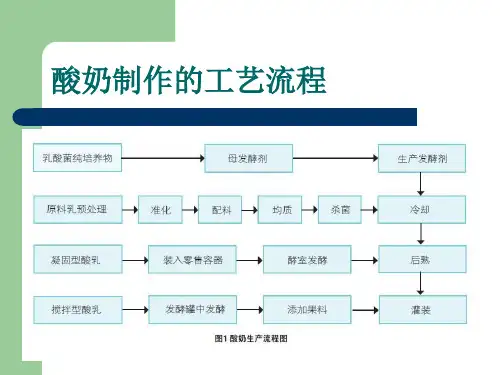

配奶操作流程图

- 格式:docx

- 大小:2.70 MB

- 文档页数:2

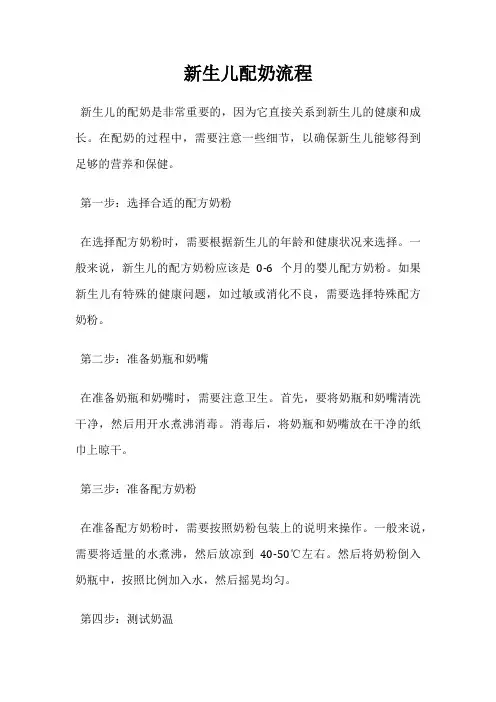

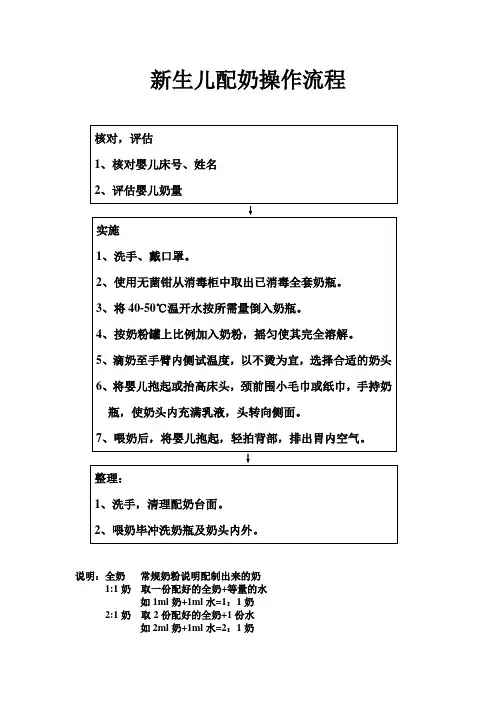

新生儿配奶流程新生儿的配奶是非常重要的,因为它直接关系到新生儿的健康和成长。

在配奶的过程中,需要注意一些细节,以确保新生儿能够得到足够的营养和保健。

第一步:选择合适的配方奶粉在选择配方奶粉时,需要根据新生儿的年龄和健康状况来选择。

一般来说,新生儿的配方奶粉应该是0-6个月的婴儿配方奶粉。

如果新生儿有特殊的健康问题,如过敏或消化不良,需要选择特殊配方奶粉。

第二步:准备奶瓶和奶嘴在准备奶瓶和奶嘴时,需要注意卫生。

首先,要将奶瓶和奶嘴清洗干净,然后用开水煮沸消毒。

消毒后,将奶瓶和奶嘴放在干净的纸巾上晾干。

第三步:准备配方奶粉在准备配方奶粉时,需要按照奶粉包装上的说明来操作。

一般来说,需要将适量的水煮沸,然后放凉到40-50℃左右。

然后将奶粉倒入奶瓶中,按照比例加入水,然后摇晃均匀。

第四步:测试奶温在喂养新生儿之前,需要测试奶温。

将一滴奶滴在手腕上,如果感觉温度适中,就可以开始喂养了。

第五步:喂养新生儿在喂养新生儿时,需要注意以下几点。

首先,要让新生儿舒适地躺在你的怀里或床上。

然后将奶瓶倾斜,让奶流到奶嘴中。

让新生儿自己吸吮,不要强迫喂养。

喂养时,要注意观察新生儿的表情和反应,如果出现呛咳或吐奶等情况,应该停止喂养。

第六步:清洗奶瓶和奶嘴在喂养结束后,需要立即清洗奶瓶和奶嘴。

将奶瓶和奶嘴用温水冲洗干净,然后用专门的奶瓶刷刷洗干净,最后用开水煮沸消毒。

新生儿的配奶流程需要注意卫生和细节,以确保新生儿能够得到足够的营养和保健。

同时,喂养新生儿时需要注意观察新生儿的表情和反应,及时调整喂养方式。

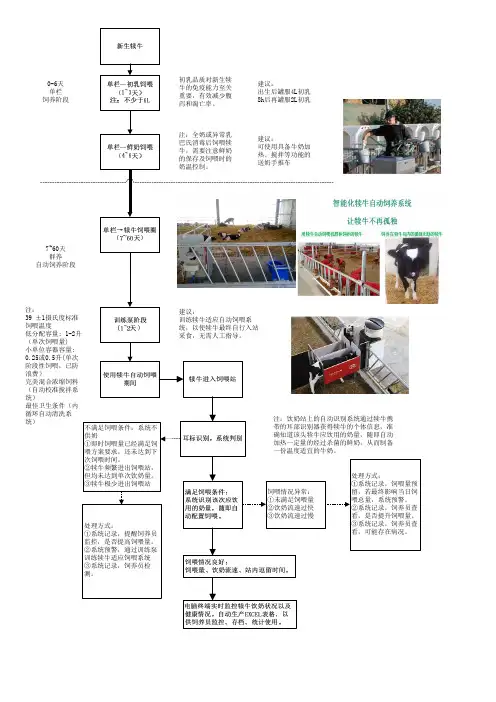

注:饮奶站上的自动识别系统通过犊牛携

带的耳部识别器获得犊牛的个体信息,准

确知道该头犊牛应饮用的奶量,随即自动

加热一定量的经过杀菌的鲜奶,从而制备

一份温度适宜的牛奶。

不满足饲喂条件:系统不

①即时饲喂量已经满足饲

喂方案要求,还未达到下

次饲喂时间。

②犊牛频繁进出饲喂站,

但均未达到单次饮奶量。

③犊牛极少进出饲喂站

处理方式:

①系统记录,提醒饲养员

监控,是否提高饲喂量。

②系统预警,通过训练泵

训练犊牛适应饲喂系统

③系统记录,饲养员检

饲喂情况异常:

①未满足饲喂量

②饮奶流速过快

③饮奶流速过慢

建议:

训练犊牛适应自动饲喂系

统,以使犊牛最终自行入站

采食,无需人工指导。

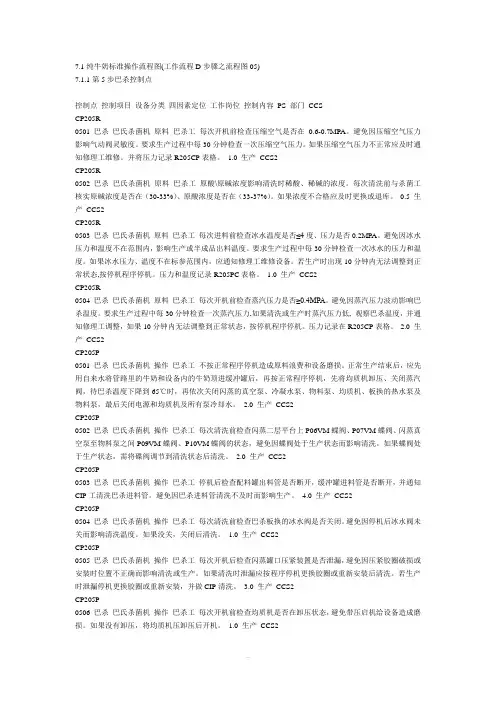

7.1纯牛奶标准操作流程图(工作流程D步骤之流程图05)7.1.1第5步巴杀控制点控制点控制项目设备分类四因素定位工作岗位控制内容PS 部门CCSCP205R0501 巴杀巴氏杀菌机原料巴杀工每次开机前检查压缩空气是否在0.6-0.7MPA。

避免因压缩空气压力影响气动阀灵敏度。

要求生产过程中每30分钟检查一次压缩空气压力。

如果压缩空气压力不正常应及时通知修理工维修。

并将压力记录R205CP表格。

1.0 生产CCS2CP205R0502 巴杀巴氏杀菌机原料巴杀工原酸\原碱浓度影响清洗时稀酸、稀碱的浓度。

每次清洗前与杀菌工核实原碱浓度是否在(30-33%)、原酸浓度是否在(33-37%)。

如果浓度不合格应及时更换或退库。

0.5 生产CCS2CP205R0503 巴杀巴氏杀菌机原料巴杀工每次进料前检查冰水温度是否≤4度、压力是否0.2MPA。

避免因冰水压力和温度不在范围内,影响生产或半成品出料温度。

要求生产过程中每30分钟检查一次冰水的压力和温度。

如果冰水压力、温度不在标参范围内,应通知修理工维修设备。

若生产时出现10分钟内无法调整到正常状态,按停机程序停机。

压力和温度记录R205PC表格。

1.0 生产CCS2CP205R0504 巴杀巴氏杀菌机原料巴杀工每次开机前检查蒸汽压力是否≥0.4MPA。

避免因蒸汽压力波动影响巴杀温度。

要求生产过程中每30分钟检查一次蒸汽压力,如果清洗或生产时蒸汽压力低, 观察巴杀温度,并通知修理工调整,如果10分钟内无法调整到正常状态,按停机程序停机。

压力记录在R205CP表格。

2.0 生产CCS2CP205P0501 巴杀巴氏杀菌机操作巴杀工不按正常程序停机造成原料浪费和设备磨损。

正常生产结束后,应先用自来水将管路里的牛奶和设备内的牛奶顶进缓冲罐后,再按正常程序停机,先将均质机卸压、关闭蒸汽阀,待巴杀温度下降到65℃时,再依次关闭闪蒸的真空泵、冷凝水泵、物料泵、均质机、板换的热水泵及物料泵,最后关闭电源和均质机及所有泵冷却水。

Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk Milk目录1长富牛奶概况 (1)1.1长富乳业简介 (1)1.2长富乳业牧场的发展状况 (1)1.3长富乳业生产技术及认证 (2)2长富牛奶配送情况调查(以漳州长富牛奶配送为例) (2)2.1调查安排 (2)2.2调查资料 (2)2.2.1主要配送的牛奶品种及各项情况列表 (2)2.2.2配送牛奶的取货流程 (3)2.2.3漳州长富牛奶配送路线 (3)3长富牛奶物流系统流程分析与优化 (5)3.1运输系统 (5)3.1.1运输路线的选择 (5)3.1.2运输工具的选择 (5)3.1.3牛奶在冷链过程中的温度控制 (6)3.1.4牛奶运输中的监控 (8)3.2仓储系统 (9)3.2.1拼装冷藏库 (9)3.2.2拼装冷库的特点 (10)3.2.3配送中心平面图 (10)3.3配送系统的优化 (13)3.3.1牛奶配送管理系统 (13)3.3.2配送过程的监控 (16)3.3.3退货处理描述 (17)3.3.4牛奶配送服务的衍生 (18)4总结 (19)1长富牛奶概况1.1长富乳业简介福建长富乳业集团创建于1998年3月。

7.1纯牛奶标准操作流程图(工作流程D步骤之流程图05)7.1.1第5步巴杀控制点控制点控制项目设备分类四因素定位工作岗位控制内容PS 部门CCSCP205R0501 巴杀巴氏杀菌机原料巴杀工每次开机前检查压缩空气是否在0.6-0.7MPA。

避免因压缩空气压力影响气动阀灵敏度。

要求生产过程中每30分钟检查一次压缩空气压力。

如果压缩空气压力不正常应及时通知修理工维修。

并将压力记录R205CP表格。

1.0 生产CCS2CP205R0502 巴杀巴氏杀菌机原料巴杀工原酸\原碱浓度影响清洗时稀酸、稀碱的浓度。

每次清洗前与杀菌工核实原碱浓度是否在(30-33%)、原酸浓度是否在(33-37%)。

如果浓度不合格应及时更换或退库。

0.5 生产CCS2CP205R0503 巴杀巴氏杀菌机原料巴杀工每次进料前检查冰水温度是否≤4度、压力是否0.2MPA。

避免因冰水压力和温度不在范围内,影响生产或半成品出料温度。

要求生产过程中每30分钟检查一次冰水的压力和温度。

如果冰水压力、温度不在标参范围内,应通知修理工维修设备。

若生产时出现10分钟内无法调整到正常状态,按停机程序停机。

压力和温度记录R205PC表格。

1.0 生产CCS2CP205R0504 巴杀巴氏杀菌机原料巴杀工每次开机前检查蒸汽压力是否≥0.4MPA。

避免因蒸汽压力波动影响巴杀温度。

要求生产过程中每30分钟检查一次蒸汽压力,如果清洗或生产时蒸汽压力低, 观察巴杀温度,并通知修理工调整,如果10分钟内无法调整到正常状态,按停机程序停机。

压力记录在R205CP表格。

2.0 生产CCS2CP205P0501 巴杀巴氏杀菌机操作巴杀工不按正常程序停机造成原料浪费和设备磨损。

正常生产结束后,应先用自来水将管路里的牛奶和设备内的牛奶顶进缓冲罐后,再按正常程序停机,先将均质机卸压、关闭蒸汽阀,待巴杀温度下降到65℃时,再依次关闭闪蒸的真空泵、冷凝水泵、物料泵、均质机、板换的热水泵及物料泵,最后关闭电源和均质机及所有泵冷却水。

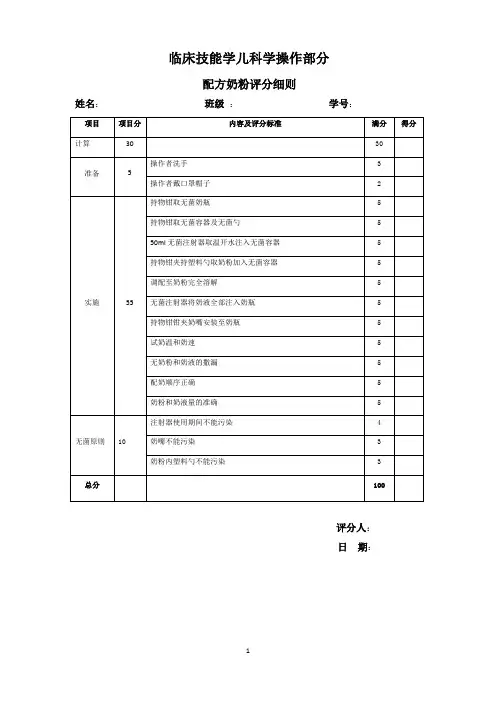

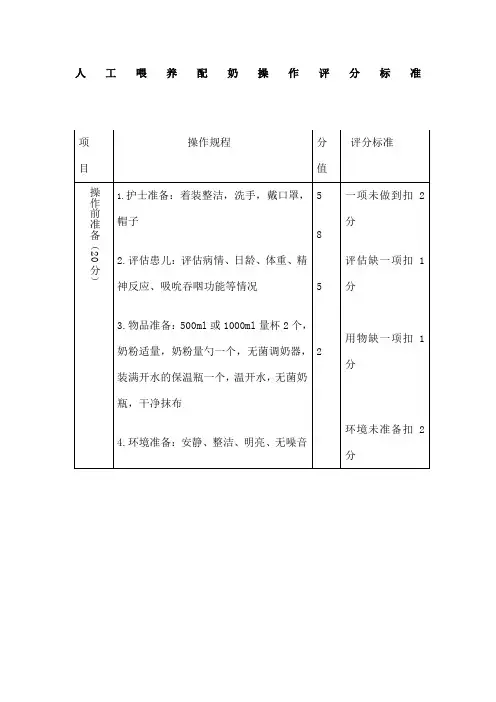

新生儿配奶的操作规范

一、操作目的

为不能母乳喂养的患儿提供清洁、卫生的配方奶。

二、评估要点

环境清洁干燥,符合要求。

三、物品准备

500ml 或 1000ml 的量杯、奶粉一罐、奶粉量勺一个、无菌勺一个、无菌奶瓶一个、温开水适量(煮沸后 5-10 分钟再冷却至

40-60℃)、干净抹布一块。

四、操作要点

1、评估环境。

2、擦净桌面,保持清洁。

3、洗手,戴口罩。

4、打开包布取出无菌量杯,无菌勺及无菌奶瓶。

5、将冷却好的温开水倒入量杯,用量勺取适量奶粉倒入量杯,用无菌勺搅匀,使其完全溶解。

6、根据新生儿的奶量将牛奶倒入奶瓶。

7、清理桌面,洗手,取口罩。

8、配奶用物清洁后,送供应室高压蒸汽消毒灭菌后备用。

五、注意事项配奶时先准备好适量的温水,再加入奶粉搅拌,防止配方奶中营养物质的破坏,注意清洁避免污染。

[键入文字]奶粉事业部生产企业生产评估管理办法一:目的为了各个生产企业在质量、成本、以及管理岗位自我提升当中对企业的关键控制点和关键控制过程当中能够完成事业部既定目标。

奶粉事业部生产管理部对相关文件和工厂生产质量管理、成本管理的相关文件为依据,旨在通过检查对工厂现行生产管理体系的有效性、符合性进行评价,以促进工厂整体管理水平的提高和生产管理体系的持续改进,制定生产评估管理办法。

二:具体内容包括原奶的验收、预处理工序、浓缩与喷粉工序、出粉工序与后段包装工序。

三:生产过程流程具体如下:图(1):配方奶粉生产工艺流程图图(2):全脂奶粉/脱脂奶粉生产工艺流程图配方奶粉生产工艺流程图1说明”表示的是过程产生的不合品处理流程;全脂奶粉/脱脂奶粉生产工艺流程图2说明:“”表示的是过程产生的不合品处理流程;生产工艺操作关键控制点1:原奶验收关键控制点:(1)采样器具无油腻感、奶垢、异味保证采样的准确性。

(2)牛奶取样到验收过程要有监管员管理制度。

(3)化验室对检验理化指标操作性与准确性负责,工厂按生鲜牛乳收购标准检验接收。

确定A、B、C类奶源(4)奶车在清洗后在用PH试纸当场验证清洗后器具是否有清洗液残留酸碱残留现场. (5)牛奶在过磅前要按要求完成对设备的进行检验与验收。

保证收奶数量的准确性。

2: 预处理工序在预热、杀菌关键控制点:(1)牛奶经85℃,15秒的热杀菌,杀死原料奶中致病菌及大部分的微生物,延长原料奶的保存时间.(2)真空吸粉:称重加粉设备中的各种粉类原料通过真空系统吸入真空混料罐中。

(3)溶化配油:按配方要求将棕榈油、大豆油或玉米油放入化油间,化油间的温度应保持在50-60℃。

待油融化后通过油泵和流量计打入各自贮油罐中贮存。

(4)预热湿混:巴氏奶经计量打入湿混缸,经板式换热器加热至40℃,当真空混料罐温度、真空度达到设定值,称重加粉设备加入配方中所需原料粉后,开始向真空混料罐中加入粉类原料,混合油料及维生素与微量元素等。