试生产控制程序中英文版本

- 格式:doc

- 大小:145.50 KB

- 文档页数:10

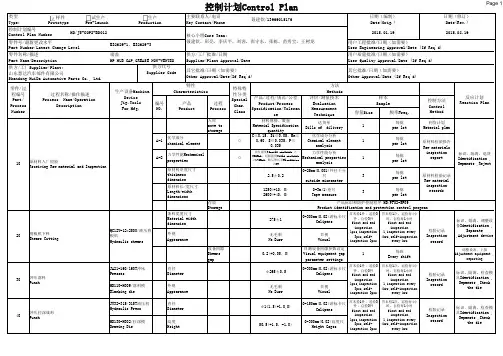

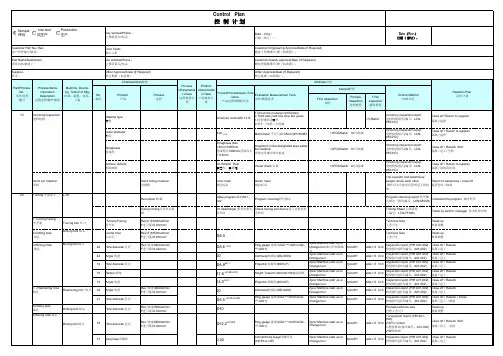

容量Size 频率Freq.入库move to storage材料规格、数量Material Specificationquantity送货单Bills of dilivery1每批per lot到货计划Material planA-1◇C≤0.15、Si≤0.05、Mn≤0.60、S≤0.035、P≤0.035化学成分分析Chemical elementanalysis1每批per lotA-2◇抗拉强度Tensile strength ≥305Mpa、屈服强度Yield strength≥175Mpa、断后伸长率Elongation≥29力学性能分析Mechanical propertiesanalysis1每批per lot2.5±0.20-25mm(0.001)外径千分尺outside micrometer3每批per lot1250(+10,0)2600(+40,0)0-3m(1)卷尺Tape measure3每批per lot存放Storage275±10-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visual设备间隙Shears gap0.2(+0.05,0)目测设备间隙参数设定Visual equipment gapparameter settings1每班Every shift调整设备、上报Adjustment equipment ,reporting φ265±0.50-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visualφ141.5(+1.0,0)0-150mm(0.02)游标卡尺Calipers50.5(+1.5,-1.0)0-300mm(0.02)高度尺Height Gages高度Height 首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)标识、隔离、调整设备Identification ,Separate,Adjustment device 生产设备Machine.DeviceJig.ToolsFor Mfg.特性Characteristics零件名称/描述Part Name/Description 端盖HP HUB CAP,GREASE NON-VENTEDJY32-315/315T油压机Hydraulic Press直径Diameter40冲压拉深成形Punch供方/工厂批准/日期Supplier/Plant Approval/Date过程名称/操作描述Process Name/OperationDescriptionHD130-H002/拉深模Drawing Die条料宽度尺寸Material widthdimension其它批准/日期(如需要)Other Approval/Date (If Req'd)检验记录Inspectionrecord用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change LevelE32629-1、E32629-3零件/过程编号Part/ Process Number评价/测量技术EvaluationMeasurementTechnique样本Sample控制方法ControlMethod特殊特性分类SpecialChar.Class方法Methods标识、隔离、退货Identification ,Separate ,Reject产品标识和防护控制程序 HD/PF02-SP09Product identification and protection control program反应计划Reaction Plan 编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10原材料入厂检验Receiving Raw material and Inspection力学性能Mechanicalproperties原材料检验报告Raw materialsinspectionreport原材料长/宽尺寸Length/widthdimensions原材料检验记录Raw materialinspectionrecords化学成分chemical element原材料厚度尺寸thicknessdimension20剪板机下料Shears CuttingQC12Y-12*2500/液压剪板机Hydraulic shears外观Appearance首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs30冲压落料Punch首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die外观AppearanceJA21-160/160T冲床PressesHD110-H009/落料模Blanking die直径Diameter容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ142.5(+0.2,-0.3)0-150mm(0.02)游标卡尺Calipers 50.5(+1.5,-2.0)0-300mm(0.02)高度尺Height GagesA-3◇47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ214±0.50-300mm(0.02)游标卡尺Calipers6×φ8.7±0.250-150mm(0.02)游标卡尺Calipers A-4◇HDJ-H0001检具Gage首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrsφ205±0.750-300mm(0.02)游标卡尺Calipers 深度Depth检验记录Inspection record50整形ShapingJY32-315/315T油压机Hydraulic Press 直径Diameter 首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs 首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs 检验记录Inspection recordHD134-H014/整形模Shaping Die高度Height检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die孔径diameter I.D.HD146-H011/切边冲孔模Trimming and Punching die位置度Location degreeJA21-160/160T冲床Presses深度Depth直径Diameter 检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die40冲压拉深成形Punch冲压切边冲孔Trimming and PunchingJB21-160B-SM/160T冲床直径Diameter首末检1件、巡检3件、自检3件first and endinspection首末检1次、巡检每4小时、自检每1小时first and end inspection60首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10(+2,0)0-300mm(0.02)高度尺Height Gages85°±0.5°0-360°(2′)万能角度尺Universal angle rulerA-5◇首末检、巡检0-10mm(0.01)百分表/自检 0-1mm塞尺First and endinspection 0-10mm(0.01) Dialindicator/Self-inspection 0-1mmFeeler首末检1件、巡检5件(X-R图)、自检5件first and end inspection 1pcs,inspectio n 5pcs(X-R chart),self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and endinspection1,inspection every2hrs,self-inspection everyhrsφ4(+2,-1)0-150mm(0.02)游标卡尺Calipers 1±0.250-300mm(0.02)高度尺Height Gages90无油污No dirt 目测Visual全检Full inspection每批per lot检验记录Inspection record 标识、隔离、退货Identification ,Separate ,Reject喷塑气压Spray pressure0.4-0.5MPa喷塑电压Spray voltage 50-60KV烘烤温度Bakingtemperature 180-200℃烘烤时间Baking time30-40min 无漏喷No leakage jet目测Visual调整设备、上报Adjustment equipment ,reporting100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines目测Visual1产线外观Appearance全检Full inspectionper lot70冲压翻边成形FlangingJB21-160B-SM/160T冲床Presses件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs80冲压压字Pressure logoJA21-160/160T冲床Presses孔径diameter I.D.首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs标识、隔离、检查模具Identification ,Separate ,Checkthe die角度AngleHD124-H008/翻边模Flanging die平面度Flatness高度Height 标识、隔离、检查模具Identification ,Separate ,Checkthe dieHD150-H006/压字模Pressure logo die(E32629-3)HD150-H005/压字模Pressure logo die(E32629-1)高度Height检验记录Inspection record首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs检验记录Inspection record外观Appearance外协镀锌Outsourcing galvanized检验记录Inspection record每班Every shift检验记录Inspection record容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/ToleranceA-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg物体)/0.15mm feeler ( cover flat on the marble countertops, pressure5kg objects above )盐雾试验≥1000小时/Salt spray test≥1000hrs盐雾腐蚀试验机/Salt spray corrosiontest machine3每季度Each quarter 盐雾试验报告Salt spray testreport 110丝印完整Full screen目测Visual全检Full inspection每批per lot检验记录Inspection record标识、隔离、退货Identification ,Separate ,RejectA-3◇47±10-300mm(0.02)深度尺Depth Gages10A-4◇HDJ-H0001检具Gage 10A-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg 物体)/0.15mm feeler (cover flat on the marble countertops,pressure 5kg objectsabove )10包装规范Packaging Specifications点数Counting 2箱2 box标识、隔离、返工Identification ,Separate ,Rework清晰Clear 目测Visual 包装规范Packaging Specifications 目测Visual 物资发货单Material Invoice点数Counting标识、隔离、返工Identification ,Separate ,Rework平面度Flatness防腐蚀性能Corrosion100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines全检Full inspection每批per lot外协丝印Outsourcing Screen外观Appearance 检验记录Inspection record深度Depth120抽检并包装Sampling inspection and packaging标识、隔离、处理Identification ,Separate ,Dealwith位置度Location degree平面度Flatness数量Quantity 每批per lot检验记录Inspection record标识Label标识、隔离、返工Identification ,Separate ,Rework包装Package 数量Quantity130入库&出货Warehousing & shipping全检Full inspection每批per lot 物资发货单Material Invoice。

控制计划控制程序(IATF16949-2016)1、目的1. Purpose对控制零件和过程的体系,通过控制特性的过程监视和控制方法来最大限度地减少过程和产品变差;并随着测量系统和控制方法的评价和改进对其进行修订,使控制计划在整个产品寿命周期中得到保持和使用,确保按顾客的要求制造出优质的产品。

It aims to control the part and process systems and reduce process and product variations to the utmost extent through process monitoring and control methods of the control characteristics; the control plan shall be revised along with the evaluation and improvement of the measurement system and the control methods and shall be maintained and used in the whole product life cycle so as to ensure that high qualify product is manufactured according to the requirements of the customer.2、适用范围2. Scope适用于本公司内产品的样件、小批量试产和批量生产所用的控制计划。

如客户有特殊要求,必须按照客户的要求执行。

It applies to the control plans used in the product sample, small-lot trial production and volume production of the company. If the customerhas special requirements, it shall be implemented according to the requirements of the customer.3、定义3. Definition无None4、职责4. ResponsibilitiesAPQP项目小组负责控制计划的策划,质量部负责编制与维护The APQP project team shall be responsible for planning of the control plan and the quality department shall be responsible for preparation and maintenance of it.5、程序5. Procedure5.1 当顾客和公司有需求和要求时,项目小组在不同阶段制订出相应的控制计划(即:样件控制计划、试生产控制计划、生产控制计划),项目组按工艺文件将其发行至相关部门,由其执行。

ABC用品有限公司质量管理体系程序文件编制: 日期:审核: 日期:批准: 日期:发放范围:公司各部门2013年10月01日生效1 目的Objective对生产计划及进度进行控制,确保生产按计划顺利执行,确保能够按照顾客的要求及时发运、交付产品。

The objective of this procedure is to control the production plan and progress, to ensure the successful implementation of production plan, and to ensure the timely shipment and deliv ery of products per the customer's requirements.2 适用范围Applicable Scope适用于本公司所有产品的生产安排。

This is applicable to the production planning of all AICQ products.3 职责Responsibilities3.1 生产计划员负责编制公司生产计划,部门经理负责审核。

The production planner is responsible to formulate the company production plan. The department manager is responsible for audit.3.2 生产计划员按项目计划编制新产品试生产计划,批生产计划。

The production planner is responsible to formulate the trial production and batch production plan for the new product per the project plan.3.3 生产计划员按制造部工艺验证、工装验证计划编制新产品、新工艺的工艺和工装验证生产计划。

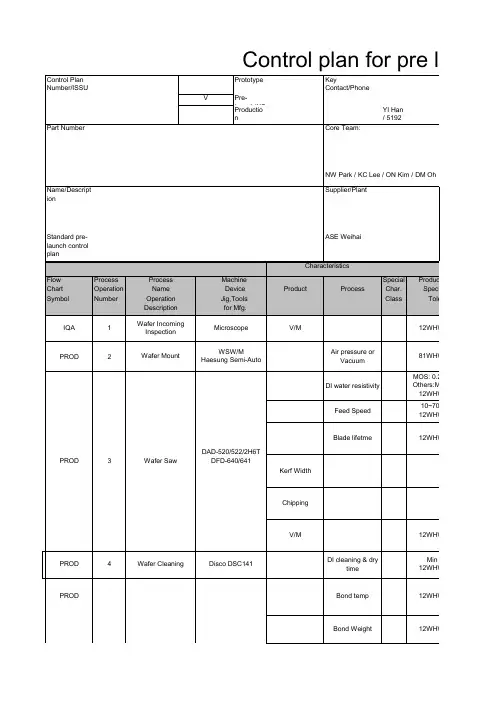

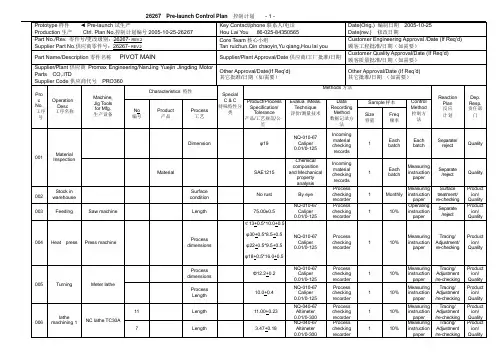

Sample 样件Trial Run试生产Production生产7.Turning OutsideDiameter车外圆Turning tool 车刀4Outside diameter 外径Rev 转速2500rad/min Φ14.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Inspection report (PIR A01-Close off / Rework隔离 / 返工Chamfer 倒角F进刀量=0.03mm/r 1.4±0.015Projector 投影仪(490127)3pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工5Outside diameter 外径Φ12.6±0.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工1Outside diameter 外径Φ16.18 0/-0.04Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工25Angle 角度45.6°±5°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8.Cutting Groove 割槽Cutting tool 切断刀2Outside diameter 外径Rev 转速2500rad/minФ 14+0.05Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework /Sort隔离 / 返工/全检38Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11Width宽度 2.2 +0.2/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8Length 长度11.8±0.2Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工41Angle 角度3°±1°Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工26Radius圆弧R0.1 +0.1(2X)Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9.Cutting off 切断Cutting tool 切断刀17Length 长度Rev 转速2500rad/minF进刀量=0.03mm/r23.4±0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工10.Drilling hole 钻孔Drilling tool 钻头22Inside diameter 外径Rev 转速2500rad/minΦ6+0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工36Concentricity 同轴度Φ0.02Concentricity Gage同轴度仪(19753-A-10P)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工40Roughness 粗糙度F进刀量=0.03mm/r Ra6.3Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工14Length 长度9±0.25Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工33Angle 角度118°±3°Contracer轮廓仪(DD-0009)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工31Chamfer 倒角0.2 +0.2/0.1*45Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11.Drilling hole 钻孔Drilling tool 钻头Hole diameter 孔径Rev 转速2500rad/minF进刀量=0.03mm/rΦ10Process technice size过程工艺尺寸Reset-up重新调整12.Boring Hole镗孔Boring tool 镗刀23Inside diameter 外径Rev 转速3000rad/minF进刀量=0.02mm/rΦ8.8±0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工30Chamfer 倒角0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13highness 高度 2.5+0.2Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工12highness 高度 1.2±0.025Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工35parallel平行度0.02Dial indicator千分表3pcs/ Machine start up orChange tool 3pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工24Inside diameter 外径Φ13 +0.04Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework / Scrap隔离 / 返工 / 报废Turning tool 车刀6Outside diameter 外径Rev 转速2500rad/minΦ14.6+0.1Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工39Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工28Chamfer 倒角0.2±0.05*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9highness 高度 3.8+0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工29Chamfer 倒角0.2±0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工7highness 高度19.6+0.05/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13.Turning Outside Diameter车外圆。

1. 目标1. PURPOSE1.1对新产品前期的注塑、喷涂、装配等的过程试验,调试和优化缩短新产品引进过程的周期,确保按时交货,并为新产品进入大批量生产制定优化工艺和程序。

1.1Set up optimize process in Molding, Painting and Assembly to ensure delivery on time andshortest cycle time for new product introduction and ramp up.2. 范围2. SCOPE2.1 适用于本公司所有试生产的通讯塑胶电子类产品2.1 Applicable to all wireless new plastic products.3. 职责3. RESPONSIBILITIES3.1 注塑负责公司制造或外来注塑模具的注塑过程3.1 Molding department is in charge of new product molding process.3.2 喷涂负责新产品喷涂移印过程3.2 Spray painting department is in charge of new product spray painting and pad printing process.3.3 装配负责新产品装配过程3.3 Assembly department is in charge of new product assembling process.3.4 物流部负责提供试生产所需要的原辅材料3.4 Logistic department is in charge of supplying all raw materials for trial run.3.5 物流部计划负责制定、下达试生产计划3.5 Logistic planning department is in charge of new product planning and issuing trial run plan.3.6 工艺工程师负责生产工艺的制定、调整3.6 Process engineer is in charge of setting and improving the process parameter and technology.3.7注塑、喷涂、装配技术员负责按作业计划,根据工艺文件要求进行控制,并和时的掌握信息,反馈给制程工程师、质量部,并负责所使用的现场清洁,负责试生产产品的入库3.7 Molding/spray painting/assembly technician is in charge of operating according to trial run plan,controlling the process according to WI, providing the feedback/information to process engineer and QA in time, keepingthe cleanliness of line and sending trial run productsto storeon time.3.8 质量部负责现场量具和检测设备的控制,检验并确认产品的质量3.8 QA department is in charge of all measuring fixture, gages and testers and ensure product qualitymeet specification.3.9工业工程设备人员负责提供适宜的设备,并对之进行保养、维护、检修。

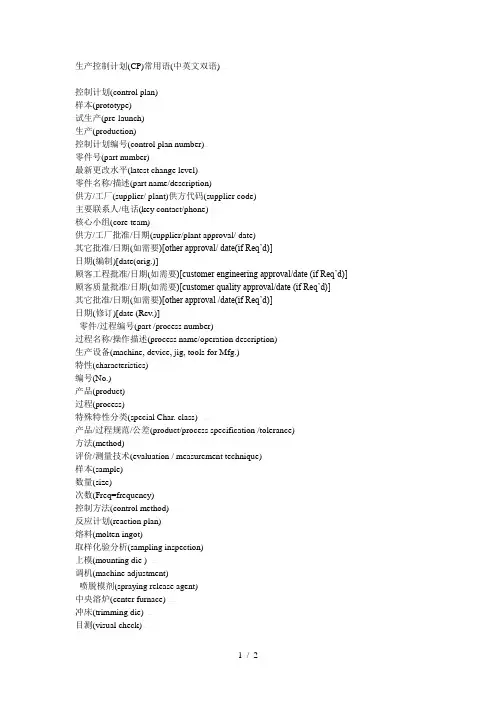

生产控制计划(CP)常用语(中英文双语), I; Z; [, o; l8 Z7 \9 E7 }9 N' [4 k* \% @0 y: M. p控制计划(control plan)样本(prototype), }# y. S3 C6 m7 c" S O试生产(pre-launch)生产(production)3 D) k/ T' V( c& W, a控制计划编号(control plan number)6 @9 Q" T5 i( V- K零件号(part number)9 s! g$ G. Z/ H4 `7 l2最新更改水平(latest change level)5 U+ h. f1 N/ }* v57 V零件名称/描述(part name/description). {5 |, j) A5 A5 i- L' i" w1 v供方/工厂(supplier/ plant)供方代码(supplier code)主要联系人/电话(key contact/phone)6 O! X# e8 e& J2 `) Q z, F" P$ K核心小组(core team)/ k' T: u/ a- Q9 |$ `7 X供方/工厂批准/日期(supplier/plant approval/ date)其它批准/日期(如需要)[other approval/ date(if Req’d)], ?% v: y0 B- W, c2 H2 P) X. z日期(编制)[date(orig.)]* X& s) \1 A1 U, W顾客工程批准/日期(如需要)[customer engineering approval/date (if Req’d)]顾客质量批准/日期(如需要)[customer quality approval/date (if Req’d)]& J( I3 T7 D, _( L* I其它批准/日期(如需要)[other approval /date(if Req’d)]日期(修订)[date (Rev.)]零件/过程编号(part /process number)过程名称/操作描述(process name/operation description) 0 `) l+ W# B \( a) z# P! g' l+ m生产设备(machine, device, jig, tools for Mfg.)特性(characteristics) ; g* o# A/ X) M! v M$ Z' F编号(No.) 3 A9 W- ]" S) u9 s产品(product)过程(process)特殊特性分类(special Char. class) : v t* M2 x" |0 A& ]0 D! I产品/过程规范/公差(product/process specification /tolerance)方法(method)评价/测量技术(evaluation / measurement technique)/ }* h( p0 ]: ]7 V3 Y1 @ p样本(sample) ; s4 ~" S' b8 g# ~数量(size) 0 G5 x! w9 V5 C4 h次数(Freq=frequency) 4 z: B' Z- G- c控制方法(control method) - h3 e7 j% X j3 k/ x6 ?& @8 g反应计划(reaction plan): p% q- J8 l( T! n) z* h" j2 P熔料(molten ingot)取样化验分析(sampling inspection)上模(mounting die ) 7 Q3 t. n+ P& k( s/ C, X"调机(machine adjustment)喷脱模剂(spraying release agent)中央溶炉(center furnace) I3 A4 N- A9 x$ V$ X' t+ t/ T冲床(trimming die) 4 M" @4 G) F% E" r, w2 ~目测(visual check) 9 z% K! y7 f5 V' ~7 n7 U6 v' B首检5啤(first inspection for 5 shots)外观(appearance) 4 J& A3 D6 W4 Q5 p9 z, v5黑胚(as-cast)每天一次(once a day) 6 s# F# p9 r5 Y4 t! g3 d连续(continuous)参考控制计划(refer to CP) ! W, b1 S) h. D& E0 m8 j每批(each batch) + v6 P7 d" m: {, _) Q8 v J每次开机(once every operation) : E; w, H3 t7 y) Q6 S厚度(thickness)中心距(c/c =between centers) : w0 d1 r: & c6 b! l+ x孔径(aperture) 9 x- A, r) I' X7 ^& @0 y宽度(width)工序间质量抽查报告(interprocess quality sampling inspection report ) - f. d9 i, j7 @4 \4 K, h) v# j3 A质量首件检查报告(quality first piece inspection report) # ? Z' I* O; q1 U7 b;制程巡回检查报告(processing tour-inspection report)质量追踪分析表(quality traceability analysis report) : g* t8 r& F! V) q. y7 |来料质量抽查报告(incoming quality sampling inspection report) 4 k4 X9 x5 H8 ?* ]6 w; b/ t# @物料标识(material identification) , h8 Q4 b2 ?3 m最终检验质量报告(quality final-inspection report) 2 B. Z. W" u ~3 ~& H, Q' H合金成份化验报告(alloy component assay report) + P0 u3 b& }) e* Q$ I. W2 H- [模具安装检查清单(mounting die inspection sheet)终检(final-inspection)光谱仪(spectrometer)针规(pin gauge ) ! x. T$ p: Y/ T+ {; {电子卡尺(digital calliper) ) |. z5 v9 x3 j W' V5 r* j熔炉温度表(furnace thermometer) 2 C7 g9 `+ k* S( {3 [投影仪(projector)通知生产拉/组长/主管/经理,停机再检查(Inform line/team leader/ supervisor/manager to shut down and recheck )。

控制计划控制程序(IATF16949-2016)1、目的1. Purpose对控制零件和过程的体系,通过控制特性的过程监视和控制方法来最大限度地减少过程和产品变差;并随着测量系统和控制方法的评价和改进对其进行修订,使控制计划在整个产品寿命周期中得到保持和使用,确保按顾客的要求制造出优质的产品。

It aims to control the part and process systems and reduce process and product variations to the utmost extent through process monitoring and control methods of the control characteristics; the control plan shall be revised along with the evaluation and improvement of the measurement system and the control methods and shall be maintained and used in the whole product life cycle so as to ensure that high qualify product is manufactured according to the requirements of the customer.2、适用范围2. Scope适用于本公司内产品的样件、小批量试产和批量生产所用的控制计划。

如客户有特殊要求,必须按照客户的要求执行。

It applies to the control plans used in the product sample, small-lot trial production and volume production of the company. If the customerhas special requirements, it shall be implemented according to the requirements of the customer.3、定义3. Definition无None4、职责4. ResponsibilitiesAPQP项目小组负责控制计划的策划,质量部负责编制与维护The APQP project team shall be responsible for planning of the control plan and the quality department shall be responsible for preparation and maintenance of it.5、程序5. Procedure5.1 当顾客和公司有需求和要求时,项目小组在不同阶段制订出相应的控制计划(即:样件控制计划、试生产控制计划、生产控制计划),项目组按工艺文件将其发行至相关部门,由其执行。

生产控制程序英语流程Production Control Program English FlowchartProduction planning is a crucial aspect of any manufacturing or industrial operation. It involves the coordination of various processes and resources to ensure efficient and cost-effective production. One of the key components of production planning is the implementation of a production control program, which helps to monitor and regulate the flow of materials, the utilization of equipment, and the overall productivity of the manufacturing process.The production control program typically consists of several interconnected components, each serving a specific purpose. These components include forecasting, capacity planning, scheduling, inventory management, and quality control. By integrating these elements, the production control program aims to optimize the production process and maximize the output while minimizing waste and inefficiencies.Forecasting is the first step in the production control program. This involves analyzing historical data, market trends, and customer demand to predict future production requirements. Accurateforecasting enables the organization to plan ahead and allocate resources accordingly, ensuring that the right products are manufactured at the right time to meet customer needs.Capacity planning is the next step in the process. This involves determining the production capacity of the manufacturing facility, taking into account factors such as equipment capabilities, labor availability, and production constraints. By understanding the production capacity, the organization can make informed decisions about production scheduling, resource allocation, and potential expansion or investment in new equipment.Scheduling is a critical component of the production control program. It involves the development of a detailed production plan that outlines the sequence and timing of various production activities. This includes the allocation of resources, the coordination of production processes, and the management of material flow. Effective scheduling helps to minimize downtime, reduce bottlenecks, and ensure the timely delivery of products to customers.Inventory management is another crucial aspect of the production control program. This involves the monitoring and control of raw materials, work-in-progress, and finished goods inventory. Efficient inventory management helps to maintain the right balance between supply and demand, minimizing the risk of stockouts or excessiveinventory levels. This, in turn, can lead to cost savings and improved cash flow for the organization.Quality control is the final component of the production control program. This involves the implementation of various quality assurance measures to ensure that the final products meet the required standards and specifications. Quality control activities may include inspection, testing, and continuous improvement initiatives. By maintaining a high level of quality, the organization can enhance customer satisfaction, reduce the risk of product recalls, and maintain a competitive advantage in the market.The production control program is typically implemented through the use of various software tools and technologies, such as Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), and Production Planning and Control (PPC) software. These systems integrate the various components of the production control program, providing real-time data and analytics to support decision-making and optimize the production process.In conclusion, the production control program is a comprehensive and integrated approach to managing the production process. By incorporating forecasting, capacity planning, scheduling, inventory management, and quality control, organizations can achieve greater efficiency, cost-effectiveness, and customer satisfaction. The effectiveimplementation of a production control program is a critical factor in the success of any manufacturing or industrial operation.。

控制计划管理实施规范程序-中英文版1.0 Purpose目的This procedure instruction describes the application of the control plan本程序文件描述的控制计划的应用。

The Control plan has the following purpose:控制计划有以下的目的:Description of the system to check the parts and processes 检验产品和过程的系统描述Support for the manufacture of quality products corresponding to the customer requirements.支持符合客户要求的产品质量的生产Written summary of the system used for the process and product control为用于过程和产品控制编制系统摘要2.0 Scope范围This procedure applies to all departments and all the automotive related products.本程序适用于所有的职能部门及所有汽车产品。

3.0 Definitions定义3.1 CP-Control Plan 控制计划4.0 Responsibility权责4.1 APQP小组负责试生产控制计划及初始量产控制计划的制定4.2 质量部负责主导协调量产后的量产控制计划的修订。

5.0 Procedure程序5.1 The control plan is compulsory for the pre series and series stage and also has to include the processsteps from incoming to out coming控制计划在预批量和批量阶段是必须的,而且要包括从进货到出货的全部阶段。

新产品试产管理程序New product trial production management procedure(IATF16949-2016)1.目的 Objective有效的对新产品试产进行管理,确保新产品质量及交货期。

Effectively manage the new product trial production to ensure the new product quality and delivery performance.2.适用范围 Applicable Scope本程序适用于公司提交客户的新产品试生产所有过程(包括 WS,ES,CS,PP 阶段产品)。

Be applied to all new products for customer trial production process, including the products at WS, ES, CS, PP phases.3. 职责 Responsibilities3.1. 计划部物流部PMC3.1.1. 负责计划进程的跟踪和反馈、实施全过程策划的落实。

The PMC is responsible for plan progress follow, feedback, and ensuring the whole process are implemented.3.1.2. 负责生产过程中物料的计划与控制,物料的追踪和反馈。

The PMC is responsible for material in production process plan, control, follow and feedback.3.1.3. PP 前主持《PP ON-LINE 判定总结会议》,主导产品量产阶段。

The PMC shall hold <PP ON-LINE summary meeting> before PP and be in charge of the mass production stage.3.2. 项目经理Project Manager3.2.1. 研发项目经理负责主导新产品导入各试产阶段(ES~PP,包括第一次 MP)与进度的制定、跟进与落实。

生产计划控制程序1.0 目的Purpose保证生产计划能根据客户的预测、出货记录以及客户订单来排定生产计划,并及时检查未完成订单、仓库成品及物料库存和设备模具是否满足生产要求,生产计划进行更加细致的安排,作为生产部门实际生产安排的依据,确保生产的顺利进行,减少停机及停工待料的不合理现象,确保能够按照客户要求保质保量准时交货。

Make sure production planning according forecast of customer, delivery record and order; check in time the unfinished order, finished products & material stock, and machine & mould; make detailed arrangement of production plan as actual production basis; make sure smooth production and reduce stopping machine to wait for material; make sure delivery according customer’s requirement in quality and quantity.2.0 范围Scope适用于本公司所有生产产品的生产计划安排与控制。

Used in all products’ plan and control in our company3.0 定义 Definition无Null.4.0职责 Responsibilities4.1 销售部负责销售订单及有关客户信息的传达SD takes charge of order and transmitting customer’s information4.2 生产部计控分部PD plan and control branch4.2.1负责根据销售订单及相关信息制定生产计划Take charge of making production plan according order and relative information4.2.2确认SAP系统生成的物料需求计划Take charge of making from SAP system material requirement plan.4.2.3与技术部、生产部生产分部、设备组协调换模及试验Cooperate with TD, PD production branch, equipment team to change mould and do trial.4.2.4负责组织协调紧急订单的计划与生产Take chare of organize plan and production of urgent order.4.2.5负责工人工时、耗用材料的统计分析Take charge of statistics and analysis of operator’s working time. 4.3 供应部SMD4.3.1 根据物料需求计划,反馈物料供应库存According material requirement plan, feed back material stocking situation.4.3.2 提供产成品的库存信息Supply finished product’s stocking information.4.4 生产部生产分部负责根据生产计划组织生产,并反馈生产的进度信息PD production branch organize production and inform production speed according to production plan.4.5 质量部负责提供产品检验报表及产品的入库信息QD is responsible to supply product’s inspection list and warehouse entering information.4.6 技术部负责提供协调试验新产品的信息(产品BOM信息)TD is responsible to supply trial information of new products. (Product’s BOM info rmation)5.0 程序 Procedure5.1 生产计划(中长期计划、周生产计划)Production plan (Mid-long term plan, weekly plan)5.1.1 生产计划员根据客户提供的预测,出货趋势,销售订单、机台模具以及产品的库存情况制定生产计划Production planner should make first draft of production plan according forecast from customers, delivery tendency, order, machine & mould and warehouse information.5.1.2 计划员确认SAP系统生成的物料需求计划,并提供给供应部,作为供应部检查确认其物料的供应是否能满足生产计划要求的依据Planner should make material requirement plan according to the plan maken out by the SAP system and SMD to check whether material can satisfy production or not5.1.3 供应部同时要将其物料信息反馈给物料计划员,同时物料计划员须将供应部的信息反馈给生产计划员SMD need to feed back material information to material planner who inturn feed back to production planner.5.1.4 生产计划员收集销售反馈的客户信息(客户要求提前或推迟交货等信息)Production planner collects S D’s feedback (information such as advance or delay delivery as customer required)5.1.5 生产计划员收集生产现场的实际生产进度以及机台模具运行信息Production planner collects information about actual production speed and operation of machine & mould.5.1.6 生产计划员根据5.1.3, 5.1.4, 5.1.5反馈的信息,确认生产计划是否需要调整Production planner confirm whether production plan need to be adjusted according all feedback.5.1.7 将更改后的生产计划报计控主管审批,同时要反馈给相关部门(生产部生产分部、供应部、销售部等)If changed, new plan should be submitted to planning and controlling supervisor for approval as well as to relative departments (PD production branch, SMD, SD)5.2 紧急订单计划安排Arrangement of urgent order5.2.1 收集销售部有关客户紧急订单通知Collect notice about urgent order from SD5.2.2 在收到销售部的通知后,生产计划员结合生产现场的实际生产以及机台模具情况,形成调整后的计划After receiving notice from SD, production planner could adjust planningdraft according actual situation of production and machine.5.2.3 SAP系统形成物料需求计划,作为供应部核实确认其库存物料能否满足生产计划调整要求的依据。

协调公司内部生产资源,满足销售需求。

Coordinate the company internal production resources to meet the sales demands.2 范围:Scope:本程序适用于公司的成品,零件车间。

This procedure is applicable to the company finished product and component factory.3 程序:Process3.1 流程:销售部采购部,计划部供应部生产部生产车间销售部,报关3.1 Flow:Decide to accept the orderSales Dept.Purchasing and planningDept.Provision Dept.Production Dept.Production workshopSales & Customs3.2 生产计划安排Production Plan arrangement3.2.1订单一经确认后,生产部负责制定每月生产计划,供应部根据订单和每月生产计划所需品种,数量等确定外购材料及供应厂商,并按“采购控制程序(****P-07-06)”进行采购。

Once the orders be accepted, Production dept. prepare the monthly production schedule, purchasingdepartment will confirm the outsourcing materials and suppliers according to the kinds and quantitiesthat required by orders and monthly production schedule,and purchase as per “Purchase ControlProcedure (****P-07-06)”.3.2.2生产部根据订单交货期要求,将该订单的开始生产时间录入SAP系统,并按照最终确认的每周销售需求安排生产。