PCS-915现场验收调试报告英文版

- 格式:docx

- 大小:404.35 KB

- 文档页数:9

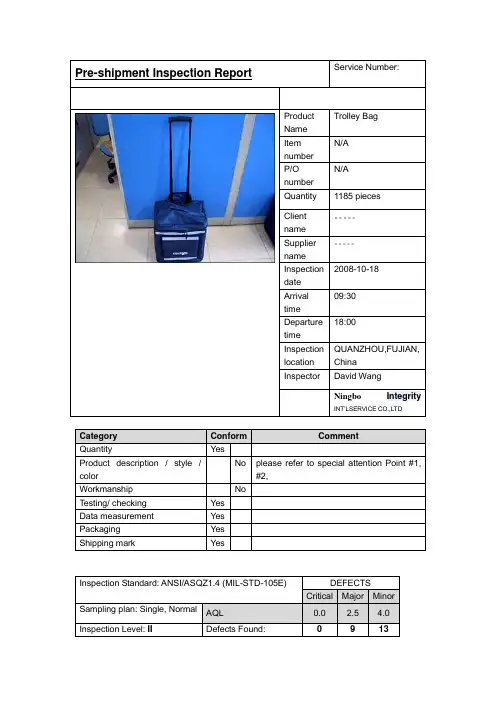

Pre-shipment Inspection Report Service Number: Summary SectionProductNameTrolley BagItemnumberN/AP/OnumberN/AQuantity 1185 piecesClientname。

Suppliername。

Inspectiondate2008-10-18Arrivaltime09:30Departuretime18:00Inspection location QUANZHOU,FUJIAN, ChinaInspector David WangNingbo IntegrityINT’LSERVICE CO.,LTDCategory Conform CommentQuantity YesProduct description / style / color No please refer to special attention Point #1, #2,Workmanship NoTesting/ checking YesData measurement YesPackaging YesShipping mark YesInspection Standard: ANSI/ASQZ1.4 (MIL-STD-105E) DEFECTSCritical Major Minor Sampling plan: Single, Normal AQL 0.0 2.5 4.0Inspection Level: II Defects Found: 0 9 13QuantityProduct description / style / colorspecificationCheck against sample submitted by client:Discrepancy was found on inspection samples, please refer to Special Attention point # 1 & #2.WorkmanshipDefectives ListDefectivesListDefectivesCRI MAJ MIN PictureDescription0 0 8Wrinkle markon fabricDirty stains 0 0 5DefectivesListDefectives ListDefectivesDescriptionCRI MAJ MIN PictureHandle standslant ( can beused)0 9 0TESTING /CHECKINGFunction test on handle, wheel, zip and Velcro.Performed on all seletced samples, the result was passed.Function checking for Velcro tape/zip Performed all selected samples, the result was acceptablePull test at handle strap by hand normal force Performed on S-3 samples, the result was passed.Adhesive test by tapes Performed on S-3 samples, Noprinting peel off, the result waspassedSize measure performed on 5 pcs samples,result is below measurement table.Internal Check performed on 5 pcs samples,Discrepancy was found oninspection samples, please refer toSpecial Attention point # 1 & # 2.(Page 2).Mass productions Approved sampleGap locationCarton Drop Test from 76cmheight, drop 10 times at 1 corner, 3edges and 6 faces.Performed on 3 cartons, the resultwas passedDATA MEASUREMENTSize MeasurementItems Spec.(cm)Samples1 2 3 4 5Product size (L * W * H) N/A 36 * 26.5* 4036 * 26.5* 4036 * 26.5* 4036 * 26.5* 4036 * 26.5* 40Side pocket23*25 23*24.5 23*24.5 23*24.5 23*24.5 23*24.5 Logo printing(L * W)N/A 11 * 2.6 11 * 2.6 11 * 2.6 11 * 2.6 11 * 2.6PE boardthickness onbottom and backpart4.0mm 4.0mm 4.0mm 4.0mm 4.0mm 4.0mmPE boardthickness around3 sides3.0mm 3.0mm 3.0mm 3.0mm 3.0mm 3.0mmGross Weight ofexport cartonN/A 5.0 KGS 5.1 KGS 5.2 KGS 5.0 KGS 5.0 KGSSize of Export carton N/A 39 * 32 *44cm39 * 32 *44cm39 * 32 *44cm39 * 32 *44cm39 * 32 *44cmPackagingUnit packingEach product was packed into anindividual poly bag ,sealed onopeningOuter packing Carton size: 39 * 32 * 44cm1 pc with an instruction sheet packed ina carton which fixed by 1 nylon strap.Shipping markShipping MarkFront mark Side markOther markingBar code label on CartonPrinting logo on bag Other PicturesSewn label Sewn label (back)Instruction sheet Bottom viewString on zipper puller Compare with approved sample (rightside one)CartonsTotal cartons Inspected cartons。

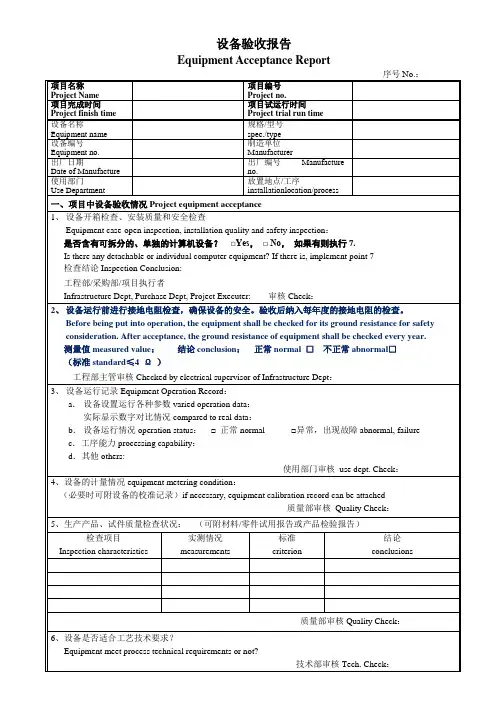

设备验收报告Equipment acceptance report设备名称/Mode ______________________使用单位/Company_______________________验收负责人/Inspector _______________________年月日 /Date:验收情况记录/Inspection1)设备外包装情况(外包装类型、表面标注、是否破损及其他情况)Packaging condition2)开箱后设备本身情况(是否有生锈、破损及其他情况)Machine condition(it there is rust or broken)3)按合同和装箱单清点所到物品是否齐全一致?Check spare parts list(if it is the same with contracted)4)质量、性能验收情况/Machine performance1安装测试的条件/If the buyer offers the right condition for machine testing验收项目/Testingcontent说明书或操作手册Machinespecifiicationand operationmanul5)验收结果/Acceptance result负责人签章/S ignature_______ 年月日验收报告Acceptance Report_____________于____年____月____日购买______________的____________仪器(或设备),价值_________,合同号是__________。

该设备于____年____月____日到货。

经供货方______来校安装调试。

各项指标,均达到合同要求,运行至今,设备一切正常,性能良好,验收合格。

特此说明。

订购单位(盖章)验收人:年月日The buyer______________purchased machine_____________from The seller___________________.And the buyer received machine on date___________.After installation,testing and adjustment, the buyer prove that each machine function reached the contract requirements and the performance is good and acceptable.Signature:Date。

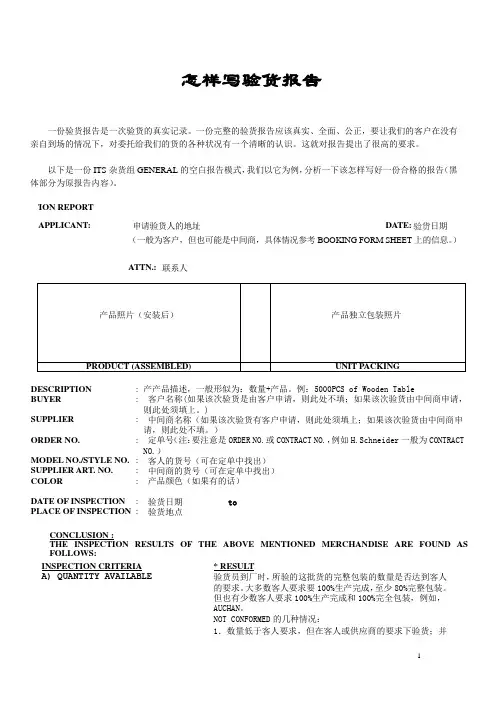

怎样写验货报告一份验货报告是一次验货的真实记录。

一份完整的验货报告应该真实、全面、公正,要让我们的客户在没有亲自到场的情况下,对委托给我们的货的各种状况有一个清晰的认识。

这就对报告提出了很高的要求。

以下是一份ITS杂货组GENERAL的空白报告模式,我们以它为例,分析一下该怎样写好一份合格的报告(黑体部分为原报告内容)。

CTION REPORTAPPLICANT: 申请验货人的地址DATE: 验货日期(一般为客户,但也可能是中间商,具体情况参考BOOKING FORM SHEET上的信息。

)ATTN.: 联系人DESCRIPTION : 产产品描述,一般形似为:数量+产品。

例:5000PCS of Wooden TableBUYER : 客户名称(如果该次验货是由客户申请,则此处不填;如果该次验货由中间商申请,则此处须填上。

)SUPPLIER : 中间商名称(如果该次验货有客户申请,则此处须填上;如果该次验货由中间商申请,则此处不填。

)ORDER NO. : 定单号(注:要注意是ORDER NO.或CONTRACT NO.,例如H.Schneider一般为CONTRACTNO.)MODEL NO./STYLE NO. : 客人的货号(可在定单中找出)SUPPLIER ART. NO. : 中间商的货号(可在定单中找出)COLOR : 产品颜色(如果有的话)DATE OF INSPECTION : 验货日期toPLACE OF INSPECTION : 验货地点CONCLUSION :RESULTS OF THE ABOVE MENTIONED MERCHANDISE ARE FOUND AS FOLLOWS:INSPECTION CRITERIA * RESULTA) QUANTITY AVAILABLE 验货员到厂时,所验的这批货的完整包装的数量是否达到客人的要求。

大多数客人要求要100%生产完成,至少80%完整包装。

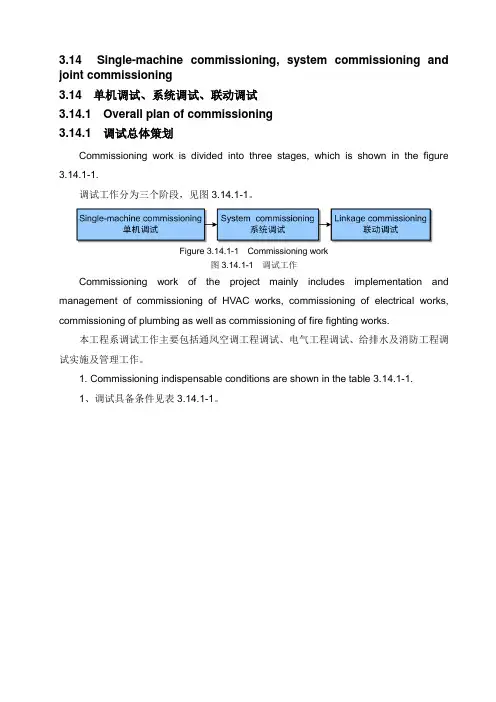

3.14 Single-machine commissioning, system commissioning and joint commissioning3.14 单机调试、系统调试、联动调试3.14.1 Overall plan of commissioning3.14.1 调试总体策划Commissioning work is divided into three stages, which is shown in the figure 3.14.1-1.调试工作分为三个阶段,见图3.14.1-1。

Figure 3.14.1-1 Commissioning work图3.14.1-1 调试工作Commissioning work of the project mainly includes implementation and management of commissioning of HVAC works, commissioning of electrical works, commissioning of plumbing as well as commissioning of fire fighting works.本工程系调试工作主要包括通风空调工程调试、电气工程调试、给排水及消防工程调试实施及管理工作。

1. Commissioning indispensable conditions are shown in the table 3.14.1-1.1、调试具备条件见表3.14.1-1。

Table 3.14.1-1 Commissioning indispensable conditions2. Organization measures of commissioning2、调试的组织措施(1)Organization chart of commissioning is shown in the figure 3.14.1-2. (1)调试的组织机构见图3.14.1-2。

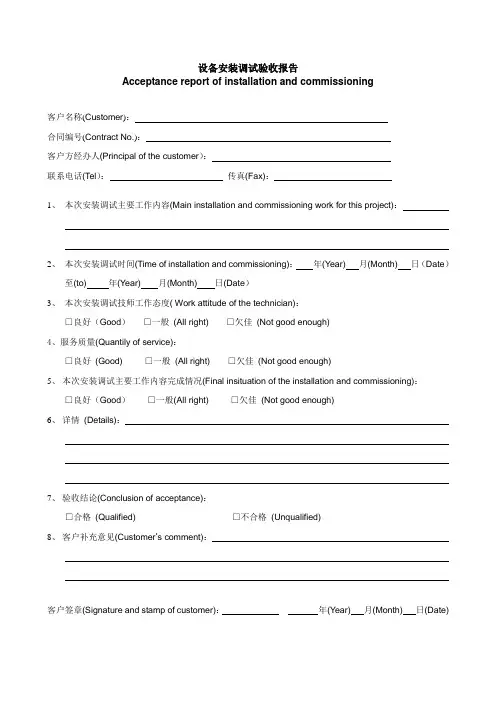

设备安装调试验收报告Acceptance report of installation and commissioning客户名称(Customer):合同编号(Contract No.):客户方经办人(Principal of the customer):联系电话(Tel):传真(Fax):1、本次安装调试主要工作内容(Main installation and commissioning work for this project):2、本次安装调试时间(Time of installation and commissioning):年(Year)月(Month)日(Date)至(to)年(Year)月(Month)日(Date)3、本次安装调试技师工作态度( Work attitude of the technician):□良好(Good)□一般(All right) □欠佳(Not good enough)4、服务质量(Quantily of service):□良好(Good) □一般(All right) □欠佳(Not good enough)5、本次安装调试主要工作内容完成情况(Final insituation of the installation and commissioning):□良好(Good)□一般(All right)□欠佳(Not good enough)6、详情(Details):7、验收结论(Conclusion of acceptance):□合格(Qualified)□不合格(Unqualified)8、客户补充意见(Customer’s comment):客户签章(Signature and stamp of customer):年(Year)月(Month)日(Date)。

***kV****变电站

220kV母线保护检验调试报告

(RCS-915AB)

一.检验设备的基本信息

1.1保护装置基本信息

1.2保护软件版本及程序校验码核查

二.检验条件

三.RCS-915AB微机母线差动保护校验

3.1 保护外观及内部插件检查

3.2 绝缘检查

3.3保护时钟失电保护功能检验

3.4开关量输入回路检验

3.4.1开关量输入回路1

3.4.2开关量输入回路刀闸辅助接点

3.4.3开关量输入回路3—失灵启动接点

3.5模数变换系统检验

3.5.1 零漂及模拟量输入的幅值特性

零漂允许范围: -0.01I N<I<0.01I N ,-0.05V<U<0.05V

3.5.1.1保护板液晶屏显示值

3.5.1.2管理板液晶屏显示值

3.5.2 模拟量输入的相位特性

液晶屏显示相角以U A为基准值

3.6保护定值检验

3.6.1差动起动电流定值检验

3.6.2差动保护比率制动特性检验

3.6.3差动保护复合电压定值校验

3.6.4 支路TA断线、TA异常定值校验

3.6.5 母联TA断线、TA异常定值校验

3.6.6失灵保护复合电压定值校验

3.6.6失灵保护动作时间定值校验

3.6.7母联过流、充电保护定值校验

3.7出口回路检查

3.8信号输出接点检查

3.9整组试验

四.结合定检完成的其他工作及尚存在的缺陷:

五.本次检验结论:

工作负责人签名。

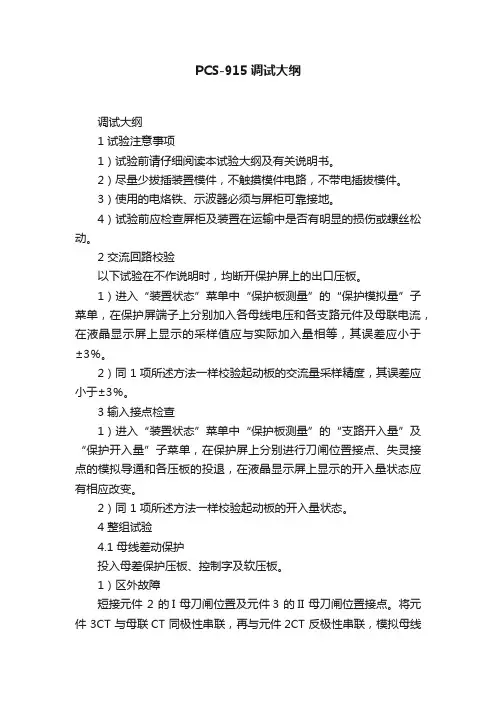

PCS-915调试大纲调试大纲1 试验注意事项1)试验前请仔细阅读本试验大纲及有关说明书。

2)尽量少拔插装置模件,不触摸模件电路,不带电插拔模件。

3)使用的电烙铁、示波器必须与屏柜可靠接地。

4)试验前应检查屏柜及装置在运输中是否有明显的损伤或螺丝松动。

2 交流回路校验以下试验在不作说明时,均断开保护屏上的出口压板。

1)进入“装置状态”菜单中“保护板测量”的“保护模拟量”子菜单,在保护屏端子上分别加入各母线电压和各支路元件及母联电流,在液晶显示屏上显示的采样值应与实际加入量相等,其误差应小于±3%。

2)同 1 项所述方法一样校验起动板的交流量采样精度,其误差应小于±3%。

3 输入接点检查1)进入“装置状态”菜单中“保护板测量”的“支路开入量”及“保护开入量”子菜单,在保护屏上分别进行刀闸位置接点、失灵接点的模拟导通和各压板的投退,在液晶显示屏上显示的开入量状态应有相应改变。

2)同 1 项所述方法一样校验起动板的开入量状态。

4 整组试验4.1 母线差动保护投入母差保护压板、控制字及软压板。

1)区外故障短接元件 2 的I 母刀闸位置及元件3 的II 母刀闸位置接点。

将元件 3CT 与母联CT 同极性串联,再与元件2CT 反极性串联,模拟母线区外故障。

通入大于差动保护启动电流定值的电流,并保证母差电压闭锁条件开放,保护不应动作。

2)区内故障短接元件 2 的I 母刀闸位置及元件3 的II 母刀闸位置接点。

将元件2CT、母联CT 和元件3CT 同极性串联,模拟I 母故障。

通入大于差流启动定值的电流,并保证母差电压闭锁条件开放,保护动作跳I 母。

将元件 2CT 和元件3CT 同极性串联,再与母联CT 反极性串联,模拟II 母故障。

通入大于差动保护启动电流定值的电流,并保证母差电压闭锁条件开放,保护动作跳II 母。

投入母线互联压板。

重复上述区内故障,保护动作切除两母线上所有的连接元件。

3)电压闭锁元件在满足比率差动元件动作的条件下,分别检验保护的电压闭锁元件中相电压、负序和零序电压定值,误差应在±3%以内。

220kV母线RCS915AB型保护调试报告1.外观及接线检查序号项目结果1检查装置是否有机械及电器上的损坏2装置地线与变电站接地网可靠连接且整机接地良好3装置端子排接线螺丝是否紧固连接正确4各插件元件无虚焊、脱焊现象,接触可靠2.逆变电源自启动试验试验项目试验结果直流电源缓慢上升的自启动试验拉合直流电源的自启动试验及保护不应误动3.装置初步上电检查检查项目检查结果键盘功能打印机联机情况时钟整定4.保护软件检查保护型号模块名称版本号CRC码生成时间RCS-915AB 保护板管理板面板5.开关量输入检查5.1刀闸位置开入检验5.1.1将模拟屏上的刀闸位置强制小开关拔到中间位置(自动),分别短接下列端子,从面板上可以观察到对应的运行状态灯应亮。

再将各支路的小开关拔到“分”位置,对应的运行状态灯熄灭。

各支路切换到I母:检验结果:_____各支路切换到II母:检验结果:_____5.1.2把所有小开关分别拨到“合”位置,对应的状态运行灯应亮。

检验结果:_____5.2失灵接点开入检验在保护屏后开入量端子排上分别短接各失灵开入量与公共端,查看I母失灵、II母失灵信号灯点亮情况应正确。

检验结果:正确5.3保护功能投退检验分别投退各压板、功能切换手把由液晶屏幕查看开入量状态显:检验项目检验结果检验项目检验结果投母差互联状态单母运行充电保护投入断路器失灵失灵电压解除母联非全相I母PT投母联带路II母PT投检修状态——6.精度检查6.1电流精度检查间隔名称相别加入值保护板管理板1#主变A0.1A0.5A1A0°0°0°B0.1A0.5A1A240°240°240°C0.1A0.5A1A120°120°120°闻喜A0.1A0.5A1A0°0°0°B0.1A0.5A1A240°240°240°C0.1A0.5A1A120°120°120°2#主变A0.1A0.5A1A0°0°0°B0.1A0.5A1A240°240°240°C0.1A0.5A1A120°120°120°绛县A0.1A0.5A1A0°0°0°B0.1A0.5A1A240°240°240°C0.1A0.5A1A120°120°120°大差电流A0.1A0.5A1A B0.1A0.5A1A C0.1A0.5A1AI母差流A0.1A0.5A1A B0.1A0.5A1A C0.1A0.5A1AII母差流A0.1A0.5A1A B0.1A0.5A1A C0.1A0.5A1A6.2相电压精度检查名称相别加入值保护板管理板Ⅰ母A10V30V57.74V0°0°0°B10V30V57.74V240°240°240°C10V30V57.74V120°120°120°Ⅱ母A10V30V57.74V0°0°0°B10V30V57.74V240°240°240°C10V30V57.74V120°120°120°6.3线电压精度检查名称相别加入值保护板管理板Ⅰ母A10V50V100V B10V50V100V C10V50V100VⅡ母A10V50V100V B10V50V100V C10V50V100V7.定值检查名称相别启动电流电流断线报警高定值1.0A低定值0.5A定值0.5A0.95倍 1.05倍0.95倍 1.05倍0.95倍 1.05倍Ⅰ母ABCⅡ母ABC名称相别低电压负序电压零序电压定值30V 定值8V 定值10V 0.95倍1.05倍0.95倍1.05倍0.95倍1.05倍Ⅰ母ABCⅡ母ABC8.比率制动特性(Kh =0.7K L =0.6启动值设为2.0A)母联开关位置I1I2K合位 5.0510.7240.83分位5 1.30.671.89.出口及逻辑回路检查9.1合上保护电源,投母差保护及出口跳闸压板,投母差保护控制字,依次向各相通入电流,模拟区内故障,各出口跳闸接点均由开到闭。

Factory Acceptance Test ReportProject:Panel Name:Panel NO. :Serial No. of Panel:Serial No. of Device:Device Type:DC Power Supply: VAC Voltage (nominal value): VRated Frequency: HzCatalog1. Target (1)2. Purpose of Test (1)3. Item of Test (1)4. Test Equipments (1)5. Test Carried Out By (1)6. Content of Examination (2)6.1 Sampling Test (2)6.2 Binary Inputs Test (2)6.3 Signal Contacts Test (4)6.4 Output Contacts Test (4)6.5 Logic Function Test (5)6.5.1 Busbar Differential Protection (87B) (5)6.5.2 Breaker Failure Protection of Busbar (50BF) (6)1. TargetTarget Name:Busbar ProtectionProgram Version:2. Purpose of TestCheck the all function of relay. To ensure the function satisfy the requirement of Busbar Protection of this substation.3. Item of TestCheck the correctness of hardware and cable. Check the accuracy of sampling, and check binary input and binary output, signal contact, tripping contact, mechanic and so on. Check the logic function of each relay element and setting value.4. Test Equipments5.Test Carried Out By6. Content of Examination6.1 Sampling TestCurrent Test Slots: 04&05Slots: 06&076.2 Binary Inputs TestSlots: 09BI Module: NR1502ASSlots: 10Slots: 116.3 Signal Contacts TestSlots: B006.4 Output Contacts TestSlots: 13Slots: 14Slots: 156.5 Logic Function Test6.5.1 Busbar Differential Protection (87B)(1)SettingsPick up setting of differential current: 4 A,slope setting(fixed):0.5 ,(2)Pick up current of busbar differential protection testTest result of pick up current:A,(3)Slope testSlope calculation:Point 9 and point 5:K=( - )÷( - )=Point 8 and point 4:K=( - )÷( - )=Point 7 and point 3:K=( - )÷( - )=Operation time:ms(4)Function of CT circuit failure blocking BBPFunction of CT circuit failure blocking BBP:Result:6.5.2 Breaker Failure Protection of Busbar (50BF)(1)settingsPhase current setting: 2 A,Zero sequence current setting:0.5 A,Negative sequence current setting:0.5 A,Setting of time delay 0.5 S。

设备安装调试验收报告Acceptance report of installation and commissioning客户名称(Customer):合同编号(Contract No.):客户方经办人(Principal of the customer):联系电话(Tel):传真(Fax):1、本次安装调试主要工作内容(Main installation and commissioning work for this project):2、本次安装调试时间(Time of installation and commissioning):年(Year)月(Month)日(Date)至(to)年(Year)月(Month)日(Date)3、本次安装调试技师工作态度( Work attitude of the technician):□良好(Good)□一般(All right) □欠佳(Not good enough)4、服务质量(Quantily of service):□良好(Good) □一般(All right) □欠佳(Not good enough)5、本次安装调试主要工作内容完成情况(Final insituation of the installation and commissioning):□良好(Good)□一般(All right)□欠佳(Not good enough)6、详情(Details):7、验收结论(Conclusion of acceptance):□合格(Qualified)□不合格(Unqualified)8、客户补充意见(Customer’s comment):客户签章(Signature and stamp of customer):年(Year)月(Month)日(Date)。

英文版调试合格确认书Debug Qualification Confirmation LetterDear [Recipient's Name],Subject: Debug Qualification ConfirmationI am writing this letter to confirm that the[product/equipment/system/software] has passed the necessary debugging process and is now considered qualified for use.This confirmation is to acknowledge that all identified issues and bugs have been successfully resolved and no critical faults or malfunctions have been reported or encountered during the testing and debugging phase.We have conducted thorough tests and simulations to ensure the stability and functionality of the[product/equipment/system/software]. Our team of qualified technicians and engineers has worked diligently to rectify any issues and ensure that it meets the required standards and specifications.Based on the successful completion of the debugging process, we hereby certify that the [product/equipment/system/software] is now ready for regular use by the end-users.We would like to express our gratitude to the entire team involved in the debugging process for their dedication, professionalism, and relentless efforts in overcoming all challenges encountered duringthis phase.Should you require any further information or assistance regarding the debugging process, please do not hesitate to contact us. Thank you for your continued support and trust in our products. Yours sincerely,[Your Name][Your Title/Position][Company Name]。

Factory Acceptance Test Report

Project:

Panel Name:

Panel NO. :

Serial No. of Panel:

Serial No. of Device:

Device Type:

DC Power Supply: V

AC Voltage (nominal value): V

Rated Frequency: Hz

Catalog

1. Target (1)

2. Purpose of Test (1)

3. Item of Test (1)

4. Test Equipments (1)

5. Test Carried Out By (1)

6. Content of Examination (2)

6.1 Sampling Test (2)

6.2 Binary Inputs Test (2)

6.3 Signal Contacts Test (4)

6.4 Output Contacts Test (4)

6.5 Logic Function Test (5)

6.5.1 Busbar Differential Protection (87B) (5)

6.5.2 Breaker Failure Protection of Busbar (50BF) (6)

1. Target

Target Name:Busbar Protection

Program Version:

2. Purpose of Test

Check the all function of relay. To ensure the function satisfy the requirement of Busbar Protection of this substation.

3. Item of Test

Check the correctness of hardware and cable. Check the accuracy of sampling, and check binary input and binary output, signal contact, tripping contact, mechanic and so on. Check the logic function of each relay element and setting value.

4. Test Equipments

5.Test Carried Out By

6. Content of Examination

6.1 Sampling Test

Current Test Slots: 04&05

Slots: 06&07

6.2 Binary Inputs Test

Slots: 09

BI Module: NR1502AS

Slots: 10

Slots: 11

6.3 Signal Contacts Test

Slots: B00

6.4 Output Contacts Test

Slots: 13

Slots: 14

Slots: 15

6.5 Logic Function Test

6.5.1 Busbar Differential Protection (87B)

(1)Settings

Pick up setting of differential current: 4 A,slope setting(fixed):0.5 ,(2)Pick up current of busbar differential protection test

Test result of pick up current:A,

(3)Slope test

Slope calculation:

Point 9 and point 5:K=( - )÷( - )=

Point 8 and point 4:K=( - )÷( - )=

Point 7 and point 3:K=( - )÷( - )=

Operation time:ms

(4)Function of CT circuit failure blocking BBP

Function of CT circuit failure blocking BBP:

Result:

6.5.2 Breaker Failure Protection of Busbar (50BF)

(1)settings

Phase current setting: 2 A,Zero sequence current setting:0.5 A,Negative sequence current setting:0.5 A,Setting of time delay 0.5 S。

(2)Breaker failure protection test

Test result of current setting:A,

Test result of zero sequence current setting:A,

Test result of negative sequence current setting:A,

Test result of time delay S。

Result:

Signature。