint Manufactures – type and colour to be checked against clients requirementsDry film thickness to be checked according to specificationSurface condition to be free from pin-holes, runs damage and other discontinuity.5.5 ADDITIONAL ITEMS5.5.1QUANTITY/QUALITY CHECKSpare parts, loose items, tools and accessories to be checked visually and for dimensions, materials, workmanship and quantity according to purchase order specification and supply list.Marking and/or Tag shall be checked for identification.MANUFACTURERS WORKS Date:11/03/045.6 REPORT AND RELEASE5.6.1REPORTINGA final report summarising the activities carried out will be issued in accordance with the contractrequirements and circulated within the laid down time limits. The report will be in the formrequired by the client and will clearly indicate the final acceptance or rejection of the goods.5.6.2RELEASE NOTESWhere required by the contract a Release Document will be issued to the manufacturer whenthe storage tank has been finally accepted.6.0 SHIPPING PREPARATION AND PACKING6.1PREPARATION AND PACKINGThe following points shall be checked to ensure they meet with contract requirements andaccepted standards of good practice.•Cleanliness and dryness of components•Rust prevention for all machined surfaces and welding bevels•Protection and covers for all openings and protruding parts•Spacing of plates•Security from warping/transit damage•Packing style and suitability for transportation including slinging points•Shipping marks and other markings7.0DOCUMENTATION PACKAGE7.1FABRICATION SHOP DOCUMENTSThe following final documents shall be reviewed and signed off to the contract requirement.These may apply to both shop and site operations.Component detail drawingsManufacturer's data reportsMaterial certificate or certified mill test reportsMaterial list or mapWelder record for each seamHeat treatment records (Temperature-time record chart during PWHT)Dimensional recordNDE recordsHardness test recordPacking listSpare parts and tool list.MANUFACTURERS WORKS Date:11/03/048.0INSPECTION CHECK LISTINSPECTION CHECK LIST(1)VISUAL INSPECTION/WITNESSING BY BUYER REPRESENTATIVE(2)CERTIFICATES/RECORDS TO BE CHECKED BY BUYER REPRESENTATIVE(3) CERTIFICATES/DATA TO BE PROVIDED BY VENDOR/SUPPLIER/MANUFACTURERPre-Fabrication/Production Requirements Specification Details/NotesPurchase Order RequirementsInspection & Test Plan (ITP)Approved Drawings (Arrangements)Sub-Assembly DrawingsWeld Procedures Specification (WPS) &Procedure Qualification Records (PQR)Welder Qualification RecordsNDT Personnel Records and ProceduresHeat Treatment ProceduresIn-Process Inspection & Testing RequirementsMaterial Test Certificates & IdentificationWeld and Edge PreparationFit Up Inspection (Shell Course Plates or BasePlates to be welded in works)Heat Treatment of Hot Formed ComponentsMonitoring Weld ConditionsWeld Back Gouging InspectionPost Weld InspectionNDE ExaminationWeld RepairsPost Weld Heat TreatmentVisual & Dimensional ExaminationTrial Assembly (if required)Final Inspection & Testing RequirementsVisual & Dimensional CheckMarkingPainting/Coating InspectionReview of Storage Tank Fabrication DataDossierAdditional/Supplementary RequirementsPreparation & Packing。