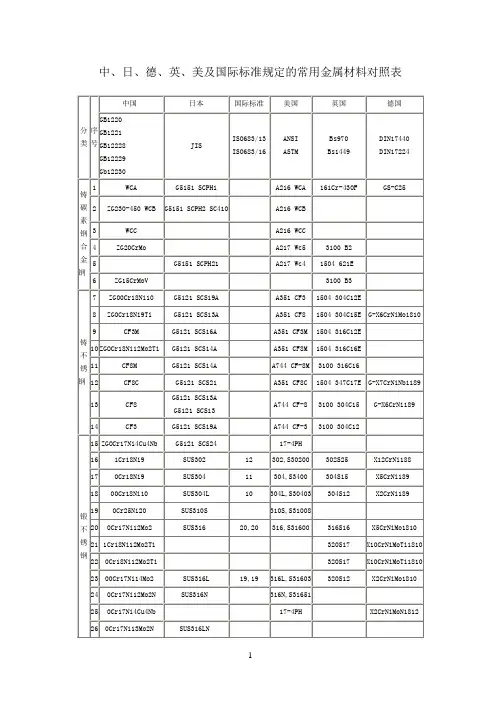

富士康公司常用金属材料说明2017版

- 格式:ppt

- 大小:260.00 KB

- 文档页数:25

![press fit 金属材质对照表[1]](https://uimg.taocdn.com/a0d2452bb0717fd5360cdcb2.webp)

第1页产品数据说明书轧制产品第3页铜以及铜合金轧制产品维兰德德国工业标准欧洲标准美国材试协会标准日工标准维兰德物料编码编号物料编码编号统一编号系统编号日工标准编号红铜K09 OFE-Cu - Cu-OFE CW009A C10100 C1011 K11 OF-Cu 2.0040 Cu-OF CW008A C10200 - K12 SE-Cu 57 2.0070 Cu-HCP CW021A C10300 - K14 SE-Cu 58 2.0070 Cu-PHC CW020A C10300 - K15 SW-Cu 2.0076 Cu-DLP CW023A C12000 C1201 K19 SF-Cu 2.0090 Cu-DHP CW024A C12200 C1220 K32 E-Cu 58 2.0065 Cu-ETP CW004A C11000 C1100 K42 CuZn0.5 2.0205 CuZn0.5 CW119C - -高性能合金K55 CuNi3SiMg - CuNi3SiMg - C70250 - K57 CuNi1Co1Si - - - C70350 - K65 CuFe2P 2.1310 CuFe2P CW107C C19400 - K75 CuCrSiTi - CuCrSiTi - C18070 - K80 CuFe0.1P - CuFe0.1P - C19210 - K81 CuSn0.15 - CuSn0.15 CW117C C14415 - K88 CuCrAgFeTiSi - CuCrAgFeTiSi - C18080 -黄铜维兰德-K09OFE-CuC10100物料指标化学成分(参考)典型应用欧洲标准无Cu ≥99.99%海底光纤电缆半导体引线框散热器统一编号系统C10100 同轴电缆和波导管真空工艺物理性能加工性能抗腐蚀性能电导率*** MS/m%IACS 58.6101冷加工极好耐受:工业环境(形成墨绿色保护层),工业和饮用水(最大流量1.5到2m/s)、纯水蒸气、非氧化性酸、碱(氨和氰化物除外)、中性盐溶液。

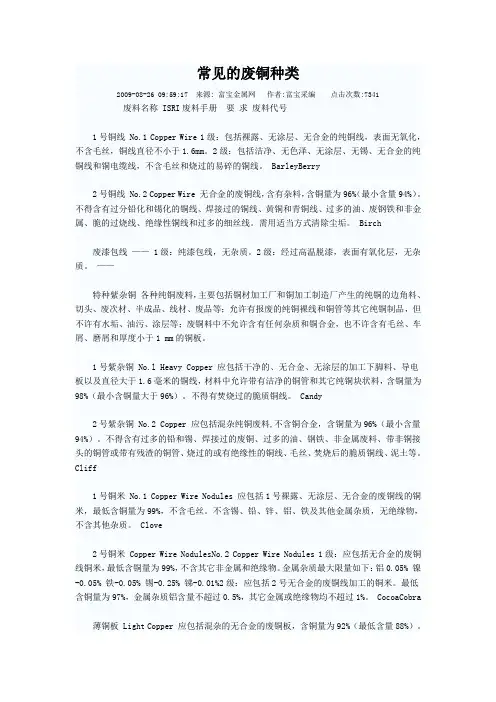

常见的废铜种类2009-08-26 09:59:17 来源: 富宝金属网作者:富宝采编点击次数:7341废料名称 ISRI废料手册要求废料代号1号铜线 No.1 Copper Wire 1级:包括裸露、无涂层、无合金的纯铜线,表面无氧化,不含毛丝,铜线直径不小于1.6mm。

2级:包括洁净、无色泽、无涂层、无锡、无合金的纯铜线和铜电缆线,不含毛丝和烧过的易碎的铜线。

BarleyBerry2号铜线 No.2 Copper Wire 无合金的废铜线,含有杂料,含铜量为96%(最小含量94%)。

不得含有过分铅化和锡化的铜线、焊接过的铜线、黄铜和青铜线、过多的油、废钢铁和非金属、脆的过烧线、绝缘性铜线和过多的细丝线。

需用适当方式清除尘垢。

Birch废漆包线—— 1级:纯漆包线,无杂质。

2级:经过高温脱漆,表面有氧化层,无杂质。

——特种紫杂铜各种纯铜废料,主要包括铜材加工厂和铜加工制造厂产生的纯铜的边角料、切头、废次材、半成品、线材、废品等;允许有报废的纯铜裸线和铜管等其它纯铜制品,但不许有水垢、油污、涂层等;废铜料中不允许含有任何杂质和铜合金,也不许含有毛丝、车屑、磨屑和厚度小于1 mm的铜板。

1号紫杂铜 No.l Heavy Copper 应包括干净的、无合金、无涂层的加工下脚料、导电板以及直径大于1.6毫米的铜线,材料中允许带有洁净的铜管和其它纯铜块状料,含铜量为98%(最小含铜量大于96%)。

不得有焚烧过的脆质铜线。

Candy2号紫杂铜 No.2 Copper 应包括混杂纯铜废料,不含铜合金,含铜量为96%(最小含量94%)。

不得含有过多的铅和锡、焊接过的废铜、过多的油、钢铁、非金属废料、带非铜接头的铜管或带有残渣的铜管、烧过的或有绝缘性的铜线、毛丝、焚烧后的脆质铜线、泥土等。

Cliff1号铜米 No.1 Copper Wire Nodules 应包括1号裸露、无涂层、无合金的废铜线的铜米,最低含铜量为99%,不含毛丝。

/article/view_1257.html选择垫片的材料主要取决于下列三种因素:温度、压力、介质。

一. 金属垫片材料1. 碳钢:推荐最大工作温度不超过538℃,特别当介质具有氧化性时。

优质薄碳钢板地不适合应用于制造无机酸、中性或酸性盐溶液的设备,如果碳钢受到在的应力,用于热水工况条件下的设备事故率非常高。

碳钢垫片通常用于高浓度的酸和许多碱溶液。

布氏硬度约120。

2. 304不锈钢18-8(铬18-20%、镍8-10%),推荐最大工作温度不超过760℃。

在温度 -196~538℃区间内,易发生应力腐蚀和晶界腐蚀。

布氏硬度160。

3. 304L 不锈钢含碳量不超过0。

03%。

推荐最大工作温度不超过760℃。

耐腐蚀性能类似304不锈钢。

低的含碳量减少了碳从晶格的析出,耐晶界腐蚀性能高于304不锈钢。

布氏硬度约140。

4. 316不锈钢18-12(铬18%、镍12%),在304不锈钢中增加约2%钼,当温度提高其强度和耐腐蚀性能提高。

当温度提高时比其它普通不锈钢具有更高抗蠕变性能。

推荐最大工作温度不超过760℃。

布氏硬度约160。

5. 316L不锈钢推荐最大连续工作温度不超过760℃~815℃。

碳含量不超过相对于316不锈钢具有更优秀的耐应力和晶界腐蚀。

布氏硬度约140。

6. 20合金45%铁、24%镍、20%铬和少量钼和铜。

推荐最大工作温度不超过760℃~815℃。

特别适用于制造耐硫酸腐蚀的设备,布氏硬度约160。

7.铝铝(含量不低于99%)。

铝具有优秀耐腐蚀性能和加工性能,适用于制造双夹垫片。

布氏硬度约35。

推荐最大连续工作温度不超过426℃。

8.紫铜紫铜的成份接近于纯铜,其含有微量的银以增加其连续工作温度。

推荐最大连续工作温度不超过260℃。

布氏硬度约80。

9.黄铜(铜66%、锌34%),在大多数工况条件下,具有良好耐腐蚀性能,但不适应醋酸、氨、盐和乙炔。

推荐最大连续工作温度不超过260℃。

布氏硬度约58。

WASHER SPECIFICATIONSThe Bonded Seal (Commonly known as a Dowty Seal) is a rectangular section metal washer, with a trapezoidal shaped ring of vulcanised rubber bonded to the inside. Both the washer and the material can be selected to suit a given application. The Bonded Seal offers an ideal sealing solution to a wide range of engineering applications. Mechanical, Hydraulic and Pneumatic sectors all benefit from the high pressure, high temperature characteristics.METALMild Steel Turned EN8Stainless Steel Pressings T316Stainless Steel Turned T303Stainless Steel Turned T316Stainless Steel Turned T304Brass Turned CZ121Brass Pressings CZ108Aluminium Bronze Turned CA104Aluminium Alloy Turned High Tensile SteelAluminium Alloy Turned HE 30(6086 - T6)SURFACE FINISHZinc Plating Gold PassivateCadmium Plating (restricted use)Chromic Anodise Sulphuric Anodise Clear Passivate Zinc Nickel Trivalent Passivate* For the restrictions of the use of these products, see “The Environmental Protection (Controls of Injurious Substances) (Number 2) Regulations 1993.”BURST PRESSURESAll our Bonded Seals are tested by our independent 3rd party, UKAS accredited test lab.Please contact our sales team with your burst pressures requirements and we will provide a suitable Bonded Seal.RoHS / REACHWe would like to confirm that we have taken all reasonable steps or precautions to ensure our products meet the RoHS + REACH regulations.TORQUE LOADINGSatisfactory performance of the seal depends on correct torque loading during assembly. The following table indicates recommended figures. (for double sealing, additional torque is generally required)TREAD SIZETORQUE REQUIREDDOUBLE SEALING FACTORMETRICBOLTBSPNmIbf.inUP to 85/16- 5.347+/-3 1.6103/81/87.163+/-3117/1611.8105+/-5 1.3121/21/415.8140+/-5149/16-22.6200+/-10165/83/830.5270+/-12183/440.7360+/-152013/161/256.5500+/-25 1.2227/85/867.8600+/-30 1.124 1.03/473.4650+/-30 1.027+1.1/16-79.0700+/-352 | The Ashton GroupNon Self - CentralisingSelf - CentralisingRubber Specifications and CompatibilityThe characteristics of the compounds used and their compatibility rating against various fluids are summarised in the following table. Key: 5 = Excellent, 4 = Very Good, 3 = Good, 2 = Fair, 1 = PoorGENERAL CHARACTERISTICSNITRILE (NBR)HYDROGENATED NITRILE (HNBR)FLUOROCARBON (VITON)*SILICONE (VMQ)FLUOROSILICONE(FVMQ)ETHYLENE PROPYLENE DIENE monomer (EPDM)CHLOROPRENE (NEOPRENE)*Rubber Specifications(Our standard compounds can meet the following specifications, but please contact us with your requirements as we can offer an a vast range of compounds to meet your demands) ASTM D2000 M2 BG714 A14 B14 EA14 EO14 EO34 EF11 EF21 F17ASTM D2000 M3 DH 710 A26 B16EO16EO36ASTM D2000 M2 HK 810 A1-10 B37 EF31ASTM D2000 M7 GE 705 A19 B37 EA14 EO16 EO36F19ASTM D2000 M2 FK 606 A19 EF31 EO36 F19ASTM D2000 M2 BA 710 A14 B13 F19ASTM D2000 M3 BC 710 A14 B14 EO14EO34Hardness range IRHD40-9040-8560-9040-8040-8080-9040-80Continuous high temperature limit 110˚C 150˚C 225˚C 250˚C 175˚C 120˚C 140˚C Low temperature capability-30˚C -30˚C -25˚C -75˚C -65˚C -30˚C 55˚C SDynamic service/Abrasion resistance 5541124Compression set resistance 4545454FLUID COMPATIBILITY Acid - Inorganic 235333 2 | 3Acid - Organic 3335333Ageing - Oxygen 2345554Ageing - Ozone 1 | 2345554Ageing - Weather 1345554Air 2545453Alcohols 4524444Aldehydes 1 | 223314 1 | 2Alkalis 1 | 2234343Amines 3333334Animal oils5543543Esters - Alkyl Phosphate (Skydrol)1113 1 | 2 1 | 23Esters - Aryl Phosphate 1 | 225342 1 | 2Esters - Silicate 3351422Ethers1111211Gas permeability3 3 | 541133Hydrocarbon fuels - Aliphatic 5552512Hydrocarbon fuels - Aromatic 355141 1 | 2Hydrocarbons - Halogenated 1 | 2151431Ketones1111 1 | 241Lubricating oils - High aniline 5554413Lubricating oils - Low aniline 455211 1 | 2Silicone oils 5553545Vegetable oils 5555543Water/steam5522252The Ashton Group | 3Please note, the information in the table above is to be used as a guide only.* Viton® is a registered trademark of DuPont Dow Elastomers * Neoprene® is a registered trademark of DuPont Dow ElastomersImperial Bonded SealsASHTON REF.ALTREF.REF. A+0.13-0.00B+0.10-0.10C+0.10-0.10DE+0.15-0.15F+0.20-0.20 BSP BOLT001PP45-1-6BA 6.35 4.09 3.050.20/ 0.451.22-002PP45-2-4BA7.26 5.26 4.12-003PP45-3-2BA8.38 6.35 5.21-004PP45-4-1/413.218.00 6.86 4.70 005PP45-5-1/413.349.53 6.99 4.70 006PP45-6-5/1613.349.538.31 6.10 007PP45-7-5/1614.2210.048.64 6.10 020PP45-A1/83/815.8811.8410.370.25/ 0.51 0.25/ 0.512.038.56008PP45-8-0.418.3612.4511.268.56 009PP45-9-7/1619.0513.0811.698.80 021PP45-B1/41/220.5715.2113.7411.45 010PP45-10-9/1622.2316.3914.8611.58 022PP45-BB-0.622.2317.3015.8312.10 011PP45-11-5/825.4018.7516.5112.90 023PP45-C3/8-23.8018.7517.2814.96012PP45-12-11/1625.4019.6918.162.5014.50024PP45-CC-3/426.9221.2119.6915.80 025PP45-D1/213/1628.5823.0121.54 2.0018.64025A1/213/1628.5823.0121.542.5018.64026PP45-E5/87/831.7524.9723.4920.60 013PP45-13-15/1633.2726.0424.2620.20 027PP45-F3/4 1.034.9328.5327.05 2.0024.13027A3/4 1.034.9328.5327.052.5024.13028PP45-FF- 1.1/1638.6130.6127.8222.90 014PP45-14- 1.1/836.5830.8629.3323.90 029PP45-G7/8 1.3/1638.1032.2930.8127.89 015PP45-15- 1.1/441.4035.6932.64 3.2527.10 030PP45-H 1.0 1.5/1642.8036.8833.89 2.5030.30030A 1.0 1.5/1642.8036.8833.893.2530.30016PP45-16- 1.3/844.4538.9935.9429.50 017PP45-17- 1.1/247.7542.0438.9632.70 032PP45-J 1.1/4 1.5/852.3845.9342.93 2.5038.96032A 1.1/4 1.5/852.3845.9342.933.2538.96018PP45-18- 1.3/457.1548.3945.3437.90 033PP45-K 1.1/2 1.7/858.6051.3948.44 2.5044.86033A 1.1/2 1.7/858.6051.3948.443.2544.86019PP45-19- 2.063.5054.7451.6943.60 034PP45-L 1.3/4 2.1/869.8558.3054.8950.80 035- 2.1/470.3661.0958.04036PP45-M 2.0-73.0363.6360.58 2.5056.67036A 2.0-73.0363.6360.583.2556.67037PP45-MM- 2.1/277.7267.4464.3955.40 038PP45-N 2.1/4-79.5069.9866.6865.80 039PP45-P 2.1/2-90.1779.3876.0872.20 079 3.0-101.4792.8489.0985.00Self-Centralising Bonded SealsAn improvement to the original concept is the self-centralising bonded seal that offers additional benefits. It is available in all sizes.When ordering Self-Centralising Bonded Seals change the first digit of Ashton reference to an 8 e.g. 823• Please note washer thickness may vary from those stated.• Specification sheets available on request.Please note that all “A reference Bonded Seals” equates to a thicker washer. Available on request.Key features of Self-Centralising:1. Elimination of seal offset2. Elimination of leaks3. Ease of installation4. Reduce assembly time5. Captive assembly4 | The Ashton Group All dimensions in mmNote: There is a permitted moulding flashline on the inner diameter C in accordance with AGS 1186Non Self - CentralisingSelf - CentralisingASHTON REF.ALT REF.A +0.13 -0.00B +0.10 -0.10C +0.10 -0.10DE +0.15 -0.15F +0.20 -0.20201PPM3.57.20 5.20 4.100.30 1.00-202PPM47.00 5.40 4.50 3.40203PPM59.00 6.80 5.70 4.50204PPM510.007.40 5.70 4.50205PPM5.59.207.20 6.20 4.70206PPM610.008.00 6.70 4.70207PPM611.008.20 6.70 4.70210PPM6.710.208.607.30 5.77212PPM813.0010.008.70 6.40213PPM814.0010.408.70 6.40215PPM8.513.3010.509.30 6.90216PPM1015.8812.0010.350.400.402.008.56217PPM1016.0012.4010.70 1.508.05218PPM1018.0012.4010.708.05219PPM1116.3012.7011.409.80221PPM1119.1013.5011.809.80222PPM1218.0014.3012.709.73223PPM1220.0014.4012.709.73225PPM1322.0015.4013.7010.80226PPM13.518.7015.7014.0011.30227PPM1422.0016.4014.7011.38229PPM1624.0018.4016.7013.41230PPM1724.0019.2017.4013.08231PPM17.524.7020.1018.0013.60232PPM1826.0020.4018.7014.76233PPM2028.0022.5020.7016.76234PPM2128.7023.3021.50 2.5017.80236PPM2230.0024.4022.70 2.0018.74237PPM2230.0024.4022.70 3.00-238PPM2432.0026.4024.70 2.0020.11239PPM2635.0028.4026.7022.30240PPM2736.0029.0027.2023.30242PPM3039.0033.0031.0025.70243PPM3342.0035.8033.7028.70244PPM3346.0036.4034.3028.70245PPM3646.0038.8036.7031.10246PPM3951.0041.9040.00 2.5034.10247PPM4253.0044.4042.70 3.0036.50248PPM4859.0050.8048.7041.90250PPM5264.5056.4053.3046.00254PPM88101.3592.1089.093.25-When ordering Self-Centralising Bonded Seals change the first digit of Ashton reference to an 6 e.g. 612• Please note washer thickness may vary from those stated.• Specification sheets available on request.All dimensions in mmNote: There is a permitted moulding flashline on the inner diameter C in accordance with AGS 1186Key features of Self-Centralising:1. Elimination of seal offset 2. Elimination of leaks 3. Ease of installation 4. Reduce assembly time 5. Captive assemblyPM1000 Metric RangeASHTON REF.SIZEA +0.20 -0.20B +0.20 -0.20C +0.20 -0.20D +0.20 -0.20E +0.20 -0.20F +0.10 -0.10H +0.20 -0.203099M610.08.07.4 6.0 1.00.404.703138M814.011.010.08.0 6.403076M1017.013.012.010.0 1.50.508.563077M1219.016.015.012.09.733063M1422.018.017.014.011.383078M1624.020.019.016.013.413064M1827.022.021.018.0 2.014.763079M2030.025.024.020.016.763098M2232.027.026.022.018.743080M2436.029.028.024.020.113065M2635.030.530.0308022.30The Ashton Group | 5When ordering Self-Centralising Bonded Seals change the first digit of Ashton reference to an 4 e.g. 4076Note: There is a permitted moulding flashline on the inner diameter C in accordance with AGS 1186 All dimensions in mmNon Self - CentralisingSelf - CentralisingASHTON REF.ALT REF. A +0.13 -0.00 B +0.10 -0.10 C +0.10 -0.10DE +0.15 -0.15F +0.20 -0.20301PPFM37.50 5.00 3.600.301.00-302PPFM49.00 6.00 4.60 3.40303PPFM510.007.00 5.60 4.50304PPFM611.008.00 6.60 4.70306PPFM611.408.407.00 4.70307PPFM813.0010.008.60 6.40310PPFM1017.0012.1010.70 1.508.56312PPFM1118.1013.2011.809.80313PPFM1219.0014.1012.709.73315PPFM1320.1015.2013.800.4010.80316PPFM1421.0016.1014.700.3011.38317PPFM1623.0018.1016.7011.41318PPFM1723.7018.8017.400.4013.08320PPFM1827.0020.4018.700.302.0014.76321PPFM2029.0022.4020.7016.76322PPFM2028.6023.0021.500.402.50-323PPFM2130.0023.4021.70 2.0017.80324PPFM2231.0024.4022.7018.74325PPFM2332.0025.4023.7019.30326PPFM2433.0026.4024.7020.11327PPFM2635.3028.7027.0022.30328PPFM2736.0029.4027.7023.30329PPFM2836.0030.3028.6024.80331PPFM3039.0032.4030.7025.70332PPFM3342.0035.4033.7028.70333PPFM3648.0039.6037.00 2.5031.10334PPFM3951.0042.6040.0034.10335PPFM4254.0045.6043.0036.50336PPFM4557.0048.6046.0039.50337PPFM4860.0051.6049.0041.906 | The Ashton GroupAll dimensions in mmNote: There is a permitted moulding flashline on the inner diameter C in accordance with AGS 1186Key features of Self-Centralising:1. Elimination of seal offset 2. Elimination of leaks 3. Ease of installation 4. Reduce assembly time 5. Captive assemblyWhen ordering Self-Centralising bonded seals change the first digit of Ashton reference to an 7 e.g. 712• Please note washer thickness may vary from those stated.• Specification sheets available on request.ASHTON REF.THREAD SIZEBSPFA +0.00 -0.20B +0.20 -0.00C +0.20 -0.00D +0.25 -0.00E +0.15 -0.155191/1612.709.908.300.251.255101/814.7012.0010.405111/418.7015.7513.855123/822.7019.2517.355131/226.7023.5521.655143/432.5029.2027.30515 1.039.5036.1034.20 2.00516 1.1/449.5044.7042.80517 1.1/255.5050.6048.705182.068.5062.4060.50CETOPS (Recommended in ISO 1179-1973)Note: There is a permitted moulding flashline on the inner diameter C in accordance with AGS 1186 All dimensions in mmNon Self - CentralisingSelf - CentralisingBodok SealsThe BODOK SEAL SpecificationsNylon Captive Sealing Washers(commonly known as Selon Washers)Rubber Covered Lock Washers(commonly known as Seloc Washers)NITRILE, NEOPRENE*, VITON*, HNBR Bodok Seals are available in a range of hardness and colour specifications.The modern day Bodok Seal is a specialised washer that has the crucial role of ensuring an air tight seal between the regulator of an anaesthetic machine and a gas cylinder .The Bodok Seal is used extensively in areas where Anaesthetic Gases are dispensed, such as, Hospitals, Dentists, Veterinary Surgeries and Medical Practices.* Viton® is a registered trademark of DuPont Dow Elastomers * Neoprene® is a registered trademark of DuPont Dow ElastomersSelf-retaining and resistant to oils and fuels, these nylon-sealing washers are suitable for most pressure systems, unlike the copper based items they replace.Working parameters of these washers are up to 200lb/in² pressure and temperatures of up to 100°C.Rubber covered to reduce the risk of corrosion, these shake proof washers are well known for their ability to resist vibration.Tightening the bolt causes metal serrations to pierce the rubber and bite into the relative metal surface, providing the necessary locking action.Ashton Seals can offer you the full range of rubber covered lock washers from our comprehensive stock.The Ashton Group | 7Metric & Imperial Bonded Seals KitsSIZEREFERENCE DESCRIPTIONQTY617M10 BONDED SEAL, MILD STEEL & NITRILE 622M12 BONDED SEAL, MILD STEEL & NITRILE 627M14 BONDED SEAL, MILD STEEL & NITRILE 629M16 BONDED SEAL, MILD STEEL & NITRILE 632M18 BONDED SEAL, MILD STEEL & NITRILE 633M20 BONDED SEAL, MILD STEEL & NITRILE 636M22 BONDED SEAL, MILD STEEL & NITRILE 638M24 BONDED SEAL, MILD STEEL & NITRILEPart No.Ashtons Part No.Thread Size (Metric)Thread Size (Imperial)269-70004-69-TA700173252BA, 10UN, 3/16269-70104-69-TA70117326¼269-70204-69-TA702173285/16269-70304-69-TA7031732103/8 (1/8 BSP)269-70404-69-TA704173211 or 127/16269-70504-69-TA7051732-½ (¼ BSP) 269-706 04-69-TA7061732165/8269-70704-69-TA7071732-3/8 BSP 269-70804-69-TA708173218¾269-70904-69-TA70917322013/16 (½ BSP)269-71004-69-TA710173222 or 247/8 (5/8 BSP)269-71104-69-TA711173227 1 (¾ BSP)269-71204-69-TA71217323013/16 (7/8 BSP)269-71304-69-TA71317323315/16 (1 BSP)269-71604-69-TA71617324215/8 (11/4 BSP)Part No.Ashtons Part No.Thread Size (Metric)Thread Size (Imperial)435-00104-91-TA00170MN 2.5 or 2.66BA – 4UNC 435-00204-91-TA00270MN 34BA – 6UNC 435-00304-91-TA00370MN 3.5 or 43BA – 8UNC 435-00404-91-TA00470MN 42BA – 3/16435-00504-91-TA00570MN 6¼435-00604-91-TA00670MN 85/16435-00704-91-TA00770MN 93/8435-00804-91-TA00870MN 107/16435-00904-91-TA00970MN 12½435-01004-91-TA01070MN 149/16435-01104-91-TA01170MN 165/8435-01204-91-TA01270MN 18¾435-01304-91-TA01370MN 227/8435-01404-91-TA01470MN241SIZE REFERENCE DESCRIPTIONQTY8201/8” BSP BONDED SEAL, MILD STEEL & NITRILE 208211/4” BSP BONDED SEAL, MILD STEEL & NITRILE 158233/8” BSP BONDED SEAL, MILD STEEL & NITRILE 158251/2” BSP BONDED SEAL, MILD STEEL & NITRILE 158265/8” BSP BONDED SEAL, MILD STEEL & NITRILE 108273/4” BSP BONDED SEAL, MILD STEEL & NITRILE 108301” BSP BONDED SEAL, MILD STEEL & NITRILE5BONDED SEAL KIT CONTENTS - METRIC STANDARD = 03-TA-SD0001062BONDED SEAL KIT CONTENTS - IMPERIAL STANDARD = 03-TA-SD0001063D e s i g n e d & p r o d u c e d b y K e y h o l e C r e a t i v e M e d i a . T - 0113 328 0190 W . w w w .k e y h o l e c r e a t i v e m e d i a .c o mB S /R e v i s i o n 7/0617。

-54-四川冶金第42卷为钢板中的夹杂物元素成分。

因此,可以推测该翘皮缺陷是炼钢生产过程中产生的。

2.2翘皮的控制措施翘皮缺陷应在生产过程中及时发现、及时处理,同时日常生产要提前做好预防工作。

翘皮缺陷的控制措施如下:(1)加强设备的管理和维护。

针对易发生翘皮缺陷的钢种集中发生的日期、浇铸号、炉次,对应其连铸机状态进行把控,浇铸间隙做好结晶器检查和辐子润滑、喷嘴检查等工作。

(2)优化排产计划。

生产组织上尽可能将易发生翘皮缺陷的钢种有针对性地进行排产,将其安排在连铸机检修前期、中期进行浇注,尽量减少翘皮发生的可能性。

(3)加强重点板坯管理。

对钢板表面质量等级要求FC级及其以上产品,应对板坯表面进行有效清理,特别是浇注异常的板坯以及头、尾坯表面易产生翘皮缺陷的位置,加强对这些板坯的重点检查和恰当清理,尽可能去除板坯的表面缺陷,保证坯料的表面质量和后续生产顺行。

(4)优化原料、辅料管理制度。

高度重视耐火材料、保护渣等原辅料的管理工作,减少其对板坯质量造成的不良影响,制定精炼一连铸之间合理的温度和时间制度,保证生产过程稳定操作。

(5)适宜的热轧加热制度。

热轧生产要严格控制板坯在加热炉的加热时间和温度,采用合理的加热制度,使板坯受热均匀,在能耗允许的前提下,尽可能提高板坯出炉温度,防止板坯局部过烧或过热,尤其是生产含铜量较高的板坯%(6)合理的控轧控冷工艺制度。

根据成品宽度和坯料宽度的要求,将立辐的减宽量控制在合适的范围内,在立辐轧制力允许的条件下,尽量采用大变形可以减少翘皮缺陷的发生率。

在轧制传输过程中,添加一定保温措施,如卷取箱和保温罩等,同时适当提高轧制速度来尽量减少边尾部与芯部的温差。

目前采取上述控制措施后,生产上取得了一定成效,钢板的翘皮缺陷得到抑制,降低了铸坯的清理难度,提高了钢板的表面质量和成材率,满足用户的使用要求%3结论(1)翘皮缺陷主要分布在带钢边尾部,在距离其边部30〜40aa处,纵向分布没有显著的规律。

钛合金垫片标准规格型号

钛合金垫片是一种常用的密封材料,通常用于在机械连接部件

中起到填充空隙、防止泄漏的作用。

钛合金垫片的标准规格型号通

常根据其直径、厚度和形状来确定。

常见的标准规格型号包括,M6、M8、M10、M12等,这些型号代表了垫片的直径。

另外,钛合金垫片

的厚度通常以毫米为单位,常见的厚度包括0.5mm、1mm、2mm等。

此外,钛合金垫片的形状也有不同,常见的形状包括圆形、方形、

矩形等。

在选择钛合金垫片时,需要根据具体的使用要求和安装环

境来确定合适的规格型号。

除了常见的标准规格型号外,钛合金垫片的定制规格型号也是

常见的。

根据具体的工程需求,可以定制特殊直径、厚度和形状的

钛合金垫片。

在选择定制规格型号时,需要与生产厂家或供应商进

行沟通,提供详细的要求和参数,以便生产出符合需求的钛合金垫片。

总的来说,钛合金垫片的标准规格型号主要包括直径、厚度和

形状,常见的规格型号有M6、M8、M10、M12等,同时也可以根据实

际需求定制特殊规格型号的钛合金垫片。

希望这些信息能够帮助到你。

垫圈washer 垫在连接件与螺母之间的零件, 一般为扁平形的金属环。

非金属垫片non-metallic gasket 用石棉、橡胶、合成树脂、聚四氟乙烯等非金属制成的垫片。

a 非金属包覆垫片non-metallic jacket gasket 外包一层合成树脂等的非金属垫片。

半金属垫片semimetallic gasket 用金属和非金属材料制成的垫片,如缠绕式垫片、金属包覆垫片。

a 缠绕式垫片spiral wound gasket 由V形或W形断面的金属带夹非金属带,螺旋缠绕而成的垫片。

1)内环inner ring 设置在缠绕式垫片内圈的金属环。

2)外环outer ring 设置在缠绕式垫片外圈的金属环。

b 金属包覆金属垫片metallic gasket 用钢、铝、铜、镍或蒙乃尔合金等金属制成的垫片。

缠绕垫片是指用金属带(一般是v型钢带)与非金属带缠绕成环形的垫片,金属带与非金属带交替缠绕,由于其具有较好的弹性,广泛用于石化、化工、电力等行业的法兰密封结构中,根据具体部位,可在垫片的内层或外层加上钢环来定位或加强。

扩展资料:精密垫片的作用介绍?精密垫片是两个物体之间的机械密封,通常以防止的两个物体之间受到压力、腐蚀、和管路自然地热胀冷缩泄漏。

由于机械加工表面不可能完美,使用垫片即可填补不规则性。

垫片通常由片状材料制成,如垫纸,橡胶,硅橡胶,金属,软木,毛毡,氯丁橡胶,丁腈橡胶,玻璃纤维或塑料聚合物(如聚四氟乙烯)。

特定应用的垫片可能含有石棉。

垫片安装要求:垫片-密封垫片安装要求1、密封垫片与法兰密封面应清洗干净,不得有任何影响连接密封性能的划痕、斑点等缺陷存在。

2、密封垫片外径应比法兰密封面外小,密封垫片内径应比管道内径稍大,两内径的差一般取密封垫片厚度的2倍,以保证压紧后,密封垫片内缘不致伸入容器或管道内,以免妨碍容器或管道中流体的流动。

3、密封垫片预紧力不应超过设计规定,以免密封垫片过度压缩丧失回弹能力。

填充PTFE材料特性的耐磨环1.填充PTFE材料特性本书将填充PTFE简称为特康。

特康是一种非常耐磨的材料,加入特别的添加剂,使其有着很好的钢性以保持密封形状在恶劣条件下不变形。

特康材料几乎可抵抗所有的化学物品,但不适于液态碱。

碳酸钾和卤化物。

特康在阳光曝晒和臭氧条件下几乎不影响寿命,吸水率为0.01%。

2.特康材料、与之相容的介质及相匹配工作表面材料特性:(由于生产厂不停改进配方,材料编号会变化。

订货应按当时厂家生产编号为准。

下述材料编号仅作参考)编号5 极好的抗化学物品腐蚀性能,良好的电绝缘性能。

适用于化工、石油、医药工业、适应任何润滑油、润滑脂。

匹配表面:硬编号10 好的抗化学物品腐蚀性能,耐高温、抗压强度高,适用于有润滑、无润滑的液压系统(液压油、水和水基乳化液)气动系统。

匹配表面:硬或软编号46 极高的抗压强度和硬度,良好的导热性,电绝缘性能、非常耐磨,可承受很高的机械负载、工作压力和运动速度。

适用于有润滑、无润滑状况的油压系统,不适于水、水基乳化液、酸。

匹配表面:硬编号109 好的抗化学性能,好的导热性,较高的抗压强度,对机械负载较平均,所受压力和温度较平均,速度中等的场合较适合。

适用于有润滑和无润滑状况的液压系统、气动系统,可用于油、水和水基乳化液。

匹配表面:硬或软编号42 好的抗化学腐蚀性能,好的绝缘性,较高的抗压强度、好的抗磨性能。

适用于速度和温度比较平均,较高的机械负载和压力。

只适用于有润滑状况的油压系统。

匹配表面:硬液压油、润滑油、油滑脂钢/钢、镀铬/铸铁不锈钢/铝、表层硬化处理46 42 510 109NBR 70水、水油乳化剂钢/钢、镀铬/铸铁不锈钢/铝、表层硬化处理10109NBR 70热水/蒸汽钢/钢、镀铬/铸铁不锈钢/铝、表层硬化处理10109EPDM 70含油气体、压缩空气 钢/钢、镀铬/铸铁钢/钢、镀铬/铸铁46 42 510 109NBR 70化学溶剂(请与分销商联络以便选择密封件) 不锈钢/铝、表层硬化处理不锈钢/铝、表层硬化处理46 4210 1093238化学溶剂(请与分销商联络以便选择密封件)钢/钢、镀铬/铸铁不锈钢/铝、表层硬化处理46 4210 109FKM 75GT孔用耐磨环沟槽尺寸密封件尺寸DH9B1-0.05W1=(ΦD-ΦB1)/2S max F1+0.2W T Z 10-25D-2W1 1.5-- 2.50 3.20 1.50-- 3.00 1.0-1.5 20-40D-2W1-2 2.50 2.50 4.20-2 2.50 4.00 1.0-2.0 25-80D-2W1-2 2.500.25-0.4 6.30-2 2.50 6.10 1.5-3.5 40-270D-2W1-2 2.500.25-0.78.10-2 2.507.90 2.0-5.0 40-320D-2W1-2 2.500.25-0.89.70-2 2.509.50 2.0-6.0 125-900D-2W1-2 2.500.25-1.115.00-2 2.5014.80 4.0-8.0 200-900D-2W1-2 2.500.25-1.120.00-2 2.5019.50 4.5-8.0 300-900D-2W1-2 2.500.25-1.125.00-2 2.5024.50 6.0-8.0 300-999D-2W1-2 2.500.25-1.130.00-2 2.5029.50 6.0-9.0订货范围(PTFE耐磨环油缸直径150mm)工作温度:80℃匹配表面:钢成卷供应订购GT型聚四氟乙烯耐磨环沟槽尺寸密封件尺寸Df8B1+0.05W1=(ΦB1-Φd)/2S max槽宽F1+0.2W T Z 8-20d+2W1 1.5-- 2.50 3.20 1.50-- 3.00 1.0-1.5 15-35d+2W1-2 2.50 2.50 4.20-2 2.50 4.00 1.0-2.0 20-75d+2W1-2 2.500.25-0.4 6.30-2 2.50 6.10 1.5-3.5 30-250d+2W1-2 2.500.25-0.78.10-2 2.507.90 2.0-5.0 35-300d+2W1-2 2.500.25-0.89.70-2 2.509.50 2.0-6.0 120-900d+2W1-2 2.500.25-1.115.00-2 2.5014.80 4.0-8.0 200-900d+2W1-2 2.500.25-1.120.00-2 2.5019.50 4.5-8.0 300-900d+2W1-2 2.500.25-1.125.00-2 2.5024.50 6.0-8.0 300-999d+2W1-2 2.500.25-1.130.00-2 2.5029.50 6.0-9.0订货范围(PTFE耐磨环轴径50mm)工作温度:80℃匹配表面:钢成卷供应订购Glyd Ring 格来圈 Step seal 斯特封格来圈和斯特封在液压行业使用多年,主要应用于液压缸之密封系统,无论使用于活塞或活塞杆,均获得良好的评价。