外文文献及翻译_Ultrasonic distance meter

- 格式:doc

- 大小:69.50 KB

- 文档页数:15

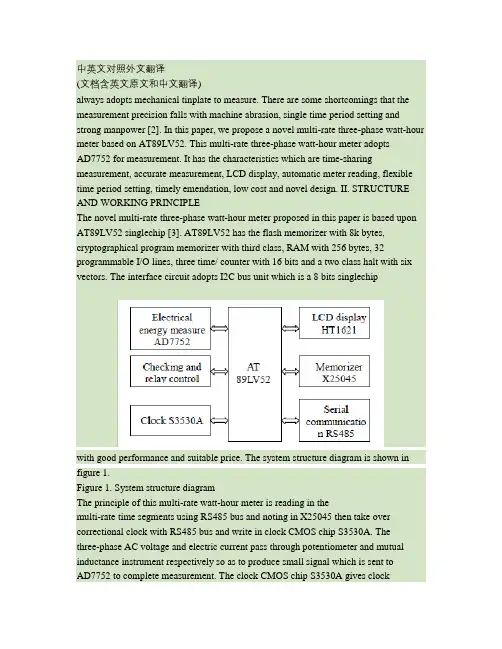

中英文对照外文翻译(文档含英文原文和中文翻译)always adopts mechanical tinplate to measure. There are some shortcomings that the measurement precision falls with machine abrasion, single time period setting and strong manpower [2]. In this paper, we propose a novel multi-rate three-phase watt-hour meter based on AT89LV52. This multi-rate three-phase watt-hour meter adoptsAD7752 for measurement. It has the characteristics which are time-sharing measurement, accurate measurement, LCD display, automatic meter reading, flexible time period setting, timely emendation, low cost and novel design. II. STRUCTURE AND WORKING PRINCIPLEThe novel multi-rate three-phase watt-hour meter proposed in this paper is based upon AT89LV52 singlechip [3]. AT89LV52 has the flash memorizer with 8k bytes, cryptographical program memorizer with third class, RAM with 256 bytes, 32 programmable I/O lines, three time/ counter with 16 bits and a two class halt with six vectors. The interface circuit adopts I2C bus unit which is a 8 bits singlechipwith good performance and suitable price. The system structure diagram is shown in figure 1.Figure 1. System structure diagramThe principle of this multi-rate watt-hour meter is reading in themulti-rate time segments using RS485 bus and noting in X25045 then take over correctional clock with RS485 bus and write in clock CMOS chip S3530A. Thethree-phase AC voltage and electric current pass through potentiometer and mutual inductance instrument respectively so as to produce small signal which is sent toAD7752 to complete measurement. The clock CMOS chip S3530A gives clockinformation per second in the course of automatic move and analyze this clock belongs to which period of time according to advance periods of time set in X25045 then save the electrical energy in RAM memorizeraccording to corresponding period of time. We write it to corresponding address ofX25045 when the electrical energy achieves one degree in order to make the multi-rate measurement come true. This watt-hour meter hasfunctions of clear LCD display, missing phase detection, burthen control, halt electricity check and storage, automatic meter reading and so on.III. THE DESIGH OF HARDWARE CIRCUITA. Electrical energy measurementThe three-phase electrical energy measurement is realized by the low consume CMOS chip AD7752 of ADI company. The inside of AD7752 adopts digital circuit besides ADC, filter and multiplication circuit which can eliminate noises effectively. The sampling course of voltage and electric current in three-phase AC power supply loop is shown in figure 2 in which IA stands for voltage sampling of A phase. The sampling circuits of B phase and C phase are similar to A phase. The power after integral is transformed to electrical pulse for output. The pulse of fan-out CF enters into interregnum INT0 of AT89LV52 through photoelectricity insulation 4N25. CPU measures the electrical energy [4]. We adjust the pulse number of CF by combining the state of S1 and S2. The connection of electrical energy and pulse is W = M C . In which, W is the electrical energy with the unit of kilowatt-hour, M is the total pulse number,C is the pulse number of ammeter. We choose C equals to 3000 that is to say every kilowatt-hour is 3000pulses.Figure 2. Circuit schematic diagramof watt-hour meterB. LCD displayThe LCD display [6] adopts HT1621 CMOS chip of HOLTEK Company toachieve twelve bits digital display. HT1621 is the LCD drivers with 128 segments (32×4) inner memorizer. The interior of HT1621 consists ofcontrol and time circuits, RAM, LCD drive and watch timer. It hasthe merits of small volume and low cost so that it is suit to watt-hour meter. We use serial interface which only has four lines between HT1621 and AT89LV52. The detailed connection is shown in figure 3. P20, P21, P22 and P23 of AT89LV52 connect to CS, RD, WR and DATA respectively with the use to refurbish the display of RAM. HT1621 drive CMOS chip has 48 nodes in which COM0, COM1, COM2, COM3 connect to the communal end and drive output of LCD and SG0, SG1, SG2, SG3 connect to drive output of every segment respectively. In addition, an adjustable resistance of 20kΩ is put between VDD and VLCD to adjust the display contrast of LCD. Experiment shows that the contrast is better with VDD=5V and VLCD=4V. C. Serial memorizerSerial memorizer adopts low power consumption chip X25045 of XICORcompany .It has three functions which are watchdog timer WTD, voltage supervision and serial memorizer E2PROM with 512 bytes. WTD can be set 200ms, 600ms and 1400ms time intervals. The software program is read into X25045. During the normal running of program, WTD receives the trigger signal in time intervals in order to ensure the normal running of program. X25045 will output a high potential through RESET line if WTD does not receive trigger signal in time intervals. The trigger watt-hour meter reset in order to prevent program flying away. As the serial memorizer chip, 512 bytes of X25045 are used to storage the watt-hour meter code, multi-rate periods of time, the apex electricity, smooth electricity, vale electricity and total electricity of last month and this month. Storage can be divided into two same areas. One is used as data storage. The other is used for backup. The number of storagecan be revised 100,000 times. Data can be stored for 100 years. It is connected withAT89LV52 by SPI agreement bus. The connection is shown in figure 3.D. Clock circuitThe clock circuit is completed by S3530A chip. It is a low powerconsumption clock chip that supports I2C Bus. It sets the clock and calendar according to the data received by CUP communicating with RS485. At the same time, it continues to walk time by its own oscillation. The crystaloscillator of 32.768 kHz is put between Xin and Xout of S3530A which is connected with CPU through latching. SDA foot and SCL foot connect to P1.6 and P1.7 ofAT89LV52 respectively. There are two interrupt alarming foots can be set as second output or minute output synchronizing pulse which supply interrupt signal toAT89LV52 with one second period. Single-chip system will readout the current time through I2C communication interface according to this signal and calculate the period of time that this moment belongs to so as to realize the electrical energy measurement in different periods of time [5]. This clock circuit has spare lithium battery. The powersupply VCC supply power in normal wiring and electrified for lithium battery of 3.6V. When there is power off, the system will automatically convert lithium battery to clock circuit for power supply. The clock will still running accurately even the power is off.Figure 3. Partial circuit figure of watt-hour meterE. RS485 CommunicationMAX485 chip can implement RS485 communication control ofmulti-rate watt-hour meter. MAX485 chip has RS485 communication protocol. It can take 128 hypogenous computers. Its transmission distance is greater than 1km and its transfer rate is up to 250kb per second. The watt-hour meter connects with the unit controller through the RS485 bus. Each unit has a cell controller can manage 128 multi-rate watt-hour meter. The cell controller connects to power management computer.Each watt-hour meter has one and only meter number with eight bits of hex. The electrician should write the user’s information and meter number and then import to the power management computer for initial installation so ad to complete the connection of user and management computer. Management computer sends setting of period of time and clock information with the manner of broadcast communication without address information. PC uploads information by the way of calling address. F. Lack Phase detection and relay controlIt can achieve relay control [7] with P27 of AT89LV52. P27 cancontrol relays using 4N25 photoelectricity isolator so as to complete powersupply and power control. Lack Phase detection gets the signal from fan-out of the relay and connects to 1 foot of photoelectricity isolator after passing a 75K resistance, the diode half-wave rectifier and capacitive filtering respectively. We detect the 4 foot of isolator to determine whether there is the lack of phase. If there is lack of phase, we detect again after 2 seconds overtime. We break off the power immediately if there is lack of power after the twice confirmation. In power protection circuit, it uses the INT1 interrupt foot of AT89LV52 to detect signal.When there is a sudden power off, INT1 jumps into a low voltage and the INT1 interrupt enters to the power protection program relying on the energy storage capacitor to save data. In the system, pulse output of AD7752, relay control port and the inputs of lack phase detection all use photoelectric isolator 4N25. It sends electrical signal by light coupling which can enhance the ability of anti-jamming. IV. THE DESIGN OF SOFTWAREA.The distribution of resourceThe software program includes main program, X25045 read and write program, RS485 serial communication program, interrupt serve program, timer handling program,HT1621 display control program, electrical energy measurement in different period of time and power down protection program, and system self-checking andanti-interference handling program. Interrupt resource distribution of system is: INT0 interrupt is used as AD7752 pulse measurement, INT1 as synchronization detecting, timer T0 as 100 ms timing, T1 as 1ms timing, and T2 as baud rate generator for serial communication program. RS485 asynchronous communication is set to receive interrupt and check information for sending.B. Module desighThe flow chart of main program is shown in figure 4. The watt-hourmeter should be able to initialize at each power up time. The initializing program includes setting working mode of timers, serial stomata and interrupts for AT89LV52,writing control word into X25045, S3530A and HT1621. This system sets three periods of time. The singlechip reads clock value from S3530A per second then analyze this clock belongs to which period of time according to advance periods of time set inX25045 then save the electrical energy in RAM memorizer according to corresponding period of time. We write it to corresponding address of X25045 when the electrical energy achieves one degree. The LCD display with 16 bits shows period of time and electrical energy information in turn. Figure 4. Flow chart of main program V. TESTING RESULTError measurement and running test have been made in Zibo Billion Electron Co., Ltd. The epigenous computer completes the setting of time management. There arethree-rate period of time. The first period of time is vale electricity from 00 point 00 minute to 06 point 30 minutes. The second period of time is apex electricity from 06 point 30 minutes to 22 point 30 minutes. The third period of time is smooth electricity from 22 point 30 minutes to 24 point 00 minute. The setting of rate period of time is sent to computer management system by electric power company according to national policy and saved in X25045. The apex electricity, smooth electricity, vale electricity and total electricity per month read saved in electrical energy meter and sent to epigenous computer through cell controller. The communication baud rate is 9600 bits per second. The checkout platform of 0.1 grade standard electronic power meter is used as standard meter and the multi-rate watt-hour meter is the tested meter. Billion Electron Company has carried out testing according to different load running. The measured data is shown in table 1 with the burthen of 30kW.TABLE I. COMPARE OF NORMAL METER AND TESTING METERThe testing result indicates that the error of this multi-ratewatt-hour meter is less than 1%, belongs to 1.0 grade. The return reading of electrical energy is precision and the emendation of time is timely and right. By testing, the method of decreasing errors for electricity metering can be obtained. Firstly, adjust the sampling resistance of AD7752 to accurate value. Secondly, the value of this resistance is needed less varying with temperature. Thirdly, during electricity metering progress, when mantissa portion of electricity is less than0.01, the remaining pulse should be accessed together, thus cumulative error caused by lack of 0.01degree energy loss could be avoided.VI. CONCLUSION AND EXPECTATIONThe multi-rate watt-hour meter achieves electrical energycomputation in different time according to different time setting. It adopts RS485 for serial communication and realizes automatic meter reading and real-time emendation. The results of production in Billion Electron Company showthat the multi-rate three-phase watt-hour meter proposed in this paper has the characteristics of novel design technique, accurate measurement, and flexible time period setting. Various technical indexes achieve the technique standard for national intelligent card watt-hour meter. Therefore, it has wide application. REFERENCES [1] Bu Zhengl iang, Yin Xianggen, Tu Guangyu. “Development of HV Watt-hour meter.” Automation of Electric Power Systems, 2006, 30(19): 89-93.[2] Kosukegawa M., Sakumoto Y. “Traceability system of electric energy standard and tendency in static watthour meter developmen t in Japan.” Sixth International Conference on Metering Apparatus and Tariffs for Electricity Supply, 1990,4: 259-263.[3] Xuehai Li. Applied tutorial of singlechip. Electronic industry publishing company, 2003.[4] Al-Khateeb Tarik, Blundel Martin. “An el ectronic meter for measuring the saving in electrical power.” The Ninth Arab International Conference on Solar Energy (AICSE-9), Kingdom of Bahrain, 2007,4 (209):328-333.[5] Liu Ying, Liu Qingyu. “Development of a self-calibration precision electricalmea suring meter.” Proceedings of the 1998 Conference Precision Electromagnetic Measurements, 1998,7:276.。

附录A 英文原文ULTASONIC RANGING IN AIRG. E. Rudashevski and A. A. GorbatovOne of the most important problems in instrumentation technology is the remote,contactless measurement of distances in the order of 0.2 to 10 m in air.Such a problem occurs,for instance,when measuring the relativethre edimensional position of separate machine members or structural units.Interesting possibilities for its solution are opened up by utilizing ultrasonic vibrations as an information carrier.The physical properties of air,in which the measurements are made,permit vibrations to be employed at frequencies up to 500 kHz for distances up to 0.5 m between a member and the transducer,or up to 60 kHz when ranging on obstacles located at distances up to 10 m.The problem of measuring distances in air is somewhat different from other problems in the a -pplication of ultrasound.Although the possibility of using acoustic ranging for this purpose has been known for a long time,and at first glance appears very simple,nevertheless at the present time there are only a small number of developments using this method that are suitable for practical purposes.The main difficulty here is in providing a reliable acoustic three-dimensional contact with the test object during severe changes in the air's characteristic.Practically all acoustic arrangements presently known for checking distances use a method of measuring the propagation time for certain information samples from the radiator to the reflecting member and back.The unmodulated acoustic(ultrasonic)vibrations radiated by a transducer are not in themselves a source of information.In order to transmit some informational communication that can then be selected at the receiving end after reflection from the test member,the radiated vibrations must be modulated.In this case the ultrasonic vibrations are the carrier of the information which lies in the modulation signal,i.e.,they are the means for establishing the spatial contact between the measuring instrument and the object being measured.This conclusion,however,does not mean that the analysis and selection of parameters for the carrier vibrations is of minor importance.On the contrary,the frequency of the carrier vibrations is linked in a very close manner with the coding method for the informational communication,with the passband of the receiving and radiating elements in the apparatus,with the spatial characteristics of the ultrasonic communication channel,and with the measuring accuracy.Let us dwell on the questions of general importance for ultrasonic ranging in air,namely:on the choice ofa carrier frequency and the amount of acoustic power received.An analysis shows that with conical directivity diagrams for the radiator and receiver,and assuming thatthe distance between radiator and receiver is substantially smaller than the distance to the obstacle,theamount of acoustic power arriving at the receiving area Pr for the case of reflection from an ideal planesurface located at right angles to the acoustic axis of the transducer comes towhere Prad is the amount of acoustic power radiated,B is the absorption coefficient for a plane wave inthe medium,L is the distance between the electroacoustic transducer and the test me -mber,d is the diameterof the radiator(receiver),assuming they are equal,and c~is the angle of the directivity diagram for theelectroacoustic transducer in the radiator.Both in Eq.(1)and below,the absorption coefficient is dependent on the amplitude and not on theintensity as in some works[1],and therefore we think it necessary to stress this difference.In the various problems of sound ranging on the test members of machines and structures,therelationship between the signal attenuations due to the absorption of a planewave and due to thegeometrical properties of the sound beam are,as a rule,quite different.It must be pointed out that the choiceof the geometrical parameters for the beam in specific practical cases is dictated by the shape of thereflecting surface and its spatial distortion relative to some average position.Let us consider in more detail the relationship betweenthe geometric and the power parameters ofacoustic beams for the most common cases of ranging on plane and cylindrical structural members.It is well known that the directional characteristic W of a circular piston vibrating in an infinite baffle is afunction of the ratio of the piston's diameter to the wavelength d/λ as found from the following expression:(2)where Jl is a Bessel function of the first order and α is the angle between a normal to the piston and aline projected from the center of the piston to the point of observation(radiation).From Eq.(2)it is readily found that a t w o-t o-o n e reduction in the sensitivity of a radiator with respectto sound pressure will occur at the angle(3)For angles α≤20.Eq.(3)can be simplified to(4) where c is the velocity of sound in the medimaa and f is the frequency of the radiated vibrations.It follows from Eq.(4)that when radiating into air where c=330 m/s e c,the necessary diameter of the radiator for a spedfied angle of the directivity diagram at the 0.5 level of pressure taken with respect to the fdc 76.05.0≈αaxis can befound to be(5)where disincm,f is in kHz,and α is in degrees of angle.Curves are shown in Fig.1 plotted from Eq.(5)for six angles of a radiator's directivity diagram.The directivity diagrm needed for a radiator is dictated by the maximum distance to be measured and bythe spatial disposition of the test member relative to the other structural members.In order to avoid theincidence of signals reflected from adjacent members onto the acoustic receiver,it is necessary to provide asmall angle of divergence for the sound beam and,as far as possible,a small-diameter radiator.These tworequirements are mutually inconsistent since for a given radiation frequency a reduction of the beam'sdivergence angle requires an increased radiator diameter.In fact,the diameter of the"sonicated"spot is controlled by two variables,namely:the diameter of theradiator and the divergence angle of the sound beam.In the general case the minimum diameter ofthe"sonicated"spot Dmin on a plane surface normally disposed to the radiator's axis is given by(6)where L is the least distance to the test surface. The specified value of Dmin corresponds to a radiator with a diameter(7)As seen from Eqs.(,6)and(7),the minimum diameter of the"sonieated"spot at the maximum requireddistancecannot be less than two radiator diameters.Naturally,with shorter distances to the obstacle the sizeof the"sonicated" surface is less.Let us consider the case of sound ranging on a cylindrically shaped object of radius R.The problem is to measure the distance from the electroacoustic transducer to the side surface of the cylinderwith its various possible displacements along the X and Y axes.The necessary angleαof the radiator'sdirectivity diagram is given in this case by the expression(8) whereα is the value of the angle for the directivity diagram,Ymax is the maximum displacement of the cylinder's center from the acoustic axis,and Lmin is the minimum distance from the center of theelectroacoustic transducer to the reflecting surface measured along the straight line connecting the center ofthe m e m b e r with the center of the transducer.It is clear that when measuring distance,the"running"time of the information signal is controlled by thefd α1400≈fcL d 5.1=fcLD 6min =min maxarcsinL R y +≥αlength of the path in a direction normal to the cylinder's surface,or in other words,the measure distance isalways the shortest one.This statement is correct for all cases of specular reflection of the vibrations from thetest surface.The simultaneous solution of Eqs.(2)and(8)when W=0.5 leads to the following expression:(9) In the particular case where the sound ranging takes place in air having c=330 m/sec,and on theasstunption that L min <<R,the necessary d i a m e t e r of a unidirectional piston radiator d can be found fromthe fomula (10) where d is in cm and f is in kHz. Curves are shown in Fig.2 for determining the necessary diameter of the radiator as a function of theratio of the cylinder's radius to the maximum displacement from the axis for four radiation frequencies.Alsoshown in this figure is the directivity diagram angle as a function of R and Y rnax for four ratios of m i n i m u mdistance to radius.The ultrasonic absorption in air is the second factor in determining the resolution of ultrasonic rangingdevices and their range of action.The results of physical investigations concerning the measurement ofultrasonic vibrations air are given in[1-3].Up until now there has been no unambiguous explanation of thediscrepancy between the theoretical and expe -rimental absorption results for ultrasonic vibrations inair.Thus,for frequencies in the order of 50 to 60 kHz at a temperature of+25oC and a relative humidity of37%the energy absorption coefficient for a plane wave is about 2.5dB/m while the theoretical value is 0.3 dB/m.The absorption coefficient B as a function of frequency for a temperature of+25o Cand a humidity of37%according to the data in[2]can be described by Table 1.The absorption coefficient depends on the relative humidity.Thus,for frequencies in the order of 10 to20kHz the highest value of the absorption coefficient occurs at 20%humidity[3],and at 40%humidity theabsorption is reduced by about two to one.For frequencies in the order of 60 kHz the maximum absorptionoccurs at 30.7o humidity,dropping when it is increased to 98% or lowered to 10%by a factor of approximatelyfour to one.The air temperature also has an appreciable effect on the ultrasonic absorption[1].When thetemperature of the medium is increased from+10 to+30,the absorption for frequencies between 30 and 50kHz increases by about three to one.Taking all the factors noted above into account we arrive at the following approximate values for theabsorption coefficient:at a frequency of 60 kHz /3min =0.15 m -1 and~max=0.5-1;at a frequency of 200 ()maxmin 76.0y L R d +=λmax25fy R d ≈kHz/~min=0.6 m -1 and B max =2 m -1.(11)The values for the minimum~min and rnaxil-num~max"transmittance"coefficients were obtained in thea bsence of aerosols and rain.Their difference is the result of the possible variations in temperature over therange from -3 0 to+50~and in relative hmnidity over the range from 10 to 98%.The overall value ofthe"transmittance"is obtained by multiplying the values of g and 0 for given values of L,f,and d.L I T E R A T U R E C I T E DMoscow(1957).Moscow(1960).附录B 中文翻译在空气中超声测距G. E. Rudashevski and A. A. Gorbatov在仪器技术中远程是最重要的一个问题。

=======大学本科生毕业设计外文文献及中文翻译文献题目: ULTRASONIC RANGING SYSTEM 文献出处: United States Patent译文题目:超声波测距系统学生:指导教师:专业班级:自动化11-4学号: 110601140416电气信息工程学院2014年5月1日超声波测距系统摘要超声波测距系统,是指选择性地激励一个变压器,使之产生换能器驱动信号。

超声换能器发射的超声波脉冲用于响应驱动信号然后接收到一个在超声波信号发出之后的回波信号。

分路开关接在变压器的绕组上,当超声波信号的传输在允许的近距离范围内达到一个稳定的等级,分路开关选择性的闭合来阻止蜂鸣器报警。

第1章发明背景像在宝丽来相机中应用的可用范围测试系统,它们都是准确而且可靠的,但都不适用于近距离测距,举个例子,2到3英寸的距离内就不适用,所以他们在9英寸甚至更远的距离测距是可靠的。

它们可以应用在很多的应用程序中,但不适用于可移动机器人领域内。

机器人通常必须通过门口只有两三英寸的间隙,如果当可移动机器人被操作于避障模式下通过狭小空间,可能机器人的规避路径过于狭窄,此外,规避动作应该使偏指定的路径距离最小化。

近距离测距不用于超声波系统的一个原因是,近距离输出脉冲输出太长以至于它重叠在回波脉冲上,即使输出脉冲缩短,输出脉冲仍然重叠回波脉冲,因为声音紧跟着输出脉冲。

备中产生的回波信号脉冲的范围为100毫伏,但设置传感器响应所必需的电路回声脉冲是大约150伏到300伏之间。

因此即使是最小的声波也会盖过回声信号。

事实上,dual-diode钳位电路用于将150伏降低到二极管的击穿电压,即0.7伏特。

但是这700毫伏足以盖过100毫伏的回波信号。

目前系统需要50毫秒将300伏特的峰值发射电压降到0.7伏特,且额外需要500到600毫秒的时间将它稳定在1毫伏范围。

第2章发明总结本发明可以提供一种改进的超声波测距系统。

本发明也可以提供一个改进的多通道超声波测距系统。

超声波测距摘要:本演示处理了测量距离的超声波传感器在当前环境中的准确性。

作为一个测量传感器的选择SFR08型配备了允许寻址的I ²C 通信接口。

这一事实使得创建传感器阵列变得简单。

控制和可视化系统是基于PC PC。

NI USB 8451是作为通信卡使用的。

验证测量的目标是确定实际的传感器精度,特别是当测量较长的距离。

当评估传感器的精度时,不包括在所测量的数据的温度补偿。

关键词:超声波传感器,I ²C 通信接口,虚拟仪器1 1 简介简介超声波传感器通常用于自动化的任务来测量距离,位置变化,电平测量,如存在检测器或在特殊应用中,例如,当测量透明材料的纯度。

它们是基于测量超声波的传播时间的原则。

这一原则确保可靠的检测是独立的颜色渲染的对象或其表面的设计和类型。

它可以可靠地检测甚至液体,散装材料,透明物体,玻璃等材料。

他们使用的另一个参数是他们在侵略性的环境中使用,不是非常敏感的污垢和测量距离的可能性。

超声波传感器在许多机械设计中被制造。

对于实验室用途,用于发射器和接收器单独或在一个单一的简单的住房,对于工业用途,往往建造坚固的金属外壳。

有些类型允许您使用电位计或数字来调整灵敏度。

此外,输出可以在统一的版本中或直接以数字形式的模拟信号直接中。

就传感器来说,可以通过通信接口连接到PC ,它是可以设置所有传感器的工作范围和测量距离的详细参数。

2 2 超声测量超声测量超声对环境中的声音具有相似的传播特性。

这是机械振动的粒子环境。

超声波可以在气体、液体和固体中传播。

对于超声波通常被认为是一个频率高于20千赫的声音。

千赫的声音。

根据超声波的用途可以分为两类: 主动超声:当应用表现出物理或化学效应。

生成的输出达到更高的值。

超声波用于清洁,焊接,钻孔等。

被动超声;输出是在低得多(通常是小)值产生的对比度。

他的主要应用领域是测量距离,检测材料的缺陷和材料的厚度,测量液体和气体的流量,以及医疗保健的诊断。

Ultrasonic distance and velocity measurement using a pair of LPM signals for cross-correlation method:Improvement of Doppler-shift compensation and examination of Doppler velocity estimation超声波距离和速度利用互相关方法对LPM信号测量:多普勒频移补偿和多普勒速度估计检测的改进数据来源Elsevier Journal Elsevier期刊刊物名Ultrasonics, 2012, Vol.52 (7), pp.873-879 超声波,2012,卷(7),pp.873-879 作者Shinnosuke Hirata, Minoru Kuribayashi Kurosawashinnosuke平田,稔栗林黑泽明单位机械工程与智能系统1,信息工程学院,电子通信,1-5-1 chofugaoka e4-329,,,布,东京182-8585大学,日本信息处理系,跨学科研究生科学与工程学院,东京工业大学,4259首席人事官g2-32,长津田,绿区,横滨,神奈川226-8502,日本AbstractReal-time distance measurement of a moving object with high accuracy and high resolution using an ultrasonic wave is difficult due to the influence of the Doppler effect or the limit of the calculation cost of signal processing. An over-sampling signal processing method using a pair of LPM signals has been proposed for ultrasonic distance and velocity measurement of moving objects with high accuracy and high resolution. The proposed method consists of cross correlation by single-bit signal processing, high-resolution Doppler velocity estimation with wide measurement range and low-calculation-cost Doppler-shift compensation. The over-sampling cross-correlation function is obtained from cross correlation by single-bit signal processing with low calculation cost. The Doppler velocity and distance of the object are determined from the peak interval and peak form in the cross-correlation function by the proposed method of Doppler velocity estimation and Doppler-shift compensation. In this paper, the proposed method of Doppler-shift compensation is improved. Accuracy of the determined distance was improved from approximately within ±140 μm in the previous method to approximately within ±10μm in computer simulations. Then, the proposed method of Doppler velocity estimation is evaluated. In computer simulations, accuracy of the determined Doppler velocity and摘要实时测量移动物体的高精度和高分辨率超声波存在的多普勒效应或信号处理的计算成本的限制的影响。

毕业设计(论文)英文翻译姓名学号0811122121所在学院理学院专业班级2008级光信1班指导教师日期2012年4月20日英文原文1.5 Experimental Setup Due to the many concepts and variations involved in performing the experimentsin this project and also because of their introductory nature Project 1 will very likelybe the most time consuming project in this kit. This project may require as much as 9hours to complete. We recommend that you perform the experiments in two or morelaboratory sessions. For example power and astigmatic distance characteristics maybe examined in the first session and the last two experiments frequency andamplitude characteristics may be performed in the second session. A Note of Caution All of the above comments refer to single-mode operation of the laser which is avery fragile device with respect to reflections and operating point. One must ensurethat before performing measurements the laser is indeed operating single-mode.This can be realized if a single broad fringe pattern is obtained or equivalently a goodsinusoidal output is obtained from the Michelson interferometer as the path imbalanceis scanned. If this is not the case the laser is probably operating multimode and itscurrent should be adjusted. If single-mode operation cannot be achieved by adjustingthe current then reflections may be driving the laser multimode in which case thesetup should be adjusted to minimize reflections. If still not operating single-modethe laser diode may have been damaged and may need to be replaced. Warning The lasers provided in this project kit emit invisible radiation that can damagethe human eye. It is essential that you avoid direct eye exposure to the laser beam.We recommend the use of protective eyewear designed for use at the laser wavelengthof 780 nm. Read the Safety sections in the Laser Diode Driver Operating Manual and in thelaser diode section of Component Handling and Assembly Appendix A beforeproceeding.1.5.1 Semiconductor Diode Laser Power Characteristics1. Assemble the laser mount assembly LMA-I and connect the laser to its powersupply. We will first collimate the light beam. Connect the laser beam to a videomonitor and image the laser beam on a white sheet of paper held about two to tencentimeters from the laser assembly. Slowly increase the drive current to the laser andobserve the spot on the white card. The threshold drive current rating of the laser issupplied with each laser. Increase the current to about 10-20 mA over the thresholdvalue. With the infrared imager or infrared sensor card observe the spot on the card andadjust the collimator lens position in the laser assembly LMA-I to obtain a bright spoton the card. Move the card to about 30 to 60 centimeters from the lens and adjust thelens position relative to the laser to obtain a spot where size does not vary stronglywith the position of the white card. When the spot size remains roughly constant asthe card is moved closer or further from the laser the output can be consideredcollimated. Alternatively the laser beam may be collimated by focusing it at adistance as far away as possible. Protect fellow co-workers from accidental exposureto the laser beam.2. Place an 818-SL detector on a post mount assembly M818 and adjust its positionso that its active area is in the center of the beam. There should be adequate opticalpower falling on the detector to get a strong signal. Connect the photodetector to thepower meter 815. Reduce the background lighting room lights so that the signalbeing detected is only from the laser. Reduce the drive current to a few milliamperesbelow threshold and again check to see that room light is not the dominantsignal atthe detector by blocking the laser light.3. Increase the current and record the output of the detector as a function of laser drivecurrent. You should obtain a curve similar to Figure 1.2. If desired the diodetemperature may also be varied to observe the effects of temperature on thresholdcurrent. When examining laser diode temperature characteristics the laser diodedriver should be operated in the constant current mode as a safeguard againstexcessive currents that damage the diode laser. Note that as the diode temperature isreduced the threshold decreases. Start all measurements with the diode current off toprevent damage to the laser by preventing drive currents too high above threshold.To prevent destruction of the laser do not exceed the stated maximum drive current ofthe laser.1.5.2 Astigmatic Distance Characteristics The laser diode astigmatic distance is determined as follows. A lens is used tofocus the laser beam at a convenient distance. A razor blade is then incrementallymoved across the beam to obtain data for total optical power passing the razor edge vs.the razor blade position. A plot of this data produces an integrated power profile of thelaser beam Figure 1.9a which through differentiation exposes the actual powerprofile Figure 1.9b which in turn permits determination of the beam diameter W.A beam diameter profile is obtained by measuring the beam diameter while varyingthe laser position. Figure 1.9c illustrates the two beam diameter profiles of interest:one for razor edge travel in the direction perpendicular to the laser diode junctionplane and the other for travel in the direction parallel to the junction plane. Theastigmatic distance for a laser diode is the displacement between the minima of thesetwo profiles. This method is known as the knife edge technique.1. Assemble the components shown in Figure 1.8 with the collimator lens LC in therotational stage assembly RSA-I placed roughly 1 centimeter away from the laser.The beam should travel along the optic axis of the lens. This is the same lens used incollimating the laser in the previous setup. The approximate placement of all thecomponents are shown in the figure. Make sure that the plane of the diode junctionxz plane in Figure 1.1 is parallel with the table surface.2. Due to the asymmetric divergence of the light the cross-section of the beamleaving the laser and further past the spherical lens is elliptical. The beam thus hastwo distinct focal points one in the plane parallel and the other in the planeperpendicular to the laser diode junction. There is a point between the two focalpoints where the beam cross-section is circular. With the infrared imager and a whitecard roughly determine the position where the beam cross-section is circular. Figure 1.9 – Procedure for finding astigmatic distance.3. Adjust the laser diode to lens distance such that the razor blades are located in thexy plane where the beam cross-section is circular.4. Move the laser diode away from the lens until minimum beam waist is reached atthe plane of razor blades. Now move the laser diode about 200 m further away fromthe lens.5. Move razor blade 1 in the x direction across the beam through the beam spreadθxand record the x position and detected intensity at each increment ≤100 mincrements. The expected output is shown in Figure 1.9. The derivative of this curveyields the intensity profile of the beam in the x direction from which the beamdiameter is determined.6. Repeat with razor blade 2 for θy in the y direction.7. Move the laser closer to the lens in increments ≤50 m through a total of at leastthan 500m. Repeat Steps 5 and 6 at each z increment recording the z position.8. Using the collected data determine the beam intensity profiles in the x and ydirections as a function of the lens position z. This is done by differentiating each dataset with respect to position. Then calculate the beam diameter and plot as a functionof z. The difference in z for the minimum in θx and θy isthe astigmatic distance of thelaser diode. Use of computer software especially in differentiating the data is highlyrecommended. If the laser junction is not parallel to the table surface then for eachmeasurement above you will obtain an admixture of the two beam divergences andthe measurement will become imprecise. If the laser is oriented at 45° to the surfaceof the table the astigmatic distance will be zero. Different laser structures will have different angular beam divergences and thusdifferent astigmatic distances. If you have access to several different laser types gainguided index guided it may be instructive to characterize their astigmatic distances.1.5.3 Frequency Characteristics of Diode Lasers In order to study frequency characteristics of a diode laser we will employ aMichelson interferometer to convert frequency variations into intensity variations. Anexperimental setup for examining frequency and also amplitude characteristics of alaser source is illustrated in Figure 1.10.1. In this experiment it is very possible that light may be coupled back into the laserthereby destabilizing it. An optical isolator therefore will be required to minimizefeedback into the laser. A simple isolator will be constructed using a polarizing beamsplitter cube and a quarterwave plate. We orient the quarterwave plate such that thelinearly polarized light from the polarizer is incident at 45° to the principal axes of thequarterwave plate so that light emerging from the quarterwave plate is circularlypolarized. Reflections change left-circular polarized light into right-circular or viceversa so that reflected light returning through the quarterwave plate will be linearlypolarized and 90° rotated with respect to the polarizer transmission axis. The polarizerthen greatly attenuates the return beam. In assembling the isolator make sure that the laser junction xz plane in Figure1.1 is parallel to the surface of the table the notch on the laser diode case pointsupward and the beam is collimated by the lens. The laser beam should be parallel tothe surface of the optical table. Set the polarizer and quarterwave λ/4 plate in place.Place a mirror after the λ/4 plate and rotate the λ/4 pl ate so that maximum rejectedsignal is obtained from the rejection port of the polarizing beam splitter cube asshown in Figure 1.11. When this signal is maximized the feedback to the laser shouldbe at a minimum.2. Construct the Michelson interferometer as shown in Figure 1.12. Place the beamsteering assembly BSA-II on the optical table and use the reflected beam from themirror to adjust the quarterwave plate orientation. Set the cube mount CM on theoptical breadboard place a double sided piece of adhesive tape on the mount and putthe nonpolarizing beam splitter cube 05BC16NP.6 on the adhesive tape. Next placethe other beam steering assembly BSA-I and the detector mountM818BB inlocation and adjust the mirrors so that the beams reflected from the two mirrorsoverlap at the detector. When long path length measurements are made the interferometer signal willdecrease or disappear if the laser coherence length is less than the two wayinterferometer path imbalance. If this is the case shorten the interferometer until thesignal reappears. If this does not work then check the laser for single-mode operationby looking for the fringe pattern on a card or by scanning the piezoelectric transducerblock PZBin BSA-II and monitoring the detector output which should be sinusoidalwith PZB scan distance. If the laser does not appear to be operatingsingle-moderealign the isolator and/or change the laser operating point by varying the bias current.Additionally to ensure single-mode operation the laser should be DC biased abovethreshold before applying AC modulation. Overdriving the laser can also force it intomultimode operation.3. The Michelson interferometer has the property that depending on the position of themirrors light may strongly couple back toward the laserinput port. In order to furtherreduce the feed-back slightly tilt the mirrors as illustrated in Figure 1.13. If stillunable to obtain single-mode operation replace the laser diode.4. Place a white card in front of the detector and observe the fringe pattern with theinfrared imager. Slightly adjust the mirrors to obtain the best fringe pattern. Try toobtain one broad fringe.5. Position the detector at the center of the fringe pattern so that it intercepts no morethan a portion of the centered peak.6. By applying a voltage to the piezoelectric transducer block attached to the mirrorpart PZB in one arm of the interferometer i.e. BSA-II maximize the outputintensity. The output should be stable over a time period of a minute or so. If it is notverify that all components are rigidly mounted. If they are then room air currents maybe destabilizing the setup. In this case place a box cardboard will do over the setupto prevent air currents from disturbing the interferometer setup.7. Place the interferometer in quadrature point of maximum sensitivity betweenmaximum and minimum outputs of the interferometer by varying the voltage on thePZB.8. The output signal of the interferometer due to frequency shifting of the laser isgiven by I∝φ 2π/c L ν where L is the difference in path length b etween thetwo arms of the interferometer and ν is the frequency sweep of the laser that isinduced by applying a current modulation. Remember that in a Michelsoninterferometer L is twice the physical difference in length between the arms sincelight traverses this length difference in both directions. L values of 3-20 cmrepresent convenient length differences with the larger L yielding higher outputsignals. Before we apply a current modulation to the laser note that the interferometeroutput signal I should be made larger than the detector or laser noise levels byproper choice of L and current modulation amplitude di. Also recall from Section1.3that when the diode current is modulated so is the laser intensity as well as itsfrequency. We can measure the laser intensity modulation by blocking one arm of theinterferometer. This eliminates interference and enables measurement of the intensitymodulation depth. We then subtract this value from the total interferometer output todetermine the true dI/di due to frequency modulation. Apply a low frequency smallcurrent modulation to the laser diode. Note that when the proper range is beingobserved 1 dv 10 5 mA 1 v diand 1 dI 0.2mA 1 I difor the amplitude change only.RecallingdI d(Δφ)2π Δv c dI ∝ΔL 10 5 mA 1 di di cΔi 2πΔLv diordI ΔL 2Kπ mA 1di λ10 -5where K is a detector response constant determined by varying L.9. With the interferometer and detection system properly adjusted vary the drivefrequency of the laser and obtain the frequency response of the laser Figure 1.4 or1.10a.You will need to record two sets of data: i the modulation depth of theinterferometer output as a function of frequency and ii the laser intensitymodulation depth. The difference of the two sets of collected data will provide anestimate of the actual dI/di due to frequency modulation. Also note that if the currentmodulation is sufficiently small and the path mismatch sufficiently large the laserintensity modulation may be negligible. You may need to actively keep theinterferometer in quadrature by adjusting the PZB voltage. Make any necessary function generator amplitude adjustments to keep thecurrent modulation depth of the laser constant as you vary the frequency. This isbecause the function generator/driver combination may not have a flat frequencyresponse. The effect of this is that the current modulation depth di is not constant andvaries with frequency. So to avoid unnecessary calculations monitor the current.。

毕业设计(论文)外文参考资料及译文译文题目:Ultrasonic distance meter超声波测距仪学生姓名:张宪旺学号: 1004104013 专业:自动化所在学院:机电工程学院指导教师:赵国树职称:讲师2014年01月08日超声测距系统设计原文出处:传感器文摘布拉福德:1993年第13页摘要:超声测距技术在工业现场、车辆导航、水声工程等领域都具有广泛的应用价值,目前已应用于物位测量、机器人自动导航以及空气中与水下的目标探测、识别、定位等场合。

因此,深入研究超声的测距理论和方法具有重要的实践意义。

为了进一步提高测距的精确度,满足工程人员对测量精度、测距量程和测距仪使用的要求,本文研制了一套基于单片机的便携式超声测距系统。

关键词:超声波,测距仪,单片机1、前言随着科技的发展,人们生活水平的提高,城市发展建设加快,城市给排水系统也有较大发展,其状况不断改善。

但是,由于历史原因合成时间住的许多不可预见因素,城市给排水系统,特别是排水系统往往落后于城市建设。

因此,经常出现开挖已经建设好的建筑设施来改造排水系统的现象。

城市污水给人们带来了困扰,因此箱涵的排污疏通对大城市给排水系统污水处理,人们生活舒适显得非常重要。

而设计研制箱涵排水疏通移动机器人的自动控制系统,保证机器人在箱涵中自由排污疏通,是箱涵排污疏通机器人的设计研制的核心部分。

控制系统核心部分就是超声波测距仪的研制。

因此,设计好的超声波测距仪就显得非常重要了。

2、超声波测距原理2.1压电式超声波发生器原理压电式超声波发生器实际上是利用压电晶体的谐振来工作的。

超声波发生器内部结构,它有两个压电晶片和一个共振板。

当它的两极外加脉冲信号,其频率等于压电晶片的固有振荡频率时,压电晶片将会发生共振,并带动共振板振动,便产生超声波。

反之,如果两电极间未外加电压,当共振板接收到超声波时,将压迫压电晶片作振动,将机械能转换为电信号,这时它就成为超声波接收器了。

Piezoelectric sensor determination of arterial pulse wave velocityArterial pulse wave velocity (APWV) is a measure of the elasticity (or stiffness) of peripheral arterial blood vessels. The pulse referred to here will be the pressure pulse as opposed to the flow pulse measured by ultrasound Doppler.The pressure pulse velocity varies over the range from about 12 m s?1 to15 m s?1 in stiff peripheral arteries, whereas in normal arteriesit has a velocity in the range of 7 to 9 m s?1.The aim of this project was the development of a fast and easy to use system for the determination of peripheral arterial pulse wave velocity. The principle of the PWV measurement is based on simultaneous measurement of two pulse waves at two different positions, such as the radial artery at the wrist and the brachial artery just above the elbow. By determining the pulse transit time between these points and the distance measured between the two locations, pulse wave velocity may then be calculated. The pressure pulse detection is done by using two piezoelectric sensors which generate a measurable voltage at the output contacts if they are mechanically deformed. The deformation produced voltage is first amplified and filtered and then digitalized with a data acquisition card. The analysis of the data obtained from the sensors includes a filtering process, the calculation of the PWV with three different methods— foot-to-foot, cross-correlation and peak-to-peak—and the determination of the arterial pulse rate.Extensive measurements with human test subjects were carried out to optimize the techniques of data acquisition and analysis. For example, it was found that the best procedure was to hold the sensors in place using elastic straps alone. The data analysis was upgraded with an additional software module, which deletes, in effect, outriders or invalid measurements. With the optimized system, a series involving eight test subjects ranging in age from 22 to 32 years was completed (all normotensive). The arterial pulse wave velocities determined covered a range from 6 m s?1to 12 m s?1, with an average standard deviation of less than 2.5 m s?1for individual results. These areslightly higher,but close to published APWV data. The results showedthat reproducible results can be obtained with the existing PWV acquirement and analysis system.The measurement of arterial pulse wave velocity (APWV) is one of the methods used to measure physiological changes in peripheral vascular disease. Others include pressure pulse contour, arterial elasticity, pulsatile flow, complex vascular impedance and cardiac work.There have been many investigations over the past 30 years or so to relate changes in age and progress of arterial disease, to vessel pathology and distensibility based on the propagation characteristics of the arterial pulse (Malindzak and Meredith 1970, McCormack 1981, Persson et al 2001, Ramsey 1995, Wilkinson 1998). They have only been partially successful from a clinical point of view, mainly due to the difficulty in controlling the effects of patient parameters (autonomic system, patient movement, etc).Early on, the methods of determining APWV involved direct invasive measurement of the pulse pressure at two points along anarterial segment and measuring the time taken for the pulse to travelthe length of the segment. Such investigations had to be limited to animals usually dogs.The sensor technique used in this work involves the piezoelectric effect in polyvinyllidene fluoride (PVDF), which produces an output voltage in response to mechanical pressure on the material.Three methods of APWV determination are used: foot-to-foot APWV; peak-to-peak APWV and cross-correlation APWV. The FFAPWV and CCAPWV methods are less sensitive to pressure wave reflections at bifurcations, etc in the arterial tree, than the PPAPWV method. Mean values and standard deviations were computed for all three methods and compared.‘Foot-to-foot’ APWV (FFAPWV). This is based on the velocity of the ‘foot’, or leading edge, of the pressure pulse wave. The ar rival times of the foot of the pulse wave at two positions along the artery are recorded. If Δt is the difference in arrival times and Δs the distance between the two recording positions (proximal and distal), the FFAPWV is simplyFFAPWV = Δs/Δt.‘Peak-to-peak’ APWV (PPAPWV). This is completely analogous to the FFAPWV except that the points of observation are the two (proximal and distal) peaks of the pulse wave andPPAPWV = Δs/Δt.Apparent pulse wave velocity (AAPWV). The pressure wave may be represented as aFourier series,P(t) = P0 +Pn sin(nωt + θn)Where P0 is the mean fluid pressure, n is the harmonic number, Pnis the amplitude of the nth harmonic and θn is the phase angle of the nth harmonic.The spatial rate of change of the phase for one harmonic based on two simultaneous pressure measurements separated by a distance _s along an artery, is related to the apparent arterial pulse wave velocity (AAPWV) by the following equation,AAPWVn = (Δs)n(f )(360o)/(θx1? θx2)Where AAPWV n is the apparent pulse wave velocity for the nth harmonic, f is the heart rate,θx1 is the phase angle for the proximal harmonic n and θx2 is the phase angle for the distal harmonic n.Cross-correlation PWV. If the arterial pulse at the proximal measurement position is represented by the pressure time series P(x1, t) and that at the distal position by P(x2, t) andthe cross-correlation coefficient is Φx1,x2(τ ), then Φwill have a maximum value at some time lag.The correlation function can be expressed asΦx1,x2(τ ) = (1/T )P(x1, t)P(x2, t) dt.The value of τ at which maximum correlation occurs represents the transit time (_t) of the pressure wave from position x1 to position x2 along the arterial segment. From the separation distance and transit time data the correlation arterial pulse wave velocity isCCAPWV = (x2 ? x1)/ Δt.In this work normal, young test subjects were used, and it has the primary objectives of optimizing the measurement procedures and establishing the statistical spread and mean values of the observed PWVs for a specific peripheral arterial segment. Based on this, it is planned to use the system in clinical trials involving patients with peripheral arterial disease (due to diabetes, hypertension, etc), pre-, during and post treatment (pharmaceutical or surgical).Analogue and digital circuitryAnalogue charge amplifier. Piezoelectric materials convert mechanical stress or strain into proportionate electrical energy, by producing a charge when subjected to mechanical stress. The charge is converted to a voltage by an operational amplifier connected as a current integrator, called a charge amplifier. The signal output of the amplifier is approximately ?30 mV. It is augmented by signal amplification.Analogue signal amplification . This is done by use of an inverting amplifier. Because a dc signal appears at the output of the chargeamplifier, dc offset removal is essential and is implemented in the inverting summingThe next phase of the analogue circuitry is a low pass filter to remove the 50 Hz noise interference.Digital controlled data acquisition and analysis. A dataacquisition board (DAQ) is required when the transducer signals need interfacing with a PC. The board contains 12 bit plus sign and a successive approximation and self-calibrating analogue-to-digital (ADC) converter. The ADC incurs a systematic error known as the quantization error. It is due to limited resolution and with the analogue input limit set at ?5 to +5 V, the quantization error of the A/D converter used here was calculated to be 0.122 mV.The data acquisition and analysis was done using Lab View—a powerful instrumentation and analysis programming language for PCs.Digital data acquisition program. The data acquisition circuit performs all the necessary operations for the data acquisition with Lab View. The functions of the circuit initialize the data acquisition and read the data from the acquisition card. These data are stored for later use in the data analysis part of the program.Lab View programs are called virtual instruments (VIs) because of their appearance and operations are analogous to measuring instruments.A VI that is called within another VI is called a sub-VI and is analogous to a subroutine in text-based languages.The data acquisition, analysis and presentation are comprised of three main procedures:(1) Data acquisition card to interface the hardware to the PC.(2) Data acquisition program to acquire and store data in a spreadsheet file.(3) Data analysis to carry out digital signal processing, calculate PWV and present results.PWV Calculation1. PWV calculation using peak detection. To calculate PWV using peaks, the location of the peaks must first be determined, so that the transit time of the wave between the peaks can be determined. It was found that the best method of peak detection is the derivative of the curve method. If the first derivative of a curve is zero, then an extreme value can exist—eithera peak or a turning point. It is necessary to take the second derivative at this point—if this is also zero, then an extreme value exists. The second VI used to determine the PWV is PWVcalc, using the time separation between the located peaks.2. PWV with pressure wave foot detection. The VI named PWV Foot determines the leading edge (foot) of the pressure wave at the upstream and downstream locations. The VI named PWVcalc is again used to compute the PWV from the time separation between the two leading edges (‘foot-to-foot’ APWV or FFAPWV).3. PWV with cross-correlation. The PWV determination with cross-correlation is done with the VI named CalcPWV. The VI is in two parts: a part for the initialization function and a part for the calculation of the CCAPWV.In all cases PWV values are assembled in an array and the mean value, standard deviation and variance are calculated.Sensor positioningSensor placement is critical to obtaining consistent measurements.A screw mechanism was first used to apply the sensors to the skin. But readings were very variable and so this technique was replaced by that in which the sensors are fixed to the skin by elastic strips. This led to better results.。

The Design of Ultrasonic Distance Measurement System Basedon S3C2410Hongjiang He Jianyi LiuCollege of Information and Electrical Engineering, Hebei University ofEngineering, Handan, Hebei Provice,China, 056038E-mail:liujianyi2002@AbstractThe system introduces the composition of the ultrasonic distance measuring system based on S3C2410 and gives the operation principle and procedure design method. The module of temperature compensation circuit has been added to hardware circuit to improve the precision. S3C2410 drive transducer sent a 40kHz square wave signal, opening the external interrupt and triggerring timer interrupt, The external interrupt receive echo signal immediately triggerring the timer to obtain ranging value. The ranging value is real-time displayed through the LCD.The structure of ultrasonic measuring module driver program is analyzed in embedded Linux system. The system can be used for the distance measurement parameters needed for a variety of application occasions.1. IntroductionWith the development of modern industry, the ultrasonic detection technology has won increasingly widely application. The ultrasonic Distance Measurement is a non-contact detection which is using a directional can be fired, point of the good features, combined with electronic technology such as micro-electronics technology to achieve. It can not be affected by factors such as light, electromagnetic waves and dust. The information processing is simple,low cost and fast. It’s widely used by robotic and automatic applications, the obstacle avoidance, vehicle positioning and the navigation, liquid level measurement and so on.2. Ultrasonic Distance Measurement System Principle2.1. Principle of piezoelectric ultrasonic sensorsThe development of ultrasonic device using of the physical characteristics and the various effects of the ultrasound in the field of ultrasound is called the ultrasonic transducer, the detector or sensor. The ultrasonic transducer can be divided into piezoelectric and electromagnetic type and so on by its operation principle. The piezoelectric is the most commonly used.Actually, Piezoelectric ultrasonic generator is using piezoelectric crystal resonator to work. There are two internal ultrasonic piezoelectric generator chips and are sonance board, when it polarized plus pulse signal and the frequency is equivalent of the inherent oscillation frequency of the piezoelectric film, piezoelectric films will be in resonance, and resonance driven plate vibration, creates ultrasonic. Conversely,if the two do not applied voltage between electrodes,when the board received ultrasonic resonance, the chip will be oppressed for piezoelectric vibration, mechanical energy is transformed into electrical signals, and then it becomes ultrasonic receiver.2.2. Ultrasonic Distance Measurement PrincipleUltrasonic Distance Measurement Principle of the system uses transit time method, that isS=1/2vtAmong them, S is the distance between the obstacles and the sensor, t is the time difference, v isthe acoustic propagation velocity. The relationship between v and temperature is as follows:T is the absolute temperature.V0 =331.4m/s. In normal circumstances ultrasonic is similar to the speed of sound velocity, under the influence of the indoor temperature is of about 340 m/s.3. System Design3.1. System ComponentsThe core of the plan is based on Samsung's S3C2410. By software programming, the plan achieves the chip timely control of peripheral circuits, and provides all the necessary signals to peripheral circuits,including frequency oscillation signal, signal and data processing translation Code display signals and so on and greatly simplifies the design of the peripheral circuit difficult, but it is even more important that the design significantly saves design cost, and because of the software programming technology, it has the good performance transplantation and can be more functional design into account in the design of circuit.The efficiency of the dissemination of the frequency of about 40kHz ultrasound is the best. The ultrasound was launched into 40 kHz modulation about with a certain interval pulse modulation signals. The Ranging System structure is shown in Figure 1, the system consists of measuring system, the control and display components.Fig. 1 component diagram of the system3.2. Ultrasonic Transmitter CircuitUltrasonic transmitter circuit schematic shows in Fig 2. The output drive circuitof the transducer is powered directly by 9V battery, and providing 18V voltage to driver the ultrasonic transducer. The birdge circuit which is formed by six reversers produced the18V voltage, One side provides driver phase shift signal, the other side is drived by reverse signal.Setting the output voltage amplitude double, and the18V is sent to transducer in the form of push-pull. Two reverse parallel to each side can provide sufficient current to drive transducer. Because the working voltage of CD4049 is 9V, the S3C2410 output voltage is 3.3V. The logic level does not match between S3C2410 and output drive circuit. The triode Q1 solves this problem.Fig 2. ultrasonic transmitter circuit3.3. Ultrasonic Receiver CircuitThe IC CX20106A is a dedicated chip for the receiving of infrared detector, which is widely used in the TV infra-red remote control receiver, taking into account its 38kHz of the carrier frequency, which is relatively close ultrasonic frequency. We can use it to produce ultrasonic detection receiver circuit, as shoun.It was proved that the CX20106A receive ultrasonicwith high sensitivity and a strong anti-jamming capability. The sensitivity and anti-jamming capability of receiver circuit can be changed by appropriate changing the size of capacitor C4. The ultrasonic receiver circuit schematic is shown in Fig 3.Fig 3. ultrasonic receiver circuit.3.4. Temperature ModuleThe design of the temperature module is using sensor DS18B20 as detection devices which isproduced by DALLAS semiconductor company in America. Temperature rangeis -55~125. Themaximum resolution is 0.0625. and The measured temperature can be directly read out. DS18B20 can connect with ARM by three-wire system, which decreases the external hardware circuit, with the characteristics of low-cost and ease to using.4. Ultrasonic Distance Measurement Module Driver DesignDevice driver is the interface between the operating system kernel and the hardware. Because of the protection of the operating system, applications for all hardware system must be visited by drivers. For application procedures, the hardware is not transparent;it must be driven by the corresponding procedure defined in the driver communication interface (write,read, ioctl, etc.) to achieve the operation of the hardware. Ultrasonic sensor equipment is the read-only characters in Linux system, it is only a response to the application of ultrasonic drive transmission control parameters, and the driven procedures have completed specific distance measurement, and the application procedures in the state users read ultrasonic equipment,receiving obstacles information from different orientations.Fig 4. The role of Linux Driver4.1. Device Driver InterfaceThe access equipment of Linux system is like a file,the characters device uses struck file operationstructure to define various operational equipment set of equipment. The structure of the various functions were similar response to the same name or the name of the system call, it is a function of operating peripheral interface, also called the device driver interface.Procedures for the preparation of character device driver are designed to achieve the various functions of struct file_operation. Of course, the driver is not to achieve all of these functions may be based on the real equipment need to achieve the necessary function.Ultrasonic sensor device driver file_operation was defined as follows:struct file operations s3c2410_sonar_fops={Owner: THIS_MODULE,Open: s3c2410_sonar_open,Read: s3c2410_sonar_read,Write: s3c2410_sonar_write,Release: s3c2410_sonar_release,Ioctl: s3c2410_sonar_ioctl,};From the function interface, we can achieve opening, reading, writing, releasing and controlling ofthe ultrasonic sensor device.4.2. Initialization and Uninstall ModuleThe Module initialization function int s3c2410_sonar_init(void) is the essential processing functions in the process of developing module,it is used for the initialization of device, interrupt initialization and handling, equipment registration and so on. In this function, through the register_chrdev(0,DEVICE_NAME, & s3c2410_sonar_fops), we realize characters device applications and use the core dynamic way to the distribution device. When the device is opened, Ultrasonic sensor device was initialization, achieving the bundled interrupt handling,interrupt application and interrupt initialization, avoid each initialization equipment related to a interrupt ofoperations.Static void s3c2410_sonar_exit(void) function is one of the essential functions in the development of the driver module, it is used to for unload at the interrupt stopped, the release of resources, and so on. At the same time the characters device was unregistered,Device unregistered from unregister_chrdev (Major,DEVICE_NAME) statement completion.4.3. Interrupt HandlingModules used the idea combined the timer ofARM9 and external interrupt, and used a timer readable numerical functions. The interrupt handling procedures used timer_isr(), eint_isr() function to achieve distance measured process. The initialization,configuration parameters and interrupt bind of timer and external interrupt relevant register are completed in interface function s3c2410_sonar_open().The cycle of the timer is 60ms, which is sufficient to received trigger external interrupt echo occurred.External interrupt completed the store of the numerical time. Through the detection which is higher or low interval of the s3c2410 specific I/O port to store thetime corresponding to the storage area. Timer interrupt completes the distance calculation; judges whether it exceeds the precise scope of distance measurement, and starts the next operation. By initiating the next time sensor of numerical values to calculate the distance, which is corresponding to the storage area,the time records and ranging array are composed of storage area.4.4. Device open, release and control FunctionThese functions fill the s3c2410_sonar_fops structure and realize the operation of ultrasonic sensor device. s3c2410_sonar_open() function is used to open the device, the Acer MOD_INC_USE_COUNT increases the driver modules reference count,request_irq() function is application for the installation of the timer and eint interrupt service procedures.Followed by complete storage area array, control port,timer and external interrupt register parameters initialization, Calling init_isr() to achieve the interrupt parameter setting and interrupt enabled. The function s3c2410_sonar_release()completes interrupt release, MOD_DEC_USE_COUNT Acer reduce driver modules reference count. s3c2410_sonar_ioctl() is major used to control ultrasonic device timer interrupt and the value of distance. Linux application ioctl() function uses sonar() function accepting the value of distance, specific using copy_to_user() or put_user()kernel functions to achieve data transfer.The working principle of the ultrasonic sensor device in embedded Linux systems: opening equipment in the application procedures. Being made real-time response according to the actual situation,through the ioctl() control accessing to the corresponding position value of distance, andachieving a core state and users state data transfer.5. ConcludeThe software and hardware design of Ultrasonic Distance Measurement System was achieved in theS3C2410 + Linux platform. The ultrasonic sensor devices of device driver structure and the development process was detailed analysis in embedded Linux. The driver module is designed. This Ultrasonic Distance Measurement System is an ideal non-contact proximity measurement method, which can be widely used in the shape measurement, control and vehicle location and orientation aspects of industrial robots.6. References1. Johathan Corbet, Alessandro Rubini, Greg Kroab-Hatman.Linux Device Drivers[M]. Beijing: China electric PowerPress. 2005. 46-74.2. Cai Yanping, Cheng Shu, etc. Ultrasonic DistanceMeasuring System Based on Embeded SPT-K Controller.Measurement and control Technique. 2005,vol. 24, NO,3.3. Li Ping. Error analyses and anti-interference measurementof the ultrasonic liquit level measuting instrument.Technology & Economy in Areas of Communications. 2006.4. Zhou Kai, Zhao Wangda, Zhao Di. A High PrescisionUltrasonic Telemeter System. Test Technology. 2007.5. Figneroa JF, Lam ancusa JS. A method for accuratedetection of time of arrival : analysis and design of anultrasonic ranging system. J. Acoust. Soc. Am[J], 1992.47。

原文:Ultrasonic distance meterDocument Type and Number:United States Patent 5442592Abstract:An ultrasonic distance meter cancels out the effects of temperature and humidity variations by including a measuring unit and areference unit. In each of the units, a repetitive series of pulses is generated, each having a repetition rate directly related to therespective distance between an electroacoustic transmitter and an electroacoustic receiver. The pulse trains are provided to respective counters, and the ratio of the counter outputs is utilized to determinethe distance being measured.Publication Date:08/15/1995Primary Examiner:Lobo, Ian J.BACKGROUND OF THE INVENTIONThis invention relates to apparatus for the measurement of distanceand, more particularly, to such apparatus which transmits ultrasonicwaves between two points.Precision machine tools must be calibrated. In the past, this has been accomplished utilizing mechanical devices such as calipers,micrometers, and the like. However, the use of such devices does notreadily lend itself to automation techniques. It is known that thedistance between two points can be determined by measuring the propagation time of a wave travelling between those two points. Onesuch type of wave is an ultrasonic, or acoustic, wave. When anultrasonic wave travels between two points, the distance between thetwo points can be measured by multiplying the transit time of the waveby the wave velocity in the medium separating the two points. It istherefore an object of the present invention to provide apparatusutilizing ultrasonic waves to accurately measure the distance betweentwo points.When the medium between the two points whose spacing is being measured is air, the sound velocity is dependent upon the temperature andhumidity of the air. It is therefore a further object of the,presentinvention to provide apparatus of the type described which isindependent of temperature and humidity variations.SUMMARY OF THE INVENTIONThe foregoing and additional objects are attained in accordance withthe principles of this invention by providing distance measuringapparatus which includes a reference unit and a measuring unit. The reference and measuring units are the same and each includes an electroacoustic transmitter and an electroacoustic receiver. Thespacing between the transmitter and the receiver of the reference unitis a fixed reference distance, whereas the spacing between thetransmitter and receiver of the measuring unit is the distance to be measured. In each of the units, the transmitter and receiver are coupled by a feedback loop which causes the transmitter to generate an acoustic pulse which is received by the receiver and converted into an electrical pulse which is then fed back to the transmitter, so that a repetitive series of pulses results. The repetition rate of the pulsesis inversely related to the distance between the transmitter and the receiver. In each of the units, the pulses are provided to a counter. Since the reference distance is known, the ratio of the counter outputs is utilized to determine the desired distance to be measured. Since both counts are identically influenced by temperature and humidity variations, by taking the ratio of the counts, the resultant measurement becomes insensitive to such variations.BRIEF DESCRIPTION OF THE DRAWINGSThe foregoing will be more readily apparent upon reading the following description in conjunction with the drawing in which the single FIGURE schematically depicts apparatus constructed in accordance with the principles of this invention.DETAILED DESCRIPTIONReferring now to the drawing, there is shown a measuring unit 10 and a reference unit 12, both coupled to a utilization means 14. The measuring unit 10 includes an electroacoustic transmitter 16 and an electroacoustic receiver 18. The transmitter 16 includes piezoelectric material 20 sandwiched between a pair of electrodes 22 and 24. Likewise, the receiver 18 includes piezoelectric material 26 sandwiched between a pair of electrodes 28 and 30. As is known, by applying an electric field across the electrodes 22 and 24, stress is induced inthe piezoelectric material 20. If the field varies, such as by the application of an electrical pulse, an acoustic wave 32 is generated.As is further known, when an acoustic wave impinges upon the receiver 18, this induces stress in the piezoelectric material 26 which causesan electrical signal to be generated across the electrodes 28 and 30. Although piezoelectric transducers have been illustrated, other electroacoustic devices may be utilized, such as, for example, electrostatic, electret or electromagnetic types.As shown, the electrodes 28 and 30 of the receiver 18 are coupled to the input of an amplifier 34, whose output is coupled to the input of a detector 36. The detector 36 is arranged to provide a signal to the pulse former 38 when the output from the amplifier 34 exceeds a predetermined level. The pulse former 38 then generates a trigger pulse which is provided to the pulse generator 40. In order to enhance the sensitivity of the system, the transducers 16 and 18 are resonantly excited. There is accordingly provided a continuous wave oscillator 42 which provides a continuous oscillating signal at a fixed frequency,preferably the resonant frequency of the transducers 16 and 18. This oscillating signal is provided to the modulator 44. To effectivelyexcite the transmitter 16, it is preferable to provide several cyclesof the resonant frequency signal, rather than a single pulse or single cycle. Accordingly, the pulse generator 40 is arranged, in response to the application thereto of a trigger pulse, to provide a control pulseto the modulator 44 having a time duration equal the time duration of a predetermined number of cycles of the oscillating signal from the oscillator 42. This control pulse causes the modulator 44 to pass a "burst" of cycles to excite the transmitter 16.When electric power is applied to the described circuitry, there is sufficient noise at the input to the amplifier 34 that its outputtriggers the pulse generator 40 to cause a burst of oscillating cyclesto be provided across the electrodes 22 and 24 of the transmitter 16. The transmitter 16 accordingly generates an acoustic wave 32 which impinges upon the receiver 18. The receiver 18 then generates an electrical pulse which is applied to the input of the amplifier 34,which again causes triggering of the pulse generator 40. This cycle repeats itself so that a repetitive series of trigger pulses results atthe output of the pulse former 38. This pulse train is applied to the counter 46, as well as to the pulse generator 40.The transmitter 16 and the receiver 18 are spaced apart by the distance "D" which it is desired to measure. The propagation time "t" for an acoustic wave 32 travelling between the transmitter 16 and the receiver 18 is given by: t=D/V swhere V s is the velocity of sound in the air between the transmitter16 and the receiver 18. The counter 46 measures the repetition rate of the trigger pulses, which is equal to 1/t. Therefore, the repetitionrate is equal to V s /D. The velocity of sound in air is a function ofthe temperature and humidity of the air, as follows: ##EQU1## where T is the temperature, p is the partial pressure of the water vapor, H isthe barometric pressure, Γ w and Γ a are the ratio of constantpressure specific heat to constant volume specific heat for water vapor and dry air, respectively. Thus, although the repetition rate of the trigger pulses is measured very accurately by the counter 46, the sound velocity is influenced by temperature and humidity so that the measured distance D cannot be determined accurately.In accordance with the principles of this invention, a reference unit12 is provided. The reference unit 12 is of the same construction asthe measuring unit 10 and therefore includes an electroacoustic transmitter 50 which includes piezoelectric material 52 sandwiched between a pair of electrodes 54 and 56, and an electroacoustic receiver 58 which includes piezoelectric material 60 sandwiched between a pair of electrodes 62 and 64. Again, transducers other than thepiezoelectric type can be utilized. The transmitter 50 and the receiver58 are spaced apart a known and fixed reference distance "D R ". The electrodes 62 and 64 are coupled to the input of the amplifier 66,whose output is coupled to the input of the detector 68. The output ofthe detector 68 is coupled to the pulse former 70 which generatestrigger pulses. The trigger pulses are applied to the pulse generator72 which controls the modulator 74 to pass bursts from the continuous wave oscillator 76 to the transmitter 50. The trigger pulses from thepulse former 70 are also applied to the counter 78.Preferably, all of the transducers 16, 18, 50 and 58 have the same resonant frequency. Therefore, the oscillators 42 and 76 both operateat that frequency and the pulse generators 40 and 72 provide equal width output pulses.In usage, the measuring unit 10 and the reference unit 12 are in close proximity so that the sound velocity in both of the units is the same. Although the repetition rates of the pulses in the measuring unit 10and the reference unit 12 are each temperature and humidity dependent, it can be shown that the distance D to be measured is related to the reference distance D R as follows: i D=D R (1/t R )/(1/t)where t R is the propagation time over the distance D R in thereference unit 12. This relationship is independent of both temperature and humidity.Thus, the outputs of the counters 46 and 78 are provided as inputs tothe microprocessor 90 in the utilization means 14. The microprocessor90 is appropriately programmed to provide an output which is proportional to the ratio of the outputs of the counters 46 and 78,which in turn are proportional to the repetition rates of therespective trigger pulse trains of the measuring unit 10 and the reference unit 12. As described, this ratio is independent oftemperature and humidity and, since the reference distance D R is known, provides an accurate representation of the distance D. The utilization means 14 further includes a display 92 which is coupled toand controlled by the microprocessor 90 so that an operator can readily determine the distance D.Experiments have shown that when the distance between the transmitting and receiving transducers is too small, reflections of the acousticwave at the transducer surfaces has a not insignificant effect which degrades the measurement accuracy. Accordingly, it is preferred that each transducer pair be separated by at least a certain minimum distance, preferably about four inches.译文:超声波测距仪文件类型和数目:美国专利5442592摘要:提出了一种超声波测距仪来抵消温度和湿度的变化,包括测量单元和参考标准。