诊断试剂加速稳定性试验方案Attachment-VII-Test-Protocol-for-Accelerated-Stability-Test20160202[1]

- 格式:docx

- 大小:23.12 KB

- 文档页数:2

体外诊断试剂运输稳定性研究方案体外诊断试剂是一种用于检测人体样本中生化指标、疾病标志物等的试剂,其质量和稳定性对于检测结果的准确性至关重要。

而试剂在运输过程中受到温度、湿度、震动等不利环境因素的影响,可能导致试剂的降解和失效。

因此,需要进行体外诊断试剂运输稳定性的研究,以保证试剂在运输过程中的稳定性和可靠性。

本研究旨在评估体外诊断试剂在运输过程中的稳定性,具体方案如下:1.样品选择从市场上随机选取一批体外诊断试剂,包括不同制造商和不同类型的试剂。

确保选取的试剂能够涵盖常见的体外诊断试剂。

2.环境条件设置模拟实际运输环境,设置不同的温度、湿度和震动条件。

可以参考国内外相关标准和规范,确定合适的环境参数。

例如,可设置不同温度(常温、低温、高温)、湿度(相对湿度20%-80%)、震动(低频、中频、高频)条件。

3.运输箱选择选择合适的运输箱,确保能够满足运输过程中的要求。

运输箱的选取应考虑到绝缘性、隔热性、防潮性和防震性等因素。

4.试剂包装将选取的试剂进行适当的包装,以保护其在运输过程中不受到外界环境的影响。

包装材料可以使用常见的防潮、防震材料,如聚乙烯泡沫、吸湿剂等。

确保包装材料不会对试剂产生污染或化学反应。

5.试剂运输将包装好的试剂放入运输箱中,根据预设的环境条件,进行试剂的运输。

运输过程中,需保证运输箱的密封性和稳定性,避免温度、湿度和震动的剧烈变化。

6.试剂检测在运输过程结束后,对试剂进行检测,评估其稳定性。

检测指标可以包括试剂的活性、纯度、保存条件等。

对于常见的体外诊断试剂,可以通过比较运输前后的检测结果,评估试剂在运输过程中的稳定性。

7.数据分析和结果评估根据试剂检测结果,进行数据分析和结果评估。

参考相关标准和规范,对运输过程中的试剂稳定性进行评价,确定是否满足要求。

8.结论和建议根据研究结果,给出相应的结论和建议。

如果试剂在运输过程中的稳定性较好,可以提出合理的运输条件和建议;如果试剂的稳定性存在问题,可以提出相应的改进措施,如调整包装材料、改善运输环境等。

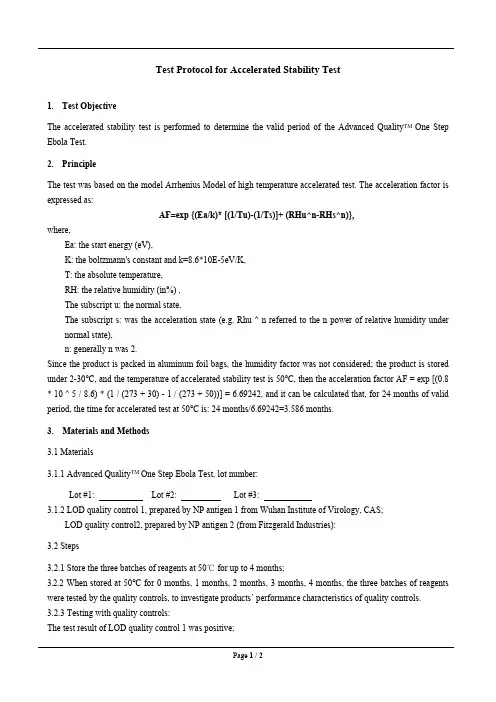

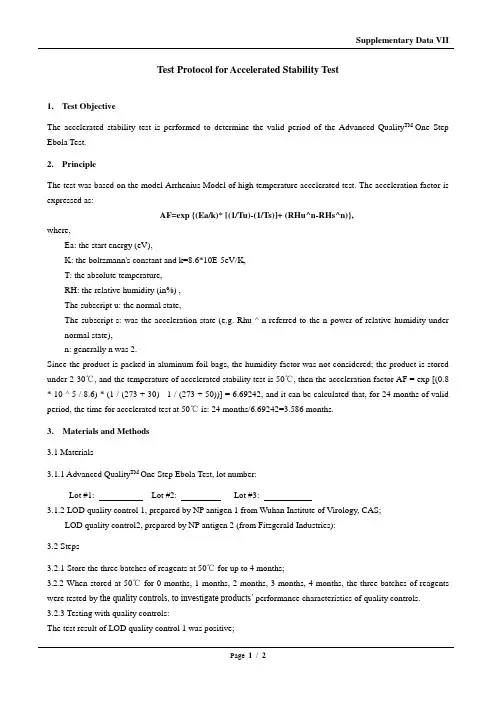

Test Protocol for Accelerated Stability Test1.Test ObjectiveThe accelerated stability test is performed to determine the valid period of the Advanced Quality TM One Step Ebola Test.2.PrincipleThe test was based on the model Arrhenius Model of high temperature accelerated test. The acceleration factor is expressed as:AF=exp {(Ea/k)* [(1/Tu)-(1/Ts)]+ (RHu^n-RHs^n)},where,Ea: the start energy (eV),K: the boltzmann's constant and k=8.6*10E-5eV/K,T: the absolute temperature,RH: the relative humidity (in%) ,The subscript u: the normal state,The subscript s: was the acceleration state (e.g. Rhu ^ n referred to the n power of relative humidity under normal state),n: generally n was 2.Since the product is packed in aluminum foil bags, the humidity factor was not considered; the product is stored under 2-30℃, and the temperature of accelerated stability test is 50℃, then the acceleration factor AF = exp [(0.8 * 10 ^ 5 / 8.6) * (1 / (273 + 30) - 1 / (273 + 50))] = 6.69242, and it can be calculated that, for 24 months of valid period, the time for accelerated test at 50℃ is: 24 months/6.69242=3.586 months.3. Materials and Methods3.1 Materials3.1.1 Advanced Quality TM One Step Ebola Test, lot number:Lot #1: Lot #2: Lot #3:3.1.2 LOD quality control 1, prepared by NP antigen 1 from Wuhan Institute of Virology, CAS;LOD quality control2, prepared by NP antigen 2 (from Fitzgerald Industries):3.2 Steps3.2.1 Store the three batches of reagents at 50℃ for up to 4 months;3.2.2 When stored at 50℃ for 0 months, 1 months, 2 months, 3 months, 4 months, the three batches of reagents were tested by the quality controls, to investigate products’ performance characteristics of quality controls.3.2.3 Testing with quality controls:The test result of LOD quality control 1 was positive;The test result of LOD quality control 2 was positive;4. Test Results4.1 Test result of storage at 50℃Lot No.Test result0 month storage1 months storage2 months storage3 months storage4 months storage5. Conclusions。

Test Protocol for Accelerated Stability Test1.Test ObjectiveThe accelerated stability test is performed to determine the valid period of the Advanced Quality TM One Step Ebola Test.2.PrincipleThe test was based on the model Arrhenius Model of high temperature accelerated test. The acceleration factor is expressed as:AF=exp {(Ea/k)* [(1/Tu)-(1/Ts)]+ (RHu^n-RHs^n)},where,Ea: the start energy (eV),K: the boltzmann's constant and k=8.6*10E-5eV/K,T: the absolute temperature,RH: the relative humidity (in%) ,The subscript u: the normal state,The subscript s: was the acceleration state (e.g. Rhu ^ n referred to the n power of relative humidity under normal state),n: generally n was 2.Since the product is packed in aluminum foil bags, the humidity factor was not considered; the product is stored under 2-30℃, and the temperature of accelerated stability test is 50℃, then the acceleration factor AF = exp [(0.8 * 10 ^ 5 / 8.6) * (1 / (273 + 30) - 1 / (273 + 50))] = 6.69242, and it can be calculated that, for 24 months of valid period, the time for accelerated test at 50℃ is: 24 months/6.69242=3.586 months.3. Materials and Methods3.1 Materials3.1.1 Advanced Quality TM One Step Ebola Test, lot number:Lot #1: Lot #2: Lot #3:3.1.2 LOD quality control 1, prepared by NP antigen 1 from Wuhan Institute of Virology, CAS;LOD quality control2, prepared by NP antigen 2 (from Fitzgerald Industries):3.2 Steps3.2.1 Store the three batches of reagents at 50℃ for up to 4 months;3.2.2 When stored at 50℃ for 0 months, 1 months, 2 months, 3 months, 4 months, the three batches of reagents were tested by the quality controls, to investigate products’ performance characteristics of quality controls.3.2.3 Testing with quality controls:The test result of LOD quality control 1 was positive;The test result of LOD quality control 2 was positive;4. Test Results4.1 Test result of storage at 50℃5. Conclusions。

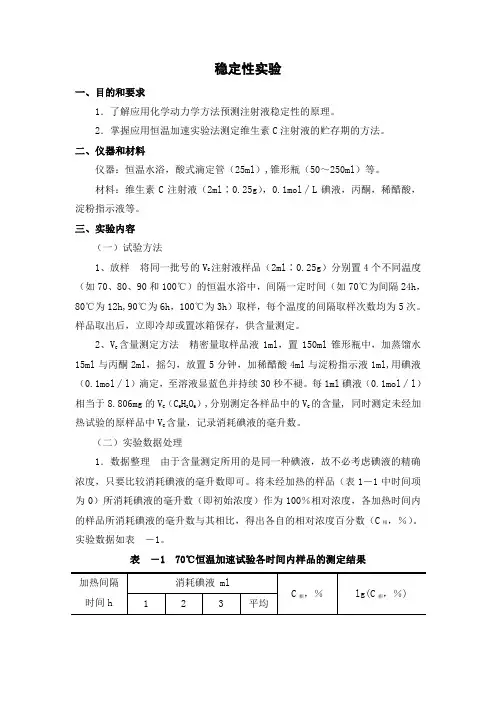

稳定性实验一、目的和要求1.了解应用化学动力学方法预测注射液稳定性的原理。

2.掌握应用恒温加速实验法测定维生素C 注射液的贮存期的方法。

二、仪器和材料仪器:恒温水浴,酸式滴定管(25ml ),锥形瓶(50~250ml )等。

材料:维生素C 注射液(2ml ∶0.25g ),0.1mol ∕L 碘液,丙酮,稀醋酸,淀粉指示液等。

三、实验内容(一)试验方法1、放样 将同一批号的V C 注射液样品(2ml ∶0.25g )分别置4个不同温度(如70、80、90和100℃)的恒温水浴中,间隔一定时间(如70℃为间隔24h ,80℃为12h,90℃为6h ,100℃为3h )取样,每个温度的间隔取样次数均为5次。

样品取出后,立即冷却或置冰箱保存,供含量测定。

2、V C 含量测定方法 精密量取样品液1ml ,置150ml 锥形瓶中,加蒸馏水15ml 与丙酮2ml ,摇匀,放置5分钟,加稀醋酸4ml 与淀粉指示液1ml,用碘液(0.1mol∕l)滴定,至溶液显蓝色并持续30秒不褪。

每1ml 碘液(0.1mol∕l)相当于8.806mg 的V C (C 6H 8O 6),分别测定各样品中的V C 的含量, 同时测定未经加热试验的原样品中V C 含量,记录消耗碘液的毫升数。

(二)实验数据处理1.数据整理 由于含量测定所用的是同一种碘液,故不必考虑碘液的精确浓度,只要比较消耗碘液的毫升数即可。

将未经加热的样品(表1-1中时间项为0)所消耗碘液的毫升数(即初始浓度)作为100%相对浓度,各加热时间内的样品所消耗碘液的毫升数与其相比,得出各自的相对浓度百分数(C 相,%)。

实验数据如表 -1。

表 -1 70℃恒温加速试验各时间内样品的测定结果2.求4种试验温度的V C 氧化降解速度常数(k 70~k 100) 用回归方法求各温度的k 值时,先将各加热时间(x )与其对应的lg(C 相,%)值(y )列表(表 -2)表16-2 加热时间及其相对浓度(%)对数值的回归计算表(70℃)用具有回归功能的计算器,将x 和y 值回归,直接得出截距,斜率和相关系。

稳定性试验整体解决方案注:此插图最好有博迅全系列试验箱整体照片我们上海博迅公司专业从事箱体制造20余年。

近年来,致力于制药和食品行业稳定性试验整体解决方案,我们努力从功能、性能、软件、硬件、设备规格等多方面全面提升,就是为了给咱们的客户提供更完美的使用体验和更完善的解决方案。

咱们博迅公司目前可提供:1.长期留样、加速试验、高温试验、光稳定性试验、近紫外影响因素、药品冷藏留样等的整体稳定性考察解决方案;2.对于样品量大的客户,可提供定制化步入式稳定性考察室;3.具有国内独家自主研发的在线监控软件,符合FDA 21 CFR PART 11 ,能实现自定义权限分级;审计最终日志;电子签名;数据完整性。

咱们博迅涉及稳定性试验的产品有:药品稳定性试验箱、综合药品稳定性试验箱、可扩展试验箱、步入式稳定性留样室、药品冷藏箱。

接下来,小编按照功能模块带大家来了解一下博迅稳定性试验相关产品的特点:一、智能控制器所有试验箱系列产品全部采用7寸高清触摸屏,触摸式操作,让显示更直观,操作更简单,BRIGHT II控制系统,可根据环境改变,对控制参数值进行自动补偿。

控制具备大容量存储,能够实现在线数据和曲线查看,电子数据备份(不可更改格式USB导出备份),审计追踪日志,自定义权限分级。

1.关于权限分级具备业内合规性最强的多级权限管理,管理员可以对操作员进行多级自定义权限分级,权限分配内容包括:时钟、报警设置、通讯设置、事件记录查询、数据记录查询、USB导出、测量校准、化霜设置、运行参数设置等14种权限。

2.关于审计追踪日志博迅试验箱具备业内最全的事件管理(操作日志)功能,开、关门,开、关机,用户登录及操作印记,参数修改,故障报警等关于设备的所有操作事件都能实时记录,并且支持USB导出备份。

3.关于数据完整性管理博迅试验箱系列产品除了标配打印机实时记录原始数据以外,还支持在控制器上直接查看历史运行数据和历史运行曲线,确保用户直观了解设备无人值守时的运行状态。

体外诊断试剂的稳定性试验欧洲标准(EN1364:2002)与英国标准具有同等效力(CEN——欧洲标准委员会)序言此英国标准为EN13640:2002文件官方英文版本英国制定的这个文件是在技术委员会CH/69授权下制定的。

在体外诊断这块,它负责:——帮助查询者理解文件内容——向欧洲委员会上报查询者对该文件的解释,修改建议,并保持该文件的权威。

——关注国际和欧洲的进展并在该文件中颁布。

可以技术委员会秘书处申请获得委员会列出的组织名单参考英国标准所参考的资料部分可在BSI标准的目录“国际统一标准索引”找到,或在BSI标准电子目录软件中点击“Find”就可找到。

该标准主旨不是要包揽一项合同的所有条款,使用者要正确使用该标准。

体外诊断试剂的稳定性试验此欧洲标准是欧洲委员会(CEN)2001年12月27日制定并实施的:CEN成员国必须遵守CEN内部规则,在此规则的制约下,CEN各成员国采用此欧洲标准作为本国标准,但不能对该标准作任何改动。

最新条款和参考文件可向管理中心或CEN成员国申请获得。

该标准有三种官方版本(英语、法语、德语)。

CEN成员国可以把它翻译成本国语言版本,并上报管理中心以获得认可作为本国的官方版本。

CEN成员国是执行该标准的主体,它们是:澳大利亚、比利时、捷克、丹麦、芬兰、法国、德国、希腊、冰岛、爱尔兰、意大利、卢森堡、荷兰、马尔他、葡萄牙齿、西班牙、瑞典、瑞士和英国。

前言该文件(EN13640:2002)由技术委员会(简写TC)制定。

“体外诊断医用设备”部分由DIN 主持的秘书处负责。

通过出版同一文本或签注,各国可采用欧洲标准作为本国的标准。

在2002年9月前,那些标准相违反的款项必须取消。

此文件在欧洲委员会和欧洲自由贸易组织批令下由CEN制定,该文件支持欧盟指令。

与欧盟批令的关系见附见ZA附件A和ZA只具告知性,不作要求。

此标准包括一个参考资料根据CEN内部规定,下列国家的国标准机构必须实施欧洲标准:澳大利亚、比利时等(与上页所列相同)1、适用范围该欧洲标准适用于体外诊断药品,包括试剂产品,校准仪器、标准品和试剂盒,下面简称IVD 药品。

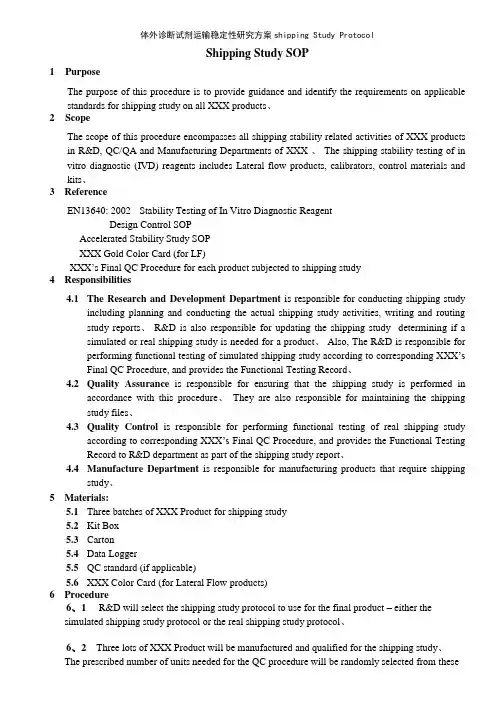

Shipping Study SOP1PurposeThe purpose of this procedure is to provide guidance and identify the requirements on applicable standards for shipping study on all XXX products、2ScopeThe scope of this procedure encompasses all shipping stability related activities of XXX products in R&D, QC/QA and Manufacturing Departments of XXX 、 The shipping stability testing of in vitro diagnostic (IVD) reagents includes Lateral flow products, calibrators, control materials and kits、3ReferenceEN13640: 2002 Stability Testing of In Vitro Diagnostic ReagentDesign Control SOPAccelerated Stability Study SOPXXX Gold Color Card (for LF)XXX’s Final QC Procedure for each product subjected to shipping study4Responsibilities4.1The Research and Development Department is responsible for conducting shipping studyincluding planning and conducting the actual shipping study activities, writing and routing study reports、R&D is also responsible for updating the shipping study determining if a simulated or real shipping study is needed for a product、 Also, The R&D is responsible for performing functional testing of simulated shipping study according to corresponding XXX’s Final QC Procedure, and provides the Functional Testing Record、4.2Quality Assurance is responsible for ensuring that the shipping study is performed inaccordance with this procedure、They are also responsible for maintaining the shipping study files、4.3Quality Control is responsible for performing functional testing of real shipping studyaccording to corresponding XXX’s Final QC Procedure, and provides the Functional Testing Record to R&D department as part of the shipping study report、4.4Manufacture Department is responsible for manufacturing products that require shippingstudy、5Materials:5.1Three batches of XXX Product for shipping study5.2Kit Box5.3Carton5.4Data Logger5.5QC standard (if applicable)5.6XXX Color Card (for Lateral Flow products)6Procedure6、1 R&D will select the shipping study protocol to use for the final product – either thesimulated shipping study protocol or the real shipping study protocol、6、2 Three lots of XXX Product will be manufactured and qualified for the shipping study、The prescribed number of units needed for the QC procedure will be randomly selected from thesetests, and evaluated for product performance using XXX’s final QC procedure、 This data will be used as the control or baseline data、6、2、1 Simulated shipping study protocola.3XFT/25℃:Perform 3 freeze/thaw cycles and at the last thaw, perform the QC testing、b.2 Days @ 55℃ /25 ℃:Place test strips in a 55℃ oven for 2 days and then perform the QC testing、* DAY 0: Run 10 test strips each with three controls、** Continue testing every 3 months thereafter until the 39th Month、c.Humidity study:Place the pouched devices in the 30%, 60% and >=80% relative humidity environments for 48 hours、After 48 hours, perform QC testing on the devices exposed under the 3 different relative humidity conditions、d.Vacuum Test:Test units from each lot of product will be randomly selected and exposed to the reduced atmospheric pressure by placing the units under vacuum to a level of approximately 500 milliTorr for 24 hours、The prescribed number of units needed for the QC procedure will be randomly selected from these reduced pressure treated units and evaluated for product performance using XXX’s final QC procedure (Refer to Vacuum Testing SOP)、6、2、2 Real Shipping Study Protocola.Vacuum Test:Test units from each lot of product will be randomly selected and exposed to the reduced atmospheric pressure by placing the units under vacuum to a level of approximately 500 mTorr for 24 hours、The prescribed number of units needed for the QC procedure will be randomly selected from these reduced pressure treated units and evaluated for product performance using XXX’s final QC procedure (Refer to Vacuum Testing SOP)、b.Shipping Study:The prescribed number of products will be placed in 2 shipping carton、 Half of the boxes will be placed in the carton in an upright position and the other will be placed in an inverted position、 The Data Logger with new battery and cleared all memory on old data logged, activated and placed in each shipping carton、The logger will collect temperature and humidity readings every 10 minutes、 The shipping cartons will be sealed、 One carton will be shipped via air cargo and the other by sea cargo to an oversea destination predetermined by R&D、 The carton will be sent back to XXX from the destination upon arrival、Upon receipt of the returned cartons, QC will be responsible visually to inspect shipping box and its contains、 Special emphasis will be placed on the leakage if liquid reagents were included in the shipping study、 The prescribed number of test units for QC will be randomly selectedwith half of the of units from the upright and half from the inverted products in boxes、XXX final QC procedure for these prescribed tests will be performed、If there is no statistical difference between the intra-lot performance data of the shipping studied products and from the controls, the air shipped products and sea shipped products, then the shipping study data will support both air and sea transportation of the product to ourcustomers、7Data7、1 When shipping study is completed, the following data should be available:1) All raw data should be included in the final report、2)The QC testing data3)The vacuum study data4)Temperature and humidity data logged and retrieved from the data loggers5)Package visual examination record8Result8、1 The results of shipping study report should contain but not limited to the items listed below:1) A summary of the shipping study2)Simulated shipping study results3)Temperature and humidity data during shipment4)The vacuum study results5)Comparison of results (intra-lot, inter-lot, air vs、 sea, etc)6)Observations7)Conclusion。

稳定性试验标准操作规程 (SOP)1.稳定性试验的内容:1.1加速破坏试验,预测样品的有效期;1.2样品在规定的保存条件下观察若干年限的检测结果。

2.稳定性试验的基本要求:2.1稳定性试验包括影响因素试验、加速试验和长期试验2.1.1影响因素试验适用于原料药的考察,用1 批原料药进行;2.1.2加速试验和长期试验适用于原料药与药物制剂,要求用3 批供试品进行。

2.2原料药供试品是一定规模生产的,所要求的批量,原料药合成工艺路线、物制剂的供试品应是放大试验的产品,致。

供试品量相当于制剂稳定性实验方法、步骤应与大生产一致。

药其处方与生产工艺应与大生产一2.3供试品的质量标准应与各项基础研究及临床验证所使用的供试品质量标准一致。

2.4加速试验与长期试验所用供试品的容器和包装材料及包装方式应与上市产品一致。

2.5研究药物稳定性,要采用专属性强、准确、精密、灵活的药物分析方法和有关物质的检查方法,并对方法进行验证以保证药物稳定性试验结果的可靠性。

在稳定性试验中,应重视有关物质的检查。

3.原料药的稳定性试验:3.1 影响因素试验3.1.1 高温试验供试品置于适宜的密封洁净容器中,60 C温度下放置10天,在第5天和第10 天取样,按稳定性重点考察项目进行检测。

若供试品有明显变化(如含量下降5%),则在40 C条件下同法进行试验。

若60 C无明显变化,不再进行40 C试验。

3.1.2高湿度试验:供试品置于恒湿密闭容器中,在25 C分别于相对湿度90%± 5%条件下放置10 天,于第5 天和第10 天取样,按稳定性重点考察项目要求检验,同时准确称量试验前后供试品的重量,以考察供试品的吸湿潮解性能。

若吸湿增重5%以上,则在相对湿度75%± 5% 条件下,同法进行试验;若吸湿增重5%以下,且其他考察项目符合要求,则不再进行此项试验。

3.1.3强光照射试验:供试品放在装有日光灯的光照箱或其他适宜的光照装置内,于照度为4500lx ±500lx 的条件下放置10 天,于第5 天和第10 天取样,按稳定性重点考察项目进行检测,特别要注意供试品的外观变化。

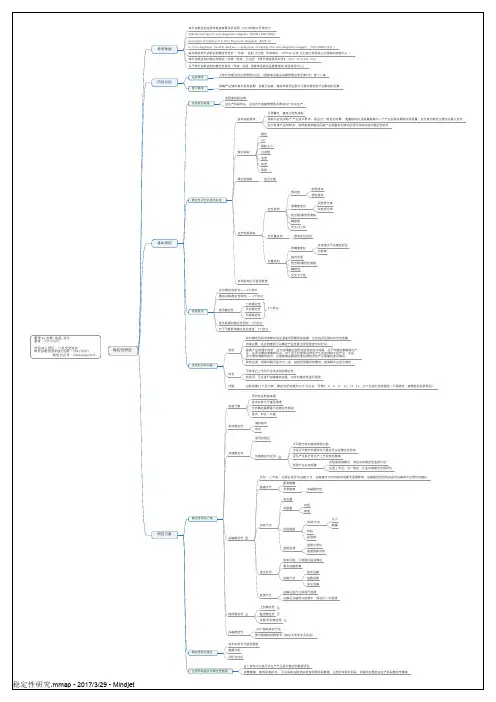

产品稳定性方案1.1 稳定性研究目的稳定性作为体外诊断试剂保持产品安全有效的重要指标,对产品的生产、运输、保存和使用等环节具有重要的指导意义。

体外诊断试剂本身就是生物试剂,一些活性基团会有不同的化学不稳定性趋向,容易发生水解、酶解和氧化等反应,从而影响到试剂的质量和稳定性。

如含有多肽类的冻干粉试剂,其储存环境中的含水量和含氧量对试剂稳定性的影响非常大。

因此,稳定性研究的目的包括:①确定产品的运输、储存和开封后的保存条件;②确定产品的保存期限和开封后保存期限;③产品储存条件和保存期限等发生变更时,验证变更后的产品稳定性;④根据稳定性研究结果,评价和调整产品组方、工艺、包装材料等。

如某体外诊断试剂产品稳定性研究目的:为考察试剂盒的稳定性,对三批产品进行储存温度2~8˚C的稳定性试验、37˚C的加速稳定性试验、2~8˚C的开瓶稳定性试验、模拟运输稳定性试验等,根据试验结果确定产品的有效期、开封有效期并确定试剂盒的运输条件。

1.2 稳定性研究的材料稳定性研究的材料包括试验仪器、试验试剂(3批)、校准品、质控品等。

稳定性研究中的试验仪器应为产品的适用机型。

除试验仪器外,稳定性研究中还会用到恒温箱、冷藏柜、恒湿箱等仪器,上述仪器应定期检查,防止因为仪器的故障导致稳定性试验失败。

试验试剂应为实际生产条件下的三批试剂,并分别说明三个批次的批号,三个批次的生产工艺与质量要求均应保持一致。

试剂的包装材料应与实际储存采用的包装材料一致。

质控品、校准品等应符合产品技术要求中的相关要求。

1.3 稳定性研究的项目稳定性研究的项目应根据产品组成和方法学原理来选择评价产品质量和有效性的项目。

一般选择产品技术要求中规定的项目,如最低检测限、准确性、重复性、线性范围、特异性、阴/阳性参考品符合率等。

如果稳定性研究结果出现不符合研究方案中确定的评价指标的情况时,应进一步分析原因。

导致产品不稳定的原因可能是组分不稳定、包装材料破损或者储存、运输条件变化等因素,企业应在确定原因后采取改进措施,并在改进之后对产品重新进行稳定性研究。

1.1 术语1.1.1 长期稳定性试验(long term stability testing)在控制的环境条件下(接近实际条件)留样,并定期进行检验。

其目的为了确认适当的贮存条件及制定产品有效期或复验期提供依据。

1.1.2 加速稳定性试验(Accelerated stability testing)通过使用超常的贮存条件来加速产品化学降解或物理变化。

评估在运输期间短期的贮存条件与标签上规定的条件不符时,可能会造成对产品质量的影响;是对长期稳定性研究数据的补充。

1.1.3 影响因素试验1.1.4 是在比加速试验更激烈的条件下进行。

其目的是探讨药物的固有稳定性、了解影响其稳定性的因素及可能的降解途径与降解产物,为制剂生产工艺、包装、贮存条件和建立降解产物分析方法提供科学依据。

1.2 稳定性年度计划1.2.1 QC经理根据生产品和QA的要求,种制订年度稳定性试验计划,包括:品名、规格、批次、批号、试验方式、稳定性试验项目及方法、责任人等。

1.2.2 稳定性计划经QC经理审核,交质量部负责人批准方可生效。

1.3 原料药影响因素试验1.3.1 原料药进行该试验。

用一批代表性的原料药进行,将样品除去包装后,平放在称量瓶或培养皿中摊成≤5 mm厚的薄层,疏松原料药摊成≤10 mm厚薄层,进行以下实验,考察各项指标的变化情况。

1.3.2 高温试验温度分别选择40℃、60℃两个温度水平。

将样品在60℃温度下放置10天,于第5天和第10天取样,按稳定性重点考察项目进行检测。

若样品无明显变化,则不进行40℃条件下的试验;若样品有明显变化(如含量下降5%,鉴别不明显,外观色泽变化大等),则须在40℃条件下同法进行试验。

1.3.3 高湿试验选择相对湿度为75%±5%、90%±5%两个湿度水平(T=25℃)。

将样品置于相对湿度90%±5%条件下(装KNO3饱和溶液的干燥器中,用封口胶密封)放置10天,于第5天和第10天取样,按稳定性重点考察项目要求检测,同时准确称量试验前后样品的重量,若样品无明显变化,则不进行75%±5%条件下的试验;若样品有明显变化(如含量下降5%,鉴别不明显,外观色泽变化大、吸湿增重5%以上等),则须在相对湿度75%±5%条件下(装有NaCl 饱和溶液的干燥器中,用凡士林密封)同法进行试验。

加速试验研究方案方案起草起草部门签名日期方案审核审核部门签名日期方案批准批准人签名日期研发部负责人目录1.研究方案依据 (1)2.研究方案概述 (1)3.试验样品要求 (1)4.实验方法 (1)5.试验条件 (1)6 加速试验结果 (2)7.试验结果分析 (3)8.试验结论 (3)9.参考文献 (3)1.研究方案依据依据《化学药物质量标准建立的规范化过程技术指导原则》、《中华人民共和国药典》2015版四部附录中有关的指导原则及FDA、ICH等法规和相关指导原则,撰写“舒更葡糖钠原料药加速试验研究方案”。

2.研究方案概述加速试验是药物稳定性试验中的一部份。

此试验是在加速条件下进行,其目的是通过加速药物的化学或物理变化,探讨药物的稳定性,为制剂设计、包装、运输、贮存提供必要的资料。

加速试验及必要时进行的中间条件试验,主要用于评估短期偏离标签上的贮藏条件对原料药质量的影响(如在运输途中可能发生的情况),并为长期试验条件的设置及制剂的处方工艺设计提供依据及支持性信息。

3.试验样品要求用三批在一定规模条件下(如中试样品)生产出来的样品,即原料药合成工艺路线、方法、步骤应与大生产一致。

为加速研究过程,尽快获得原料药的性质,降低风险,为工艺人员及时提供质量研究数据,在有一定纯度的样品产生后、小试工艺稳定、中试规模样品三个阶段均应放样研究。

其中中试规模样品,必须严格按照本方案进行完整的研究。

4.实验方法原料药供试品要求三批,按市售包装,在温度40℃±2℃,相对湿度75%±5%的条件下放置6个月。

所用设备应能控制温度±2℃、相对湿度±5%,并能对真实温度与湿度进行监测。

在试验期间第1个月、2个月、3个月、6个月末分别取样一次,按稳定性重点考察项目检测,其中0个月和6个月末样品需按质量标准要求全检。

舒更葡糖钠原料药引湿性较强,加速试验的水分测定可以为包装材料的选择提供依据。

根据资料描述,本产品稳定性良好。

稳定性实验方案(参考)诊断原料稳定性考核主要包括热稳定性、真实稳定性、运输稳定性及冻融稳定性四部分,工作流程如下图所示,具体方案见下文。

根据抗原和抗体进行分类,此外结合产品的用途,综合考虑上述实验内容的安排和设计,以便满足市场客户需求,合理调配公司资源。

现给出各类型开展稳定性评价分具体实验方案。

1蛋白的稳定性实验方案1.1发货蛋白的稳定性实验各项目负责人根据项目特点,确定发货的蛋白稳定性实验内容。

因为发货浓度一般都是以mg/ml作为单位,所以考核其稳定性主要是用于存放条件的确定。

考核方案以持续检测和对比实验为主,一般不开展高温热加速实验,因为高温热加速实验本身就很难保证稳定性合格,此外为了使其稳定,添加的稳定剂或类似物质后影响抗原的后期使用。

发货蛋白初始存放条件为-20℃,可以开展2-8℃稳定性对比实验。

以分别在-20℃和2-8℃条件下存放一定时间(根据项目而异),采用免疫学或适宜方法开展平行比较,以平行分析之间的差异评价蛋白是否可以存放于2-8℃条件下。

只有在2-8℃条件下评价稳定,再根据项目情况来综合考虑是否要做37℃下的热稳定性实验。

根据上述实验进一步确定发货蛋白的存放条件,以此确保在特定保存条件下的稳定性。

持续检测的实验主要目的是为了在较长时间内监测蛋白真实稳定性而开展的评价内容。

主要采用相对稳定的检测方法,对存放在特定条件下的蛋白开展的结果重现性实验。

例如:采用经过热稳定性评价合格的抗体制备的检测系统,该检测系统批间差异在理想范围内,采用该系统对考核蛋白进行持续检测,持续检测的结果在一定范围内(可以参考绘制质控图,如L-J质控图),判定为稳定性是否合格。

1.2工作条件下蛋白的稳定性实验各项目负责人根据项目特点,确定工作条件下的蛋白稳定性实验内容。

工作条件下的稳定性考核主要涉及校准品、质控品等的稳定性问题,是基于客户使用的立场开展的用途评价及相关研究。

工作重点主要是稳定性基质的筛选和评价、稳定性的持续监测等。

Test Protocol for Accelerated Stability Test

1.Test Objective

The accelerated stability test is performed to determine the valid period of the Advanced Quality TM One Step Ebola Test.

2.Principle

The test was based on the model Arrhenius Model of high temperature accelerated test. The acceleration factor is expressed as:

AF=exp {(Ea/k)* [(1/Tu)-(1/Ts)]+ (RHu^n-RHs^n)},

where,

Ea: the start energy (eV),

K: the boltzmann's constant and k=8.6*10E-5eV/K,

T: the absolute temperature,

RH: the relative humidity (in%) ,

The subscript u: the normal state,

The subscript s: was the acceleration state (e.g. Rhu ^ n referred to the n power of relative humidity under normal state),

n: generally n was 2.

Since the product is packed in aluminum foil bags, the humidity factor was not considered; the product is stored under 2-30℃, and the temperature of accelerated stability test is 50℃, then the acceleration factor AF = exp [(0.8 * 10 ^ 5 / 8.6) * (1 / (273 + 30) - 1 / (273 + 50))] = 6.69242, and it can be calculated that, for 24 months of valid period, the time for accelerated test at 50℃ is: 24 months/6.69242=3.586 months.

3. Materials and Methods

3.1 Materials

3.1.1 Advanced Quality TM One Step Ebola Test, lot number:

Lot #1: Lot #2: Lot #3:

3.1.2 LOD quality control 1, prepared by NP antigen 1 from Wuhan Institute of Virology, CAS;

LOD quality control2, prepared by NP antigen 2 (from Fitzgerald Industries):

3.2 Steps

3.2.1 Store the three batches of reagents at 50℃ for up to 4 months;

3.2.2 When stored at 50℃ for 0 months, 1 months, 2 months, 3 months, 4 months, the three batches of reagents were tested by the quality controls, to investigate products’ performance characteristics of quality controls.

3.2.3 Testing with quality controls:

The test result of LOD quality control 1 was positive;

The test result of LOD quality control 2 was positive;

4. Test Results

4.1 Test result of storage at 50℃

5. Conclusions。