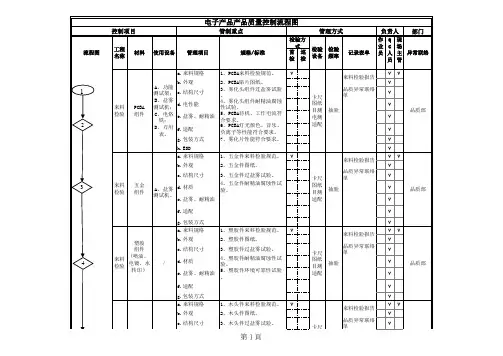

电子产品 质量控制工程图(ch)

- 格式:xls

- 大小:96.00 KB

- 文档页数:53

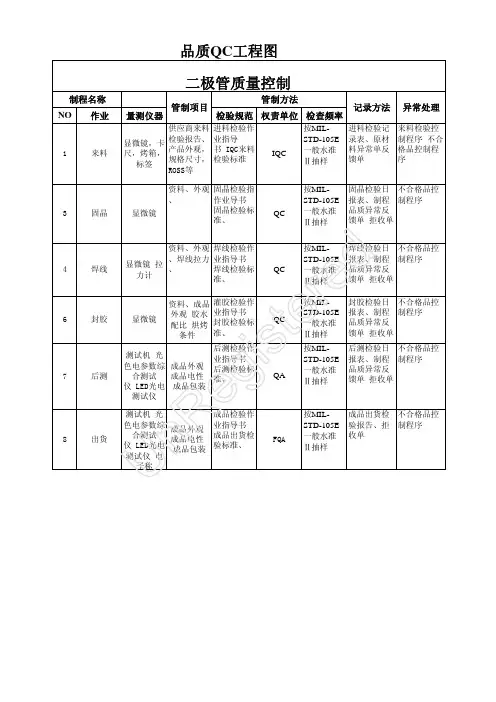

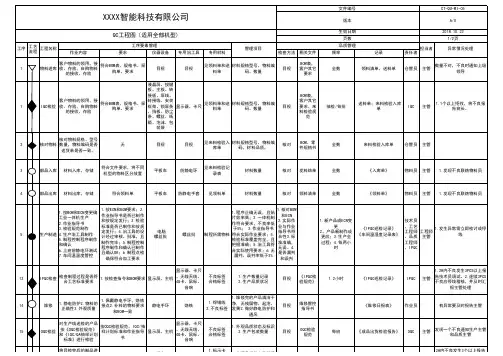

品质QC 工程图NO作业量测仪器检验规范权责单位检查频率不合格品控制程序8出货测试机,光色电参数综合测试仪,LED光电测试仪,电子称成品外观,成品电性,成品包装成品检验作业指导书,成品出货检验标准、FQA按MIL-STD-105E 一般水准Ⅱ抽样成品出货检验报告、拒收单不合格品控制程序后测检验作业指导书,后测检验标准、QA 按MIL-STD-105E 一般水准Ⅱ抽样后测检验日报表、制程品质异常反馈单,拒收单显微镜资料、成品外观,胶水配比,烘烤条件,按MIL-STD-105E 一般水准Ⅱ抽样封胶检验日报表、制程品质异常反馈单,拒收单7后测测试机,光色电参数综合测试仪,LED光电测试仪成品外观,成品电性,成品包装不合格品控制程序灌胶检验作业指导书,封胶检验标准、QC6封胶不合格品控制程序4焊线显微镜,拉力计资料、外观、焊线拉力、焊线检验作业指导书,焊线检验标准、QC按MIL-STD-105E 一般水准Ⅱ抽样焊线检验日报表、制程品质异常反馈单,拒收单不合格品控制程序固晶检验指作业导书,固晶检验标准、QC按MIL-STD-105E 一般水准Ⅱ抽样固晶检验日报表、制程品质异常反馈单,拒收单3固晶显微镜资料、外观、来料检验控制程序,不合格品控制程序进料检验作业指导书,IQC来料检验标准IQC按MIL-STD-105E 一般水准Ⅱ抽样进料检验记录表、原材料异常单反馈单1来料显微镜,卡尺,烤箱,标签供应商来料检验报告、产品外观,规格尺寸,ROSS等二极管质量控制制程名称管制项目管制方法记录方法异常处理Un Re gi st er edderetsigeRnU。

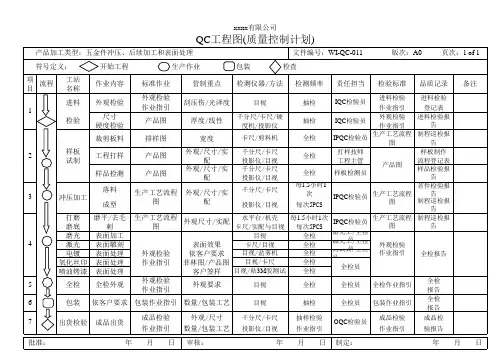

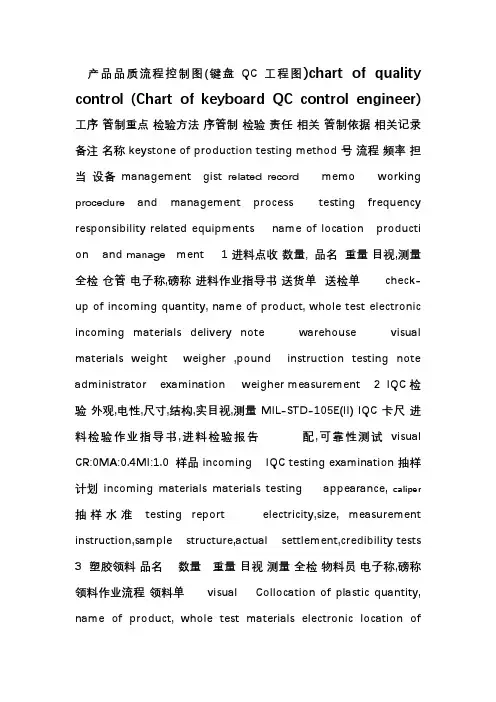

产品品质流程控制图(键盘QC工程图)chart of quality control (Chart of keyboard QC control engineer)工序管制重点检验方法序管制检验责任相关管制依据相关记录备注名称keystone of production testing method 号流程频率担当设备management gist related record memo working procedure and management process testing frequency responsibility related equipments name of location producti on and manage ment 1 进料点收数量, 品名重量目视,测量全检仓管电子称,磅称进料作业指导书送货单送检单 check-up of incoming quantity, name of product, whole test electronic incoming materials delivery note warehouse visual materials weight weigher ,pound instruction testing note administrator examination weigher measurement 2 IQC检验外观,电性,尺寸,结构,实目视,测量 MIL-STD-105E(II) IQC 卡尺进料检验作业指导书,进料检验报告配,可靠性测试visual CR:0MA:0.4MI:1.0 样品 incoming IQC testing examination 抽样计划incoming materials materials testing appearance, caliper抽样水准testing report electricity,size, measurement instruction,sample structure,actual settlement,credibility tests 3 塑胶领料品名数量重量目视测量全检物料员电子称,磅称领料作业流程领料单visual Collocation of plastic quantity, name of product, whole test materials electronic location of materials location of injection materials weight examination weigher ,pound process materialsadministrator weigher sheet measurement 4 成型目视全检成型作业员刀片,成型机成型作业指导书设备保养记录表外观 visualMoulding moulding working QC记录表examination whole testoperator instruction moulding Razor blade, maintenance of appearancemolding machine equipments note sheet 5 塑胶制品制程检验外观,电性,尺寸,结构,实目视测量 MIL-STD-105E(II) IPQC 卡尺,拉拔力测试塑胶检验指导书,样品巡检记录表配,可靠性测试CR:0MA:0.4MI:1.0 仪色卡 plastic testing instruct visual process ofplastic 抽样计划caliper,die pull book,sample polling note appearance, examination, injection product testing 抽样水准tester,sheet electricity,size, measurement and production colour chart structure,actual settlement,credibility tests 6 半成品领料品名,数量目视,测量全检物料员电子称领料作业流程领料单semi-manufactured visual quantity, name of product weigher oflocation electronic whole testmaterials location of materials located examination, materials processadministratormeasurementsheet 审核:批准:制定:任宏献 WI-QD-060 A/0 产品品质流程控制图(键盘QC工程图)chart of quality control(Chart of keyboard QC control engineer) 7 SOP 插件外观,结构,DIP电目测,测量全检作业员/拉长万用表首件记录单operator/chief 子原件的性能 visual plug-in board of party Multimeter whole testappearance, structure, examination, first piece note measurementsheet performance of electronic DIPcomponent 8 SOP贴片外观,结构,SMT电目测,测量全检作业员/拉长万用表首件记录单operator/chief 子原件的性能visual patch appearance, of party Multi meter examination, whole testfirst piecenote structure, measurementsheet performance of electroniccomponent DIP 9 SOP DIP过炉DIP温度,速度,助焊剂目测,测量每小时一次技术员/拉长测温计设备点检记录/electrictechnician/ one time per hour 的浓度温度记录单 cooker testingvisual thermodetector SMT过炉波峰焊speed,Centigrade, examination, chief of partyinstrument SMT chroma of welding fluxcheckout wave crest electric cooker testingmeasurementsheet,jointing centigrade 回流焊note sheetcircumfluence jointingSOP 后焊 SEAL 外观目测,测量每两小时一次拉长测计温铬铁温度点 10 Chrome ironan appearance, thermodetector visualchief of party centigrade one time every 温度 examination,checkout sheet Centigrade two hours 铬铁 measurement Chromeironan检表 SOP 半成品测试电性测试全检电测QC 电程,示波器QC日报表 11 semi-manufactured electric performance Electrictest electric QCdaily report measurement testing QC measurement,sheet whole test oscillograph 审核:批准:制定:任宏献 WI-QD-060 A/0产品品质流程控制图(键盘QC工程图)chart of quality control (Chart of keyboard QC control engineer) IPQC 半成品制程检验及外观,电性,结构,目视,测量成用表,卡尺检验规范 checking 巡检记录表 12 MIL-STD-105E(II) finished product standard 抽检尺寸实装,可靠性测CR:0MA:0.4MI:1.0 polling note 抽样计划 semi-manufactured measurement 试测试作业指书 visual sheet抽样水准 production process apparatus, Testing working 异常单appearance, electric examination, caliper abnormity check and sample instruction performance, structure, measurement sheetsize of packing, credibility tests FQC PCBA出货检验外观,电性,结构,目视,测量专用测试治具,测试标准出货记录表 13 MIL-STD-105E(II) Testing shipment 尺寸实装,可靠性测 visual CR:0MA:0.4MI:1.0 special use check standard, 抽样计划 goods note PCBA 试检验标准 examination, tools CARGO 抽样水准 sheet checking standard 万用表CHECKappearance, electric measurement performance, structure, Multi meter size of packing, credibility tests 14 组装领料数量, 品名目视全检领料作业流程领料单物料员电子称,磅称 Collocated materials Quantity, name of product location of materials location of materials electronic Visual test assembling bywhole test process materials administrator weigher ,pound packaging weigher sheet 插键帽全检作业员/拉长压键帽专用冶具,SOP 首件记录单作业手式,数量,品名,规格目视 15 Insert cover of Operator/ chief of 电子称 First piecenote handle working type, Visual test keyboard whole test partyspecial machine for sheet quantity, name of product, specificationcovering cover of keyboard,electronic weigher 外观QC 污点比对板样品,外观检验规范 OQ记录表 16 面壳外观检验外观,结构,实配目视全检 appearance appearance, , sample, standard of OQ note sheet appearance of crust Visual testQC structure,actual blot compared appearance checkout testing whole test settlement board 作业员镭射机,自动印刷印刷/镭射外观, 结构目视全栓 17 镭射机作业指导书,印首件记录表 Printing/Laser appearance, , 机,手动移印机刷机作业指导书 first piece note Visual test Laser machine structure Lasermachine and OPERATOR whole test sheet automatic printingmachine printing working machine, instruction handle print审核:批准:制定:任宏献 WI-QD-060 A/0 产品品质流程控制图(键盘QC工程图)chart of quality control(Chart of keyboard QC control engineer) machine 成品组装面盖外观,结构,目视全检作业员电批,铬铁,扭力SOP 首件记录表18 finished product appearance, , 测试仪 first piece note Visual testcovering structure dynamoelectric whole test OPERATOR sheetto install screw machine, Chrome ironan ,instrum ent of thetorque tests, / 19 手感测试手感感觉,目视全检手感QC SOP 首件记录表first sense, visual handle testing handle piece note sheetexamination, Whole test HANDLE QC QC报表 QC report forms 20 打后盖螺丝外观目视全检作业员电批SOP 首件记录表dynamoelectric Make screw of behind first piece note appearanceVisual testWhole test to install screw cover OPERATOR sheet machine 程序测试全检电测1 电性电测QC 电脑电测作业指导书QC日报表21 Electric test Eltctric nature electric test computer guidance of electric QC Quality control process test Whole test quality control test form /day 目视全检外观检验面壳外观外观QC 污点比对板外观检验标准 QC日报表 22 aspect test Shell aspect Aspect QC Standard aspect test Comparison QCQuality control Visual test Whole test board of flot form /day 目视,比对全检键帽比对字体,外观比对QC 外观检验标准比对板 QC日报表23 Visual test Whole test Key and shell Letterform ,aspect Comparison Standard aspect test Comparison sheet QC Quality control Comparison Comparison of QC form /day 程序测试全检电测2 电性电测QC 电测作业指导书电脑 QC日报表 24 process test Whole test Electric test Electric nature electric test guidance of electric computer QC Quality control quality control test form /day 程序测试全检复检电测电性电测QC 电测作业指导书电脑 QC日报表25 process test Whole test Electric retest Electric nature electric test guidance of electric computer QC Quality control quality control test form /day 目视全检总检,测试平台外观,结构外观QC 外观检验标准平台板 QC日报表 26 Visual test Whole test Generaltest, Aspect , Aspect QC Standard aspect test board structureQCQuality control Test flat board form /day 审核:批准:制定:任宏献 WI-QD-060 A/0产品品质流程控制图(键盘QC工程图)chart of qualitycontrol (Chart of keyboard QC control engineer)包装外观,结构,正侧麦目视全检作业员 / SOP 送检单,入库单 27packing 数量Visual test Whole test operator List of inspectionAspect , structure , List of amount warehouse 外观,电性,尺寸,结构,FQC 卡尺,样品 FQC 目视,测量电性测试标准 FQC成品检验 28MIL-STD-105E(II) 实配,可靠性测试电脑实装,实用外观检验标准记录 CR:0MA:0.4MI:1.0 Aspect, electric Visual test Standard of electricNote inspection Calipers nature , Measurement test of finishedSample Structure, Fact of Standard of aspect product computerreliability test packing test 品名,数量入库目视全检仓管磅称入库作业指导书成品入库单 29 warehouse Visual test Whole testAdminister of weight guidance of 成品送检单Article quantity warehouse warehouse Inspection list of finished product仓管出货品名,数量目视全检磅称成品出货作业指导出货单30 Administer of Visual test Whole test weight 书 List of outing Outingof product Article quantity warehouse Guidance of finished productproduct OQC 目视,称重全检磅称出货检验运输工具,产品正侧出货作业规范出货检验报告31 Visual test Whole test weightInspection of outing 麦Guidance of outing shipment goods measurement product 数量,品名,序号,product checkout note 箱号,重量,外观等sheet Conveyance amount serial number, itemname ,weight, aspect管制流程说明:输入入转接端:品质检验控制工位:生产流程:成品输出端:Process explain of Control : input interface inspection and qualitycontrol position produce process interface of outingproduct 审核:批准:制定:任宏献 WI-QD-060 A/0。

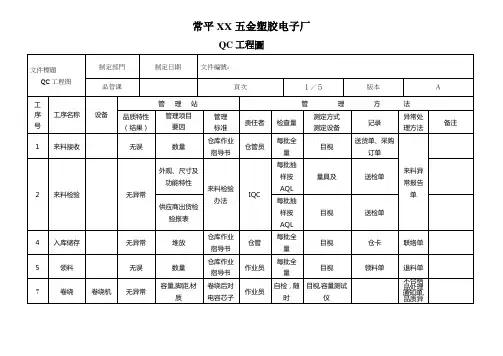

文件编号页号1/3A发行日期2013/8/28修订日期阶段检查(P/D/B/R频次电路板干燥温度设备技术员设备主管《干燥箱温度记录表》《干燥箱维护及点检记录表》干燥干燥时间操作员组长/拉长《干燥存贮品记录表》存贮温度设备技术员设备主管《冰箱温度控制表》《冰箱维护及点检记录表》解冻时间操作员组长/拉长《锡浆存贮品记录表》设备及夹具/辅料控制项目标准/规格S-02锡浆存贮/解冻R 电冰箱温度2-10℃发行范围:SMT生产线(一份、SMT办公室(一份、资料室(一份 SMC蚬华多媒体制品有限公司WI-SVP-000022文件名称: 40G6731 QC工程图版本号修订号相关记录S-01R干燥箱(银河 D6T202A 或科通 101-4APCB板:120±5℃1次/天PCB板:3小时-5小时序号工序名称1次/班次锡浆解冻:1小时(自然解冻责任人报告对象锡浆搅拌R锡浆搅拌机(智茂 GAM-60搅拌时间1次/班次设备技术员设备主管《锡浆搅拌机点检记录表》设备技术员设备主管《丝印机维护及点检记录表》操作员组长/拉长《钢网使用时间记录表》设备技术员设备主管《锡浆测试仪维护及点检记录表》操作员组长/拉长《锡浆高度测试记录表》设备技术员设备主管《贴片机维护及点检记录表》操作员组长/拉长《SMD装料核对表》S-041次/班次S-03时间:0.5-1分钟锡浆高度测试R锡膏检测仪(Lascan L3000 3D锡浆高度锡浆高度:(0.13-0.17mm印锡浆R丝印机(Speedline SPM/B或Speedline ACCUFLEX、锡浆(无铅、40G6731钢网气压、钢网使用次数气压(5.0Kgf/C㎡-7.0Kgf/C㎡、钢网使用次数2.5万次3pcs/小时气压气压:〔4.0Kgf/C㎡-6.0Kgf/C㎡〕1次/天批准S-06贴装元件RSONY贴片机(SS-H2F或SI-F130或SI-F130AIS-05编写审核文件编号页号2/3A发行日期2013/8/28修订日期阶段检查(P/D/B/R频次ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC检验记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产作检验记录表发行范围:SMT生产线(一份、SMT办公室(一份、资料室(一份 SMC蚬华多媒体制品有限公司WI-SVP-000022相关记录文件名称:40G6731 QC工程图版本号修订号序号工序名称设备及夹具/辅料控制项目标准/规格S-07炉前目检R5×放大镜(CTBRAND NO:CT-200M、防静电手腕带、防静电手套责任人报告对象S-08洄流炉焊接R 热风洄流炉(科隆威NW-850N或科隆威 FL-VP860N温度曲线图参考〔40G6731炉温曲线图〕5×放大镜(CTBRAND NO:CT-200M、目检模1次/首件设备技术员设备主管《洄流炉维护及点检记录表》《每日温度曲线图》参考《IPC-A-610D》参考《IPC-A-610D》S-9炉后目检R生产质量100%操作员组长/拉长《QC检验记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC 检验记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC检验记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC检验记录表》审核板、防静电手腕带、防静电手套防静电手腕带、防静电手套、手指套S-10插插件R防静电手腕带、手指套、防静电物料盒参考《IPC-A-610D》参考《IPC-A-610D》S-12波峰焊R波峰机(科隆威 FL-MD300N、锡条、助焊剂温度曲线图参考每日炉温曲线图S-11炉前理板RR防静电手腕带、防静电手套1次/首件设备技术员设备主管《波峰炉维护及点检记录表》《炉温测试确认表》批准参考《IPC-A-610D》编写S-13炉后目检文件编号页号3/3A发行日期2013/8/28修订日期阶段检查(P/D/B/R频次ESD防护 2次/天组长拉长《手腕带检测记录表》电烙铁温度100%操作员组长/拉长《烙铁温度记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC检验记录表》发行范围:SMT生产线(一份、SMT办公室(一份、资料室(一份SMC蚬华多媒体制品有限公司WI-SVP-000022文件名称:40G6731 QC工程图版本号修订号序号工序名称设备及夹具/辅料控制项目标准/规格S-14执锡R防静电手腕带、手指套、电烙铁(HAKO FX-951S-15分板R 分板机(PeeiMoGer、防静电手腕带、防静电盒子、防静电手套责任人报告对象相关记录参考《IPC-A-610D》电烙铁温度:390±5℃参考《IPC-A-610D》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC检验记录表》操作员组长/拉长《QC检验记录表》《ICT样板测试记录表》设备技术员设备主管《ICT维护及点检记录表》操作员组长/拉长《QC检验记录表》《CFT样板测试记录表》设备技术员设备主管《CFT维护及点检记录表》ESD防护2次/天组长拉长《手腕带检测记录表》生产质量100%操作员组长/拉长《QC 检验记录表》包装R防静电盒子、防静电胶箱、防静电手套ESD防护2次/天操作员组长《手腕带检测记录表》审核参考《IPC-A-610D》防静电手腕带、手指套、条行码100%参考《IPC-A-610D》ICT测试R RS-16.贴条码测试仪(捷智 JET-300NT或振华 T623F电脑及传输设备、40G6731针床样板校验参考40G6731合格样板100%样板校验气压(4.0Kgf/C㎡-6.0Kgf/C ㎡参考40G6731合格样板S-18功能测试R 功能测试工装S-17编写批准S-19QC生产质量总检R防静电手腕带、防静电手套、5×放大镜(CTBRAND NO:CT-200M、防静电胶箱、QC印章参考《IPC-A-610D》S-20.。