S4-3批号追溯表中英文版

- 格式:xls

- 大小:90.50 KB

- 文档页数:19

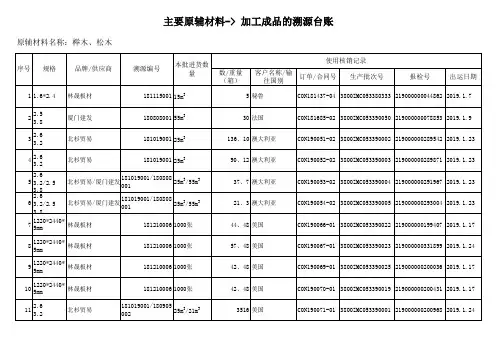

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木

原辅材料名称:榉木、松木。

7.5.3标识和可追溯性Identification and Traceability7.5.3.1标识和可追溯性的目的Identification and Traceability Purpose1)组织应在产品实现的全过程中,对产品及其检验试验状态进行标识,防止在服务和交付过程中不同产品或不同状态产品的混用误用;对环境管理状态进行标识,减少或避免环境影响事故的发生。

The organization shall identify the product status with respect to inspection and testing throughout the complete product realization in order to prevent the confusion and misapplication during the service and delivery by various products or different status of the products; identify the environment management status for reducing or avoidance the environmental impact accidents.2)必要时实现产品和事故的可追溯性。

When necessary to achieve the products and accidents traceability7.5.3.2标识可通过标牌、标签、刻制、卡片、分存放地点、涂漆、及各种记录等多种方式实施。

Identification can be carried into execution by placards, labels, engraving, cards, storage locations, painting, all kinds of records and other means.7.5.3.3标识的分类Identification Classification1)产品标识,包括产品的型号、规格、顾客名称、生产日期等。

产品标识与可追溯性管理程序Product id entification and traceability management procedure(IATF16949-2016)1.目的 Objective为能控制从原材料到成品出货的整个流程的质量状况及其追溯性,对各制程的产品标识追溯予以控制,特制定本程序。

To control the quality conditions and related traceability from the raw material to the final product delivery to ensure the product identification and traceability are under control.2.适用范围 Applicable Scope本程序适用于所有在公司范围内的原材料、半成品和成品的标识及追溯均适用本程序。

Be applied to the identification and traceability of the raw material, semi-finished product and finished product in our company.3. 职责Responsibilities3.1. 生产部:负责在线产品和生产过程中原材料、半成品、成品状态的标识储存及保护。

Production department: identify, store and protect the online productsand raw material, semi-finished product, finished product.3.2. 品质部:负责成品、半成品、不良品、原材料等对不同检验和试验状态的产品进行标识。

Quality department: identify the products of different inspection and test status.3.3. 仓管部:负责原材料和成品入库的标识、保护以及出入库时都有明显的标识和记录。

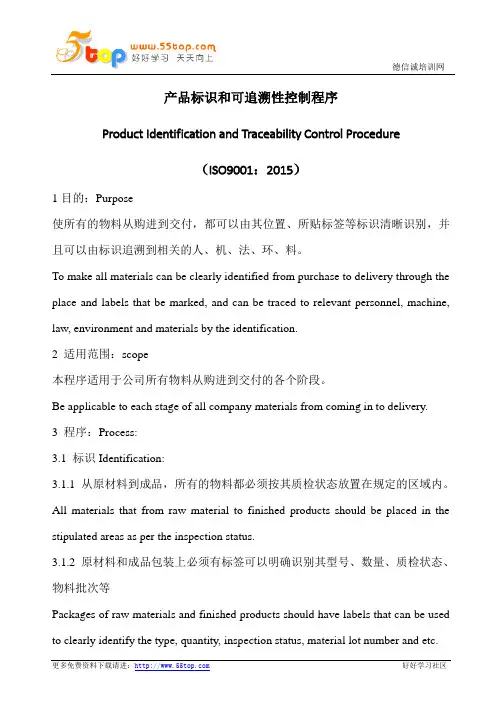

产品标识和可追溯性控制程序Product Identification and Traceability Control Procedure(ISO9001:2015)1目的:Purpose使所有的物料从购进到交付,都可以由其位置、所贴标签等标识清晰识别,并且可以由标识追溯到相关的人、机、法、环、料。

To make all materials can be clearly identified from purchase to delivery through the place and labels that be marked, and can be traced to relevant personnel, machine, law, environment and materials by the identification.2 适用范围:scope本程序适用于公司所有物料从购进到交付的各个阶段。

Be applicable to each stage of all company materials from coming in to delivery.3 程序:Process:3.1 标识Identification:3.1.1 从原材料到成品,所有的物料都必须按其质检状态放置在规定的区域内。

All materials that from raw material to finished products should be placed in the stipulated areas as per the inspection status.3.1.2 原材料和成品包装上必须有标签可以明确识别其型号、数量、质检状态、物料批次等Packages of raw materials and finished products should have labels that can be used to clearly identify the type, quantity, inspection status, material lot number and etc.3.1.3 车间流动的半成品通过生产流程卡识别其型号、物料批次等。

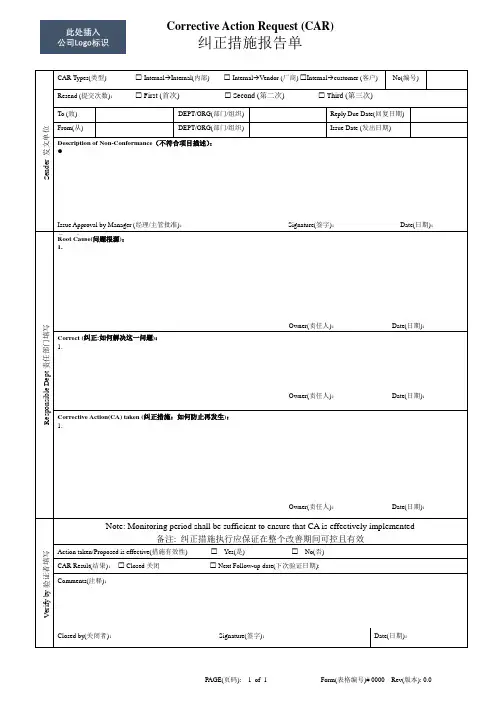

Corrective Action Request (CAR)纠正措施报告单PAGE(页码): 1 of 1 Form(表格编号)# 0000 Rev(版本): 0.0 S e n d e r 发文单位 CAR Types(类型)Internal →Internal(内部) Internal →Vendor (厂商) Internal →customer (客户) No(编号) Resend (提交次数):First (首次) Second (第二次) Third (第三次) To (致)DEPT/ORG(部门/组织) Reply Due Date(回复日期) From(从) DEPT/ORG(部门/组织) Issue Date (发出日期)Description of Non-Conformance (不符合项目描述): ●Issue Approval by Manager (经理/主管批准): Signature(签字): Date(日期): R e s p o n s i b l e D e p t 责任部门填写 Containment (): Root Cause(问题根源): 1.Owner(责任人): Date(日期): Correct (纠正:如何解决这一问题): 1. Owner(责任人): Date(日期):Corrective Action(CA) taken (纠正措施:如何防止再发生):1.Owner(责任人): Date(日期): V e r i f y b y 验证者填写 Note: Monitoring period shall be sufficient to ensure that CA is effectively implemented备注: 纠正措施执行应保证在整个改善期间可控且有效Action taken/Proposed is effective(措施有效性) Yes(是) No(否) CAR Result(结果): Closed 关闭 Next Follow-up date(下次验证日期): Comments(注释):Closed by(关闭者): Signature(签字): Date(日期):。

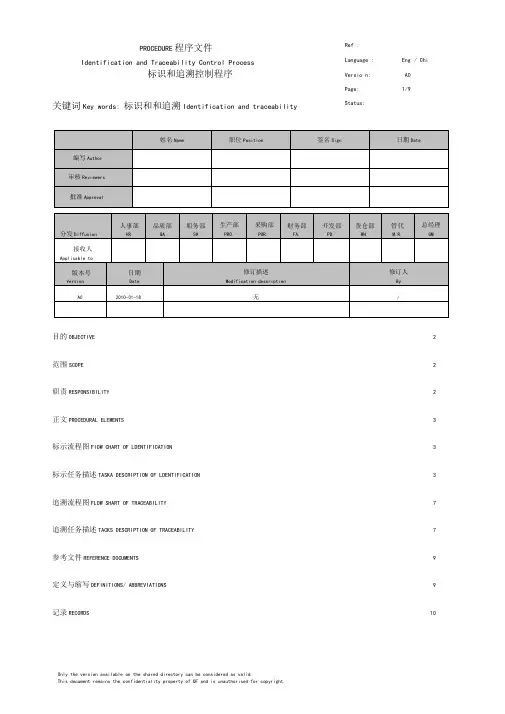

Language : Eng Versio n: A0 Page:1/9Status:PROCEDURE 程序文件Identification and Traceability Control Process标识和追溯控制程序关键词 Key words: 标识和和追溯 Identification and traceability目的 OBJECTIVE2范围SCOPE2职责 RESPONSIBILITY2正文 PROCEDURAL ELEMENTS3标示流程图 FIOW CHART OF LDENTIFICATION3标示任务描述 TASKA DESCRIPTION OF LDENTIFICATION3追溯流程图 FLOW SHART OF TRACEABILITY7追溯任务描述 TACKS DESCRIPTION OF TRACEABILITY7参考文件 REFERENCE DOCUMENTS9定义与缩写 DEFINITIONS/ ABBREVIATIONS9记录 RECORDS10Ref : / ChiObjective 目的To ensure the identification and traceability of products and raw materials can meet the requirements of customers and performa nee policy. 确保产品和原材料的标示与追溯可以满足客户以及绩效方针的要求。

Scope 范围Apply to the identification and traceability of raw materials and products used throughout the procedure from incoming to output.用于产品及原材料从来料到岀货整个过程的标示与追溯。

Responsibility 职责It is the responsibility of related department managers to ensure the implementation of this procedure. 各相关部门经理/主管负责本程序的执行。

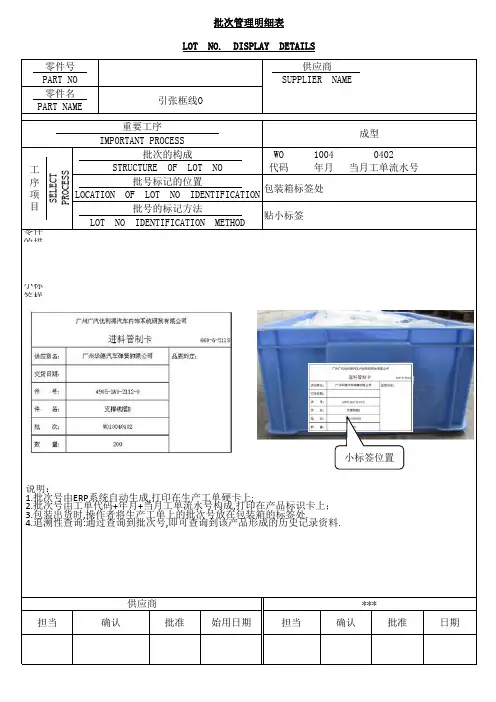

1.0 Purpose目的Standardize the material from incoming materials - semi-finished products - finished products - delivery, and the parts can be traced and controlled between each process.规范物料从来料-半成品-成品-出货,各工序之间零件可追溯可控制。

2.0 Scope范围The whole process from feeding to delivery.从进料到出货全过程。

3.0 Definitions定义None无4.0 Responsibility权责4.1Logistics Department: send raw materials to the quality department for inspection after they arrive; Make production plan according to customer order and provide related material and delivery.物流部:原材料到料后送检质量部检验;根据客户定单编制生产计划并提供相关的物料及发货。

4.2 Quality department: after receiving the inspection application form from logistics department, be responsible for incoming inspection; Monitor the quality of parts in the production process.质量部:收到物流部的报检单后,负责进料检验;对生产过程中零件质量进行过程监控。

4.3 Production department: arrange related production activities according to the production plan made by logistics department.生产部:根据物流部编制的生产计划安排相关的生产活动。

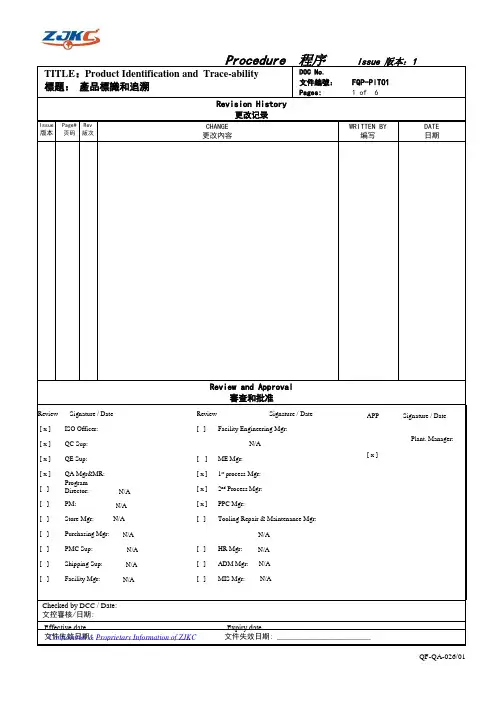

1.0 PURPOSE 目的1.1 This procedure defines the product Identification and Traceability system to prevent unintendeduse and ensure the traceability for production and quality.定义产品标识和追溯性系统,防止产品混用,确保对产品质量及形成的过程实现可追溯性。

2.0 SCOPE 范围2.1 Apply to the materials, semi-products and finished products.适用于原料,半成品及成品的标识和追溯。

3.0 DEFINITIONS定义3.1 Product identification: make clear and understandable mark by special number, part number orcomparable mark and status mark.产品标识:通过特定的编号、零件号、或可比较的记号和状态标记,对产品做出清楚的、易理解的标记。

3.2 Traceability: the capability to trace the history, application or location, it refers to resource ofmaterial and component, manufacturing process, distribution status of delivered products.可追溯性:追溯产品的历史、应用情况或所处场所的能力,涉及材料和零件的来源、加工过程、交付后产品的分布状况。

4.0 REFERENCE DOCUMENTS参考文件4.1 ISO/TS 16949 Clause 7.5.3 Identification and Traceability 标识和可追溯性5.0 RECORDS 记录5.1 FN-AS-003 Production batch record form 《生产批号记录表》6.0 RESPONSIBILITY职责6.1 Program department create part number.项目部负责创建材料和产品料号。