(美国)婴儿床检测标准[1]

- 格式:doc

- 大小:27.00 KB

- 文档页数:2

cfr1615-1616儿童睡标准指的是美国联邦法规第16章第一节第1615和1616条的规定,其主要内容是关于儿童睡眠产品对甲醛含量的要求。

甲醛是一种有毒的化学物质,长期接触甲醛会对人体健康造成严重影响,特别是对儿童的影响更为严重。

根据cfr1615-1616标准的规定,儿童睡眠产品必须符合一定的甲醛含量限制,以保护儿童的健康。

根据cfr1615-1616标准的规定,对甲醛的要求主要包括以下几点:1. 甲醛含量限制:根据cfr1615-1616标准,儿童睡眠产品的甲醛含量限制为0.05ppm(parts per million),超过这个限制的产品将被禁止销售。

2. 甲醛检测标准:儿童睡眠产品必须进行甲醛含量的检测,并且必须符合相关的检测标准。

产品必须通过认可的实验室进行测试,并且测试结果必须符合cfr1615-1616标准的要求。

3. 标签要求:符合cfr1615-1616标准的儿童睡眠产品必须在产品上清晰标注甲醛含量,并注明符合相应的标准要求。

4. 监管要求:cfr1615-1616标准明确规定了对儿童睡眠产品的监管要求,监管部门有权对儿童睡眠产品进行抽样检测,并对不符合标准要求的产品进行处罚。

cfr1615-1616儿童睡标准对甲醛的要求严格,旨在保护儿童免受甲醛对健康的危害。

这一标准的实施不仅可以有效保障儿童睡眠产品的质量和安全,也有利于提升儿童的生活质量和健康水平。

希望生产商和监管部门能够严格执行这一标准,共同维护儿童的健康权益。

根据cfr1615-1616儿童睡标准对甲醛的要求,可以看出美国联邦法规对儿童睡眠产品的甲醛含量设置了非常严格的限制标准。

这一规定的背后是对儿童健康的高度关注和保护,甲醛是一种有毒的化学物质,长期暴露在甲醛中对儿童的呼吸系统和免疫系统都会造成很大的危害。

在cfr1615-1616标准规定的甲醛含量限制之外,还有一些其他的相关要求和标准需要满足。

这些要求和标准的严格执行对于确保儿童睡眠产品的质量安全至关重要。

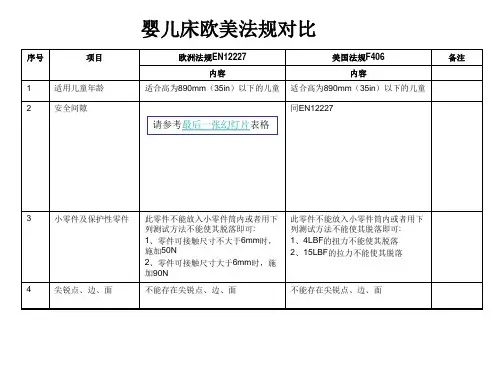

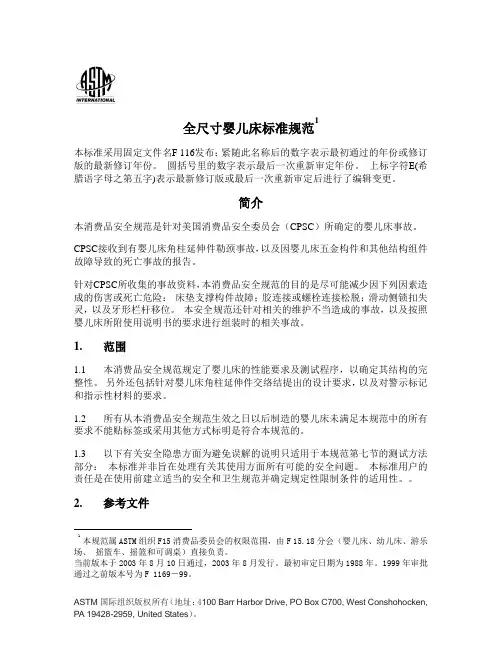

全尺寸婴儿床标准规范1本标准采用固定文件名F 116发布;紧随此名称后的数字表示最初通过的年份或修订版的最新修订年份。

圆括号里的数字表示最后一次重新审定年份。

上标字符Ε(希腊语字母之第五字)表示最新修订版或最后一次重新审定后进行了编辑变更。

简介本消费品安全规范是针对美国消费品安全委员会(CPSC)所确定的婴儿床事故。

CPSC接收到有婴儿床角柱延伸件勒颈事故,以及因婴儿床五金构件和其他结构组件故障导致的死亡事故的报告。

针对CPSC所收集的事故资料,本消费品安全规范的目的是尽可能减少因下列因素造成的伤害或死亡危险:床垫支撑构件故障;胶连接或螺栓连接松脱;滑动侧锁扣失灵,以及牙形栏杆移位。

本安全规范还针对相关的维护不当造成的事故,以及按照婴儿床所附使用说明书的要求进行组装时的相关事故。

1. 范围1.1 本消费品安全规范规定了婴儿床的性能要求及测试程序,以确定其结构的完整性。

另外还包括针对婴儿床角柱延伸件交络结提出的设计要求,以及对警示标记和指示性材料的要求。

1.2 所有从本消费品安全规范生效之日以后制造的婴儿床未满足本规范中的所有要求不能贴标签或采用其他方式标明是符合本规范的。

1.3 以下有关安全隐患方面为避免误解的说明只适用于本规范第七节的测试方法部分:本标准并非旨在处理有关其使用方面所有可能的安全问题。

本标准用户的责任是在使用前建立适当的安全和卫生规范并确定规定性限制条件的适用性。

2. 参考文件1本规范属ASTM组织F15消费品委员会的权限范围,由F 15.18分会(婴儿床、幼儿床、游乐场、摇篮车、摇篮和可调桌)直接负责。

当前版本于2003年8月10日通过,2003年8月发行。

最初审定日期为1988年。

1999年审批通过之前版本号为F 1169-99。

2.1 联邦标准16 CFR 1303 含铅油漆与特定含铅油漆消费品禁令16 CFR 1500.50–.52 模拟使用测试方法以及玩具和其它专为儿童使用物品的滥用16 CFR 1501 测定方法—因含有微粒材料对具有潜在窒息、吸入或摄食危害的专用于三岁以下儿童设计的玩具和其它物品16 CFR 1508 全尺寸婴儿床要求23. 术语3.1 滑动侧/滑动门,名词:为更容易接近占用者而特意设计的,在产品按制造商建议的使用位置使用时在框架上滑动的一侧。

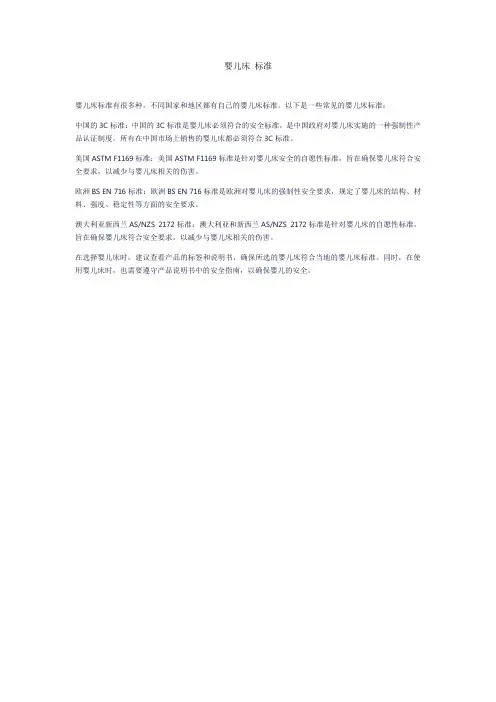

婴儿床标准

婴儿床标准有很多种,不同国家和地区都有自己的婴儿床标准。

以下是一些常见的婴儿床标准:

中国的3C标准:中国的3C标准是婴儿床必须符合的安全标准,是中国政府对婴儿床实施的一种强制性产品认证制度。

所有在中国市场上销售的婴儿床都必须符合3C标准。

美国ASTM F1169标准:美国ASTM F1169标准是针对婴儿床安全的自愿性标准,旨在确保婴儿床符合安全要求,以减少与婴儿床相关的伤害。

欧洲BS EN 716标准:欧洲BS EN 716标准是欧洲对婴儿床的强制性安全要求,规定了婴儿床的结构、材料、强度、稳定性等方面的安全要求。

澳大利亚新西兰AS/NZS 2172标准:澳大利亚和新西兰AS/NZS 2172标准是针对婴儿床的自愿性标准,旨在确保婴儿床符合安全要求,以减少与婴儿床相关的伤害。

在选择婴儿床时,建议查看产品的标签和说明书,确保所选的婴儿床符合当地的婴儿床标准。

同时,在使用婴儿床时,也需要遵守产品说明书中的安全指南,以确保婴儿的安全。

美国全尺寸婴儿床标准1、范围结构完整性测试、警告标识和指导性材料。

包括摇篮、可更换桌子(需要同时满足F2388)或类似的婴儿床附件。

该标准不包括充气产品。

5、一般要求5.1 首先所有木质部件都应该光滑且没有毛刺。

5.1.1 所有木质部件不得破裂或脱落导致结构破坏。

5.2 表面涂层——产品表面涂层要符合16 CFR 1303. 5.3小零件——测试前和测试后不能出现16 CFR 1501定义的小零件。

5.4 角杆541从角柱或转角(见图1)的最外轮廓线3英寸(76mm)以内的床头板或侧板上缘的最低点进行测量,任何角柱组件均不能伸出床头板或侧板上缘0.06 英寸(1.5mm)以上(以较高者为准)。

5.4.1.1 此项要求在滑动侧/滑动门处于较高或较低位置时均适用。

5.4.2 5.4.1 条的限制不适用于伸出侧栏最高位置时的外表面16英寸(400mm)以上的角柱组件。

5.4.3 用于连接两部分或多部分(如顶盖柱延伸件)组成的可拆卸式垂直延伸件的角柱,不能与单个部件连接在一起,否则连接在一起的垂直延伸尺寸将与 5.4 节的尺寸要求不符。

5.5 板条结构——板条不能包含任何侧面/横向连接处,如指装连接点,不允许有其它连接木片两端的部位。

5.6 婴儿床侧面构造5.6.1 侧面有可移动部件的婴儿床:为方便儿童进入而带有可移动部件的婴儿床,侧面必须牢固地固定于婴儿床末端,且在其最低可调节位置上,活动部分超过垫子顶端部分不得少于20in (51cm)。

5.6.2 只有不可移动的侧面的婴儿床应遵循以下标准:在其可调节最高位置,从垫子上表面以上部分开始,所有顶部水平围栏的最高面高度不得低于15in (38cm)。

5.6.3所有具有板条或轴的相邻侧面,它们顶部围栏的高度差大于6in,且其中一个顶部围栏高度小于40in(102cm)(从处于最低位置的垫子支撑顶部到侧面顶部),则较高的侧面不能有脚支撑( 5.9 中定义的)位于侧面顶部以下超过6in(15cm)处。

cpsia标准美国儿童安全产品标准协会(CPSIA)定义了适用于儿童安全产品的标准,所有在美国销售或制造儿童相关产品都需要遵守CPSIA标准,以确保安全性以及符合法规要求。

这些标准规定了针对不同儿童安全产品的检测、报告、标签和标准的要求,以及安全性的指导原则。

CPSIA标准涵盖了从婴儿尿布到游乐设施的各种儿童安全产品,以及在家庭环境中使用的其他产品,如家居床、婴儿床、童车、围兜和宠物笼等。

产品需符合CPSIA标准,以避免引起损伤或死亡,其中包括检测项目、产品标签以及其他标准。

CPSIA标准要求使用检测这些产品的材料,以确保产品安全可靠。

这些检测项目包括:阻燃性、尘埃和潮湿物质、尘埃和潮热性、吸水性、有害物质检测、有害涂层及其他性能测试等。

在报告中,还包括了检测的细节,以及检测结果的报告,以显示产品是否符合CPSIA标准的要求。

CPSIA标准还要求产品提供标签,以提醒消费者关注产品的健康和安全问题。

这些标签应该包含产品供应商的姓名、电话号码、邮政编码以及产品的其他信息等。

产品应当标明适用的安全指导原则,并需要提供产品所有警告标记,以便消费者了解产品可能存在的风险。

CPSIA标准还规定关于儿童安全产品的标准,它包括了婴儿尿布的尺寸限制和尿布的拼接缝纫,以及婴儿床的限制在低于任何一个角落的距离要小于4英寸,以及其他标准。

这些标准可以有效地实施,确保儿童安全产品产品的安全性,消除可能对婴儿和小孩造成的潜在风险。

最后,美国儿童安全产品标准协会(CPSIA)定义了适用于儿童安全产品的标准,以确保为孩子们提供安全而值得信赖的产品。

CPSIA 标准旨在保护儿童,帮助家长从中受益,让宝宝们可以拥有一个安全的环境,快乐成长。

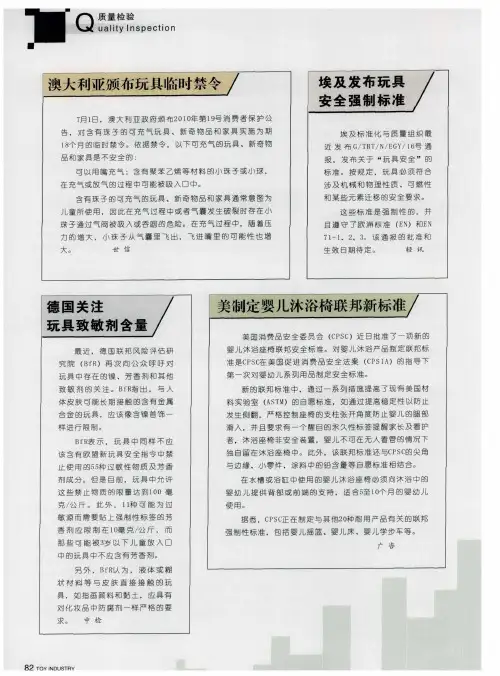

国外对儿童设施的安全标准对儿童设施的安全标准是国际共识,各国都有相应的法规和标准来规范儿童玩具、游乐设施、童车等产品的设计、生产和销售。

在这些安全标准中,对儿童年龄、身高、重量、智力等方面进行了考虑,以确保其安全性和可靠性。

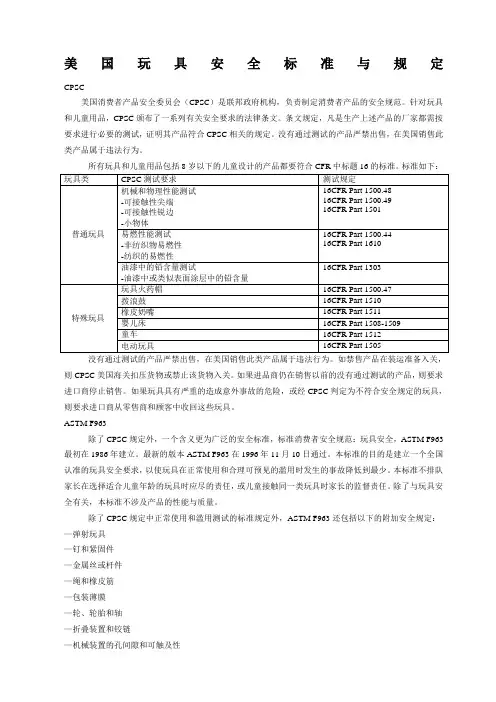

以下是几个主要国家的儿童设施安全标准介绍:1. 美国美国的儿童设施安全标准由美国消费品安全委员会(CPSC)制定,其主要是针对玩具、游乐设施和儿童家具的安全问题进行监管。

比如,在美国,婴儿床必须符合CPSC标准,床栏高度不能低于26英寸,底部的床板必须能承受50磅的重量,同时还要有防止婴儿侧身越过床栏的设计。

此外,CPSC还规定了玩具的小零件大小、抗拉强度、毒性等要求,并对于一些特定的游乐设施如滑梯、秋千、攀爬架等,制定了相应的安全标准。

2. 欧洲欧洲的儿童设施安全标准主要由欧洲标准化委员会(CEN)和欧洲技术标准化组织(CENELEC)制定。

CEN和CENELEC共同制定了EN71系列标准,主要是监管欧洲市场上的玩具安全,对于儿童年龄、身高、重量等要求,分不同的等级来考虑。

此外,欧洲还制定了EU机动车儿童座椅安全标准,该标准要求儿童座椅主要采用五点式安全带,并且会对于座椅的安装、使用以及维护等方面也有具体要求。

3. 日本在日本,日本工业标准化组织(JIS)制定了针对不同类别的儿童设施的安全标准。

比如,JIS S 3005是关于婴儿床的标准,该标准要求婴儿床的床栏高度不能低于600mm,栏杆间隔不得大于60mm,同时要求实现一定的耐震性能和稳定性。

此外,日本还制定了适用于婴儿车和童车的JIS T 9201标准,该标准包括车身强度、车轮尺寸以及刹车系统等方面的要求。

总体来说,对于儿童设施的安全标准,不仅仅要考虑儿童的年龄与体重等因素,还会考虑到产品设计的舒适性和实用性,这样才能确保产品不仅能保护儿童的安全,还可以为他们提供更好的体验。

(美国)婴儿床检测标准联邦法规Code of Federal Regulations代号:16 CFR 1508标准尺寸童床规范Requirements for Full-Size Baby CribsPART 1508 –标准尺寸童床规范§ 1508.1 定义:(a)“标准尺寸童床”指的是具有下列特征的童床:(1)为婴儿睡觉设计的一种床,(2)设定在室内使用,和(3)内部长宽尺寸在§ 1508.3规定的标准尺寸童床的± 5.1cm(± 2in.)范围内。

§ 1508.2 本部分的范围本部分阐述了标准尺寸童床(如§ 1508.1(a)的定义)的要求,根据该要求,标准尺寸童床不被本章节§ 1508.18(a)(13)列为禁止的产品。

§ 1508.3 尺寸标准尺寸童床应该具有下列尺寸:(a)内部尺寸。

从童床侧面最内表面量得的宽度应该为71±1.6cm(28±5/8in.),从端面上的板、板条、圆棒或栏杆最内表面量得的长度应该为133±1.6cm(52 3/8±5/8in.)。

长宽测量应该在床垫支撑弹簧处于各调节位置时的平面上进行,测量位置距离童床角柱或者距离第一根栏杆至童床另一端第一根栏杆的相应点不超过5cm(2in.)。

如果童床在侧面和/或端面具有曲线形或装饰性栏杆,应该从处于各调节位置的床垫支撑弹簧之上的10cm(4in.)范围内的第一根弯曲栏杆最大直径至童床对面第一根栏杆相应点或最内表面进行测量。

(b)围栏高度。

围栏应该具有下列高度:(1)从处于最低位置的围栏或面板顶部至处于最高位置的床垫顶部之间的围栏和端面板高度至少应为22.8cm(9in.)。

(2)从处于最高位置的围栏或面板顶部至处于最低位置的床垫顶部之间的围栏和端面板高度至少应为66cm(26in.)。

§ 1508.4 童床部件的间距(a)部件(如板条、栏杆、圆棒和角柱)在任何点之间的距离都不得超过6cm(2 3/8in.)。

婴儿床出口美国办理什么检测?不同国家检测标准是什么?

婴儿床作为婴儿休息的地方,在使用中也存在一些安全隐患,产品办理检测认证的目的是为了可以更好的监管产品的质量,帮助消费者排除隐患,让消费者的安全可以得到保障。

ASTM F1169是美国关于婴儿床的检测标准,2009年的修订版本代替了2007版本。

目前,ASTM F1169为工业中自愿通用标准。

按照计划,本标准将于2011 年2 月成为《2008消费品安全改进法案》(CPSIA) 第104 条中的强制性标准。

美国婴儿床标准ASTM F1169适用范围:

ASTM F1169该标准适用于在家里使用的设计供婴儿睡觉的全尺寸童床。

包括摇篮、可更换桌子(需要同时满足F2388)或类似的婴儿床附件。

该标准不包括充气产品。

美国非全尺寸童床婴儿床标准ASTM F1169测试流程:

第一步:客户提供产品图片及申请表;

第二步:世通实验室根据提供资料进行报价;

第三步:客户确认报价后,签订立案申请表及服务协议并支付全额项目费,并准备好测试样品;

第四步:客户安排邮寄样品到实验室测试;

第五步:测试通过,出具报告。

婴儿床不同国家的检测标准:

中国:3C

美国:ASTM F1169

欧洲:EN 16890

澳大利亚新西兰:AS/NZS 2172。

美国婴儿床安规文件1全尺寸婴儿床标准规范本标准采用固定文件名F 116发布;紧随此名称后的数字表示最初通过的年份或修订版的最新修订年份。

圆括号里的数字表示最后一次重新审定年份。

上标字符Ε(希腊语字母之第五字)表示最新修订版或最后一次重新审定后进行了编辑变更。

简介本消费品安全规范是针对美国消费品安全委员会(CPSC)所确定的婴儿床事故。

CPSC接收到有婴儿床角柱延伸件勒颈事故,以及因婴儿床五金构件和其他结构组件故障导致的死亡事故的报告。

针对CPSC所收集的事故资料,本消费品安全规范的目的是尽可能减少因下列因素造成的伤害或死亡危险:床垫支撑构件故障;胶连接或螺栓连接松脱;滑动侧锁扣失灵,以及牙形栏杆移位。

本安全规范还针对相关的维护不当造成的事故,以及按照婴儿床所附使用说明书的要求进行组装时的相关事故。

1. 范围1.1 本消费品安全规范规定了婴儿床的性能要求及测试程序,以确定其结构的完整性。

另外还包括针对婴儿床角柱延伸件交络结提出的设计要求,以及对警示标记和指示性材料的要求。

1.2 所有从本消费品安全规范生效之日以后制造的婴儿床未满足本规范中的所有要求不能贴标签或采用其他方式标明是符合本规范的。

1.3 以下有关安全隐患方面为避免误解的说明只适用于本规范第七节的测试方法部分:本标准并非旨在处理有关其使用方面所有可能的安全问题。

本标准用户的责任是在使用前建立适当的安全和卫生规范并确定规定性限制条件的适用性。

2. 参考文件1本规范属ASTM组织F15消费品委员会的权限范围,由F 15.18分会(婴儿床、幼儿床、游乐场、摇篮车、摇篮和可调桌)直接负责。

当前版本于2003年8月10日通过,2003年8月发行。

最初审定日期为1988年。

1999年审批通过之前版本号为F 1169-99。

2.1 联邦标准16 CFR 1303 含铅油漆与特定含铅油漆消费品禁令16 CFR 1500.50–.52 模拟使用测试方法以及玩具和其它专为儿童使用物品的滥用16 CFR 1501 测定方法—因含有微粒材料对具有潜在窒息、吸入或摄食危害的专用于三岁以下儿童设计的玩具和其它物品16 CFR 1508 全尺寸婴儿床要求23. 术语3.1 滑动侧/滑动门,名词:为更容易接近占用者而特意设计的,在产品按制造商建议的使用位置使用时在框架上滑动的一侧。

ASTMF1917-20婴儿床上用品及相关配件的标准消费者安全性能规范的主要变化点美国材料试验协会(ASTM)于2020年5月发布了最新的ASTMF1917-20“婴儿床上用品及相关配件的标准消费者安全性能规范”。

本标准规定了安全性能要求、试验方法和标签要求,以尽量减少婴儿床上用品和相关配件对儿童的危害。

旧版ASTM F1917-12相应被取代。

以下是几个主要变更:1.新增定义3.1.3婴儿床软垫/衬垫,名词-任何靠着婴儿床内圆周部分放置的产品,减少或消除婴儿接触婴儿床板条或主轴和/或这些部件之间的间隙。

2.新增定义3.1.7网眼布,名词-一种经纱和纬纱交织的机织物,一种纬纱和相邻纱线圈套而成的针织物,或可在其中形成开口的任何其他类型的织物。

3.新增定义3.1.8非纸质标签,名词-任何标签材料,如塑料或金属,在没有工具帮助的情况下不会撕裂,或撕裂留下清晰的边缘,或由织物制成的标签。

4.新增定义3.1.9纸质标签,名词-任何不用工具就能撕开并留下纤维状边缘的标签材料(织物除外)。

5.新增标签要求5.5标签警告标签(无论是纸质还是非纸质)在按照7.5进行测试时应是永久性的。

5.5.1.根据7.6进行试验时,通过热冲压、热转印、印刷、木材燃烧等方式直接应用于产品表面的警告声明应是永久性的。

5.5.2.当按照7.6进行试验时,非纸质标签不应产生小部件。

5.5.3.当产品处于制造商建议的所有使用位置时,当按照7.5.3进行试验时,贴在带接缝的婴儿床软垫/衬垫织物上的警告标签应与标签周围的织物保持接触。

6.新增测试5.6产品必须符合消费品安全改进法案的适用要求。

7. 新增测试6.4婴儿床软垫紧实度–为安装厚度为0.59英寸(15毫米)或者更大的婴儿床软垫,当按照7.7进行试验时,软垫的任何部分不得接触紧实度测试装置的接触片。

(美国)婴儿床检测标准

联邦法规

Code of Federal Regulations

代号:16 CFR 1508

标准尺寸童床规范

Requirements for Full-Size Baby Cribs

PART 1508 –标准尺寸童床规范

§ 1508.1 定义:

(a)“标准尺寸童床”指的是具有下列特征的童床:(1)为婴儿睡觉设计的一种床,(2)设定在室内使用,和(3)内部长宽尺寸在§ 1508.3规定的标准尺寸童床的± 5.1cm(± 2in.)范围内。

§ 1508.2 本部分的范围

本部分阐述了标准尺寸童床(如§ 1508.1(a)的定义)的要求,根据该要求,标准尺寸童床不被本章节§ 1508.18(a)(13)列为禁止的产品。

§ 1508.3 尺寸

标准尺寸童床应该具有下列尺寸:

(a)内部尺寸。

从童床侧面最内表面量得的宽度应该为71±1.6cm(28±5/8in.),从端面上的板、板条、圆棒或栏杆最内表面量得的长度应该为133±1.6cm(52 3/8±5/8in.)。

长宽测量应该在床垫支撑弹簧处于各调节位置时的平面上进行,测量位置距离童床角柱或者距离第一根栏杆至童床另一端第一根栏杆的相应点不超过5cm(2in.)。

如果童床在侧面和/或端面具有曲线形或装饰性栏杆,应该从处于各调节位置的床垫支撑弹簧之上的10cm(4in.)范围内的第一根弯曲栏杆最大直径至童床对面第一根栏杆相应点或最内表面进行测量。

(b)围栏高度。

围栏应该具有下列高度:

(1)从处于最低位置的围栏或面板顶部至处于最高位置的床垫顶部之间的围栏和端面板高度至少应为22.8cm(9in.)。

(2)从处于最高位置的围栏或面板顶部至处于最低位置的床垫顶部之间的围栏和端面板高度至少应为66cm(26in.)。

§ 1508.4 童床部件的间距

(a)部件(如板条、栏杆、圆棒和角柱)在任何点之间的距离都不得超过6cm(2 3/8in.)。

对于测量弯曲的或不规则的板条或栏杆之间的距离,需要使用6×10×10cm(2 3/8×4×4in.)的矩形块,该矩形块不得穿过被测间距。

(b)当按§ 1508.5的试验方法的规定直接施加9kg (20磅)的力时,此类构件间不得产生大于6.3cm (2½ in.)的间距。

对于曲线型或不规则的板条或栏杆,当按上述试验方法的规定施加9kg (20磅)的力时,在负载楔块的上、下均不得通过6.3×8.2×8.2cm(2½×3¼×3¼in.)的矩形块。