CP8000A系列 示波器电流探头说明书

- 格式:pdf

- 大小:1.02 MB

- 文档页数:16

CURRENT MEASUREMENT PROBESAmpFlex ®Flexible AC Current ProbeENGLISHUser ManualCopyright© Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments. All rights reserved.No part of this documentation may be reproduced in any form or by any means (including electronic storage and retrieval or translation into any other language) without prior agreement and written consent from Chauvin Arnoux®, Inc., as governed by United States and International copyright laws.Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments15 Faraday Drive • Dover, NH 03820 USATel: (800) 945-2362 or (603) 749-6434 • Fax: (603) 742-2346This documentation is provided “as is,” without warranty of any kind, express, implied, or otherwise. Chauvin Arnoux®, Inc. has made every reasonable effort to ensure that this documentation is accurate; but does not warrant the accuracy or completeness of the text, graphics, or other information contained in this documentation. Chauvin Arnoux®, Inc. shall not be liable for any damages, special, indirect, incidental, or inconsequential; including (but not limited to) physical, emotional or monetary damages due to lost revenues or lost profits that may result from the use of this documentation, whether or not theChauvin Arnoux ®, Inc.d.b.a AEMC ® Instruments Statement of ComplianceChauvin Arnoux ®, Inc. d.b.a. AEMC ® Instrumentscertifies that this instrument has been calibratedusing standards and instruments traceable tointernational standards.We guarantee that at the time of shipping yourinstrument has met the instrument’s publishedspecifications.An NIST traceable certificate may be requested at the time of purchase, or obtained by returning the instrument to our repair and calibration facility, for a nominal charge.The recommended calibration interval for thisinstrument is 12 months and begins on the date ofreceipt by the customer. For recalibration, pleaseuse our calibration services. Refer to our repair andcalibration section at .Serial #:Cata log #:Model #:Please fi ll in the appropriate date as indicated:Date Received: Date Calibration Due:TABLE OF CONTENTS1. INTRODUCTION (5)1.1 PRECAUTIONS FOR USE (6)1.2 RECEIVING YOUR SHIPMENT (6)1.3 PACKAGING (6)2. PRODUCT FEATURES (7)2.1 DESCRIPTION (7)2.2 AMPFLEX® (8)2.3 FEATURES (9)2.4 ACCESSORIES (9)2.5 STANDARD MODELS (10)3. OPERATION (11)3.1 MAKING MEASUREMENTS WITH THE AMPFLEX® (11)3.2 TIPS FOR MAKING PRECISE MEASUREMENTS (12)3.3 TYPICAL RESPONSE CURVES (15)4. SPECIFICATIONS (17)4.1 COMMON SPECIFICATION (18)4.1.1 Electrical (18)4.1.2 Environmental Specifications (18)4.1.3 Mechanical Specifications (19)4.1.4 Sensor Specifications (19)4.1.5 Material Specifications (20)4.1.6 Safety Specifications (20)4.2 INSTRUMENT COMPATIBILITY (20)5. MAINTENANCE (21)5.1 BATTERY REPLACEMENT (21)5.2 CLEANING (21)5.3 REPAIR AND CALIBRATION (22)5.4 TECHNICAL ASSISTANCE (22)5.5 LIMITED WARRANTY (23)5.5.1 Warranty Repairs (23)1. INTRODUCTIONThank you for purchasing an AEMC® Instruments AmpFlex® Flexible AC Current Probe.For the best results from your instrument and for your safety, you must read the enclosed operating instructions carefully and comply with the precautions for use. Only qualified and trained operators should use this product.Symbols and DefinitionsDefinition of Measurement Categories (CAT)CAT IV:Corresponds to measurements performed at the primary electrical supply (< 1000 V).Example: primary overcurrent protection devices, ripple control units,and meters.CAT III:Corresponds to measurements performed in the building installation at the distribution level.Example: hardwired equipment in fixed installation and circuitbreakers.CAT II:Corresponds to measurements performed on circuits directlyconnected to the electrical distribution system.Example: measurements on household appliances and portable tools.1.1 PRECAUTIONS FOR USEThese safety warnings are provided to ensure the safety of personnel and proper operation of the instrument.■Read the instruction manual completely and follow all the safety information before attempting to use or service this instrument.■Wear protective clothing and gloves as required.■Use caution on any circuit: potentially high voltages and currents may be present and may pose a shock hazard.■Read the safety specifications section prior to using the current probe. Never exceed the max voltage ratings given.■Safety is the responsibility of the operator. The AmpFlex® must be used only by qualified personnel using applicable safety precautions.■ALWAYS de-energize the circuit before wrapping the AmpFlex® around bare conductors, bus bars, or near live parts. Do not wrap on live conductors.■ALWAYS connect the electronic module to the display device before wrapping the AmpFlex® around the sample being tested.■ALWAYS inspect the module, sensor, sensor cable, and output terminals prior to use. Replace any defective parts immediately. Use only factory parts.■NEVER use the AmpFlex® on electrical conductors rated above600 V CAT IV; 1000 V CAT III.1.2 RECEIVING YOUR SHIPMENTUpon receiving your shipment, make sure that the contents are consistent with the packing list. Notify your distributor of any missing items. If the equipment appears to be damaged, file a claim immediately with the carrier and notify your distributor at once, giving a detailed description of any damage.1.3 PACKAGINGYour AmpFlex® shipment consists of the following items:■Flexible probe with electronic module.■User manual.■9 V battery.2. PRODUCT FEATURES2.1 DESCRIPTIONThe AmpFlex® is a flexible AC current transformer composed of a flexible sensor and an electronic module. The flexible sensor permits measurements on conductors where standard clamp-on probes could not be used. In particular, it can be installed in tight spaces, around breaker panels, around cable bundles, around wide or large bus bars, or even wrapped around irregular shapes. The Shape Memory feature enables the user to “pre-shape” the sensor before inserting it between or around conductors. This feature facilitates closing, enhances user safety, and alleviates the drooping effect typically associated with flexible sensors.The AmpFlex® is lightweight and does not use magnetic cores like standard transformers. The transformation principle is based on an air core. It presents virtually no load to the system under test, has a low phase shift, has excellent frequency response, and cannot be damaged by overloads.The sensor assembly is waterproof and insulated for 600 V CAT IV; 1000 V CAT III. The AmpFlex® meets EN 61010-1, is CE marked, and is designed with materials and components to meet international agency standards.The AmpFlex® has an mV output proportional to the current measured fordirect readings on DMMs, data loggers, oscilloscopes, and power or harmonic meters. TRMS measurements are taken when connected to a TRMS meter.The AmpFlex® is insensitive to DC currents and only the AC component of the measured signal is measured.The length of the flexible sensor can be selected in lengthsof 24 in, 36 in, and 48 in lengths. Consult the factory for custom lengths, ranges and/or features.2.2 AMPFLEX®Figure 11.Positive: Red Banana Plug (+).mon: Black Banana Plug (-).3.Power ON Indicator (Green LED).4.Overload Indicator (Red LED).5.Range Selection Switch.6.AmpFlex® Connector/Latch.7.Flexible Sensor (Diameter 0.5 in, 12.5 mm).8.Lead from Sensor to Module (6.5 ft, 2 m).9.Electronic Module - Descriptive Label on Back Case (range, model, etc.)2.3 FEATURES■Models to measure from 0.5 A rms to 30,000 A rms.■Accuracy: 1 % of reading.■TRMS measurements when connected to a TRMS instrument.■No core saturation or damage if overloaded.■Overrange LED for measurement circuitry.■600 V CAT IV; 1000V CAT III; EN 61010; CE Mark.■Waterproof sensor.■9 V battery for typical 150 h continuous operation.■Shape Memory for custom pre-shaping of sensor before use (no drooping).■Very high frequency response.■Low phase shift for power.■Insensitive to DC, measures only AC component on DC + AC signals.■Excellent linearity.■Lightweight.2.4 ACCESSORIESBanana (Female) / BNC (Male) Adapter ........................................Cat. # 2118.46 For connection of the AmpFlex® to SLII Models L101, L102, L562,BNC terminals on scopes and other displaying instruments.2.5 STANDARD MODELSAll AmpFlex® models are designed to be used with recorders or power analyzers with a voltage AC input. A scale factor may need to be entered into the recorder to display the exact value.Custom lengths and ranges are available.Contact us: ************************3. OPERATIONPlease ensure that you have already read and fully understand the Precautions for Use section on page 6.3.1 MAKING MEASUREMENTS WITH THE AMPFLEX®■Connect the electronic module to the AC Volt range of your Digital Multi-Meter (DMM)or measuring instrument. Select the appropriate module output voltage range. If the current magnitude is unknown, and if AmpFlex® has two ranges, select the lowest mV/A output setting.■Wrap the flexible core around the conductor to be tested. If possible within range, select the higher mV/A AmpFlex® output range to obtain the best resolution. Do not exceed specified current range for the output. Do not use on selected range if overload LED goes on.■Read the displayed value on the DMM and divide it by the range selected (i.e. if reading = 2.59 V with the 10 mV/A output range, the current flowing through the probe is 2590 mV ÷ 10 = 259 A).■For best accuracy, carefully center the conductor inside the flexible core, and avoid if possible, the proximity of other conductors which may create noise and interference (particularly near the latch).■True RMS measurements are obtained when the AmpFlex® is connected to a True RMS meter. Note that the DC component is not measured.3.2 TIPS FOR MAKING PRECISE MEASUREMENTS■When using the AmpFlex® with a meter, it is important to select the range that provides the best resolution. Failure to do this may result in measurement errors.■For best results, select the highest AmpFlex® output signal possible and the most sensitive meter range for this output.■Make sure the DMM or measuring instrument can accurately measuremV AC. Certain inexpensive DMM have poor resolution and accuracy when measuring low mV AC.■For best accuracy, center the AmpFlex® around the conductor to be measured (see figure 2).■To increase sensitivity or measure on low currents, the AmpFlex® may be wrapped several times around the conductor. Divide your reading by the number of turns for the actual measurement (see Figure 4).■The overall measurement accuracy is the sum of the AmpFlex® accuracy and the displaying instrument accuracy.For best accuracy, center the AmpFlex®Figure 2■The AmpFlex® may be doubled around the conductor to be measured to double the output (see Figures 3 and 4 to show the different values on a DMM while measuring 250 A ac).One turn around a conductor carrying 250 A ACFigure 3Double the turns to double the output in low-current applications or for higher sensitivity.Figure 43.3 TYPICAL RESPONSE CURVES1 Hz10 Hz100 Hz 1000 Hz 10 kHz 100 kHzTypical Accuracy % vs. Frequency @ 100 A, 1 mV/A OutputFrequency1 Hz10 Hz100 Hz1000 Hz10 kHz 100 kHzTypical Accuracy % vs. Frequency @ 100 A, 10 mV/AFrequency%± 10± 9± 8± 7± 6± 5± 4± 3± 2± 1± 0Typical Accuracy % per Range to 100 AAmps3000 A 2500 A 2000 A1500 A 1000 A 500 A 0 A1000 Hz10 kHz100 kHzCurrent Derating Curve (I < 3000 A)FrequencyA m p s100 Hz1000 Hz10 kHz 100 kHzCurrent Derating Curve (I > 3000 A)FrequencyA m p s1 Hz10 Hz100 Hz1000 Hz10 kHz100 kHzTypical Phase Shift vs. Frequency @ 200 A, 1 mV/A OutputFrequencyD e g r e e s4. SPECIFICATIONS*Reference Conditions: 25 °C ± 5 °K, (20 to 75) % RH, 1 minute warm-up, battery at 9 V ± 0.5 V, conductor center, external DC magnetic field < 40 A/m, no external AC magnetic field, no external electrical field, (10 to 100) Hz, sine wave. See accuracy curves for low currents.4.1 COMMON SPECIFICATION4.1.1 ElectricalAccuracy: 1 % of reading ± residual noise.Frequency Range: (10 to 20,000) Hz with current derating.Signal Output: 4.5 V max.Working Voltage: 600 V CAT IV; 1000 V CAT III.Frequency Influence:See Accuracy vs. Frequency curves on pages 15 and 16.Frequency Limitation:See current derating curves (NOTE: no limitation on 300 A Range) page 16. Influence of adjacent conductor in contact with sensor and with AC signal: 0.2 % typical, 2 % maximum.Influence of conductor position in sensor: 0.5 % typical, 4 % max. Influence of shape of sensor: Oblong shape: 0.2 % typical, 1 % max. Common Mode Rejection: 100 dB typical, 80 dB min.4.1.2 Environmental SpecificationsOperating Temperature Range: (-14 to 131) °F (-10 to +55) °C.Storage Temperature Range: (-40 to 158) °F (-40 to +70) °C.Influence of Temperature:Sensor: (14 to 194) °F (-10 to 90) °C; 0.15 % per 18 °F (10 °C)typical, 0.5 % per 18 °F 10 °C max.Module: (14 to 131) °F (-10 to 55) °C; 0.15 % per 18 °F (10 °C)typical, 0.5 % per 18 °F (10 °C) max.Influence of Relative Humidity:(10 to 90) % RH: 0.2 % typical, 0.5 % maximum.Operating Relative Humidity:(50 to 86) °F (10 to 30) °C; 85 ° ± 5 % RH (without condensation).(104 to 122) °F (40 to 50) °C; 45 ° ± 5 % RH (without condensation). Altitude:Operating: (0 to 2000) m, working voltage derating above.Non-operating: (0 to 12,000) m.4.1.3 Mechanical SpecificationsModule Output:Two 4 mm safety banana jacks.Standard 3/4 in (19 mm) spacing.Battery: 9 V Alkaline (NEDA 1604A, IEC 6LR61) recommended.Battery Life: Useable from (9 to 7) V, 150 h typical (continuous use).Low Battery:Power ON indicator (green LED) when battery voltage 7 V, LED blinks when battery voltage is low.Overload Indication:Red LED ON indicates the selected range is overloaded. Module output may not reflect the actual measurement.Dimensions (sensor):24 in, 36 in, and 48 in nominal (± 1 in), other lengths optional.Dimensions (Electronic Module): (4.9 x 2.5 x 1.1) in (124 x 64 x 28) mm. Weight:AmpFlex® 24 in with battery: 0.74 lb.AmpFlex® 36 in with battery: 0.89 lb.AmpFlex® 48 in with battery: 0.95 lb.Connection Cable Length (sensor to module): 6.5 ft (2 m).Colors:Red sensor with dark gray connector and module, black connection cable (sensor to module).Drop Test: Per IEC 68-2-32.Vibration: Per IEC 68-2-6.Mechanical Shock: Per IEC 68-2-27.Weatherproofing: Module: IP40 (EN 60529).4.1.4 Sensor SpecificationsWeight: 10.8 oz (302.4 g).Bend Radius: 0.75 in (19 mm) minimum.Bending Life: > 10,000 without performance deterioration. Waterproofing: IP 65.Resistance to Chemicals: Resistant to oils and aliphatic hydrocarbons.Diameter: 12 mm ± 0.5 mm.Outer Sheath Material: Polyurethane, UL94V0.Dielectric Strength: 7500 V.Latch Spring Life: > 10,000 maneuvers.4.1.5 Material SpecificationsModule: UL 94V2, Color dark gray, Polycarbonate.Sensor Latch: Material: Lexan 500R, UL94V0.Cable Assembly to Sensor: UL94V0, 1000V rating.4.1.6 Saf ety SpecificationsElectrical:Double insulation or reinforced insulation between primary or secondary and outer case per EN 61010.■600 V CAT IV; 1000 V CAT III.Pollution Degree 2.■7.50 kV, 50/60 Hz, dielectric between secondary and the outer case. Electromagnetic Compatibility:■Immunity: meets BF EN 61326-1 – Industrial environment category.Electrostatic discharge (meets EN 61000-4-2).-8 kV in air – level 3 – class B.- 4 kV on contact – level 2 – class B.10 V/m radiated electromagnetic field (in line with EN 61000-4-3) – class B.Rapid transients (in line with EN 61000-4-4).- 1 kV – level 2 – class B.Electric shocks (in line with EN 61000-4-5).- 6 kV – class B.4.2 INSTRUMENT COMPATIBILITYThe AmpFlex® is compatible with any multimeter, AC voltmeter, or other voltage measuring instrument with an input impedance greater than 1 MΩ. To achieve the best overall accuracy, use the AmpFlex® with an AC voltmeter with an accuracy of 0.75 % or better.5. MAINTENANCEWarning■For maintenance use only specified replacement parts.■To avoid electrical shock, do not attempt to perform any repair or servie on the instrument unless you are qualified to do so.■Do not perform any service while the AmpFlex® is on any circuit.■To avoid electrical shock and/or damage to the instrument, do not get water or other foreign agents into the electronic module.■Also see warning on page 2.5.1 BATTERY REPLACEMENT■If the power ON indicator (green LED) blinks or does not light up, replace the battery.■Remove the AmpFlex® from any circuit before replacing the battery.■To replace the battery, open rear case, replace battery, and reassemble. The green LED should go on when the module is turned on.5.2 CLEANING■It is important to keep the probe sensor latch mating surfaces clean and prevent foreign bodies from hampering the closing. The sensor may be gently cleaned with a soft cloth, soap and water. Dry immediately after cleaning. Avoid water penetration into the electronic module.■Make sure the sensor, electronic module, and all leads are dry before any further use.5.3 REPAIR AND CALIBRATIONTo ensure that your instrument meets factory specifications, we recommend that the instrument be sent back to our factory Service Center at one-year intervals for recalibration or as required by other standards or internal procedures.For instrument repair and calibration:You must contact our Service Center for a Customer Service Authorization Number (CSA#). Send an email to *************** requesting a CSA#,you will be provided a CSA Form and other required paperwork along with the next steps to complete the request. Then return the instrument along with the signed CSA Form. This will ensure that when your instrument arrives, it will be tracked and processed promptly. Please write the CSA# on the outside of the shipping container. If the instrument is returned for calibration, we need to know if you want a standard calibration or a calibration traceable to N.I.S.T. (includes calibration certificate plus recorded calibration data).Ship To: Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments15 Faraday Drive ▪ Dover, NH 03820 USAPhone: (800) 945-2362 (Ext. 360) / (603) 749-6434 (Ext. 360)Fax: (603) 742-2346***************E-mail:(Or contact your authorized distributor.)Contact us for the costs for repair, standard calibration, and calibration traceable to N.I.S.T.NOTE: You must obtain a CSA# before returning any instrument.5.4 TECHNICAL ASSISTANCEIf you are experiencing any technical problems or require any assistance with the proper operation or application of your instrument, please call, e-mail or fax our technical support team:Chauvin Arnoux®, Inc. d.b.a. AEMC® InstrumentsPhone: (800) 343-1391 (Ext. 351)Fax: (603) 742-2346E-mail: ********************5.5 LIMITED WARRANTYThe instrument is warrantied to the owner for a period of two years from the date of original purchase against defects in manufacture. This limited warranty is given by AEMC® Instruments, not by the distributor from whom it was purchased. This warranty is void if the unit has been tampered with, abused, or if the defect is related to service not performed by AEMC® Instruments.Full warranty coverage and product registration is available on our website at /warranty.html.Please print the online Warranty Coverage Information for your records.What AEMC® Instruments will do:If a malfunction occurs within the warranty period, you may return the instrument to us for repair, provided we have your warranty registration information on file or a proof of purchase. AEMC® Instruments will repair or replace the faulty material at our discretion.REGISTER ONLINE AT: /warranty.html5.5.1 Warranty RepairsWhat you must do to return an Instrument for Warranty Repair: First, send an email to *************** requesting a Customer Service Authorization Number (CSA#) from our Service Department. You will be provided a CSA Form and other required paperwork along with the next steps to complete the request. Then return the instrument along with the signed CSA Form. Please write the CSA# on the outside of the shipping container. Return the instrument, postage or shipment pre-paid to:Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments15 Faraday Drive, Dover, NH 03820 USAPhone: (800) 945-2362 (Ext. 360)(603) 749-6434 (Ext. 360)Fax: (603) 742-2346***************E-mail:Caution: To protect yourself against in-transit loss, we recommend that you insure your returned material.NOTE: You must obtain a CSA# before returning any instrument.AEMC ® Instruments15 Faraday Drive • Dover, NH 03820 USAPhone: +1 (603) 749-6434 • +1 (800) 343-1391 • Fax: +1 (603) 742-234609/2399-MAN 100122 v27。

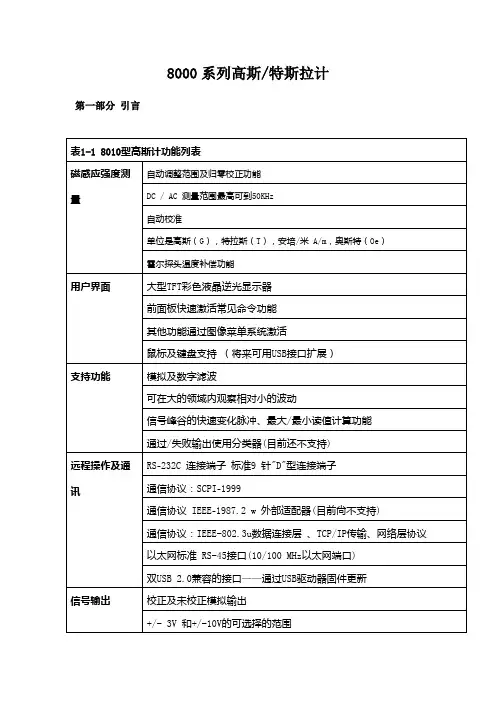

8000系列高斯/特斯拉计第一部分引言说明8000系列高斯计/特斯拉计利用霍尔探头测量磁感应强度,测量单位是G、T、A/m、Oe。

可以一个平衡状态及交互领域使用其测量磁感应强度;测量值可低于10μGauss (0.001 μT)或超过30万高斯( 30特斯拉),在高达50 kHz的频率测量下,具有极高的精度和分辨率。

通过高斯计内的数据对每个通道进行标准化及线性化。

当探头的温度发生变化时,通过温度补偿霍尔探头,设备可以校正其中的错误。

用户界面显示面板高分辨率达到600×480(像素),清晰的TFT 彩色LCD 显示屏。

操作者可以自己调节显示器和仪器的字体大小,这样使操作者更容易观察屏幕信息;可以使用前面板快速启动,每条通道都拥有自己独立的设置键。

此外每个按键上都有背景光,当工作时显示其处于工作状态。

其他一些常用功能通过菜单系统操作使用;说明注意:每个通道独立运行并且具有以下特征;自动设置范围基于目前被测量的磁感应强度可手动选择四个测量范围或仪器自动选择最佳范围。

校零归零功能使用户消除探测器附近的(包括地球带来的)或者电器设备产生的不利磁场。

“零通量室”是仪器其中的一个配件,可以保护探头使在操作过程中不受外部磁场影响。

保持功能保持功能使得设备可以“保持”,使得显示器显示测量到的最高及最低磁感应强度;保持功能包括捕获脉冲快速变化时的波峰和波谷,计算信号缓慢变化时的最大和最小的值。

相对性另一个功能,称为“相对模式”,允许大幅度的读数受到抑制,这样小的变化在更大的领域可以直接观测到。

更新间隔读数更新间隔可以自己调整。

调整到短的更新间隔时,此感应强度的快速波动可以观察到;长的更新间隔在测量磁感应强度时提供更高的分辨率及稳定性;模拟输出每个通道可以从标准BNC连接器提供了一个修正和未修正的模拟输出信号。

修正后的输出信号经过霍尔探头和仪器补偿温度及消除频率变化的影响,以及非线性计算后的输出的信号。

未修正的信号输出及修正后的信号输出都提供一段波形或者记录输出数据,并伴有3v和10v的满刻度的输出范围;修正输出刻度到9.9v,有效增量为0.1v(可调节刻度当前不支持)。

用户使用手册CA8000A系列双踪示波器中文使用说明书(本说明书适用下列机型)CA8020A 20MHz基本功能CA8040A 40MHz基本功能目录一、简介1、概述2、特性二、技术指标(见表)三、操作前注意事项1、开封2、检查电源电压3、环境4、示波管磁光质涂层5、输入端的最大电压四、操作方式l、前面板介绍1.1示波管1.2垂直轴1.3触发1.4时基1.5其它2、后面板介绍3、基本操作3.1输入耦合的选择3.2信号连接3.3单通道操作3.4双通道操作3.5加减操作3.6触发模式的选择3.7扫描速度控制3.8扫描扩展3.9 x-Y操作3.10 z轴调制的应用五、测量1、测量前的检查和调整2、幅值的测量3、时间的测量4、电视场信号的测量一、简介1.概述CA8000系列示波器是便携式双通道示波器,本机垂直系统具有5mV/DIV一5V/DIV的偏转灵敏度,水平统具有0.5S/DIV--O.2uS/DIV,并设有扩展×10,可将扫速提高到20nS/DIV。

2.特性2.1均采用国产示波管,根据客户要求,可以使用荷兰示波管(这种示波管快,亮度高。

加速极电压为2千伏,即使在高速扫描的情况下也能显示清晰的轨迹。

)2.2峰一峰值自动触发功能将触发方式选择在峰一峰值自动时,当输入信号幅度,频率变化时无需再调整触发电平即可获得稳定波形。

2.3交替触发功能可以分别用两个通道观察两个不同的信号波形2.4电视场信号同步功能2.5外测频信号输出在后面板上输出的与输入信号频率相同的脉冲信号可以直接驱动频率计。

2.6 Z轴输入’亮度调制功能可以给示波器加入频率或时间标识,正信号轨迹消隐,TTL匹配。

(本功能在用户提出时提供)2.7 X-Y操作:当设定在X-Y位置时,该仪器可作为X-Y示波器,Y1为水平轴,Y2为垂直轴。

2.8释放控制功能可以方便地观察多重复周期的复杂波形。

2.9扩展与被扩展的波形可以同时显示在屏幕上。

二、技术指标:(表一)续表一电源要求:电压:固定AC220V土10%功耗:约40VA工作环境:室内使用海拔2000m环境温度:10℃~35℃最大工作范围:0℃~40℃湿度:85%RH,干燥机械尺寸:310×130×418mm重量:约6.5kg存贮温度:.-10℃~70℃三、操作前注意事项:l、开封示波器出厂前都做过严格的检验和测试,收到仪器后请立即检查是否在运输途中有损坏,一旦发现请立即与供应商或发货人联系。

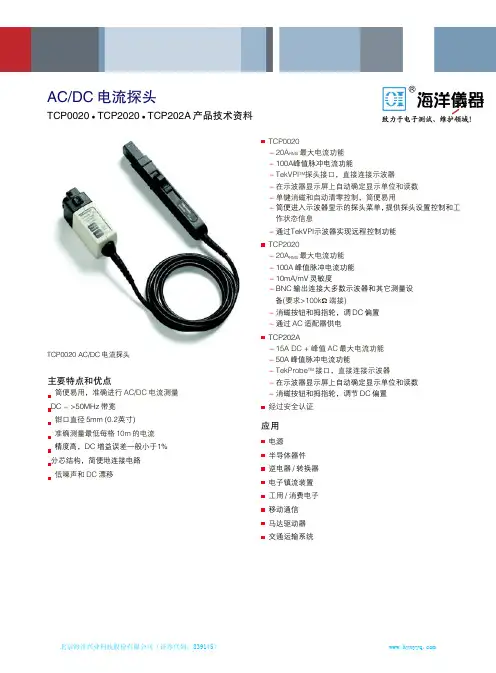

AC/DC 电流探头-TCP0020TCP2020 TCP202AAC/DC 电流探头TCP0020 TCP2020 TCP202A 产品技术资料TCP0020-20A RMS 最大电流功能-100A峰值脉冲电流功能-TekVPI TM 探头接口,直接连接示波器-在示波器显示屏上自动确定显示单位和读数-单键消磁和自动清零控制,简便易用-简便进入示波器显示的探头菜单,提供探头设置控制和工作状态信息-通过TekVPI示波器实现远程控制功能TCP2020-20A RMS 最大电流功能-100A 峰值脉冲电流功能-10mA/mV 灵敏度-BNC 输出连接大多数示波器和其它测量设备(要求>100k Ω 端接)-消磁按钮和拇指轮,调 DC 偏置-通过 AC 适配器供电 TCP202A-15A DC + 峰值 AC 最大电流功能-50A 峰值脉冲电流功能-TekProbe TM 接口,直接连接示波器-在示波器显示屏上自动确定显示单位和读数-消磁按钮和拇指轮,调节 DC 偏置 经过安全认证应用电源 半导体器件 逆电器/转换器 电子镇流装置 工用/消费电子 移动通信 马达驱动器 交通运输系统主要特点和优点简便易用,准确进行 AC/DC 电流测量 DC - >50MHz 带宽钳口直径 5mm (0.2英寸)准确测量最低每格 10m 的电流 精度高,DC 增益误差一般小于1%分芯结构,简便地连接电路 低噪声和 DC 漂移TCP0020 AC/DC 电流探头产品技术资料TCP0020、TCP2020、TCP202ATCP0020、TCP2020和TCP202A是简便易用的高性能AC/DC 电流探头家族,设计用于各种示波器。

TCP0020设计采用TekVPI TM探头接口直接连接示波器,TCP202A设计采用TekProbe TM探头接口直接连接示波器。

TCP2020设计用于带有BNC输入及>100 kΩ输入端接的任何仪器。

高频电流探头CP8000系列CP8000系列电流探头是一款能够同时测量直流和交流的高频电流探头。

型号多样,包括CP8030B、CP8030H、CP8050A、CP8150A、CP8300A、CP8500A。

CP8030B 30A/DC~ 50 MHzCP8030H 30A/DC~100 MHzCP8050A 50A/DC~ 50 MHzCP8150A 150A/DC~12 MHzCP8300A 300A/DC~ 6 MHzCP8500A 500A/DC~ 5 MHz一、产品特点1、高带宽,可准确快速捕捉电流波形;2、高精度,在电流测量量程范围内,精度高达1%,满足大部分测试领域的需要;3、两个量程可供选择,方便小电流测量;4、自动消磁调零功能,使用方便;声光过流报警功能,提醒量程切换;5、电子轻触式按键设计,使用寿命更长;6、标准的BNC输出接口,可匹配任何厂家示波器。

二、产品概述CP8030B/H体积轻巧,可在当前拥挤的电路板中使用自如;小型钳夹可以在紧张的空间中探测电流,同时仍能夹住直径达5mm的导线;可以测量30A的连续电流和50A的峰值电流,CP8030B提供50MHz的带宽,CP8030H提供100MHz带宽;探头具有30A (10X)和5A (1X)两个量程可选择,5A (1X)量程特别适用于小电流测量,分辨率高达1mA。

CP8050A 钳口可夹住直径达5mm的导线;可以测量50A的连续电流和75A的峰值电流,提供50MHz带宽;探头具有50A (10X)和7.5A (1X)两个量程可选择,7.5A (1X)量程特别适用于小电流测量,分辨率高达1mA。

CP8150A钳口可夹住直径达20mm的导线,适用于大电流应用场合;可以测量150A的连续电流和300A的峰值电流,提供了12MHz的带宽;探头具有150A (100X)和30A (10X)两个量程可选择,10X量程用于小电流测量,分辨率高达10mA。

AC柔性电流探头CP9000(S / L)系列深圳市知用电子有限公司首先,感谢您购买该产品,这份产品使用说明书,是关于该产品的功能、使用方法、操作注意事项等方面的介绍。

使用前,请仔细阅读说明书,正确使用。

阅读完后请好好保存。

说明书中,注释将用以下的符号进行区分。

为安全使用本机器,必须严格遵守以下安全注意事项。

如果不按照该说明书使用的话,有可能会损害机器的保护功能。

此外,违反注意事项进行操作产生的人身安全问题,本公司概不负责。

● 探头BNC 输出线连接示波器或者其它设备时,确保BNC 端子可靠接地。

● 被测电路接入探头环之前,确保先关闭被测电路。

● 使用之前,请检查探头环外皮是否有破损,若出现破损情况,请停止使用!● 接入被测电路前,应避免被测电路有尖刺,锋利的边角容易造成探头环损坏情况发生。

● 探头环上已明确标有使用电压要求,请确保在安全电压范围内使用! ●选择本产品标配的适配器供电。

该符号表示对人体和机器有危害,必须参照说明书操作。

在错误操作的情况下,用户有受伤的威胁,为避免此类危险,记载了相关的注意事项。

错误操作时,用户有受轻伤和物质损害的可能,为避免此类情况,记载的注意事项。

该符号表示对人体和机器有危害,必须参照说明书操作。

错误操作时,用户有受轻伤和物质损害事项。

记载着使用该机器时的重要说明。

前言 (1)概述 (3)应用 (3)电气规格 (4)产品及附件说明 (5)主体说明 (5)附件说明 (7)机械规格 (7)环境特性 (7)操作方法 (8)测量时注意事项 (8)保养及维护 (9)保修 (9)装箱单 (9)1. 概述CP9000(S/L)系列柔性电流探头是仅测试AC电流信号的探头,具有高带宽,高精度(典型值2%)等特点。

可以实现宽广的电流测量范围,频率可从几Hz到数十MHz,电流范围从mA级别到数kA 级别,大大解决了电流测试的难题。

其主要特点包括:线圈轻巧柔软且可以自由插拔,可以探测到许多硬制探头无法达到的地方,轻而易举的实现与被测对象连接;插入损耗几乎为零,仅为几个皮亨,对被测对象近乎为零的干扰;标准的BNC输出接口,很方便实现与示波器,数据采集器,数字电压表等连接,观测电流波形;USB供电接口设计,使用更加灵活方便;声光过流报警功能,更具人性化设计;探头环和连接线长度可以根据客户要求定制,满足特殊场合测试要求。

AC Current ProbeModel JM800AUser ManualDESCRIPTIONThe JM800A (Catalog #2110.79) is designed for use in industrial environments. The “squared” jawspermit multiple conductor or bus bar positioning. The current output makes it the perfect tool for measurement with DMMs, recorders, power and harmonic meters. The Model JM800A offers a 5 ft. lead with safety 4mm banana plug.WARNINGThese safety warnings are provided to ensure the safety of personnel and proper operation of the instrument.• Read the instruction manual completely and follow all the safety information before attempting to use or service this instrument.• Use caution on any circuit: Potentially high voltages and currents may be present and may pose a shock hazard.• Read the Safety Specifications section prior to using the current probe. Never exceed the maximum voltage ratings given.• Safety is the responsibility of the operator.• ALWAYS connect the current probe to the display device before clamping the probe onto the sample being tested.• ALWAYS inspect the instrument, probe, probe cable, and output terminals prior to use.Replace any defective parts immediately.• NEVER use the current probe on electrical conductors rated above 600 V. Use extreme caution when clamping around bare conductors or bus bars.INTERNATIONAL ELECTRICAL SYMBOLSThis symbol signifies that the current probe is protected by double or reinforced insulation. Useonly factory specified replacement parts when servicing the instrument.This symbol signifies CAUTION! and requests that the user refer to the user manual beforeusing the instrument.This is a type A current sensor. This symbol signifies that application around and removal fromHAZARDOUS LIVE conductors is permitted.RECEIVING YOUR SHIPMENTUpon receiving your shipment, make sure that the contents are consistent with the packing list. Notify your distributor of any missing items. If the equipment appears to be damaged, file a claim immediately with the carrier and notify your distributor at once, giving a detailed description of any damage. PACKAGINGThe AC Current Probe JM800A is shipped with this instruction manual and a product warranty and registration card. You can now register online at INSTRUMENT COMPATIBILITYThe Model JM800A is compatible with any AC Ammeter, multimeter, or other current measuring instrument with an input impedance lower than 5Ω. To achieve the stated accuracy, use the JM800A with the DMM having an accuracy of 0.75%.ELECTRICAL SPECIFICATIONS Current Range:1 to 1000 A AC, continuous cycle forthe full temperature range Transformation Ratio:1000:1Output Signal:1 mA AC/A AC (1 A at 1000 A) Accuracy and Phase Shift*:Primary current 50A 200A 1000A Accuracy % 2% 1.5% 1% Phase shift 2° 1.5° 1°*(Reference conditions: 23°C±3°K, 20 to 85% RH, 48 to 65 Hz, external magnetic field < 40 A/m, no DC component, no external current carrying conductor, test sample centered.) Load impedance 0.5Ω.Overload: 1200 A permanent;1500 A for 5 mnAccuracy: Per IEC 185-26-27Class 1 from 48 to 1000 HzFrequency Range:30 Hz to 5 kHzLoad Impedance: ≤ 5ΩWorking Voltage: 600 V ACCommon Mode Voltage: 600 V AC Influence of Adjacent Conductor:0.005 A / A ACInfluence of Conductor in Jaw Opening: 1% ± 0.1 A of readingMECHANICAL SPECIFICATIONS Operating Temperature:14° to 122°F (-10° to 50°C)Storage Temperature:-13° to 176°F (-25° to 80°C)Influence of Temperature:< 0.1% per 10°KJaw Opening: 3.54" (90 mm)Maximum Conductor Size:Cable: 2.52" ∅ max. (64 mm)Bus bar: 1.97 x 5.31" (50 x 135 mm)2.52 x3.94" (64 x 100 mm) Envelope Protection:IP 20 (IEC 529)Drop Test:500 mm (IEC 68-2-32)Mechanical Shock:100 g (IEC 68-2-27)Vibration:10/55/10 Hz, 0.15 mm (IEC 68-2-6) Polycarbonate Material:Handles:10% fiberglass chargedpolycarbonate UL 94 V0Jaws: ABS UL 94 V2 Dimensions:4.72 x 12.40 x 1.89" (120 x 315 x 48 mm) Weight:2.65 lbs. (1200 g)Colors:Dark gray handles with red jawsOutput:5 ft. (1.5 m) lead with safety 4 mm banana plug SAFETY SPECIFICATIONS Electrical:- IEC 348- 4 kV 50/60 Hz dielectric for 1 mn- 600 V max. common mode between outputand groundORDERING INFORMATIONCurrent Probe JM800A................Cat #2110.79 Accessories:Banana plug adapter(to nonrecessed plug)....................Cat #1017.45OPERATIONPlease make sure that you have already read and fully understand the WARNING section on page 1. Making Measurements with the AC Current Probe Model JM800A• Connect the black and red terminals to the Ampere AC range of your DMM or current measuring instrument. Select the appropriate current range (2 A AC). Clamp the probe around the conductor to be tested. If the reading is less than 200 mA, select the lower range until you obtain the best resolution. Read the value display on the DMM and multiply it by the probe ratio (1000/1). (If reading = 0.592 A AC, the current flowing through the probe is 0.592 A x 1000 = 592 A AC). • For best accuracy: carefully center the conductor inside the probe jaw, avoid if possible, the proximity of other conductors which may create noise. Tips for Making Precise Measurements• When using a current probe with a meter, it is important to select the range that provides the best resolution. Failure to do this may result in measurement errors. • Make sure that probe jaw mating surfaces are free of dust and contamination. Contaminants cause air gaps between the jaws, increasing the phase shift between primary and secondary. It is very critical for power measurement. MAINTENANCEWarning:• For maintenance use only original factory replacement parts.• To avoid electrical shock, do not attempt to perform any servicing unless you are qualified to do so. • To avoid electrical shock and/or damage to the instrument, do not get water or other foreign agents into the probe. Cleaning:To ensure optimum performance, it is important to keep the probe jaw mating surfaces clean at all times. Failure to do so may result in error in readings. To clean the probe jaws, use very fine sand paper (fine 600) to avoid scratching the jaw, then gently clean with a soft oiled cloth.REPAIR AND CALIBRATIONYou must contact our Service Center for a Customer Service Authorization number (CSA#). This will ensure that when your instrument arrives, it will be tracked and processed promptly. Please write the CSA# on the outside of the shipping container. If the instrument is returned for calibration, we need to know if you want a standard calibration, or a calibration traceable to N.I.S.T. (includes calibration certificate plus recorded calibration data).Chauvin Arnoux ®, Inc. d.b.a. AEMC ® Instruments15 Faraday Drive • Dover, NH 03820 USATel: (800) 945-2362 (Ext. 360)(603) 749-6434 (Ext. 360) Fax: (603) 742-2346 or (603) 749-6309 ***************(Or contact your authorized distributor)Costs for repair, standard calibration, and calibration traceable to N.I.S.T. are available. NOTE: All customers must obtain a CSA# before returning any instrument.TECHNICAL AND SALES ASSISTANCEIf you are experiencing any technical problems, or require any assistance with the proper use or application of this instrument, please call our technical hotline:(800) 343-1391 • (508) 698-2115 • Fax (508) 698-2118 Chauvin Arnoux ®, Inc. d.b.a. AEMC ® Instruments ********************。

6000系列数字监控系统使用说明6000系列产品说明第一章系统简介 (2)1.1简介 (2)1. 1. 1系统基本配置要求 (2)1.2系统参数 (3)第二章硬件安装 (3)第三章驱动程序安装 (4)第四章系统程序安装 (4)第五章系统软件功能和操作说明 (5)附录: 常见问题解答: (18)第一章系统简介1.1简介本说明书描述了与6000系列视频压缩卡(简称6000压缩卡)有关的硬件安装、软件安装、系统设置、软件使用等方面的内容,请务必按照说明书的指导进行这些工作,以确保监控系统正常、稳定地运行。

注:1、显示器分辨率设定为1024×768,1280x1024,1440x900。

2、在系统安装完后,在控制面版中的电源选项里将关闭硬盘、关闭监视器和系统待机等选项设置为“从不”。

3、检查所有设备是否存在冲突,对于存在冲突的设备,可以通过调整中断号、内存地址或者重新安装驱动程序等方法来解决。

1.2系统参数视频特性*视频输入:CVBS输入*支持制式:PAL、NTSC*压缩分辨率:352*288(PAL),320*240(NTSC)*单通道帧率:25F/S(PAL),30F/S(NTSC)音频特性*语音输入:语音线路输入*监听采样率:32KHz*录像采样率:8 KHz功能特性硬件符合PCI-Ex 规范,PNP支持使用10bit 梳妆噪声滤波器,视频信号清晰度;使用改进型H264压缩方式,内置数字水印,防止篡改;视频编码标准完全符合H264,音频信号清楚,码流低;支持宽屏显示,智能识别1024x768,1280x1024,1440x900 三种分辨率;支持VGA转电视墙显示方式;支持视频定时遮盖,具有高度监控区域保密性;使用整合式文件结构,系统更加稳定,去除文件打包概念,有断电保存功能录像输出格式可选音视频符合流或单独视频流;单路录像帧率在1-25帧(1-30帧)支持多路同时预览,支持视频预览无级缩放支持压缩流/预览流叠加时钟,多国文字的功能支持音视频的实时同步压缩多区域多灵敏度移动侦测支持静态图像捕捉录像格式全面兼容微软播放器超低功耗设计,板卡结构紧凑,系统稳定第二章硬件安装1、打开机箱,露出主机板和PCI-Ex 插槽。

目录眼图和消光比测试方法3一、测试所需硬件31.1 测试仪表31.2 所需附件3二、测试原理32.1 眼图和消光比的概念32.2 测试配置图4三、通讯信号分析仪面板指示及功能介绍43.1 ON/OFF43.2 软驱/光驱43.3 信号输入43.4 显示屏/操作系统5四、眼图的测试步骤分步设置54.1 正常启动54.2 开机界面54.3 设置测试环境64.4 选择测试通道64.5 校正电流74.6 选择眼图的测试模板84.7 设置测试的波数104.8 选择时钟的选取方式114.9 光输入注意光的强度11五、测试消光比的设置12六、眼图图形的保存输出方法14七、实用本卷须知14眼图和消光比测试方法-----CSA8000通讯信号分析仪测试实用指导一、测试所需硬件1.1 测试仪表Tektronix CSA 8000 Communications Signal Analyzer 通讯信号分析仪。

分析仪上配置Tektronix 80C01-CR 光电转换:此仪表实现光电转换。

测试眼图时,将光信号转换成电信号,然后由示波器显示出波形。

1.2 所需附件FC/PC-SC/PC、FC/PC-FC/PC光纤连接器两根、SC/PC-SC/PC、FC/PC-FC/PC珐兰盘两个、时钟线、软盘、鼠标、键盘、标准电源线一根,酒精棉球。

二、测试原理2.1 眼图和消光比的概念眼图把信号的上升时间、下降时间、脉冲过冲、脉冲下冲以及震荡等特性都包含了,眼图可以这样来理解:时间轴为一个周期的长度,眼图由四个局部组成:常“1〞,“1〞电平,“0〞电平,常“0〞电平。

“1〞电平和“0〞电平并不是理想中的方波,而是有一定的上升和下降坡度,因此将这四种波形叠加起来,那么就形成眼图。

我们测试的要求是不能有点子落在这个眼图模板内,否那么,经过一定的光纤衰减,在承受机处很难分辩出该点是“1〞还是“0〞。

假设数据信号为全“1〞时,平均光功率为A;数据信号为全“0〞时,平均光功率为B,那么消光比〔EX〕为:EX=10lgA/B2.2 测试配置图光接口的眼图和消光比的测试配置大致一样,如以下图所示:注:按照标准的测试配置,还要向SDH设备发送伪随机信号,以使输出有“0〞和“1〞的信号。

AC/DC Current Measurement SystemsTCPA300, TCP312A, TCP305A, TCP303, TCPA400, TCP404XL DatasheetThe TCP300 and TCP400 Series AC/DC current measurement family is a highly advanced current measurement system for today's current measurement needs. When connected to Tektronix oscilloscopes with TEKPROBE Level II, TekConnect (w/ TCA-BNC), or TekVPI (w/ TPA-BNC)interfaces, current measurements and calculations are simple and easy.Key performance specificationsDC - 100 MHz, Current Probe Amplifier (TCPA300) uses:DC - 100 MHz, 30 A DC (TCP312A)DC - 50 MHz, 50 A DC (TCP305A)DC - 15 MHz, 150 A DC (TCP303)DC - 50 MHz, Current Probe Amplifier (TCPA400) Uses:DC - 2 MHz, 750 A DC 1 (TCP404XL) (500 A DC Continuous)Key featuresAutomatic scaling and units 2 - Oscilloscope on-screen readout of magnitude and amps reduces measurement errors with no more handcalculationsAC/DC input couplingLow insertion impedance reduces device under test loadingSplit-core construction allows easy circuit connectionStatus indicators provide visual operating status and notification of potential error conditions - degauss, probe open, overload, notterminated into 50 Ω, noncompatible probe typeLow DC drift and noise allows improved low-level currentmeasurements3rd party safety certificationApplicationsDevelopment and analysis solutions for designers, installers, and service personnel in telecom, data comm, computer, andsemiconductor power electronics environments for:Power supplies (switching and linear)Semiconductor devices (SCRs, IGBTs, MOSFETs, CMOS, BJTs)Power inverters/convertersElectronic ballastsIndustrial/consumer electronicsMobile communications (phone, satellite, relay stations)Motor drivesTransportation systems (electronic vehicles, electric trains,locomotives, avionics)Meets today's AC/DC current measurement applicationsThe TCPA300 amplifier, when used with TCP312A, TCP305A, or TCP303probes, provides a wide range of current measurement capability and spans the gap between low-level milliamp measurements to very high current levels. These three probes provide current measurement capabilities of 30 A, 50 A, and 150 A DC continuous. For even higher current levels, the TCPA400 amplifier with the TCP404XL current probe measures 500 A DC continuous and 750 A DC continuous, derated with duty cycle.Higher-frequency performance is available with the TCP312A w/TCPA300providing ≥100 MHz bandwidth and a maximum current of 30 A DC.1Derated with duty cycle2Requires a TDS TEKSCOPE oscilloscope or a TekConnect oscilloscope with TCA-BNC adapterMeasurement errors and manual calculations are now a thing of the pastWith this new series of current measurement tools, automatic control and on-screen scaling and units is provided for users of Tektronix TDS3000, TDS500, TDS600, TDS700, TDS5000, TDS6000, and TDS7000B series oscilloscope systems (the DPO3000, MDO/MSO/DPO4000, MSO/DPO5000, and DPO7000 series oscilloscopes, the TPA-BNC adapter is required).The TCP300/TCP400 current measurement systems seamlessly integrate with your TDS series oscilloscope.Even non-TEKPROBE systems can use the TCPA300/400 series to make proper current measurements by simply multiplying the measured output voltage on the oscilloscope by the TCPA300/400 series range setting.SpecificationsAll specifications are guaranteed unless noted otherwise. All specifications apply to all models unless noted otherwise. Model overviewDatasheetCharacteristicsMaximum current ratingsHigh-current sensitivityLow-current sensitivityRange 1 A/V 5 A/V 5 A/V N/A DC (continuous) 5 A 25 A 25 A N/A RMS (sinusoidal) 3.5 A 17.7 A 17.7 A N/A Peak50 A50 A500 AN/APhysical characteristicsAmplifiersProbesMaximum conductor sizeCable length1.5 m (60 in)1.5 m (60 in)2 m (78.7 in)8 m (315 in)EMC environment and safetySafety complianceElectromagnetic compatibility,amplifiers onlyEC Council Directive 89/336/EEC, FCC Part 15, Subpart B Class A, AS/NZS 2064.1/2.AC/DC Current Measurement SystemsTemperatureOperating0 °C to +50 °C (32 °F to 122 °F)Nonoperating-40 °C to +75 °C (-40 °F to 167 °F)HumidityOperating5% to 95% R.H. to +30 °C (86 °F)5% to 85% R.H. +30 °C to +50 °C (86 °F to 122 °F)Nonoperating5% to 95% R.H. to +30 °C (86 °F)5% to 85% R.H. +30 °C to +75 °C (86 °F to 167 °F)AltitudeOperating2000 m (6800 ft.) maximumNonoperating12,192 m (40,000 ft.) maximumOrdering informationModelsProbesTCP312A Probe AC/DC current, DC to 100 MHz; 30 A DC (Requires TCPA300 amplifier)TCP305A Probe AC/DC current, DC to 50 MHz; 50 A DC (Requires TCPA300 amplifier)TCP303 Probe AC/DC current, DC to 15 MHz; 150 A DC (Requires TCPA300 amplifier)TCP404XL Probe AC/DC current, DC to 2 MHz; 500 A DC (750 A DC derated with duty cycle) (Requires TCPA400 amplifier)All TCP300/400 probes include: compliance and safety instructions, certificate of traceable calibration.AmplifiersTCPA300 Amplifier AC/DC current probe, DC to 100 MHz, (Requires TCP305A or TCP312A or TCP303 probes)TCPA400 Amplifier AC/DC current probe, DC to 50 MHz, (Requires TCP404XL probe)All TCPA300/TCPA400 Current Probe Amplifiers Include: AC/DC current probe amplifier, compliance and safety instructions, TEKPROBE interface cable, certificate of traceable calibration.Recommended accessoriesCover, large probe protective; (forTCP303, TCP404XL)016-1924-00Case, transit; currentmeasurement systems016-1922-0050 Ω feedthrough termination011-0049-0250 Ω BNC-to-BNC coaxial cable012-0117-00TEKPROBE interface cable,TCPA300 or TCPA400 amplifier toTDS series oscilloscopes012-1605-00Current loop, 1 turn, 50 Ω, BNCconnector (for TCP305A, TCP312A,TCP202A)067-2396-00Current loop, 1 turn, 50 Ω, BNC connector (for TCP303, TCP404XL)015-0601-50DatasheetEMC environment and safetyAC/DC Current Measurement Systems TCPA300/TCPA400 amplifier174-4765-00calibration adapter067-1478-00Power measurements deskewfixture for TCP202A, TCP305A,TCP312A, TCP303 probesWarrantyOne year parts and labor.Power requirementsAmplifiers90 V to 264 V, 47 to 440 Hz, 50 W; Maximum CAT II (auto switch)Probes TCP312A, TCP305A, TCP303 probes require a TCPA300 Amplifier; TCP404XL probe requires a TCPA400 Amplifier OptionsPower plug optionsOpt. A0North America power plug (115 V, 60 Hz)Opt. A1Universal Euro power plug (220 V, 50 Hz)Opt. A2United Kingdom power plug (240 V, 50 Hz)Opt. A3Australia power plug (240 V, 50 Hz)Opt. A5Switzerland power plug (220 V, 50 Hz)Opt. A6Japan power plug (100 V, 50/60 Hz)Opt. A10China power plug (50 Hz)Opt. A11India power plug (50 Hz)Opt. A12Brazil power plug (60 Hz)Opt. A99No power cordServiceOptionsOpt. C3Calibration Service 3 YearsOpt. C5Calibration Service 5 YearsOpt. D1Calibration Data ReportOpt. D3Calibration Data Report 3 Years (with Opt. C3)Opt. D5Calibration Data Report 5 Years (with Opt. C5)Opt. R3Repair Service 3 Years (including warranty)Opt. R3DW Repair Service Coverage 3 Years (includes product warranty period). 3-year period starts at time of instrument purchase Opt. R5Repair Service 5 Years (including warranty)Opt. R5DW Repair Service Coverage 5 Years (includes product warranty period). 5-year period starts at time of instrument purchase Opt. SILV400Standard warranty extended to 5 years (TCP305A, TCP312A, TCPA300, TCPA400 )Opt. SILV600Standard warranty extended to 5 years (TCP303, TCP404XL)Tektronix is registered to ISO 9001 and ISO 14001 by SRI Quality System Registrar.DatasheetASEAN / Australasia (65) 6356 3900 Austria 00800 2255 4835*Balkans, Israel, South Africa and other ISE Countries +41 52 675 3777 Belgium 00800 2255 4835*Brazil +55 (11) 3759 7627 Canada180****9200Central East Europe and the Baltics +41 52 675 3777 Central Europe & Greece +41 52 675 3777 Denmark +45 80 88 1401Finland +41 52 675 3777 France 00800 2255 4835*Germany 00800 2255 4835*Hong Kong 400 820 5835 India 000 800 650 1835 Italy 00800 2255 4835*Japan 81 (3) 6714 3010 Luxembourg +41 52 675 3777 Mexico, Central/South America & Caribbean 52 (55) 56 04 50 90Middle East, Asia, and North Africa +41 52 675 3777 The Netherlands 00800 2255 4835*Norway 800 16098People's Republic of China 400 820 5835 Poland +41 52 675 3777 Portugal 80 08 12370Republic of Korea +822 6917 5084, 822 6917 5080 Russia & CIS +7 (495) 6647564 South Africa +41 52 675 3777Spain 00800 2255 4835*Sweden 00800 2255 4835*Switzerland 00800 2255 4835*Taiwan 886 (2) 2656 6688 United Kingdom & Ireland 00800 2255 4835*USA180****9200* European toll-free number. If not accessible, call: +41 52 675 3777For Further Information. Tektronix maintains a comprehensive, constantly expanding collection of application notes, technical briefs and other resources to help engineers working on the cutting edge of technology. Please visit . Copyright © Tektronix, Inc. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification andprice change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks, or registered trademarks of their respective companies.23 May 2019 60W-16458-12。

高频电流探头CP8300A国产300A高频电流探头CP8300ACP8300A电流探头是一款是一款能够同时测量直流和交流的高频电流探头。

请看如下型号参数:CP8030B30A/DC~50MHzCP8030H30A/DC~100MHzCP8050A50A/DC~50MHzCP8150A150A/DC~12MHzCP8300A300A/DC~6MHzCP8500A500A/DC~5MHz深圳市优测科技有限公司其特点包括:高带宽,可准确快速捕捉电流波形高精度,在电流测量量程范围内,精度高达1%,满足大部分测试领域的需要两个量程可供选择,方便小电流测量自动消磁调零功能,使用方便;声光过流报警功能,提醒量程切换电子轻触式按键设计,使用寿命更长标准的BNC输出接口,可匹配任何厂家示波器二、产品概述CP8300A钳口可夹住直径达20mm的导线,适用于大电流应用场合测量300A的连续电流和500A的峰值电流,提供了6MHz的带宽探头具有300A(100X)和50A(10X)两个量程可选择,10X量程用于小电流测量,分辨率高达10mA三、应用电源(开关式和线性)设计LED照明设计电动汽车设计新能源变频家电电工实验半导体器件设计逆变器/变压器设计电子镇流器设计工控/消费电子设计发动机驱动装置设计电力电子和电力传动实验等通运输系统(电动车辆、机车、航空电子设备等)设计五、产品及附件说明■探头主体说明CP8030B CP8030H CP8050A1.传感器头检测导体电流的核心元件。

元件由一个精密的半导体等构成,周围温度的急剧变化,外部压力冲击等,有可能导致其受到损伤。

因此操作时必须十分注意。

2.开关控制杆控制传感器头开合的操纵杆。

测量电流时应先拉操纵杆打开传感器,放入被测导线。

然后再推操纵杆使探头处于LOCK状态。

3.输出接口标准的BNC输出接口,通过标配的BNC同轴线可连接任何厂家的示波器。

4.电源指示灯通电后,指示灯亮绿色。

利用知用电流探头时示波器的设置指南深圳市知用电子生产的电流探头能与市面上所有品牌的示波器兼容利用。

为了准确方便地对电流进行测量,需要对示波器的参数进行设置。

本文以市面上最为常见的三大示波器品牌:Tektronix ,KEYSIGHT ,LeCroy 为例,讲解搭配深圳知用电子公司的高频电流探头CP8030B/H,CP8150A利历时参数的设置。

示波器耦合方式和阻抗设置为:DC 1MΩ;本公司电流探头已经把所测得的电流转化为电压形式输出,默许的示波器阻抗是1MΩ。

若是阻抗误设为50Ω,信号会小一半。

Tektronix MDO3032KEYSIGHT DSOX2021A(注:KEYSIGHT该型号示波器无50Ω可选,因此默以为1MΩ)LeCroy 62Xs示波器的衰减比的设置依照所用的探头及其传输比,正确地设置示波器的衰减比,用户就能够够在示波器上直接读出电流的数值而不需要进行手工换算(显示的单位仍然是V)。

下面以CP8030B/H、CP8150A探头为例:CP8030B/H分为30A和5A两个量程:30A量程,探头电流传输比为:;利用该档位测量时,示波器衰减比应设置为“÷10”,“10X”或“10:1”如以下图:Tektronix MDO3032KEYSIGHT DSOX2021ALeCroy 62Xs5A量程,探头电流传输比为:1V/A,示波器衰减比应设置为“÷1”“1:1”或“1X”如以下图:Tektronix MDO3032KEYSIGHT DSOX2021ALeCroy 62XsCP8150A分为150A和30A两个量程:150A量程,传输比为:;测量时,示波器衰减设置为“÷100”,“100:1”或“100X”如以下图:Tektronix MDO3032KEYSIGHT DSOX2021ALeCroy 62Xs30A量程,探头电流传输比为:;利用该档位测量时,示波器衰减比应设置为“÷10”,“10X”或“10:1”,设置方式与CP8030B/H 30A量程的档位一样。

电流探头测量实例和使用技巧电流探头的应用十分广泛,其基本原理是流经导线的电流会在周围产生磁场,电流探头把磁场转化成相应的电压信号,通过和示波器配合,观察对应的电流波形。

广泛应用于开关电源、马达驱动器、电子整流计、LED照明、新能源等领域。

本文将讲述常见的电流探头的分类、原理、重要技术指标,并通过实例分析了解探头之间的差别,让大家能够对探头有个基本的了解。

一、电流探头分成AC电流探头和AC/DC电流探头。

目前示波器上的电流探头基本分成两类:即AC电流探头和AC/DC电流探头,AC电流探头常见的是无源探头,成本低,但不能处理直流分量;AC/DC电流探头通常是有源探头,分为低频探头和高频探头,低频探头常见的带宽在几百KHZ以下,高频探头带宽一般在几MHZ以上。

二、电流探头重要指标2.1 精度精度:是指电流到电压转换的精度。

拿 AC/DC 电流嵌为例,一般开环系统的精度比较差一点,典型值在 3%左右;闭环系统的精度比较高,典型值在 1%左右。

我们的高频电流探头的精度就是1%。

2.2 带宽带宽:所有探头都有带宽。

探头的带宽是指探头响应导致输出幅度下降到70.7%(-3 DB)的频率,如图5所示。

在选择示波器和示波器探头时,要认识到带宽在许多方面影响着测量精度。

在幅度测量中,随着正弦波频率接近带宽极限,正弦波的幅度会变得日益衰减。

在带宽极限上,正弦波的幅度会作为实际幅度的70.7% 进行测量。

因此,为实现最大的幅度测量精度,必需选择带宽比计划测量的最高频率波形高几倍的示波器和探头。

这同样适用于测量波形上升时间和下降时间。

波形转换沿(如脉冲和方形波边沿)是由高频成分组成的。

带宽极限使这些高频成分发生衰减,导致显示的转换慢于实际转换速度。

为精确地测量上升时间和下降时间,使用的测量系统必需使用拥有充足的带宽,可以保持构成波形上升时间和下降时间的高频率成份。

最常见的情况下,使用测量系统的上升时间时,系统的上升时间一般应该比要测量的上升时间快4-5 倍。

检测中心CA800系列双踪示波器操作规程

一、输入耦合的选择

直流(DC)耦合:使用于观察包含直流成分的被测信号,如信号的逻辑电平和静态信号的直流电平,当被测频率很低时,也必须采用这种方式。

交流(AC)耦合:信号中的支流成分被隔断,用于观察信号的交流分量,如观察较高直流电平上的小信号。

接地(GND):通道输入接地(输入信号断开),用于确定输入为零时光迹所处位置。

二、信号连接

1、探极操作

CA8000示波器附件中有两根衰减比为10:1和1:1可转换的探极,为减小探极对被测电路的影响,一般使用10:1,此时探极的输入阻抗为10MΩ,12pF,;,衰减比为1:1时用于观察小信号,但此。

深圳市知用电子有限公司SHENZHEN ZHIYONG ELECTRONICS CO.,LTD高频电流探头说明书CP8000A系列CP8030A 30A/D C~40MHzCP8150A 150A/D C~12MHzCP8300A 300A/D C~6MHz目录首先、注意事项 (3)CP8000A系列构成 (4)概述 (5)应用 (5)产品及附件说明 (6)探头主体说明 (6)附件说明 (8)产品电气规格 (9)机械规格 (12)环境特性 (13)操作方法 (13)使用时的注意事项 (13)测量前准备 (14)消磁、调零 (14)测量方法 (14)异常时的处理方法 (15)常见问题解答 (15)装箱单 (16)订购方式 (16)首先,感谢您购买我公司的产品。

本使用说明书,是介绍关于我公司CP8000A 系列产品的功能、使用方法、操作注意事项等方面内容的。

使用前,请仔细阅读说明书,并正确使用。

阅读完后请妥善保存,以便在测量过程中遇到问题,可及时翻阅。

说明书中,注释将用以下的符号进行区分。

安全使用本产品使用该产品时请务必严格遵守以下安全注意事项。

否则有可能会损害产品的保护功能。

此外,违反注意事项进行操作所产生的问题,本公司概不负责z 为避免短路及人体伤害,被测电压要求CAT I 300V 以下。

z 请避免接触裸导体。

因为探头前端传感器头没有绝缘,危险! z 测量时不要接触被测导体和传感器头。

z 测量使用的示波器,请使用带有保护接地的双重绝缘结构。

z当示波器连接其它测试终端时,该测试终端会因为连接了其他输入部分,使得本产品的连接端子和内部线路产生某种隐患,此时必须注意以下几点:·连接本产品的测试终端和其他测试终端之间,请使用带有符合过电压范畴及污染度的基础绝缘设备·若测试终端的基本绝缘无法满足的话,请不要输入超出安全电压。

·请参照连接电器的触电等安全性相关的注意事项,进行使用。

z 避免在潮湿环境中进行测量,以免发生触电事故,请注意。

指出错误的操作可能会造成人身伤害或危及生命安全。

指出错误的操作可能会造本产品或者其他财产损坏。

记载着使用该产品时的重要说明。

该符号表示对人体和仪器有危害,必须参照说明书操作。

z 使用前,请检查产品是否由于不当的保存条件或运输等原因而发生损坏。

z 电流探头前端传感器为高精密器件,搬运或测量使用时应避免震动、外力冲击、撞击,以免器件损坏。

z 避免在阳光直射、高温、潮湿、结露的环境下存放和使用。

防止因探头结构变形、绝缘恶化等因素导致的测量精度降低甚至产品损坏。

z 此电流探头没有防水、防尘构造,请避免在灰尘多和易粘水的环境中使用。

z 电流探头前端传感器经过精密研磨步骤制成,测量使用时应避免异物接触时的碰伤、磨花等,以免影响探头精度。

z 电流探头各数据线及电源线请勿严重曲折、拉拽,避免因线路断裂产生接触不良等故障。

z 探头传感器会因上下部分连接面有异物影响闭合性导致精度降低,清洁传感器或者探头其他部件时,请使用柔软的防静电布轻轻擦拭,并只能使用中性清洁剂,请勿使用含有酒精、丙酮、醚、酮、稀释剂等,以免发生变形、变色。

CP8000A 系列型号构成型号连续电流最大值带宽 量程选择电流传输比 CP8030A 30A 40MHz 30A/5A1V/A(5A) 0.1V/A(30A) CP8150A 150A 12MHz 150A/30A0.1V/A(30A) 0.01V/A(150A) CP8300A300A 6MHz 300A/50A0.1V/A(50A) 0.01V/A(300A)1. 概述CP8000A系列电流探头是一款能够同时测量直流和交流的高频电流探头。

其特点包括:高带宽,可准确快速捕捉电流波形;高精度,在电流测量量程范围内,精度高达1%,满足大部分测试领域的需要;两个量程可供选择,方便小电流测量;自动消磁调零功能,使用方便;声光过流报警功能,提醒量程切换;电子轻触式按键设计,使用寿命更长;标准的BNC输出接口,可匹配任何厂家示波器。

CP8000A系列电流探头常用于开关电源、马达驱动器、电子整流计、LED照明、新能源等产品的设计和测试应用中。

CP8030A体积轻巧,可在当前拥挤的电路板中使用自如;小型钳夹可以在紧张的空间中探测电流,同时仍能夹住直径达5mm的导线;可以测量30A的连续电流和50A的峰值电流,并提供了40MHz的带宽;探头具有30A (10X)和5A (1X)两个量程可选择,5A (1X)量程特别适用于小电流测量,分辨率高达1mA。

CP8150A钳口可夹住直径达20mm的导线,适用于大电流应用场合;可以测量150A 的连续电流和300A的峰值电流,提供了12MHz的带宽;探头具有150A (100X)和30A (10X)两个量程可选择,10X量程用于小电流测量,分辨率高达10mA。

CP8300A钳口可夹住直径达20mm的导线,适用于大电流应用场合;测量300A的连续电流和500A的峰值电流,提供了6MHz的带宽;探头具有300A (100X)和50A (10X)两个量程可选择,10X量程用于小电流测量,分辨率高达10mA。

2. 应用● 电源(开关式和线性)设计● LED照明设计● 电动汽车设计● 新能源● 变频家电● 电工实验● 半导体器件设计● 逆变器/变压器设计● 电子镇流器设计● 工控/消费电子设计● 发动机驱动装置设计● 电力电子和电力传动实验等● 交通运输系统(电动车辆、机车、航空电子设备等)设计3. 产品及附件说明■ 探头主体说明1)CP8030A2)CP8150A、CP8300A1. 传感器头该部件用于夹住被测导体,检测电流。

由磁芯、霍尔等精密器件组成。

周围温度的急剧变化,外部压力的冲击等,都有可能导致其受损,因此,操作时必须十分注意。

2. 开关控制杆控制传感器头开关的操纵杆。

传感器头的开关必须通过此操纵杆进行控制。

测量电流时,探头必须处于LOCK状态,否则无法正确测量。

3. 输出接口标准的BNC输出接口。

通过标配的BNC同轴线可连接任何厂家的示波器。

4. 电源指示灯通电后,该指示灯亮绿色。

5. 过载指示灯被测电流超过量程时,指示灯亮红色,并有报警声,提示切换量程。

6. 消磁指示灯按下消磁按键后,该指示灯亮绿色;消磁结束后,指示灯灭。

消磁若成功,蜂鸣器会“嘀嘀”响两声;消磁若失败,蜂鸣器“嘀”声延长,大约1S。

7. 消磁自动调零(Degauss AutoZero)按钮机器经常使用后,探头传感器会有剩余磁场。

测量前先消磁调零,可提高测量精度。

按下消磁自动调零按钮,机器消磁并自动调零,时间大约5S。

8. 量程(Range)指示灯指示当前量程状态。

9. 量程(Range)选择按钮用于选择电流测量量程。

CP8030A分为30A和5A两个量程:30A量程,探头电流传输比0.1V/A;5A量程,探头电流传输比1V/A。

CP8150A分为150A和30A两个量程:150A量程,探头电流传输比0.01V/A;30A量程,探头电流传输比0.1V/A。

CP8300A分为300A和50A两个量程:300A量程,探头电流传输比0.01V/A;50A量程,探头电流传输比0.1V/A。

10.偏置上调按钮输出偏置上调按钮:每按一次,偏置向上步进一位;长按该按键2S左右,输出偏置将连续向上。

11.偏置下调按钮输出偏置下调按钮:每按一次,偏置向下步进一位;长按该按键2S左右,输出偏置将连续向下。

12.电源插口外部供电插孔,标配DC12V/1.2A适配器。

■ 附件说明同轴电缆输出线(CK-305)电源适配器(CK-612)产品标配附件说明:型号 CP8030A CP8150A CP8300A 同轴电缆输出线BNC同轴线:50cm(CK-305)电源适配器DC12V/1.2A(CK-612)4. 产品电气规格型号 CP8030A CP8150A CP8300A 带宽(-3dB) DC-40MHz(图1) DC-12MHz(图4) DC-6MHz(图7)上升时间 8.75ns or less 29ns or less 58ns or less 连续电流最大值30Arms(随频率上升而下降,图2)150Arms(随频率上升而下降,图5)300Arms(随频率上升而下降,图8)峰值电流 50A 300A500A5A 1X 衰减 30A 10X 衰减 50A 10X 衰减 量程 30A 10X 衰减 150A 100X 衰减 300A 100X 衰减 5A ≥5A 30A ≥30A 50A ≥50A 过流报警值 30A≥50A 150A ≥300A 300A ≥500A5A 1V/A 30A 0.1V/A 50A 0.1V/A 电流 传输比 30A 0.1V/A 150A 0.01V/A 300A 0.01V/A 5A 1mA 30A 5mA 50A 5mA 分辨率 30A 10mA 150A 50mA 300A 50mA 5A ±1%±1mA 30A ±1%±10mA 50A ±1%±10mA 精度(DC,45-66Hz ,最大连续电流)30A ±1%±10mA 150A ±1%±100mA 300A ±1%±100mA输入阻抗参考图3参考图6 参考图9 供电方式 DC 12V/1.2A (标配适配器) 最大绝缘线电压 300V CAT I600V CATII300V CATIII600V CATII 300V CATIII安全符合标准IEC61010-1: 2010 IEC61010-2-32: 2012 EN61010-1: 2010 EN61010-2-32: 2012图1 CP8030A 幅频曲线图2 CP8030A最大测量电流VS频率曲线图3 CP8030A输入阻抗VS频率曲线图4 CP8150A幅频曲线图5 CP8150A最大测量电流VS频率曲线图6 CP8150A输入阻抗VS频率曲线图7 CP8300A幅频曲线图8 CP8300A最大测量电流VS频率曲线图9 CP8300A输入阻抗VS频率曲线5. 机械规格型号CP8030A CP8150A CP8300A 钳口直径约5mm 约20mm数据线长度约1m 约1.5m同轴电缆输出线(CK-305)约50cm电源适配器(CK-612)约72*62*31mm 线长:1.5m电流钳手柄尺寸(L*W*H)约75*40*18mm约175*68*29mm控制盒尺寸(L*W*H)约119*49*28mm探头净重约240g 约500g 约510gCP8030A钳口尺寸图 CP8150A和CP8300A钳口尺寸图6. 环境特性型号CP8030A CP8150A CP8300A 工作温湿度 0-40℃,80% or less存储温湿度 -10-50℃,80% or less工作海拔高度 < 2000m存储海拔高度 < 12000m7. 操作方法使用时的注意事项z该产品的输出终端设置在内部,选择测量使用示波器时,请选择高输入电阻(1MΩ),若输入电阻为50Ω,则不能正确测量。