特斯拉专利汇总

- 格式:xlsx

- 大小:24.95 KB

- 文档页数:6

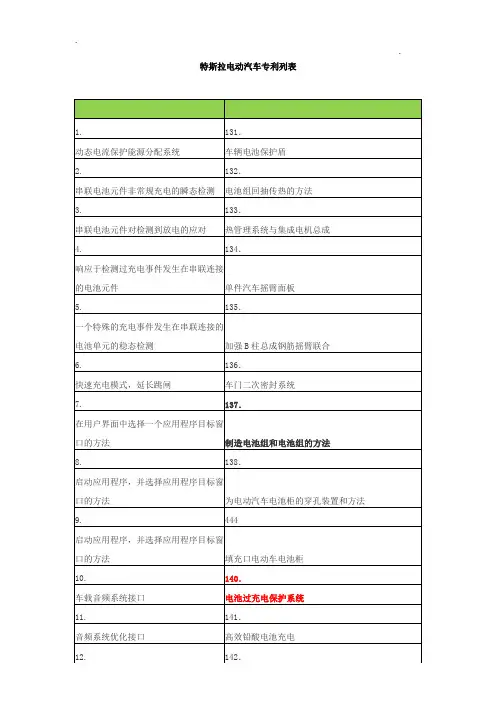

特斯拉专利汇总资料1 20150239331 15/8/27 吸收和分布利用集成的电池包的侧面冲击能量系统2 20150244036 15/8/27 储能系统的热管散热管理3 20150244047 15/8/27 电池安装和冷却系统4 20150217654 15/8/6 冷却的充电电缆5 20150222162 15/8/6 加压和地心吸力-液体冷却的电动马达 6 20150165921 15/6/18 确定电池直流阻抗7 20150168477 15/6/18 在冗余通讯线中断检测 8 20150171644 15/6/18 快速充电的电池使用可调电压控制 9 20150155112 15/6/4 电磁开关与阻尼界面10 20150147600 15/5/28 电化学电池盖11 20150137768 15/5/21 充电率优化12 20150123511 15/5/7 电机的磁通盾13 20150111082 15/4/23 单元模块程序集14 20150083505 15/3/26 集成的电机装配15 20150077057 15/3/19 低温快速充电16 20150060558 15/3/5 暖通空调系统的正温度系数沿热杆长度变化时 17 20150061321 15/3/5 挤压的成员与蚀变径向鳍 18 20150035296 15/2/5 控制器设备和传感器的车门把手 19 20150039180 15/2/5 控制器设备和传感器的车门把手20 20150039255 15/2/5 充电电池安全的方法 21 20140375166 14/12/25 控制预平衡纺丝过程结束环平衡 22 20140376995 14/12/25 气密滑结构缝不使用密封胶23 20140368064 14/12/18 转子装配与热管冷却系统 24 20140368082 14/12/18 限制在转子动平衡的径向膨胀 25 20140347018 14/11/27 基于位置的充电控制系统 26 20140339950 14/11/20 转子装配与电子束焊接端盖 27 2014033208514/11/13 自激活的排水系统28 20140333086 14/11/13 折叠和充填面向后方车辆座椅 29 2014032635114/11/6 异种两端挤压件30 20140253023 14/9/11 快速充电的电池使用可调电压控制31 20140257613 14/9/11 全轮驱动电动汽车的控制系统32 20140209344 14/7/31 电力电子联网为电动马达驱动器 33 20140212695 14/7/31 作为高压挠性印制电路互连在电池模块 34 20140212708 14/7/31 电池包排气喷嘴35 20140193683 14/7/10 电池包基地板式换热器36 20140182958 14/7/3 吸收和分布利用集成的电池包的侧面冲击能量系统37 20140178722 14/6/26 电池安装和冷却系统38 20140152258 14/6/5 稳态探测到的一系列特殊收费事件连接电池元件 39 20140152259 14/6/5 探测到的一系列滥收费用事件响应连接电池元件 40 20140152260 14/6/5 探测到的一系列电池过放事件响应连接电池元件 41 20140152315 14/6/5 瞬态探测到的一系列特殊收费事件连接电池元件 42 20140153150 14/6/5 能源分布系统中的动态电流保护 43 20140121866 14/5/1 快速充电模式下为长时间的旅行的 44 20140093107 14/4/3 自动音频优化系统45 20140095023 14/4/3 汽车空气悬架控制系统46 20140095029 14/4/3 天窗控制接口47 20140095031 14/4/3 利用位置预设的天窗控制接口48 20140095997 14/4/3 音频系统优化界面49 20140096003 14/4/3 汽车音响系统接口50 20140096050 14/4/3 启动应用程序,然后选择应用程序目标窗口的方法51 20140096051 14/4/3 启动应用程序,然后选择应用程序目标窗口的方法 5220140096069 14/4/3 在用户界面中选择目标应用程序窗口的方法 53 20140088809 14/3/27 在电池组的过电流的检测54 20130337705 13/12/19 高压电缆连接器55 20130327511 13/12/12 改进的冷却系统的被动空气流血 56 20130328531 13/12/12 作为环境氧浓度函数的金属-空气电池充电速率调制 57 2013030747513/11/21 充电率优化58 20130307476 13/11/21 用于服务高电压电池包方法和系统 59 20130307478 13/11/21 高电压电池包的二级服务端口60 20130307480 13/11/21 自放电高电压电池包61 20130307491 13/11/21 双向多相多模转换器包括升压和降压-升压模式62 20130293251 13/11/7 在冗余通讯线中断检测 63 20130294222 13/11/7主机通信体系结构64 20130294529 13/11/7 在电噪声环境下的鲁棒通讯 65 2013029453013/11/7 冗余态信号66 20130297954 13/11/7 在通信系统中的远程客户端发起的主机状态控制 67 20130284559 13/10/31 狭窄的传输公园锁68 20130285602 13/10/31 综合归纳和导电电子收费系统 69 2013027074913/10/17 在模块化的程序集的嵌入式的光学 70 20130260192 13/10/3 电池包压力监测热事件检测系统 71 20130241445 13/9/19 操作的双电机驱动和控制系统的电动汽车的方法 72 20130234648 13/9/12 低温快速充电73 20130228431 13/9/5 电气接口联锁系统74 20130221916 13/8/29 电动汽车电池寿命优化业务模式 75 2013022192813/8/29 电动汽车电池寿命优化业务模式 76 20130211579 13/8/15 自动焊接控制77 20130196184 13/8/1 电池模块与综合热管理系统 78 2013018759113/7/25 扩展范围混合动力电池组系统的电动汽车 79 20130181511 13/7/18 扩展范围混合动力电池组系统的电动汽车 80 20130179012 13/7/11 在电池组的过电流的检测 81 20130153317 13/6/20 汽车电池包热障82 20130154352 13/6/20 烟火的高电压电池断开连接 83 2013009794013/4/25 控制双铰接的车辆门的方法 84 20130099523 13/4/25 双铰接的车辆门85 20130099524 13/4/25 用双铰接的车辆门控制系统系统的吸收和分布侧冲击能量利用集成的电池包和侧窗台86 2013008804413/4/11 大会系统的吸收和分布侧冲击能量利用与湿陷性的窗台上插入87 2013008804513/4/11 侧窗台大会88 20130088051 13/4/11 天窗定位和定时元素89 20130082486 13/4/4 与连续的一部分指南天窗机制联系跟踪 90 20130082487 13/4/4 在行外滑动全景天窗轨道91 20130082488 13/4/4 集成到结构天窗框架机制组件 92 2013008248913/4/4 利用两个独立的马达的天窗 93 20130074411 13/3/28 燃料与无线端口门unlatching 致动器的耦合器 94 20130074525 13/3/28 与混合阀换热器的热管理系统 95 20130074985 13/3/28 车港门与无线驱动 unlatching 大会 96 20130076051 13/3/28 综合的能量吸收车辆碰撞构造 97 20130076059 13/3/28 电荷港门与电磁闭锁大会98 20130076076 13/3/28 棱形前车盖密封总成99 20130078494 13/3/28 为尽量减少内部电池热失控传播刚性细胞分离器100 20130078839 13/3/28 漏斗形收费入口101 20130078841 13/3/28 为控制车辆收费入口访问机电棘爪 102 20130078900 13/3/28 空气出口方向流控制器与集成的关断门 103 20130069476 13/3/21 一个电动马达的转子设计104 20130071701 13/3/21 对高压电解电池包中的冷却液的反应 105 20130073229 13/3/21 高电压电解的冷却剂在电池组的检测 106 2013007323313/3/21 低电压电解电池包中的检测 107 20130073234 13/3/21 低电压电解电池包中的响应 108 20130066504 13/3/14 双模式范围扩大电动汽车109 20130066505 13/3/14 双模式范围扩大电动汽车110 20130066506 13/3/14 双模式范围扩大电动汽车111 20130057209 13/3/7 多端口车辆直流充电系统与可变功率分布 112 20130057210 13/3/7 操作多端口的汽车充电系统的方法 113 20130059181 13/3/7 高效率通风口电池盖组件114 20130049971 13/2/28 利用电池包隔离监测的电池热事件检测系统 115 20130027049 13/1/31 通过双总线监测电池包绝缘电阻的测定方法 116 20130015814 13/1/17 收费混乱监视和通知系统117 20130015823 13/1/17 作为环境氧浓度函数的金属-空气电池充电速率调制 118 20130002173 13/1/3 牵引电机控制器与散热方式 119 2013000482013/1/3 电池冷却液夹克120 20120312615 12/12/13 汽车电池包防弹盾牌121 20120315517 12/12/13 电池包除湿机与积极恢复系统122 20120305283 12/12/6 电力电子联网为电动马达驱动器 123 20120308857 12/12/6 方法和维护细胞壁完整性用高屈服强度外壳 124 20120308858 12/12/6 电池包外壳与控制热失控发布系统 125 20120308859 12/12/6 电池包外壳与控制热失控发布系统 126 20120280662 12/11/8 使用变量隔离的充电效率 12720120266914 12/10/25 清洗功能电动充电连接器 128 20120270080 12/10/25 集成的电池卸压和终端隔振系统 129 20120237803 12/9/20 电池组指示排气系统130 20120229098 12/9/13 使用可选隔离的充电效率 131 2012023130612/9/13 电池组排气系统132 20120222833 12/9/6 多功能汽车散热器、冷凝器系统中控制气流活跃百叶系统133 20120194119 12/8/2 快速开关逆变电源134 20120195079 12/8/2 快速开关逆变电源135 20120195085 12/8/2 快速开关逆变电源136 20120195087 12/8/2 快速开关逆变电源137 20120180997 12/7/19 冷却剂曝气水库138 20120183815 12/7/19 双模式冷却剂回路的热管理系统 139 20120183826 12/7/19 装置的外部应用程序的电池包灌封胶 140 20120175897 12/7/12 汽车前部结构参数的前纵梁配置 141 20120175898 12/7/12 保险杠安装双通道前纵梁板142 20120175899 12/7/12 前纵梁加固系统143 20120175900 12/7/12 一辆车的双重负载路径设计 144 2012017591612/7/12 扫描前扭矩框145 20120168125 12/7/5 多功能汽车散热器、冷凝器气流系统 146 20120169023 12/7/5 车辆前避震器支架147 20120169089 12/7/5 后方车辆转矩框148 20120160088 12/6/28 汽车电池包防弹盾牌149 20120160583 12/6/28 一个汽车电池组的集成系统 150 2012016142912/6/28 增广的车辆座位安装151 20120161430 12/6/28 三-车用 cng (压缩天然气) 缸安装装置 45W 20120161472 12/6/28 吸收和分布利用集成的电池包的侧面冲击能量系统153 20120151843 12/6/21 汽车车门二次密封系统154 20120153675 12/6/21 增强 b 柱与钢筋摇杆联合大会 155 20120153682 12/6/21 单件车辆摇杆面板156 20120153718 12/6/21 热管理系统集成的电机装配用 157 20120153901 12/6/21 从一个电池组撤出热的方法 158 20120111444 12/5/10 填补港口为电动汽车电池外壳 159 20120111445 12/5/10 穿孔电动车电池外壳160 20120105015 12/5/3 电池组过充保护系统161 20120098501 12/4/26 高效铅酸电池充电162 20120091953 12/4/19 交流电流控制的手机电池充电器 163 20120046795 12/2/23 方法和延长生存期充电固定能源存储设备 164 20120046815 12/2/23 优化电池包温度的方法165 20120037310 12/2/16 胶粘剂在模块化的程序集的选择性治疗 166 20120038314 12/2/16 扩展范围混合动力电池组系统的电动汽车利用这两个金属-空气和金属-空气电池包的电源热能量传167 20120040210 12/2/16 输系统168 20120040212 12/2/16 在使用金属-空气电池的电池包内减灾 169 20120040253 12/2/16 收集、存储和使用的金属-空气电池包出水 170 20120040255 12/2/16 通过气体流动通信之间电池组减灾 171 2012004162212/2/16 作为环境氧浓度函数的金属-空气电池充电速率调制 172 20120041623 12/2/16 作为环境氧浓度函数的金属-空气电池充电速率调制 173 20120041624 12/2/16 扩展范围混合动力电池组系统的电动汽车 174 20120041625 12/2/16 高效的双源电池组系统的电动汽车 175 20120041626 12/2/16 高效的双源电池组系统的电动汽车 176 20120041627 12/2/16 高效的双源电池组系统的电动汽车 177 20120041628 12/2/16 控制、收集和使用的金属-空气电池包出水 178 20120030932 12/2/9 电池内部的控制单元格级融合方法 179 20120034497 12/2/9 电池组与单元格级融合180 20120034501 12/2/9 要减少灾害与内部短路的电池包配置 181 20120025765 12/2/2 电动汽车的充电状态指示灯 182 20120019194 12/1/26 泄漏电流减少组合电机驱动和能量存储补给系统中183 20120019212 12/1/26 双向多相多模转换器包括升压和降压-升压模式184 20120021258 12/1/26 系统温度控制的方法来延长电池包寿命 185 20120013341 12/1/19 方法和电动自行车电池单元来模拟内部短路转子温度估计和电机控制的矢量控制交流感应电机的转矩186 2012000753212/1/12 限制187 20110296855 11/12/8 双模式冷却剂回路的热管理系统 188 20110298417 11/12/8 充电电池安全的方法189 20110267004 11/11/3 操作利用的电压除以加热器充电系统的方法 190 20110262783 11/10/27 电池单元组成的一种膨胀型材料的中心销 191 20110254512 11/10/20 涓流充电器的高能存储系统 192 20110214808 11/9/8 胶粘剂在模块化的程序集的选择性治疗 193 20110212356 11/9/1 挤压和肋热接口用于冷却系统电池 194 20110206969 11/8/25 塑封热接口用于冷却系统电池 195 20110197431 11/8/18 缠绕线型三层膜的制作方法 196 20110198960 11/8/18 双层缠绕模式及制造相同的方法 197 20110198961 11/8/18 三层缠绕模式及制造相同的方法 198 20110198962 11/8/18 感应电机的铺层设计199 20110198963 11/8/18 双层缠绕线型200 20110174556 11/7/21 电池包气排气系统201 20110165446 11/7/7 耐腐蚀电池安装好202 20110156641 11/6/30 状态的收费范围203 20110156661 11/6/30 快速充电与消极但凡当前配置文件 204 20110117403 11/5/19 电池单元组成的一种低熔点材料中心销 205 20110091760 11/4/21 系统和抑制的放热的事件传播 30W 20110082615 11/4/7 用户可配置车辆用户界面 207 20110082616 11/4/7 车辆与邻近激活的用户界面 208 20110082618 11/4/7 自适应听觉反馈提示车辆用户界面 209 20110082619 11/4/7 汽车用户界面自适应软按钮 210 20110082620 11/4/7 自适应车辆用户界面211 20110082627 11/4/7 变形车用户界面212 20110082628 11/4/7 巡航控制修改213 20110076538 11/3/31 方法和外部电池包胶粘剂的应用 214 20110077879 11/3/31 确定电池直流阻抗215 20110062819 11/3/17 一个电动马达的转子设计 216 2011001256211/1/20 低温充电的锂离子电池217 20110014506 11/1/20 方法和维护使用高屈服强度外套筒的细胞壁完整性218 20110014514 11/1/20 用膨胀材料外层细胞219 20110003183 11/1/6 在电池组的常见模式电压枚举 220 2011000443811/1/6 在电池组的常见模式电压枚举 221 20100316894 10/12/16 集成的电池卸压和终端隔振系统 222 20100318266 10/12/16 汽车功能控制通过触摸屏接口 223 20100302051 10/12/2 使用热可中断的电导体的电池热事件检测系统 224 20100273034 10/10/28 电池包外壳与控制热失控发布系统 225 2010024461210/9/30 交流电机绕组模式226 20100222953 10/9/2 双电机驱动和控制系统的电动汽车 227 20100212338 10/8/26 电池组温度优化控制系统 228 20100212339 10/8/26 为延长电池包寿命智能温度控制系统 229 20100187024 10/7/29 所有轮驾驶电动汽车动力都辅助传动系统 230 20100187905 10/7/29 所有轮驾驶电动汽车动力都辅助传动系统 231 20100188043 10/7/29 优化电池包截止电压系统 232 20100188046 10/7/29 电池单元监测和平衡回路 233 20100188047 10/7/29 电池单元监测和平衡回路 234 20100151308 10/6/17 通过差热转移热失控增加的抗性 235 20100141080 10/6/10 改进的转矩密度感应电动机 33W 20100133023 10/6/3 所有轮驾驶电动汽车动力都辅助传动系统 237 20100134073 10/6/3 电池充电时间优化系统238 20100135355 10/6/3 使用光纤的电池热事件检测系统 239 20100136384 10/6/3 电导体用热可中断的绝缘子的电池热事件检测系统方法和维护期间使用外层的膨胀材料的热失控的细胞壁完240 20100136385 10/6/3 整性241 20100136387 10/6/3 电池盖组件与嵌入式的终端和扩大绝缘垫片 242 20100136391 10/6/3 在电池组内使用主动热失控减灾系统243 20100136396 10/6/3 为尽量减少内部电池热失控传播细胞分离器 244 20100136402 10/6/3 密封的电池外壳245 20100136404 10/6/3 包含内部电池热失控传播热障结构 34W 20100136407 10/6/3 为改进的电池包力学性能和热性能的部分介质阻挡电池 247 20100136409 10/6/3 为改进的电池包力学性能和热性能的部分介质阻挡电池 248 20100136413 10/6/3 方法和外部应用程序的电池包灌封胶 249 2010013642110/6/3 电池盖组件与嵌入式的终端和扩大绝缘垫片System for absorbing and distributing side impact energy 1 20150239331 08/27/15 utilizing an integrated battery packEnergy storage system with heat pipe thermal 2 20150244036 08/27/15 management3 20150244047 08/27/15 Battery mounting and cooling system4 20150217654 08/06/15 Cooling of charging cablePressurized and gravity-fed liquid cooling of electric 5 20150222162 08/06/15 motor6 20150165921 06/18/15 Determining battery dc impedance7 20150168477 06/18/15 Wire break detection in redundant communications8 20150171644 06/18/15 Fast charging of battery using adjustable voltage control9 20150155112 06/04/15 Electromagnetic switch with damping interface10 20150147600 05/28/15 Cap for electrochemical cell11 20150137768 05/21/15 Charge rate optimization12 20150123511 05/07/15 Flux shield for electric motor13 20150111082 04/23/15 Cell module assemblies14 20150083505 03/26/15 Integrated electric motor assembly15 20150077057 03/19/15 Low temperature fast chargeHvac system with positive temperature coefficient varying 16 20150060558 03/05/15 along length of heat rod17 20150061321 03/05/15 Extruded member with altered radial fins 18 20150035296 02/05/15 Controller apparatus and sensors for a vehicle door handle19 20150039180 02/05/15 Controller apparatus and sensors for a vehicle door handle 20 20150039255 02/05/15 Methodology for chargingbatteries safely 21 20140375166 12/25/14 Controlling end ring balance in pre-balancing spinning process 22 20140376995 12/25/14 Air-tight slip-on structural joint not using sealant 23 20140368064 12/18/14 Rotor assembly with heat pipe cooling system 24 20140368082 12/18/14 Limiting radial expansion in rotor balancing 25 20140347018 11/27/14 Location based charging control system 26 20140339950 11/20/14 Rotor assembly with electron beam welded end caps 27 20140332085 11/13/14 Self-activated draining system28 20140333086 11/13/14 Folding and stowing rear-facing vehicle seat29 20140326351 11/06/14 Extrusion piece with dissimilar ends30 20140253023 09/11/14 Fast charging of battery using adjustable voltage control 31 20140257613 09/11/14 Control system for an all-wheel drive electric vehicle 32 20140209344 07/31/14 Power electronics interconnection for electric motor drivesFlexible printed circuit as high voltage interconnect in battery 33 20140212695 07/31/14 modules34 20140212708 07/31/14 Battery pack exhaust nozzle35 20140193683 07/10/14 Battery pack base plate heat exchangerSystem for absorbing and distributing side impact energy 36 20140182958 07/03/14 utilizing an integrated battery pack37 20140178722 06/26/14 Battery mounting and cooling systemSteady state detection of an exceptional charge event in a 38 20140152258 06/05/14 series connected battery elementResponse to detection of an overcharge event in a series 39 20140152259 06/05/14 connected battery elementResponse to detection of an overdischarge event in a series 40 20140152260 06/05/14 connected battery elementTransient detection of an exceptional charge event in a series 41 20140152315 06/05/14 connected battery element42 20140153150 06/05/14 Dynamic current protection in energy distribution systems 43 20140121866 05/01/14 Fast charge mode for extended trip44 20140093107 04/03/14 Automated audio optimization system45 20140095023 04/03/14 Vehicle air suspension control system 46 20140095029 04/03/14 Sunroof control interface47 20140095031 04/03/14 Sunroof control interface utilizing position presets 48 20140095997 04/03/14 Audio system optimization interface 49 20140096003 04/03/14 Vehicle audio system interfaceMethod of launching an application and selecting the 50 20140096050 04/03/14 application target windowMethod of launching an application and selecting the 51 20140096051 04/03/14 application target windowMethod of selecting an application target window in a user 52 20140096069 04/03/14 interface53 20140088809 03/27/14 Detection of over-current in a battery pack54 20130337705 12/19/13 High voltage cable connector55 20130327511 12/12/13 Passive air bleed for improved cooling systemsCharge rate modulation of metal-air cells as a function of 56 20130328531 12/12/13 ambient oxygen concentration57 20130307475 11/21/13 Charge rate optimization58 20130307476 11/21/13 Method and system for servicing high voltage battery packs 59 20130307478 11/21/13 Secondary service port for high voltage battery packs 60 20130307480 11/21/13 Self-discharge for high voltage battery packsBidirectional polyphase multimode converter including boost 61 20130307491 11/21/13 and buck-boost modes62 20130293251 11/07/13 Wire break detection in redundant communications 63 20130294222 11/07/13 Host communications architecture 64 20130294529 11/07/13 Robust communications in electrically noisy environments 65 20130294530 11/07/13 Redundant multistate signaling Host initiated state control of remote client in communications 66 20130297954 11/07/13 system67 20130284559 10/31/13 Park lock for narrow transmission68 20130285602 10/31/13 Integrated inductive and conductiveelectrical charging system 69 20130270749 10/17/13 Embedded optics in modular assembliesBattery pack pressure monitoring system for thermal event 70 20130260192 10/03/13 detectionMethod of operating a dual motor drive and control system for 71 20130241445 09/19/13 an electric vehicle72 20130234648 09/12/13 Low temperature fast charge73 20130228431 09/05/13 Electrical interface interlock system74 20130221916 08/29/13 Electric vehicle battery lifetime optimization operational mode 75 20130221928 08/29/13 Electric vehicle battery lifetime optimization operational mode 76 20130211579 08/15/13 Control for automated soldering77 20130196184 08/01/13 Battery module with integrated thermal management system 78 20130187591 07/25/13 Electric vehicle extended range hybrid battery pack system 79 20130181511 07/18/13 Electric vehicle extended range hybrid battery pack system 80 2013017901207/11/13 Detection of over-current in a battery pack 81 2013015331706/20/13 Vehicle battery pack thermal barrier82 20130154352 06/20/13 Pyrotechnic high voltage battery disconnect83 20130097940 04/25/13 Method of controlling a dual hinged vehicle door84 20130099523 04/25/13 Dual hinged vehicle door85 20130099524 04/25/13 Control system for use with a dual hinged vehicle doorSystem for absorbing and distributing side impact energy 86 20130088044 04/11/13 utilizing an integrated battery pack and side sill assemblySystem for absorbing and distributing side impact energy 87 20130088045 04/11/13 utilizing a side sill assembly with a collapsiblesill insert 88 20130088051 04/11/13 Sunroof positioning and timing elementsSunroof mechanism linkage with continuous one part guide 89 20130082486 04/04/13 track90 20130082487 04/04/13 In-line outer sliding panorama sunroof tracksMechanism components integrated into structural sunroof 91 20130082488 04/04/13 framework92 20130082489 04/04/13 Sunroof utilizing two independent motors 93 20130074411 03/28/13 Fuel coupler with wireless port door unlatching actuatorThermal management system with heat exchanger blending 94 20130074525 03/28/13 valve95 20130074985 03/28/13 Vehicle port door with wirelessly actuated unlatching assembly 96 20130076051 03/28/13 Integrated energy absorbing vehicle crash structure97 20130076059 03/28/13 Charge port door with electromagnetic latching assembly 98 20130076076 03/28/13 Angled front hood sealing assemblyRigid cell separator for minimizing thermal runaway 99 20130078494 03/28/13 propagation within a battery pack100 20130078839 03/28/13 Funnel shaped charge inletElectromechanical pawl for controlling vehicle charge inlet 101 20130078841 03/28/13 access102 20130078900 03/28/13 Air outlet directional flow controller with integrated shut-off door 103 20130069476 03/21/13 Rotor design for an electric motorResponse to high voltage electrolysis of coolant in a battery 104 20130071701 03/21/13 packDetection of high voltage electrolysis of coolant in a battery 105 20130073229 03/21/13 pack106 20130073233 03/21/13 Detection of low voltage electrolysis in a battery pack 107 20130073234 03/21/13 Response to low voltage electrolysis in a battery pack 108 20130066504 03/14/13 Dual mode range extended electric vehicle 109 20130066505 03/14/13 Dual mode range extended electric vehicle 110 20130066506 03/14/13 Dual mode range extended electric vehicleMultiport vehicle dc charging system with variable power 111 20130057209 03/07/13 distribution112 20130057210 03/07/13 Method of operating a multiport vehicle charging system 113 20130059181 03/07/13 Battery cap assembly with high efficiency ventBattery thermal event detection system utilizing battery pack 114 20130049971 02/28/13 isolation monitoringMethod for determining battery pack isolation resistance via 115 20130027049 01/31/13 dual bus monitoring116 20130015814 01/17/13 Charge disruption monitoring andnotification systemCharge rate modulation of metal-air cells as a function of 117 20130015823 01/17/13 ambient oxygen concentration118 20130002173 01/03/13 Traction motor controller with dissipation mode 119 20130004820 01/03/13 Battery coolant jacket120 20120312615 12/13/12 Vehicle battery pack ballistic shield121 20120315517 12/13/12 Battery pack dehumidifier with active reactivation system122 20120305283 12/06/12 Power electronics interconnection for electric motor drivesMethod and maintaining cell wall integrity using a high yield 123 20120308857 12/06/12 strength outer casingBattery pack enclosure with controlled thermal runaway 124 20120308858 12/06/12 release systemBattery pack enclosure with controlled thermal runaway 125 20120308859 12/06/12 release system126 20120280662 11/08/12 Charging efficiency using variableisolation 127 20120266914 10/25/12 Cleaning feature for electric charging connector 128 20120270080 10/25/12 Integrated battery pressure relief and terminal isolation system 129 20120237803 09/20/12 Battery pack directed venting system 130 20120229098 09/13/12 Charging efficiency using selectable isolation 131 20120231306 09/13/12 Battery pack venting systemActive louver system for controlled airflow in a multi-function 132 20120222833 09/06/12 automotive radiator and condenser system 133 20120194119 08/02/12 Fast switching for power inverter134 20120195079 08/02/12 Fast switching for power inverter135 20120195085 08/02/12 Fast switching for power inverter136 20120195087 08/02/12 Fast switching for power inverter137 20120180997 07/19/12 Coolant de-aeration reservoir138 20120183815 07/19/12 Thermal management system with dual mode coolant loopsApparatus for the external application of battery pack 139 20120183826 07/19/12 encapsulant140 20120175897 07/12/12 Front rail configuration for the front structure of a vehicle 141 20120175898 07/12/12 Bumper mounting plate for double channel front rails 142 20120175899 07/12/12 Front rail reinforcement system143 20120175900 07/12/12 Dual load path design for a vehicle144 20120175916 07/12/12 Swept front torque boxMulti-function automotive radiator and condenser airflow 145 20120168125 07/05/12 system146 20120169023 07/05/12 Vehicle front shock tower147 20120169089 07/05/12 Rear vehicle torque box148 20120160088 06/28/12 Vehicle battery pack ballistic shield149 20120160583 06/28/12 Integration system for a vehicle battery pack 150 20120161429 06/28/12 Augmented vehicle seat mountThree - cng (compressed natural gas) cylinder mounting device 151 20120161430 06/28/12 for a vehicleSystem for absorbing and distributing side impact energy 152 20120161472 06/28/12 utilizing an integrated battery pack 153 20120151843 06/21/12 Vehicle door secondary sealing system 154 20120153675 06/21/12 Reinforced b-pillar assembly with reinforced rocker joint 155 20120153682 06/21/12 Single piece vehicle rocker panel Thermal management system for use with an integrated motor 156 20120153718 06/21/12 assembly157 20120153901 06/21/12 Method of withdrawing heat from a battery pack 158 20120111444 05/10/12 Fill port for electric vehicle battery enclosure 159 20120111445 05/10/12 Perforation electric vehicle battery enclosure 160 20120105015 05/03/12 Battery pack overcharge protection system 161 20120098501 04/26/12 Efficient lead acid battery charging 162 20120091953 04/19/12 Ac current control of mobile battery chargersMethod and extending lifetime for rechargeable stationary 163 20120046795 02/23/12 energy storage devices164 20120046815 02/23/12 Method for optimizing battery pack temperature 165 20120037310 02/16/12 Selective cure of adhesive in modular assemblies 166 20120038314 02/16/12 Electric vehicle extended range hybrid battery pack systemThermal energy transfer system for a power source utilizing 167 20120040210 02/16/12 both metal-air and non-metal-air battery packs 16820120040212 02/16/12 Hazard mitigation within a battery pack usingmetal-air cells 169 20120040253 02/16/12 Collection, storage and use of metal-air battery pack effluentHazard mitigation through gas flow communication between 170 20120040255 02/16/12 battery packsCharge rate modulation of metal-air cells as a function of 171 20120041622 02/16/12 ambient oxygen concentrationCharge rate modulation of metal-air cells as a function of 172 20120041623 02/16/12 ambient oxygen concentration173 20120041624 02/16/12 Electric vehicle extended range hybrid battery pack system 174 20120041625 02/16/12 Efficient dual source battery pack system for an electric vehicle 175 20120041626 02/16/12 Efficient dual source battery pack system for an electric vehicle 176 20120041627 02/16/12 Efficient dual source battery pack system for an electric vehicle 177 20120041628 02/16/12 Control, collection and use of metal-air battery pack effluent 178 20120030932 02/09/12 Method of controlled cell-level fusing within a battery pack 179 2012003449702/09/12 Battery pack with cell-level fusingBattery pack configuration to reduce hazards associated with 180 20120034501 02/09/12 internal short circuits181 20120025765 02/02/12 Charge state indicator for an electric vehicleLeakage current reduction in combined motor drive and energy 182 20120019194 01/26/12 storage recharge systemBidirectional polyphase multimode converter including boost 183 20120019212 01/26/12 and buck-boost modesMethod of controlling system temperature to extend battery 184 20120021258 01/26/12 pack lifeMethod and electrically cycling a battery cell to simulate an 185 20120013341 01/19/12 internal shortRotor temperature estimation and motor control torque limiting 186 20120007532 01/12/12 for vector-controlled ac induction motors 187 20110296855 12/08/11 Thermal management system with dual mode coolant loops 188 20110298417 12/08/11 Methodology for charging batteries safelyMethod of operating a recharging system utilizing a voltage 189 20110267004 11/03/11 dividing heaterBattery cell with center pin comprised of an intumescent 190 20110262783 10/27/11 material191 20110254512 10/20/11 Trickle charger for high-energy storage systems 192 20110214808 09/08/11 Selective cure of adhesive in modular assembliesExtruded and ribbed thermal interface for use with a battery 193 20110212356 09/01/11 cooling systemOvermolded thermal interface for use with a battery cooling 194 20110206969 08/25/11 system195 20110197431 08/18/11 Manufacturing methods for a triple layer winding pattern 196 20110198960 08/18/11 Dual layer winding pattern and methods of manufacturingsameTriple layer winding pattern and methods of manufacturing 197 20110198961 08/18/11 same198 20110198962 08/18/11 Induction motor lamination design199 20110198963 08/18/11 Dual layer winding pattern200 20110174556 07/21/11 Battery pack gas exhaust system201 20110165446 07/07/11 Corrosion resistant cell mounting well 202 20110156641 06/30/11 State of charge range203 20110156661 06/30/11 Fast charging with negative ramped current profileBattery cell with a center pin comprised of a low melting point 204 20110117403 05/19/11 material205 20110091760 04/21/11 System and inhibiting the propagation of an exothermic event 206 20110082615 04/07/11 User configurable vehicle user interface 207 20110082616 04/07/11 Vehicle user interface with proximity activation 208 20110082618 04/07/11 Adaptive audible feedback cues for a vehicle user interface 209 20110082619 04/07/11 Adaptive soft buttonsfor a vehicle user interface 210 20110082620 04/07/11 Adaptive vehicle user interface211 20110082627 04/07/11 Morphing vehicle user interface212 20110082628 04/07/11 Cruise control modification213 20110076538 03/31/11 Method and the external application of a battery pack adhesive 214 20110077879 03/31/11 Determining battery dc impedance215 20110062819 03/17/11 Rotor design for an electric motor216 20110012562 01/20/11 Low temperature charging of li-ion cells Method and maintaining cell wall integrity using a high yield 217 20110014506 01/20/11 strength outer sleeve218 20110014514 01/20/11 Cell with an outer layer of intumescent material 219 20110003183 01/06/11 Common mode voltage enumeration in a battery pack 220 20110004438 01/06/11 Common mode voltage enumeration in a battery pack 221 20100316894 12/16/10 Integrated battery pressure relief and terminal isolation system 222 20100318266 12/16/10 Interface for vehicle function control via a touch screenBattery thermal event detection system using a thermally 223 20100302051 12/02/10 interruptible electrical conductorBattery pack enclosure with controlled thermal runaway 224 20100273034 10/28/10 release system225 20100244612 09/30/10 Ac motor winding pattern226 20100222953 09/02/10 Dual motor drive and control system for an electric vehicle 227 20100212338 08/26/10 Battery pack temperature optimization control systemIntelligent temperature control system for extending battery 228 20100212339 08/26/10 pack life。

![特斯拉线圈[外观专利]](https://uimg.taocdn.com/5e8179427ed5360cba1aa8114431b90d6c858905.webp)

(19)中华人民共和国国家知识产权局

(12)外观设计专利

(10)授权公告号 (45)授权公告日 (21)申请号 202030729570.0

(22)申请日 2020.11.30

(73)专利权人 占桂滨

地址 334500 江西省上饶市铅山县永平镇

西门报本坊1号-2

(72)设计人 占桂滨

(51)LOC(13)Cl.

13-02

(54)使用外观设计的产品名称

特斯拉线圈

立体图图片或照片 7 幅 简要说明 1 页CN 306511643 S 2021.05.04

C N 306511643

S

主视图

后视图

左视图

右视图

俯视图

仰视图立体图

外观设计图片或照片1/1页CN 306511643 S

1.本外观设计产品的名称:特斯拉线圈。

2.本外观设计产品的用途:电力传输。

3.本外观设计产品的设计要点:在于形状。

4.最能表明设计要点的图片或照片:立体图。

简 要 说 明1/1页CN 306511643 S。

看过那么多特斯拉“开源专利”,⼩鹏该怎么造好⼀辆汽车?✎征稿邮箱:liujing@相⽐以前需要⼏⼗亿元的技术研发投⼊,还不⼀定研发得出来,现在能花⼏亿元造出辆(还不错的)电动车,门槛有所降低。

⽂▍威猛先⽣特斯拉家的专利不好学踩中特斯拉“开源专利”的时间节点,2014年年中,在UC创始⼈何⼩鹏、YY创始⼈李学凌的领投之下,⼩鹏汽车(⼴州)应运⽽⽣。

所谓特斯拉“开源专利”,⽤⼩鹏CEO夏珩的话讲,有点类似给了你⼀张电视机说明书,经过集齐各种所需零部件和后期组装,再把电动车给造出来。

“不过,要把电视机做起来不容易。

况且,汽车⽐电视机复杂太多了,不仅需要资⾦密集,还要技术密集。

”夏珩说道。

资⾦⽅⾯,除了采购各式各样的零部件外,改造代⼯车企的整条⽣产线也是⼀⽐不⼩的开⽀;技术⽅⾯,例如单纯⼀个电池包就需要⼏百样零部件进⾏组装,⽽且这些专利技术就像散落的拼图⼀样,⾮专业⼈⼠是很难拼接得起来的。

“当然,相⽐以前需要⼏⼗亿元的技术研发投⼊,还不⼀定研发得出来。

现在能花⼏亿元造出辆(还不错的)电动车,门槛还是有所降低。

”夏珩补充道。

给专利加点料既然门槛有所降低,也就不难理解这两年来造车企业如⾬后春笋般冒出了。

已知公开使⽤特斯拉“开源专利”的就有⼩鹏汽车、游侠等,未知是否借鉴了特斯拉“开源专利”技术的还有乐视、蔚来汽车、智车优⾏等。

那么,关于如何保证⼩鹏汽车在这些造车企业中的独特性。

夏珩表⽰,主要是在硬件升级和粉丝参与上下功夫。

与特斯拉主要只能靠软件升级不同,⼩鹏汽车还能在汽车硬件上进⾏升级。

打个粗俗的⽐⽅,特斯拉各个零部都是⽤铁定钉起来起来的,⽽⼩鹏汽车有部分零部件则可以轻松拆解更换,有点类似中国古代⽊匠都不⽤钉⼦,⽽是通过模块化的拼接⼯艺。

⼩鹏汽车还希望借助粉丝的⼒量,⽣产出⼀款更适合中国消费者,特别是适合互联⽹年轻⼀代的车型。

例如1⽉9⽇,⼩鹏汽车2进1造型评审活动上海站,就接受了包括电动车发烧友、⾏业专家、核⼼供应商等⼈⼠的赏鉴。

特斯拉专利解析报告北京新能源汽车股份有限公司2014年7月目录1特斯拉专利简介 (5)1.1特斯拉公司简介 (5)1.2特斯拉专利总体介绍 (5)1.3专利初步筛选分析 (6)1.4重点专利介绍 (9)1.5重点专利分布统计 (9)1.6重点专利的专利所有权 (10)2锂离子电池 (12)2.1电池热管理系统 (12)2.1.1冷却系统结构优化 (13)2.1.2温度控制的结构 (16)2.1.3温度控制的控制策略 (19)2.1.4热失控的检测 (22)2.1.5防止或抑制热失控蔓延的措施 (27)2.1.6小结 (45)2.2电池系统充电控制策略 (45)2.2.1不同充电倍率的控制策略 (45)2.2.2基于工况确定充电SOC阈值的控制策略 (53)2.2.3充电控制器 (53)2.2.4过充保护系统 (55)2.2.5小结 (56)2.318650电池单体结构改进报告 (56)2.3.1针对电池端盖的改进 (57)2.3.2针对电池外壳的改进 (59)2.3.3针对电池中心销的改进 (62)2.3.4小结 (63)2.4电池箱密封 (63)2.4.1电池包外用密封胶方法及装置 (63)2.4.2密封的电池包壳体 (65)2.4.3小结 (66)2.5冷却液泄露的检测和处理方法 (66)2.5.1高压电解与低压电解简介 (67)2.5.2低压电解的监测与响应 (68)2.5.3高压电解的监测与响应 (69)2.5.4小结 (69)2.6动力电池安全性检测技术 (69)2.6.1电池箱安全防护措施 (69)2.6.2安全性辅助评估技术 (75)2.6.3小结 (76)3电机部分 (77)3.1电机电压超调估计反馈 (77)3.1.1电机电压超调控制流程 (77)3.1.2电机空间矢量调节SVM (79)3.2基于电机转子组件温度估计的矢量控制 (79)3.2.1电机转子关键温度组件的替代物 (79)3.2.2电机关键温度组件替代物温度的测量 (80)3.2.3基于温度的电机转矩控制 (81)3.3电机低速和高速加权控制 (81)3.3.1整个速度范围电机磁通估计 (82)3.4低温下电机发热控制模式 (83)3.4.1低温电机发热系统 (83)3.4.2低温电机供热多通道系统 (84)3.5总结 (85)4整车部分 (86)4.1驱动系统 (86)4.1.1电动车辆双电机驱动控制系统 (86)4.1.2全驱电动车辆控制系统 (91)4.2整车碰撞防护结构 (94)4.2.1电池系统防护结构 (95)4.2.2碰撞防护装置 (100)4.2.3与国内专利比较 (105)4.3总结 (106)5界面控制系统 (108)5.1界面控制系统介绍 (108)5.1.1控制系统模块化 (108)5.1.2控制界面个性化 (109)5.1.3控制界面自适应化 (111)5.1.4听觉反馈控制系统 (114)5.1.5接近激活系统 (114)5.1.6触摸屏在车内的安装位置 (115)5.2总结 (115)参考专利 (116)1特斯拉专利简介1.1特斯拉公司简介特斯拉(Tesla)汽车公司成立于2003年,总部设在美国加州的硅谷地带,以生产和销售电动汽车为主要业务,2010年6月29日,特斯拉在纳斯达克上市,其旗下的车型包括MODEL S、ROADSTER,以及即将上市的MODEL X。

特斯拉汽车与其专利技术探析特斯拉汽车公司(Tesla Motors,以下简称特斯拉)是电动车中的明星,被誉为“汽车界的苹果”。

在2014年6月,特斯拉首席执行官埃隆·马斯克宣布开放了特斯拉的所有专利。

到目前为止,国内几乎没有文献报道有关特斯拉专利技术的分析。

1 特斯拉汽车与其专利技术的对比分析据称,特斯拉汽车上应用上特斯拉的200多项专利,事实上是这样的吗?本文通过将特斯拉汽车内部构造图片与其专利申请中的图片进行对比分析,来了解特斯拉的专利技术和其汽车实际采用的技术之间的关系。

1.1 整车结构布置图1(a)是特斯拉Model S整车结构布置图。

由该图可知,电动汽车主要由车身、底盘和电池包构成,其中电动车的动力电池组位于车辆的底盘,与轮距基本同宽,长度略短于轴,电动机位于两后轮之间。

图1(b)是特斯拉专利申请US2012160583A1中出现的整车结构布置图,两者具有完全相同的布置方式。

在特斯拉的很多其他专利申请中均采用了这种结构布置图,例如US2012161429A1、US2012160088A1、US2013088044A1等。

这在一定程度上反映了特斯拉专利申请的实用价值,另外也说明了特斯拉专利申请外延的范围较小,基本上都是为了实际应用所进行的针对性的技术改进,这也是特斯拉专利申请总量不大的原因之一。

(a)特斯拉整车结构布置(b)US2012160583A1中的附图1.2 电池包图2(a)是特斯拉Model S电动车内电池包的结构图。

由图可知,该电池包一共有16个电池模块。

图2(b)是特斯拉专利申请US2012160583A1中出现的电池包的结构图,其具有与特斯拉Model S电动车内电池包的拆解结构图基本相同的结构布置,根据该专利中记载的技术方案,所述电池包也由16个电池模块组成,每一个电池模块由多节18650单体电池串并联形成,且在整个电池包的外部还具有壳体进行保护。

特斯拉Model S电动车内电池包的结构图与该专利申请文件中的电池包的差别在于,Model S采用的电池包中,每两个并列放置的电池模块之间还具有一个分隔件,将两个电池模块之间分开,从而形成主体部分具有14个分隔空间和端部突出的一个分隔空间的电池包框体。

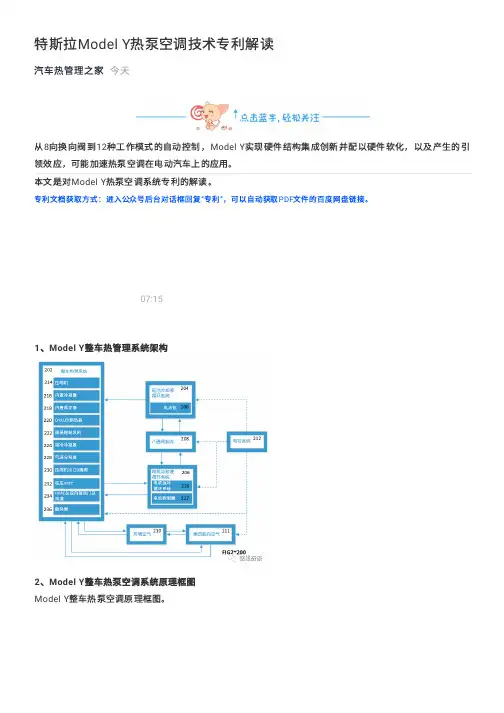

特斯拉Model Y 热泵空调技术专利解读从8向换向阀到12种⼯作模式的⾃动控制,Model Y 实现硬件结构集成创新并配以硬件软化,以及产⽣的引领效应,可能加速热泵空调在电动汽⻋上的应⽤。

本⽂是对Model Y 热泵空调系统专利的解读。

专利⽂档获取⽅式:进⼊公众号后台对话框回复“专利”,可以⾃动获取PDF ⽂件的百度⽹盘链接。

07:151、Model Y 整⻋热管理系统架构2、Model Y 整⻋热泵空调系统原理框图Model Y 整⻋热泵空调原理框图。

今天汽⻋热管理之家从视频中也可以看到Model Y机舱有电动压缩机,液冷冷凝器,AC-Chiller,膨胀⽔壶,HVAC总成进⻛⼝,冷却模块等。

3、Model Y整⻋热泵空调系统控制框图Model Y热泵空调系统控制框图分为⾏驶状态及远程控制状态,下⾯分别进⾏说明。

3.1 ⾏驶状态的控制框图3.2 远程控制状态的控制框图4、Model Y整⻋热泵空调系统不同模式的介绍4.1 Model Y热泵空调系统模式选择相⽐于现在已经应⽤热泵系统的⻋型,特斯拉在热泵与整⻋的集成上做得更进⼀步。

特斯拉热泵集成应⽤的策略可以通过下⾯这张图来说明,在满⾜乘员舱乘客舒适性需求的前提下,来采⽤COP较⾼的模式运⾏,减少能源消耗,提⾼续航⾥程。

即根据环境温度与电池温度的关系,从COP的划分,来规划热泵系统参与加热的程度,以及启动不同级别的加热模式。

4.2 各模式运⾏框图及应⽤场景介绍(1)乘员舱制热场景⼀热泵系统202通过AC-Chiller从电池系统204吸取热量。

给乘员舱进⾏加热,此时COP>>1;当电机循环系统中部件温度( DCDC,电机控制器,电机等)⾼于电池系统106的温度时,此时电池循环系统204和电机循环系统206通过阀系统208来实现串联,这对于提⾼效率有所帮助。

场景⼆热泵系统202通过吸收环境空⽓中的热量,同时不对电池循环系统204造成不利的影响。

特斯拉汽车公司的全球专利分析作者:张攀邹卫兵来源:《中国新技术新产品》2016年第21期摘要:本文通过对特斯拉汽车公司在全球的专利进行年代、地区、技术领域的统计分析,总结了特斯拉有关电动汽车的技术研发特点和趋势,提出特斯拉的核心技术在于它的电池和充电相关技术。

最后对我国电动汽车行业专利技术的发展提出了建议,为我国汽车企业的技术研发提供参考。

关键词:特斯拉;电动汽车;专利分析中图分类号:TM91 文献标识码:A特斯拉汽车(Tesla Motors Inc,以下简称特斯拉)是由Elon Musk于2003年在美国成立的一家生产纯电动汽车的公司。

在成立后的短短十年时间里,特斯拉以其独特的资源整合策略以及工业设计创新能力,在电动汽车行业刮起了一阵“特斯拉旋风”,也带了整个新能源电动汽车行业最近的发展热潮。

特斯拉的核心竞争力主要体现在它的研发及制造能力上,从2003年创建到2008年交付给客户的第一台电动汽车Roadster,花了5年的时间,这似乎并不符合传统商业模式中的一夜暴富。

特斯拉在创建后的发展历程,更像是一个研发机构,而非规模汽车制造商。

特斯拉极其注重科技研发,并取得了成功,目前特斯拉Model S电动轿车的一次充电的巡航里程能达到300英里(480公里)、支持45分钟快速充电。

一个公司的专利申请状况往往能够体现出该公司的技术研发重点和思路。

特斯拉也非常重视知识产权,自2005年提交了第一件专利后,在十年的时间里一共申请了294件专利,其中包括2012年的8件外观设计专利申请。

本文从技术角度出发,分析了特斯拉在世界范围内的专利分布,尝试总结出特斯拉的专利申请战略和技术分布,也希望能给国内相关企业在确定研发方向以及制定专利战略方向提供参考意见。

本文用于分析的数据均来源于德温特专利摘要数据库,截止到检索日,特斯拉在全球的专利/专利族为294篇。

下面笔者从年代、地区、技术领域进行分析。

一、年代分布图1显示了特斯拉的专利年代分布趋势。

特斯拉专利解析报告北京新能源汽车股份有限公司2014年7月目录1特斯拉专利简介 ....................................... 错误!未定义书签。

特斯拉公司简介.................................... 错误!未定义书签。

特斯拉专利总体介绍................................ 错误!未定义书签。

专利初步筛选分析.................................. 错误!未定义书签。

重点专利介绍...................................... 错误!未定义书签。

重点专利分布统计.................................. 错误!未定义书签。

重点专利的专利所有权.............................. 错误!未定义书签。

2锂离子电池 ........................................... 错误!未定义书签。

电池热管理系统.................................... 错误!未定义书签。

冷却系统结构优化.............................. 错误!未定义书签。

温度控制的结构................................ 错误!未定义书签。

温度控制的控制策略............................ 错误!未定义书签。

热失控的检测.................................. 错误!未定义书签。

防止或抑制热失控蔓延的措施.................... 错误!未定义书签。

小结.......................................... 错误!未定义书签。

电池系统充电控制策略.............................. 错误!未定义书签。

【免费公开专利】特斯拉共享专利的商业逻辑来源:IT时代周刊对很多科技公司而言,技术就是一切,所以科技公司对于专利的申请和维护都是非常在意的事情。

这种心情,看看苹果三星几乎遍布全球的专利大战,就能略知一二。

但是现在,正在火爆兴头上的电动汽车厂商特斯拉宣布:将免费公开其所有专利。

虽然互联网的精神是“自由、平等、开放、分享”,但是特斯拉也太大方了吧。

事实上,特斯拉的这种决定除了践行互联网的伟大精神外,还有另一方面的考量,那就是定义电动汽车市场的未来的野心。

开放专利表面上看,是让竞争对手占了便宜,然而此举却无形中提高了Tesla 技术的普适性,使得它在未来标准制定中抢占了有利的地位——如此看来,国内的BAT大战的段位,实在是太低了,BAT和Tesla之间,也许还差着100个潘石屹的情怀吧。

特斯拉CEO首席执行官埃伦-穆斯克(Elon Musk)可谓是一个难得的天才生意人,12岁就编写了一个名叫“Blastar”的游戏并卖了500美元;28岁把自己创办在线内容出版软件公司Zip2以数亿美元卖给了康柏;31岁把网络支付公司PayPal卖给了ebay;更难得的是,他并未像那些少年得志的硅谷英雄耽于醇酒美人,而是追随内心的直觉,把儿时那些的疯狂的梦想一一化为现实:他创办了世界上首家商用火箭发射公司Space X,你无须成为宇航员也可以进入太空;他入主了电动汽车制造商Tesla,让这家独立汽车厂商完成了汽车巨头们都无法完成的任务;40岁不到时,他还成立了美国最大的太阳能发电系统供应商SolarCity,在互联网、清洁能源和太空三个领域内如鱼得水,能够把生意做成“生活的意义”,也才会发生最新的石破天惊之举:免费公开Telsa所有专利。

6月12日,Elon Musk在Tesla网站上发布了一封公开信,宣布将免费公开其所有专利。

Elon Musk在声明中称:当他创立第一个公司ZIP2时,他曾经认为专利是一个好东西因此努力去获得和保护它;但是很快他就意识到,很长时间以来,专利仅仅是巩固了大公司的地位、肥了法律从业者,而对实际创新者而言,更多的只是扼杀了进步。

特斯拉专利引用

特斯拉是一家全球知名的电动汽车制造公司,以其创新和领先的电动汽车技术而闻名。

为了实现其技术创新,特斯拉积极申请和引用专利,以确保其技术的独特性和竞争优势。

本文将探讨特斯拉专利引用的相关内容。

首先,特斯拉积极申请专利,这是其推动技术创新和保护知识产权的重要手段。

特斯拉在过去几年中申请了大量的专利,涵盖了从电动车辆的电池技术到自动驾驶技术的各个方面。

这些专利的申请反映了特斯拉在技术研发上的持续投入和努力。

其次,特斯拉的专利引用是其技术发展的重要支撑。

特斯拉在开发新产品和改进现有技术时,经常会引用自身已有的专利。

这种引用有助于确保技术的一致性和连续性,避免重新发明轮子,同时也可以提高研发的效率和质量。

特斯拉的专利引用还体现了其开放创新的理念。

特斯拉并不仅仅局限于利用自身的专利,而是积极引用其他公司的专利。

通过与其他公司的专利交叉引用,特斯拉可以更好地借鉴其他领域的技术创新并将其应用于自身的产品和技术中。

最后,特斯拉积极参与开放的专利共享。

特斯拉于2014年宣布,将不会对其他公司使用特斯拉的专利提出专利侵权诉讼,以鼓励行业内的技术创新和发展。

这种开放的姿态体现了特斯拉对整个行业的贡献和愿景,同时也促进了电动汽车技术的普及和进步。

总的来说,特斯拉专利引用是其推动技术创新和保护知识产权的重要方式。

特斯拉积极申请专利,引用自身和其他公司的专利,以确保技术的独特性和竞争优势。

特斯拉的开放创新理念和参与专利共享进一步促进了电动汽车技术的发展。

通过专利引用,特斯拉将不断推动电动汽车行业的进步和创新。

Patent applicationnumber 2014015315020140152315 20140152260 20140152259 20140152258 2014012186620140096069 20140096051 2014009605020140096003 20140095997 20140095031 20140095029 20140095023 2014009310720140088809 20130337705 20130328531 20130327511 20130307491 20130307480 20130307478 2013030747620130307475 20130297954 2013029453020130294529 20130294222 2013029325120130285602 2013028455920130270749 2013026019220130241445 20130234648 20130228431 20130221928 2013022191620130211579 20130196184 20130187591 20130181511 20130179012 20130160376 2013016037420130154352 20130153317 20130099524 20130099523 20130097940TESLA MOTORS, INC. Patent applicationsTitleDYNAMIC CURRENT PROTECTION IN ENERGY DISTRIBUTION SYSTEMS - An electric circuit, including an electric load operable from an operating current; an energy storage system providing the operating current at both a first mode and a second mode with the first mode having a first current in a first range of zero to a first particular current value and with the second mode having a second current in a second range of the first particular current value to a second particular current value; and an active protection coupled to the energy storage system, the active protection dynamically reconfigurable between a first mode and a second mode, the first mode applying a first overcurrent protection rating to the operating current when the operating current is operating in the first mode and the second mode applying a second overcurrent protection rating to TRANSIENT DETECTION OF AN EXCEPTIONAL CHARGE EVENT IN A SERIES CONNECTED BATTERY ELEMENT - A system and method for identifying and responding to exceptional charge events of series-connected energy storage elements.RESPONSE TO DETECTION OF AN OVERDISCHARGE EVENT IN A SERIES CONNECTED BATTERY ELEMENT -A system and method for identifying and responding to exceptional charge events of series-connected energy storage elements.RESPONSE TO DETECTION OF AN OVERCHARGE EVENT IN A SERIES CONNECTED BATTERY ELEMENT - A system and method for identifying and responding to exceptional charge events of series-connected energy storage elements.STEADY STATE DETECTION OF AN EXCEPTIONAL CHARGE EVENT IN A SERIES CONNECTED BATTERY ELEMENT - A system and method for identifying and responding to exceptional charge events of series-connected energy storage elements.FAST CHARGE MODE FOR EXTENDED TRIP - A system and method for early identification of an impending fast-charge or fast-charge opportunity and use of that information to prepare the battery cells for the fast-charge.Method of Selecting an Application Target Window in a User Interface - A method for controlling application windows is provided for use with a graphical user interface (GUI) display which is divided into at least first and second application windows. Various software applications may be launched in the first and second application windows. In order to switch locations of the software applications launched in the first and second application windows the user selects a swap window button, for example by tapping or clicking on a swap window icon on the GUI display.Method of Launching an Application and Selecting the Application Target Window - A method of launching a software program or application is provided for use with a graphical user interface (GUI) display. One portion of the GUI display includes a taskbar while a second portion is divided into a plurality of windows. To launch one of the programs/applications represented by the icons within the taskbar, the user first selects the icon representing the icon to be launched. When the user drags the selected icon into one of the windows and then releases the icon, the selectedprogram/application is launched in the selected window.Method of Launching an Application and Selecting the Application Target Window - A method of launching a software program or application is provided for use with a graphical user interface (GUI) display. One portion of the GUI display includes a taskbar while a second portion is divided into a plurality of windows. To launch one of the programs/applications represented by the icons within the taskbar, the user first selects the icon representing the icon to be launched. Once an icon is selected, avisual cue is displayed, where the visual cue includes a plurality of mini-windows representing the plurality of display windows. When the user drags the selected iconinto one of the mini-windows and then releases the icon, the selectedVehicle Audio System Interface - A vehicle audio system interface is provided, as wellas a method of using same, in which a visual representation of the vehicle's passengercabin is displayed on the vehicle's touch-screen. Also displayed on the touch-screen isa touch sensitive balance slide controller and a touch sensitive fade slide controller.As the user makes left-right balance selections on the balance controller, and front-rear fader selections on the fade controller, an acoustic sweet spot designator ispresented on the displayed representation of the passenger cabin. The acoustic sweetspot designator, which corresponds to the pre-determined acoustic sweet spot, is basedon the combination of the current left-right balance and front-rear fader settings. Audio System Optimization Interface - An audio system interface is provided, as well asa method of using same, in which a visual representation of the vehicle's passengercabin is displayed on the vehicle's touch-screen. When a user's touch registers on thevisual representation of the passenger compartment, the system matches the touch withone of a plurality of pre-defined acoustic sweet spots within the passenger compartment,and then adjusts the left-right speaker balance controller and the front-rear speakerfade controller to the specific left-right speaker balance setting and the specificfront-rear speaker fader setting defined by the selected acoustic sweet spot.Sunroof Control Interface Utilizing Position Presets - A sunroof control interface, aswell as a method of using the interface, is provided. The interface may use a visualrepresentation of the vehicle's exterior and/or a slide controller to help the user toquickly identify the desired sunroof position. Preset sunroof positions are used withthe control interface to simplify sunroof positioning. Assuming a touch-screeninterface, the user can simply tap on the visual representation of the vehicle, or tapon the slide controller, to select a preset sunroof position. The preset sunroofposition may also be selected using a mouse controller. The visual depiction of thevehicle may include a phantom sunroof overlay to further aid the user in selecting thedesired sunroof position. A numerical indicator may be used with either the overlay orthe slide controller to indicate the selected sunroof position relative to a fully open Sunroof Control Interface - A sunroof control interface, as well as a method of using the interface, is provided. The interface may use a visual representation of thevehicle's exterior and/or a slide controller to help the user to quickly identify thedesired sunroof position. Assuming a touch-screen interface, the user can simply tap onthe visual representation of the vehicle, or tap on the slide controller, to select thedesired sunroof position. The desired sunroof position may also be selected using amouse controller. The visual depiction of the vehicle may include a phantom sunroofoverlay to further aid the user in selecting the desired sunroof position. A numericalindicator may be used with either the overlay or the slide controller to indicate theselected sunroof position relative to a fully open or fully closed sunroof.Vehicle Air Suspension Control System - A method of automatically adjusting the rideheight of a vehicle each time the vehicle is in a particular location is provided, wherethe automatic ride height adjustment is based on location and ride height informationpreviously gathered from a user.Automated Audio Optimization System - An audio system is provided, as well as a methodof using same, which utilizes a plurality of sensors integrated into the vehicle's seatsto determine which of the seats are occupied. The system selects a pre-defined optimumacoustic sweet spot from a plurality of stored acoustic sweet spots based on which seatsare occupied and based on a set of acoustic optimization configuration instructions. Thesystem automatically adjusts the left-right speaker balance controller and the front-rear speaker fade controller to the specific left-right speaker balance setting and thespecific front-rear speaker fader setting defined by the optimum acoustic sweet spot.The acoustic optimization configuration instructions, which define the optimum acousticsweet spot for each combination of occupied vehicle seats, may be stored in the system'sDETECTION OF OVER-CURRENT IN A BATTERY PACK - A controller identifies a condition of a hazardous internal short by comparing patterns of series element voltages to the last known balance condition of the series elements. If the loaded or resting voltage of one or more contiguous series elements uniformly drop from the previously known condition by an amount consistent with an over-current condition, an over-current internal short circuit fault is registered. The desired response is to prevent the affected series elements from heating to a hazardous temperature by summoning the maximum heat rejection capability of the system until the short ceases and the affected elements cool, the cooling function is no longer able to operate due to low voltage, or the affected series string has drained all of its energy through the short. Also includes are responses that allow the battery pack to continue to power the cooling system even though it may enter HIGH VOLTAGE CABLE CONNECTOR - A system and method for a shielded coaxial cableincluding a collar including a cylindrical housing having a cylindrical inner bore, the inner bore having top and bottom openings the top opening having a diameter about equal to an outer diameter of an outer insulating layer of the cable and the bottom opening having a diameter about equal to an outer diameter of a shield layer of the cable with a terminating portion of the shield layer exposed and returned over an exterior portion of said collar near the bottom opening with the terminating portion overlapping said exterior portion; and a termination ferrule joined to the terminating portion that overlaps the exterior portion to simultaneously provide an electrical communication between the shield layer and the collar and provide a strain relief for the shielded Charge Rate Modulation of Metal-Air Cells as a Function of Ambient Oxygen Concentration - A method for charging a metal-air battery pack at the maximum possible rate while maintaining an ambient oxygen concentration below a preset concentration is provided, thereby minimizing the risks associated with generating oxygen during the charging cycle.PASSIVE AIR BLEED FOR IMPROVED COOLING SYSTEMS - An apparatus, including a sealed housing defining a manifold having an inlet port for receiving an input fluid streaminto the manifold and an outlet port for exiting an output fluid stream from the manifold; and a bleed structure having a proximal end, a distal end, and a hollow channel communicating a first opening at the proximal end to a second opening at the distal end, the distal end disposed within the manifold and the proximal end disposed in the outlet port outside of the manifold.BIDIRECTIONAL POLYPHASE MULTIMODE CONVERTER INCLUDING BOOST AND BUCK-BOOST MODES - A charging method using a multiphase line voltage for charging an energy storage system (ESS) using a polyphase motor drive circuit communicated to a polyphase motor, the polyphase motor drive circuit including a plurality M of driver stages, one driver stage for each phase of the polyphase motor with each driver stage coupled across the energy storage system.SELF-DISCHARGE FOR HIGH VOLTAGE BATTERY PACKS - A system and method for providing energy management and maintenance of a high energy battery pack through use self-discharge features and processes. A battery pack is configured with self-discharger enabled-components that selectively discharge energy from the battery pack without the battery pack providing operational power.SECONDARY SERVICE PORT FOR HIGH VOLTAGE BATTERY PACKS - A system and method for providing energy management and maintenance of a high energy battery pack that does not require installation of the battery pack into an operational EV. A secondary service port is provided to enable certain maintenance operations while by-passing battery pack interlocks and protection mechanisms used when the battery pack is installed into an operating environment.METHOD AND SYSTEM FOR SERVICING HIGH VOLTAGE BATTERY PACKS - A system and method for providing energy management and maintenance of a high energy battery pack that does not require installation of the battery pack into an operational EV. A battery service unit has multiple access mechanisms to charge or discharge a high energy battery pack through a primary or secondary high voltage port of the pack, irrespective of whether thebattery pack is installed into an operating environment by adding a capability of providing a signature duplicating installation of the pack in the operating environmentCHARGE RATE OPTIMIZATION - A charging system for a battery pack, including a chargingstation transferring energy to the battery pack at a maximum fast charge rate in a firstoperational mode and transferring energy to the battery pack at a slower charge rate ina second operational mode; a data collection system acquiring data indicating a state ofcharge of the battery pack and one or more desired charge optimization parameters; and astation control, responsive to the data and to the desired charge optimizationparameters, automatically establishing a charging profile for the battery pack to asserta control signal and operate the charging station in the second operational modewhenever the charging station is able to transfer sufficient energy to the battery packat the slower charge rate to meet an SOC target and a charge completion time target. HOST INITIATED STATE CONTROL OF REMOTE CLIENT IN COMMUNICATIONS SYSTEM - A system andmethod for low-cost, fault tolerant, EMI robust data communications, particularly for anEV environment. A data communications method, including a) enabling a transmission of awake signal from a host to a remote client through an isolator disposed at the remoteclient when the wake signal is asserted from the host at a host-portion of the isolatorconcurrent with a periodic enablement of a client-portion of the isolator by the remoteclient; and thereafter b) transmitting the wake signal from the host to the remoteclient through the isolator; c) controlling enablement of the client-portion responsiveto the wake signal transmitted through the isolator; and thereafter d) disabling the REDUNDANT MULTISTATE SIGNALING - A data communications system having a plurality of communication devices including a host having a first receiver and a second receiver; and one or more clients, each client including a transmitter coupled between a signal node and a transmitter node, the transmitter selectively transmitting a multistatesignal from the signal node to the transmitter node; and a single conductor daisy-chainloop redundantly communicating each multistate signal from each the transmitter to bothreceivers, the single conductor daisy-chain loop electrically communicating eachtransmitter node to the receivers. A data communications method including a)transmitting selectively a multistate signal from each of one or more clients; b)communicating electrically each multistate signal to a first location on a host using asingle conductor coupled to each the client; and c) communicating electrically each ROBUST COMMUNICATIONS IN ELECTRICALLY NOISY ENVIRONMENTS - A system and method for low-cost, fault tolerant, EMI robust data communications, particularly for an EV environment.HOST COMMUNICATIONS ARCHITECTURE - A system and method for low-cost, fault tolerant, EMIrobust data communications, particularly for an EV environment.WIRE BREAK DETECTION IN REDUNDANT COMMUNICATIONS - A system and method for low-cost,fault tolerant, EMI robust data communications, particularly for an EV environment. INTEGRATED INDUCTIVE AND CONDUCTIVE ELECTRICAL CHARGING SYSTEM - An apparatus and method efficiently integrating inductive and conductive charging systems, including embodiments directed towards enabling user selection of either, or both, of conductive and inductive charging. Conductive charging and inductive charging both have, in certain contexts or when judged by different criteria, advantages over the other. Systems and methodsrelying on one or the other would not have as wide-spread value to a user withopportunities to access both types of charging modalities.PARK LOCK FOR NARROW TRANSMISSION - A park lock of a transmission, including a parkgear; a park pawl rotating about a pawl shaft, the park pawl having a pawl portionlocking the park gear, the park pawl including a cam contact portion; a park rodresponsive to an operation of a controller, the park rod having a cam portion pressingthe cam contact portion to have park pawl engage the park gear; a park sleeve receivingthe cam portion and defining a first contact point providing a reactive force to the camcontact portion of the park pawl pressing against the cam portion at a second contactpoint; a pawl torsional spring biasing the park pawl towards disengagement; and a pawlstopper limiting the rotation of the park pawl wherein motions are constrained within aplane of the transmission and components are rotatingly disposed in parallel axis boresEMBEDDED OPTICS IN MODULAR ASSEMBLIES - An enhanced multiobject potting fixture forexposure to a curing modality that sets an adhesive includes a fixture housingsupporting a plurality of objects, the fixture housing having a wall defining aplurality of bonding wells with each the bonding well receiving a first portion of oneof the objects, each the bonding well including an aperture in the wall proximate thefirst portion wherein each bonding well includes a target zone for selective cure of theadhesive to inhibit the adhesive from exiting the aperture; and a fixture enhancementstructure integrated into the wall concentrating the curing modality in each the target Battery Pack Pressure Monitoring System for Thermal Event Detection - A system fordetecting thermal events, e.g., thermal runaway, within a sealed battery pack based on acharacterization of monitored pressure variations within the pack is provided. Thesystem includes at least one pressure sensor coupled to the battery pack and to apressure monitoring system that outputs pressure data representative of the battery packpressure over time; a system controller that analyzes the pressure data and outputs acontrol signal when the pressure data fits a specific curve shape; and a thermal eventresponse subsystem that performs a preset response upon receipt of the control signalfrom the system controller. The system may include a secondary effect monitoring system,wherein the thermal event response subsystem performs the preset response when thepressure data fits a specific curve shape and the secondary effect is detected by the Method of Operating a Dual Motor Drive and Control System for an Electric Vehicle - A method for optimizing the torque applied by each motor of a dual motor drive system of an all-electric vehicle is provided, the torque adjustments taking into account wheel slip as well as other vehicular operating conditions.LOW TEMPERATURE FAST CHARGE - An automated charge preparation method periodicallydetermines critical parameters for the set of relevant operating conditions, determineswhether fast charging is possible, applies fast charging when possible, otherwiseapplies a dynamically scaled charging rate that is optimized based upon current criticalparameters (while optionally heating the individual battery cells as long as fastcharging is not available) to reduce/eliminate a risk of lithium-plating.Electrical Interface Interlock System - A high voltage (HV) interface housing isprovided that includes an assembly of levers within the housing that detect whether ornot the HV lines are coupled to the interface housing. If the HV lines are not in place,the lever assembly prevents the interface cover from being fully installed onto theinterface housing, thereby preventing the HV interlock loop switch from being closed. Asa result, when the HV cables are not in place, the HV interlock loop switch preventspower from being applied to the HV circuit. If, however, the HV lines are properlypositioned within the interface housing, the levers of the lever assembly automaticallyretract, thus allowing the interface cover to be fully installed onto the interfacehousing. In this state, the interface cover closes the HV interlock loop switch, thus Electric Vehicle Battery Lifetime Optimization Operational Mode - A method of setting the operational mode of an electric vehicle is provided, where the operational mode is selected from a plurality of operational modes that include at least a Battery Life mode and a Standard mode, wherein the Battery Life mode is configured to select operating and charging parameters that emphasize battery health and battery life over vehicle range and/or vehicle performance. The system includes a thermal management system for maintaining the vehicle's battery pack to within any of a plurality of temperature ranges, and a charging system for charging the vehicle's battery pack to any of a plurality of minimum and maximum SOC levels and at any of a plurality of charging rates. Electric Vehicle Battery Lifetime Optimization Operational Mode - A multi-mode operating system for an electric vehicle is provided, the system including means for a user to select a preferred mode of operation from a plurality of operational modes that include at least a Battery Life mode and a Standard mode, wherein the Battery Life mode is configured to select operating and charging parameters that emphasize battery health and battery life over vehicle range and/or vehicle performance. The system includes a thermal management system for maintaining the vehicle's battery pack to within any of a plurality of temperature ranges, and a charging system for charging the vehicle'sbattery pack to any of a plurality of minimum and maximum SOC levels and at any of aCONTROL FOR AUTOMATED SOLDERING - A robotic processing system includes a microprocessor-controlled workpiece processor having a mobile processing element to be positionedindependently in three orthogonal dimensions with respect to each of a plurality oftarget locations on a workpiece, with each particular target location of the pluralityof target locations including an element to be processed, the mobile processing elementprocessing the element at each particular target location by first moving to an initiallocation that is offset from the particular target location in a single dimension andthen second moving along the single dimension towards the element at the particulartarget location until a contact signal is detected; and a control, coupled to theworkpiece and to the mobile processing element, communicating the contact signal to theworkpiece processor when the processing element makes physical contact with the element BATTERY MODULE WITH INTEGRATED THERMAL MANAGEMENT SYSTEM - A controller identifies acondition of a hazardous internal short by comparing patterns of series element voltagesto the last known balance condition of the series elements. If the loaded or restingvoltage of one or more contiguous series elements uniformly drop from the previouslyknown condition by an amount consistent with an over-current condition, an over-currentinternal short circuit fault is registered. The desired response is to prevent theaffected series elements from heating to a hazardous temperature by summoning themaximum heat rejection capability of the system until the short ceases and the affectedelements cool, the cooling function is no longer able to operate due to low voltage, orthe affected series string has drained all of its energy through the short. Alsoincludes are responses that allow the battery pack to continue to power the cooling Electric Vehicle Extended Range Hybrid Battery Pack System - A power source comprised of a first battery pack (e.g., a non-metal-air battery pack) and a second battery pack (e.g., a metal-air battery pack) is provided, wherein the second battery pack is only used as required by the state-of-charge (SOC) of the first battery pack or as a result of the user selecting an extended range mode of operation. Minimizing use of the second battery pack prevents it from undergoing unnecessary, and potentially lifetime limiting, charge cycles. The second battery pack may be used to charge the first battery pack or used in combination with the first battery pack to supply operational power to the Electric Vehicle Extended Range Hybrid Battery Pack System - A power source comprised of a first battery pack (e.g., a non-metal-air battery pack) and a second battery pack (e.g., a metal-air battery pack) is provided, wherein the second battery pack is used when the user selects an extended range mode of operation. Minimizing use of the second battery pack prevents it from undergoing unnecessary, and potentially lifetime limiting, charge cycles.DETECTION OF OVER-CURRENT IN A BATTERY PACK - A controller identifies a condition of ahazardous internal short by comparing patterns of series element voltages to the lastknown balance condition of the series elements. If the loaded or resting voltage of oneor more contiguous series elements uniformly drop from the previously known condition byan amount consistent with an over-current condition, an over-current internal shortcircuit fault is registered. The desired response is to prevent the affected serieselements from heating to a hazardous temperature by summoning the maximum heat rejectioncapability of the system until the short ceases and the affected elements cool, thecooling function is no longer able to operate due to low voltage, or the affected seriesstring has drained all of its energy through the short. Also includes are responses thatallow the battery pack to continue to power the cooling system even though it may enter SEALING MECHANISM OF AUTOMOBILE DOOR - A sealing mechanism of an automobile door including a sliding window pane configured to be raised or lowered to/from the door window part and a side panel, includes: a retainer fixed to the side panel; and a glass run held by the retainer. The glass run includes a hollow seal part, and the base of the seal part has a slit. A pair of engagement parts of the retainer is engaged with both sides of the base of the seal part. A ridge located between the engagement parts of the retainer is fitted in the slit of the base.GLASS-RUN RETAINER FOR AUTOMOBILE DOOR AND DOOR STRUCTURE OF AUTOMOBILE - An integratedretainer in which an inner part of a retainer upper part extending above a door beltline and an inner part of a retainer lower part extending below the door belt arecontinuous without a joint line is employed for an automobile door. The retainer lowerpart has an approximate U shape including an inner part and an outer part as glass-runholding parts. The retainer upper part includes only an inner part as a glass-run。

BEST AVAILABLE COP'(No Model';.) ... '2'Sheets—Sheet l.N. TESLA.DYNAMO ELECTRIC MACHINE.自激发电机No. 390,414, ' Patented Oct. 2,.1888。

图1WITNESSES:INVENTORBEST AVAILABLE COP'(No Model';.) ... '2'Sheets—Sheet 2.N. TESLA.DYNAMO ELECTRIC MACHINE.自激发电机No. 390,414, ' Patented Oct. 2,.1888。

WITNESSES:BEST AVAILABLE COP'United States Patent Office.对于所有关心的人来说:我们知道,尼古拉-特斯拉,一个奥地利帝国的国民,来自于奥地利-匈牙利边境国家Lika的Smiljan;目前住在纽约。

他已经在自激电机上发明了新的有用的改进。

以下是对应同样的上图的详细说明。

在已经授权给Charles F. Peck和我的一些专利中,尤其是专利381968和382280—1888.5.1,我已经提到一个建造和操作电机以及变压器等等的计划;通过一个与电机和变压器有关的发电机的两个或更多的独立电路产生的交流电,这样就产生了磁极或者磁力线的连续变化。

在前面所提到的申请中描述的电机都被限制在交流电机器的类型,这种机器的线圈产生的电流是独立的或分离的。

但是我现在已经发现普通形式的直流的电机可能更容易用于我的系统也更便宜,或者用我本文提到的方法在建造时稍微改变一下就可以既适用直流也适用交流电了。

一般规定,我提出的这个发明计划具体如下:在一个给定电机的轴上,或者也可以是固定换向器上,我绑上和电路一样多的多对绝缘的集电环。

??现在将可以理解,在任何发电电机的操作中,线圈的电流在运动中通过场或者力经历了不同阶段----那就是说,在线圈的不同位置电流有确定的方向和强度。

2019年7月23日消息,据国外媒体报道,电动汽车制造商特斯拉日前提交了一份有关新型布线结构的专利申请,这种模块化布线结构更适用于汽车的自动化组装。

当特斯拉为扩大Model 3产能而引入更多的自动化流程时,机器人在布设长而柔软的汽车线束(汽车电路的连接主体)时遇到了麻烦,特斯拉不得不人工布设汽车线束。

在这个全新的布线体系结构中,子系统将被打包并定义在特定实施例中的一个或多个程序组装。

除了减少所需的布线数量和长度外,创建这些子安装并将它们连接到线路体系结构主干的做法还将能减少总装的组装时间,这对于提高汽车制造过程中的生产率是非常理想的。

这种方法可能还使得汽车的电子元件和系统能够更容易进行升级,因为它不会影响到整个汽车线束。

特斯拉的新型布线系统仍在专利申请过程中,但这种设计很简洁,如果实现的话,可能会帮助特斯拉节省大量的劳动力成本。

据悉,特斯拉已经缩短了其汽车的电线束长度,从Model S的3千米减少到了Model 3的1.5千米,而其最终目标是等到量产Model Y的时候将该长度减少到100米。

据悉,这项技术有望在特斯拉未来推出的2020款紧凑型SUV--Model Y中首次得到应用。

标题:线束系统结构摘要:一种用于汽车的新型线束、电源分配以及通信系统,包括多个设备,其中所属设备连接到具有外护套的主干节段,第一导线设置在外覆层内,第二导线设置在外覆层内,一对内部护套设置在外覆层内并至少包裹住一根导线,作为第一导线和第二导线之间的绝缘层,并且外覆层内也设置了屏蔽部件。

背景技术领域本发明设计一种新型线束、电源和通信分配系统。

更具体地,本发明设计汽车的线束系统。

背景技术传统的汽车线束系统是零散的解决方案。

通常,由不同的线束将每个不同的电气部件连接到一个中央电池或者电源。

每个部件都分配电源,但是通信和信号则需要多个线束。

在一辆车内,线束的总长可达数英里。

这些线束通常由多个不刚性的圆形导体组成。

圆形导体不适合传输电流,并且传统线束不够刚性导致需要采用人力将其组装到汽车上,进而拖慢生产节奏。

特斯拉专利开放条件(中英文实用版)Title: Tesla"s Open Patent Policy with Conditions特斯拉的专利开放政策是有条件的。

Tesla"s patent open policy is conditional.特斯拉宣布对其专利实行开放政策,允许其他公司免费使用其技术,但有一定的条件。

Tesla has announced an open patent policy, allowing other companies to use its technology for free, but with certain conditions.首先,使用特斯拉专利的公司必须遵守非歧视原则,即不能因为专利权而限制其他竞争对手的使用。

Firstly, companies using Tesla"s patents must adhere to a non-discriminatory principle, which means they cannot restrict the use of competitors due to patent rights.其次,使用特斯拉专利的公司必须公开其改进的技术细节,以便整个行业共享和进步。

Secondly, companies using Tesla"s patents must disclose the details of their improvements, so that the entire industry can share and progress.最后,特斯拉保留在必要时对违反上述条件的企业采取法律行动的权利。

Lastly, Tesla reserves the right to take legal action against companies that violate the above conditions when necessary.总的来说,特斯拉的专利开放政策旨在促进电动汽车技术的发展,但同时也要求其他公司遵守一定的规则和条件。

专利经典案例在知识产权领域,专利是一项非常重要的法律工具,它保护了发明者的创新成果,鼓励科学技术的发展。

本文将介绍几个专利经典案例,以展示专利的作用和价值。

一、Wright兄弟的飞行器专利1903年12月17日,美国的Wright兄弟成功进行了第一次有人驾驶的飞行,他们的飞行器具有独特的机翼设计和可操纵的双翼平衡装置。

然而,尽管他们的创新彻底颠覆了人们对航空的认识,但他们并没有立即受到认可。

直到1906年,Wright兄弟才获得了他们的专利权。

这个专利对于之后航空业的发展有着重要的影响。

为了保护他们的权益,Wright兄弟成立了Wright公司,开始积极维护他们的专利,起诉那些侵犯了他们知识产权的企业。

这个案例展示了专利的重要性,它不仅保护了专利持有人的权益,还为他们提供了商业竞争的优势。

二、特斯拉的无线电专利尼古拉·特斯拉是一位杰出的发明家和物理学家,他的很多发明都对现代科技产生了深远的影响。

其中最著名的是他的无线电技术发明,这项技术被广泛应用于通信和电力传输领域。

特斯拉于1897年申请了无线电传输的专利,这项专利保护了他的发明权,并且使他能够控制无线电技术的市场。

然而,在后来的几年里,他的主要竞争对手马克·托马斯·爱迪生也开始对无线电技术感兴趣,并试图通过法律手段阻止特斯拉的发展。

这场专利纷争最终在1915年以特斯拉的胜利而告终,他成功地保护了他的无线电专利。

这个案例强调了专利在技术竞争中的作用,它不仅能够保护发明者的权益,还能够促进技术的进步。

三、苹果公司的多点触控专利多点触控技术是现代智能手机和平板电脑的核心功能之一,它革命性地改变了我们与数字设备互动的方式。

苹果公司是首家将多点触控技术应用到移动设备上的公司,他们于2007年发布的第一代iPhone搭载了这项技术。

为了保护他们的创新成果,苹果公司积极申请了多点触控技术的专利。

他们的专利涵盖了触摸屏幕、手势识别和多点输入等多个方面,确保了他们在市场上的独占地位。

特斯拉汽车公司专利申请中的发明人分析作者:杜凯等来源:《中国高新技术企业》2016年第06期摘要:发明人分析在专利分析中具有重要的作用,通过研究特斯拉专利申请中的发明人的排名、技术生涯和合作关系,可以了解特斯拉在各领域的主要研发人员和研发团队。

分析结果表明:特斯拉专利申请量排名第一位的是HERMANN WESTON ARTHUR,排名第二位的KOHN SCOTT IRA是特斯拉电池领域的核心发明人,他们掌握着特斯拉在电池领域的核心技术。

关键词:特斯拉汽车公司;专利申请;统计分析;发明人;电池领域文献标识码:A中图分类号:G302 文章编号:1009-2374(2016)06-0190-02 DOI:10.13535/ki.11-4406/n.2016.06.094特斯拉汽车公司(Tesla Motors,以下简称特斯拉)是电动车中的明星,被誉为“汽车界的苹果”。

在2014年6月12日,特斯拉公司首席执行官埃隆·马斯克宣布开放了特斯拉的所有专利。

到目前为止,国内几乎没有文献报道有关特斯拉专利申请的分析,更没有有关其发明人分析的相关文献报道。

发明人分析在专利分析中具有非常重要的作用,以发明人为研究入口,不仅可以针对单个发明人展开分析,明确其擅长的主要研究技术领域,还可以了解目标企业在各领域的主要研发人员或研发团队,从而获得有益的技术信息。

1 数据来源和检索方法本文以申请人“Tesla motors”在德文特数据库(DWPI)进行了检索,获得特斯拉的发明专利申请286项,文中数据截止到2015年6月1日。

2 发明人信息分析为了全面而深入地了解特斯拉专利申请中的发明人信息,笔者对特斯拉的全部专利进行了技术构成的分解,并对其全部专利进行了标引。

根据标引的数据从以下方面进行专利信息的分析:2.1 发明人排名图1为特斯拉专利申请量前10位发明人排名,从图1可以看出,其中排名第1位的是HERMANN WESTON ARTHUR,达到了83项,排名第2位的是KOHN SCOTT IRA,达到了67项,而排名第3位的是STRAUBEL JEFFREY BRIAN,只有39项。