西门子MES介绍

- 格式:pdf

- 大小:3.43 MB

- 文档页数:29

MES系统基本要素介绍MES系统基本要素介绍:01、技术构架尽管绝大部分的客户不容易关注MES系统布置的技术构架,但假如是好的MES系统产品,需最先务必具有优秀的技术支撑点(如SOA构架),只能优秀的平台相互配合上可配备的控制模块摸组,才可迅速搭建出合乎不一样客户情景的业务流程作用。

假若一下下:在生产制造管理方法中所有人的业务流程企业愿景和管理方法设计风格都不同,有的规定认真细致、有的期待灵便,有的重视监管、有的潜心实行,如果不是1个强劲的平台主龙骨而无限定地沉积客制化控制模块,那麼再多的系统软件都是坍塌、服务器宕机。

这就是说为何西门子PLC、达索等工业生产软件项目大多数选用SOA构架的缘故,在这个基础上,再相互配合上MVVM方式的编码撰写标准,通常用好几百、数千个灵便的、低耦合性的基本摸组就能搭建出百万种不一样的业务流程作用,让众口已不难调。

因而,针对有高规定、非常要以朝向智能制造系统为方向的顾客,必须在挑选MES系统产品以前,先认识一下该产品的最底层技术。

02、基本功能从作用包含性上来讲,作用全方位的MES系统系统软件需具有产品和加工工艺管理方法、方案生产调度企业生产管理、原材料仓储管理、产品质量管理、生产车间设备维护管理的几大基础控制模块,或许也应一起包含生产制造资源优化配置等控制模块。

而应对智能制造系统的MES系统,还务必具有信息系统集成和机器设备插口控制模块(另述),不然没法建立生产车间內部各种信息内容相通,并支撑点智能化系统生产车间需要的智能化生产调度、提升、数据可视化等作用。

这都是将要公布的国家标准《智能化生产车间通用性技术标准》、《智能工厂通用性技术标准》中常明确规定的,因而,具有以上作用的MES系统才具有了基本建设智能车间的基本标准。

03、平台化销售市场上的MES系统关键分成根据客户满意度的新项目级、客制化产品,及其通用性的平台化产品二种种类。

新项目级別MES系统优势是:人性化、可接受性强、成本低、迅速交货,但产生的缺陷是:开发设计要求叙述时会缺乏制造行业的客观性标准,非常容易导致系统软件不符变化多端的业务流程要求及制造行业标准,如果企业规划发展趋势后有新的要求就必须资金投入很多的程序开发,这对软件体系结构的可靠性都是不容乐观的磨练。

应用MES(生产执行系统),对工厂进行整体优化摘要:中国加入WTO以后, 中国的钢铁工业面临诸多挑战, 如更加灵活的生产, 更苛刻的质量要求以及具备竞争力的成本。

这些目标只有通过投资具有成本效益的生产线,使用最新的科技才能够达到。

目前,独立的生产线的自动化水平和优化程度已经很高,进行进一步改进的空间非常有限。

而ERP(企业资源策划)系统仅局限于总体生产计划的编制,并没有考虑设备的实际状态和生产线的工艺约束。

因而现代化的工厂需要通过使用最新技术,联合多个独立的生产线组成一个优化的生产链并连接基础自动化级,过程级与管理级。

根据MESA(制造执行系统协会)的定义,MES是对从下达订单到生产出最终成品的生产过程进行优化的信息系统。

本文详细描述了钢铁工业MES系统的不同功能模块和典型的系统结构。

通过分析一个具有成熟功能的实际案例,揭示了MES系统为工厂的所有者带来的效益。

正文MES系统是企业信息化建设的重要组成部分中国加入世界贸易组织后,中国的钢铁工业正在面临几个主要的挑战;它们是:∙更为灵活的生产钢铁工业的客户期望在定单执行、定单修改方面有更大的灵活性,同时缩短和保证交货时间。

∙产品质量方面的更高要求对于所有客户的复杂产品结构,卓越的产品质量是企业成功的关键因素。

同时,国际质量标准要求详细而完整的产品生产质量文档。

∙具有竞争力的成本定位具有竞争力的价位是能够在国际化的钢铁市场中生存的重要因素。

这必须通过以提高生产率,设备作业率为手段,提高产量和经济效益才能够达到。

所有这些目标,只有通过投资具有经济效益的生产线并使用最新科技才能够实现。

目前,独立的生产线的自动化程度和优化水平已经很高,进一步改进的空间非常有限。

另一方面,ERP (企业资源策划)系统局限于总体生产计划的编排,而没有考虑设备的实际运行状态和生产线的工艺约束。

因而现代化的工厂需要现代科技作为企业信息化建设的重要组成部分,联合多个独立的生产线构成生产链(水平集成),并连接生产层与管理层(垂直集成)。

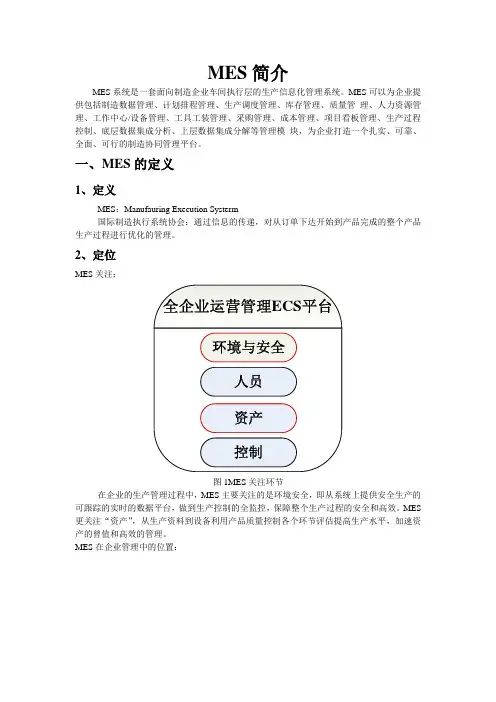

MES简介MES系统是一套面向制造企业车间执行层的生产信息化管理系统。

MES可以为企业提供包括制造数据管理、计划排程管理、生产调度管理、库存管理、质量管理、人力资源管理、工作中心/设备管理、工具工装管理、采购管理、成本管理、项目看板管理、生产过程控制、底层数据集成分析、上层数据集成分解等管理模块,为企业打造一个扎实、可靠、全面、可行的制造协同管理平台。

一、MES的定义1、定义MES:Manufauring Execution Systerm国际制造执行系统协会:通过信息的传递,对从订单下达开始到产品完成的整个产品生产过程进行优化的管理。

2、定位MES关注:图1MES关注环节在企业的生产管理过程中,MES主要关注的是环境安全,即从系统上提供安全生产的可跟踪的实时的数据平台,做到生产控制的全监控,保障整个生产过程的安全和高效。

MES 更关注“资产”,从生产资料到设备利用产品质量控制各个环节评估提高生产水平,加速资产的曾值和高效的管理。

MES在企业管理中的位置:企业控制系统图2MES 在企业生产管理中的环节从图2可以看出MES 是所处环节是企业生产过程中的运营管理中的生产执行环节,企业从生产计划到产品的的产出过程都在MES 的考虑之中。

按照ERP 制定的计划MES 从材料的输入,设备生产过程监控效率分析,产品质量评估,次品率监控等环节提供整体解决方案真正做到生产的透明化,将以往难以估计的环节量化,让企业发现那些难以发现又有限生产的环节提高企业效率曾强竞争力。

MES 在系统结构中的位置:PLC 器,现场设备图3MES 在企业软件系统中的所处的环节图3 所反映的是MES 在生产过程中的作用即将ERP 和制造过程中的间隙填补使企业的ERP和生产过程紧密的结合起来,保障企业的生产过程的效益分析。

对生产过程的的各个环节进行效益分析,使生产过程不仅仅自动化而且效益化。

企业管理层次架构图4MES所处管理层次从管理角度上看MES间于企划层和控制层之间,负责企业计划的执行和对执行的分析。

应用MES(生产执行系统),对工厂设备进行整体优化Werner Klein,西门子(中国)有限公司摘要:中国加入世界贸易组织后,中国的钢铁工业正在面临挑战,需要进行更为灵活的生产,满足产品质量方面的更高要求,并进行具有竞争力的成本定位。

这些目标的实现,只能通过投资具有成本效益的生产线,使用最新的科技才能够达到。

目前,独立的工序已经实现了自动化,并进行了优化,因此很少留有改进的空间。

ERP(企业资源规划)系统在总体生产规划方面的作用是有限的。

对实际工厂设备状况的知识,以及生产工序在工艺方面的限制,都是ERP 系统所不能提供的。

因此,现代工厂设备需要新的工艺,这是企业IT的重要内容,能够将不同的独立工序联系在一起,组成一个最佳的工序链,并与自动化建立联系,使工序水平达到管理水平的要求。

根据MESA(生产执行系统协会)的定义,MES交付的信息能够优化从定单到成品全过程的生产活动。

本报告详细说明了MES对技术工业和典型系统架构的不同技术功能。

通过对具有高度精密功能的实际MES进行分析,报告阐述了工厂设备所有者能够获得的益处。

MES系统是企业信息化建设的重要组成部分中国加入世界贸易组织后,中国的钢铁工业正在面临几个主要的挑战;它们是:•更为灵活的生产钢铁工业的客户期望在定单执行、定单更新方面有更大的灵活性,同时缩短和保证交货时间。

•产品质量方面的更高要求即使在提高产品组合,以向所有客户提供服务的情况下,优异的产品质量也是企业成功的关键因素。

此外,国际质量保证还要求对生产过程中的产品质量,进行详细而完整的记录。

•具有竞争力的成本定位具有竞争力的成本定位,对立足于全球钢铁市场是至关重要的。

这一目标的实现,需要增加生产率、产量和设备可用性来提高生产力和成本效率。

这些目标的实现,只能通过高成本效率生产工序方面的投资,并使用最新技术水平的工艺。

目前,独立的生产线已经实现了自动化,并进行了优化,因此很少留有改进的空间。

什么是一个成功的MES?什么是一个成功的MES? 这好像是一个没有答案的问题,没有答案的问题不代表不可以探讨。

笔者借对MES的一点认识,从技术和工具的层面谈一点理解,与大家探讨。

一、MES 需要标准产品“我们在MES上投资了很多。

可是几个月后,由于我们的新产品以及一些流程改进,我们发现我们需要双倍的投资来满足当前的需求。

” 这是在一次与客户交流中听到的。

这实在是值得我们思考的一个问题。

据不完全统计,去年全球有将近4000个MES项目,如果每一个项目都是这种情形,客户岂不是痛苦难堪。

-- 这告诉我们,MES是需要标准产品的。

基于标准产品的MES才能更好的来帮助客户降低总体拥有成本。

然而我们知道,MES是一个很特殊的领域:不同的行业需要不同的解决方案:汽车制造和电子制造是不同的,离散制造与流程制造是不同的. . .相同的行业解决方案也不尽相同:戴尔和联想的PC生产是不同的,蒙牛与伊利的制造无法相同 . . .即便是同一公司不同的工厂,他们的设备、他们的管理、他们的流程都有可能不同。

这就给标准产品一个巨大挑战,标准产品如何能够来满足各个领域内不同的需求,而且又能针对客户的流程变化、工艺变化、设备变化等等不同的情况很容易的对系统进行修改。

MES 需要能够自上而下的满足客户的需求看看今天的制造业所处的环境,我们不难发现,越来越多的公司进行着大规模的资源整合、企业并购,企业以各种不同的方式进行着变革。

公司管理标准化、流程标准化, 企业流程重组、ISO、GMP、6西格玛、精益制造…等等,都要求企业管理不断地上台阶。

对于制造业而言,公司所有下属工厂的统一管理当然是一个重头戏。

而对于MES,当仁不让的需要能够帮助企业对所有工厂进行统一的管理。

能够从公司层出发,对所有的公司按照同样的管理思路与理念,建立整合的MES系统,并且按照同样的模式与ERP、SCM系统进行集成。

当然,在这个过程中,MES必须能够考虑到每一家工厂的不同特性:·他们的自动化水平不尽相同:有的是先进的现代化工厂,有的是传统的老式工厂. .·他们的设备和控制系统不尽相同:他们的设备和控制系统可能来自各个不同的厂家,甚至完成着个不相同的工作 . . .·他们使用着不同的原材料,甚至生产着不同的产品·他们甚至根本就不属于同一行业MES 需要能够自下而上的满足客户的需求看到这里,很多客户会说,这样的 MES是好,可是我在这个领域已经发展了很多年,开发了很多自己的应用程序,按你的说法,我不是要把他们全给废了?这是现实生活中处处可见的例子,我们走进任何一家工厂,他们都多多少少的建立各种计算机系统来帮助管理,比如有的建立了质量管理系统、有的有物料跟踪系统、有的有设备停机管理系统等等,而且很多系统在使用中深受好评。

Siemens PLM SoftwareCamstar Semiconductor Suite Global MES to keep pace with demanding change in frontend and backend operationsBenefits• Rapidly implement a manufacturing execution system platform for maximum ROI• Increase process yields by building quality into processes• Quickly adapt to changing processes and product designsapplication can grow with and conform totheir business needs.Camstar Semiconductor Suite is designedfor frontend and backend manufacturingoperations, offering a high level of out-of-the-box industry functionality, the highestlevel of configurability and completeinteroperability with other business sys-tems. It provides instant intelligence; fromtest results and yields to statistical qualitycontrol that enable you to improve qualityand productivity.SummaryCamstar™ Semiconductor Suite effectivelyreplaces legacy and siloed manufacturingsystems that haven’t kept pace with thedemanding and ever-changing require-ments of semiconductor manufacturing.With Camstar Semiconductor Suite, manu-facturers are no longer hindered by islandsof automation and disjointed systems: nowthey can innovate, adapt and succeed.Manufacturers that choose CamstarSemiconductor Suite are up and runningquickly, and are assured that the/mom/camstarGetting moreReplace the basic work-in-progress (WIP) tracking of your legacy manufacturing exe-cution system (MES) with CamstarSemiconductor Suite and also get dispatch-ing, statistical process control (SPC), nonconformance management, dash-boards, maintenance management,paperless manufacturing and much more.Standardizing on a single systemDeploy one configurable enterprise MES across your global frontend and backend operations, including Fab, Probe, Assembly Test and Subcontractors. Standardization enables consistency in global reporting and simplification of application support.Benefits continued• Quickly and accurately deploy manufacturing process changes• Easily integrate withbusiness systems and shop floor equipment • Standardize on a single solution for frontend and backend plants • Eliminate the cost and risk of aging systemsCamstar Semiconductor SuiteEnhance efficiencyReplace your cumbersome systems with a modern and robust MES that is powerful enough to handle high transaction vol-umes, and is flexible enough to meet each site’s specific needs. Camstar MES platform enables you to efficiently innovate, adapt and change.One platform for semiconductor manufacturingComplete traceabilityCamstar Semiconductor Suite provides the complete history of all manufactured lots, wafers and serialized units, spanning pro-duction in multiple plants. Some of the information captured as part of the search-able, electronic audit trail includes materials consumed, processes utilized, parametric data collected, splits and com-bines, bins, shipments and receipts as well as dates and times.Visibility and control of WIPMultilevel work-in-process tracking provides unprecedented visibility and control over production processes. Data can be collected by lot, wafer, serial number, etc., as well as in combinations of these categories. Operators are presented with instructions for each product and process. Movement and processing can be controlled by myriad business logic functions, such as time lim-its, future holds and test results. Maintenance managementIntegrated equipment maintenance man-agement supports proactive problem resolution and optimal equipment schedul-ing for both primary and sub tools. It automatically tracks and schedules mainte-nance based on time or usage, which can include enforcement of predefined job pro-cess flows. It also tracks equipment, tool and carrier states, and ensures that only qualified and calibrated resources are used for processing. Downtime registration pro-vides grouped reason codes and operator logging functionality.Statistical process controlCamstar Statistical Process Control (SPC) applies statistical process control to quality and defect data that is collected during the manufacturing process, allowing manufac-turers to identify, analyze and solve potential problems while production continues before equipment is shut down, material is scrapped and production time is lost. Engineers select the statistical rules that the SPC engine will apply to the chart. Violation of a rule causes an alarm, and can also trig-ger actions such as generating an alert or email notification, changing the status of a machine, or placing material on hold. With ad hoc access to control charts, engineers can use Camstar SPC to monitor current con-ditions and to perform historical analysis. Graphical resource layoutDrawing on real-time data from Camstar MES, resource layout graphically displays the status of all your manufacturing resources so you can maximize throughput, pinpoint potential capacity issues and prior-itize maintenance.Manufacturing process change managementSuperior manufacturing process change management capabilities enable the swift deployment of new or updated products and processes across your global manufac-turing operations. It is a game changer for manufacturers of complex products who must quickly accommodate high volumes of manufacturing changes.Features• Visibility and control of work-in-progress• Automatically enforced dispatching• Integrated equipment maintenance management • Statistical process control and nonconformance management• Manufacturing process change management and quality enforcement• Comprehensive workflow management• Operator certification and trainingManufacturing quality enforcement Camstar Semiconductor Suite facilitates a self-auditing manufacturing process to con-trol production and collect detailed manufacturing quality data in real time. Electronically managed specifications and procedures significantly reduce the possibil-ity of human error, and direct integration with equipment and tools allows for maxi-mum data acquisition. Automatic detection and control of parametric data results com-bined with structured data and reporting and analysis tools make it possible to solve problems quickly, easily preventing recur-rences. Visualization of key manufacturing and quality performance indicators, root cause analysis of issues and controlled exe-cution of changes all facilitate continuous product and process prehensive workflow management Intuitive workflow modeling employs drag-and-drop tools, making it easy to set up dynamic routings, add new steps, vary pro-duction requirements and make customer order changes, all with revision control and an audit trail. Camstar Semiconductor Suite enables you to manage complex workflows with hundreds of Fab operations, frequent rework paths and parametric data collec-tion. Multiple products on a wafer, multi-die parts, stacked die assembly, wafer sort, bumping, back grind, assembly, test and binning are all part of the application, elimi-nating the need to modify the system.Achievements• Reduced costs while increasing throughput and quality• Reduced operating costs from between $2.6 and $3.3 million over three years• Lowered rollout costs for new sites by 75 percent • Met 90 percent of business requirements with an out-of-the-box solution• Implemented MES in new plant environment in 60 days • Implemented MES in three operating plants in 11monthsManufacturing business intelligenceA wide range of monitoring, reporting, ana-lytical and notification capabilities enable better and faster business decisions based on real-time, relevant manufacturing and qual-ity data across multiple manufacturing sites. Camstar Intelligence software provides state-of-the-art dashboard visualization of key manufacturing performance indicators with drill-down analysis, as well as the ability to close the loop on identified problems by managing root cause analysis and enforcing changes that prevent issue recurrence. Enterprise business process interoperabilityCamstar Semiconductor Suite creates an enterprise manufacturing and quality hub that aggregates real-time production and quality data for collaboration within the business and with suppliers and customers. It interacts easily with enterprise resource planning (ERP), applied power systems (APS), quality management system (QMS), data warehouse (DWH) and product lifecy-cle management (PLM) applications for synchronizing products and bills of material (BOM); downloading orders and providing timely and accurate work-in-process infor-mation for improving designs, quality, inventory, processes, planning and financial analysis. Camstar Semiconductor Suite delivers best practices interoperability with leading ERP systems such as SAP® software, Oracle® software and Microsoft Dynamics® software.Equipment tool trackingDetailed resource tracking supports the Semiconductor Equipment Materials Initiative (SEMI E10) and other state models and allows overall equipment effectiveness (OEE) key performance indicator (KPI) cal-culations to determine bottlenecks and inefficiencies on the shop floor. It also sup-ports tracking tools, tool life, tool usage and job models such as cleaning and refur-bishment. The flexibility of Camstar Semiconductor Suite supports processing multiple lots within different chambers of equipment and auto lines consisting of con-nected equipment.Nonconformance management Nonconformance management is used to automatically recognize and react to excep-tions or failures with parametric data specification limits, percent defect allow-ances and yield limits, material issues, binning and retest requirements. It enforces structured failure analysis, root cause iden-tification, quarantine and final disposition (release, rework, scrap, etc.), and prevents product shipment or processing beyond a prescribed step until all issues are resolved. Event managementEvent management enables the identifica-tion and documentation of quality events from any production or nonproduction source across the enterprise, and applies standard risk criteria to triage and route events appropriately. It monitors the enter-prise and identifies quality incidents, enables the necessary investigation and enforces quality processes.BEFORE… replace obsolete and cumbersome islands of automation and disjointed systems.Equipment type 1Equipment type 2Equipment type 3+1 314 264 8499 +852 2230 3308 Label printingLabel printing automatically prints product labels from actual specification and manu-facturing data, ensuring that labels are accurate, produced in a timely manner and are attached to the proper lot, wafer or unit.Operator certification and trainingOperator certification and training enables you to establish manufacturing roles, define training for the various roles, define process certification requirements, maintain train-ing records and establish certificationexpiration. Automatic certification verifica-tion ensures that only qualified employees perform prescribed shop floor functions. Fast, easy operator interactionOperators use simple forms to view instruc-tions and record data and events. Browser- based user interfaces can be configured to effectively guide and respond to the way people work. In addition, any data can be collected directly from production systems and equipment, ensuring maximum speed.Customization without programmingConfigurable business logic, rather than hard- coded logic, allows Camstar Semiconductor Suite to be tailored to meet unique factory requirements without changing program code. Server-side logic makes it easy to integrate the application with existing sys-tems, make new functionality available without disrupting operations and com-pletely support thin-client workstations. Process automation controlCamstar for Process Automation Control software integrates multiple pieces ofequipment within the factory infrastructure into the MES, providing fully automated control, status monitoring, material track-ing and data collection. The bi-directional communication allows the MES to verify that correct lots, products, tools, recipes and parameters are being used. Camstar for Process Automation Control supports multi-ple protocols, including Semiconductor Equipment Communication Standard/SEMI connectivity standard E30 (SECS/GEM), Extensible Markup Language (XML), SEMI PV2, OLE for process control (OPC),Structured Query Language (SQL) and sev-eral others, enabling rapid, reliable and cost effective integration.。

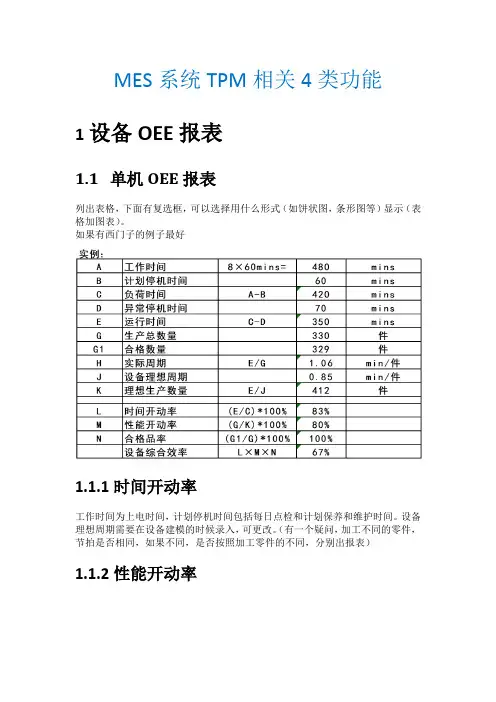

MES系统TPM相关4类功能1设备OEE报表1.1单机OEE报表列出表格,下面有复选框,可以选择用什么形式(如饼状图,条形图等)显示(表格加图表)。

如果有西门子的例子最好1.1.1时间开动率工作时间为上电时间,计划停机时间包括每日点检和计划保养和维护时间。

设备理想周期需要在设备建模的时候录入,可更改。

(有一个疑问,加工不同的零件,节拍是否相同,如果不同,是否按照加工零件的不同,分别出报表)1.1.2性能开动率1.1.3合格率1.1.4 OEE设备综合利用率OEE=时间开动率*性能开动率*合格率整线OEE的公式目前没有,最好有依据可以参考,提出公式之后,最好到现场模拟,看看是否适用。

2设备维护管理设备维修时间精确到分2.1设备点检点检按照人员来分,分为操作人员点检,专业人员点检。

2.1.1每日点检每日/每班点检要做出提示:例如8点-8点半,请OP100做点检/保养。

PDA输入,人工输入,每个员工只能点检他对应的机床(防止代他人点检机床),点检项目库由excel导入。

每日点检,点检所有的项目。

每个员工都要有他可以操作,点检,维修,保养的设备的资质或者说授权。

可以查看点检信息,点检时会停机(计划停机例如15分钟),在这段时间内,看板上提示需要点检,在规定保养时间内(设备停机)采集到设备运行(程序运行),发消息给点检人员的上层领导每日点检错误若发现有故障可以通过PDA或者人工录入的方式记录并累计故障时间和响应时间,进入维修流程。

有权限的人才可以消除提示。

2.1.2计划点检计划点检(例如每周,周期可配置),点检项目更多,到时间自动做提示。

周点检需要点检人员确认周点检完成,如果24小时后未确认,提交给上级领导,48小时后未确认,再向上级提交,72小时后未确认,直接提交到最上层。

有计划新建,编辑,删除功能。

信息提交最好集成到该企业的OA(办公软件)中,OA为重庆红帆的软件。

点检记录可查询,分为按设备查询和按时间查询。

MES简介MES系统是一套面向制造企业车间执行层的生产信息化管理系统。

MES可以为企业提供包括制造数据管理、计划排程管理、生产调度管理、库存管理、质量管理、人力资源管理、工作中心/设备管理、工具工装管理、采购管理、成本管理、项目看板管理、生产过程控制、底层数据集成分析、上层数据集成分解等管理模块,为企业打造一个扎实、可靠、全面、可行的制造协同管理平台。

一、MES的定义1、定义MES:Manufauring Execution Systerm国际制造执行系统协会:通过信息的传递,对从订单下达开始到产品完成的整个产品生产过程进行优化的管理。

2、定位MES关注:图1MES关注环节在企业的生产管理过程中,MES主要关注的是环境安全,即从系统上提供安全生产的可跟踪的实时的数据平台,做到生产控制的全监控,保障整个生产过程的安全和高效。

MES 更关注“资产”,从生产资料到设备利用产品质量控制各个环节评估提高生产水平,加速资产的曾值和高效的管理。

MES在企业管理中的位置:企业控制系统图2MES 在企业生产管理中的环节从图2可以看出MES 是所处环节是企业生产过程中的运营管理中的生产执行环节,企业从生产计划到产品的的产出过程都在MES 的考虑之中。

按照ERP 制定的计划MES 从材料的输入,设备生产过程监控效率分析,产品质量评估,次品率监控等环节提供整体解决方案真正做到生产的透明化,将以往难以估计的环节量化,让企业发现那些难以发现又有限生产的环节提高企业效率曾强竞争力。

MES 在系统结构中的位置:PLC 器,现场设备图3MES 在企业软件系统中的所处的环节图3 所反映的是MES 在生产过程中的作用即将ERP 和制造过程中的间隙填补使企业的ERP和生产过程紧密的结合起来,保障企业的生产过程的效益分析。

对生产过程的的各个环节进行效益分析,使生产过程不仅仅自动化而且效益化。

企业管理层次架构图4MES所处管理层次从管理角度上看MES间于企划层和控制层之间,负责企业计划的执行和对执行的分析。

西门子MES系统规划方案V6(共34页)一、引言随着制造业的不断发展,企业对于生产过程的管理和优化提出了更高的要求。

为了提高生产效率、降低成本、提升产品质量,许多企业开始引入制造执行系统(MES)。

西门子MES系统作为一种先进的生产管理系统,能够帮助企业实现生产过程的自动化、智能化和透明化。

本方案将详细介绍西门子MES系统V6版本的规划方案,包括系统架构、功能模块、实施步骤等内容。

二、系统架构1. 数据采集层:通过传感器、设备接口等手段,实时采集生产过程中的各种数据,如设备状态、产品质量、生产进度等。

2. 数据处理层:对采集到的数据进行清洗、转换、汇总等处理,为上层应用提供准确、实时的数据支持。

3. 应用层:包括生产计划、质量管理、设备管理、库存管理等功能模块,帮助企业实现生产过程的全面管理。

4. 用户界面层:提供直观、易用的操作界面,方便用户进行生产过程的监控、分析和决策。

三、功能模块1. 生产计划管理:根据企业的生产目标、订单需求、设备能力等信息,制定合理的生产计划,确保生产任务的按时完成。

2. 质量管理:对生产过程中的产品质量进行实时监控,及时发现并处理质量问题,确保产品质量符合标准。

3. 设备管理:对生产设备进行实时监控和维护,提高设备利用率,降低设备故障率。

4. 库存管理:对生产过程中的物料进行实时监控和管理,确保物料的充足供应,降低库存成本。

四、实施步骤1. 需求分析:深入了解企业的生产管理需求,明确系统实施的目标和范围。

2. 系统设计:根据需求分析结果,设计合适的系统架构和功能模块。

3. 系统开发:根据系统设计文档,进行系统的开发和测试。

4. 系统部署:将系统部署到企业内部,进行试运行和调试。

5. 培训和推广:对企业的员工进行系统操作培训,确保系统得到有效推广和应用。

6. 运维和优化:对系统进行日常运维和优化,确保系统的稳定运行和持续改进。

西门子MES系统V6版本作为一种先进的生产管理系统,能够帮助企业实现生产过程的自动化、智能化和透明化。

应用MES(生产执行系统),对工厂进行整体优化摘要:中国加入WTO以后, 中国的钢铁工业面临诸多挑战, 如更加灵活的生产, 更苛刻的质量要求以及具备竞争力的成本。

这些目标只有通过投资具有成本效益的生产线,使用最新的科技才能够达到。

目前,独立的生产线的自动化水平和优化程度已经很高,进行进一步改进的空间非常有限。

而ERP(企业资源策划)系统仅局限于总体生产计划的编制,并没有考虑设备的实际状态和生产线的工艺约束。

因而现代化的工厂需要通过使用最新技术,联合多个独立的生产线组成一个优化的生产链并连接基础自动化级,过程级与管理级。

根据MESA(制造执行系统协会)的定义,MES是对从下达订单到生产出最终成品的生产过程进行优化的信息系统。

本文详细描述了钢铁工业MES系统的不同功能模块和典型的系统结构。

通过分析一个具有成熟功能的实际案例,揭示了MES系统为工厂的所有者带来的效益。

正文MES系统是企业信息化建设的重要组成部分中国加入世界贸易组织后,中国的钢铁工业正在面临几个主要的挑战;它们是:∙更为灵活的生产钢铁工业的客户期望在定单执行、定单修改方面有更大的灵活性,同时缩短和保证交货时间。

∙产品质量方面的更高要求对于所有客户的复杂产品结构,卓越的产品质量是企业成功的关键因素。

同时,国际质量标准要求详细而完整的产品生产质量文档。

∙具有竞争力的成本定位具有竞争力的价位是能够在国际化的钢铁市场中生存的重要因素。

这必须通过以提高生产率,设备作业率为手段,提高产量和经济效益才能够达到。

所有这些目标,只有通过投资具有经济效益的生产线并使用最新科技才能够实现。

目前,独立的生产线的自动化程度和优化水平已经很高,进一步改进的空间非常有限。

另一方面,ERP (企业资源策划)系统局限于总体生产计划的编排,而没有考虑设备的实际运行状态和生产线的工艺约束。

因而现代化的工厂需要现代科技作为企业信息化建设的重要组成部分,联合多个独立的生产线构成生产链(水平集成),并连接生产层与管理层(垂直集成)。