常用接头标准选用方法PARKER

- 格式:doc

- 大小:331.00 KB

- 文档页数:7

派克焊接接头公制对照表派克焊接接头是一种常用的焊接接头,在日常生活中,我们也经常会见到它的身影。

派克焊接接头广泛应用于电工,管道,照明和专业音响系统。

它们强度极高,可以抵御强力拉力,是传输电流和气体的理想选择。

派克焊接接头是一种外部零件,由垫圈、链接螺栓、衬垫以及外部螺纹连接而成,可以让电线,管道和设备相互连接。

焊接接头可以大大减少安装过程中的行程时间和安装空间,是一种更便捷的连接方式。

焊接接头主要由规格不同的外部螺纹,衬垫,罩子和三重密封组成,在不同的工作环境中运行性能优异。

派克焊接接头的公制尺寸主要有PG7,PG11,PG13.5,PG16,PG21,PG29等。

PG7的外径是7mm,内管孔的直径是5mm,外壳尺寸为21.4mm;PG11的外径是11mm,内管孔的直径是9mm,外壳尺寸为27.1mm;PG13.5的外径是13.5mm,内管孔的直径是11mm,外壳尺寸为30.1mm;PG16的外径是16mm,内管孔的直径是14mm,外壳尺寸为33.7mm;PG21的外径是21mm,内管孔的直径是19mm,外壳尺寸为41.2mm;PG29的外径是29mm,内管孔的直径是25mm,外壳尺寸为54.8mm。

派克焊接接头的优点很多,比如高质量、高强度、良好的隔离性能和防爆性能,而且它是单一构件,可以提高整体支架的强度。

另外,派克焊接接头的连接方式简单、安装快捷,灵活应用于不同的电机操作现场,这些优点使得它用于各种曲线和折线地设计非常方便。

总之,派克焊接接头是一种可靠的连接方式,在高强度的作业情况下,具有很高的可靠性和耐用性。

由于其公制尺寸的多样性,使派克焊接接头在各种曲线和折线地设计中灵活运用,成为工作之佳伴。

parker液压管接头标准

Parker液压管接头标准通常由Parker公司制定,以适应其液压系统的需求。

这些标准包括管接头的尺寸、材料、压力等级和连接方式等方面。

以下是Parker液压管接头标准的一些关键方面:

1.尺寸:Parker液压管接头的尺寸通常是根据液压系统的需求进行设计

的。

根据不同的应用场景,管接头的尺寸也会有所不同。

2.材料:Parker液压管接头的材料通常为金属或塑料。

金属管接头具有更

高的强度和耐压性能,而塑料管接头则更轻便和易于安装。

3.压力等级:Parker液压管接头的压力等级是根据系统的需求进行设计

的。

不同的压力等级意味着管接头能够承受不同的液压压力。

4.连接方式:Parker液压管接头的连接方式有多种,包括螺纹连接、卡套

连接、法兰连接等。

根据不同的应用场景和需求,会选择不同的连接方

式。

总之,Parker液压管接头标准是针对其液压系统的特定需求而制定的,以确保液压系统的正常运行和安全性。

在选择和使用Parker液压管接头时,应遵循相关的标准和技术要求。

Parker派克A-LOK系列双卡套接头派克的 A-LOK双卡套接头系列产品能够为仪器仪表,过程控制和分析⾏业等提供稳定的⽆泄漏密封连接。

接头严格按照更⾼质量标准制造,多种尺⼨、耐腐蚀材料和结构可选。

根据⾏业标准,派克的 A-LOK管接头采⽤316不锈钢制造,其它材质如:6Mo合⾦,825合⾦,625合⾦和C-276合⾦可选。

直通接头⽤冷加⼯⼯艺制造,⽽其他特殊形状管件通过细晶粒锻造⼯艺制成。

该管接头适⽤于不同规格的钢管,英制管外径从1/16” 到 2” ,公制管外径从2mm到25mm。

Parker A-LOK two ferrule compression tube fittings are designed to provide reliable leak-free connections for instrumentation, process and control, and analyzer applications that specify a two ferrule system. Manufactured to the highest quality standards, these tube fittings are available in a broad range of sizes, corrosion resistant materials and configurations.As standard, Parker A-LOK tube fitting are manufactured from heat code traceable 316 stainless steel. Other materials include 6Mo, Alloy 825, Alloy 625 and Alloy C-276. Straight fittings are machined from cold finished bar stock, while shaped bodies are machined from close grain forgings.The fittings are available for imperial pipe sizes from 1/16” through to 2” O.D., and for metric sizes from 2 mm through to 25 mm O.D.市场:- 半导体/微电⼦- 化⼯- ⽯化- 电⼒- 核能- 油⽓- 科研机构特征和优势:- 拥有⼴泛的可选结构;卡套管-外螺纹接头卡套管-内螺纹接头联合接头卡套转换接头37扩⼝ (AN) 与 A-LOK 转换接头O型圈密封管接头卡套管转焊接接头⾊谱分析⽤接头软管接头- 采⽤ Suparcase™ 表⾯硬化处理⼯艺- 硬化处理后的卡套能够提供⽆泄漏连接- 螺母内壁经镀银处理,减少螺纹咬死现象发⽣应⽤:- 蒸汽管线- 海上井⼝控⾯板- 传感线路。

parker 接头简介Parker 接头,是美国ParkerHannifin 公司德国工厂的德国工程师Ermto(埃米托)发明于上世纪30 年代,为了纪念其用其名字命名为parker接头,parker接头又名parker卡套式管接头。

Parker接头在中国------parker 接头特性:派克卡套式管接头因其特有的装配方便(仅需两把扳手)而广受欢迎。

经过近80多年的发展,EO工厂始派克接头图册(7张)终保持着卡套式管接头技术的领先地位。

今天,parker管接头是世界上使用最为广泛的一种管接头。

EO管接头是为公制管子设计的,历史上曾经依照德国标准DIN3861、DIN3859和DIN2353,现在这些标准已被国际标准ISO8434取代。

Parker管接头以体积小,压力等级高而著称。

分为低压、中压和高压三个系列(LL、L、S系列)这样使得各种不同的应用场合可以实现最经济化和空间最小化的方案。

parker 接头材质及规格Parker 管接头的材料除了最常见的碳钢镀锌以外,还提供铜和不锈钢两种材料,以适应不同的流体或环境条件。

Parker不锈钢接头的螺母螺纹采用镀银并预先润滑(规格15L-42L,12S-38S),较小规格的螺母螺纹采用蜡封,这样不仅有效的消除了不锈钢螺纹的咬合现象,同时减少40%装配拧紧力矩。

Parker管接头具有50多种不同的形式,可供各种不同应用场合的灵活选择,加上许多parker功能管接头,如旋转接头、球阀、单向阀、截止阀、测压接头等与parker 管接头配合使用,可大大方便系统的配套,提高系统密封的可靠性。

PARKER 液压软管具有防腐、耐高温、抗拉强度高,柔韧性好等诸多性能,而被广泛采用在各行业的液压工程中,派克软管有一层至多层钢丝编织增强层(6层以上),有低、中、高、超高三种压力等级,有轻、重两系列,公称通径在3 — 32mm。

有普通型和特殊型两种软管以满足在普通环境及特殊环境下使用,先进的不剥胶软管极大减轻装配劳动强度,广泛应用在各行业液压系统管路中。

派克标准19243一体式液压软管接头

派克标准19243一体式液压软管接头是一种常用于液压系统中的连接器件。

它由派克公司设计和生产,采用一体式设计,具有可靠性高、安装方便等优点。

派克标准19243一体式液压软管接头通常由两个部分组成:一个是内部的连接器,也称为接头头部;另一个是外部的连接器,也称为接头底座。

接头头部和接头底座通过螺纹连接,形成完整的接头。

派克标准19243一体式液压软管接头具有以下特点:

1. 采用金属材料制造,如钢材,具有高强度和耐用性;

2. 采用O型密封圈,确保接头的密封性能;

3. 设计合理,连接稳固,能够承受高压力和大流量的液体;

4. 安装方便,只需将接头头部和接头底座螺纹连接即可;

5. 可根据使用环境和需求选择不同的接头尺寸和型号。

派克标准19243一体式液压软管接头广泛应用于各种工业领域,如机械设备、航空航天、冶金等,用于连接液压系统中的软管和管路,起到传递液体、控制液压流动的作用。

parker接头:为流体传输提供更可靠的连接方式在液压和气动领域,流体传输连接件的重要性毫不言而喻。

为了确保传输的可靠性和稳定性,连接件的选用和设计必须得到高度重视。

Parker Hannifin是一家全球领先的流体传输技术公司,其接头产品在行业内占据重要地位。

本篇文章将对进行介绍和分析,以便更深入地了解这种连接方式,以及其在相关领域的优良表现。

概述是一种高质量的金属管接头产品,可用于液压和气动系统。

它通过将金属管子连接在一起,来传输流体。

这种连接方式比其他连接方式更可靠和耐用。

采用耐高温,耐磨损和耐腐蚀的材料制成,例如不锈钢、铜和铝。

这些优质材料确保了具有长寿命和强度,而且不会因系统内高压或高温而出现故障。

的一大优势是,它可以在高压和高温的情况下保持稳定的连接,从而确保了系统的安全性和稳定性。

此外,Parker提供一系列的接头产品类型,可以满足各种需求。

产品类型Parker Hannifin提供几种不同类型的接头产品,以满足液压和气动系统的不同需求。

以下是主要产品类型的基本介绍:1.管帽接头管帽接头是一种金属管接头,可以让两根金属管子连在一起。

这种接头产品非常适合于连接相对移动的管子。

管帽接头不仅在液压和气动系统中运用广泛,而且在车辆制造、工业生产和石油化工等行业中也有广泛的应用。

2.嵌入式接头嵌入式接头是一种金属接头,适用于安装在液压和气动系统的管子中。

这种接头可以方便地安装在管道内部,从而在系统内部占用空间较少。

嵌入式接头可用于连接不同直径和形状的管子,以适应不同的应用场合。

3.弯头接头弯头接头是一种可以弯曲的金属接头。

这种接头可用于连接两根金属管子并让它们沿着不同的角度弯曲,从而适应各种弯曲和紧凑的空间。

弯头接头也是一种常用的连接方式,能够满足庞大和复杂的液压系统的需求。

4.插入式连接器插入式接头是一种具有高度可靠性和紧凑性的接头方式,它通常用于连接小直径的金属管子和软管。

插入式接头通常采用环状密封设计,以确保连接点的稳定性和密封性。

气动元件论坛接头基础知识接头基础知识•什么是接头? 其功能是什么?•接头解析•螺纹型式•接头密封型式什么是接头?其功能是什么?使用接头的目的:各种流体动力元件间的液压或气压管路的连接需要各种类型的接头。

把管联接到液压系统上. 接头提供防渗漏密封和系统的接口接头解析油口端&管末端:接头是一种连接流体动力系统元件的连接件,所有的接头除了堵头、堵帽之外,都至少有两个端口。

接头解析油口端&管末端连接到系统元件例:阀、气缸的接头末端称为油口端。

连接到软管、硬管的接头末端称为管末端。

P=油口端T=管末端接头形状直接头接头形状弯接头:有多种角度,但通常为45度或90度接头形状T型接头(三通)接头形状其他接头解析接头螺纹*螺纹是接头的重要部分*提供机械支持力和密封接头螺纹-特征牙顶和牙底:接头螺纹-特征牙侧和牙型角:接头螺纹-特征牙形角和锥度:螺纹角度锥度接头螺纹-特征螺距:螺纹之间的距离接头螺纹-特征公制螺纹常用接头公制螺纹螺距:1.0mm、1.5mm、2.0mm接头螺纹-特征英制螺纹:1英寸牙数(TPI)常用接头英制螺纹螺距:11、14、18、20接头螺纹-尺寸OD:螺纹大径:螺纹外径(牙顶-牙顶)接头螺纹-命名•螺纹的命名系统是个严密的逻辑系统,描述了螺纹尺寸、螺距和型式•英制螺纹:尺寸-牙距-型式例: 螺纹尺寸=-12(3/4“),螺距=20TPI,型式是UNF 螺纹命名: 3/4-20 UNF尺寸螺距型式12 20 UNF常用英制螺纹型式:NPT、NPTF、UN、UNF、BSPT、BSPP接头螺纹-命名•公制螺纹:公制-螺纹尺寸-螺距例: 螺纹尺寸=12,螺距=1.5mm 螺纹命名: M12*1.5公制尺寸螺距M 12 1.5接头螺纹平行螺纹(直螺纹):每个螺纹的外径都相等平行接头螺纹平行螺纹:•平行螺纹只能提供机械支持力•通过其他方式来完成密封例如: O-ring接头螺纹锥形螺纹:螺纹的外径逐渐变小锥形接头螺纹锥形螺纹:•锥形螺纹有2方面作用:z机械支持力z密封 (通常需要其他辅助密封剂)螺纹型式•英制螺纹•公制螺纹英制螺纹管螺纹:管螺纹有锥形螺纹的特征可提供机械支撑力和密封,通常还需使用密封剂防止泄漏。

如何快速识别派克液压接头的规格型号昨天一个老客户跟我诉苦,原来他正在为不知如何判断从设备上拆下的派克液压接头规格型号而发愁。

其实不止是这个客户有这样的问题,小编刚入职也是傻傻分不清楚,后来还是在咱哲隆机电资深技术工程师培训过后才能正确判断液派克压接头的规格型号。

下面小编告诉大家如何快速识别派克液压接头螺纹尺寸。

首先大家都知道常见的派克液压接头螺纹形式有以下六种:1. NPT/NPTF(美制管螺纹)2. UN/UNF(美制直螺纹)3. 英制锥管螺纹(BSPT) (JIS-PT)4. 英制直管螺纹(BSPP) (JIS-PF)5. 公制锥螺纹6. 公制直螺纹然后记住下面3点:1.螺纹:确定该螺纹是直螺纹还是锥螺纹。

方法:目测或者使用直角尺。

2. 螺距:测量螺距,注意螺距有两种表示方法。

对于公制螺纹来说,螺距是指相邻两个螺纹牙顶之间的距离(如1.5mm);对其他形式的螺纹类型来说,其表示方法是每英寸长度内的螺纹牙数(如每英寸14牙)。

测量螺距可使用螺距规。

使用不同的螺距规,直至找到最合适的,此螺距规上标注的螺距就是所测量螺纹的螺距。

3.螺纹大径:这里我们可以使用卡尺来测量螺纹大径尺寸。

对于直螺纹可以直接测量,而锥螺纹的大径测量第二个螺纹的尺寸。

看到这里相信,大家基本能确定派克管接头的螺纹尺寸,小编整理了一些经验供大家作为参考,美国进口的设备,一般是美制螺纹;欧洲进口的设备,一般是英制螺纹;国内生产的设备,一般是公制或英制螺纹,在管接头螺纹大径相彷,螺距粗的是英制,螺距细的是公制。

如果不想这么费神费力的话,可以联系哲隆机电——我们有最专业的技术工程师为您提供性价比最好的选型;我们有最全的接头库存提供最快的供货速度;当然,最重要的一点就是我们的产品原装正品,质量保证。

您还等什么呢?赶紧拿起电话与我们联系吧!。

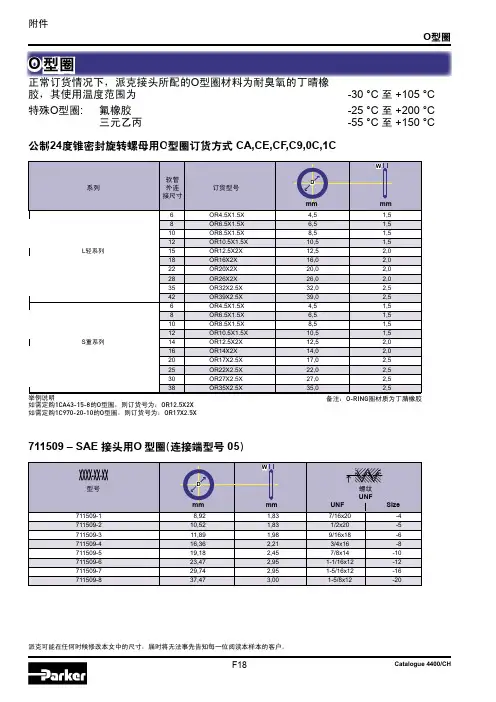

软管接头的确定:确定接头的密封形式螺纹密封O型圈密封配合角度或金属与金属硬密封带O型圈的斜面确定螺纹形式:螺纹规:确定螺距,公制螺纹(螺距),英制螺纹(一英寸【25.4mm】长度内的牙数)测径法:外螺纹(大径),内螺纹(小径)一、德标软管接头:这些接头通常是公制的,采用金属斜面硬密封或金属面带O型圈的弹性密封结构,共有超轻系列,轻系列和重系列三种形式。

密封锥面的角度要么是24°(带或不带O型圈),或者24°/60°内锥。

通常通过测量接头的螺纹及钢管外径来对其进行识别。

1 .DIN超轻系列(LL):内螺纹60°外锥与外螺纹60°紧密的结合在一起,两者都是公制直螺纹。

标准:DIN 20078-31),派克外连接代号:C0DN 螺纹公制外螺纹大径A(mm)内螺纹小径B(mm)20 M30X1.5 30 28.5025 M38X1.5 38 36.5032 M45X1.5 45 43.5040 M52X1.5 52 50.5050 M65X2 65 632 .DIN轻系列(L)及重系列(S)不带O型圈结构:此类60°外锥接头可与24°或60°内锥相配合,三者均为公制直螺纹。

标准:DIN20078-21)已作废,尚无替代标准轻系列外连接端的派克代号:C3,C4,C5,C63 .DIN24°轻系列(L)和重系列(S)带O型圈结构外螺纹接头为公制直螺纹带24°内锥接头,内螺纹接头为公制直螺纹配24°外锥带O型圈结构标准:ISO 12151-2/ISO 8434-1&ISO 8434-4(原DIN20078-4,5,8,9)派克轻系列外连接型号:CA,CE,CF,D0派克重系列外连接型号:C9,0C,1C,D2钢管外径规格公制螺纹内螺纹小径(mm)外螺纹大径(mm)钢管深入高度6 6L M12X1.5 10.5 12 76 6S M14X1.5 12.5 14 78 8L M14X1.5 12.5 14 78 8S M16X1.5 14.5 16 7 10 10L M16X1.5 14.5 16 7 10 10S M18X1.5 16.5 18 7.5 12 12L M18X1.5 16.5 18 7 12 12S M20X1.5 18.5 20 7.514 14S M22X1.5 20.5 22 815 15L M22X1.5 20.5 22 716 16S M24X1.5 22.5 24 8.5 18 18L M26X1.5 24.5 26 7.5 20 20S M30X2 27.9 30 10.5 22 22L M30X2 27.9 30 7.5 25 25S M36X2 33.9 36 1228 28L M36X2 33.9 36 7.530 30S M42X2 39.9 42 13.535 35L M45X2 42.9 45 10.538 38S M52X2 49.9 52 1642 42L M52X2 49.9 52 11二、英制标准管螺纹(BSP)BSP英制管螺纹接头也是采用金属斜面硬密封或金属面带O型圈的弹性密封结构,密封锥面的角度为60°。

★ PARKER液压快速接头

PARKER液压快速接头,是一种即不需要工具又能迅速拆装的管接头,这种接头使用轻巧灵便、密封可靠,适用于液压油、润滑油、水乙二醇等介质。

超高压快速接头压力:700bar、1000bar、1500bar、2000bar、3000bar

超高压软管压力:700bar、1000bar、1800bar、2620bar、2800bar

超高压压力表压力:0--7000bar

通用接头

无溢流型接头

★FASTER快速接头

FASTER拥有最广泛的快换接头选择范围,能和市场上绝大多数工业用快换接头互换。

产品符合 UNI EN ISO9001和UNI ISO/TS 16949标准要求,其设计和制造完全满足性能和质量要求。

FASTER快换接头能用于多种领域:农业机械,工业控制,建筑和工程机械,液压工具,空调和制冷行业,石油化工,海上平台,冶金,汽车等。

尺寸:1/4” - 2”

压力: 最高可达105MPA

连接螺纹: BSP-NPT-JPT-SAE-METRIC

常用工业标准:ISO 7241-1

ISO 7241-2

ISO 16028

HTMA。

派克硬管接头已经获得世界上各种不同机构的认证,如:德国劳氏(GL)英国劳氏(LR)挪威船级社(DNV)美国船级社(ABS)认证通常针对特定的产品、应用领域、工况条件、有效期或其他限制条件。

我们可为不同应用情况提供相应的资料文件。

派克的硬管接头同时也被世界上许多主机设备生产商或最终用户认可。

目 录技术信息认证证书 .................................................................................................................................... B -2简介 ........................................................................................................................................... B -5硬管接头产品及应用概览 ........................................................................................................... B -6PSR 卡套及特点 .........................................................................................................................B-8DPR 不锈钢卡套及特点 ...........................................................................................................B-10EO-2 型接头及特点..................................................................................................................B-11EO2-FORM 型接头及特点 .......................................................................................................B-13O-Lok ® 型接头及特点 ..............................................................................................................B-15如何选择合适的硬管接头产品..................................................................................................B-17硬管接头产品的国际标准 .........................................................................................................B-25推荐使用的钢管 .......................................................................................................................B-26温度的压降影响 .......................................................................................................................B-28表面处理 ..................................................................................................................................B-29介质兼容性表 ...........................................................................................................................B-30安全指南 ..................................................................................................................................B-32装配指南装配流程简介 ...........................................................................................................................B-33EO 卡套接头装配指南 .............................................................................................................B-34EO-2 卡套接头装配指南 ..........................................................................................................B-38EO 安装工具检查.....................................................................................................................B-42EO2-FORM 装配指南 ..............................................................................................................B-43EO2-FROM 安装工具检查 .......................................................................................................B-48O-Lok ® 装配指南 .....................................................................................................................B-49Parflange ® 工具检查及夹具调整..............................................................................................B-52油口端安装指导 .......................................................................................................................B-53目录可调向接头及旋转螺母安装指导 ..............................................................................................B-57法兰连接安装指导....................................................................................................................B-59硬管布管指导 ..........................................................................................................................B-60安装设备KONU 锥面规 ..........................................................................................................................B-62AKL 测距仪 .............................................................................................................................B-63EO-KARRYMAT.......................................................................................................................B-64EOMAT UNI ............................................................................................................................B-65EO2-FORM F3 ........................................................................................................................B-69KARRYFLARE .........................................................................................................................B-72Parflange ® 1025 ......................................................................................................................B-75Parflange ® 50 .........................................................................................................................B-76EO-NIROMINT ........................................................................................................................B-81手动去毛刺工具 .......................................................................................................................B-82电动去毛刺工具 .......................................................................................................................B-82螺纹识别包 ..............................................................................................................................B-82接头产品EO 接头产品目录.....................................................................................................................B-83如何订购EO 接头......................................................................................................................B-87阀 产品目录..............................................................................................................................B-163阀 技术信息 .............................................................................................................................B-165EO 旋转接头 ............................................................................................................................B-187旋转接头技术信息....................................................................................................................B-188O-Lok ® 产品目录 ...................................................................................................................B-200如何订购O-Lok ® 接头 ..............................................................................................................B-203公制钢管信息及订货 ..............................................................................................................B-236钢管管夹概览 ...........................................................................................................................B-240目录作为管路元件供应商,派克一直致力于为您提供一个更高压力,更易安装,无需维护的无泄漏液压系统。

常见快速接头规格型号和选型方法快速接头行业是伴随着工业发展而不断进度的,其接头方法和规格型号是根据需要封堵连接的管件的规格来决定。

快速接头的规格型号分类主要可分为直管、孔接头,凸缘管、扩口管、宝塔管接头,气瓶充装接头和螺纹接头等,具体的选型方法详见如下:一、直管、孔快速接头规格型号和选型直管、孔是指形状为规则的圆形,外壁或内壁光洁的管件,如医用导管、无缝不锈钢钢管、气管等。

在进行快速接头规格型号选型时需要了解:管件内外壁光洁度、工差、内径、外径、可插入深度、操作环境是否有障碍碰撞、测试要求(压力、流体性质、检测方式)等信息。

气动快速接头如上图所示,为气动快速接头分为外包式(接头密封圈部位包裹管件外径)和内胀式(接头密封圈部位深入管件内部),采用气压来驱动。

在接头的尾部设有驱动气孔、测试流体口和固定孔,固定孔是用于对接头进行安装到自动化工装夹具的,从而形成自动化的密封操作。

手动快速接头如上是直管、孔的手动密封方法,采用弯折手柄来实现密封连接和断开,操作简单,密封稳定。

同样分为外包式和内胀式密封方式,其中低压款适用于3Bar以内的气密测试,高压款可使用压力范围真空到70Bar,高压款符合氦检要求。

二、凸缘管、扩口管、燃油管等异型管快速接头选型由于这类管件种类多,规格不确定,在进行相应快速接头确定时需要具体参数进行确定。

管件类型如上图的管件类型,可以用G70系列相应规格型号的接头进行对应。

在选型的时候需要了解凸缘管径、管件直径、凸缘长度、工差、测试要求等信息。

其中油导轨接头是符合J2044标准的,分为自带阀门和不带阀门的(带阀在拔出接头时自动封堵,避免燃油流出)。

还有用于金属软管密封连接的G70非标定制接头。

凸缘管快速接头在新能源车和新能源电池行业水道测试等应用较多,可以很好的替代以往用软管加卡箍的方式。

凸缘管快速接头三、气瓶充装快速接头规格型号气瓶充装快速接头主要用于工业气站的氦气、氮气等惰性气体或医用氧气等气体的充注。

D r y T e c h no l o g yIntroductionProduct selectionUltimate target is to fi nd the “best solution”. This optimumsolution provides high system reliability, easy assemblycharacteristics, low maintenance effort and avoids the useof exotic components.This “best solution” is not the ultimately achieveable tech-nology, but an adequate solution which fulfi ls the require-ments of the individual application with minimum systemcost.The “best solution” looks different depending on the spe-cifi c criteria of the given application.Dry TechnologyModern TFDE fi ttings are designed for high reliability, easyassembly and lowest toal cost performance.These products are marked Dry Technology and indicated greyin selection charts.Parker recommends to select only Dry Technology products forall new designs.Design criteria for fi tting selectionStep 1First clarify all design criteria for the given application orproject.Step 2Then determine the “best solution” product. Use selectioncharts on following pages.Application● Hydraulic● Pneumatic● central lubrication● process industry● severenessAssembly● Mass production● On-site installation● Industrial assembly● Field repairSpecifi cations● International standards●End user specifi cation● approvals● availabilityEnvironment● weather● humidity● Stationary/mobileSpace● Space limitations●T ube bending capabilitiesFlow rate● Volume flow● medium viscosity● System dynamics● T ube selectionMedium●hydraulic oil type● Compressed air● Water/seawater● other fluidsTemperature● Medium● Environment● Operation/standstillPressure● System pressure● Pressure peaksBest solution● zero leakage● high reliability● easy assembly●low total cost● standard products123Material selection: Fitting materialEnvironment● select fi tting material withsuitable corrosion resistanceMedium● select compatible fi tting materialTemperature● check suitability123Material selection: Sealing materialMedium●select compatible fi tting materialTemperature● check suitabilityAssembly●Prefer elastomer sealing for easyassembly and economic service123LL/L/S Series selection for EO fi ttingsPressure● select series with adequatepressure performanceSpace● select series according to available spaceSpecifi cation● prefer L or S series for best availability1234Tube end selectionPressure● select connection type with adequate pressure performance● prefer elastomeric seal for most reliable sealing performanceAssembly● select product with adequate assembly processSpace● select most suitable productSpecifi cation● fi tting type according to project specifi cation1234Tube end selectionPressure● select connection type withadequate pressure● prefer elastomeric seal for most reliable sealing performanceAssembly● select product with adequate assembly processSpace● select most suitable productSpecifi cation● fi tting type according to project specifi cation3512Space● select fl ange typeaccording to available spaceSpecifi cation● select fl ange type according to project specifi cationPressure● select fl ange type connection with adequate pressure performanceApplication● select suitable fl ange type for specifi c applicationFlange type selection12Port/Stud selectionPressure●select connection withadequate pressureperformance Temperature●Use elastomeric sealwhen suitable43Application● select standard connection for specifi c applicationPort/Stud selectionAssembly ● prefer O-Ring/ ED-sealfor easy assembly and economic service ● avoid tapered threads5Port/Stud selectionSpecifi cation● select connection type according to projectspecifi cation● prefer international standards ● select ISO 6149 for new designs12Systematic fi tting selectionOrientable Fitting SelectionPressure ● pre-select orientable fi ttingwith suffi cient pressure performance● prefer elastomeric seal for most reliable sealing performanceFlow Rate● select optimum solution for best fl ow rate and available space34Systematic fi tting selectionOrientable Fitting SelectionSpace● select optimum solution foravailable space and best fl owAssembly● check, if assembly process issuitable5Systematic fi tting selection ApprovalsParker tube fi ttings are recognized by various acceptance or-ganizations, among which are:Germanischer Lloyd (GL)Lloyds Register of Shipping (LR)Det Norske Veritas (DNV)American Bureau of Shipping (ABS)Russian Maritime Register of Shipping (RMS)China Classifi cation Society (CCS)Deutscher Verein des Gas- und Wasserfaches (DVGW)For other applications, Parker tube fittings also approved by diverse national authorities.Numerous original equipment manufacturers and end-users of various industries have approved Parker tube fi ttings.Attention:T ype Approvals usually are limited to certain products, appli-cations, working conditions, validity time or other restrictions. We gladly inform you on your individual application and send out the required documentation.StandardisationSpecifi cation● select fi ttings according tointernational standardisation● check specifi cation of end-customer/end user● consider project-specifi cguidelines●avoid non-standard itemsSystematic fi tting selectionTube Specifi cationsubes with metric outside diametersTGood bendability and weldability.2) T olerance on large tube OD’s not as tight as EO tube.3) Precision tubes for very high pressure hydraulic applications. Tight tolerances for easy handling.Good bendability and weldability.4) T olerance on large tube OD’s not as tight as EO tube.5) Recommended EO standard precision tubes for high pressure hydraulic applications. Tight tolerances (same as steel tubes) for easy handling.Good weldability and corrosion resistance. ( ) = on request6) Recommended EO standard precision tubes for high pressure hydraulic applications. Tight tolerances (same as steel tubes) for easy handling.Good weldability. ( ) = on request7) Common tube, OD. tolerance not as tight as EO tube. Good weldability and corrosion resistance. ( ) = T olerance at 42 mm tube OD is too large8) Common tube, OD. tolerance not as tight as EO tube. ( ) = T olerance at 42 mm tube OD is too large9) Common tube, OD. tolerance not as tight as EO tube. ( ) = T olerance at 42 mm tube OD is too large10) Used in Pneumatic (low pressure) applications. ( ) = Only for tube with smooth outer and inner surface.11) Support sleeve “VH” may be required, e.g. for R250-28x1.5.* = For DPR/PSR/EO-2 systems: thin walled tubes which need a support sleeve require tighter tolerance class T4. T ube O.D. tolerance class D3 is not recommended. D3 may reduce function and capability of the tube connection systems.Systematic fi tting selectionTube Specifi cationsubes with imperial (inch) outside diametersT1) Recommended EO tubes for Hydraulic/Pneumatic applications2) Common tubes in North-America3) Recommended tubes for Hydraulic/Pneumatic applications. Good weldability and corrosion resistance4) T ubes in North-AmericaD r yT ec h n o lo g y Systematic fi tting selectionDry technology versus traditional technologyEO-2 versus bite type+ Elastomeric seal + Suffi ciant seal volume to compensate tube tolerance + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress+ Clear hit-home-feel at assembly + Easy assembly check+ Integrated preassembly tool + No stress of inner cone of fi tting body + No wear of preassembly tools+ Direct assembly of stainless steel tubes possible (EO-2)+ No galling of stainless steel threads+ Existing tools and EOMA T machines can be used for effi cient assembly (EO-2)+ All parts integrated in Functional Nut (EO-2)+ No confusion of individual ferrules + Less handling effort+ Unlimited repeated assembly + Seal can be individually replaced+ ISO-standardised (DIN EN ISO 8434-1)+ Million times proven product since 1993 (EO-2)+ Interchangeable with EO Progressive Ring (EO-2)– Higher component cost than traditional bite-type fi ttings + Low total cost+ Best value for end user + Mandatory specifi ed from various industries, such as:automotive production, injection molding, mobile equipment, shipbuilding and offshore exploration+ Globally gaining popularityBite typeEO-2Fitting selection summaryT raditional bite-type fi ttings have been originally devel-oped and designed for operating conditions of fl uidpowersystems completely different from todays and future mar-ket requirements.New products and improved assembly technologies have been developed and introduced by Parker to fulfi ll todays and future requirements of the operators of fl uidpower equipment. This new tube fi tting generation and the ac-cording assembly methods are classifi ed as Dry Technology . All qualifying products are explicitly Dry Technology -labelled throughout this catalogue.For all new designs of ● hydraulic systems ● pneumatic systems,● coolant systems,● lubrication systems and ● sprinkler systemsonly Dry Technology -classifi ed components should be se-lected.Dr yT e c h n o lo g y Dr yT e c hn o l o g y Systematic fi tting selectionO-Lok ® versus traditional Triple-Lok ®+ Higher pressure resistance than T riple-Lok ®+ Elastomeric seal + Suffi ciant seal volume to compensate tube tolerance + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress+ Clear hit-home-feel at assembly + Easy assembly check + Easy installation of fl at-face components + Superior vibration resistance+ Parfl ange ® orbital flanging technology + Unlimited repeated assembly + Seal can be individually replaced+ ISO-standardised (DIN EN ISO 8434-2)+ Million times proven product– Higher component cost than T riple-Lok ®– Parfl ange ® machine required + braze sleeves can be used for fi eld repair + Low total cost+ Best value for end user + Mandatory specifi ed from various industries, such as:agricultural equipment, mobile construction machines, injec-tion molding+ Globally gaining popularityEO2-FORM versus traditional Weld nipple+ Safe, form-fi t connection + Easy assembly process+ trouble-free with zinc-plated tube + Elastomeric seal + Suffi ciant seal volume to compensate tube tolerance + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress+ Clear hit-home-feel at assembly + Easy assembly check + Easy tube preparation + Easy quality inspection + No rework of welding+ Use of existing EO-2 seals + Unlimited repeated assembly + Seal can be individually replaced+ ISO-standardised (DIN EN ISO 8434-1/-4)+ Basic product EO-2 is million times proven+ Interchangeable with EO Progressive Ring (EO-2)+ No new or additional components required– Higher component cost than traditional bite-type fi ttings – EO2-FORM machine required + EO-2 can be used for fi eld repair + Low total cost+ Best value for end user+ Approved for application in hydraulic presses, injection mold-ing, lifts, waterlocks and shipbuilding + Globally gaining popularityTriple-Lok ®O-Lok ®Weld nippleEO2-FORMDr yT e c h no lo g y r yT e c hn o l o g y Systematic fi tting selectionSwivel adjustable versus traditional standpipe+ Elastomeric seal + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress+ Superior pressure rating + High mechanical strength+ No blow-out at incomplete assembly + Easy fi tting installation+ No stress of inner cone of fi tting body + No wear of preassembly tools + Unlimited repeated assembly + Seal can be individually replaced+ ISO-standardised (DIN EN ISO 8434-1/-4)+ Milliontimes proven product since 1970+ Interchangeable with EO standpipe fi ttings– Higher component cost than traditional standpipe fi ttings + Low total cost+ Best value for end user + Mandatory specifi ed from various industries, such as:automotive production, injection molding, mobile equipment, shipbuilding and offshore exploration+ Most frequently used and still gaining popularityMale stud with Eolastic or O-ring seal versus traditional Metal sealt apered thread + Elastomeric seal + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress+ Superior pressure rating+ Clear hit-home-feel at assembly + No damage to port surface+ Assembly and performance almost independant of port material + Low assembly torques+ No metal sealing edge which may be damaged at transport or handling + Unlimited repeated assembly + Seal can be individually replaced+ ISO-standardised (ISO 1179/ISO 6149/DIN ISO 6149)+ Million times proven product since 1964+ Interchangeable with traditional fi ttings + Wider product range and better availability– Higher component cost than traditional bite-type fi ttings + Low total cost+ Best value for end user + Mandatory specifi ed from various industries, such as:automotive production, injection molding, mobile equipment, shipbuilding and offshore exploration+ Most frequently used and still gaining popularityStandpipeswivelMetal sealED-sealtaperO-ringD ry Te c h no lo g y Dr yT e c h n o lo gy Systematic fi tting selectionLocknut Adjustables versus tapered thread + Elastomeric seal + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress + Good fl ow characteristic + 360° orientable+ More compact than swivel orientable combination + No additional sealant required + Clear hit-home-feel at assembly + No damage to port surface+ Assembly and performance almost independant of port material + Low assembly torques+ Unlimited repeated assembly + Seal can be individually replaced + Interchangeable with traditional fi ttings+ Available in 90°, 45° elbow, T - and Run-T -confi guration – Machined spot surface required + Lower price than Banjo fi ttings + Low total cost+ Best value for end user + Globally gaining popularityHigh pressure banjo versus traditional low pressure elbow+ Elastomeric seal + High degree of fi ne sealing+ Long-term reliability without retightening + No air ingress + 360° orientable + Compact design+ Suitable for high pressure applications + Matching small spot surface + Clear hit-home-feel at assembly + No damage to port surface+ Assembly and performance almost independant of port material + Seal does not fall off+ Only one hollow bolt needs to be tightened + No hidden screw+ Unlimited repeated assembly + Seal can be individually replaced+ Million times proven product since 1980+ Interchangeable with traditional fi ttings + Available in 90°elbow and T -confi guration – Slight fl ow restriction + Low total cost+ Best value for end user + Globally gaining popularitytaperLocknutLow pressureHigh pressureErmetoOriginal Performance dataFormula:(100%–20fitting 200C PN °=×400100bar %%)=320bar 62(100%–t 200CPN ube bar °=×3100%21,5%)=284barPressure ratingPressure reductions and temperaturesRequired pressure reductions (dependant on the material) with reference to the catalogue pressures for higher temperatures. Both metal fitting material and elastomeric sealing compound have to be selected according to the temperature range of the system.Attention: Fluid Compatibility see page C5.Perbunan = registered trademark of Bayer 1) 35% (if not extra shown in PN-Column “MS” for Brass)2) EPDM is not compatible with oil (not nor-mally held in Stock)Calculation example:PN fitting 16S/71 = 400 bar T emperature = 200°C Material = Stainless steelPressure reduction fittings = 20%Pressure reduction tubes = 21,5%PN tube 16 w 2.5/71, DIN 2413 III = 362 barNominal pressure PNThe Nominal pressure PN is a figure relating to the pressure rat-ing of a fluid component for continuous dynamic applications. It is rounded to correspond to internationally standardised ratings. Logical series of fittings are grouped together, with the nominal pressure of the group being that of the “lowest common denomi-nator” within the group.Internationally, these nominal pressures are recognised and serve to match common sizes of components together. Parker tube fittings meet or exceed common standardised pressure rat-ings.T o prove the long term dynamic load resistance, components are tested under pressure impulse conditions of PN × 1.33, at 1Hz for 1 million cycles. Static test burst pressures are at least 4 times the PN value.Exception: for ball valves the static test burst pressures are at least 1.5 times the PN value according to DIN 3230 T5 and ISO5108.Permissible operating temperatureAmbient temperature of hydraulic and pneumatic applications Temperature not permissibleSealings NBR e.g. N552-90, Perbunan (registered trademark of Bayer) FKM e.g. V894-90EPDM e.g. E540-80PTFE e.g. T eflon® (registered trademark of DuPont)POM e.g. Delrin (registered trademark of DuPont)MaterialsFittings Raw materialMaterialFitting typeEO O-Lok®Triple-Lok®Designation2)MaterialNo.Standard USDesignation2)Bodies Nuts Ferrules WeldfittingsBodies Nuts Sleeves Bodies Nuts SleevesSteel Barstock 11SMnPb30 1.0718 DINEN10277-3SAE 12L14X X X X X Free cuttingsteel11SMn30 1.0715 DINEN10277-3SAE 1213X46S20 1.0727DINEN10277-3SAE 1146XForgings15S10 1.0710DIN 1651XFree cuttingsteel11SMn30modified1.0715 DINEN10087SAE 1213modified X X 36SMn14 1.0764 DINEN10087XC45 modified 1.0503 DIN EN10083SAE 1045modified X X X ExtrusionsteelC10C 1.0214 DIN EN SAE C1010X X X X X WeldablesteelC15 1.0401DIN10277-3XOther Steel at the manufacturers discretion special heat treated X XStainless steel Barstock X6CrNiMoTi17-12-21.4571 DINEN10088ANSI 316TIX X XX2CrNiMo17-13-21.4404 DINEN10088ANSI 316LX X X X X X Forgings X6CrNiMoTi17-12-21.4571 DINEN10088ANSI 316TIX X XX5CrNiMo17-12-21.4401 DINEN10088ANSI 316X X X X X X Other Stainless steel at the manufacturers discretion special heat treated XBrass Barstock CuZn35Ni2 2.0540 DIN17660X X XASTMB16/B453CA360/345X X X X X X Forgings CuZn35Ni2 2.0540 DIN17660XASTMB124CA377X X1) Non standard fitting types like e.g. banjo fittings, rotary fittings, adjustable fittings with locknut and flanges might be made from different materials.2) Equivalent materials may be usedForging: 11 SMn 30+Bi (similar to 1.0715/DIN EN 10087)Straight: 11 SMn Pb30 (1.0718/DIN EN 102773)Surface treatmentParker tube fittings from steel are delivered worldwide with a high quality surface protection:Galvanic zinc plated and bright passivated with special sealer (suffix CF).Why zinc plated?The requirements for corrosion resistance of tube fittings have been increasing in the past few years. Increasingly tube systems are not painted. Higher demands are re-quested also for an aesthetic point of view.The traditional black-grey surface “phosphated and oiled” (Znphr5f – DIN 50942) used for tube connections in the past does not longer meet these demands. An galvanized deposit zinc layer offers the following advantages: The cor-rosion resistance increases significantly due to a plating of min. 8 R and additional sealing by chromating process. In case of scratches or nicks – which are unavoidable d uring assembly – zinc develops a cathodical protection of the steel fitting body against localised corrosion and abrasion.The corrosion resistance of the CF surface is 400% above zinc plated surfaces to meet highest requirements. The CF surface is also Cr(VI)-free to avoid any contamination in the manufacturing process and meets current regulations e.g. European “End of Life Vehicles“ directive.The silver bright colour due to the chromating or passiva-tion process offers an attractive appearance.All major TFDE manufacturing locations are equipped with their own modern galvanic plants. The process control is specially orientated to the tube fitting product.The users of Parker fittings benefit from:– homogeneous thickness of plating (average 13 μm), measured on outside contour for good screwable threads– high quality above-average concerning avoidance of nicks– very good corrosion resistanceContinuous corrosion tests like salt spray tests according to ISO 9227/5% NaCI show an average resistance of 500 hr in contrast to white rust and 700 hr in contrast to red rust for CF surfaces.Particular fitting series or fitting components and valves are delivered with other or modified surfaces for functional reasons or for better differentiation.Surface protection/SurfaceMaterial Fittingsystem Fitting type CF/Cr3*Zinc platedbrightpassivatedCF+ GlidecoatingA3KZinc platedbrightpassivatedZnphr5fblackphosphatedPlainno coatingPlain+ GlidecoatingPlain+ InsidesilverSteel EO-2Fitting bodies XFunctional nuts XEO Fitting bodies XNuts XProgressive stop rings XWeld fittings X EO2-FORM Bodies and nuts from EO are usedO-Lok®Fitting bodies XNuts XParflange® sleeves XBrazing sleeves X Triple-Lok®Fitting bodies XNuts XSleeves XStainless steel EO-2Fitting bodies XFunctional nutsup to 12-L/10-SXFunctional nutsfrom 15-L/12-S XA3K according to DIN EN ISO 4042 / Znphr5f according to DIN EN ISO 3892 and DIN 50942O-Lok and Triple-Lok parts are plated Cr3 and conform to FC-F01 specification, 120 hours to white rust, 240 hours to red rust.Fluid compatibilityBoth metal fitting material and elastomeric seal compound have to be selected according to the fluid used.Standard recommendations for static seals based on experience and sealing compound manufacturers specification. For use of sealing compounds that are used for dynamic seals like rotary fittings or non-return-valves, see note at end of table.Surface protection/SurfaceMaterial Fitting system Fitting typeCF/Cr3* Zinc plated bright passivatedCF + Glide coatingA3KZinc plated bright passivatedZnphr5f blackphosphatedPlainno coatingPlain + Glide coatingPlain + Inside silverStainless steelEOFitting bodiesXNuts up to 12-L/10-S XNuts from 15-L/12-S XProgressive ringsXEO2-FORM Bodies and nuts from EO are used O-Lok ®Fitting bodies X Nuts X SleevesX Triple-Lok ®Fitting bodies X Nuts X SleevesX Brass All systemsFitting bodies X NutsX Sleeves & ferrulesXFitting material Sealing materialFluid Steel Stainless steelBrass NBR FKM EPDM Acetone 211331Acetylene 213332Air (oil free)111111Ammonia liquid 213231Ammonia gas, cold 113131Animal oils (Lard oil)222112Aral, Vitam BAF 11X 113Argon 111111Asphalt313213ASTM-Oil, no. 1111113ASTM-Oil, no. 2111113ASTM-Oil, no. 3111113ASTM-Oil, no. 4111213ATF oil111113Automotive brake fluid 111331Benzene111313Brine (sodium chloride)X 2X 111Butane113113Carbon bisulphide 11331X Carbon dioxide 111121Carbon oxide111111Castrol, Biotec HVX 11X 113Chlorine (dry)31331X Compressed air 111111Crude oil 213213Fitting material Sealing materialFluid Steel Stainless steel Brass NBR FKM EPDM Cutting oil11X131 DEA, Econa E2211X1X3 DEA, Econa E4611X1X3 Diesel fuel111113 ECOOL11X11X ESSO, Univis 1311X113 ESSO, Univis 2611X113 ESSO, Univis 3211X113 ESSO, Univis 4611X113 Ethanol (Ethylacohol)111131 Ether111332 FINA, Biohydran RS 3811X113 Flue gas31332X FRAGOL, Hydrolub 12511X1X3 Freon 11X X1223 Freon 12131213 Freon 22311323 Gasoline211213 Gas, liquid propane (LPG)111113 Glycerine212111 Glycol (Ethylenglykol)112111 Heating fuel oil111113 Helium111111 Houghton Safe 112011X311 Houghton Safe 62011X121 Hydrochlorid acid323312 Hydrogen31X333 Hydrogen peroxide313312 Hydrolube111111 Iodine313212 Kerosene111113 Lubricating oil SAE 10,20,30,40,50111113 Methane111113 Methanol111131 MIL-F-8192 (JP-9)111313 MIL-H-5606111113 MIL-H-6083111113 MIL-H-7083111121 MIL-H-8446 (MLO-8515)112213 MIL-L-2104 & 2104B111113 MIL-L-7808213213 Mineral oil111113 Natural gas112113 Natural gas, untreated321)3333 Natural mineral oil113213 Neon311111 Nitric acid313323 Nitrogen111111 Oil113113 Oxygen (gas, cold)312333 Ozone113311 Petrolatum111113 Petroleum oil111113 Phosphoric acid331312 Plantohyd 32 S11X1X3 Plantohyd 40 N11X113 Propane111113R134A111331Applicability: 1 = satisfactory NBR = e.g. Perbunan (registered trademark of Bayer)2 = fair FKM3 = not recommended X = unsufficiant data1) Untreated natural gas requires stainless steel with reduced material hardness.2) Brass is resistant against crack under normal circumstances. If overloaded (e.g. by overassembly) the resistance especially against ammo-niac and nitric derivatives can be negatively influenced. This might cause the defect of the connection.This fluid compatibility chart is only applicable on so called “static seals”, such as O-rings and profile sealing rings (e.g. ED-seal, DOZ-seal) in tube fitting and flange systems.For fluid compatibility data of valves, rotary fittings or other multi-function components please review the relevant product pages.Fitting material Sealing materialFluidSteel Stainless steelBrass NBR FKM EPDM Sea Water323111SHELL, Naturelle HF-E-4611X 113SHELL, Tellus Oil DO 3211X 113Silicone oil 11X 111Skydrol 500113331Skydrol 7000113321Soap solutions 313111Steam212331Stoddard solvent 112113Sulphur dioxide 313331Sulphuric acid 323313T oluol111323T ransmission fluid 111113T richlorethane 21X 313Turpentine 213113Water 2112)121Xylol 111313Biodegradable oilsDue to environmental concerns and new legislation bio-degradable oils are rapidly gaining importance for both mobile and stationary applications. The usage of non-in-flammable fluids will remain limited to special applications like mining, steel mills and heavy machines.MediaBiodegradable oils can be classified into 3 categories: HEPG (Glycol based fluids)+ Wide temperature range (–45°C … 100°C)+ Very stable against ageing+ NBR and FKM seals are compatible+ Moderate viscosity change with temperature+ Water soluble– Not mixable with mineral oils or HEES, HETG types– Careful flushing recommended when changing from mineral oil– Paints can be dissolved– Care required with material compatibility(e.g. do not use any zinc containing materials)– Density > 1,100 kg/m3 possible design changes– Price?HETG (Vegetable-based fluids)+ Mixable with mineral oils+ Normal sealing material are compatible(e.g. NBR or FKM)+ Good lubricating properties+ Paint resistant to fluid+ Viscosity changes with temperature are moderate– Limited temperature range (–25°C to +70°C)– Max. temperature not to be exceeded– Limited lifetime– UV and ozone sensitive– Beware of water take-up (cracking?)– Price?HEES (Synthetic ester based fluids)+ Wide temperature range(–30°C … +90°C or over 100°C with some variants)+ Good lifetime+ Mixable with mineral oils+ Normal sealing materials compatible(FKM and NBR recommended)+ Machine paints resistant to fluid+ Viscosity changes with temperature are moderate+ Good lubricating properties– Danger of hydrolysis with water take-up(filters, dryer, occlusion)– Price?CompatibilityGenerally, TFDE steel fittings with standard NBR seals aresuitable for most applications.Suitable sealing compoundsExperience shows that media compatibility is not a critical issue for static seals used on tube fittings. In doubt p lease contact TFDE application engineering.Pragmatic approachIf there is doubt about switching over to softseal fitting s ystems (ISO6149/Eolastic/O-Lok®/EO-2), it might be a good idea to have a close look on the existing hydraulic system. If NBR seals perform well on hoses, cylinders, valves or filters there is nothing to worry about standard TFDE fittings. Usually the design engineers know when special seal compounds like FKM have to be used.。

软管接头的确定:

确定接头的密封形式

螺纹密封

O型圈密封

配合角度或金属与金属硬密封带O型圈的斜面

确定螺纹形式:

螺纹规:确定螺距,公制螺纹(螺距),英制螺纹(一英寸【25.4mm】长度内的牙数)

测径法:外螺纹(大径),内螺纹(小径)

一、德标软管接头:

这些接头通常是公制的,采用金属斜面硬密封或金属面带O型圈的弹性密封结构,共有超轻系列,轻系列和重系列三种形式。

密封锥面的角度要么是24°(带或不带O型圈),或者24°/60°内锥。

通常通过测量接头的螺纹及钢管外径来对其进行识别。

1 .DIN超轻系列(LL):

内螺纹60°外锥与外螺纹60°紧密的结合在一起,两者都是公制直螺纹。

标准:DIN 20078-31),

派克外连接代号:C0

DN 螺纹公制外螺纹大径A

(mm)内螺纹小径B (mm)

20 M30X1.5 30 28.50

25 M38X1.5 38 36.50

32 M45X1.5 45 43.50

40 M52X1.5 52 50.50

50 M65X2 65 63

2 .DIN轻系列(L)及重系列(S)不带O型圈结构:

此类60°外锥接头可与24°或60°内锥相配合,三者均为公制直螺纹。

标准:DIN20078-21)已作废,尚无替代标准

轻系列外连接端的派克代号:C3,C4,C5,C6

3 .DIN24°轻系列(L)和重系列(S)带O型圈结构

外螺纹接头为公制直螺纹带24°内锥接头,内螺纹接头为公制直螺纹配24°外锥带O型圈结构

标准:ISO 12151-2/ISO 8434-1&ISO 8434-4(原DIN20078-4,5,8,9)

派克轻系列外连接型号:CA,CE,CF,D0

派克重系列外连接型号:C9,0C,1C,D2

二、英制标准管螺纹(BSP)

BSP英制管螺纹接头也是采用金属斜面硬密封或金属面带O型圈的弹性密封结构,密封锥面的角度为60°。

BSP英制螺纹有两种最常用的型式:英制标准直管螺纹(BSPP)和英制标准锥螺纹(BSPT)。

通过测量螺纹的大径和每英寸(25.4mm)的螺牙数来识别英制标准管螺纹。

1 .BSPP金属与金属斜面硬密封标准

标准:BS5200

派克外连接型号:92,B1,B2,B4,D9

2 .BSPP带O型圈软密封

标准:ISO 12151-62)

派克外连接型号:EA,EB,EC,EE,D9

3 .BSPT:接头通过螺纹齿面互锁来密封

注意区别BSPT螺纹和NPTF螺纹,BSPT螺纹的牙型角为55°而NPTF 螺纹的牙型角为60°。

派克外连接型号:91

4 .BSP平面密封

这些接头采用BSP直管螺纹,密封型式为平面密封。

此类接头通过平面与带平面O型圈的外螺纹接头顶在一起来密封。

派克连接型号:B5,B6,B7。