flowchartdrawing流程图的制作方法

- 格式:ppt

- 大小:1.05 MB

- 文档页数:12

快速做流程图的三种小方法

在职场中我们要会熟练使用各种办公软件,才能提高我们的工作效率,下面我为大家分享三种制作流程图的方法,非常简单哦!

一,在Word中制作流程图

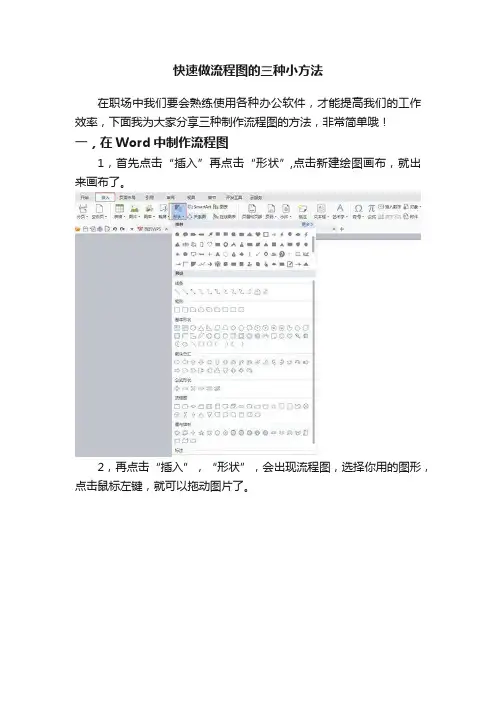

1,首先点击“插入”再点击“形状”,点击新建绘图画布,就出来画布了。

2,再点击“插入”,“形状”,会出现流程图,选择你用的图形,点击鼠标左键,就可以拖动图片了。

3,选择“插入”“形状”在线条中选择连接符,点击选中连接符,鼠标会变成十字形,移动到流程图上,图像上会出现四个点,把鼠标放到要链接的点上,按鼠标左键,再把鼠标移动到下面的流程图上的连接点上,完成两个图的链接。

点击线条颜色可对线条进行设置线型,颜色等。

二,在Excel中制作流程图

1,打开Excel,新建工作簿,点击插入,形状,流程图,选择流程图形,点击一下,鼠标就会变成很细十字架,然后在网格线中拖一下就出来了,点击图形就可输入文字了。

2,点击形状,线条,连接流程图。

3,当把流程图做好的时候,点击图形点击右键给流程图设计样式等,做好后点击“视图”,点击“显示网格线”去掉勾就可以了。

三,迅捷流程图制作软件

这款软件可以在线使用,也有PC软件,提供多种流程图制作模板,页面简介,操作简单,使用非常方便。

以上就是三种方法,欢迎评论转发。

工艺流程图绘制总结Drawing a process flowchart is a crucial step in any manufacturing or production process. 工艺流程图的绘制是任何制造或生产过程中的关键步骤。

It helps visually represent the steps involved in a particular process, making it easier for teams to understand and follow. 它有助于以视觉形式表现特定过程中涉及的步骤,使团队更容易理解和遵循。

By creating a process flowchart, you can identify inefficiencies, bottlenecks, and opportunities for improvement. 通过创建工艺流程图,您可以识别出效率低下、瓶颈以及改进机会。

It also allows for better communication among team members and stakeholders, ensuring everyone is on the same page. 它还能够促进团队成员和利益相关者之间更好的沟通,确保每个人都在同一页面上。

Overall, a well-designed process flowchart is a valuable tool for streamlining operations and enhancing productivity. 总的来说,一个设计良好的工艺流程图是优化运营和提高生产效率的有价值工具。

When creating a process flowchart, it is essential to start by defining the scope of the process. 在创建工艺流程图时,首先要定义过程的范围是至关重要的。

工艺流程图怎么画简单又漂亮工艺流程图是一种用于展示工艺过程的图表,它通过图形和符号的组合,清晰地展示了工艺过程中各个环节的顺序和关系。

工艺流程图在工程设计、制造流程、生产管理等领域起着很重要的作用。

然而,对于许多人来说,画出一张简单又漂亮的工艺流程图并不容易。

本文将介绍几个简便实用的方法,帮助你轻松绘制出令人满意的工艺流程图。

选择合适的绘图工具在开始绘制工艺流程图之前,首先需要选择一款合适的绘图工具。

市面上有很多绘图软件可供选择,例如Visio、Lucidchart等。

这些软件提供了丰富的符号库和绘图功能,能够满足不同绘图需求。

此外,如果你对绘图软件不熟悉,也可以选择使用一些在线绘图工具,例如Draw.io,这些工具简单易用,可以轻松实现工艺流程图的绘制。

确定绘图风格在绘制工艺流程图之前,可以先确定一种适合自己的绘图风格。

绘图风格包括线条粗细、颜色搭配、符号形状等方面。

可以根据自己的喜好和实际需求,选择一种简洁明了的风格。

一般来说,线条应该保持一致,颜色选择上尽量简洁鲜明,符号形状要遵循行业常规。

通过统一的绘图风格,可以使工艺流程图看起来更加整齐美观。

组织好绘图结构绘制工艺流程图时,需要合理组织绘图结构,使得图表更加清晰易懂。

可以先绘制出主要的流程框架,然后再填充细节。

对于复杂的工艺流程,可以将其分解成多个子流程,分别进行绘制。

在每个流程之间使用箭头或线条连接,表示工艺流程的顺序关系。

同时,可以对重要的流程环节进行标注,以便读者更好地理解工艺流程。

使用适当的符号和标识工艺流程图中使用的符号和标识对于传达信息非常重要。

常用的符号包括流程框、箭头、加工符号等。

在绘制工艺流程图时,要尽量使用行业通用的符号,以避免歧义。

此外,可以根据需要添加一些特殊的标识,例如关键环节、决策点等。

这些标识能够帮助读者更好地理解工艺流程,并且使得整个图表更加直观清晰。

注意排版和字体选择在绘制工艺流程图时,排版和字体的选择也是需要注意的。

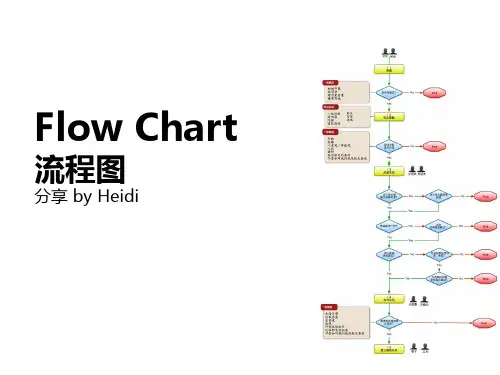

流程图的规范画法流程图是一种用来展示一个过程的图表,通常被用来描述一系列动作或决策的步骤。

它可以帮助人们更好地理解一个过程的流程,从而帮助工作人员更好地执行工作。

然而,如果一个流程图没有按照规范去画,很容易导致误解和混淆。

因此,在画流程图时,要遵循以下几个规范。

1. 用标准符号不同的符号代表不同的含义,使用标准符号可以让读者快速理解流程图中的信息,减少误解和混淆的可能。

比如,开始和结束的符号就应该使用正圆形和通过圆形来指定它们,而决策和分支应该使用菱形。

2. 使用正常的流程流向流程图应该按照从左向右或从上向下正常的流程流向来绘制。

这种方式可以确保读者更容易理解流程中的每一步骤。

3. 保持一致性同样类型的步骤应该使用相同的符号,并按照相同的流程流向。

这种一致性可以帮助读者更容易记忆和理解流程,加快学习流程的速度。

4. 使用容易理解的文本流程图需要和文本相结合,使用容易理解的文字可以帮助读者更好地理解流程中的每一个步骤。

在文本描述方面,要使用简明扼要、易于理解的语言。

5. 为决策创建正确数量的分支管道不同的决策需要不同数量的管道来表示。

如果决策只有两个选项,那么只需要一个分支管道;如果有三个选项,那么就需要两个分支管道,以此类推。

6. 绘制清晰的线条流程图中的线条应该绘制清晰,以避免产生误解。

线条的方向应该清晰,并且在不同符号之间应该具有合理的间隔。

线条的长度应该尽可能少,这样可以使流程图更加紧凑和可读。

7. 避免交叉线条可能会出现交错的线条(也称为反指针)的情况,这会使流程图的可读性降低。

在绘制流程图时,应该避免出现交叉线条。

总结流程图可以在许多领域中被广泛应用。

为了提高流程图的可读性并避免误解和混淆,需要遵循一些规范。

这种规范的应用可以让流程图更清晰、具有条理和信息密度,大大提高读者处理流程图的能力。

绘制ns流程图实现九九乘法表的方法Drawing a flowchart to implement a multiplication table for the nine times nine multiplication is a fun and challenging task. The first step in creating the flowchart is to determine the structure and logic of the program. We need to plan out how the program will calculate and display the multiplication table in a systematic and efficient manner. This involves breaking down the problem into smaller, more manageable tasks that can be easily represented in a flowchart.通过绘制流程图来实现九九乘法表是一项有趣而具有挑战性的任务。

首先,在创建流程图时的第一步是确定程序的结构和逻辑。

我们需要规划程序将如何以系统化和高效的方式计算并显示乘法表。

这涉及将问题分解为更小、更易管理的任务,这些任务可以在流程图中轻松表示出来。

Once we have a clear idea of how the program will function, we can start designing the flowchart. The flowchart will visually represent the step-by-step process of calculating the multiplication table. Each step in the flowchart will be connected by arrows, indicating the flow of control from one step to the next. This helps to illustrate theprogram's logic and ensures that all necessary calculations are performed in the correct order.一旦我们清楚了程序的工作方式,就可以开始设计流程图了。

双击打开

用翰文软件绘制横道图、网络图

翰文软件绘制横道图方法

1、点左上角的空格,打开软件,输入横道图的名称,点下面的横道图,点确定。

2、从白条下滑右拐,输入分项工程名称、天数、开、完工时间,点确定。

3、直到绘制完全部分项工程的横线。

4、遇到一条红线要分段的(柱子钢筋、砼浇筑等),要一条线从开始时间画到结束时间,然后再分段,按段编辑。

需要删除的部分双击,点右侧的工作间隙,再点确定即可删除间隔的时间段。

翰文软件绘制网络图方法

1、点左上角的空格,打开软件,输入网络图的名称,点下面的网络图,点确定。

2、从白条下滑右拐,输入分项工程名称、天数、开、完工时间,点确定。

3、一直做完全部工程红线关键线路。

4、连接非关键工作、虚工作、补足波浪线的画法。

5、右键点击添加工作,输入虚工作会出竖向虚线。

6、画虚工作到本工作的收尾结束。

7、波浪线向上连用挂起工作。

8、如拉线没反应时点添加后再拉线。

9、直到把全部图画完。

1。

图解两个工作流程图的一般画法,你肯定能轻松掌握!在工作中我们使用流程图的频率极高,一方面利用它能清楚展示各个项目活动的流程,另一方面还可以明确各部分之间的逻辑关系。

这么实用的办公工具,当然不能错过。

所以下面两个工作流程图的一般画法,你就需要认真学一学了。

以上两个画法都是借助在线版迅捷流程图完成的,来看看操作步骤吧!一、借助流程图模板搜索并打开在线迅捷流程图制作软件的首页,登录微信账号,接着在右上角点击【在线版】的按钮。

打开绘图页面后,在右上角点击你的头像,进入模板中心。

接着就可以在【精品模板】中,挑选一个最适合的流程图模板了。

将模板导入到绘图页面中后,就可以对模板进行编辑修改了:选中模板后,可以在左右两边的侧工具栏对模板中的文本框、文字、图像进行编辑、修改、删减、项目增加。

绘制完成后,点击【文件】众中的【导出】按钮,就可以将这份流程图导出为指定格式的文件了。

二、创建空白图表想自行绘制不想套用模板?也可以!首先在左侧功能栏中选择文本框并将其添加到图纸中,文本框的外观可以在右侧菜单栏中自行设置。

接着双击文本框,输入文本或者添加图片,文本的字体可以在右侧【文本】功能栏中进行设置。

在左侧工具栏中,选择箭头并用它们连接上下两个文本框,有必要的话也可以在箭头旁边做个注释表明两个文本框之间的关系。

最后一步,同样地,依次点击【文件】-【导出】,以某种格式将这份思维导图导出到电脑中!以上两则方法,不知道能否解决你关于工作流程图画法的疑惑呢?出师表两汉:诸葛亮先帝创业未半而中道崩殂,今天下三分,益州疲弊,此诚危急存亡之秋也。

然侍卫之臣不懈于内,忠志之士忘身于外者,盖追先帝之殊遇,欲报之于陛下也。

诚宜开张圣听,以光先帝遗德,恢弘志士之气,不宜妄自菲薄,引喻失义,以塞忠谏之路也。

宫中府中,俱为一体;陟罚臧否,不宜异同。

若有作奸犯科及为忠善者,宜付有司论其刑赏,以昭陛下平明之理;不宜偏私,使内外异法也。

侍中、侍郎郭攸之、费祎、董允等,此皆良实,志虑忠纯,是以先帝简拔以遗陛下:愚以为宫中之事,事无大小,悉以咨之,然后施行,必能裨补阙漏,有所广益。

How to Create Flow Charts in WordFlow charts are good visual tools. You can use one to displayfunctions, such as how a system operates or how a business's accounting procedures work. A flow chart can present a process, progression or structure with easily readable pictures and aminimal amount of text. For instance, you can create a flow chart to show your organization's supervisory structure so employees can know at a glance who reports to whom. Using Microsoft Word, you can create an effective flow chart in a short amount of time.Instructions1.o1Open a new blank Word document. If you are using Word 2003 or earlier, click"AutoShapes" on the "Drawing" toolbar. In Word 2007, go to the "Insert" tab of the ribbon and click on "Shapes."o2Point to "Flowchart" in Word 2003 and click on the first shape that you want in your flow chart. In Word 2007, click the shape you want to use in the "Flowchart" section of the "Shapes" dropdown gallery.∙3Click on the blank page where you want to apply the first shape. Drag the shape into the size you require. Choose and apply more shapes onto the page until you have all of the shapes you need for your flow chart.∙4Add connectors between the shapes to show your flow. Go back to the "AutoShapes"menu in the Word 2003 "Drawing" toolbar, or the "Shapes" dropdown in Word 2007.Click on a connector, line or arrow and apply it to the page between the first andsecond shape. Repeat with the remaining shapes, connecting all of the requiredshapes to show the process flow.∙5Add color to your flow chart shapes. Click on the shape to select it, right-click and choose "Format Shape." Choose the color or fill effect you want to use.∙6Right click the first shape and click on "Add Text." Type the text you want in the first box and press "Enter." Repeat with the remaining shapes. Save your flow chart and print it out if desired.Tips & Warnings∙If you can't find the "Drawing" toolbar in Word 2003, go to the "View"menu and point to "Toolbars." Click "Drawing" and the "Drawing"toolbar will appear at the bottom of the Window.How to Make a Flowchart in ExcelExcel is a good Office application to use if you want your files to include visual aids.You can make charts, graphs and pivot tables in Excel to show (rather than tell) the information you want to get across. You can also use Excel to create flowcharts, which show a progression or how something operates. Adding a flowchart to an existing Excel spreadsheet can provide further impact. Or you can make a flowchart in a new worksheet as an independent file.Instructions1.o1Make the "Drawing" toolbar available in Excel 2003 by going to the "View" menu and pointing to "Toolbars." Click on "Drawing"; the "Drawing" toolbar will appear at the bottom of the window. In Excel 2007, go to the "Insert' tab of the ribbon and find the "Illustrations" section.o2Click on "AutoShapes" in Excel 2003 and point to "Flowchart." Click on the firstshape you want to use and click onto the worksheet to place it in the appropriate area.In Excel 2007, click the "Shapes" button and choose the shape you want to use first from the "Flowchart" gallery. Click onto the worksheet and place the shape there. For the best results, begin your flowchart near the top of the worksheet, but leave a few rows in case you decide to add text above it.o Sponsored LinksFlash Drive ManagementCentral management of secure USB flash drives anywhere in the world!o3Add more shapes to your flowchart in the same manner. You need to have one shape for each step in the process. The position of the shape will depend on when the step takes place, as well as how you determine whether to take the step. For instance, if Step One is a yes or no question, you might put "Yes" in a shape that is down and to the right of the first shape and "No" down and to the left. Right-click each shape and click on "Add Text" to add the information needed.o4Add connectors between the shapes. In Excel 2003, click the "AutoShapes" button and click on "Connectors." Choose a connector and click on the first shape. Drag into place, linking the two shapes. In Excel 2007, choose a connector from the "Shapes"drop-down menu. Connect all of the appropriate shapes.o5Format the shapes for more interest and effect. Right-click a shape and choose"Format Shape" (or "Format AutoShape"). On the "Font" tab, you can choose adifferent font, change the font size or color or add effects. On the "Alignment" tab, you can center your text. On the "Colors and Lines" tab, you can fill the shape with a color or other fill effect. When you are finished making changes, clck "OK."o6Save your worksheet. You can use thHow to Write a Flow ChartFlow charts are commonly used diagrams that help a readerunderstand a process. The chart uses boxes and arrows to convey the information. In each box, the writer lists key words or phrases in the process; the arrows indicate the progression of the process.While each flow chart will vary depending on the specific subject matter, the majority of flow charts diagram a process from start to finish. To help illustrate how to write a flowchart, consider how a person brushes his teeth.Instructions1.o1Title the flow chart. In this example, use a title such as "Brushing Teeth."o2Draw a rectangle under the title. Write the first step in the process in this rectangle.Here, the first step might be "Rinse toothbrush under water briefly."∙3Draw a line from the box with an arrow pointing downward. Connect the arrow to a second box. Write the second step of the process in the second box. In this example, you may write "Apply toothpaste to the brush."∙4Repeat Steps 2 and 3 listing each subsequent step. At points in the process where one of two outcomes can occur, draw two lines from one box leading to two separate steps in the process. An example here may be the proper motion to use whenbrushing teeth. Underneath the box stating "Apply toothpaste to the brush", draw two separate lines at angle away from the box. In one of the outcomes, write "Use a circular brushing pattern"; in the other, write "Use an up-and-down brushingpattern."∙5Connect the final box of the process. Write "Finish" or, for this example, "Rinse and repeat as necessary.Tips & Warnings∙Use different shapes to help readers understand complex processes. For example, suggests using ovals for start and finish,rectangles for instructions, and diamonds for times during the processwhere a person needs to make a decision. Use these shapes or come upwith your own.Symbols Used in a FlowchartThe symbols in a flowchart are geometric shapes used to illustrate the different actions that can occur during a process, program or algorithm.Although flowcharts included text descriptives as well, the symbols on the chart vary in shape to give visual cues to the reader that aid in the understanding of the chart. Without even reading the text, a user can quickly grasp the general process based on the order of the symbolsRounded Rectangle∙The rounded rectangle symbol on a flowchart is known as a "terminator." It is used to show the start, stop, beginning or end of a process. They are commonly seen at the top and bottom of a flowchart, but may appear within a flowchart if sub-processes branch off then terminate before the end of the overall process.Arrow∙The arrow symbol is used to show the flow of information through the program. The arrow points in the direction the process moves from start to finish. If a section of the flowchart indicates information goes into one block and back out again to an earlier step in the process, the arrow line will be bent, with right angles like a square,pointing up and back around to a previous section of the chart, illustrating a "loop"or step that repeats. A double arrow may appear on flowcharts to indicate digital data read/write actions to the same device.Diamond∙A diamond is used on a flowchart to show decision. It can mark the appearance of anIF statement, for example, or any question in the process that has multiple outcomes that lead to new directions in the process. A "yes" to the question posted in thediamond would take the process in one direction indicated by a point on thediamond. A "no" response would send the process in another direction indicated by a second point on the diamond. They don't necessarily need to be opposite points.Plain Rectangle∙One of the more common symbols seen in a flowchart, the plain rectangle is used to show individual steps or actions in the process and is often used directly after the start of the process and after any decision symbols to show the next action to take place.Rectangle with Wavy Bottom∙This symbol resembled a torn piece of paper and indicates a "document" in theprocess. It could be physical document created during the process, as in a printout, or an electronic document, such as an email message, generated by the process. A "stacked" version of this symbol indicates multiple documents output.Rounded Rectangle with Concave End∙This symbol is used to show data being stored for those processes that include data moving to certain locations. A terminating symbol would follow if the data storage is the end of a particular process branch on the chart.。

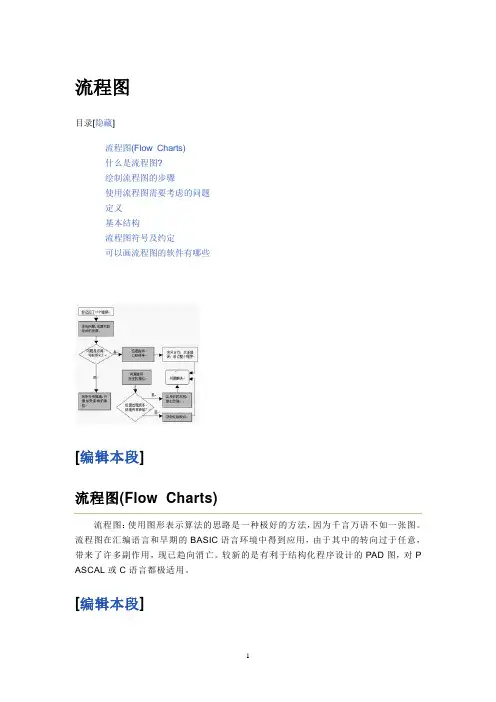

流程图目录[隐藏]流程图(Flow Charts)什么是流程图?绘制流程图的步骤使用流程图需要考虑的问题定义基本结构流程图符号及约定可以画流程图的软件有哪些[编辑本段]流程图(Flow Charts)流程图:使用图形表示算法的思路是一种极好的方法,因为千言万语不如一张图。

流程图在汇编语言和早期的BASIC语言环境中得到应用,由于其中的转向过于任意,带来了许多副作用,现已趋向消亡。

较新的是有利于结构化程序设计的PAD图,对P ASCAL或C语言都极适用。

[编辑本段]什么是流程图?流程图是流经一个系统的信息流、观点流或部件流的图形代表。

在企业中,流程图主要用来说明某一过程。

这种过程既可以是生产线上的工艺流程,也可以是完成一项任务必需的管理过程。

例如,一张流程图能够成为解释某个零件的制造工序,甚至组织决策制定程序的方式之一。

这些过程的各个阶段均用图形块表示,不同图形块之间以箭头相连,代表它们在系统内的流动方向。

下一步何去何从,要取决于上一步的结果,典型做法是用“是”或“否”的逻辑分支加以判断。

流程图是揭示和掌握封闭系统运动状况的有效方式。

作为诊断工具,它能够辅助决策制定,让管理者清楚地知道,问题可能出在什么地方,从而确定出可供选择的行动方案。

[编辑本段]绘制流程图的步骤为便于识别,绘制流程图的习惯做法是:一般用椭圆表示“开始”与“结束”。

行动方案普通工作环节用矩形表示问题判断或判定(审核/审批/评审)环节用菱形表示箭头代表工作流方向流程图实例图输入输出为平行四边形[编辑本段]使用流程图需要考虑的问题使用流程图需要考虑很多问题,如:过程中是否存在某些环节,删掉它们后能够降低成本或减少时间?还有其他更有效的方式构造流程吗?整个过程是否因为过时而需要重新设计?应当将其完全废弃吗?[编辑本段]定义流程图是由一些图框和流程线组成的,其中图框表示各种操作的类型,图框中的文字和符号表示操作的内容,流程线表示操作的先后次序。

c语言程序流程图符号及绘制方法Flowchart symbols in C programming include start/end symbol, input/output symbol, process symbol, decision symbol, and connector symbol. These symbols are used to represent different elements in a C program and to illustrate the flow of the program. The start/end symbol is represented by an oval shape with the word "Start" or "End" inside it. This symbol marks the beginning and end of the program. The input/output symbol is represented by a parallelogram shape with the words "Input" or "Output" inside it. This symbol indicates the input or output of data in the program. The process symbol is represented by a rectangle shape with a description of the process inside it. This symbol represents the various calculations and operations performed in the program.在C语言编程中,流程图符号包括开始和结束符号、输入/输出符号、处理符号、决策符号和连接符号。

3工艺流程图的绘制(The drawing of 3 process flow chart)3 process flow drawing.Txt I was degraded, and I can't swim until now. I know I was the fastest one before I was born. This article was contributed by zx55107499Ppt documents may experience poor browsing on the WAP side. It is recommended that you select TXT first or download the source file to the local machine.Synthesis process design of polymerSchool of materials science and EngineeringXu lili1Section 5 rendering process flow chartThe basic knowledge of drawing drawing, technological process sketch, process flow chart and piping instrument flow chartBasic knowledge of chemical process drawing1 the basic composition of the drawings2 drawings format3 graphics proportionGraphics should comply with the national standard "the proportion of technical drawing ratio (GB/T1469093) regulations". Stipulation of drawing proportion should be marked in Title column. If some of the main view and view the proportion of different proportion, in a drawing, if some views and the proportion of the different proportion of the main viewin a drawing, the proportion should be marked in the figure, the view above the line fine line. Mark the scale above the view, such as the graph, where the line is a fine solid line. Beta beta alpha alpha alpha 1?? to not according to the proportion of 1: 5 1: 5 1:54 text formatThe writing format of Chinese characters, letters and numbers in drawings should be unified and suitable in size. The writing format of Chinese characters, letters and numbers in drawings should be unified and suitable in size.Layout of engineering drawingsTechnical explanationBreadth linePatternLegendFrameDetail listDetail listDetail table title barFigure 3-11 width and size of drawingTwo process sketch 1 program flow chart: the flow chart can be expressed by block diagram, and the flow chart can be expressed by block diagram,Relationship between. Relationship between.2345Sketch of process flow: sketch of process flow: also called process flow diagram. Material balance diagram process flow chart (PFD) (PFD). Process flow chart (PFD). Piping instrument flow chart (PID) (PID). Piping instrument flow chart (PID).2 process sketch: also called process flow diagram. Sketch of process flow:(symbol of equipment). Equipment schematic diagram (equipment) material pipeline (material piping). Material pipeline (material piping).Thick lines draw all the raw material and the arrow indicates the direction of pipeline, draw all the raw material of pipeline, with thick lines draw all the raw material of pipeline, and the arrow indicates the direction, with thick lines to draw important auxiliary material pipelines. The valve and meter thick lines to draw important auxiliary materials, pipeline valves draw important auxiliary material pipelines. And so on. And so on.(3) text annotation (notes). Text annotation (notes) (notes).The equipment is annotated (code name, name) to annotate the equipment (code name), indicating the name, source and whereabouts of the material entering and leaving the stock. Mark names, sources, whereabouts.3 material flow chart (material balance diagram)The number chart of the material in the whole production process is represented by the chart to represent the quantity balance relationship of the whole process of production, the state parameter and the performance parameter of each stock material. The quantity balance relation, the state parameter and performance parameter of each stock material. Each material has a logistics number (material stream each material has a logistics number number), and corresponds to the material balance table. And corresponding to the material balance table. The top left side box frame or rectangular diamond diamond on the pipeline of logistics, the corresponding diamond frame or rectangle on the pipeline of logistics, corresponding on the pipeline of the corresponding material or pipeline), (above),Material flow in the box or above the material pipeline (left), material flow and various parameters are given in the material balance table. And various parameters are given in the material balance sheet.Three process flow chart process flow diagram(a) schematic diagram of the main content of the material flowand drawing (two) notes (legend and note legend and legend and notes) (note) (three) the title bar and list of the equipment (title Panel and equipment date sheet)(1) the main contents and drawing methods of the material flow diagramThe 1 painting equipment according to the material flow through the main sequence from left to right, in order to draw, the main material flows through the reserve order from left to right in turn on drawing, through the order from left to right, the devices do not need to draw a line of the same, just don't draw a draw, a number of production lines don't draw; equipment, production lines of the same, only need to draw a fine line;2 in proportion to draw the outline and main equipment of each internal node thin lines equipment outline and main characteristics of the internal structure of drawing in proportion. Structural characteristics. Pumps, compressors and other equipment is not drawing in proportion. Table 3-7 the compressor equipment is not drawn to scale. The PFD should be in the size of the equipment list marked equipment; PFD should be in the size of the equipment list of equipment shall be marked in the size of the equipment list marked equipment; the indicating device name (equipment name) and a number (equipment number), the equipment classification code can see table 3-8. The code for classification of equipment may be shown in table, in which the device classification code can be seen, and can be seen in figure 13. Method can be seen in figure 3-13.Table 3-7 common painting equipment2 material pipeline representation methodWith the flow of the solid line in the process flow diagram as a solid line with the pipeline flow with the flow of the solid line in the process flow diagram as the pipeline (material piping) said the flow of logistics and logistics; and said flow and flow of the logistics; each need to define a number of logistics logistics (material stream number), logistics in the diamond shape or rectangular box, you can also write to put the box in the logistics logistics, a diamond or a rectangle on a diamond or a rectangular box in the pipeline pipeline above the top or left or left, top or left in the pipeline, the logistics and material balance in the corresponding logistics No. the key point of operation; the key point of operation in logistics number corresponding; for the key point of operation should also show the logistics point temperature Or pressure, temperature, or pressure. The temperature or pressure of the logistics point.In PFD, the drawing between the material pipeline and the material pipeline and the PFD intersection of the control instrument should be disconnected. The drawing should be broken when crossing. The pipeline open principle: the main pipeline connection, the principle of pipeline disconnected: main materials and auxiliary materials pipeline pipeline connection is disconnected; disconnect the horizontal or vertical line; disconnect pipeline, continuous control line; disconnect the horizontal or vertical line; the pipeline system, continuous meter connections disconnected etc.. Instrument wiring disconnection and so on. 3-14. The main valves and important fittings must be drawn in the material pipeline of PFD. PFDmaterial pipeline must draw the main valve and important pipe material, the pipeline must draw the main valve and important pipe fittings.If a graph can not fully represent the whole process, it can be drawn into multiple process flow charts when the whole process is not completely expressed when a graph can not fully represent the whole process. When the part is disconnected, the drawing process is drawn. In the figure, the inlet and outlet points of the material are represented by a sharp box with a sharp box. The inlet and outlet points of the material pipeline are represented by a sharp box, and the flow chart number and the equipment number of the material coming or going are explained.Flow chart number and equipment position number. Figure 3-153 control scheme representation methodThe main contents of the main content of control scheme and testing, detection and control parameters and control scheme: the main content detection point, control parameters, instrument function, regulating valves, actuators, instrument function, regulating valves, executive structure, instrument installation position. Position, etc.. In the process, the control scheme is breaks in the process flow diagram of the instrument graphics, graphic character control scheme through the instrument regulating valve and actuator graphic symbols, number, regulating valves and actuators of the graphic symbols, the instrument connection said that. Tables, lines, etc..The instrument graphical symbol should indicate the instrument installation position, the test control instrument graphical symbol should indicate the instrument installation position, the test control parameter should indicate the instrument installation position, the instrument function and so on. Function content, instrument function and so on. The instrument graphic symbol consists of the instrument installation position, the graphic symbol and the instrument position number group, the instrument graphic symbol is installed by the instrument, the position symbol and the instrument position number group 16. A. Figure 3-16. The instrument position is composed of letters and numbers. The number of the instrument is composed of letters and numbers. Form。