分散液液微萃取PPCPs—三氯生

- 格式:pptx

- 大小:1.10 MB

- 文档页数:22

![冷诱导分散液-液微萃取用于牛奶中三聚氰胺的检测[开题报告]](https://uimg.taocdn.com/ea9572e8dd3383c4ba4cd23b.webp)

毕业论文开题报告环境工程冷诱导分散液-液微萃取用于牛奶中三聚氰胺的检测一、选题的背景、意义2008年9月,国内爆发了三鹿问题奶粉事件,导致数百万名食用含三聚氰胺奶粉的婴幼儿患肾结石等病症住院治疗。

国家质检总局在全国紧急开展婴幼儿奶粉三聚氰胺含量专项检查。

由于三聚氰胺的含氮量高达66.63%,而目前测定牛奶中含蛋白质的含量是采用食品行业通行的“凯氏定氮法”,即通过测定食品中氮原子的含量而间接推算的方法,因此,三聚氰胺经常被不法生产者和销售商作为“蛋白精”用来提升牛奶中所谓蛋白质含量的指标。

三聚氰胺是一种重要的氮杂环有机化工原料,白色无味结晶粉末[1]。

这种化学品常被用于生产塑料、胶水和阻燃剂,在部分亚洲国家,它也被用于制造化肥。

不易被机体代谢,具有肾毒性与致癌作用。

大量动物实验表明,长期摄入三聚氰胺会造成生殖泌尿系统的损害,膀胱,肾结石,尿毒症和慢性肾衰竭,并可进一步诱发膀胱癌,对消费者造成了极大的危害。

卫生部等五部门立即颁布了“2008年第25号乳制品及含乳食品中含三聚氰胺临时管理限量值规定”的公告,规定:婴幼儿配方乳粉中三聚氰胺的限量值为1 mg/kg液态奶(包括原料乳),奶粉及其他配方乳粉中三聚氰胺的限量值为2.5 mg/kg。

因此,建立快速的检测方法以确保食品的安全十分必要。

样品预处理是色谱试验成功的关键步骤,由于真实样品组成复杂,且待测挥发性物含量一般较少,所以要求样品预处理方法既能较好的将待测物同其他物质分离,又有较高的富集能力。

传统的样品前处理方法,如液液萃取,索氏萃取,层析、蒸馏及吸附等,普遍存在操作繁琐耗时,需要使用大量对人体和环境有毒、有害的有机溶剂,以及难以实现自动化等缺点,因此,发展省时高效、有机溶剂耗用量少的样品前处理新技术一直是分析化学研究的一个热点领域[1-4]。

为节省时间,减轻劳动强度,减少样品用量,实现样品前处理的自动化、在线化,以及尽量减少有机溶剂的使用,近年来发展起来了多种新型样品前处理技术,例如固相萃取( SPE)[5]、分子印迹技术(MIT)[6]、固相微萃取( SPME)[ 7 ]、悬滴微萃取( SDME)[ 8] 、基于中空纤维的液相微萃取(HF-LPME)等。

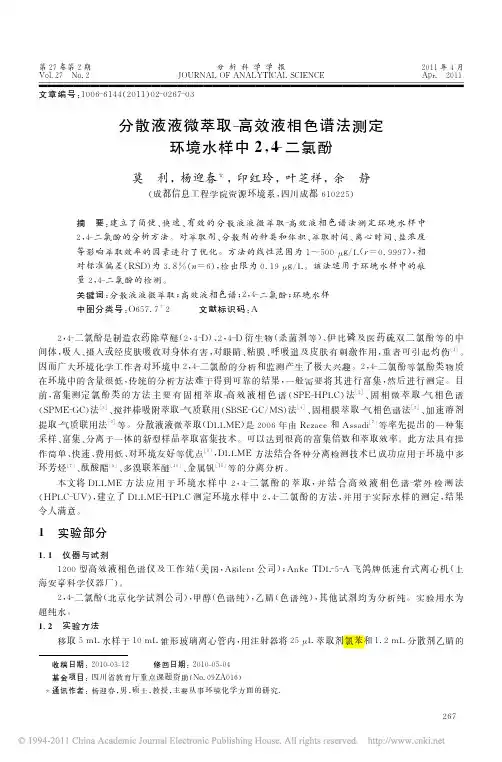

第!4卷第1期Vol . 34 No . 1水资源保护WATER RESOURCES PROTECTION2018年1月Ja n . 2018DOI :10. 3880/j . issn . 1004 -6933. 2018. 01 13水环境中PPCPs 检测技术及风险评价研究进展姚晶晶\吴东海2!陆光华1!2,周超2!沈兴厚3(1.西藏农牧学院水利土木工程学院,西藏林芝860000;2.河海大学环境学院,江苏南京210098;3.河南省水文水资源局,河南郑州450004)摘要:概述了目前水环境中药物及个人护理品(PPCPs )的检测技术,对比分析了常用的水样前处理 方法和仪器分析技术的原理、优缺点,介绍了 PPCPs 的风险评价体系,总结了人体健康风险和生态 风险的评价方法,并综述了不同PPCPs 的风险水平。

指出多技术联合、精准定量的检测技术和综 合风险评价方法是今后环境领域PPCPs 研究的重点。

关键词!药物及个人护理品;前处理;仪器分析技术;人体健康风险;生态风险中图分类号:X 830 文献标志码:A 文章编号= 1004-6933 (2018)01 -0076 -07Research progress of aquatic PPCPs detection technology and risk, assessmentYAO Jingjiiig 1,WU Donghai 2,LU Guanghua 1,2,ZHOU Chao 2,SHEN Xinghou 3(1.College of Hydraulic and Civil Engineering ,Tibet Agriculture and Animal Husban Linzhi .60000,China ; 2. College of Environment ,Hohai University ,Nanjing 210098,China ; 3. Hyd r+0#7and Water Resources Bureau of Henan Province ,Zhengzhoo 450004,China )Abstract : The detection technology of aquatic pharmaceuticals and personal care products ( PPCPs ) were summarized . The principles ,advantages and disadvantages of the sample pretreatment method and instrument analysis technology were a nalyzed and compared . The risk assessment systems of aquatic PPCPs were introduced and the methods of human health risks and ecological risk assessment were summarized . PPCPs was reviewed . It is pointed out tliat multi-technique combination ,precise quantitative de and comprehensive risk assessment method are the key points of PPCPs research in the Keywords : pharmaceuticals and personal care products (PPCPs ); sample pretreatment ; instrument analysis technology ; human health risk ; ecological risk药物及个人护理品(pharmaceuticals andpersonal care products ,PPCPs )广泛应用于医药、工 业、畜牧业、农业、水产养殖等领域[1]。

废水中药品及个人护理用品(PPCPs)的去除技术研究进展废水中药品及个人护理用品(PPCPs)的去除技术研究进展引言:随着工业化和城市化的快速发展,人类活动产生的废水中含有大量的药品及个人护理用品(PPCPs)。

这些化合物对环境和人体健康构成潜在风险。

为了净化废水和保护环境健康,研究人员开展了各种技术研究,以去除废水中的药品及个人护理用品。

本文旨在综述各种技术在该领域的研究进展,并提出未来的研究方向。

一、废水中药品及个人护理用品的来源和潜在危害1. 药品和个人护理用品的种类和用途目前市场上常见的药品和个人护理用品包括抗生素、镇痛剂、激素、抗癌药物、香水、洗发水、洗衣粉等。

这些物质广泛应用于医疗、家庭、美容等方面。

2. PPCPs的进入环境途径PPCPs通过多种途径进入废水系统,其中包括人类排泄、医疗废物的处理、药物生产和使用过程中的泄漏和废水排放,以及家居和农业用水系统中的直接释放。

3. PPCPs对环境和人体健康的潜在影响研究表明,PPCPs在环境中的存在可能导致水体中的生态系统失衡,对水生生物和陆地生态系统产生毒性效应。

此外,长期暴露于PPCPs可能对人体健康产生不良影响,如内分泌干扰、细胞毒性、致突变性等。

二、常用的废水处理技术及其去除效果1. 活性炭吸附技术活性炭是一种具有强吸附性能的材料,广泛用于废水处理和水质净化领域。

研究表明,活性炭对药品和个人护理用品具有较好的去除效果。

2. 生物降解技术生物降解技术利用微生物降解废水中的有机物。

生物降解技术可通过使用具有降解能力的微生物、调节环境条件等方式去除废水中的药品和个人护理用品。

3. 高级氧化技术高级氧化技术利用自由基或氧化剂,在氧化、还原等化学反应中去除水中的有机污染物。

典型的高级氧化技术包括过氧化氢、紫外光催化氧化、臭氧氧化等。

研究表明,高级氧化技术对PPCPs的去除效果显著。

4. 光催化技术光催化技术通过利用半导体材料吸收太阳光能,产生电子-空穴对,从而引发光催化反应。

液相色谱检测前处理方法织取10g草莓样品于50mLPPTE离心管中,加入10mL乙腈,振荡器上以200rpm的转速振荡30min 后,加入3g氯化钠和5g无水硫酸镁,剧烈手摇30s。

然后将盛装样品的离心管在离心机离心5mi n(离心力RCF=1006g),取1.5mL 上清液转入含有50mgPSA+50mgC i8+150mgMgSO4的2mL离心管。

充分振荡混匀后将混合液离心3mi n(离心力RCF=7155g ),吸取上清液0.5mL过0.22卩m有机滤膜后进UPLC-MS/MS 检测。

[QuEChERS-超咼效液相色谱-串联质谱法同时测定草莓中85种农药残留]2、加速溶剂萃取技确称取均质后的样品2.50g于50mL塑料离心管中,加入3 mL水涡旋混合1min,再加入 5mL 5 %(v/v )甲酸乙腈涡旋混合1 min,超声提取10min。

加入Won dapokQuEChERS多兽残专用提取包4g,剧烈振摇1 min,于10 C 以8000r/mi n 下离心10min。

取1 mL上清液转移至Won dapokQuEChERS多兽残专用净化包中,涡旋混合 1 min ,12000r/min下离心5min。

取上清液,过0.22呵微孔滤膜,取滤液进行LC-MS/MS 分析。

[分散固相萃取-液相色谱—串联质谱法测定常见动物源性食品中42种兽药残留]称取5.00 g样品于50 mL玻璃离心管中,力廿20 mL乙酸乙酯,涡旋,超声提取15 min,5000 r / min离心5 min,移岀上清液至100 mL旋转蒸发瓶中,剩余残渣再加入20 mL乙酸乙酯,重复提取1次,合并上清液,旋转蒸发至近干。

加入1 mL 甲醇水溶液(80: 20,V / V),涡旋30 s,过CaptivaND Lipids小柱净化,收集液体,上机检测。

[超高效液相色谱一四极杆/静电场轨道阱高分辨质谱筛查水产品中21种环境激素]术(ASE ):①样品经匀浆,于4C避光保存备用。

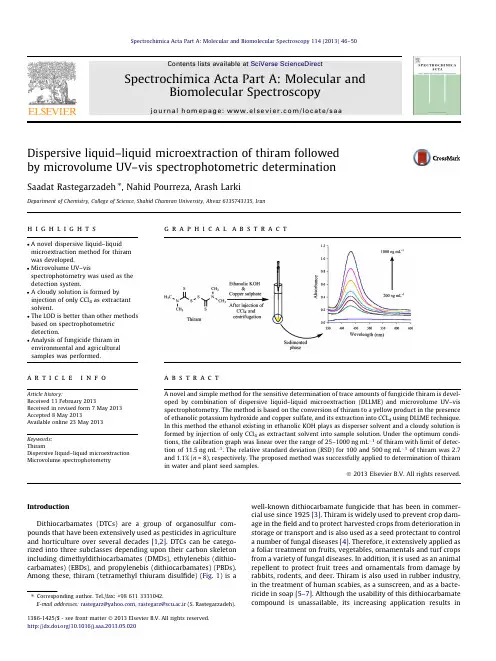

Dispersive by microvolume Saadat Rastegarzadeh Department of Chemistry,detection.Analysis of fungicide thiram in environmental and agricultural samples was performed.a r t i c l e i n f o Article history:Received 11February 2013Received in revised form 7May 2013Accepted 8May 2013Available online 23May 2013Keywords:ThiramDispersive liquid–liquid microextraction Microvolume spectrophotometrya b s t r a c tA novel and simple method for the sensitive determination of trace amounts of fungicide thiram is devel-oped by combination of dispersive liquid–liquid microextraction (DLLME)and microvolume UV–vis spectrophotometry.The method is based on the conversion of thiram to a yellow product in the presence of ethanolic potassium hydroxide and copper sulfate,and its extraction into CCL 4using DLLME technique.In this method the ethanol existing in ethanolic KOH plays as disperser solvent and a cloudy solution is formed by injection of only CCl 4as extractant solvent into sample solution.Under the optimum condi-tions,the calibration graph was linear over the range of 25–1000ng mL À1of thiram with limit of detec-tion of 11.5ng mL À1.The relative standard deviation (RSD)for 100and 500ng mL À1of thiram was 2.7and 1.1%(n =8),respectively.The proposed method was successfully applied to determination of thiram in water and plant seed samples.Ó2013Elsevier B.V.All rights reserved.IntroductionDithiocarbamates (DTCs)are a group of organosulfur com-pounds that have been extensively used as pesticides in agriculture and horticulture over several decades [1,2].DTCs can be catego-rized into three subclasses depending upon their carbon skeleton including dimethyldithiocarbamates (DMDs),ethylenebis (dithio-carbamates)(EBDs),and propylenebis (dithiocarbamates)(PBDs).Among these,thiram (tetramethyl thiuram disulfide)(Fig.1)is a well-known dithiocarbamate fungicide that has been in commer-cial use since 1925[3].Thiram is widely used to prevent crop dam-age in the field and to protect harvested crops from deterioration in storage or transport and is also used as a seed protectant to control anumber of fungal diseases [4].Therefore,it extensively applied as a foliar treatment on fruits,vegetables,ornamentals and turf crops from a variety of fungal diseases.In addition,it is used as an animal repellent to protect fruittrees and ornamentals from damage by rabbits,rodents,and deer.Thiram is also used in rubber industry,in the treatment of human scabies,as a sunscreen,and as a bacte-ricide in soap [5–7].Although the usability of this dithiocarbamate compound is unassailable,its increasing application results in1386-1425/$-see front matter Ó2013Elsevier B.V.All rights reserved./10.1016/j.saa.2013.05.020Corresponding author.Tel./fax:+986113331042.E-mail addresses:rastegarz@ ,rastegarz@scu.ac.ir (S.Rastegarzadeh).being released into the environment leading to contamination of water,soil,and food.These contaminants adversely affect the envi-ronment and have serious hazardous effect in the living organisms.The reported studies on rats showed that the exposure to thiram has harmful effects on hepatic system and skin such as skin lesions (e.g.hand eczema or dermatitis),hepatic dysfunctions,neurotox-icity and citotoxicity [8].The residual amounts of thiram in human diet in combination with nitrite represent the potential precursor for the formation of carcinogenic nitrosamine.Furthermore,it has been mentioned that in body,carbon disulfide is formed from the breakdown of thiram and contributes to the toxicity of thiram to the liver [9].According to the US EPA (Environmental Protection Agency),thiram is expected to be sufficiently mobile and persistent in some cases to reach surface waters in concentrations high enough to impact aquatic life [10].To evaluate the risks of its intensive use,the determination of thiram in environmental matrixes is necessary to assay the thiram residues.Various analytical methods have been reported for the determi-nation of thiram in different crop matrices and environmental samples,including mass spectrometry [3,5],high-performance liquid chromatography [10–12],spectrophotometry [7,13,14],gas chromatography [15],polarography and voltammetry [16–18]chemiluminescence analysis [6,8,19]and surface-enhanced Raman scattering spectroscopy [1].The sample preconcentration step which has attracted much attention in analytical procedure includes the extraction of inter-ested components from a sample matrix.The most popular pre-treatment methods are liquid–liquid extraction (LLE)and solid phase extraction (SPE).Nevertheless,these conventional extraction methods are laborious,time-consuming and require large volumes of samples and toxic organic solvents.In the past years,several techniques particularly microextraction have been developed for sample preconcentration,due to the many advantages which makes it more attractive with respect to classic extraction approaches.Dispersive liquid–liquid microextraction (DLLME)as a considerable microextraction technique was emerged by Assadi et al.in 2006[20],which was based on a ternary solvent system like homogeneous LLE and cloud point extraction.In this method,an appropriate mixture of extraction and dispersive solvents is in-jected rapidly into an aqueous sample,resulting in the formation of a cloudy solution.The contact area between the extracting solvent and the sample solution is extremely large;thus,the extraction equilibrium is obtained rapidly.The advantages of DLLME are the usage of a small volume of organic solvents,simplicity of the oper-ation,rapidity,low cost,high recovery,high enrichment factor and environmentally friendly nature.Recently,this method has been applied for the determination of trace organic compounds and metal ions in environmental samples [21–27].In this work,a DLLME method followed by UV–vis spectropho-tometry equipped with a microcell is applied to sensitivedetermination of thiram.A colored organic phase is formed by reaction between thiram,ethanolic KOH and copper (II)sulfate and injection of CCl 4as extractant solvent.The important parame-ters,such as reaction conditions,the type and volume of extraction solvent and extraction time are investigated and optimized.Experimental ApparatusRecording the spectra and the absorbance measurements were made by a Jenway UV–vis spectrophotometer model 6320using quartz microcells with capacity of 350l L.A Metrohm 632(Swit-zerland)pH-meter was used to measure pH with a combined glass electrode.A model BHG HERMLE centrifuge (Germany)was used for the phase separation.ReagentsAll chemicals used were of analytical grade and double distilled water was used throughout.A stock solution of 100l g mL À1of thiram was prepared by dis-solving 0.0100g of pure thiram (Merck)in ethanol and diluting to 100mL in a volumetric flask.Working standard solutions were obtained daily by successive dilutions of this stock solution.A 0.10mol L À1ethanolic KOH solution (Merck)was prepared by dis-solving 0.561g of KOH in ethanol and diluting to 100mL.A stock solution of copper (II),1000l g mL À1,was prepared by dissolving of 0.391g CuSO 4Á5H 2O (Merck)in water and diluting to 100mL.Copper (II)working standard solutions were prepared daily by stepwise dilution of the stock solution.Dispersive liquid–liquid microextraction procedureFor DLLME under optimum conditions,an aliquot of the solu-tion containing thiram was placed in a 10mL volumetric flask,then 1mL of ethanolic potassium hydroxide solution (0.1mol L À1)and 5mL of 1l g mL À1of copper (II)were added.The resulting solution was then diluted to the mark with water and mixed thoroughly.After 10min the solution was transferred to a glass test tube with a conical bottom.Since ethanol (as disperser solvent)exists in solution,only 200l L of carbon tetrachloride (as extraction sol-vent)was rapidly injected into the sample solution by a microsy-ringe.After shaking manually,a cloudy solution (water,ethanol and CCl 4)was rapidly produced,and then the mixture was centri-fuged for 5min at 5000rpm.Accordingly,the dispersed fine drop-lets of the extraction phase deposited at the bottom of the conical test tube (170±5l L).The remained organic phase was removed with a microsyringe and subsequently placed into the quartz microcell and the absorbance was measured at 430nm against the blank.A blank solution was also run under the same procedure without adding any thiram.Preparation of plant seeds samplesAppropriate amounts of tomato,cucumber and watermelon seeds were weighed and placed into a 100mL beaker,then 30mL of ethanol was added,covered by a lid and stirred for 24h.The solution was then filtered and diluted to 50mL in a vol-umetric flask.An aliquot of the solutions was treated under the recommended procedure for DLLME and subsequent determina-tion of thiramcontent.Fig.1.Chemical structure of thiram (tetramethylthiuram disulfide).and Biomolecular Spectroscopy 114(2013)46–5047Results and discussionA dispersive liquid–liquid microextraction procedure based on the reaction of thiram in ethanolic KOH solution and in the pres-ence of copper(II)sulfate was developed for preconcentration of thiram.In order tofind the appropriate conditions for DLLME,dif-ferent experimental parameters were studied and optimized using a thiram standard solution.Wavelength selectionIn order to perform quantitative analysis spectrophotometri-cally the maximum absorption wavelength should be established. Therefore,the sample solution containing different concentrations of thiram was examined according to the recommended procedure of DLLME and corresponding spectra of sedimented phase were recorded in the range of350–650nm.As seen in Fig.2,upon increasing thiram concentration the absorbance at maximum wavelength,430nm,was increased.Therefore this wavelength was selected for measuring the absorbance of the extracted phase throughout this study.Effect of ethanolic KOH solutionThe presence of ethanolic KOH has strong effect on developing the color product.For this purpose the influence of ethanolic KOH solution in the concentration range of0–0.05mol LÀ1was studied in DLLME procedure.As can be seen from Fig.S1in the absence of KOH the absorbance of sedimented phase is very low which indi-cates that the colored product has not been formed efficiency. However,the maximum absorbance due to high extraction effi-ciency was obtained at0.01mol LÀ1.Therefore,1mL of ethanolic KOH solution0.1mol LÀ1was added to10mL sample solution to achieve this concentration.The effect of volume of ethanolic KOH 0.1mol LÀ1was also studied in the range of0.2–4.0mL.No signif-icant effect was observed in volume range of0.5–2.0mL.Nature of the extraction solvent and disperser solventSince the ethanol(as a dispersive solvent)was provided by the addition of ethanolic KOH,the cloudy solution appeared with rapid injection of only the extraction solvent.Thus,the effect of type of extraction solvent on DLLME was studied.The characteristics of extraction solvent in DLLME are similar to conventional LLE,namely low solubility in water and high effi-ciency for extraction of the target analyte.Therefore,carbon tetra-chloride,chloroform,dichloromethane and cyclohexane were considered for this purpose.A cloudy solution and two-phase sys-tem was formed using these solvents,however in the case of car-bon tetrachloride the signal was higher and more reproducible. Therefore,carbon tetrachloride was selected as extraction solvent.Additional experiments showed that the injection of a mixture of CCl4and different disperser solvents including methanol,etha-nol,acetonitrile and acetone at different ratios decreased the extraction efficiency.As mentioned previously the disperser sol-vent(ethanol)exists in solution and further addition of this solvent caused part of carbon tetrachloride to be dissolved in disperser sol-vent and migrated into aqueous phase.For this reason,the dis-solved carbon tetrachloride could not be sedimented down and accordingly extraction efficiency was decreased.Finally,the sug-gested method was carried out only by injecting the extraction sol-vent and the solution was shaking manually after injection of carbon tetrachloride.Thereby,a cloudy solution was formed and the extraction occurred.Effect of extraction solvent volumeThe volume of carbon tetrachloride as extraction solvent has strong effect on the sensitivity due to its effect on enrichment fac-tor.For this purpose a series of experiments were carried out with different volumes of carbon tetrachloride in the range of200–1000l L.As it is observed in Fig.S2,the absorbance of organic phase was decreased by increasing of the CCl4volume.This could be due to the dilution effect which decreases in concentration of the extracted species in sedimented ing injection vol-umes less than200l L of CCl4lower volume of organic phase was obtained,so that the absorption signal could not be measured by spectrophotometerfitted with microcells.Thus,in order to achieve high enrichment factor and low detection limit value, 200l L of CCl4was selected as optimum extractant solvent volume throughout the experiments.Effect of copper(II)amountIn order to achieve highest extraction efficiency the effect of the copper(II)concentration in the range of0.1–0.8l g mLÀ1was investigated.The obtained results revealed that the absorbance increased with increasing of the copper(II)concentration up to 0.5l g mLÀ1and remained nearly constant above this value.There-fore,the concentration of0.5l g mLÀ1was chosen as the optimum amount of the copper(II)concentration.Effect of standing timeIt was found that the incubation time before injection of carbon tetrachloride has an effect on the formation of the colored product. Therefore the dependence of absorbance of sedimented phase upon time in the range of2–40min was studied under previously optimized conditions.The obtained results show a considerable increase in the analytical signal with incubation time up to 10min and remained constant above that.Thus the injection of extraction solvent was carried out10min after mixing of the reagents.Since the extraction solvent was injected to the solution and it appeared cloudy without the addition of disperser,for breaking up of organic phase intofine droplets[28–30],it was necessary to shake the solution after injection of extraction solvent.48S.Rastegarzadeh et al./Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy114(2013)46–50Accordingly,the effect of shaking time on the DLLME of thiram was investigated in the range of0–60s.The obtained results denoted that the highest extraction efficiency was achieved about10s and above that shaking time had no significant effect on the absor-bance of sedimented phase.As the cloudy solution appeared with-infirst few seconds the infinitely large surface area between extraction solvent and aqueous phase was achieved and the color product diffuses quickly into the extraction solvent.This is the remarkable advantage of DLLME technique.The influence of centrifugation time on DLLME of thiram was also studied.The results indicated that for a complete separation of organic and aqueous phase the mixture should be centrifuged for5min at5000rpm.Interference studiesThe effect of potential interference of cations and anions on the DLLME and determination of thiram using the proposed procedure was studied.An error of±5%in the absorbance reading was consid-ered tolerable.In these experiments,sample solutions containing of200ng mLÀ1of the thiram and different concentrations of other ions were treated under the recommended procedure using opti-mum conditions.The results given in Table S1indicate that themethod is more selective to thiram than a large number of cations and anions.Analyticalfigures of meritAfter optimization of all parameters,quantitative characteris-tics of the proposed method were studied.The linear dynamic range,correlation coefficient(r),repeatability,limit of detection (LOD)and preconcentration factor were determined to evaluate the method performance.The analytical characteristics of the opti-mized method summarized in Table1.The preconcentration factor for the suggested DLLME method is calculated by the ratio of the highest sample volume(10mL)and thefinal lowest volume (170l L).Thus,a preconcentration factor of about58.8was achieved using this procedure.Application to real samplesTo demonstrate the performance and validation of the present method,it was utilized to determine the thiram in two water samples,which were selected from Karun River(Khuzestan Prov-ince,Iran)and Tap water(Ahvaz,Iran).The tested water samples were found to be free from thiram according to the optimized pro-cedure.The recovery tests were performed by the analysis of the samples spiked with known amounts of thiram.The analytical data of this investigation are given in Table2,as can be seen,the thiram recovery for the spiked samples is quantitative(94.7–104.9%).The proposed method was then applied for the determination thiram in three plant seed samples preserved by thiram.In addi-tion for evaluation of the accuracy of the method,a comparison between results obtained by suggested method and HPLC[11] was performed.The obtained results from both methods were sta-tistically evaluated by performing Student’s t-test and F-test.As can be seen in Table3the values calculated were found to be less than tabulated values at95%confidence level indicating no signif-icant differences in the accuracy and precision of the recom-mended method and the HPLC.ConclusionsIn the present study a DLLME method has been employed for sensitive determination of thiram.Miniaturization of toxic organic solvent using dispersive liquid–liquid microextraction combined with microvolume UV–vis spectrophotometry allows the develop-ment of a green method which is environment-friendly.Besides simplicity of operation,rapidity,low sample volume,low cost and high preconcentration factor are some advantages of the sug-gested method.There is no need for additional dispersive solvent because ethanol provided by the addition of ethanolic KOH acts as a disperser too.A comparison between presented approach and previously reported method for the determination of thiramTable1Analytical characteristics of the presented DLLME method for determination of thiram.Parameter Analytical featuresLinear range(ng mLÀ1)(n=10)25–1000Correlation coefficient(r)0.9985Detection limit(ng mLÀ1)(3r,n=10)11.5Precision(RSD%for100and500ng mLÀ1,n=8) 2.7,1.1Preconcentration factor58.8Table2Determination of thiram in water samples by proposed method.Sample Added(ng mLÀ1)Found a(ng mLÀ1)Recovery(%)River water(Karun)0N.D b–250257.8±3.2103.1500524.4±5.9104.9Tap water(Ahvaz)0N.D–250241.1±2.796.4500473.6±5.394.7a Mean±standard deviation(n=5).b Not detected.Table3Determination of thiram in plant seed samples by proposed method.Seed sample Thiram found(mg gÀ1)a t-Test b F-test cProposed method HPLCTomato0.428±0.0130.451±0.016 1.93 1.51 Cucumber 1.114±0.033 1.152±0.040 1.27 1.47 Watermelon0.748±0.0210.726±0.025 1.17 1.42a Mean±standard deviation(n=3).b Tabulated t-value for four degrees of freedom at95%confidence level is2.78.c Tabulated F-value for(2,2)degrees of freedom at95%confidence level is39.Table4Comparison of the proposed method with other methods for determination of thiram.DetectiontechniqueLinear range(ng mLÀ1)LOD(ng mLÀ1)RSD(%)Ref.SERS a 3.3–400.0 2.0NG b[1]FI-CL c50.0–1000 5.0 2.6[6]Spectrophotometry0–24,000300 1.9[7]CL-ELISA d9.0–15009.0NG[8]HPLC–UV500–450088<5[10]HPLC–UV 5.0–600 1.0NG[11]Spectrophotometry500–2500330NG[13]Voltammetry240.4–144,258103.4 1.6[17]FI-CL7.5–25007.0 2.5[19]Voltammetry48–2400132–5.8[31]Spectrophotometry Up to20,000161NG[32]DLLME-UV–vis25–100011.5 1.1–2.7Thisworka Surface-Enhanced Raman Scattering.b Not given.c Flow Injection-Chemiluminescence.d Chemiluminescence-Enzyme-Linked Immuno-Sorbent Assay.S.Rastegarzadeh et al./Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy114(2013)46–5049is given in Table4.As can be seen in table the LOD of suggested method is better or comparable to many of the reported tech-niques.Furthermore the application of spectrophotometric detec-tion has merits of simplicity,cheapness and portability.This methodology gives good accuracy,low limits of detection and excellent precision which show its potentiality in analysis of thi-ram in environmental and agricultural samples.AcknowledgementThe authors are grateful to Shahid Chamran University Research Council forfinancial support of this work(Grant1391). Appendix A.Supplementary materialSupplementary data associated with this article can be found,in the online version,at /10.1016/j.saa.2013.05.020. References[1]X.Zheng,Y.Chen,Y.Chen,N.Bi,H.Qi,M.Qin,D.Song,H.Zhang,Y.Tian,J.Raman Spectrosc.43(2012)1374–1380.[2]D.Bohrer,P.C.D.Nascimento,H.M.Gomes,J.Agric.Food Chem.47(1999)212–216.[3]T.Cajka,K.Riddellova,P.Zomer,H.Mol,J.Hajslov,Food Addit.Contam.A28(2011)1372–1382.[4]A.L.Queffelec,F.Boisde,rue,J.P.Haelters,B.Corbel,D.Thouvenot,P.Nodet,J.Agric.Food Chem.49(2001)1675–1680.[5]A.Peruga,S.Grimalt,F.J.Lopez,J.V.Sancho,F.Hernandez,Food Chem.135(2012)186–192.[6]A.Waseem,M.Yaqoob,A.Nabi,Anal.Sci.25(2009)395–400.[7]V.K.Sharma,J.S.Aulakh,A.K.Malik,Talanta65(2005)375–379.[8]S.Girotti,E.Maiolini,S.Ghini,E.Ferri,F.Fini,Anal.Lett.41(2008)46–55.[9]V.K.Sharma,J.S.Aulakh,A.K.Malik,J.Environ.Monit.5(2003)717–723.[10]O.M.S.Filipe,M.M.Vidal,A.C.Duarte,E.B.H.Santos,J.Agric.Food Chem.56(2008)7347–7354.[11]J.S.Aulakha,A.K.Malikb,R.K.Mahajan,Talanta66(2005)266–270.[12]S.B.Ekroth,B.Ohlin,B.G.Osterdahl,J.Agric.Food Chem.446(1998)5302–5304.[13]O.M.S.Filipe,M.M.Vidal,A.C.Duarte,E.B.H.Santos,Talanta72(2007)1235–1238.[14]E.D.Caldas,M.H.Conceicao,M.C.C.Miranda,L.C.K.R.de Souza,J.F.Lima,J.Agric.Food Chem.49(2001)4521–4525.[15]Z.Vryzas,E.N.Papadakis,E.P.Mourkidou,J.Agric.Food Chem.50(2002)2220–2226.[16]D.K.Sharma,A.Gupta,R.Kashyap,Toxicol.Environ.Chem.93(2011)1319–1331.[17]M.A.Hernandez-Olmos,L.Agui,P.Yanez-Sedeno,J.M.Pingarron,Electrochim.Acta46(2000)289–296.[18]Y.G.Zhao,X.W.Zheng,Z.Y.Huang,M.M.Yang,Anal.Chim.Acta482(2003)29–36.[19]A.Waseem,M.Yaqoob,A.Nabi,Luminescence25(2010)71–75.[20]M.Rezaee,Y.Assadi,M.M.Hosseini, E.Aghaee, F.Ahmadi,S.Berijani,J.Chromatogr.A1116(2006)1–9.[21]S.Khodadoust,M.Hadjmohammadi,Anal.Chim.Acta699(2011)113–119.[22]Z.Gao,X.Ma,Anal.Chim.Acta702(2011)50–55.[23]X.Jia,Y.Han,X.Liu,T.Duan,H.Chen,Spectrochim.Acta B66(2011)88–92.[24]M.Moradi,Y.Yamini,A.Esrafili,S.Seidi,Talanta82(2010)1864–1869.[25]Q.Zhoua,N.Zhaob,G.Xie,J.Hazard.Mater.189(2011)48–53.[26]H.Sereshti,V.Khojeh,S.Samadi,Talanta83(2011)885–890.[27]A.N.Anthemidis,K.G.Ioannou,Talanta84(2011)1215–1220.[28]X.Wen,Q.Yang,Z.Yan,Q.Deng,Microchem.J.97(2011)249–254.[29]L.Fu,X.Liu,J.Hu,X.Zhao,H.Wang,X.Wang,Anal.Chim.Acta632(2009)289–295.[30]J.Skrlikova,V.Andruch,I.Balogh,L.Kocurova,L.Nagy,Y.Bazel,Microchem.J.99(2011)40–45.[31]C.Fernhndez,A.J.Reviejo,J.M.Pingarron,Anal.Chim.Acta305(1995)192–199.[32]A.Tunçeli,H.Bag˘,A.R.Türker,Fresen.J.Anal.Chem.371(2001)1134–1138.50S.Rastegarzadeh et al./Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy114(2013)46–50。

分散液液微萃取-气相色谱法测定地表水中三氯苯于洪【摘要】采用分散液液微萃取-气相色谱法测定地表水中3种三氯苯同分异构体.实验考察了萃取剂及其用量、分散剂及其用量对萃取效率的影响.实验结果表明,三氯苯3种同分异构体在质量浓度2.00~64.0μg/L范围内线性良好,测定结果的相对标准偏差均小于4%(n=7),平均加标回收率为94.1%~103.9%.该方法操作简便、快捷,有机试剂用量少,样品富集倍数高.三氯苯3种同分异构体的检出限分别为0.03,0.04,0.03μg/L,测量精密度和准确度能满足分析测度要求,适用于地表水中痕量三氯苯的测定.【期刊名称】《化学分析计量》【年(卷),期】2019(028)001【总页数】4页(P99-102)【关键词】分散液液微萃取;气相色谱法;地表水;三氯苯同分异构体【作者】于洪【作者单位】新疆吉方坤诚检测技术有限公司,乌鲁木齐 830000【正文语种】中文【中图分类】O657.7三氯苯包括 1,3,5-三氯苯、1,2,4-三氯苯、1,2,3-三氯苯3种同分异构体,不溶于水,易溶于乙醚、苯、石油醚、二硫化碳等有机溶剂,在有机合成、染料、农药和涂料等领域中应用广泛[1]。

三氯苯属于化学性质稳定、毒性较大的化合物,对水生生物及水体环境存在长期的不良影响。

人体吸收三氯苯后中枢神经系统会受到抑制作用,引起肝肾损害等症状[2]。

地表水中的三氯苯主要来源于工业废水的排放。

GB 3838-2002 《地表水环境质量标准》规定集中式生活饮用水地表水源地特定项目中三氯苯的标准限值为0.02 mg/L,因此准确测定地表水中三氯苯含量具有重要的现实意义。

地表水中的三氯苯一般以痕量级存在,为提高测定灵敏度,测定前需要对水样进行浓缩处理。

地表水中三氯苯的浓缩一般采用液液萃取[3-4]、固相萃取[5-6]、吹扫捕集[7-8]和顶空[9-10]等前处理方法,其中液液萃取和固相萃取方法有机萃取试剂用量大且不环保,操作步骤繁琐;吹扫捕集法操作耗时长,仪器成本较高;顶空法不能浓缩样品,方法检出限较高。

分散液液微萃取技术及其在食品安全分析中的应用作者:马智玲魏长宾刘新艳,李凌云刘玉革刘肃方佳来源:《热带作物学报》2015年第02期摘要分散液液微萃取是2006年发展起来的一种新型的液相微萃取技术,该方法因操作简单、快速、成本低、富集倍数高、所需有机溶剂用量少、萃取时间短等特点而成为一种备受关注的绿色友好的分离富集技术。

近些年,该技术已经在环境水样、饮品、食品、矿物样品以及生物流体、土壤样品的分析中得到广泛应用。

综述分散液液微萃取技术近期的研究进展及其在食品安全分析领域的应用,包括饮品、蔬菜水果、谷物及动物性组织等食品中农药、酚类物质、持久性污染物、金属及其他一些物质的分析检测,并对其发展趋势进行了阐述。

关键词分散液液微萃取;食品安全;样品前处理;分析检测中图分类号 TS201.6 文献标识码 A完整的食品污染物分析过程包括样品前处理和仪器分析两个部分。

目前,气相色谱、液相色谱、原子吸收光谱等已成为当前主要的污染物残留分析检测技术,而在进行仪器分析前,样本前处理的时间约占到整个分析方法的2/3左右,是分析过程中最重要的环节。

由于食品种类多样复杂,有些待测组分的含量很低,所以要求样品前处理过程不仅要有效地将目标物从复杂的样品基体中分离出来,还要除去基体中的干扰物质,富集低含量待测组分,从而提高分析灵敏度,延长分析仪器使用寿命。

传统的样品前处理方法有液液萃取、固相萃取、凝胶渗透色谱、加速溶剂萃取等,其处理过程繁琐耗时、成本高、效率低、劳动强度大,还需要使用大量对人体和环境有毒、有害的有机溶剂[1-4]。

液相微萃取技术(LPME)是一项新型样品前处理技术,克服了液液萃取消耗大量溶剂以及固相微萃取萃取头较昂贵、寿命短、多次使用存在交叉污染等缺点。

该技术操作简单,无需特殊装置,具有成本低、富集倍数高、有机溶剂用量少等特点,是一种环境友好的样品前处理技术,因适应了当前绿色化学发展的需要而受到分析人员的广泛关注[5]。

药品及个人护理用品(PPCPs)的污染来源、环境残留及生态毒性药品及个人护理用品(PPCPs)的污染来源、环境残留及生态毒性引言:药品及个人护理用品(Pharmaceuticals and Personal Care Products,简称PPCPs)是人们日常生活中必不可少的产品,它们通过治疗疾病、保护个人卫生、美容等方面发挥着重要作用。

然而,随着人口的增长和生活水平的提高,PPCPs的使用量不断增加,导致这些产品及其代谢物越来越广泛地进入到环境中,对水体、土壤和生态系统产生了潜在的危害。

因此,了解PPCPs的污染来源、环境残留情况以及它们对生态系统的影响,对于制定合理的管理和保护措施具有重要意义。

一、PPCPs的污染来源:1. 医疗废弃物:医院和家庭等医疗场所产生的废弃药物、药品包装材料等,直接或间接地进入到环境中。

2. 农业和畜牧业:在农业生产中,兽药和抗生素等药物的使用及其残留物通过农田排水和动物粪便等途径进入水体和土壤中。

3. 个人护理用品:洗发水、沐浴液、口服避孕药等个人护理用品在使用过程中产生的废水,含有活性成分和防腐剂等物质,会被排入下水道或环境中。

4. 城市生活污水:城市污水中含有大量的药物和个人护理产品的代谢物,人们的用药习惯和生活习惯也是城市污水中PPCPs的重要来源。

二、PPCPs在环境中的残留:1. 水体:污水处理厂未能彻底去除所有的PPCPs,导致这些物质进入河流、湖泊、地下水等水体中。

研究表明,水体中已检测到多种抗生素、避孕药等药物类化合物。

2. 土壤:PPCPs通过灌溉、施肥以及农田排水等途径进入土壤中,导致土壤中也存在这些化合物的残留。

这些物质不仅对土壤中的微生物和生态系统产生潜在影响,还可能通过食物链进入人体。

3. 饮用水:由于自来水处理厂对PPCPs的去除效率有限,一些药物和个人护理用品成分及其代谢物可能在最终的饮用水中存在。

这对公众的健康提出了潜在风险。

三、PPCPs对生态系统的生态毒性:1. 对水生生物:PPCPs对水中无脊椎动物、鱼类和藻类等生物产生毒性影响。

分散液液微萃取-气相色谱法快速测定水中十五种有机磷类农残王雷;张艳霞【摘要】建立了分散液液微萃取结合气相色谱-火焰光度检测器(GC-FPD)技术快速检测水体中15种有机磷农残的检测方法.重点对影响萃取效率的参数,如萃取剂和分散剂的类型及用量等进行了优化.在最佳条件下,15种有机磷的富集倍数可达108~135.在两个加标水平下,方法的加标回收率在80.4 %~119.2%之间,相对标准偏差在3.4 %~6.5%之间,定量限在0.078 μg/L~0.14 μg/L之间,可满足各种水体中有机磷类农残的检测要求.【期刊名称】《能源环境保护》【年(卷),期】2016(030)002【总页数】5页(P58-61,31)【关键词】分散液液微萃取;气相色谱;有机磷;水【作者】王雷;张艳霞【作者单位】德州市平原县环保局,山东德州253100;德州市平原县环保局,山东德州253100【正文语种】中文【中图分类】U268.5+2有机磷农药是20世纪30年代末问世的第二代人工合成农药。

目前,全世界有机磷农药达数百种,其中杀虫剂的使用量约占70%[1]。

我国有机磷农药的产量占全世界总量的1/3,有机磷农药的产量占我国农药总量的一半以上。

研究表明,OPPs多数属于中、高毒性农药,可使人畜中毒,影响人畜内激素的代谢平衡,尤其影响儿童神经系统的正常发育[2]。

水体中的OPPs主要来源于农业及工业废水的排放,通过食物链的富集后,可能对人畜健康构成潜在的危害。

为有效控制水体中有机磷农药残留污染,首要任务是发展快速、可靠、灵敏度高、应用范围广和成本低的检测技术。

残留分析包括样品前处理和分离检测两个环节,而样品前处理是残留分析检测的关键步骤。

传统的样品前处理技术,如液液萃取(LLE),存在效率低下、耗时等问题,已满足不了现代分析的发展要求。

近年来,样品前处理方法正朝着简单化、节约化和微型化发展。

目前国内外水体中有机磷残留的测定方法中,样品前处理方法除了LLE[3],主要是固相萃取(SPE)[4]和固相微萃取(SPME)[5]等技术。

现代科学仪器Modern Scientific Instruments第3期2010年6月N o.3 J u n. 2010123一种新的液液萃取模式-分散液液微萃取邓勃(清华大学化学系 北京 100084)摘 要 分散液-液微萃取是2006年才问世的一种新型微萃取技术。

它基于使用微量注射器将微升级萃取剂快速注入样液内,在分散剂-水相内形成萃取剂微珠,很大地扩展了有机萃取剂和水样之间相接触面, 大大加快了萃取平衡的速度,使目标化合物迅速萃入萃取剂微珠内,提高了萃取效率和富集倍数。

萃取富集操作与后续检测方法有很好的相容性,萃取相可直接进样气相色谱、高效液相色谱、薄层色谱、气相色谱-质谱、分光光度、火焰原子吸收光谱和电热原子吸收光谱,对目标化合物进行测定。

它不仅适用于痕量有机物的分离富集,也适用于痕量无机金属离子的分离富集,已成功地应用于各种坏境水样(包括高含盐量水样)、多种饮料、生物样品、煤和矿物样品中痕量组分的分离富集,是一种有发展前途的环境友好的分离富集技术。

关键词 分散液-液微萃取;溶剂萃取;样品制备;金属离子萃取;水分析;农药残留分析;衍生化-液液微萃取中图分类号 O65A Novel Liquid/liquid Extraction Mode-dispersive Liquid/liquid Microextraction Deng Bo(Department of Chemistry,Tsinghua University,Beijing,100084)Abstract The dispersive liquid–liquid microextraction(DLLME) developed by Y .Assadi et al in 2006 was a new liq-uid/liquid extraction mode. In this mode, the appropriate mixture of extractant of μL level (such as, CH 2Cl 2,CHCl 3,CCl 4,C 2Cl 4, C 6H 5Cl or CS 2 etc) and disperser solvent (such as acetone, ethanol, methanol,acetonitrile or Tetrahydrofuran etc)are injected by microsyringe rapidly into the aqueous sample containing target compounds, forming a cloudy solution.In the solution many fi ne droplets of extractant dispersed entirely into aqueous phase. Due to very large surface area between ex-traction solvent and aqueous phase, transition of target compounds from aqueous phase to extraction solvent and achieving equilibrium state are very quickly.The advantages of DLLME method are simplicity of operation, rapidity, low cost, high recovery and enrichment factor as well as favorable compatibility of extraction phase with subsequent instrumental detec-tion methods such as GC,HPLC, GC–MS,FAAS,ETAAS etc.It has been applied to extraction separation and preconcentra-tion of trace organic compounds and inorganic metallic ions in environmental water samples, drinks, biological samples, coal and Minerals etc. DLLME is a very promising‘environment friendly’technique of separation and preconcentraction.Key words Dispersive liquid–liquid microextraction; Solvent extraction; Sample preparation Metal ions extraction; Water analysis; Pesicide residue analysis; Derivatization combined with DLLME收稿日期:2010-02-07作者简介:邓勃,清华大学化学系教授,主要从事原子吸收光谱分析和分析化学计量学的教学和研究工作液-液萃取作为有效的分离技术,已广泛地用于工业和分析化学中,但常规的液-液萃取处理样品量大,需使用大量的有机溶剂,由于有机溶剂的高挥发性、毒性和可燃性,造成环境污染和易引发安全事故。

超声波辅助分散液液微萃取测定水样中的多氯联苯

胡佳;乐莎

【期刊名称】《河北化工》

【年(卷),期】2010(033)012

【摘要】将超声波辅助分散液液微萃取(USADLLME)与气相色谱-大新技术公司电子捕获检测器(GC-ECD)联合,建立了一种高灵敏度检测水样中多氯联苯的新方法.对影响微萃取的因素进行了优化.在优化的条件下,该方法的线性范围为0.05~50 μ g/L(r2>0.9995),相对标准偏差在1.4%~6.9%之间.相对检出限为7.24~16.3

ng/L(S/N=3).在自来水、塘水、江水中分别加入0.1、0.5、1μ g/L 多氯联苯溶液,加标回收率为81.1%~100.6%、88.1%~95.6%和85.0%~101.8%.本方法可以对水环境中的痕量多氯联苯进行检测,具有操作简便、快速等优点.

【总页数】4页(P49-52)

【作者】胡佳;乐莎

【作者单位】中南民族大学工商学院,湖北,武汉,430065;中南民族大学工商学院,湖北,武汉,430065

【正文语种】中文

【中图分类】O657.7+1

【相关文献】

1.分散液液微萃取-紫外分光光度法测定环境水样中碱性品红 [J], 周亚文; 刘幻; 吕瑞

2.分散液液微萃取-气相色谱法测定水样中14种农药残留量 [J], 刘峰

3.分散液液微萃取-气相色谱法测定水样中14种农药残留量 [J], 刘峰

4.基于饱和中链脂肪酸的凝固-漂浮分散液液微萃取/高效液相色谱法测定水样中紫外屏蔽剂 [J], 胡西洲;洪伟;张仙;彭茂民;夏虹;彭西甜

5.超声辅助悬浮固化分散液液微萃取-液相色谱-串联质谱法测定环境水样中氯硝柳胺 [J], 廖且根;张大文;罗林广

因版权原因,仅展示原文概要,查看原文内容请购买。

分散液相微萃取-高效液相色谱法测定水中丙溴磷农药沈英;孙福生;董杰【期刊名称】《分析化学》【年(卷),期】2010(38)4【摘要】应用分散液相微萃取(DLLME)技术,建立了水中丙溴磷农药的高效液相色谱(HPLC)分析方法.考察了萃取剂、分散剂、萃取剂体积、分散剂体积、时间、盐度和pH等因素对分散液相微萃取的影响,并确定了最佳萃取条件为:15 μL三氯乙烷(萃取剂)和700 μL乙腈(分散剂), 混匀后,加入水样,室温静置2 min,以3000r/min离心2 min,吸取3 μL沉积相,进行HPLC分析.在此优化条件下,富集倍数达到270,检出限为2 μg/L,相对标准偏差(RSD)为1.4%~6.1%(n=6);标准加入回收率为81.9%~118%.本方法操作简单,成本低,结果令人满意.【总页数】4页(P551-554)【作者】沈英;孙福生;董杰【作者单位】苏州科技学院,环境科学与工程学院,苏州,215011;苏州科技学院,环境科学与工程学院,苏州,215011;苏州科技学院,环境科学与工程学院,苏州,215011【正文语种】中文【相关文献】1.超声辅助离子液体分散液相微萃取-高效液相色谱法测定废水中雌激素的研究 [J], 刘美华;邱彬;陈国南;陈曦2.离子液体分散液相微萃取-高效液相色谱法测定番茄中的氨基甲酸酯类农药 [J], 郝家勇;罗小玲;唐宗贵;王东健3.超高效液相色谱-串联质谱法测定水中拟除虫菊酯和有机磷农药残留 [J], 杨敏娜;秦兴秀;王来梁4.高效液相色谱-三重四级杆质谱法测定水中15种氨基甲酸酯类农药 [J], 曾家源;张晓淳;陈嘉文5.基于离子液体的分散液相微萃取-高效液相色谱法测定水中三唑类农药 [J], 张敏;黄其亮;殷帅;杨愿愿;杨晓云因版权原因,仅展示原文概要,查看原文内容请购买。