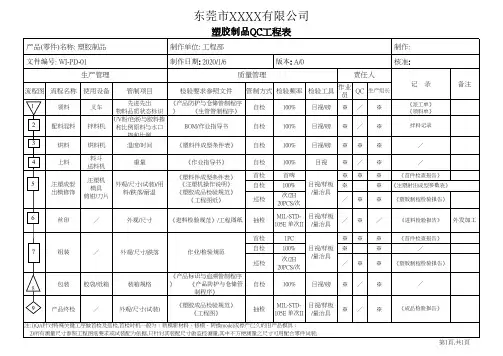

注塑QC流程图

- 格式:doc

- 大小:70.00 KB

- 文档页数:2

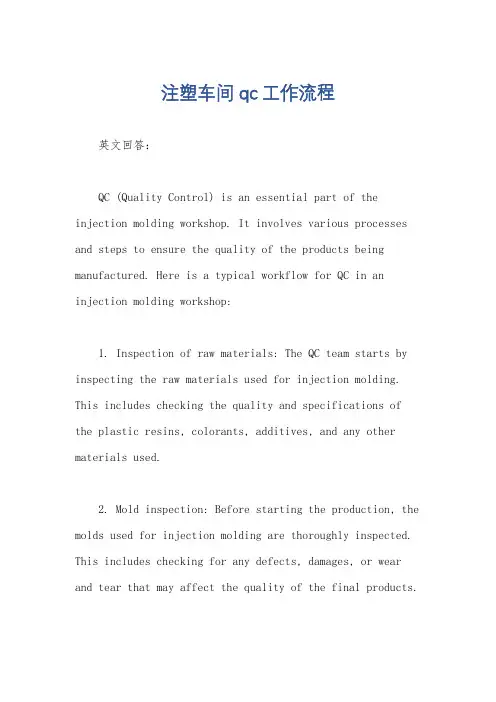

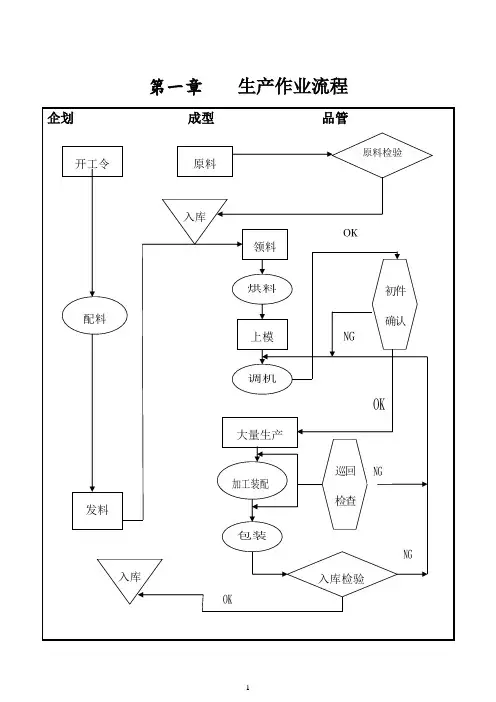

注塑车间qc工作流程英文回答:QC (Quality Control) is an essential part of the injection molding workshop. It involves various processes and steps to ensure the quality of the products being manufactured. Here is a typical workflow for QC in an injection molding workshop:1. Inspection of raw materials: The QC team starts by inspecting the raw materials used for injection molding. This includes checking the quality and specifications of the plastic resins, colorants, additives, and any other materials used.2. Mold inspection: Before starting the production, the molds used for injection molding are thoroughly inspected. This includes checking for any defects, damages, or wear and tear that may affect the quality of the final products.3. First article inspection: Once the production starts, the QC team conducts a first article inspection. This involves inspecting the first few parts produced to ensure that they meet the required specifications and quality standards.4. In-process inspection: During the production process, the QC team performs regular inspections to check thequality of the products at different stages. This helps in identifying any defects or issues early on and taking corrective measures.5. Dimensional inspection: The QC team conducts dimensional inspections to ensure that the products meetthe required dimensions and tolerances. This is done using measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM).6. Visual inspection: Visual inspection is another important aspect of QC in injection molding. The QC team visually inspects the products for any cosmetic defects, such as scratches, dents, or discoloration.7. Functionality testing: Depending on the product requirements, functionality testing may be performed. This involves testing the products to ensure that they function as intended and meet the performance criteria.8. Final inspection: Once the production is complete, a final inspection is conducted to ensure that the products meet all the required specifications and quality standards. This includes checking for any defects, damages, or issues that may have occurred during the production process.9. Documentation and reporting: Throughout the QC process, detailed documentation is maintained, including inspection reports, test results, and any corrective actions taken. This helps in tracking the quality performance and identifying any recurring issues.中文回答:注塑车间的质量控制(QC)是非常重要的环节。

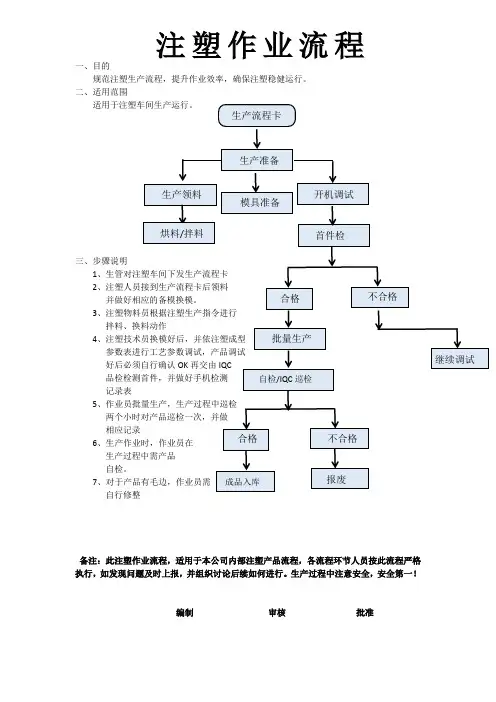

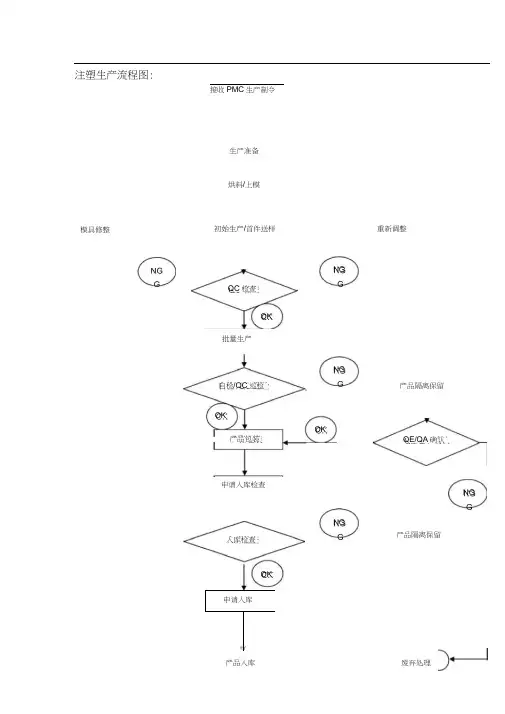

注塑生产流程图:

接收PMC 生产制令

生产准备

烘料/上模

模具修整 初始生产/首件送样 重新调整

QC 检查

OK

批量生产

NG

OK

OK

申请入库检查

自检/QC 巡检

NG

产品隔离保留

产品包装

QE/QA 确认

OK

入库检查

NG

NG

产品隔离保留

申请入库

理 f

产品入库

废弃处理

材料使用记录 材料干燥记录 成型条件参数表 模具状态票 模具装卸记录 样品送样单 成型条件日常点检表 设备日常点检表 注塑生产记录 构成 LOT NO 如:

06 (年) 04(月) 10(日) 112(机器) 01(编号) 入

库记录表

入库反检记录表 产品废弃记录表

用到的表格有

001。

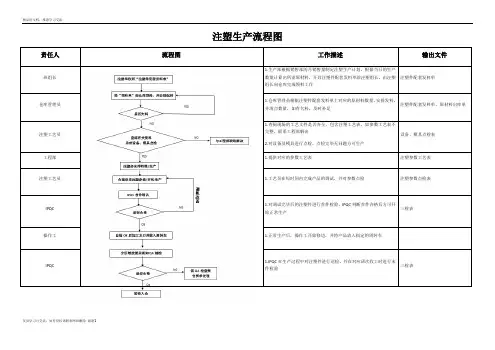

注塑生产流程图责任人流程图工作描述输出文件班组长1.生产部根据销售部的月销售量制定注塑生产计划,根据当日的生产数量计算出所需原材料,开具注塑件配套发料单给注塑组长,由注塑组长向仓库完成领料工作注塑件配套发料单仓库管理员1.仓库管理员根据注塑件配套发料单上对应的原材料数量,安排发料,并清点数量,如有欠料,及时补足注塑件配套发料单,原材料出库单注塑工艺员1.查阅现场的工艺文件是否齐全,包含注塑工艺表,如参数工艺表不完整,联系工程部解决2.对设备及模具进行点检,点检完毕无问题方可生产设备、模具点检表工程部 1.提供对应的参数工艺表注塑参数工艺表注塑工艺员 1.工艺员在短时间内完成产品的调试,并对参数点检注塑参数点检表IPQC 1.对调试完毕后的注塑件进行首件检验,IPQC判断首件合格后方可开始正常生产三检表操作工 1.正常生产后,操作工开始修边,并将产品放入指定的周转车IPQC 1.IPQC在生产过程中对注塑件进行巡检,并在对应班次收工时进行末件检验三检表范例:Good afternoon. I am glad to be here for this interview. First let me introduce myself to you. My name is XXX, and I am XXX years old. I come from the city of XXX, XXX province. I graduated from XXX University in July, 20XX, and I majored in XXX (such as Computer science and technology).In past XXX years, I worked in XXX Company as XXX engineer. I have XXX years’ experience in XXX (Java/.Net) development. Now I'd like to find a job which is more challenging. Moreover HP is a global company, so I feel I can gain the most from working in this kind of company environment. That is the reason why I come here for this position.I think I'm a good team player and I'm a person of great honesty to others. Also I am able to work under great pressure.That’s all. Thank you for giving me the chance.请根据你的实际情况替换范例中XXX部分(Please replace XXX part of the model with your actual information).常见问题对答:Interviewer:I面试官;Applicant:A求职者1.Major(专业)I:What is your major?(你的专业是什么?)A:My major is computer science and technology. I am very interested in software development.pany(公司)I:Which company are you in now?(你现在在哪家公司工作?)A:Now I am working in XXX Company as XXX engineer.3.Experience(经验/经历)I:Have you any work/project experience in this field?(你在这个领域有工作或项目经验吗?)A:Yes. I have XXX years’ experience in XXX development/testing. …… (工作经验丰富)A:Yes, I have several months experience, notvery sufficient. But I believe I can study it in project step by step. (有些经验);A:I haven’t been involved in this kind of big project before. But I have studied this course in the International Business Training Center of the XXX Company.(没有经验);4.Weakness(缺点)I:What is your major weaknesses?A:I’m afraid I’m a poor talker. I’m not comfortable talking with the people whom I have just met for the first time. That is not very good for business so I am studying public speaking.A:I’m not very confident when I face many unfamiliar people/issue.5.Strengths优点/特长。

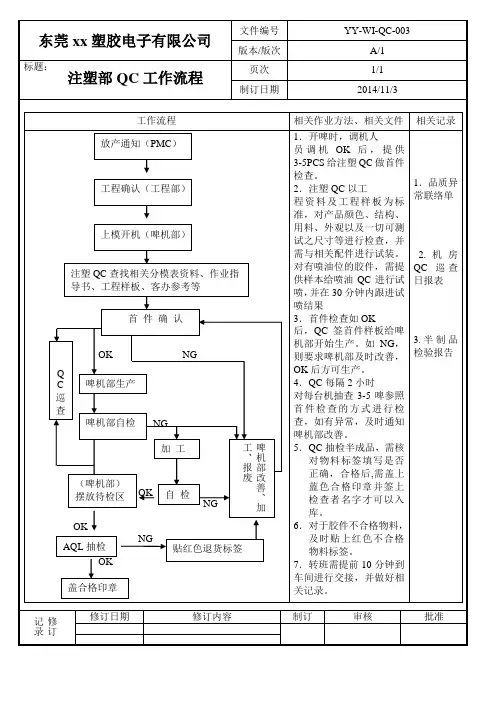

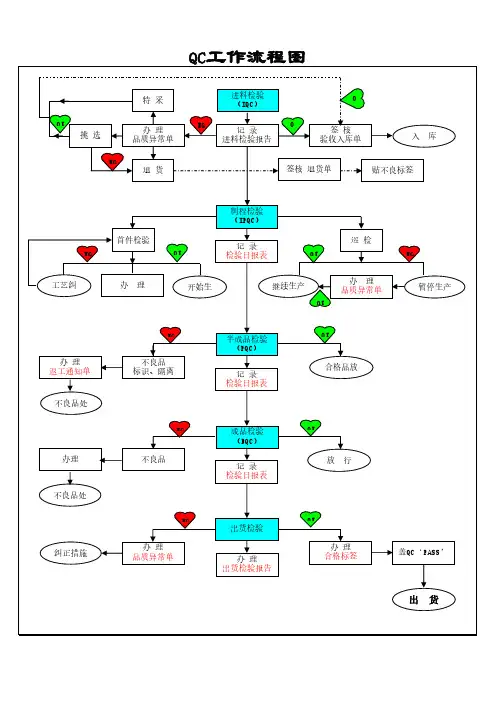

注塑QC工作流程注塑QC工作流程1目的为了确保对注塑产品质量有影响的各工序按规范作业,以保证这些检验处于受控状态。

保证产品的制造过程满足客户的需求,确保产品质量满足客户要求。

2范围适用于注塑产品生产过程中的质量各检验工序控制。

3职责1QE负责注塑原辅料、在制品和成品的检验和监督,及时向生产部门反馈质量情况品检员负责按客户要求或相应的工艺文件进行注塑过程的产品质量控制及对当班的注塑产品出货前全面检查3检验中如有疑问及争执,须由QE或品质主管协调处理。

4工作程序1过程的实施;1注塑生产过程中,作业员做好自检,检验产品的外观,品检员做好开机产品的首件并填写《注塑首(末)件确认单》,做好开机首检封样,同时做好生产产品抽检工作,并填写《注塑巡检记录表》,巡检要求操作工对自检不合格的产品进行返工,并对返工产品进行记录和标示,并对返工产品进行复查,直至达到产品质量要求。

2对产品的放行执行《过程和产品的测量和监控管理程序》的有关规定,对出现的不合格品执行《不合格品的管理程序》。

3巡检员巡检产品检验控制按《注塑件的检验规范》要求进行判定执行。

4过程中环境的控制1注塑的成品、半成品、合格和不合格品等,应按规定的区域整齐放置,并按《标识和可追溯性管理程序》的规定进行标识,检验员并有权对过程进行控制和协调。

2过程监督1过程的测量和监控是监督和控制质量的重要手段和方法,操作人员的自检和巡检员的检验的目的是监督和控制生产过程中的质量和过程效果。

按《过程和产品的测量和监控管理程序》实施,并填写相应的检验记录。

2各注塑工段完成后合格后巡检在《产品生产流程卡》上签名,才能转入下一道工序。

3品质部按《培训、意识和能力的管理程序》对检验各工序相关人员进行岗位培训,特殊过程的人员应经过专门的培训,经考核合格后上岗,品控人员的合理配置。

3过程的改进1品控人员发现的问题应及时纠正,进行分析、找出改进的方法,并按《纠正和预防措施控制程序》实施。

注塑QC工作流程注塑QC工作流程注塑QC工作流程1目的为了确保对注塑产品质量有影响的各工序按规范作业,以保证这些检验处于受控状态。

保证产品的制造过程满足客户的需求,确保产品质量满足客户要求。

2范围适用于注塑产品生产过程中的质量各检验工序控制。

3职责3.1QE负责注塑原辅料、在制品和成品的检验和监督,及时向生产部门反馈质量情况3.2.品检员负责按客户要求或相应的工艺文件进行注塑过程的产品质量控制及对当班的注塑产品出货前全面检查3.3检验中如有疑问及争执,须由QE或品质主管协调处理。

4工作程序4.1过程的实施;4.1.1注塑生产过程中,作业员做好自检,检验产品的外观,品检员做好开机产品的首件并填写《注塑首(末)件确认单》,做好开机首检封样,同时做好生产产品抽检工作,并填写《注塑巡检记录表》,巡检要求操作工对自检不合格的产品进行返工,并对返工产品进行记录和标示,并对返工产品进行复查,直至达到产品质量要求。

4.1.2对产品的放行执行《过程和产品的测量和监控管理程序》的有关规定,对出现的不合格品执行《不合格品的管理程序》。

4.1.3巡检员巡检产品检验控制按《注塑件的检验规范》要求进行判定执行。

4.1.4过程中环境的控制4.1.4.1注塑的成品、半成品、合格和不合格品等,应按规定的区域整齐放置,并按《标识和可追溯性管理程序》的规定进行标识,检验员并有权对过程进行控制和协调。

4.2过程监督4.2.1过程的测量和监控是监督和控制质量的重要手段和方法,操作人员的自检和巡检员的检验的目的是监督和控制生产过程中的质量和过程效果。

按《过程和产品的测量和监控管理程序》实施,并填写相应的检验记录。

4.2.2各注塑工段完成后合格后巡检在《产品生产流程卡》上签名,才能转入下一道工序。

4.2.3品质部按《培训、意识和能力的管理程序》对检验各工序相关人员进行岗位培训,特殊过程的人员应经过专门的培训,经考核合格后上岗,品控人员的合理配置。

彩丽电子(深圳)有限公司质 量 文 件文件编码: 修改状态:0/A注塑QC 巡查检验流程第 1 页,共 1 页流程图作业内容1.啤件检查1.1每2小时注塑QC 需到机台取6See 啤件在外观、结构颜色等方面与首件进行核对并作一些机台简单试装;1.2对一些结构可疑性大且机台试装无法完成可交办LAB 测试;1.3检查结果有异常时,第一时间知会生产负责人,若大问题需报备领班,并跟进改善情况直至OK ; 1.4改善后需检查己做出的啤件品质有否异常。

2.相关项检查 2.1模具2.1.1观察啤件出模是否正常,留意啤件因出模不顺导致啤件翘曲及断内针等;2.1.2检查模具温度是否高低孔或顶裂,运水通畅情况,防止啤件因模温度过高导致啤件冷却不好而变形或拖胶或模温度低导致流级和表面无花; 2.2塑胶料2.2.1检查塑胶料是否有不同胶料品种等混现象,确定是否可混或混用后对料性的影响;2.2.2检查塑胶料水口回用比例与工程要求有否差别,有差别有否合格证明,无则交LAB 测试; 2.3工艺2.3.1检查机台工艺参数是否为确定OK(首件)之参数,有调动是否有确认OK ;2.3.2一些需工装夹具泡水的是否正确使用,使用效果如何;2.3.3检查需加工位的效果,脱模剂使用,油漆件表面水口加工;2.3.4检查有异常及时知会生产负责人并跟进改善OK ;3.把以上检查结果记录于工序巡查记录表,交生产签名确认;4.完成以上步骤,一轮巡查工作完成,等待下一轮巡查编写:审核:批准: 日期:异常记录正常生产LAB测 试无法检测出 与工程差别大 QC 改 善效果 验 证生产负责人机台简单试装目测结构颜色检查外观检查加工位效果水口回用比例检查塑胶料制检查模具温度运水检查模具出模情况夹具加工工艺机台工艺参数OK车间生产现场 QC 取机台啤件6See2小时OK异常。