comprehensive analysis

In the third scheme, the datum is basically coincident, the structure of the fixture is not too nvenient to install, so it should be used.

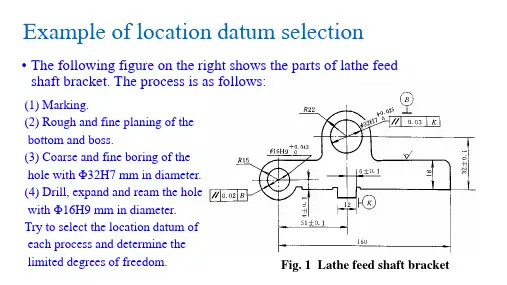

Fourth process, drilling, expanding and reaming the hole with Φ16H9 mm in diameter.

• (3)Three degrees of freedom are limited on the bottom, and two degrees of freedom are limited on the Φ32H7 hole.

• In addition to the accuracy requirements of the hole itself, the position requirements of this process shall be 4±0.1mm, 51±0.1mm and the parallelism of the two holes shall be 0.02mm.

• In this scheme, there is datum non coincidence error for dimension 4 ± 0.1mm, and the locating pin is long and thin with poor rigidity. So, this scheme is also not feasible.

• The datum of design size 4±0.1mm coincides. The process datum of size 51±0.1mm is the center line of hole Φ32H7, while the location datum is k plane, and the location dimension is 6±0.1mm, with datum non coincidence error, which is equal to 0.2mm. The parallelism of two holes is 0.02mm, with datum non coincidence error, which is equal to 0.03mm. It can be seen that the datum non coincidence error of this scheme has exceeded the allowable range. So, this scheme is not feasible.