壳牌资料

- 格式:pptx

- 大小:6.60 MB

- 文档页数:4

壳牌5w40机油参数

(最新版)

目录

1.壳牌 5w40 机油概述

2.壳牌 5w40 机油的参数

3.壳牌 5w40 机油的性能特点

4.壳牌 5w40 机油的使用范围

5.壳牌 5w40 机油的更换周期

正文

壳牌 5w40 机油是一种高品质的机油,适用于多种车辆。

它具有优越的润滑性能,可以有效保护发动机,延长发动机的使用寿命。

壳牌 5w40 机油的参数如下:粘度等级为 5w40,这意味着它在低温

下具有良好的流动性,在高温下则有足够的粘度,可以有效润滑发动机。

它的密度为 0.85g/cm3,闪点为 204℃,倾点为 -35℃。

壳牌 5w40 机油具有优良的润滑性能,可以减少发动机的磨损,延长发动机的使用寿命。

同时,它还具有优异的抗氧化性能,可以有效地防止机油的氧化,延长机油的使用寿命。

此外,它还具有防锈和防腐蚀的特性,可以保护发动机免受腐蚀和锈蚀的损害。

壳牌 5w40 机油适用于各种轿车、SUV 和轻型商用车。

它适用于各种路况和气候条件,无论是城市道路还是高速公路,无论是寒冷的冬季还是炎热的夏季,都可以提供优良的润滑保护。

壳牌 5w40 机油的更换周期一般为 5000 公里或半年,以先到者为准。

更换机油时,应选择符合车辆制造厂规定的机油,并确保机油的质量和性能。

总的来说,壳牌 5w40 机油是一种优质的机油,可以提供优良的润滑

保护,延长发动机的使用寿命。

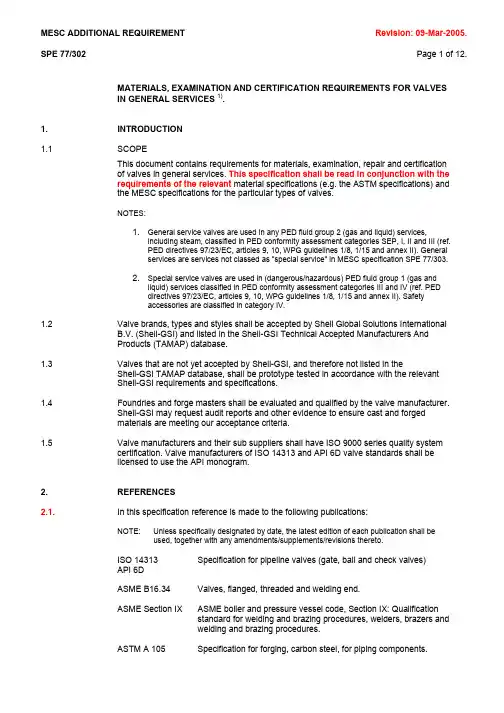

ASME boiler and pressure vessel code, Section IX: Qualification standard for welding and brazing procedures, welders, brazers and welding and brazing procedures.MATERIALS, EXAMINATION AND CERTIFICATION REQUIREMENTS FOR VALVES IN GENERAL SERVICES 1).1. INTRODUCTION 1.1 SCOPEThis document contains requirements for materials, examination, repair and certification of valves in general services. This specification shall be read in conjunction with the requirements of the relevant material specifications (e.g. the ASTM specifications) and the MESC specifications for the particular types of valves.NOTES:1. General service valves are used in any PED fluid group 2 (gas and liquid) services,including steam, classified in PED conformity assessment categories SEP, I, II and III (ref. PED directives 97/23/EC, articles 9, 10, WPG guidelines 1/8, 1/15 and annex II). General services are services not classed as "special service" in MESC specification SPE 77/303.2. Special service valves are used in (dangerous/hazardous) PED fluid group 1 (gas andliquid) services classified in PED conformity assessment categories III and IV (ref. PED directives 97/23/EC, articles 9, 10, WPG guidelines 1/8, 1/15 and annex II). Safety accessories are classified in category IV.1.2Valve brands, types and styles shall be accepted by Shell Global Solutions International B.V. (Shell-GSI) and listed in the Shell-GSI Technical Accepted Manufacturers And Products (TAMAP) database.1.3Valves that are not yet accepted by Shell-GSI, and therefore not listed in theShell-GSI TAMAP database, shall be prototype tested in accordance with the relevant Shell-GSI requirements and specifications.1.4Foundries and forge masters shall be evaluated and qualified by the valve manufacturer. Shell-GSI may request audit reports and other evidence to ensure cast and forged materials are meeting our acceptance criteria.1.5Valve manufacturers and their sub suppliers shall have ISO 9000 series quality system certification. Valve manufacturers of ISO 14313 and API 6D valve standards shall be licensed to use the API monogram.2. REFERENCES 2.1.In this specification reference is made to the following publications:NOTE:Unless specifically designated by date, the latest edition of each publication shall be used, together with any amendments/supplements/revisions thereto.ISO 14313 API 6D Specification for pipeline valves (gate, ball and check valves) ASME B16.34 Valves, flanged, threaded and welding end.ASME Section IXASTM A 105Specification for forging, carbon steel, for piping components.ASTM A 182 Forged or rolled alloy-steel pipe flanges, forged fittings, valves and parts for high temperature service.ASTM A 216 Steel castings, carbon, suitable for fusion welding, hightemperature service.ASTM A 217 Steel castings, martensitic stainless and alloy, for pressurecontaining parts, suitable for high temperature service.ASTM A 262 Standard Practices for detecting susceptibility to intergranularattack in austenitic stainless steels.ASTM A 336 Specification for alloy steel forging for pressure and hightemperature parts.ASTM A 350 Specification for forging, carbon and low-alloy steel, requiring notch toughness testing for piping components.ASTM A 351 Specification for steel castings, austenitic, austenitic-ferritic(Duplex) for pressure containing parts.ASTM A 352 Steel castings, ferritic and martensitic, for pressure containingparts, suitable for low temperature service.ASTM A370 Standard test methods and definitions for mechanical testing ofsteel products.ASTM A 494 Specification for castings, nickel and nickel alloy.ASTM A 516 Specification for pressure vessel plates, carbon steel, formoderate-and lower temperature service.ASTM A 744 Standard specification for castings, iron-chromium-nickel, corrosion resistant for severe service.ASTM A 890 Specification for castings, iron-chromium-nickel-molybdenumcorrosion resistant, Duplex (austenitic-ferritic) for generalapplication.ASTM B 150 Specification for aluminium bronze rod, bar and shapes.ASTM G28 Standard test methods of detecting susceptibility tointergranular corrosion in wrought, nickel-rich, chromium-bearing alloys.EN 10204 Metallic products – types of inspection documents.ISO 148 Steel – Charpy impact test (V-notch).ISO 9000 Quality management system requirements.ISO 10474 Steel and steel products - inspection documents.ISO 14313 Petroleum and natural gas industries – Pipeline transportationsystems – Pipeline valves.MSS SP-55 Quality standard (visual method) for steel castings for valves,flanges and fittings and piping.NACE MR 0175 (Edition 2002)Standard material requirements; Metals for sulphide stress cracking and stress corrosion cracking resistance in sour oilfield environments.PED 97/23/EC Pressure Equipment Directive, 97/23/ECSTOOMWEZEN Rules for pressure vessels.3. MATERIALSREQUIREMENTS3.1 CHEMICALCOMPOSITION3.1.1 BasematerialsFor the materials mentioned below, the following restrictions in chemical compositionshall apply:Material grade Additional restrictionsASTM A105 Carbon content shall be 0.23% weightmaximum.Carbon equivalent (CE) shall be 0.43% weightmaximum.ASTM A516 grades 60 and 65ASTM A216 grade WCB Carbon content shall be 0.25% weight maximumASTM A350 grade LF2 class 1 and 2 Carbon equivalent (CE) shall be 0.43% weight maximum and shall be determined by the formula mentioned previously.ASTM A352 grade LCC Manganese content shall be 1.30% maximum ASTM A182 grades F316 UNSS316000.Carbon content shall be 0.03% weight maximumASTM A351-CF8M andASTM A351-CF3M(Ref. Note 1)Carbon content shall be 0.03% weight maximumASTM A182 grade F51; and Duplex stainless steel UNS S31803 Nitrogen content shall be 0.15% weight minimumASTM B 150 grade UNS C63200 Aluminium content shall be 8.50% weightminimum and 10% weight maximumThe carbon equivalent (CE) shall be determined by the formula as mentioned below:CE= C + Mn/6 + (Cr+Mo+V)/5 + (Ni+Cu)/153.2 HEATTREATMENT3.2.1 The Cr-Mo steels to ASTM A 182 grade F5a, F9, F11 class 2, ASTM A 182 grade F22class 3, ASTM A 217 grade WC6 and ASTM A 217 grade WC9 shall be furnished in thenormalised and tempered condition.3.2.2 Austenitic/ferritic(duplex) stainless steel UNS S31803UNS S31803 materials (including castings) shall be solution annealed between 1020ºCand 1100ºC, followed by rapid quench, after all forming operations.Repair welding of UNS S31803 castings shall be in accordance with the requirements ofASTM A744 Paragraph 10.3.2.3 Austenitic stainless steel forging to ASTM A182 and ASTM A336 andcasting to ASTM A351.All austenitic stainless steels shall be supplied in the solution heat treated condition.For non-stabilized grades with a carbon content larger than 0.03% solution annealingshall be repeated after any welding.3.2.4 Austenitic Steel Forgings to ASTM A182 grades F321 and F347If specified in the relevant MESC description a stabilising heat treatment shall beperformed between 900ºC and 950ºC for two hours, followed by cooling in still air. Thisshall be applied after the solution heat treatment and again after any welding.3.2.5 Nickel alloy castings to ASTM A494 grade N-7MNickel alloy castings to ASTM A494 grade N-7M shall be solution annealed at 1180 ºC+/- 10 ºC. Annealing at other temperatures can be accepted provided qualification testsshow that this leads to a fully solution annealed structure which is free of precipitates.Castings to ASTM A494 N-7M shall be post-weld heat treated following weld repairsusing the same solution annealing procedure as used earlier.3.2.6 Carbon steel and alloy 400:3.2.6.1 If welding is applied on valve parts made of Alloy 400, they shall be Post Weld HeatTreated (PWHT) at 590 ºC for at least 1 hour.3.2.6.2 All repair welds in carbon steel and Alloy-400 material shall be PWHT at 590 ºC for atleast 1 hour per 25 mm thickness, followed by X-ray re-examination.3.2.7 All heat treatment procedures shall be subject to statistical process control to ensure thatthe final material properties comply with the material standard and this specification. Theprocess control data and related periodic quality control checks shall be documented.3.3 HARDNESSIf wet H2S or sour service conditions are specified, the hardness requirements ofNACE MR 0175 Edition 2002 shall apply for any process-wetted part of the valve andpressure-retaining bolting.For all other (non-NACE MR 0175) services the maximum allowable hardness shall be:Base metal, welds and heat affected zones of pressure containing parts 248 HV10Base metal of internals with weld deposits or hard facings 400 HV1013% chromium steel internals 400 HV10Hardness indentations shall be avoided on any sealing or sliding surfaces.TESTING3.4 IMPACTImpact testing is required for:-Cr-Mo steels to ASTM A 182 grade F11 class 2, ASTM A 182 grade F22 class 3, ASTMA 217 grade WC6 and ASTM A 217 grade WC9 if the thickness of any section of thesematerials is greater than 50 mm.-Low temperature carbon steel to ASTM A352 grade LCC-Carbon manganese forging to ASTM A350 grade LF2, class 1-fine grained C-Mn steels to ASTM A 516 grades 60 and 65- Austenitic/ferritic duplex 22%Cr stainless steels to ASTM A351 grades CH10, CH 20and CE8MN and ASTM A 890 grade 4A and the 25 % Cr duplex stainless steels toASTM A890 grades 5A and 6A.- Martensitic stainless steel to ASTM A182-F6NM.For low temperature carbon steel valves the notched bar impact test shall be performed,in accordance with the applicable ASTM standard, at a temperature of minus 50degrees Celsius with an average energy value of 26 joules minimum for 2 and anyof 3 specimens and 22 joules minimum for the single specimen.Where welding is perfomed on austenitic stainless steel forgings to ASTM A182and castings to ASTM A351 as part of the valve assembly, having a minimumdesign temperature of <-29°C, welding procedures shall be qualified by impacttesting at the minimum design temperature specified in accordance with therequirements in ASME B31.3, section 323.22.In addition to these requirements as stated in API RP582 section 6.3.2, all weldsshall have a ferrite number for the weld material not exceeding 8FN.For all other materials the impact tests shall be performed on test pieces from the sameheat as the valve body and which have been simultaneously subjected to the same heattreatment.The test temperature shall be for:-Cr-Mo valves (thickness > 50 mm): +20ºC and-Duplex stainless steels: minus 50ºCThe test specimens of forged/wrought material shall be taken in the transversedirection at 1/4 and 1/2 of the thickness. Castings shall have one set of impacts takenfrom a test block of the same melt and heat treatment batch.For each section, three tests shall be performed and the resulting Charpy-V notchenergy impact values shall be for:-Cr-Mo steels: 55 joules average, 48 joules minimum for single specimen-Duplex stainless steels: 40 joules average, 31 joules minimum for single specimenNote: On the impact testing requirements of Cr-Mo and Duplex, these are additionalrequirements due to the fact that there are no limits set for these materials in the ASTMstandard and therefore no reference can be made to a specific ASTM standard.TESTING3.5 CORROSION3.5.1 For austenitic stainless steels (AISI 201, 202, 301, 304H, 316, 316H, 317, 317L, 321and 347) and austenitic/ferritic (duplex) stainless steels the statistical process control,mentioned in section 3.2.8, shall include inter granular corrosion testing in accordancewith ASTM A 262, Practice E.Tested specimens shall reveal no signs of inter-granular corrosion.3.5.2 For austenitic stainless steels (AISI 304, 304L, CF3, CF8) and UNS N08028 thestatistical process control, mentioned in section 3.2.8, shall include inter granularcorrosion testing in accordance with ASTM A 262, Practice C and shall result in anaverage corrosion rate of no more than 0.3 mm per annum.3.5.3 For wrought Nickel-Rich, Chromium-Bearing alloys (UNS N06007, N06022, N06030,N06059, N06200, N06455, N06600, N06625, N06686, N06985, N08020, N08367,N08800, N08825, N10276) the statistical process control, mentioned in section3.2.8, shall include inter granular corrosion testing in accordance with ASTM G28method A.3.5.4 For other materials (not listed in ASTM A 262 and ASTM G 28) where inter granularcorrosion could be of concern (e.g., cast nickel-rich, chromium-bearing alloys) thestatistical process control, mentioned in section 3.2.8, shall include inter granularcorrosion testing with a relevant test. The procedure and acceptance criteria shallbe submitted to the Principal for approval.4. NON-DESTRUCTIVE EXAMINATION (NDE)4.1 Regardless of the sampling specified in section 4.2.1, a prototype casting shall be (orshall have been) fully inspected and tested by the manufacturer in accordance with thespecified acceptance criteria. In addition to the NDE specified in table 1, the prototypecasting shall be (or shall have been) radio-graphed (Ref. 4.2.5 note 5) in accordance withASME B16.34 section 8, with 100% full coverage of the casting. Acceptance level shallbe based on the requirements of ASME B16.34 annex B.4.2 NDE extent (sampling), methods and acceptance criteria shall be in accordance with thevalve design code and sections 4.2 and 4.3 of this MESC additional requirement.4.2.1 The valves on an order shall be separated into inspection lots.For valves produced by the same manufacturer a different lot is applicable for each ofthe following:- valve type (gate, globe, check, etc.)- valve body basic material type (carbon steel, LTCS, ferritic alloy, austenitic alloy,non-ferrous alloy, ferritic ductile iron, non-ferrous alloy)- quantity per heat batch (produced by the foundry) or heat treatment batch,whatever gives the biggest lot size.Each inspection lot shall be further divided into categories A and B as specified below:ACategoryASME rating: classes 150, 300, 600 All sizesBCategoryASME rating: classes 800, 900,All sizes1500, 1500 special class & 25004.2.2 From each inspection lot, percentage samples shall be taken in accordance with table 1,with a minimum of one valve per lot (which shall be the largest valve in that lot).4.2.3 A lot shall be accepted if all the samples of the lot meet the specified acceptance criteria.4.2.4 If any of the samples fails to meet the acceptance criteria, additional samples equal tothe original number shall be inspected.If these samples meet the acceptance criteria, the lot shall be accepted with theexception of the initially rejected items. If any of the additionally inspected samples failsto meet the acceptance criteria, then 100% of the lot shall be inspected or, at theprincipal's discretion, the entire lot shall be rejected.4.2.5 A sampling and inspection scheme shall be submitted to the principal.Table 1 Initial sample percentages per categoryComponentmaterial:carbon steels ferritic alloys(note 1) austeniticalloysnon-ferrousalloysSample (%) per category (section 4.2.1)Category(section 4.2.1)A B A B A B A B Visualinspection(notes 2 and 3)100 100 100 100 100 100 100 100Forging(notes 2, 6, 7 and 8)UT(note12)0 1000 1000 1000 100 MT10 10 10 10 0 0 0 0 PT 0 0 0 0 10 10 10 10Casting(notes 2,6, 7 and 8)RT 0 10 0 10 0 10 0 10MT10 10 10 10 0 0 0 0PT 0 0 0 0 10 10 10 10Butt welds (notes 5, 6, 8, 11)RT(note 9)100 100 100 100 100 100 100 100MT(note13)10 10 100 1000 0 0 0PT(note13)0 0 0 0 10 10 100100Butt weld valveends of casting(notes 8, 9)RT 100 100 100 100 100 100 100 100Butt weld valve ends of forging (notes 6, 8 )MT 10 10 100 100 0 0 0 0PT 0 0 0 0 10 10 100 100Butt weld valveends of “fabricated” valves(notes 5, 6, 8, 11)RT (note 9)100 100 100 100 100 100 100 100MT (note 13)1010 100 100 0 0 0 0PT(note 13)0 0 0 0 10 10 100 100 Weld overlays(note 3)PT 10 10 10 10 10 10 10 10Hardness test(note 4)10 10 10 10 10 10 10 10 Positive Material Identification (note 10)PMI ApplicableNOTES:1. Including duplex stainless steel and martensitic stainless steel.2. Body, bonnet, cover, body adapter and screwed ball valves inserts.3. Closure members such as gate/wedge, disc, ball, plug, seat rings and seat pocket / stem seal area.4. If required by the applicable standard (e.g. ASTM, NACE MR 0175).5. UT in lieu of RT may be applied if the configuration precludes RT. The UT acceptance criteria shall comply with ASME B16.34 Annex E.6. PT shall be applied if MT is not feasible or when the work efficiency and detection rate of defects is better.7. PT may be applied instead of MT for: - seat rings;- duplex stainless steel materials; - butt-welding ends.8. RT = radiographic examination; MT = magnetic particle examination PT = liquid penetrant examination; UT =ultrasonic examination.9. For all butt welds in cast and fabricated valve bodies including butt weld end preparations, with exception of those made by friction welds. For welded bonnet gate and globe check valves, DN 50 and smaller (designed toAPI 600, API 602, ISO15761) RT is 1% of the lot with a minimum of 1 valve.10. For CS valves as per manufacturer’s standard practice for materials having a P-number of 3 or more (ref. ASME section IX), i.e. alloy steel valves: PMI = 100% for forged & cast pressure retaining components, weld constructions and welding ends (if applicable).PMI = 10% for closure members in valves in nominal sizes DN 40 and smaller.11. For valves with welded on flanged ends and /or welded on bonnets (flanges).12. Only applicable in case of:- valve body and bonnet wall thickness over 100 mm, - end flange thickness over 100 mm, - adaptor flange thickness over 100 mm, - cover flange thickness over 100 mm.13. Weld surface after welding and weld bevel preparation prior to welding.4.3 NDE METHODS AND ACCEPTANCE CRITERIA4.3.1 Visual examination of castings shall be in accordance with MSS SP-55. Visual surfaceexamination of forging shall be in accordance with ASME B16.34 section 8.3.2.2.4.3.2 RT shall comply with ASME B16.34 section 8.3.1.1 (casting) and 8.3.2.1 (forging).UT shall comply with ASME B16.34 section 8.3.1.3 (casting) and 8.3.2.1 (forging).MT shall comply with ASME B16.34 section 8.3.1.2 (casting), 8.3.2.2 (forging) andAnnex C andPT shall comply with ASME B16.34 section 8.3.1.2 (casting), 8.3.2.2 (forging) andAnnex D.4.3.3 Exterior and accessible interior surfaces shall be examined (MP and PT) in the finalmachined condition.4.4 REPAIRDefect removal and repair shall be in accordance with ASME B16.34 section 8.All repairs to duplex stainless steel castings (UNS 31803) require liquid penetrant testingafter excavation of the defect and on completion of repair welding.5. CERTIFICATION AND TRACEABILITY5.1 GENERAL5.1.1 Documentary evidence shall be included in the technical dossier. The manufacturershall store this dossier for at least 10 years. The applicable type of inspectiondocuments shall be as specified in the purchase order.5.1.2 All certificates shall be originals or certified copies.5.1.3 The certificates shall be in the English language or in other languages if they areaccompanied by an endorsed and dated English translation of the contents.5.1.4 Certificates for components shall include certification of the base materials if physicaland mechanical properties of the components differ from those of the base materials. 5.1.5 In case a component is supplied by a processor, or an intermediary, and the componentmaterial deviates from base material, the certificate shall consist of two documentscovering both parts of the manufacturing process, and shall comply with ISO 10474. 5.1.6 The level of certification for both the base materials and the components shall be equal.5.1.7 The manufacturer shall implement a materials tracking system to ensure the correctmaterials are used. The manufacturer shall implement a materials traceability system toensure that materials requiring type 3.1.B certificates are fully traceable to theircertificates.DOCUMENTS5.2 INSPECTION5.2.1 The manufacturer shall be able provide:- inspection certificates in accordance with ISO 10474 type 3.1.B orEN 10204, type 3.1.B ,- test reports in accordance with ISO 10474 type 2.2 or EN 10204, type 2.2 or- certificate of compliance to ISO 10474 type 2.1, as defined in table 2.Table 2 Inspection certificates and test reportsComponent EN 10204 or ISO10474 certificate ortest reportMain pressure bearing parts in PED category I: e.g. body, bonnet, body (screwed) insert, cover, adapter and pressure retaining plugs / bleed connections (flanges)2.2 (note 4)Main pressure bearing parts in PED categories II, III & IV: e.g. body, bonnet, body (screwed) insert, cover, trunnion (in case it is part of the body) adapter and pressure retaining plugs / bleed connections (flanges)3.1.B (notes 2 and 4)Pressure controlling parts: e.g. closure members (gate/wedge, disc, ball, plug and seat rings,2.2 (see note 1)Stem and trunnion 2.2(see note 1)Non pressure bearing parts and sealing components (gaskets,packing, “O”- rings)2.1Hingepin 2.2 Bellows,springs 2.2 Stuffing box follower and gland flange 2.2Bolting (i.e. studs, bolts, screws, nuts). 2.2(notes 1 and 3) Examination (NDE), pressure testing and fugitive emission testing 3.1.B Finished valve in compliance with the specifications 3.1.BNOTES:1. For end users in European member states and countries in the European Free TradeAssociation (EFTA) traceability is sufficiently covered by the PED through Annex I, section3.1.5, Guideline 7/5, note 6.3.For other end users batch traceability is accepted provided the manufacturers documentedbatch traceability procedures guarantee that certification of parts without identification marks are fully traceable to a specific heat or heat treatment lot.2. Ref.: PED guidelines 7/5 and 7/16. Provided the manufacturer has an ISO 9000 series qualitymanagement system certified by a competent notified body and having undergone a specific assesment for materials.3. Ref.: PED guideline 7/8. Bolting is not considered to be main pressure bearing parts unless itsfailure would result in a sudden discharge of pressure. When bolting is used as main pressure bearing parts they shall be certified similar.4. Ref. PED guideline 7/6. Main pressure bearing parts are parts that constitute the pressureenvelope and are essential for the integrity of the equipment.5. Contents of documents:compliance shall state:ofCertificate2.1The manufacturer certifies that the products supplied comply with therequirements of the purchase order, without mention of any test results.The certificate of compliance is a document drawn up on the basis of non-specific inspection and testing.2.2 Test reports shall state:-test results, based on non-specific inspection and testing, specified in thepurchase order;-Principal’s purchase order number;-applicable material standards;-corresponding materials/items including relevant identification markings;-compliance with the specified requirements.3.1.B inspection certificates shall include:-test results, based on specific inspection and testing, specified in the purchaseorder,-manufacturer’s order number;-certificate identification number and date of issue;-a fully detailed material specification;-charge, batch or heat numbers;-both specified and actual mechanical properties and chemical compositions;-N.D.E. methods and results (when applicable);-Positive Material Identification (PMI) test results for materials having a P-number of 3 or more, as defined in ASME section IX;-results of hardness tests (when applicable);-results of impact tests (when applicable);-reference to heat treatment procedure, furnace charge number and heattreatment records (when applicable).6. DOCUMENTATION6.1 The valve manufacturer shall be able to provide documentation, which shall be availableprior to shipment. Computerised data or photo-copies of originals (verified and signed bythe QA/QC-department) may be provided instead of originals.The documentation shall include the following:-purchase order and identification of the valves by serial number or manufacturer's code.-materials test reports and inspection certificates as specified.-NDE reports, including sketches, if necessary, showing the locations of examination.Radiographs shall be retained by the manufacturer for at least five years.-listing of applicable and authorised concessions, waivers and/or material substitutions.-manufacturer's statement of compliance signed by an authorised representative.-all other requirements when valves are supplied with CE mark.-listing of applicable manuals (e.g. assembly/maintenance manuals).7. WITNESSING BY THE PRINCIPAL7.1 The principal shall specify if, and to what extent, he (or his representative) will witnessthe manufacturer's inspections and tests and/or will perform a document review beforeshipment.。

各种品牌机油的特点机油是汽车维护保养中非常重要的一部份,它起到润滑、冷却和清洁发动机内部零件的作用。

市场上有许多不同品牌的机油可供选择,每一个品牌都有其独特的特点和优势。

以下是各种品牌机油的特点的详细介绍:1. Shell 壳牌机油壳牌是全球率先的能源和石油化工公司,其机油产品备受消费者信赖。

壳牌机油的特点包括:- 高品质:壳牌机油采用先进的技术和高质量的原材料创造,确保发动机得到最佳的润滑和保护。

- 强大的清洁能力:壳牌机油能够有效清除发动机内部的杂质和沉积物,保持发动机的清洁。

- 适合性广泛:壳牌提供多种不同类型和粘度等级的机油,以满足各种不同车型和发动机的需求。

2. Mobil 美孚机油美孚是全球知名的润滑油品牌,其机油产品以其卓越的性能和可靠性而闻名。

美孚机油的特点包括:- 强大的润滑性能:美孚机油能够在各种工作条件下提供出色的润滑效果,减少发动机磨损。

- 高温稳定性:美孚机油能够在高温环境下保持稳定的性能,防止发动机过热。

- 节油效果明显:美孚机油具有减少磨擦和能量损失的特性,提高燃油经济性。

3. Castrol 嘉实多机油嘉实多是一家历史悠久的机油品牌,其产品以其卓越的品质和创新性能而受到广泛认可。

嘉实多机油的特点包括:- 先进的技术:嘉实多机油采用先进的添加剂和合成基础油,提供卓越的润滑和保护性能。

- 长期保护:嘉实多机油能够在长期使用中保持其性能,延长发动机的使用寿命。

- 适合性广泛:嘉实多提供多种不同类型和粘度等级的机油,以满足各种车型和发动机的需求。

4. Total 道达尔机油道达尔是一家全球能源公司,其机油产品以其卓越的性能和可靠性而闻名。

道达尔机油的特点包括:- 高级保护:道达尔机油采用高品质的原材料和添加剂,提供出色的发动机保护,减少磨损和沉积物的产生。

- 高温稳定性:道达尔机油能够在高温条件下保持稳定的性能,保护发动机免受过热的影响。

- 环保性能:道达尔致力于研发环保型机油,减少对环境的负面影响。

壳牌(中国)有限公司������Shell (China) Limited �网址: ������技术服务热线:(8610)65058880�安全、健康与环境保护�根据现有资料,在本产品的正确使用过程中,不会对人体健康产生不良影响,但在使用过程中需遵循物料安全数据表(MSDS )上所提供的指引,有关物料安全数据表可向壳牌销售代表索取。

如需处理使用过的油脂,请送到有关当局指定的回收点,不可将其排入下水道、土地和水中。

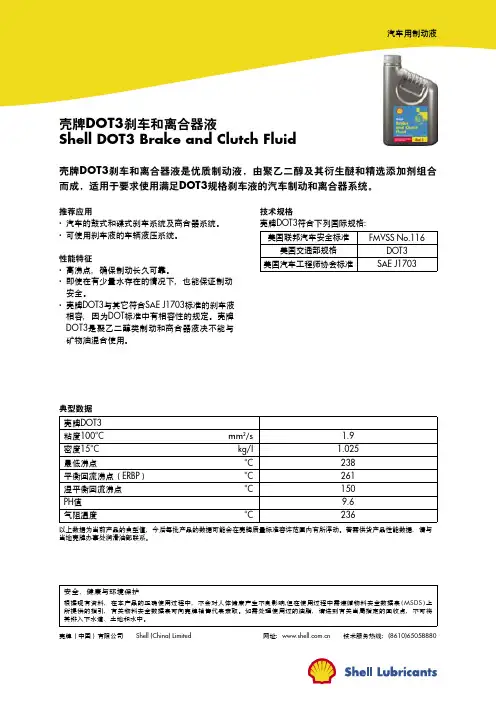

汽车用制动液壳牌DOT3刹车和离合器液Shell DOT3 Brake and Clutch Fluid壳牌DOT3刹车和离合器液是优质制动液,由聚乙二醇及其衍生醚和精选添加剂组合而成,适用于要求使用满足DOT3规格刹车液的汽车制动和离合器系统。

技术规格壳牌DOT3符合下列国际规格:美国联邦汽车安全标准FMVSS No.116美国交通部规格DOT3美国汽车工程师协会标准SAE J1703推荐应用· 汽车的鼓式和碟式刹车系统及离合器系统。

· 可使用刹车液的车辆液压系统。

性能特征· 高沸点,确保制动长久可靠。

· 即使在有少量水存在的情况下,也能保证制动安全。

· 壳牌DOT3与其它符合SAE J1703标准的刹车液相容,因为DOT 标准中有相容性的规定。

壳牌DOT3是聚乙二醇类制动和离合器液决不能与矿物油混合使用。

典型数据壳牌DOT3粘度100°C �mm 2/s 1.9密度15°C �kg/l 1.025最低沸点�°C 238平衡回流沸点(ERBP )�°C 261湿平衡回流沸点�°C150PH 值9.6气阻温度�°C 236以上数据为当前产品的典型值,今后每批产品的数据可能会在壳牌质量标准容许范围内有所浮动。

若需供货产品性能数据,请与当地壳牌办事处润滑油部联系。

壳牌的发家史可以追溯到19世纪末。

起初,壳牌石油公

司由英籍犹太商人马库斯·塞缪尔创立,主要从事贸易业务。

后来,他意识到运输石油的商机,于是开始将石油从亚洲市

场运输到当地,逐渐拓展了石油业务。

在19世纪80年代,

美国标准石油托拉斯和德士古、海湾等公司先后成立,壳牌

石油公司也在这个时期迅速发展壮大。

1901年,荷兰皇家石

油公司和英国壳牌运输贸易公司合并成为壳牌集团,这标志

着壳牌石油公司的全球化经营进入了一个新的阶段。

随着时

间的推移,壳牌石油公司逐渐成为全球最大的石油公司之一,业务遍及世界各地。

一、历史壳牌荷兰皇家/壳牌集团(Royal Dutch Shell,又译蚬壳公司)是世界第二大石油公司,总部位于荷兰海牙。

壳牌由荷兰皇家石油与英国的壳牌两家公司合并组成。

荷兰皇家石油于1890年创立,并获得荷兰女王特别授权,因此被命名为荷兰皇家石油公司。

为了与当时最大的石油公司,美国的标准石油竞争,1907年荷兰皇家石油与英国的壳牌运输贸易合并。

壳牌是所谓的七姊妹(Seven Sisters)之一,至今依然是石油、能源、化工与太阳能领域的重要竞争者。

壳牌拥有五大核心业务,包括勘探与生产、天然气及电力、煤气化、化工与可再生能源。

壳牌在全球140多个国家与地区拥有分公司或业务。

壳牌在中国的历史壳牌在中国发展业务,已超过一百多年。

在十九世纪90年代初,壳牌运输贸易的始创人马科·森默与森姆·森默兄弟,便已开始把煤油输入中国,并在香港、上海、广州与厦门建立油库。

1894年,森默兄弟已用散装油轮运送煤油到上海。

同年,荷兰皇家石油公司开始进"Crown"牌煤油到中国。

(当时内地称这"Crown"的品牌为僧帽牌;在香港则称宝盖牌)壳牌运输贸易与荷兰皇家石油公司原是竞争对手。

1903年,两家公司合作经营远东的业务,在伦敦成立亚细亚火油公司。

亚细亚火油公司分别於1906年及1908年在香港及上海成立办事处。

1913年,两个办事处分别成为亚细亚火油(华南)与亚细亚火油(华北)的总办事处。

1907年,荷兰皇家与壳牌运输合并业务,成立荷兰皇家/壳牌集团。

但当时公司在中国的业务仍通过亚细亚火油公司的名义经营。

至二次大战前,壳牌在中国设立了超过50间附属公司,在约20个省份经营1000个经销处。

大战期间,所有设备给日军占据,并严重破坏,一切经营活动停顿。

战后,壳牌的重建工作迅速进行。

当中华人民共与国于1949年成立时,壳牌已雇有员工超过1000人,其中包括35名外籍员工与4名华籍经理。

一.营销宗旨:以市场为导向,以满足消费者“高品味、个性化”之需求为营销宗旨。

通过广告宣传,产品促销来提升壳牌的市场竞争力。

壳牌自入主中国市场以来,一直致力于为不同的消费者提供专、.环保、标准化的服务,以满足不同用户的需求为宗旨。

壳牌坚持“诚实、正直、尊重他人”的核心价值观,提出了“只为驾御挑战“的宣传口号。

自2002年以来,经过多年发展,壳牌已在全国形成一个完善的销售网络,遍布全国的近千家壳牌喜力爱车养护中心广大车主提供优质、专业的换油及全方位的汽车保养服务,获得了广泛赞誉。

同时引进国外先进的管理理念,通过全方位的生意发展支持,帮助合作伙伴增强行业竞争力,最终成为行业中的精英。

二.产品策略中国是目前世界上汽车增长率最高的国家,近5年中国汽车的年复合增长率为20%,这对于润滑油等后汽车养护产品来说是一个巨大的机会。

中国润滑油领域的某位中国区高管表示:“未来十年,中国将全面进入汽车时代,谁将赢得中国市场,谁就将赢得未来润滑油的市场。

”可以说,中国将成为未来润滑油企业争夺最为激烈的市场,面对高端润滑油所展现出的巨大商机,众多润滑油企业都在思考如何将广阔的市场转变为收入囊中的商业前景。

我国润滑油市场主要服务于轿车市场,而轿车对于润滑油的要求更高。

根据目前的发展状况,高端润滑油的市场份额将进一步加大,这对于壳牌润滑油来说,是一个巨大的商机。

1.产品定位壳牌润滑油自入住中国市场以来,一直坚持走中高端路线,根据不同的用户,推出不同的产品,以满足消费者的需求。

目前在中国的壳牌润滑油市场上主要出现的产品有汽机油“喜力”,柴机油“劲霸”和摩托车机油“爱德王子”三大主打品牌。

2.产品质量功能方案壳牌自收购统一以来,凭借其成功的经验,产品技术、管理等支持统一提升到新的高度,利用最短的时间就实现了基础油采购、内部资源整合、技术配方等多方面的提高和改进,特别在产品质量主要是在产品使用效果方面取得了很好的成绩。

解决了粘度下降比较快和高温氧化速度比较快的问题,特别在QC(质量控制)和QA(质量考证)的监控体系上有很大的完善,另外对于产品的性能指标API上,壳牌保证了与实际润滑油品质的一致性。