ZCYS1512中文资料

- 格式:pdf

- 大小:53.41 KB

- 文档页数:2

aisi1215 成分AISI 1215是一种低碳钢,含有约0.09-0.13%的碳和约0.60-0.90%的锰。

它在热处理后具有良好的可加工性和可焊接性,被广泛应用于制造机械零件和汽车组件等领域。

1. AISI 1215的化学成分AISI 1215的化学成分对其性能和加工性能有着重要影响。

其中,碳含量的控制可以提高钢的硬度和强度,同时也会降低其可塑性和可焊性。

锰含量的增加可以提高钢的硬度和韧性。

此外,钢中还可能含有微量的硫和磷,这些元素可以在加工过程中起到润滑剂的作用,提高加工性能。

2. AISI 1215的热处理AISI 1215在热处理过程中主要通过控制温度和冷却速率来改变其组织和性能。

一般而言,通过淬火可以提高钢的硬度和强度,但会降低其可塑性。

而回火则可以减少内部应力,提高钢的韧性和可塑性。

在进行热处理时,需要注意控制温度和时间,以避免产生不均匀的组织和性能。

3. AISI 1215的机械性能AISI 1215具有较高的切削加工性能,适用于自动化机械加工和高速切削。

其硬度一般在150-200HB之间,强度较低。

由于含碳量较低,AISI 1215的韧性较好,不易出现脆性断裂。

此外,AISI1215还具有较好的可焊性,可以通过常规的焊接方法进行连接。

4. AISI 1215的应用领域由于AISI 1215具有良好的可加工性和可焊性,广泛应用于制造机械零件和汽车组件等领域。

例如,它可以用于制造螺钉、螺母、轴承、销子、键和挡圈等小型零件。

由于AISI 1215的加工性能优秀,可以减少加工成本和提高生产效率。

5. AISI 1215的注意事项在使用AISI 1215钢材时,需要注意以下几点。

首先,由于碳含量较低,AISI 1215的强度较低,不适用于承受高强度要求的零件。

其次,由于硫和磷的存在,AISI 1215在高温条件下容易产生热裂纹,因此需要注意控制加工温度和冷却速率。

此外,由于AISI 1215的可焊性较好,但焊接过程中会产生硫化物和磷化物,可能对焊接接头的性能产生不利影响,因此需要采取适当的焊接工艺和控制焊接条件。

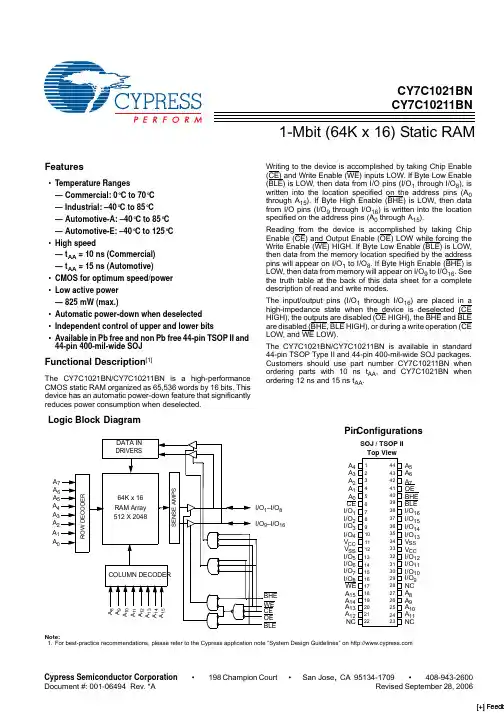

1-Mbit (64K x 16) Static RAMCY7C1021BN CY7C10211BNFeatures•Temperature Ranges —Commercial: 0°C to 70°C —Industrial: –40°C to 85°C —Automotive-A: –40°C to 85°C —Automotive-E: –40°C to 125°C •Highspeed—t AA = 10 ns (Commercial)—t AA = 15 ns (Automotive)•CMOS for optimum speed/power •Low active power—825 mW (max.)•Automatic power-down when deselected •Independent control of upper and lower bits•Available in Pb free and non Pb free 44-pin TSOP II and 44-pin 400-mil-wide SOJFunctional Description [1]The CY7C1021BN/CY7C10211BN is a high-performance CMOS static RAM organized as 65,536 words by 16 bits. This device has an automatic power-down feature that significantly reduces power consumption when deselected.Writing to the device is accomplished by taking Chip Enable (CE) and Write Enable (WE) inputs LOW. If Byte Low Enable (BLE) is LOW, then data from I/O pins (I/O 1 through I/O 8), is written into the location specified on the address pins (A 0through A 15). If Byte High Enable (BHE) is LOW, then data from I/O pins (I/O 9 through I/O 16) is written into the location specified on the address pins (A 0 through A 15).Reading from the device is accomplished by taking Chip Enable (CE) and Output Enable (OE) LOW while forcing the Write Enable (WE) HIGH. If Byte Low Enable (BLE) is LOW,then data from the memory location specified by the address pins will appear on I/O 1 to I/O 8. If Byte High Enable (BHE) is LOW, then data from memory will appear on I/O 9 to I/O 16. See the truth table at the back of this data sheet for a complete description of read and write modes.The input/output pins (I/O 1 through I/O 16) are placed in a high-impedance state when the device is deselected (CE HIGH), the outputs are disabled (OE HIGH), the BHE and BLE are disabled (BHE, BLE HIGH), or during a write operation (CE LOW, and WE LOW).The CY7C1021BN/CY7C10211BN is available in standard 44-pin TSOP Type II and 44-pin 400-mil-wide SOJ packages.Customers should use part number CY7C10211BN when ordering parts with 10 ns t AA , and CY7C1021BN when ordering 12 ns and 15 ns t AA .Note:1.For best-practice recommendations, please refer to the Cypress application note “System Design Guidelines” on Logic Block Diagram64K x 16RAM Array I/O 1–I/O 8R O W D E C O D E RA 7A 6A 5A 4A 3A 0COLUMN DECODERA 9A 10A 11A 12A 13A 14A 15512 X 2048S E N S E A M P SDATA INOE A 2A 1I/O 9–I/O 16CE WE BLEBHE A 8DRIVERSWE 12345678910111431323635343337403938Top ViewSOJ / TSOP II 12134144434216152930V CC A 15A 14A 13A 12NCA 4A 3OE V SS A 5I/O 16A 2CE I/O 3I/O 1I/O 2BHE NC A 1A 018172019I/O 42728252622212324NCV SS I/O 7I/O 5I/O 6I/O 8A 6A 7BLE V CC I/O 15I/O 14I/O 13I/O 12I/O 11I/O 10I/O 9A 8A 9A 10A 11Pin ConfigurationsCY7C10211BNSelection Guide7C10211B-107C1021B-127C1021B-15 Maximum Access Time (ns)101215 Maximum Operating Current (mA)Com’l / Ind’l150140130Automotive-A130Automotive-E130 Maximum CMOS Standby Current (mA)Com’l / Ind’l101010Com’l / Ind’l (L version)0.50.50.5Automotive-A (L version)0.5Automotive-E15Pin DefinitionsPin Name SOJ, TSOP–Pin Number I/O Type DescriptionA0–A151–5,18–21, 24–27, 42–44Input Address Inputs used to select one of the address locations.I/O1–I/O167–10, 13–16, 29–32,35–38Input/Output Bidirectional Data I/O lines. Used as input or output lines depending on operation.NC22, 23, 28No Connect No Connect s. Not connected to the die.WE17Input/Control Write Enable Input, active LOW. When selected LOW, a Write isconducted. When deselected HIGH, a Read is conducted.CE6Input/Control Chip Enable Input, active LOW. When LOW, selects the chip. WhenHIGH, deselects the chip.BHE, BLE40, 39Input/Control Byte Write Select Inputs, active LOW. BHE controls I/O16–I/O9,BLE controls I/O8–I/O1, .OE41Input/Control Output Enable, active LOW. Controls the direction of the I/O pins.When LOW, the I/O pins are allowed to behave as outputs. Whendeasserted HIGH, I/O pins are tri-stated, and act as input data pins.V SS12, 34Ground Ground for the device.Should be connected to ground of thesystem.V CC11, 33Power Supply Power Supply inputs to the device.CY7C10211BNMaximum Ratings(Above which the useful life may be impaired. For user guide-lines, not tested.)Storage Temperature .................................–65°C to +150°C Ambient Temperature withPower Applied.............................................–55°C to +125°C Supply Voltage on V CC Relative to GND[2]....–0.5V to +7.0V DC Voltage Applied to Outputsin High Z State[2]......................................–0.5V to V CC+0.5V DC Input Voltage[2]...................................–0.5V to V CC+0.5V Current into Outputs (LOW).........................................20 mA Static Discharge Voltage............................................>2001V (per MIL-STD-883, Method 3015)Latch-Up Current.....................................................>200 mA Operating RangeRangeAmbientTemperature (T A)[3]V CC Commercial0°C to +70°C 5V± 10% Industrial–40°C to +85°CAutomotive-A–40°C to +85°CAutomotive-E –40°C to +125°CElectrical Characteristics Over the Operating RangeParameter DescriptionTestConditions-10-12-15UnitMin.Max.Min.Max.Min.Max.V OH Output HIGHVoltageV CC = Min., I OH = –4.0 mA 2.4 2.4 2.4VV OL Output LOWVoltageV CC = Min., I OL = 8.0 mA0.40.40.4VV IH Input HIGHVoltage2.2 6.0 2.2 6.0 2.2 6.0VV IL Input LOWVoltage[2]−0.50.8–0.50.8–0.50.8VI IX Input LeakageCurrent GND < V I < V CC Com’l / Ind’l−1+1–1+1–1+1µA Automotive-A–1+1µAAutomotive-E–4+4µAI OZ Output LeakageCurrent GND < V I < V CC,Output DisabledCom’l / Ind’l−1+1–1+1–1+1µAAutomotive-A–1+1µAAutomotive-E–4+4µAI CC V CC OperatingSupply Current V CC = Max.,I OUT = 0mA,f = f MAX = 1/t RCCom’l / Ind’l150140130mAAutomotive-A130Automotive-E130I SB1Automatic CEPower-DownCurrent—TTLInputs Max. V CC,CE > V IHV IN > V IH orV IN < V IL, f = f MAXCom’l / Ind’l404040mAAutomotive-A40Automotive-E50I SB2Automatic CEPower-DownCurrent—CMOS Inputs Max. V CC,CE > V CC – 0.3V,V IN > V CC – 0.3V,or V IN < 0.3V, f = 0Com’l / Ind’l101010mACom’l / Ind’l (L) 0.50.50.5Automotive-A (L)0.5Automotive-E15Capacitance[4]Parameter Description Test Conditions Max.UnitC IN Input Capacitance T A = 25°C, f = 1 MHz,V CC = 5.0V 8pFC OUT Output Capacitance8pF Notes:2.V IL (min.) = –2.0V and V IH(max) = V CC + 0.5V for pulse durations of less than 20 ns.3.T A is the “Instant On” case temperature.4.Tested initially and after any design or process changes that may affect these parameters.CY7C10211BNThermal Resistance [4]ParameterDescriptionTest Conditions44-pin SOJ 44-pin TSOP-IIUnit ΘJA Thermal Resistance (Junction to Ambient)Test conditions follow standard test methods and procedures for measuring thermal impedance, per EIA / JESD51.64.3276.89°C/W ΘJCThermal Resistance (Junction to Case)31.0314.28°C/WAC Test Loads and WaveformsSwitching Characteristics [5] Over the Operating RangeParameter Description7C10211B-107C1021B-127C1021B-15UnitMin.Max.Min.Max.Min.Max.Read Cycle t RC Read Cycle Time 101215ns t AA Address to Data Valid101215ns t OHA Data Hold from Address Change 333ns t ACE CE LOW to Data Valid 101215ns t DOE OE LOW to Data Valid 567ns t LZOE OE LOW to Low Z [6]0ns t HZOE OE HIGH to High Z [6, 7]567ns t LZCE CE LOW to Low Z [6]333ns t HZCE CE HIGH to High Z [6, 7]567ns t PU CE LOW to Power-Up 0ns t PD CE HIGH to Power-Down 101215ns t DBE Byte Enable to Data Valid 567ns t LZBE Byte Enable to Low Z 0ns t HZBEByte Disable to High Z567nsNotes:5.Test conditions assume signal transition time of 3 ns or less, timing reference levels of 1.5V, input pulse levels of 0 to 3.0V, and output loading of the specified I OL /I OH and 30-pF load capacitance.6.At any given temperature and voltage condition, t HZCE is less than t LZCE , t HZOE is less than t LZOE , and t HZWE is less than t LZWE for any given device.7.t HZOE , t HZBE , t HZCE , and t HZWE are specified with a load capacitance of 5 pF as in part (b) of AC Test Loads. Transition is measured ±500 mV from steady-state voltage.INCLUDING INCLUDING R 481ΩR 481ΩR2255R2255167Equivalent to:THÉVENINEQUIVALENT1.73VFall Time: 1 V/ns90%10%3.0VGND90%10%ALL INPUT PULSES 5V OUTPUT30 pFJIG AND SCOPE 5V OUTPUT5 pFJIG AND SCOPE (a)(b)OUTPUT ΩΩ30 pFRise Time: 1 V/nsCY7C10211BNWrite Cycle [8]t WC Write Cycle Time 101215ns t SCE CE LOW to Write End 8910ns t AW Address Set-Up to Write End 7810ns t HA Address Hold from Write End 000ns t SA Address Set-Up to Write Start 000ns t SD Data Set-Up to Write End 568ns t HD Data Hold from Write End 000ns t LZWE WE HIGH to Low Z [6]333ns t HZWE WE LOW to High Z [6, 7]567ns t BWByte Enable to End of Write789nsSwitching WaveformsRead Cycle No. 1[9, 10]Read Cycle No. 2 (OE Controlled)[10, 11]Notes:8.The internal write time of the memory is defined by the overlap of CE LOW, WE LOW and BHE / BLE LOW. CE, WE and BHE / BLE must be LOW to initiate a write, and the transition of these signals can terminate the write. The input data set-up and hold timing should be referenced to the leading edge of the signal that terminates the write.9.Device is continuously selected. OE, CE, BHE and/or BHE = V IL .10.WE is HIGH for read cycle.Switching Characteristics [5] Over the Operating Range (continued)Parameter Description7C10211B-107C1021B-127C1021B-15Unit Min.Max.Min.Max.Min.Max.PREVIOUS DATA VALIDDATA VALIDt RCt AAt OHAADDRESSDATA OUT50%50%DATA VALIDt RCt ACEt DOE t LZOE t LZCE t PUHIGH IMPEDANCEt HZOEt HZBEt PDHIGHICC ISB IMPEDANCEDATA t DBE t LZBEt HZCE I CCI SBADDRESSOE CEBHE,BLEOUT V CC SUPPLY CURRENTCY7C10211BNWrite Cycle No. 1 (CE Controlled)[12, 13]Write Cycle No. 2 (BLE or BHE Controlled)Notes:11.Address valid prior to or coincident with CE transition LOW.12.Data I/O is high impedance if OE or BHE and/or BLE= V IH .13.If CE goes HIGH simultaneously with WE going HIGH, the output remains in a high-impedance state.Switching Waveforms (continued)t HDt SDt SCEt SA t HAt AWt PWEt WCBWDATA ADDRESSBHE,t CEWEBLEI/Ot HDt SDt BWt SA t HAt AWt PWEt WCt SCEDATA I/OADDRESSBHE,BLEWECECY7C10211BNWrite Cycle No. 3 (WE Controlled, OE LOW)Switching Waveforms (continued)t HDt SDt SCEt HAt AWt PWEt WCt BWDATA I/OADDRESSCEWEBHE,BLEt SAt LZWEt HZWETruth TableCE OE WE BLE BHE I/O 1–I/O 8I/O 9–I/O 16ModePowerH X X X X High Z High Z Power-Down Standby (I SB )LLHL L Data Out Data Out Read - All bits Active (I CC )L H Data Out High Z Read - Lower bits only Active (I CC )HL High Z Data Out Read - Upper bits only Active (I CC )LXLL L Data In Data In Write - All bits Active (I CC )L H Data In High Z Write - Lower bits only Active (I CC )HL High Z Data In Write - Upper bits only Active (I CC )L H H X X High Z High Z Selected, Outputs Disabled Active (I CC )LXXHHHigh ZHigh ZSelected, Outputs DisabledActive (I CC )CY7C10211BN Ordering InformationSpeed(ns)Ordering Code PackageDiagram Package TypeOperatingRange10CY7C10211BN-10ZXC51-8508744-pin TSOP Type II Commercial 12CY7C1021BN-12VC51-8508244-pin (400-Mil) Molded SOJ Commercial CY7C1021BN-12VXC44-pin (400-Mil) Molded SOJ (Pb-Free)CY7C1021BN-12ZC51-8508744-pin TSOP Type IICY7C1021BN-12ZXC44-pin TSOP Type II (Pb-Free)CY7C1021BN-12VI51-8508244-pin (400-Mil) Molded SOJ IndustrialCY7C1021BN-12VXI44-pin (400-Mil) Molded SOJ (Pb-Free) 15CY7C1021BN-15VC51-8508244-pin (400-Mil) Molded SOJ Commercial CY7C1021BN-15VXC44-pin (400-Mil) Molded SOJ (Pb-Free)CY7C1021BNL-15VXC44-pin (400-Mil) Molded SOJ (Pb-Free)CY7C1021BN-15ZC51-8508744-pin TSOP Type IICY7C1021BN-15ZXC44-pin TSOP Type II (Pb-Free)CY7C1021BNL-15ZC44-pin TSOP Type IICY7C1021BNL-15ZXC44-pin TSOP Type II (Pb-Free)CY7C1021BN-15VI51-8508244-pin (400-Mil) Molded SOJ IndustrialCY7C1021BN-15VXI44-pin (400-Mil) Molded SOJ (Pb-Free)CY7C1021BN-15ZI51-8508744-pin TSOP Type IICY7C1021BNL-15ZI44-pin TSOP Type IICY7C1021BN-15ZXI44-pin TSOP Type II (Pb-Free)CY7C1021BNL-15ZXI44-pin TSOP Type II (Pb-Free)CY7C1021BNL-15ZSXA51-8508744-pin TSOP Type II (Pb-Free)Automotive-ACY7C1021BN-15VXE51-8508244-pin (400-Mil) Molded SOJ (Pb-Free)Automotive-ECY7C1021BN-15ZSXE51-8508744-pin TSOP Type II (Pb-Free)Package DiagramsCY7C10211BN Package Diagrams (continued)44-Pin TSOP II (51-85087)51-85087-*AAll products and company names mentioned in this document may be the trademarks of their respective holders.Document #: 001-06494 Rev. *A Page 9 of 10CY7C10211BN Document History PageDocument Title: CY7C1021BN/CY7C10211BN (64K x 16) Static RAMDocument Number: 001-06494REV.ECN NO.Issue Date Orig. ofChange Description of Change**423877See ECN NXR New Data Sheet*A505726See ECN NXR Removed I OS parameter from DC Electrical Characteristics table.Added Automotive productsUpdated ordering Information table。

目录表-氰化钠的理化性质及危险特性 (1)表-氰化钾的理化性质及危险特性 (2)表-氰化铜的理化性质及危险特性 (4)表-氰化银的理化性质及危险特性 (5)表-氰化锌的理化性质及危险特性 (6)表-氰化金钾的理化性质及危险特性 (7)表-三氧化(二)砷的理化性质及危险特性 (9)表-碳酸钡的理化性质及危险特性 (10)表-氯化钡的理化性质及危险特性表 (11)表-氢氧化钡的理化性质及危险特性表 (12)表-环氧氯丙烷的理化性质和危险特性表 (13)表-硝基苯的理化性质和危险特性表 (15)表-氯化苄的理化性质和危险特性表 (16)表-二氯化苄的理化性质及危险特性 (18)表-苯酚的理化性质及危险特性表 (19)表-邻甲(苯)酚的理化性质及危险特性 (20)表-N,N-二甲(基)苯胺的理化性质和危险特性表 (21)表- 甲苯-2,4-二异氰酸酯的理化性质及危险特性表 (22)表-六亚甲基二异氰酸酯的理化性质及危险特性 (24)表-己酮肟威的理化性质及危险特性表 (25)表-克百威[含量>10%]的理化性质及危险特性表 (27)表-自克威[含量>25%]的理化性质及危险特性表 (28)表-间异丙威的理化性质及危险特性表 (30)表-杀线威的理化性质及危险特性表 (31)表-敌蝇威[含量>50%]的理化性质及危险特性表 (32)表-涕灭威的理化性质及危险特性表 (33)表-腈叉威的理化性质及危险特性表 (34)表-恶虫威[含量>65%]的理化性质及危险特性表 (36)表-异索威[含量>20%]的理化性质及危险特性表 (37)表-硒粉的理化性质及危险特性 (38)表-氧化钡的理化性质及危险特性表 (39)表-一氧化铅的理化性质和危险特性表 (40)表-四氧化(三)铅的理化性质和危险特性表 (42)表-硫酸汞的理化性质和危险特性表 (43)表-硝酸亚汞的理化性质和危险特性表 (44)表-氟化铵的理化性质及危险特性表 (45)表-氟化钠的理化性质及危险特性 (46)表-氟化钾的理化性质及危险特性 (48)表-氟化钡的理化性质及危险特性 (49)表-氟硅酸钠的理化性质和危险特性表 (50)表-氟锆酸钾的理化性质及危险特性 (51)表-二氯甲烷的理化性质及危险特性 (53)表-三氯甲烷的理化性质及危险特性表 (55)表-四氯化碳的理化性质及危险特性 (56)表-1,1,1-三氯乙烷的理化性质及危险特性表 (58)表1,1,2-三氯乙烷的理化性质及危险特性表 (59)表- 1,1,2,2-四氯乙烷的理化性质和危险特性表 (60)表-溴代乙烷的理化性质和危险特性表 (61)表-三氯乙烯的理化性质及危险特性表 (63)表-四氯乙烯的理化性质及危险特性表 (64)表-十二硫醇的理化性质和危险特性表 (65)表-乙二醇丁醚的理化性质及危险特性表 (66)表-水杨醛的理化性质和危险特性表 (68)表-二苯甲烷-4,4’-二异氰酸酯的理化性质及危险特性 (69)表-异佛尔酮二异氰酸酯的理化性质及危险特性表 (70)表-邻二氯苯的理化性质和危险特性表 (71)表-3,4-二氯苄基氯的理化性质及危险特性 (73)表-对甲苯磺酰氯的理化性质和危险特性表 (74)表-邻硝基(苯)酚的理化性质和危险特性表 (75)表-对硝基(苯)酚的理化性质和危险特性表 (76)表-邻氨基(苯)酚的理化性质和危险特性表 (77)表-间氨基(苯)酚的理化性质和危险特性表 (79)表-邻苯二酚的理化性质及危险特性表 (81)表-间苯二酚的理化性质和危险特性表 (82)表-对苯二酚的理化性质及危险特性表 (83)表-间苯三酚的理化性质和危险特性表 (84)表-丙烯酰胺的理化性质及危险特性表 (85)表-苯胺的理化性质和危险特性表 (87)表-邻苯二胺的理化性质和危险特性表 (88)表-间苯二胺的理化性质和危险特性表 (89)表-对苯二胺的理化性质和危险特性表 (90)表-苯肼的理化性质和危险特性表 (91)表-硫脲的理化性质及危险特性表 (93)表-苯醌的理化性质及危险特性表 (94)表-α-萘乙酸的理化性质和危险特性表 (95)表-α-萘胺的理化性质和危险特性表 (96)表-盐酸-1-萘乙二胺的理化性质和危险特性表 (97)表-喹啉的理化性质和危险特性表 (98)表-乙酸铅的理化性质和危险特性表 (100)表-酒石酸锑钾的理化性质和危险特性表 (101)表-二丁基二月桂酸锡的理化性质和危险特性表 (102)表-辛酸亚锡的理化性质和危险特性表 (104)表-三苯(基)磷的理化性质及危险特性表 (105)表-煤焦沥青的理化性质及危险特性 (106)表-2,4-滴[含量>75%]的理化性质和危险特性表 (107)表-1,2,2-三氯三氟乙烷的理化性质及危险特性 (108)表-氰化钠的理化性质及危险特性表-氰化钾的理化性质及危险特性表-氰化铜的理化性质及危险特性表-氰化银的理化性质及危险特性表-氰化锌的理化性质及危险特性表-氰化金钾的理化性质及危险特性表-三氧化(二)砷的理化性质及危险特性表-碳酸钡的理化性质及危险特性表-氯化钡的理化性质及危险特性表表-氢氧化钡的理化性质及危险特性表表-环氧氯丙烷的理化性质和危险特性表表-硝基苯的理化性质和危险特性表表-氯化苄的理化性质和危险特性表表-二氯化苄的理化性质及危险特性表-苯酚的理化性质及危险特性表表-邻甲(苯)酚的理化性质及危险特性表-N,N-二甲(基)苯胺的理化性质和危险特性表表- 甲苯-2,4-二异氰酸酯的理化性质及危险特性表表-六亚甲基二异氰酸酯的理化性质及危险特性表-己酮肟威的理化性质及危险特性表表-灭害威的理化性质及危险特性表表-克百威[含量>10%]的理化性质及危险特性表表-自克威[含量>25%]的理化性质及危险特性表表-间异丙威的理化性质及危险特性表表-杀线威的理化性质及危险特性表表-敌蝇威[含量>50%]的理化性质及危险特性表表-涕灭威的理化性质及危险特性表表-腈叉威的理化性质及危险特性表表-恶虫威[含量>65%]的理化性质及危险特性表表-异索威[含量>20%]的理化性质及危险特性表表-硒粉的理化性质及危险特性表-氧化钡的理化性质及危险特性表表-一氧化铅的理化性质和危险特性表表-四氧化(三)铅的理化性质和危险特性表表-硫酸汞的理化性质和危险特性表表-硝酸亚汞的理化性质和危险特性表表-氟化铵的理化性质及危险特性表。

![一种铝钪合金靶材及其制备方法与应用[发明专利]](https://uimg.taocdn.com/86dd5116abea998fcc22bcd126fff705cc175c64.webp)

(19)中华人民共和国国家知识产权局(12)发明专利申请(10)申请公布号 (43)申请公布日 (21)申请号 202011547239.2(22)申请日 2020.12.24(71)申请人 有研稀土高技术有限公司地址 065200 河北省廊坊市三河市燕郊高新区孤山南路北侧、幸福路东侧有研稀土高技术有限公司申请人 有研稀土新材料股份有限公司(72)发明人 吴道高 陈德宏 王志强 庞思明 徐明磊 钟嘉珉 钟强 王育民 程军 (74)专利代理机构 北京中创云知识产权代理事务所(普通合伙) 11837代理人 肖佳(51)Int.Cl.C23C 14/34(2006.01)B22F 3/14(2006.01)B22F 5/00(2006.01)(54)发明名称一种铝钪合金靶材及其制备方法与应用(57)摘要一种铝钪合金靶材及其制备方法与应用,将金属铝和金属钪进行合金化,得到铝钪母合金;采用甩带快淬法将所述铝钪母合金制成铝钪合金薄带;对所述铝钪合金薄带进行破碎制粉、筛分,得到铝钪合金粉末;对含有所述铝钪合金粉末的原料进行热压烧结、加工,得到铝钪合金靶材。

该方法得到的铝钪合金靶材致密度高、成分均匀,晶粒细化、达到微晶级(尺寸<10μm),氧质量百分比含量控制在0.05%以内,整个制备工艺操作简单、易产业化、成本低。

权利要求书2页 说明书6页 附图2页CN 112725745 A 2021.04.30C N 112725745A1.一种铝钪合金靶材的制备方法,其特征在于,包括:步骤1:将金属铝和金属钪进行合金化,得到铝钪母合金;步骤2:采用甩带快淬法将所述铝钪母合金制成铝钪合金薄带;步骤3:对所述铝钪合金薄带进行破碎制粉、筛分,得到铝钪合金粉末;步骤4:对含有所述铝钪合金粉末的原料进行热压烧结、加工,得到铝钪合金靶材。

2.根据权利要求1所述的铝钪合金靶材的制备方法,其特征在于,步骤1所述的铝钪母合金中金属钪的质量百分比为35~78%。

旭硝子折射率

旭硝子是一家知名的玻璃制造厂商,其生产的TN型玻璃的折射率为1.52±0.005。

折射率是光在真空中的传播速度与光在该介质中的传播速度之比,是物质的一种重要特性。

不同类型的旭硝子玻璃,其折射率也有所不同。

例如,旭硝子平板铝硅玻璃的折射率为1.5325(黄光)。

这种玻璃具有较高的透过率和抗弯强度,以及较低的膨胀系数,被广泛应用于钢铁、冶金、石油化工、电厂、半导体、新型光源、手机屏幕、精密光学仪器、航空、军工、仪表、印染、锅炉厂、压力容器等领域。

如果你需要其他类型的旭硝子玻璃的折射率信息,可以继续向我提问。

1易车铁编辑易车铁即易切削钢,是钢的一种,主要通过加入硫或铅等元素加强其金属切削性,机床切削性能好。

其中12L14(Y15Pb)易切削钢广泛用于仪表,汽车、电子及各种精密零部件。

基本信息:牌号:国标Y15执行标准:GB/T 8731-1988密度:7.85 cm/g*3美标1215化学成分:C:≤0.09Mn:0.75-1.05P:0.04-0.09S:026-0.35美标12L14化学成分:C:≤0.15Mn:0.85-1.15P:0.04-0.09S:0.26-0.35Pb:0.15-0.35国标Y15化学成分:C:0.10-0.18Mn:0.80-1.20P:0.05-0.10S:0.23-0.33国标Y15Pb化学成分:C:0.1-0.18Mn:0.8-1.22易车铁钢材特性:编辑1. 易车铁加工性能好:产品具有切削流畅,材质优良,加工稳定,金相组织好,化学成份稳定、偏差小,钢质纯度净,不易损伤刀具等特点;极容易在车床切削,刀具使用寿命和生产效率均提高40%;2.电镀性能好:切削加工非常容易;可钻深孔、铣深槽等;加工效率比普钢可大幅提高;产品的电镀性能好,能替代铜制品,大大降低产品成本;3. 易车铁光洁性好:经车加工后的工件表面光洁度好;4. 易车铁环保性:可以满足欧盟RoHS环境认证标准。

产品可以出口机械设备:木工机械、陶瓷机械、造纸机械、玻璃机械、食品机械、建筑机械、塑料机械、纺织机械、千斤顶、液压机等;电器产品部件:电机轴、风扇轴、缝纫机轴等;家具:特别是出口金属家具,如茶几、椅子、户外家具;金属器具:园林工具、烧烤炉网架、螺丝刀、防盗锁等;小五金零配件:如导轨、机键、螺母、螺丝、圆钉、六角钉八角钉以及各种不同规格标准件等;汽车、摩托车零配件等。

我司银钢精密制品厂拥有高端科技抛光、进口设备生产!。

3AS/NZS1252:1996目录第一章范围和概述1.1范围 (4)1.2应用 (4)1.3参考文献 (4)1.4定义 (5)1.5标记 (5)1.6名称 (6)第二章高强度螺栓2.1生产方式 (8)2.1外形,尺寸&表面处理 (8)2.3材料和机械性能 (9)2.4试验方法 (9)第三章高强度螺母3.1生产方式 (16)3.2外形,尺寸&表面处理 (16)3.3材料和机械性能 (17)3.4试验方法 (17)第四章圆式平垫圈4.1外形,尺寸和表面处理 (20)4.2材料和热处理 (20)4.3硬度 (20)附录A机械性能试验的建议取样计划 (22)B检验螺栓从螺纹到螺母面垂直度的推荐测量方法 (23)C镀锌螺栓的装配测试 (24)D方斜垫圈 (25)AS/NZS1252:19964澳大利亚标准/新西兰标准建筑用高强度螺栓(装配有螺母&垫圈的螺栓)第一章范围和概述1.1范围该标准规定了ISO公制粗牙螺纹系列直径16mm---36mm并带有调质钢垫圈的钢结构用螺栓8.8级螺栓和8级螺母的尺寸,材料&钢印要求。

1.2运用螺栓,螺母和垫圈应符合第一章&如下章节规定的要求:(a)螺栓…………………………………………………………第一章(b)螺母…………………………………………………………第二章(c)垫圈………………………………………………………….第三章1.3参考文献该标准参考如下文献:AS1014公制螺纹的测量1214带螺纹螺栓的热镀锌锌层(公制粗牙螺纹螺栓ISO标准)1275公制螺纹螺栓1650亚铁物的热镀锌锌层1789钢铁表面的电镀层——锌1815金属材料——洛氏硬度试验1817金属材料——维氏硬度试验1897螺纹部件上的电镀层AS/NZS4291紧固件机械性能4291.1第一部分:螺栓,螺丝和图钉4291.2第二部分:达到规定的试验应力的螺母——粗牙螺纹SAA/SNZHB18第三方鉴定&委任的指导HB18.22指引22:生产方声称符合标准&技术规范的信息ISO6157紧固件——表面不连续6157.1第一部分:螺栓,螺丝&图钉的一般要求SAEJ122a螺母的表面不连续性5AS/NZS1252:1996 1.4定义如下定义适用用该标准。