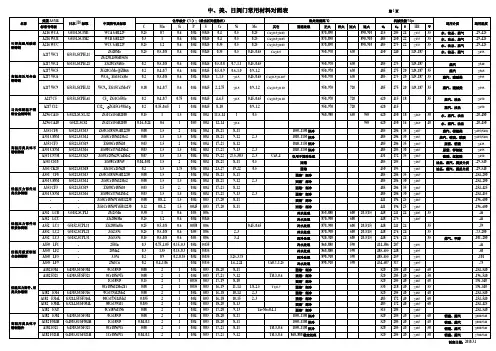

中美日阀门常用材料对照表

- 格式:xls

- 大小:94.00 KB

- 文档页数:12

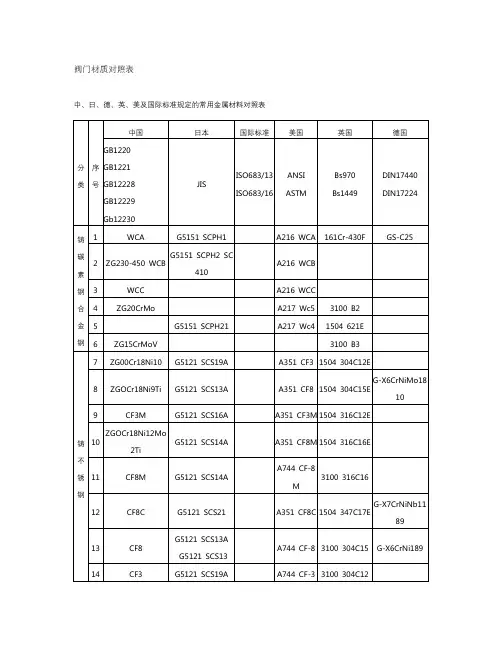

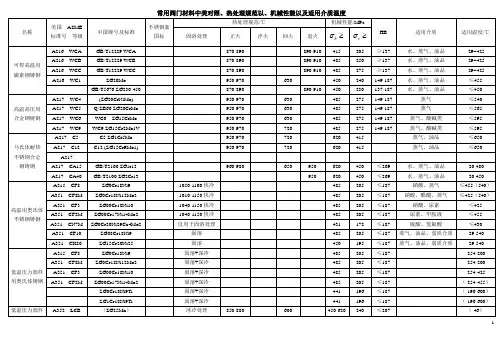

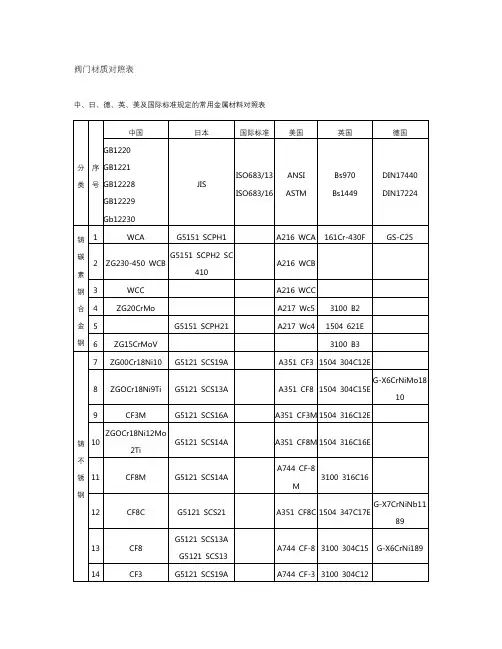

阀门常用材质对照表

阀门防腐材料选用表

注:A-能够或正成功地使用;B-应用过程应该注意;C-不能使用;IL缺乏资料

调节阀选型指南

1.型号

2.公称通径... ...*

3.公称压力和法兰连接型式... ...*

4.阀体和阀内组件材料,表面硬化处理要求

5.流量特性

6.填料类型(代码)

7.执行机构型号,是否配手轮及供气压力... ...*

8.阀作用型式(正作用、反作用)... ...*

9.附件(是否要带定位器、减压阀等)

10.是否禁油、禁铜等特殊规格

11.介质名称、状态(液、气、蒸汽等)... ...*

12.配管尺寸、管壁厚(入口侧、出口侧)... ...*

13.常用流量及最大、最小流量... ...*

14.流体压力及压差(全开、全关时)... ...*

15.流体的温度、比重或密度... ...*

16.介质压力、最大流量和最小流量时的进口压力和出口压力... ...*

17.介质比重粘度,有无浆料、闪蒸... ...*

18.是否用于高温、高压、防爆等工作条件

19.其他特殊要求

注:带*号参数必须提供。

中、日、美常用阀门材质对照表锻件料(马氏体)剪应力与抗拉强度关系我们在设计的时候常常取许用剪切应力,在一拉伸钢材的屈服强度与许用拉伸应力的关系二剪切许用剪应力与许用拉应力的关系1 对于塑性材料[τ]=0.6—0.8[δ]2 对于脆性材料[τ]=0.8--1.0[δ]三挤压许用挤压应力与许用拉应力的关系1 对于塑性材料[δj]=1.5—2.5[δ2 对于脆性材料[δj]=0.9—1.5[δ 注::[σj]=(1.7—2)[σ](部分教科四扭转许用扭转应力与许用拉应力的关系:1 对于塑性材料[δn]=0.5—0.6[δ2 对于脆性材料[δn]=0.8—1.0[δ轴的扭转变形用每米长的扭转角来衡量。

五弯曲许用弯曲应力与拉应力的关系:1 对于薄壁型钢一般采用轴向拉2 对于实心型钢可以略高一点,具许用剪切应力,在不同的情况下安全系数不同,许用剪切应力就不一样...校核各种许用应力常度与许用拉伸应力的关系的关系料[τ]=0.6—0.8[δ]料[τ]=0.8--1.0[δ]用拉应力的关系料[δj]=1.5—2.5[δ]料[δj]=0.9—1.5[δ](1.7—2)[σ](部分教科书常用)力的关系:料[δ料[δ米长的扭转角来衡量。

对于一般传动可取[υ]=0.5°--/m;对于精密传动,可取[υ]=0.25°—0.5°/M;对于要求不应力的关系: 钢一般采用轴向拉伸应力的许用值.钢可以略高一点,具体数值可参见有关规范..拉应力与材料的屈服强度有关,应力常常与许用拉应力有联系,而许用材料的屈服强度(刚度)与各种应力的关系0.25°—0.5°/M;对于要求不严格的轴,[υ]可大于1°/M 计算。

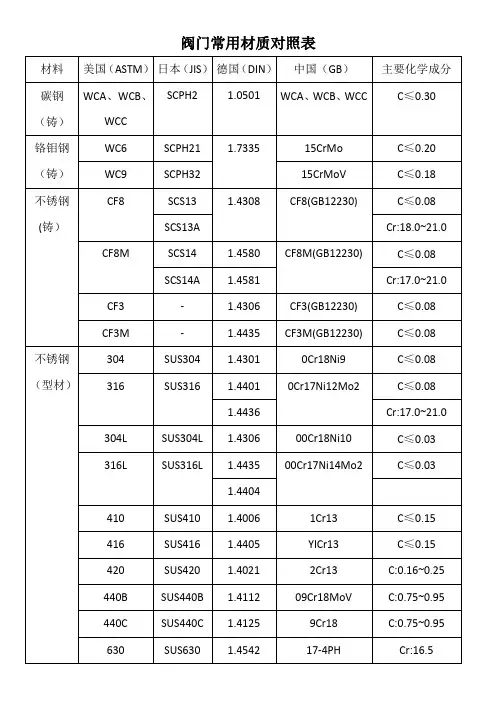

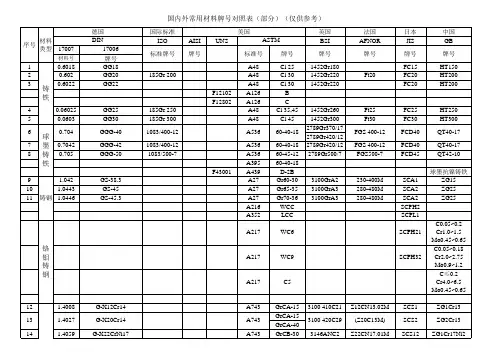

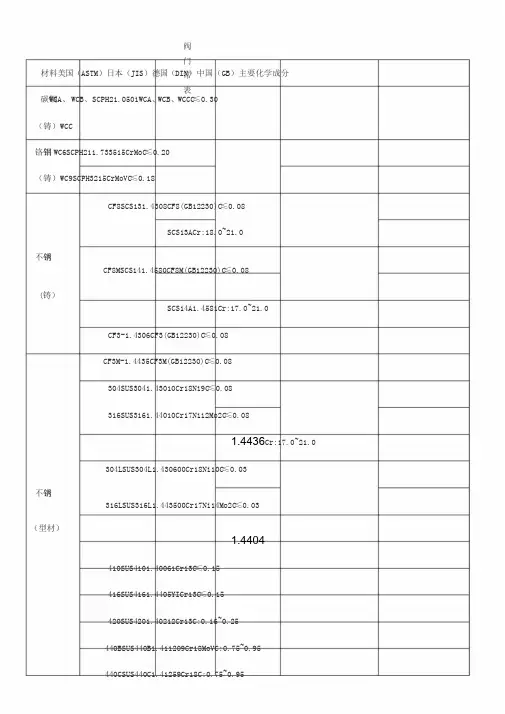

阀门材料美国(ASTM)日本(JIS)德国(DIN)中国(GB)主要化学成分常表W CA、WCB、SCPH21.0501WCA、WCB、WCCC≤0.30碳钢(铸)WCC铬钼钢WC6SCPH211.733515CrMoC≤0.20(铸)WC9SCPH3215CrMoVC≤0.18CF8SCS131.4308CF8(GB12230)C≤0.08SCS13ACr:18.0~21.0钢不锈CF8MSCS141.4580CF8M(GB12230)C≤0.08(铸)SCS14A1.4581Cr:17.0~21.0CF3-1.4306CF3(GB12230)C≤0.08CF3M-1.4435CF3M(GB12230)C≤0.08304SUS3041.43010Cr18Ni9C≤0.08316SUS3161.44010Cr17Ni12Mo2C≤0.081.4436Cr:17.0~21.0304LSUS304L1.430600Cr18Ni10C≤0.03钢不锈316LSUS316L1.443500Cr17Ni14Mo2C≤0.03(型材)1.4404410SUS4101.40061Cr13C≤0.15416SUS4161.4405YICr13C≤0.15420SUS4201.40212Cr13C:0.16~0.25440BSUS440B1.411209Cr18MoVC:0.75~0.95440CSUS440C1.41259Cr18C:0.75~0.95630SUS6301.454217-4PHCr:16.5阀门防腐材料选用表介质材料碳316青铜蒙乃416440C17-4PH铸铁302/哈C不锈钛钴铬钢304尔合金合金不锈不锈不锈钢钢20#6#钢钢乙醛AAAAAAAAILILAAA醋酸(无气)CCBBBBAAAACCB醋酸(充气)CCAAAAAAAACCB醋酸蒸汽CCAAAAABAACCB丙酮AAAAAAAAAAAAA乙炔AAAAILAAAILAAAA乙醇AAAAAAAAAAAAA硫酸铝CCAABBAAAILCCIL氨AAAACAAAAAAAIL氯化氨CCBBBBAAABCCIL硝酸铵ACAACCAAAACBIL磷酸铵CCAABBABAABBIL硫酸铵CCBABAAAAACCIL亚硫酸铵CCAACCAAAACCIL苯胺CCAACBAAAACCIL沥青AAAAAAAAILAAAA啤酒BBAABAAAAABBA苯AAAAAAAAAAAAA苯甲酸CCAAAAAAAILAAA硼酸CCAAAAAAAABBIL丁烷AAAAAAAAAAAAA氯化钙BBCBCAAAAILCCIL次氯酸钙CCBBBBAAAILCCIL石碳酸BBAAAAAAAAILILIL二氧化碳AAAAAAAAAAAAA(干)二氧化碳CCAAAAAAAAAAA(湿)二硫化碳AAAACBAAAABBIL四氯化碳BBBBAAAAAILCAIL碳酸CCBBBAAAILILAAA氯气(干)AABBBAAACBCCC氯气(湿)CCCCCCBCABCCC液氯CCCCBCABCBCCC铬酸CCCBCAACABCCC柠檬酸ILCBAABAAAILBBB焦炉气AAAABBAAAAAAA硫酸铜CCBBBCAAAILAAA棉籽油AAAAAAAAAAAAA杂酚油AAAAAAAAILAAAA 乙烷AAAABBAAAAAAA乙醚BBAAAAAAILAAAA氯乙烷CCAAAAAAAABBIL乙烯AAAAAAAAAAAAA乙二醇AAAAAAILAILAAAA氯化铁CCCCCCBCABCCIL甲醛BBAAAAAAAAAAA甲酸ILCBBAAAACBCCB氟利昂(干)BBBAAAAAAAILILIL 氟利昂(湿)BBAAAAAAAAILILIL 糠醛AAAAAAAAAABBIL汽油AAAAAAAAAAAAA葡萄糖AAAAAAAAAAAAA盐酸(充气)CCCCCCBCCBCCC盐酸(无气)CCCCCCBCCBCCC氢氟酸(充BCCBCCABCBCCC气)氢氟酸(无ACCBCAABCILCCIL 气)氢AAAAAAAAAAAAA过氧化氢ILAAACABAAILBBIL 硫化氢液CCAACCABAACCIL氢氧化镁AAAABAAAAAAAIL汞AAAACBAAAAAAB甲醇AAAAAAAAAAABA甲乙酮AAAAAAAAILAAAA牛奶CCAAAAAAAACCC天然气AAAAAAAAAAAAA硝酸CCABCCBAACCCB氧气AAAAAAAAAAAAA石油AAAAAAAAAAAAA磷酸(充气)CCAACCAABACCIL 磷酸(无气)CCAACBAABACCIL 磷酸蒸汽CCBBCCILABCCCIL苦味酸CCAACCAAILILBBIL氯化钾BBAABBAAAILCCIL氢氧化钾BBAABAAAAILBBIL丙烷AAAAAAAAAAAAA松香BBAAAAAAILAAAA硝酸银CCAACCAAABBBIL醋酸钠AABAAAAAAAAAA碳酸钠AAAAAAAAAABBA氯化钠CCBBAAAAAABBB铬酸钠AAAAAAAAAAAAA氢氧化钠AAAAAAAAAABBA次氯酸钠CCCCCCABAILCCIL硫代硫酸钠CCAACCAAAILBBIL 氯化亚锡BBCACBAAAILCCIL硬脂酸ACAABBAAAABBIL硫酸盐溶液AAAACAAAAAILILIL硫AAAACAAAAAAAA二氧化硫AAAAAAAAAABBIL(干)三氧化碳AAAAAAAAAABBIL(干)硫酸(充气)CCCCCCAABBCCC硫酸(无气)CCCCBBAABBCCC亚硫酸CCBBBBAAABCCIL焦油AAAAAAAAAAAAA三氯乙烯BBBAAAAAAABBIL松节油BBAAABAAAAAAA醋CCAABAAAILACCA水(锅炉给BCAACAAAAABAA水)纯水AAAAAAAAAABBIL海水BBBBBAAAAACCIL葡萄酒CCAAABAAAACCIL氯化锌CCCCCCAAAACCIL硫化锌CCAABAAAAABBIL注:A-能够或正成功地使用;B-应用过程应该注意;C-不能使用;IL缺乏资料调节阀选型指南1.4437型号1.4438公称通径......*1.4439公称压力和法兰连接型式......*1.4440阀体和阀内组件材料,表面硬化处理要求1.4441流量特性1.4442填料类型(代码)1.4443执行机构型号,是否配手轮及供气压力......*1.4444阀作用型式(正作用、反作用)......*1.4445附件(是否要带定位器、减压阀等)1.4446是否禁油、禁铜等特殊规格1.4447介质名称、状态(液、气、蒸汽等)......*1.4448配管尺寸、管壁厚(入口侧、出口侧)......*1.4449常用流量及最大、最小流量......*1.4450流体压力及压差(全开、全关时)......*1.4451流体的温度、比重或密度......*1.4452介质压力、最大流量和最小流量时的进口压力和出口压力......* 1.4453介质比重粘度,有无浆料、闪蒸......*1.4454是否用于高温、高压、防爆等工作条件1.4455其他特殊要求注:带*号参数必须提供。

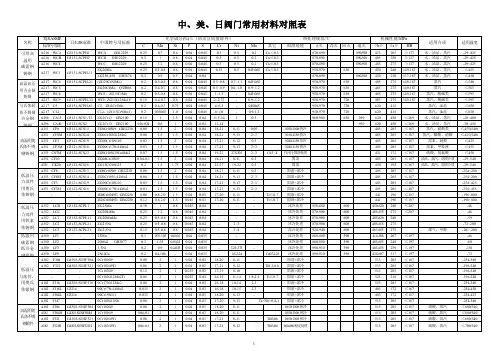

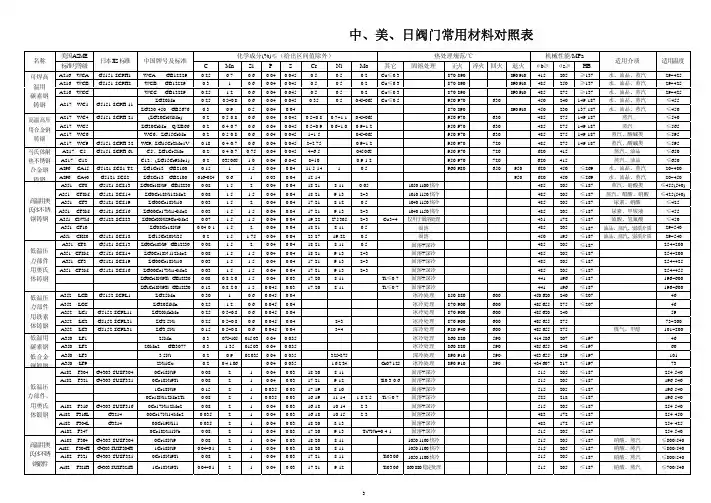

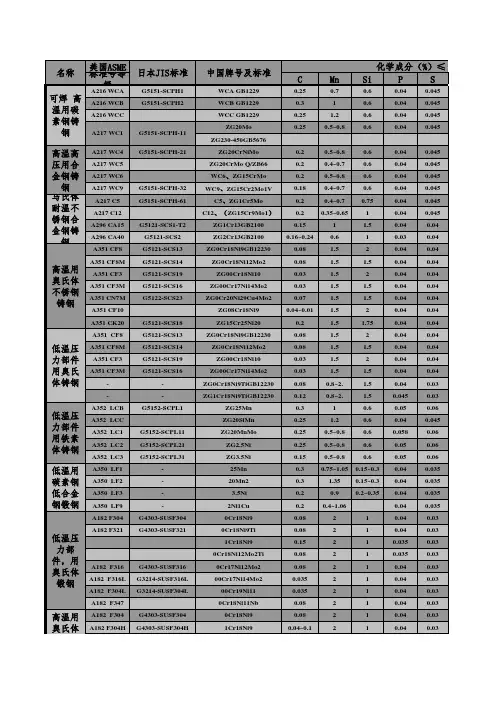

常用阀门材料中美对照、热处理规范以、机械性能以及适用介质温度名称美国ASME标准号等级中国牌号及标准热处理规范/℃适用温度/℃固溶处理正火淬火回火退火可焊高温用碳素钢铸钢A216 WCA GB/T12229 WCA 870-890 890-910 -29~425 A216 WCB GB/T12229 WCB 870-890 890-910 -29~425 A216 WCC GB/T12229 WCC 870-890 890-910 -29~425 A216 WC1 ZG20Mo 950-970 630 ≤455 GB/T5676 ZG230-450 870-890 890-910 ≤450高温高压用合金钢铸钢A217 WC4 (ZG20CrNiMo 950-970 630 ≤540 A217 WC5 Q/ZB66 ZG20CrMo 950-970 630 ≤565 A217 WC6 WC6 ZG15CrMo 950-970 630 ≤595 A217 WC9 WC9 ZG15Cr2Mo1V 950-970 720 ≤595马氏体耐热不锈钢合金钢铸钢A217 C5 C5 ZG1Cr5Mo 950-970 720 ≤650 A217 C12 C12 (ZG15Cr9Mo1 950-970 720 ≤650 A217A217 CA15 GB/T2100 ZG1r13 960-980 650 950 -20-480 A217 CA40 GB/T2100 ZG2Cr13 950 -20-450高温用奥氏体不锈钢铸钢A315 CF8 ZG0Cr18Ni9 1050-1100快冷≤455(540 A351 CF8M ZG0Cr18Ni12Mo2 1010-1150快冷≤425(540 A351 CF3 ZG00Cr18Ni10 1040-1150快冷≤425A351 CF3M ZG00Cr17Ni14Mo2 1040-1150快冷≤455A351 CN7M ZG0Cr20Ni29Cu4Mo2 仅用于固溶处理≤430A351 CF10 ZG08Cr18Ni9 固溶-29-540A351 CK20 ZG15Cr20Ni25 固溶-29-540低温压力部件用奥氏体铸钢A315 CF8 ZG0Cr18Ni9 固溶+深冷-254-200 A351 CF8M ZG0Cr18Ni12Mo2 固溶+深冷-254-200 A351 CF3 ZG00Cr18Ni10 固溶+深冷-254-425 A351 CF3MZG00Cr17Ni14Mo2 固溶+深冷(-254-455 - ZG0Cr18Ni9Ti 固溶+深冷(-196-600 -ZG1Cr18Ni9Ti 固溶+深冷(-196-600低温压力部件用铁素体铸钢A352 LCB (ZG25Mn冰冷处理850-880 600 (-46A352 LCC (ZG20SiMn冰冷处理870-900 600 (-46A352 LC1 (ZG20MnMo冰冷处理870-900 600 (-59A352 LC2 (ZG2.5Ni冰冷处理870-900 600 (-73-200 A352 LC3 (ZG3.5Ni深冷处理920-940 600 (-101-200低温用碳素钢合金钢铸钢A350 LF1 25Mn 冰冷处理860-880 590 (-46 A350 LF2 20Mn2 GB/T3077 冰冷处理860-880 590 (-60 A350 LF3 (3.5Ni深冷处理890-910 590 (-101 A350 LF9 (2Ni1Cu冰冷处理890-910 590 (-73低温压力部件用奥氏体锻钢A182 F304 0Cr18Ni9 固溶+深冷(-254-540 A182 F321 0Cr18Ni9Ti 固溶+深冷(-196-540 - 1Cr18Ni9Ti 固溶+深冷(-196-540 - 0Cr18Ni12Mo2Ti 固溶+深冷(-196-540A182 F316 0Cr17Ni12Mo2 固溶+深冷(-254-540 A182 F316L 00Cr17Ni14Mo2 固溶+深冷(-254-450 A182 F304L 00Cr19Ni11 固溶+深冷(-254-425 A182 F3470Cr18Ni11Nb 固溶+深冷(-254-540高温用奥氏体不锈钢锻件A182 F304 0Cr18Ni9 1050-1100快冷≤800/540 A182 F304H (1Cr18Ni91050-1100快冷≤800/540 A182 F321 0Cr18Ni9Ti1050-1100快冷+860-880稳定处理≤800/540 A182 F321H (1Cr18Ni9Ti≤700/540 - 1Cr18Ni9Ti ≤700/540 -0Cr18N i12Mo2Ti ≤700/540 - 1Cr18Ni12Mo2Ti ≤700/540 A182 F316 0Cr17Ni12Mo2 1040-1150快冷≤800/540 A182 F316H - 1040-1150快冷≤800/540 A182 F316L00Cr17Ni14Mo2 1040-1150 ≤450 A182 F304L 0Cr19Ni11 1040-1150 ≤425 A182F304N 0Cr18Ni10N 1040-1150 ≤800/540 A182 F304LN 00Cr18N i10N 1040-1150≤800/540 A182 F316N 0Cr17Ni12Mo2N 1040-1150 ≤800/540 A182 F316LN00Cr17Ni12Mo2N 1040-1150 ≤800/540 A182 F310 1Cr25Ni20 1040-1180 -29-800A182 F347 0Cr18Ni11Nb 1040-1150 ≤540A182 F347H - 1040-1150 ≤450 A182 F10 (15Cr8Ni20 1040-1150 ≤540 A182 F44 (000Cr18Ni20Mo6CuN 1150-1200 ≤540 A182 F45 (08Cr21Ni11NCe 1040-1100 ≤540高温用铁素体奥氏体钢锻件A182 F50 (00Cr25Ni6Mo2N 1050-1100 ≤540 A182 F51 (00Cr22Ni5.5Mo3N 1020-1080 ≤425马氏体高温用合金钢锻件A182 F1 16Mo(YB 900-950 620 900-950 ≤425 A182 F2 GB/T3077 12CrMo 900-950 620 ≤540 A182 F11 GB/T3077 15CrMo 955-970 620 ≤545 A182 F12 GB/T3077 15CrMo 955-970 620 ≤545马氏体耐热钢锻件A182 F9 Cr9Mo1 955-970 677 ≤673 A182 F91 1Cr9Mo1VNb 1040-1095 730 ≤673 A182 F5 1Cr5Mo 955-970 677 ≤550 A182 F5a 2Cr5Mo 955-970 677 ≤550 A182 F61Cr13 950-1000 700-720 850-900 -101-480 A182 F6a 1Cr13Mo 955-1000 650-750 830-900 ≤450 A276 420 2Cr13 920-980 650-750 -101-480 A182 F21 12Cr3MoV 955-980≤550 A182 F3V 12Cr3MoVSiTi 955-980 ≤550 A182 F22 12Cr2Mo1V 955-980 670-700 ≤550 12Cr1MoV 980-1020 720-760 ≤570铁素体钢锻件A182 FXM27cb000Cr27Mo1010-1050≤540 A182 F430 1Cr17(08Cr17 800-850 ≤450优质碳素钢低碳钢锻件- 10 910-925 ≤450 - 20 890-910 ≤450 - 25 870-890 ≤450 A105(N 35Mn(25Mn 860-880 ≤450 - 35 845-860 ≤450 - 40 820-840 ≤450高温用合金钢螺栓材料A193 B7 35CrMoA 900-930 600-640 -46-510 A193 B7M (35CrMoA 910-930 620-650 -20-510A193 B16 42Cr2MV(YB 850-900 650-670 -10-600高低温用合金钢螺栓材料A320 L7 42CrMo 850-900 560-600 -101-550 A320 B8 0Cr18Ni9 固溶-254-700A320 B8A 0Cr18Ni9 固溶-254-700 A320 B8M 0Cr17Ni12Mo2 固溶-254-816 A320B8T 0Cr18Ni9Ti 固溶化-195-700高温高压用碳钢及合金钢螺母材料A194 2H 45 820-840 620-640 -38-450 A194 6 1Cr13 980-1050 540-600 -101-480 A194 8\8A 0Cr18Ni9 固溶-254-800 A194 8M/8MA 0Cr17Ni12Mo2 固溶-254-816A194 8T/8TA 0Cr18Ni9Ti 固溶化-196-700核工程用合金钢螺栓材质A540 B21 40CrMoV 850-880 560-580 -12-570 A540B22 42CrMo 850-880 560-580 -101-550 A540 B23 40CrNi2MoA 850-870 600-620 -12-570 A540 B24 40CrNi2MoA 850-870 600-620 -12-570高温高压用热扎合金钢棒A739 B11 15CrMo 950-980 650-670 -38-545 A739 B22 (12Cr2Mo1 955-983 680-700 -38-540 - 20CrMo 850-910 500-520 -38-520 - 40Cr 840-860 620-660 -38-425 - 25Cr2Mo1V A 850-870 700-740 -38-570不锈耐酸钢棒型材A276 420 2Cr13 980-1050 200-620 -101-400 - 3Cr13 980-1050 200-620 -101-420 A276 431 1Cr17Ni2 150-1040 380-420 -38-425 - 4Cr9Si2 1000-1050 680-720 -38-900 A276 416 Y1Cr13 950-1000 700-750 -38-350沉淀硬化型不锈钢A705 630 0Cr17Ni4Cu4Nb 固溶+时效-196-427 A705 631 0Cr17Ni7Al 固溶+时效-196-427 A705 XM-25(632 0Cr15Ni7Mo2Al 固溶+时效-196-427奥氏体不锈耐酸钢- 00Cr18Ni14Mo2Cu2 1010-1050水冷-38-200 AISI 318 0Cr17Ni14Mo2N 1120-1140水冷-38-200 AISI 317 00Cr19Ni13Mo3 1010-1150水冷≤200蒙乃尔400 B564 N04400 (15Ni67Cu28 910-930 ≤200 Fe2.5Mn1.5蒙乃尔R405 B164 N04400 (15Ni67Cu28Fe1Mn11910-930 ≤200蒙乃尔K500 (08Ni67Cu29FeMnAl2.5沉淀硬化≤20020号合金锻件B462 N08020(0Cr20Ni35Fe35Cu4Nb927-954 -253-427哈氏合金棒材H-BB335 N010001 (0Ni65Mo28Fe5V粗加工后固溶退火1050-1100 ≤700H-B2 B335 N010665 (00Ni70Mo28 ≤700 H-C B574 N06455 (00Ni60Cr16Mo16W4 ≤700H-X276 B574 N06455 (000Cr16Ni60Mo16W4≤700H-C4 B574 N10276 (000Cr16Ni60Mo16Ti≤700H-G B446 N06625(0Cr22Ni55Mo8Cu2Nb2酸洗前退火1000-1050≤700H-F B572 N06002 (0Cr22Ni47Mo7Fe17 固溶退火≤700。

剪应力与抗拉强度关系

我们在设计的时候常常取许用剪切应力,在不同的情况下安全系数不同,许用剪切应力就不一样...校核各种许用应力常常与许用拉应力有联系,而许用材料的屈服强度(刚度)与各种应力的关系一拉伸

钢材的屈服强度与许用拉伸应力的关系

[δ ]= δu/n n为安全系数

二剪切

许用剪应力与许用拉应力的关系

1 对于塑性材料 [τ]=0.6—0.8[δ]

2 对于脆性材料 [τ]=0.8--1.0[δ]

三挤压

许用挤压应力与许用拉应力的关系

1 对于塑性材料 [δj]=1.5—2.5[δ]

2 对于脆性材料 [δj]=0.9—1.5[δ]

注::[σj]=(1.7—2)[σ](部分教科书常用)

四扭转

许用扭转应力与许用拉应力的关系:

1 对于塑性材料 [δn]=0.5—0.6[δ]

2 对于脆性材料 [δn]=0.8—1.0[δ]

轴的扭转变形用每米长的扭转角来衡量。

对于一般传动可取[υ]=0.5°--/m;对于精密传动,可取[υ]=0.25°—0.5°/M;对于要求不严格的轴,[υ]可大于1°/M计算。

五弯曲

许用弯曲应力与拉应力的关系:

1 对于薄壁型钢一般采用轴向拉伸应力的许用值.。

中美日阀门常用材料对照表美国ASME 标准符号等级C Mn Si P S 可焊高A216 WCA G5151-SCPH1WCA GB122290.250.70.60.040.045温用A216 WCB G5151-SCPH2WCB GB122290.310.60.040.045碳素钢A216 WCC WCC GB122290.25 1.20.60.040.045ZG20Mo0.250.5-0.80.60.040.045ZG230-450 GB56760.30.90.60.040.04高温高压A217 WC4G5151-SCPH-21(ZG20CrNiMo)0.20.5-0.80.60.040.045用合金钢A217 WC5(ZG20CrMo) Q/ZB660.20.4-0.70.60.040.045A217 WC6WC6、ZG15CrMo 0.20.4-0.70.750.040.045A217 WC9G5151-SCPH-32WC9、ZG15Cr2Mo1V 0.180.35-0.6510.040.045马氏体耐A217 C5G5151-SCPH-61C5、ZG1Cr5Mo 0.21 1.50.040.045热不锈钢A217 C12C12、(ZG15Cr9Mo1)0.20.610.040.045合金钢A296 CA15G5121-SCS1-T2ZG1Cr13 GB21000.15 1.520.040.04铸钢A296 CA40G5121-SCS2ZG2Cr13 GB21000.16-024 1.5 1.50.040.04高温用奥A351 CF8G5121-SCS13ZG0Cr18Ni9 GB122300.08 1.520.040.04氏体不锈A351 CF8M G5121-SCS14ZG0Cr18Ni12Mo20.08 1.5 1.50.040.04A351 CF3G5121-SCS19ZG00Cr18Ni100.03 1.5 1.50.040.04A351 CF3M G5121-SCS16ZG00Cr17Ni14Mo20.03 1.520.040.04A351 CN7M G5122-SCS23ZG0Cr20Ni29Cu4Mo20.07 1.5 1.750.040.04A351 CF10ZG08Cr18Ni90.04-0.1 1.520.040.04A351 CK20G5121-SCS18ZG15Cr20Ni250.2 1.5 1.50.040.04低温压304A351 CF8ZG0Cr18Ni9 GB122300.08 1.5 1.50.040.04力部件316A351 CF8M G5121-SCS14ZG0Cr18Ni12Mo20.08 1.5 1.50.040.04用奥氏304L A351 CF3G5121-SCS19ZG00Cr18Ni100.03 1.5 1.50.040.04A351 CF3MG5121-SCS16ZG00Cr17Ni14Mo20.03 1.5 1.50.040.04ZG0Cr18Ni9Ti GB122300.080.8-2.0 1.50.040.04ZG1Cr18Ni9Ti GB122300.120.8-2.0 1.50.0450.04低温压A352 LCB G5152-SCPL1ZG25Mn 0.310.60.0450.04力部件A352 LCC ZG020SiMn 0.25 1.20.60.0450.04用铁素A352 LC1G5152-SCPL11ZG20MnMo 0.250.5-0.80.60.0450.04A352 LC2G5152-SCPL21ZG2.5Ni 0.250.5-0.80.60.0450.04A352 LC3G5152-SCPL31ZG3.5Ni0.150.75-1.050.15-0.30.040.035A217 WC1铸钢钢铸钢体铸钢316L 体铸钢铸钢G5151-SCPH-11名称日本 JIS标准中国牌号及标准化学成分(%)≤(给出区间值除外低温用A350 LF125Mn0.3 1.350.15-0.30.040.035碳素钢A350 LF220Mn2 GB30770.30.90.2-.350.040.035低合金A350 LF3 3.5Ni 0.20.4-1.06-0.040.035钢锻钢A350 LF92Ni1Cu 0.2210.040.03低温压A182 F304G4303-SUSF3040Cr18Ni90.08210.040.03力部件A182 F321G4303-SUSF3210Cr18Ni9Ti 0.08210.040.03用奥氏1Cr18Ni90.15210.0350.030Cr18Ni12Mo2Ti 0.08210.0350.03A182 F316G4303-SUSF3160Cr17Ni12Mo20.08210.040.03A182 F316L G321400Cr17Ni14Mo20.035210.040.03A182 F304L G32140Cr19Ni110.035210.040.03A182 F3470Cr18Ni11Nb 0.08210.040.03高温用奥A182 F304G4303-SUSF3040Cr118Ni90.08210.040.03氏体不锈A182 F304H G4303-SUSF304H 1Cr18Ni90.04-0.1210.040.03A182 F321G4303-SUSF3210Cr18Ni9Ti 0.08210.040.03A182 F321HG4303-SUSF321H1Cr18Ni9Ti 0.04-0.1210.040.03高温用奥--1Cr18Ni9Ti 0.12210.350.03氏体不锈--0Cr18Ni12Mo2Ti 0.08210.350.03--1Cr18Ni12Mo2Ti 0.12210.350.03A182 F316G4303-SUSF3160Cr17Ni12Mo20.08210.040.03A182 F316H G4303-SUSF316H -0.04-0.1210.040.03A182 F316L G4303-SUSF316L 00Cr17Ni14Mo2 GB12200.035210.040.03A182 F304L G4303-SUSF304L0Cr19Ni11 GB12200.035210.040.03A182 F304N -0Cr18Ni10N GB12200.0820.750.040.03A182 F316LN -00Cr18Ni10N GB12200.0320.750.040.03A182 F316N -0Cr17Ni12Mo2N GB12200.0820.750.040.03A182 F316LN -00Cr17Ni12Mo2N GB12200.0320.750.040.03A182 F310G3214-SUSF3101Cr25Ni200.15210.040.03A182 F347-0Cr18Ni11Nb GB12200.08210.040.03A182 F347H --0.04-0.1210.040.03A182 F10-15Cr8Ni200.1-0.20.5-0.81-1.40.040.03A182 F44-000Cr18Ni20Mo6CuN 0.0210.80.030.01A182 F45-08Cr21Ni11NCe 0.05-0.10.8 1.4-20.040.03高温用铁A182 F50-00Cr25Ni6Mo2N 0.03210.0450.03素体-奥氏体钢锻件A182 F5100Cr22Ni5.5Mo3N 0.03210.030.02马氏体高温A182 F1G3213SFHV12B16mo(YB)0.280.6-0.90.15-0.350.0450.045钢锻件钢锻件体锻钢A182 F2G3213SFHV13B 12CrMoGB30770.05-0.210.3-0.80.1-0.60.040.04A182 F11G3213SFHV23B 15CrMoGB30770.1-0.20.3-0.80.5-1.00.040.04A182 F12G3213SFHV22B 15CrMoGB30770.1-0.20.3-0.80.1-0.60.040.04马氏体耐热A182 F9G3213SFHV26BCr9Mo10.150.3-0.60.5-1.00.030.03A182 F91G32131Cr9Mo1VNb 0.08-0.120.3-0.60.2-0.50.020.01A182 F5G3213 SFHV251Cr5MoGB12210.150.3-0.60.50.030.03A182 F5a -2Cr5Mo(YB)0.250.60.50.040.03A182 F6a G4303SUS4101Cr130.15110.040.03A182 F6a G4303SUS410J11Cr13Mo 0.1510.10.020.02A276 420-2Cr13 GB12200.16--0.25110.0350.03A182 F21-12Cr3MoV0.05-0.150.3-0.60.50.040.04A182 F3V -12Cr3MoVSiTiB(YB6)0.05-0.150.3-0.60.10.020.02A182 F22G3213SFHV24B12Cr2Mo1V 0.05-0.150.3-0.60.50.040.04-12Cr1MoV GB30770.08-0.150.04--0.70.17-0.370.0350.035铁素体钢A182 FXM27cb -00Cr27Mo 0.010.40.40.020.02锻件A182 F430-(08Cr17)1Cr170.1210.750.040.04优质碳素钢-G4051-S10C 10 (GB699)0.07-0.140.35-0.650.17-0.370.0350.04-G4051-S20C 20 (GB699)0.17-0.240.35-0.650.17-0.370.040.04-G4051-S25C 25 (GB699)0.22-0.30.5-0.80.17-0.370.040.04A105(N)G3021-SF50A 30Mn(25Mn)0.350.6-1.050.350.040.05-G4051-S35C 35 (GB699)0.32-0.40.5-0.80.17-0.350.040.04-G4051-S40C 40 (GB699)0.37-0.450.5-0.80.17-0.350.040.04高温用合金A193 B7G4107-SNB735CrMoA (GB3077)0.37-0.490.65-1.10.15-0.350.0350.04钢螺栓材料A193 B7M - -(35CrMoA)0.37-0.490.65-1.10.15-0.350.0350.04(马氏体)A193 B16G4107-SNB1640Cr2MoV(YB)0.36-0.470.45-0.70.15-0.350.0350.04高低温用合A320 L7G4015-SCM440CrMoV(GB3077)0.38-0.480.75-1.00.15-0.350.0350.04钢螺栓材料A320 B8G4303-SUS3040Cr18Ni90.08210.04518-20A320 B8A-0Cr18Ni90.08210.04518-20A320 B8MG4303-SUS3160Cr17Ni12Mo20.08210.04516-18A320 B8TG4303-SUS3210Cr18Ni9Ti0.08210.04517-19高温高压用A194 2H G4051-S45C 450.45--0.040.05碳钢和合金钢A194 6JIS161Cr130.15110.040.03螺母材料A194 8、8AG4303-SUS3040Cr18Ni90.08210.0450.03A1948M、8MAG4303-SUS3160Cr17Ni12Mo20.08210.0450.03A1948T、8TAG4303-SUS3210Cr18Ni9Ti 0.08210.04517-19核工程用合A540 B21-40CrMoV 0.36-0.440.45-0.70.15-0.350.0250.025(用于低温阀门须进行深冷处理)(用于低温阀门,必须进行深冷处理)用合金钢锻件钢锻件低碳钢锻件A540 B22-40CrMo 0.39-0.460.65-1.10.15-0.350.0250.025A540 B23-40CrNi2MoA 0.37-0.440.7-0.90.15-0.350.0250.025A540 B24-40CrNi2MoA 0.37-0.440.7-0.90.15-0.350.0250.025高温高压用A739 B11-15CrMo 0.20.4-0.650.5-0.80.0350.04热轧合金A739 B22-(12Cr2Mo1)0.150.3-0.60.50.0350.04--20CrMo 0.17-0.240.4-0.70.17-0.370.0350.04-G4104-SC44040Cr GB33070.37-0.450.5-0.80.2-0.40.0350.03--25Cr2Mo1VA 0.22-0.290.5-0.80.17-0.370.0350.04不锈耐酸钢A276 420G4303-SUS420112Cr13 GB12200.16-0.240.60.60.0350.03-G4303-SUS420122Cr13 GB12200.25-0.340.60.60.0350.03AISI 431SUS4311Cr17Ni20.11-0.170.80.80.0350.03--4Cr9Si20.35-0.50.7 2-30.0350.03AISI 416SUS416Y1Cr130.15 1.2510.060.15沉淀硬化型A705 630SUS6300Cr17Ni4Cu4Nb 0.07110.040.03A705 631SUS6310Cr17Ni7AL 0.09110.040.03A705 XM-25(632)-0Cr15Ni7Mo2AL 0.05110.030.03奥氏体不锈-00Cr18Ni14Mo2Cu20.03210.0350.03AISI 3180Cr17Ni14Mo2N0.08210.0350.02AISI 317SUS31700Cr19Ni13Mo30.03210.0350.03蒙乃尔400B462N080200.2 1.2-1.30.20.020.01蒙乃尔R405B335N0100010.210.20.0350.04蒙乃尔K500-0.10.80.20.0050.00520号合金锻件B462N080200.07210.0350.035哈氏合金(棒材)H-BB335N0100010Ni65Mo28Fe5V 0.05110.030.03H-B2B335N01066500Ni70Mo280.0210.10.030.03H-C B574N0645500Ni60C16Mo16W40.0310.070.020.02H-X276 B574N0645500Cr16Ni60Mo16W40.0210.050.020.02H-C4B574N1027600Cr16Ni60Mo16Ti 0.01510.050.020.02H-G B446N066250Cr22Ni55Mo8Cu2Nb20.10.50.50.0150.015H-FB572N060020Cr22Ni47Mo7Fe170.05-0.150.10.10.040.03酸钢金刚螺栓材料钢棒棒型材(马氏体)不锈钢0Cr20Ni35Fe35Cu4Nb15Ni67Cu28Fe2.5Mn1.515Ni67Cu28Fe1Mn1108Ni67Cu29FeMnAl2.5材料对照表Cr Ni Mo 其它固溶处理正火淬火回火退火σb≥σs≥HB 0.50.50.2Cu≤0.3870-890890-910415203≥1370.50.50.2Cu≤0.3870-890890-910485250≥1370.50.50.2Cu≤0.3870-890890-910485275≥1370.350.50.45-0.65Cu≤0.5950-970630450240149-187870-890890-910450230137-1870.5-0.80.7-1.10.45-0.65950-970630485275149-1870.5-0.90.6-1.00.9-1.2950-970630485275149-1871-1.5-0.45-0.65950-970630485275149-1872-2.75-0.9-1.2950-970720485275149-1874-6.5-0.45-0.65950-970720620415 8-10-0.9-1.2950-97072062041511.5-1410.5960-980650950620450≤269 12-14950620450≤26918-21 8-110.051050-1100快冷485205≤18718-21 9-13 2-31010-1150快冷485205≤18717-21 8-120.51040-1150快冷485205≤18717-21 9-13 2-31040-1150快冷485205≤18719-22 2.75-3.05 2-3Cu3-4仅用于固溶处理431172≤18718-21 8-110.5固溶485205≤18723-27 19-220.5固溶450193≤18718-21 8-110.5固溶+深冷485205≤18718-21 9-13 2-3固溶+深冷485205≤18717-21 9-13 2-3固溶+深冷485205≤18717-21 9-13 2-3固溶+深冷485205≤18717-20 8-11 -Ti≤7固溶+深冷441196≤18717-20 8-11-Ti≤7固溶+深冷441196≤187---冰冷处理850-880600450-620240≤207---冰冷处理870-900600485-655275≤207---冰冷处理870-900600485-620240- 2-3冰冷处理870-900600485-655275- 3-4冰冷处理920-940600485-655275机械性能/MPa热处理规范/℃值除外)--冰冷处理960-880590414-586207≤197--冰冷处理960-880590485-655248≤197- 3.25-3.75-冰冷处理890-910590483-655259≤197- 1.6-2.24-Cu0.7-1.25冰冷处理890-910590434-607317≤19718-20 8-11固溶+深冷515205≤18717-21 9-12Ti0.3-0.6固溶+深冷515205≤18717-19 8-10固溶+深冷515205≤18716-19 11-14 1.8-2.5Ti≤0.7固溶+深冷525218≤18716-18 10-14 2-3固溶+深冷515205≤18716-18 10-15 2-3固溶+深冷483172≤18718-20 8-13-固溶+深冷483172≤18717-20 9-13固溶+深冷515205≤18718-20 8-111050-1100快冷515205≤18718-20 8-111050-1100快冷515205≤18717-21 8-11Ti0.3-0.61050-1100快冷515205≤18717-21 9-12Ti0.3-0.6860-880稳定处理515205≤18717-19 8-11-Ti0.4-0.8525205≤18716-19 11-14 1.8-2.5Ti≤0.71040-1100快冷525215≤18716-19 11-14 1.8-2.5Ti≤0.7525218≤18716-18 10-14 2-3 1040-1150快冷515205≤18716-18 10-14 2-31040-1150快冷515205≤18716-18 10-15 2-31040-1150483172≤18716-18 8-13-1040-1150483172≤18718-208-10.5-N=0.1-0.161040-1150550240≤21718-208-10.5-N=0.1-0.161040-1150515205≤21716-18 11-14 2-3 N=0.1-0.161040-1150550240≤21716-18 11-14 2-3N=0.1-0.161040-1150515205≤19724-2619-22--1040-1180515205≤19717-20 9-13-Ta+Nb=0.4-11040-1150515205≤19717-20 9-13--1040-1150515205≤197 7-919-22--1040-1150550205≤19719.5-20.517.5-18.56-6.5u0.5-1 NO.18-0.21150-1200650300≤19720-22 10-12-14-0.2 Ce0.03-01040-1100600310≤19724-26 5.5-6.5 1.2-2NO.14-0.21050-1100690-900450≤19721-23 4.5-6.5 2.5-3.5NO.0.8-0.21020-1080620450≤197--0.44-0.65--900-950620900-950485275143-192Ta+Nb=0.4-1860-880稳定处理0.5-0.81-0.44-0.65--900-950620900-950485275143-1921-1.5-0.44-0.65--955-970620900-950485275143-2070.8-1.25-0.44-0.65--955-970620900-950485275143-207 8-10-0.9-1.1--955-970677900-950585380179-2178-9.50.40.85-1.0508-0.25 Nb0.06--1040-1095730585415≤248 4-60.50.44-0.65--955-970677485275143-217 4-60.50.44-0.65--955-970677620450187-248115-1350.5---585380167-229115-135 1-20.4-0.6--760-930620235-285 12-14---630440≥1922.65-3.35-0.8-1.06-5150.9-1.1.3 V0.2-0.30.B001-0.003585-760415174-2372.25-0.87-1.13955-980515310156-2070.9-1.2-0.25-0.35V0.15-0.3980-1020485255≤17925-270.50.75-1.515 Cu<0.2 Nb<0.05-0.2415240≤19016-180.5415240≤1900.150.25910-925330205≤1370.250.25890-910415240≤1560.0250.25870-890455270≤1700.30.40.12.03 Cu<0.4 Nb<0860-880485250≤1870.250.25-845-860515260≤1870.250.25-820-840565330≤2170.75-1.20.15-0.25860720≤2570.75-1.20.15-0.25690550201-2350.8-1.150.5-0.65V0.25-0.35860720197-2170.8-10.15-0.25860725201-23518-208-10.5固溶515205≤22318-208-10.5固溶515205≤19216-18 10-14固溶690550≤32117-19 9-122-3 Ti0.3-0.6固溶化515205≤192635350217-255540245228-2718-10.5固溶515205126-30016-18 10-14 2-3 固溶515205126-30017-19 9-12Ti0.3-0.6固溶化515205126-3000.8-1.15-0.5-0.65V0.25-0.35827724241-385310 156-207910-930 620-650980-1050 540-600850-880 560-580720-7601010-1050800-850900-930 600-640850-900油冷 650-670850-900油冷 560-600820-840 620-660955-1000 700-720 850-900955-1000 650-750 830-900920-980 650-750955-980955-980677-7002.75-3.2511.5-13.518-200.75-1.2-0.15-0.25827724248-2930.65-0.95 1.55-20.2-0.3827724248-3110.7-0.95 1.65-20.3-0.4827724248-3111-1.5-0.45-0.65950-980483-655310207-2412-2.5-0.9-1.1955-983517-655310≤1790.8-1.1-0.15-0.2880785≤1970.8-1.1--940885228-2692.1-2.5-0.9-1.1V0.2-0.3735585228-269 12-14-注1650445228-26912-14-注183363516-18 1.5-2.5注11078 8-10-注1860680235-277 12-14-注1调质540345≤20015-17.5 3-5-Cu3-5 Nb>8*%C 固溶+时效1000860≥30215-187.5-7.75-AL0.75-1.5固溶+时效12751035≥38814-16 5-70.5-11.25-1.75 Nb<8*固溶+时效11051035≤31117-19 12-16 1.2-2.5Cu-2.5515205≤18717-1913-15 1.75-2.75N0.18-0.22Rc18-2418-20 11-15 3-4 -485205≤187-余量-550220HV110-150-余量-910-930550220HV110-150-余量沉淀硬化2000600HV250-32019-2132-38 2-3551241自定1余量26-30<100HRB 1余量26-30<100HRB 15-17余量16-18<100HRB 15-17余量16-18Fe≤7 Co2.5粗加工后<100HRB 15-17余量16-18Fe≤7Ti0.7<100HRB 20-23余量 8-10o1 Fe5Ti0.4 Ta4.<100HRB 20.5-23余量 8-10<100HRB827 σ0.2 414655 σ0.2 241927-954795 σ0.2 315758 σ0.2 352950-1040 380-4201000-1050 680-720950-1000 700-750910-930840-860 620-660850-870 700-740850-880 560-580850-870 600-620980-1050油冷600-660980-1040油冷200-220850-870 600-620650-670680-700880-910油冷500-520690 σ0.2 276690 σ0.2 276690 σ0.2 283FeLAl27Cu295Fe2-3 Cu≤31.5Fe1.2 Cu(27-29)1010-1050水冷1120-1140水冷1010-1050水冷酸洗前退火 1000-1025Fe17-20 Co0.5-2.5 固溶退火Cu3-4 Nb0.32-1 Fe余量Fe4-6 V0.2-0.4 Co.25Fe2Fe≤7 Co1固溶退火e≤7W<4 W<4Co2.5 1050-110适用介质适用温度水、油品、蒸汽 -29-425水、油品、蒸汽 -29-425水、油品、蒸汽 -29-425水、油品、蒸汽≤455水、油品、蒸汽≤450蒸汽≤540蒸汽≤565蒸汽、酸碱类≤595蒸汽、酸碱类≤595蒸汽、油品≤650蒸汽、油品≤650水、油品、蒸汽 -20-480水、油品、蒸汽 -20-450蒸汽、硝酸类≤455(540)蒸汽、醋酸、硝酸≤425(540)尿素、硝酸≤425尿素、甲胺液≤455硫酸、氢氟酸≤450油品、蒸汽、弱介质 -29-540油品、蒸汽、弱介质 -29-540-54-200-254-200-254-425-196-600-196-600-46-46-59-73-200煤气、甲醇 -101-200-46-60-101-73-254-540-196-540-196-540-196-540-254-540-254-450-254-425-254-540硝酸、蒸汽≤800/540硝酸、蒸汽≤800/540硝酸、蒸汽≤800/540硝酸、蒸汽≤700/540硝酸、蒸汽≤700/540硫酸、醋酸、蒸汽≤700/540硫酸、醋酸、蒸汽≤700/540甲氨液、磷酸、碱蒸汽800/540甲氨液、磷酸、碱蒸汽800/540尿素、甲氨液、核电站、碱≤450醋酸、食品、核电站、碱≤425化工、食品、核电站、碱800/540化工、食品、核电站、碱800/540化工、食品、核电站、碱800/540海水、蒸汽、油品、碱800/540蒸汽、油品 -29-800 醋酸、食品、核电、化工≤540醋酸、食品、核电、化工≤450蒸汽、油品≤540硫酸、醋酸、氢氯酸≤540核电≤540海水≤540水、油品、蒸汽含CL离子≤425水、蒸汽、油品≤425水、蒸汽、油品≤540水、蒸汽、油品≤545水、蒸汽、油品≤545水、油品、蒸汽含CL离子≤673水、油品、蒸汽含CL离子≤673水、蒸汽、油品≤550水、蒸汽、油品≤550水、蒸汽、油品 -10-480水、蒸汽、油品≤450水、蒸汽、油品、内件 -10-480水、蒸汽≤550水、蒸汽≤550水、蒸汽≤550蒸汽≤570有机酸、卤离子、苛性酸≤540水、油品、重油≤450内件≤450水、蒸汽、油品≤450水、蒸汽、油品≤450水、蒸汽、油品≤450水、蒸汽、油品≤450氮、氢、碱液氨≤200- -45.6-510- -20-510- -10-600- -101-550- -254-700- -254-700- -254-816- -196-700- -38-450- -101-480- -254-800- -254-816- -196-700- -12.5-570--101-550--12.2-540--12.2-540水、蒸汽、油品 -38-545水、蒸汽、油品-38-540 -38-520 -38-425 -36-570内件-101-400 -101-450 -38-425 -38-900水、油品38-351核电、航天-196-427核电、航天-196-427核电、航天、耐蚀-196-427硫酸-38-200内件、硫化氢-38-200尿素、甲氨液、磷酸、碱≤200乙烯丙醇≤200氢氟酸、有机酸≤200盐、海水、氯化物≤200硫酸、苯、乙烯 - 253-427盐酸、硫酸≤700盐酸、硫酸≤700乙烯、氯化物、氢氟酸≤700盐酸、硫酸≤700盐酸 、硫酸、氢氟酸≤700硫酸 、磷酸、氢氟酸≤700硫酸、盐酸、磷酸≤700HRC45-50HRC37-42。