Waiting is mostly due to long runs , poor production flow and machine downtime , Including waiting for the next process step or for parts or for tools . Waiting is a major cause of production and sales bottlenecks and high inventory levels of raw material, parts , sub-assembly and finished goods storage.

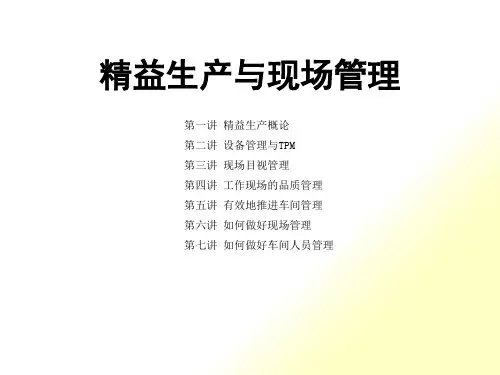

约定最好的质量、成本、交货期时间, 重量轻

可持续的改进

团队合作

完美交付

资源的质量

标准化和稳定过程 工作场所组织(5 s)和可视化管理 管理通过事实使用适当的工具

清晰的战略基础

Lean Manufacturing can be defined as it is a systematic approach to identifying and Eliminating waste(non-value-added activities) through continuous improvement by flowing the product at the pull of the customer in pursuit of perfection. 精益生产定义:为了追求完美,一个很好的方法是通过拉动生产使产品流动 起来以确定和清除浪费。

Countermeasures 方法: 市场预测 系统计划 供应链管理

Defects : result in rework and scrap . It requires additional resources and time to correct defects before shipping or flowing to next station. Defects cause additional material cost , production capacity losses and work rescheduling. 缺陷:会导致返工和废品,还会浪费额外的资源和时间,在运输或者到下 一个工作流程之前需要额外的时间跟资源去修正那些缺陷,缺陷会导致额外 的材料成本,影响生产力,会影响工作时间的分配。