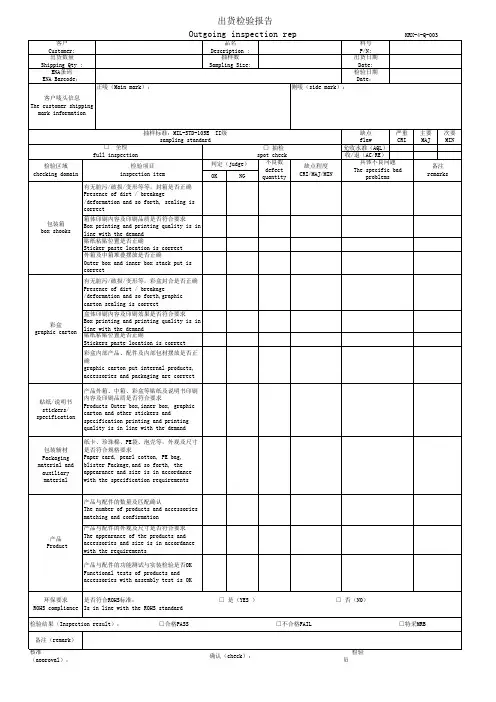

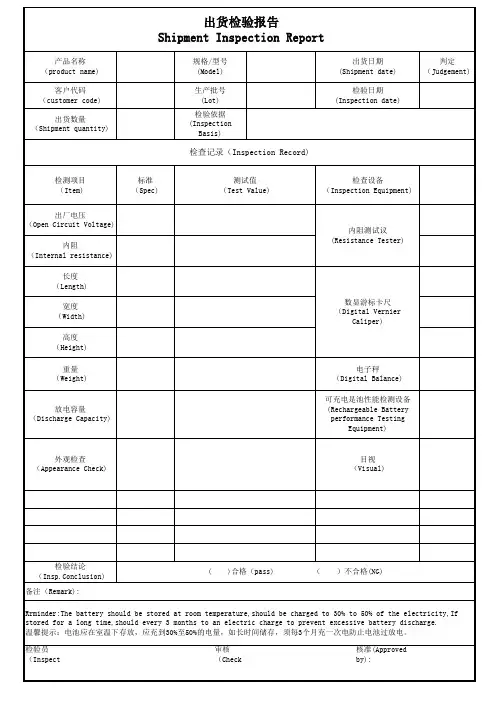

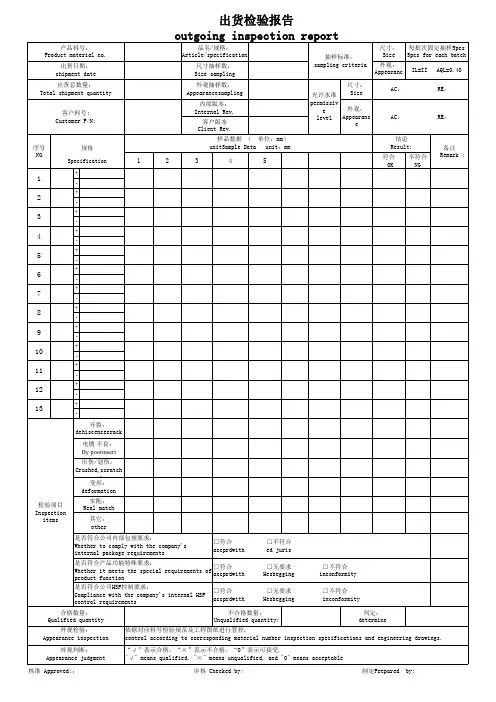

出货检验报告英文版模板

- 格式:xlsx

- 大小:17.90 KB

- 文档页数:2

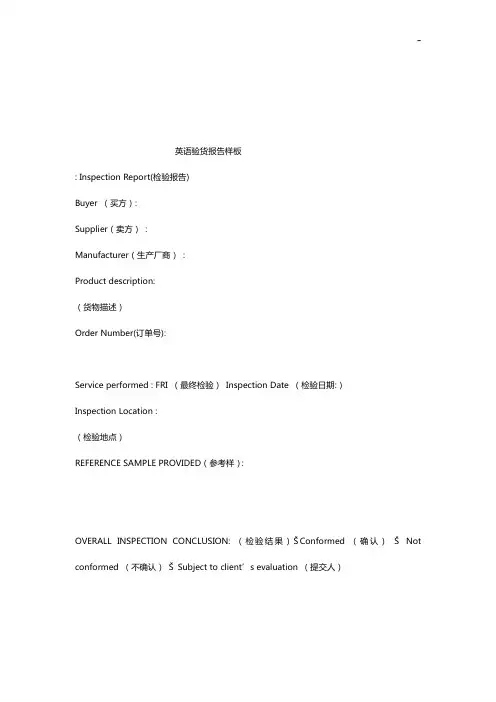

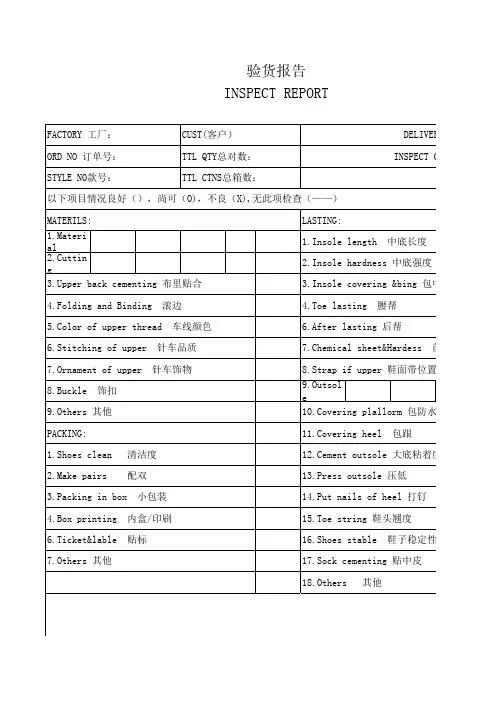

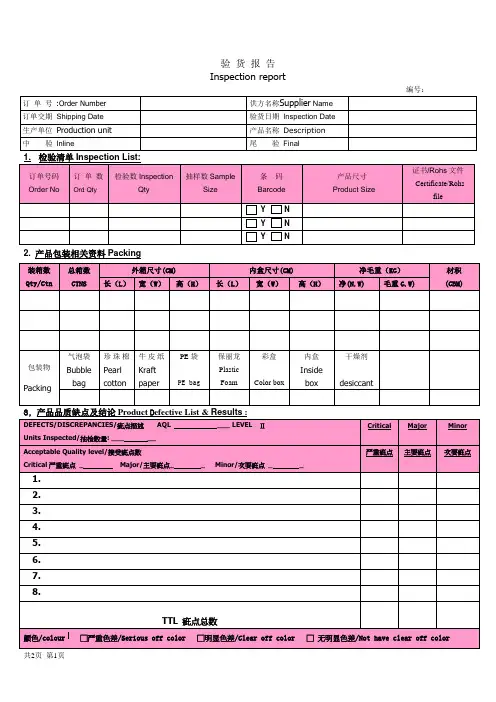

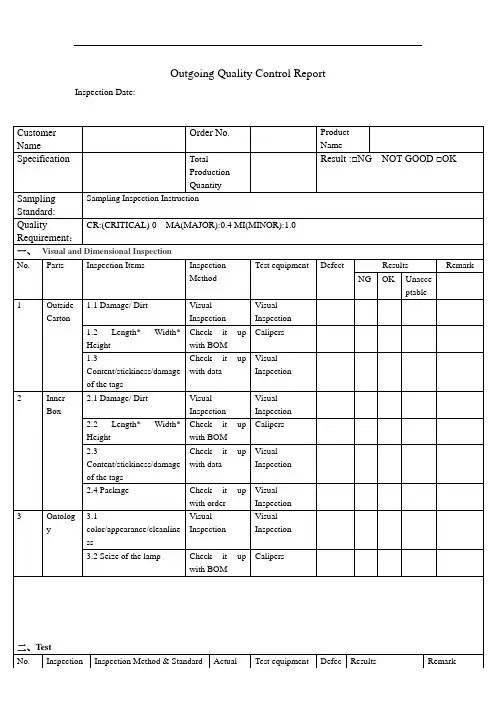

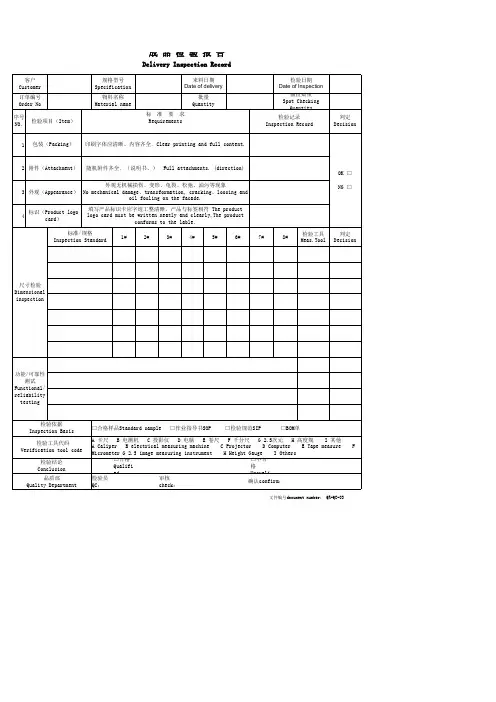

~英语验货报告样板: Inspection Report(检验报告)Buyer (买方):Supplier(卖方):Manufacturer(生产厂商):Product description:(货物描述)Order Number(订单号):Service performed : FRI (最终检验)Inspection Date (检验日期:)Inspection Location :(检验地点)REFERENCE SAMPLE PROVIDED(参考样):OVERALL INSPECTION CONCLUSION: (检验结果)ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)INSPECTION SUMMARY: (检查总结)1. Quantity(数量): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)2. , color (,颜色): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)3. Workmanship appearance / function (工艺,做工): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)4. Packing (包装): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)be l(标签): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)6. onlinetranslation / field tests (高宽/重量): ŠConformed (确认)ŠNot conformed (不确认)ŠSubject to client’s evaluation (提交人)INSPECTION METHOD APPLIED: (检验标准)Acceptable Quality Level (AQL) for (可接受的质量标准): Critical(严重毛病: Major(大毛病): Minor(小毛病):Sample size inspected(抽验数量):Samples selected from carton numbers (抽验箱号):Reservation:(备注)Manufacturer Signature(工厂签字):Inspector Signaturer (检验员签字):。

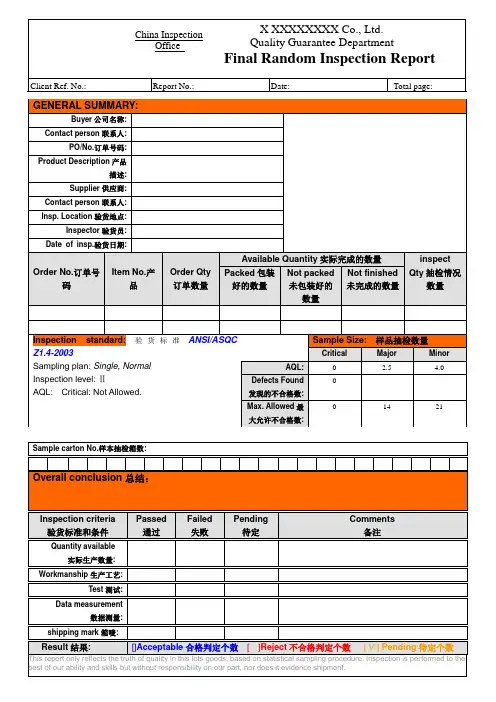

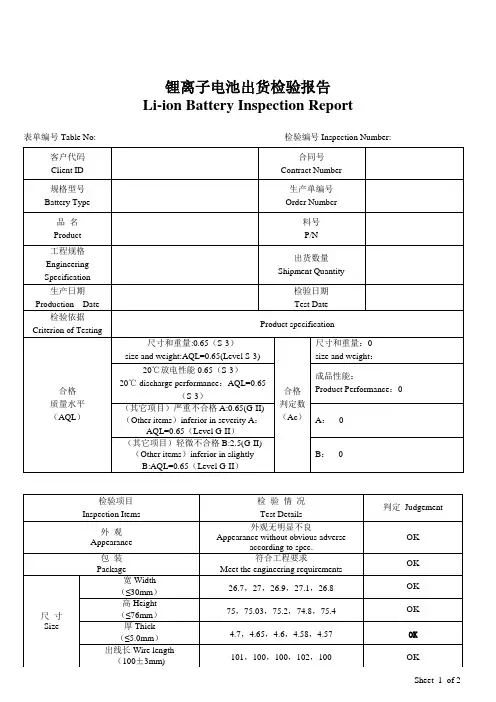

出厂质检报告模板英文IntroductionThis report presents the findings of the quality inspection conducted at the factory. The purpose of this inspection is to ensure that the products meet the required standards and specifications before they are shipped to the customers. The inspection was carried out on [date] by a team of experienced inspectors.Product Information- Product Name: [Name of the product]- Product Model: [Model number]- Batch Number: [Batch number]- Quantity Inspected: [Number of units]Inspection CriteriaThe inspection was conducted based on the following criteria:- International standards and regulations- Customer specifications and requirements- Industry best practicesInspection Process1. Initial assessment of product documentation2. Visual inspection of the products3. Measurement of product dimensions and specifications4. Testing of product functionalities and performance5. Assessment of packaging and labelingFindingsBased on the inspection conducted, the following findings were identified:1. Visual Inspection- The overall appearance of the products is in conformity with the specified requirements.- No visible scratches or damages were observed on the surface of the products.- The color consistency across the products is satisfactory.2. Measurement of Dimensions and Specifications- All the measured dimensions are within the specified tolerances.- The weight of the products matches the required specifications.- The materials used in the products are of the specified quality.3. Testing of Functionalities and Performance- The products function satisfactorily according to the specified requirements.- All the functions and features of the products were tested and found to be in working order.- The safety features incorporated in the products operate as intended.4. Assessment of Packaging and Labeling- The products were packed securely to prevent any damage duringtransportation.- The labeling on the packaging is clear, accurate, and in accordance with the customer requirements.- The packaging materials used are of good quality and provide adequate protection.ConclusionBased on the findings of the inspection, it is concluded that the products meet the required standards and specifications. The quality of the products is satisfactory and they are suitable for shipment to the customers.RecommendationsNo major issues were identified during the inspection. However, minor improvements in packaging design and labeling clarity are suggested to enhance the overall customer experience.AcknowledgmentWe would like to express our gratitude to the factory management and staff for their cooperation and support during the inspection. Appendix- Photographs of the inspected products- Test results and measurements data。