电力机车简介--中英文翻译

- 格式:doc

- 大小:52.50 KB

- 文档页数:8

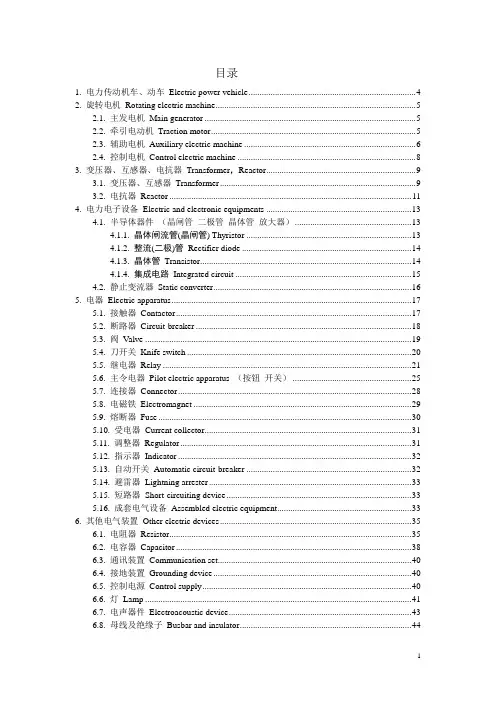

目录1. 电力传动机车、动车Electric power vehicle (4)2. 旋转电机Rotating electric machine (5)2.1. 主发电机Main generator (5)2.2. 牵引电动机Traction motor (5)2.3. 辅助电机Auxiliary electric machine (6)2.4. 控制电机Control electric machine (8)3. 变压器、互感器、电抗器Transformer,Reactor (9)3.1. 变压器、互感器Transformer (9)3.2. 电抗器Reactor (11)4. 电力电子设备Electric and electronic equipments (13)4.1. 半导体器件(晶闸管二极管晶体管放大器) (13)4.1.1. 晶体闸流管(晶闸管) Thyristor (13)4.1.2. 整流(二极)管Rectifier diode (14)4.1.3. 晶体管Transistor (14)4.1.4. 集成电路Integrated circuit (15)4.2. 静止变流器Static converter (16)5. 电器Electric apparatus (17)5.1. 接触器Contactor (17)5.2. 断路器Circuit-breaker (18)5.3. 阀Valve (19)5.4. 刀开关Knife switch (20)5.5. 继电器Relay (21)5.6. 主令电器Pilot electric apparatus (按钮开关) (25)5.7. 连接器Connector (28)5.8. 电磁铁Electromagnet (29)5.9. 熔断器Fuse (30)5.10. 受电器Current collector (31)5.11. 调整器Regulator (31)5.12. 指示器Indicator (32)5.13. 自动开关Automatic circuit-breaker (32)5.14. 避雷器Lightning arrester (33)5.15. 短路器Short-circuiting device (33)5.16. 成套电气设备Assembled electric equipment (33)6. 其他电气装置Other electric devices (35)6.1. 电阻器Resistor (35)6.2. 电容器Capacitor (38)6.3. 通讯装置Communication set (40)6.4. 接地装置Grounding device (40)6.5. 控制电源Control supply (40)6.6. 灯Lamp (41)6.7. 电声器件Electroacoustic device (43)6.8. 母线及绝缘子Busbar and insulator (44)7. 电测仪表Electrical measuring instrument (44)7.1. 指示仪表lndicating instrument (44)7.2. 传感器Sensor (46)8. 电机主要部件Main component of electrical machine (46)8.1. 同步电机Synchronous machine (46)8.2. 直流电机DC machine (48)8.3. 电机绕组Winding of electrical machine (52)9. 变压器主要部件Main component of transformer (54)9.1. 铁心Core (54)9.2. 绕组与线圈Winding (54)9.3. 绝缘Insulation (56)9.4. 附属装置Accessory equipment (56)10. 电器主要部件Main Component of electric apparatus (57)10.1. 线圈Coil (57)10.2. 磁系统与铁心Magnetic system and core (58)10.3. 触头系统Contact assembly (59)10.4. 灭弧装置Arc-control device (62)10.5. 底座与机构Base and mechanism (63)10.6. 脱扣器Release (65)GB中华人民共和国国家标准GB/T 3367.10-84铁路机车名词术语牵引电气设备名称Glossary of terms for railway locomotivesNomenclature of electric traction equipments1984—12—26发布1985—11—01实施国家标准局批准铁路机车名词术语牵引电气设备名称Glossary of terms for railway locomotivesNomenclature of electric traction equipments 本标准是对铁路电力机车,电力传动柴油机车、动车的电气设备及其主要部件名称的规定,包括电机,电力电子设备、变压器、互感器、电抗器、电器及电测仪表,供编制技术标准及设计文件时撰用。

电力机车—定义电力机车Electric locomotives 是指从外界撷取电力作为能源驱动的铁路机车,电源包括架空电缆、第三轨、电池等。

同样使用牵引电动机的电传动柴油机车、燃气机车等不属于电力机车。

电力机车-概况由牵引电动机驱动车轮的机车。

电力机车因为所需电能由电气化铁路供电系统的接触网或第三轨供给,所以是一种非自带能源的机车。

电力机车具有功率大、过载能力强、牵引力大、速度快、整备作业时间短、维修量少、运营费用低、便于实现多机牵引、能采用再生制动以及节约能量等优点。

使用电力机车牵引车列,可以提高列车运行速度和承载重量,从而大幅度地提高铁路的运输能力和通过能力。

电力机车起动加速快,爬坡能力强,工作不受严寒的影响,运行时没有煤烟,所以在运输繁忙的铁路干线和隧道多、坡度陡的山区线路上更能发挥优越性。

此外,电力旅客列车,可为客车空气调节和电热取暖提供便利条件。

电力机车由于电气化铁路基本建设投资大,所以应用不如内燃机车和蒸汽机车广泛。

电力机车没有空气污染,且善于保养,牵引列车速度可达几百千米,所以高速列车都是电力机车牵引的。

电力机车另一个优点就是能够在短时间内完成启动和制动,这个性能比蒸汽机车和内燃机车要优秀很多。

所以在世界范围内,正大力发展电气化铁路。

在绿色环保的今天,电力机车的发展更加受到重视。

电力机车的牵引力和爬坡能力比内燃机车和蒸汽机车要大得多,在载重过大或坡度较大的情况下无需采用多机牵引。

电力机车最大的优点就是无限行程,只要车辆不驶离电气化段,就不会“饿倒”(故障除外)。

无需像内燃机车和蒸汽机车那样经常补充燃料。

由于我国的电气化铁路较少,所以会选择把原本无电气化的铁路经电气化改造。

电气化改造后的铁路速度将从100-120km/h提高到160-200km/h,这样不仅能缩短列车的运输时间,还能达到5000t以上的货运列车运输。

如今,走向“高铁时代”的中国,正大力发展电气化铁路。

电力机车总体第一章绪论本章重点电力机车总体的组成和各部分的作用机车轴列式一、电力机车的优点电力机车是一种通过外部接触网或轨道供给电能,由牵引电动机驱动的现代化牵引动力。

其优点是:1.清洁无污染。

2.功率大,速度快。

3.热效率高,成本低。

4.综合利用资源,降低能源消耗。

5.维修便利,成本低。

6.工作条件舒适。

7.适应能力强。

二、电力机车总体的组成和各部分的作用电力机车由电气部分、机械部分和空气管路系统三大部分组成。

电气部分包括牵引电动机、牵引变压器、整流硅机组等各类电气设备。

作用:通过它们把取自接触网的电能转变为机械能,同时实现对机车的控制。

机械部分包括车体、转向架、车体与转向架的连接装置和牵引缓冲装置。

空气管路系统包括风源系统、制动机管路系统、控制管路系统和辅助管路系统。

电力机车机械部分各部分的作用如下:1.车体车体是电力机车上部车箱部分。

可分为:(1)司机室:乘务人员操纵机车的工作场所。

(2)机械间:用于安装各种电气和机械设备。

2.转向架转向架是机车的走行部分,它是电力机车机械部分中最重要的组成部分,主要包括:(1)构架:是转向架的基础受力体,也是各种部件的安装基础。

(2)轮对:是机车在线路上的行驶部件,由车轴、车轮及传动大齿轮组成。

(3)轴箱:用以固定轴距,保持轮对正确位置,安装轴承等。

(4)轴箱悬挂装置:也称一系弹簧。

缓冲轴箱以上部分的振动,减小运行中的动力作用。

(5)齿轮传动装置:通过降低转速,增大转矩,将牵引电动机的功率传给轮对。

(6)牵引电动机:将电能变成机械能转矩,传给轮对。

(7)基础制动装置:是机车制动机制动力的部分,主要由制动缸、传动装置,闸瓦等组成。

3.车体与转向架连接装置车体与转向架连接装置也称二系弹簧悬挂,设置在车体和转向架之间。

它是转向架与车体之间的连接装置,又是活动关节,同时承担各个方向力的传递以及减振作用。

4.牵引缓冲装置牵引装置即指车钩,它是机车与列车的连接装置,为了缓和连挂和运行中的冲击,还设置有缓冲器。

电机简介英文作文英文:Electric motors are devices that convert electrical energy into mechanical energy. They are widely used in various applications, such as industrial machinery, household appliances, and electric vehicles.There are different types of electric motors, including AC motors and DC motors. AC motors, or alternating current motors, are commonly used in household appliances like washing machines and fans. On the other hand, DC motors, or direct current motors, are often found in electric vehicles and industrial machinery.One of the key advantages of electric motors is their efficiency. Compared to traditional internal combustion engines, electric motors can convert a higher percentage of electrical energy into mechanical energy, making them more environmentally friendly and cost-effective in the long run.In addition, electric motors are also known for their reliability and low maintenance requirements. Unlike combustion engines, electric motors have fewer moving parts, which means they are less prone to wear and tear. This can result in lower maintenance costs and longer lifespan.Furthermore, electric motors offer precise control and high torque at low speeds, making them suitable for a wide range of applications. For example, in electric vehicles, electric motors provide instant torque, allowing for quick acceleration and smooth operation.Overall, electric motors play a crucial role in modern society, powering everything from household appliances to industrial machinery and transportation.中文:电机是一种将电能转换为机械能的设备。

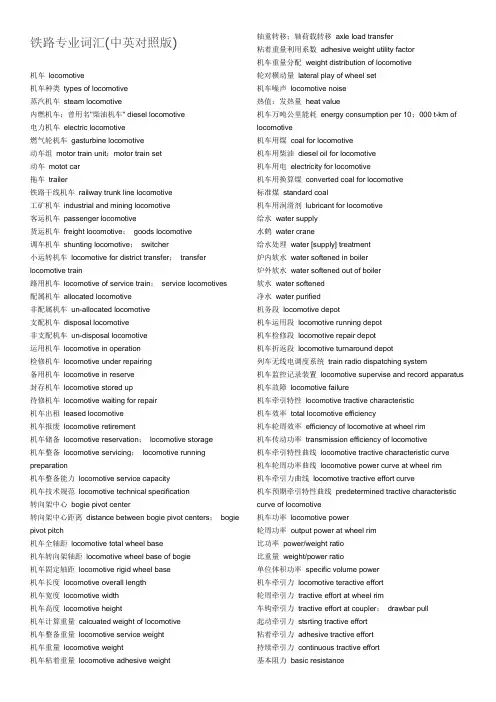

机车locomotive机车种类types of locomotive蒸汽机车steam locomotive内燃机车;曾用名“柴油机车”diesel locomotive电力机车electric locomotive燃气轮机车gasturbine locomotive动车组motor train unit;motor train set动车motot car拖车trailer铁路干线机车railway trunk line locomotive工矿机车industrial and mining locomotive客运机车passenger locomotive货运机车freight locomotive;goods locomotive调车机车shunting locomotive;switcher小运转机车locomotive for district transfer;transfer locomotive train路用机车locomotive of service train;service locomotives配属机车allocated locomotive非配属机车un-allocated locomotive支配机车disposal locomotive非支配机车un-disposal locomotive运用机车locomotive in operation检修机车locomotive under repairing备用机车locomotive in reserve封存机车locomotive stored up待修机车locomotive waiting for repair机车出租leased locomotive机车报废locomotive retirement机车储备locomotive reservation;locomotive storage机车整备locomotive servicing;locomotive running preparation机车整备能力locomotive service capacity机车技术规范locomotive technical specification转向架中心bogie pivot center转向架中心距离distance between bogie pivot centers;bogie pivot pitch 机车全轴距locomotive total wheel base机车转向架轴距locomotive wheel base of bogie机车固定轴距locomotive rigid wheel base机车长度locomotive overall length机车宽度locomotive width机车高度locomotive height机车计算重量calcuated weight of locomotive机车整备重量locomotive service weight机车重量locomotive weight机车粘着重量locomotive adhesive weight轴重转移;轴荷载转移axle load transfer粘着重量利用系数adhesive weight utility factor机车重量分配weight distribution of locomotive轮对横动量lateral play of wheel set机车噪声locomotive noise热值;发热量heat value机车万吨公里能耗energy consumption per 10;000 t-km of locomotive机车用煤coal for locomotive机车用柴油diesel oil for locomotive机车用电electricity for locomotive机车用换算煤converted coal for locomotive标准煤standard coal机车用润滑剂lubricant for locomotive给水water supply水鹤water crane给水处理water [supply] treatment炉内软水water softened in boiler炉外软水water softened out of boiler软水water softened净水water purified机务段locomotive depot机车运用段locomotive running depot机车检修段locomotive repair depot机车折返段locomotive turnaround depot列车无线电调度系统train radio dispatching system机车监控记录装置locomotive supervise and record apparatus机车故障locomotive failure机车牵引特性locomotive tractive characteristic机车效率total locomotive efficiency机车轮周效率efficiency of locomotive at wheel rim机车传动功率transmission efficiency of locomotive机车牵引特性曲线locomotive tractive characteristic curve机车轮周功率曲线locomotive power curve at wheel rim机车牵引力曲线locomotive tractive effort curve机车预期牵引特性曲线predetermined tractive characteristic curve of locomotive 机车功率locomotive power轮周功率output power at wheel rim比功率power/weight ratio比重量weight/power ratio单位体积功率specific volume power机车牵引力locomotive teractive effort轮周牵引力tractive effort at wheel rim车钩牵引力tractive effort at coupler;drawbar pull起动牵引力stsrting tractive effort粘着牵引力adhesive tractive effort持续牵引力continuous tractive effort基本阻力basic resistance运行阻力running resistance惰行阻力idle runing resistance;coasting resistance起动阻力starting resistance附加阻力additional resistance坡道阻力gradient resistance曲线阻力curve resistance空气阻力air resistance单位阻力unit resistance;specific resistance换算阻力;加算阻力converted resistance速度控制系统speed control system加速acceleration减速deceleration恒速constant speed加速力acceleration force减速力deceleration force列车制动train braking制动方式brake mode空气制动air brake真空制动vacuum brake动力制动dynamic brake液力制动hydraulic brake电阻制动rheostatic brake再生制动regenerative brake电空制动electropneumatic brake蓄能制动energy-storing brake涡流制动eddy current brake磁轨制动electromagnetic rail brake踏面制动tread brake盘型制动disc brake机车制动周期locomotive braking period机车制动距离locomotive braking distance机车每轴闸瓦作用力brake shoe force per axle of locomotive制动braking常用制动service braking;service application最大常用制动;常用全制动full servive braking;full service application 阶段制动graduated application自然制动unintended braking;undesired braking紧急制动emergency braking;emergency application意外紧急制动undesirable emergency braking;UDE缓解release直接缓解;一次缓解direct release阶段缓解graduated release自然缓解unintended release;undesired release漏泄leakage充风;充气charging阶段提升graduated increasing保持位suppression;maintaining position;holding position 制动管减压量brake pipe pressure reduction过量减压over reduction局部减压local reduction分段减压split reduction最大常用减压full servive reduction常用局减quick service紧急局减quick action前后风压差false gradient列车管压差train pipe pressure gradient保压停车stopping at maintaining position缓解停车stopping at release缓解波速release propagation rate制动波速braking propagation rate机车制动机locomotive brake gear空气压缩机air compressor调压器pressure regulator给风阀feed valve减压阀reducing valve机车分配阀locomotive distributing valve切换阀transfer valve自动制动阀automatic brake valve单独制动阀independent brake valve滤尘止回阀strainer check valve机车紧急放风阀locomotive emergency vent valve高压保安阀high pressure safety valve低压保安阀low pressure safety valve无载起动电空阀no-load starting electropneumatic valve油水分离器oil-water separator总风缸main air reservoir空气干燥器air dryer撒砂装置sanding device砂箱sand box撒砂阀sanding valve撒砂器sandingsprayer紧急撒砂emergency sanding自动撒砂automatic sanding间隙效应slack actionL/V比值L/V ratio弓网关系pantograph-contact line relation机车牵引区段locomotive tractive district机车交路locomotive routing单肩回交路single-arm routing双肩回交路double-arm routing半循环交路semi-loop routing循环交路loop routing环形交路circular routing短交路short routing长交路long routing直通交路through routing机车乘务制度locomotive crew working system机车包乘制system of assigning crew to designated locomotive机车轮乘制locomotive crew pooling system机车随乘制locomotive caboose crew system机车乘务组locomotive crew司机driver副司机assisant driver指导司机driver instructor司炉fireman机车运用指标index of locomotive operation机车出入段作业preparation of locomotive for leaving and arriving at depot 机车全周转complete turnround of locomotive机车在段停留时间detention time of locomotive at depot机车全周转距离diatance of one complete turnround of locomotive机车全周转时间period of one complete turnround of locomotive机车走行公里locomotive running kilometers换算走行公里converted running kilometers沿线走行公里running kilometers on the road辅助走行公里auxiliary running kilometers本务走行公里leading locomotive running kilometers单机走行公里light locomotive running kilometers重联机车走行公里multi-locomotive running kilometers机车日车公里average daily locomotive running kilometers机车平均牵引总重average gross weight hauled by locomotive机车日产量average daily output of locomotive运用机车台数number of locomotive in service机车需要系数coefficient of locomotives requirment单机运行light locomotive running双机牵引;双机重联牵引double locomotive traction多机牵引multi-locomotive traction主机;本务机车leading locomotive机车超重牵引traction for train exceed mass norm机车调度命令locomotive diapatching order机务段运行揭示running service-bulletin of depot司机运转保单driver’s service-report;driver’s log司机室driver’s cab司机操纵台driver’s desk司机模拟操纵装置simulator for driver train-handling优化操纵optimum handling;optimum optimum operation机车自动操纵automatic locomotive operation机车保养locomotive maintenance机车检修locomotive inspection and repair机车检修修程classification of locomotive repair机车大修locomotive overhaul [repair];locomotive general overhaul架修intermediate repair定修periodical repair;light repair蒸汽机车洗修steam locomotive boiler washout repair机车厂修locomotive repair in works机车段修locomotive repair in depot日常检查routine inspection机车临修locomotive temporary repair定期检修repair based on time or running kilometers状态检修repair based on condition of component换件大修component exchange repair配件互换修repair with interchangeable component预防维修制preventive maintenance system检修周期period of inspection and repair月检monthly inspection定检公里running kilometers between predetermined repairs定检时间time between predetermined repairs检修范围scope of repairing course;scope of repair超范围修理repair beyond the scope of repairing course检修停时standing time under repair集中化修理;集中修centralization of repair检修基本技术条件fundamental technical requirements for repair and inspection 检修工艺规程technological regulations for repair and inspection检修作业程序repair procedure;shop program磨耗限度limit of wear检修限度locomotive repair limit第一限度1st limit第二限度2nd limit使用限度operation limit中间工艺检验intermediate inspection at the technological process。

Automatic Train Protection列车自动保护系统Automatic Train Protection (ATP) in Great Britain英国的列车自动保护refers to指的是either of two implementations of a train protection system安装的两种列车保护系统之一installed in some trains安装在一些列车上in order to为了help prevent collisions防止碰撞through a driver's failure to observe a signal 观测一个信号or speed restriction限制速度. Note that注意ATP列车自动保护can also refer to 也能指automatic train protection systems列车自动保护系统in general通常, as implemented当列车自动保护应用in other parts of Europe and elsewhere在欧洲的其他地方和别处.英国的列车自动保护系统指的是安装在一些列车上的两种列车保护系统之一,列车保护系统是为了有助于避免由于驾驶员没有观测一个信号或者限制速度而发生碰撞。

注意:当列车自动保护应用在欧洲的其他地方和别处时,列车自动保护通常也指列车自动保护系统。

Overview概述This system uses a target speed目标速度indication指出and audible warnings音响警报信号to warn the train driver if they are likely to有可能exceed 超过a speed profile轮廓that will cause the train to pass a red (danger) signal or exceed a speed restriction速度限制. The system will apply the brakes制动if the driver fails to未能respond to响应these warnings警告信息. The system takes into account考虑the speed and position工况of the train relative to the end of its 'movement authority'行车许可in issuing the warnings and applying the brakes制动.列车自动保护系统用一个既定速度指示和音响报警来提醒司机他们是否有可能超过限制速度而造成错过红灯(危险)信号或者超过速度限制。

世界电力机车的发展中英文电力机车本身的原始动机同意触网发出的电流作为能源,由机车牵引电机驱动车轮。

随着电力机车功率,热效率,速度的提升,以及有力和可靠的操作过载能力成为其要紧优势,但不污染环境,因此专门适用于繁忙的铁路运输和隧道,以及斜坡的山区铁路。

电力机车从接触线获得电力,接触网供电电流机车差不多上直流和交流。

按照目前的供电电流形式的不同,而不涉及电力机车本身,电力机车系统可分为差不多直-直流电力机车,交-直流电力机车,交-直-交电力机车三种。

直-直流电力机车采纳直流电源系统,牵引变电所装有整流装置,它将成为一个三相交流-直流装置,然后访咨询互联网。

因此,电力机车可直截了当从网上联络供应DC系列直流牵引电动机使用,简化了机车设备。

直流系统的缺点是接触网电压低,通常l500伏或3000伏,接触线要求较粗,因此要消耗大量的有色金属,并增加建设投资。

关于交-直流电力机车交流电源系统,世界上大多数国家使用的是频率(50赫兹)交换系统,或25赫兹的低频通信系统。

在此电力供应系统中,牵引变电所将改为三相交流电频率的25千伏单相交流电源,然后传送到网络。

然而,在电力机车内使用的字符串仍旧是直流电动机(这是最大的优势:调速简单,只需改变电机端电压,因此就能够专门容易地实现在较大范畴内的机车速度,但这种电机由于需要使用换向器,制造和爱护是专门复杂的,体积更大),如此,交流到直流机车的转变任务完成。

接触网系统的直流电压没有提升专门多。

但接触导线的直径能够相对减少,从而减少了消费的非铁金属,但建设投资并没有减少。

因此,高频通信系统已被广泛采纳,世界上大多数的电力机车也开始采纳交-直流方式。

交-直-交流,交流非电力机车牵引电机换向器(即三相异步电动机),其在汽车制造,性能,功能,大小,重量,成本以及爱护性和可靠性等方面比换向器容易得多。

这是失败的电力机车,其要紧的缘故是提升速度相当困难。

但这种机车具有优良的牵引能力。

简介1879年出世的世界第一台电力机车,是利用两条铁轨之间的第三条轨将电力引进机车里的。

这种供电方式适合于电压和功率都比较低的情况。

随着电力机车的发展,要使它跑得快,运载量大,就得提高电力机车供电系统的电压和功率,因而需要使用高压输电线和变电装置。

在这种情况下,就不能再使用设在地面上的第三条轨供电的方式了,因为这既不安全,又给使用带来不便。

1881年,德国试验成功一种适合以高压输电线供电的电力机车新的供电系统,叫做“高架接触网”供电系统,也就是将电力机车的供电线路由地面转向空中。

实际上,这种供电系统和现在城市中的有轨电车相似,在车顶上装着一条“长辫子”。

它与以前使用蓄电池的电动机车的主要不同在于,它自身不带电源,由电厂供电,所以机车的结构比较简单,但需要一套供电设备。

这种装有“长辫子”的火车,依靠装在车顶上的受电弓子把电力从架在空中的电线上引到机车里。

高压输电线送来的电是高达110千伏的三相交流电,必须经过牵引变电所变成25千伏的单相交流电,方能供机车使用。

因此,在电力机车行驶的铁道沿线上,每隔50公里左右设一个牵引变电所。

变电所的电又被送到邻近的沿线接触网上,通过机车上的受电弓将交流电引到机车的整流器上,把交流电变成直流电,使直流电动机旋转,再经过一套传动装置,带动车轮转动,机车就会跑动起来。

电力机车虽然问世较早,但直到20世纪60年代才开始受到人们的重视,被大量普遍地使用起来,已成为铁路机车家族中的佼佼者。

人们将电力机车称为神通广大的“火车头”,就是因为它比蒸汽机车有着以下独特的优点:一是它的马力大,拉得多、跑得快、爬坡的劲头足。

例如,我国在50年代末期修筑的第一条电气化铁路——宝(鸡)成(都)铁路,就充分发挥了电力机车的优越性。

从宝鸡到成都,第一道关口就是要翻越气势雄伟的秦岭。

过去用3台蒸汽机车拉一列950吨货车上秦岭时,像老牛拉车每小时才行走18公里。

蒸汽机车下坡时是靠闸瓦制动的,而闸瓦因摩擦就会变热,如果不及时冷却就难以将机车制动住。

Introduction to LocmotiveA locomotive is a railway vehicle that provides the motive power for a train,and has nohy detached from their trains, are known as power cars.Traditionally,locomotive hual their trains. Increasingly common these days in passenger service is push-pull operation,where the locomotive push the trains in one direction and are controled from a control cab at the opposite end of the train in the other.Beniefits of locomotivesThere are many reasons why the motive power for trains has been traditonally isolated in a locmotive,rather than is self-propelled vehicles.these include: Ease of maintenance –it is easier to maintain one locomotive than many self-propelled cars.Safety –it is often safer to locate the train’s power system away from passenger. This was particularly the case for the steam locomtive,but still has some relevance.Easy replacement of motive power –should the locomotive break down, it is easy to replace it with a new one . Failure of the motive power unit does not require taking the whoole train out of service.Efficiency – idle trains do not waste expensive motive power resources. Separate locomotives mean that the costly motive power assets can be moved around as needed.Obsolescence cycles –separating the motive power from the payload-hauling cars means that either can be replaced without affecting the other. At some times, locomotive have become obsolete when their cars are not, or vice versa..Electric LocomotivesThe electric locomotive is supplied externally with electric power, either through an overhead pickup or through a third-rail. While the cost of electrifying track is rather high, electric trains and locomotives are significantly cheaper to run than diesel ones, and are capable of superior acceleration as well as regenerative braking, making them ideal for passenger service in densely populated areas. Almost all high speed train systems(e.g..IEC,TGV, bullet train) use electric power, because the power needed for such performance is not easily carried on board. Fot example the most powerfu electric locomotives that are used today on the channel tunnel freight services use 7Mwatts of power.The first known electric locomotive was buit by a Scotsman, Roert Davidson of Aberdeen in 1837 and was powered by galvanic cells.Modern electric locomotive range from small battery-powered machines for use in mines to large main-line locomotives of 6,000 horsepower(4.5MW) or more.In reality most modern locomotives are electricaly driven. Pure electric locomotives take their electrical supply from an external source while diesel-electric locomotives carry their own generating station.Main line electric locomotives first appeared at the beginning of the 20th century.The reason for their introduction was the problem of smoke, especially in tunnlels caused by steam locomotives. In the UK this was the London underground system while in the USA, it was under river tunnles and needs to eliminate smoke in built up areas.Early electric locomotives all relied on external power sourcing. Once up and running they tend to be reliable and efficint, but the supply infrastructure is a large capital expense that does require ongoing maintenance. For this reason only heavily used lines could justify electrification. For suburban lines the reduction in pollution from steam locomotives was a benefit all were aware oflThe world speed record for a wheeled train was set in 1990 ba a French TGV which reached a speed of 515.3km/h (320mph).While recently designed electrififed railway systems invariably operate on alternating current, many existing direct current sytems are still in use –e.g. in South Africa,Spain,and the United Kingdom(750v and 1500v); Netherlands(1500v); Belgiu, Italy, Poland (3000 v), and the cites of Mumbia and Chicagio (which will be switched to AC by 2025).Early locomotives came in a variety of forms. Generally they were designed to run off the supplied current. so locomotives with a direct current (DC) supply had DC motors while a alterntating current(AC) supplied locomotives with AC motors. AC can be either single or three phase. While the former requies two wire supply, one overhead the other being the track, three phase require three supply wire.Three phase locomotives therefore had two overhead supplies,the track being the third.DC supplies were either overhead or by means of a track level supply, commonly called the third rail.AC traction motors tended to be smaller than DC motors. This often meant electric locomotives with steam engine type cranks. DC motors could be smaller and set up to drive the ually through a gear ,but in some early examples by being part of the axle. Even so, some notable DC electric locomotives had large DC motors driving large driving wheels.One possibility with electric locomotives is that the motor can be used as a generator during braking, feeding electricity back into the supply system; this is called regenerative barking. This is not a new idea, it was one reason for the adoption by some railways of 3 phase AC suppies. Especially in mountainous aresa where the locomotive going down would generate much of the suppy for a locomotive going up. The Swiss railway uses the system; three modern locomotives heading downwards generate enough power to power a single locomotive in its upward journey.Today all eclctric locomotives tend to have drive motors close to the axles, although some still have the motor in the body driving the wheels through internal drive shafts.Modern solid state electrical control systems means the motor does not need to match the supply. This meams multi-voltage cross border locomotives are now quitecommon. Drive motors are generally DC, but there are 3 phase motors on some locomotives.A small number of electric locomotives can also operate off batery power to enable short journeys or shuting to occur on non-electrified lines or yards. Pure battery locomotives also found usage in mines and other underground workings where diesel fumes or smoke are not safe aand where external electricity supplies could not be used. Battery locomotives are also used on many underground railways for maintenance operations as they are required to operate in areas where the electricity supply has been temmporarily disconnected..Parts of Electric LocomotiveAwynchronoux MotorModern traction motor type using three phase AC electrical supply and now the favoured deisgn for modern train traction systems . Can be used on DC and AC electrified. railways with suitable control electronics and on diesel-electric locomtives.Axle BrushThe means by which the power supply ciruit is completed with the substation once power has been drawn on the locomotive. Current collected from the overhead line or third rail is returned via the axle brush and one of the running rails.BatteryAll trains are provided with a battery to provide start up current for supplying essential circuitts, such as emergency lighting ,when the line supply fails. The battery is usually connected across the DC control supply circuit.Circuit BreakerAn electric train is almost always provied with some sort of circuit breaker to isolate the power supply when there is a fault, or for maintenance. On AC systems they are usually on the roof near the pantograph. There are two types-the air blast circuit breaker and the vacuum circuit breaker or VCB. The air or vacuum part is used to extinguish the arc which occurs as the two tips of the circuit breaker are opened. The VCB is popular in the UK and the air blast circuit breaker is more often seen on the continent of Europe.ConverterGeneric term for any solid state electronic system for converting alternating current to direct current or vice versa. Where an AC supply has to be converted to DC it is called a rectifier and where DC is converted to AC it is called an inverter. The word originated in the US but is now common elsewhere.Cooling FansTo keep the thyristors and other electronic power systems cool, the interior of a modern locomotive is equipped with an air management system, electronically controlled to keep all systems operating at the correct temperature. The fans are powered by an auxiliary inverter producing 3-phase AC at about 400 volts.DC linkUsed on modern electronic power systems between the single phase rectifier and the 3-phase inverter. It is easier to convert the single phase AC from the overheak line to the 3-phase required for the motors by rectifying it to DC and then inverting the DC to 3-phase AC.InverterElectronic power device mounted on trains to provide alternating current from direct current. Popular nowadays for DC railways to allow three phase drive or for auxiliary supplies which need an AC supply.Line BreakerElectro-mechanical switch in a traction motor power circuit used to active or disable the circuit the circuit. It is nomally closed to start the train and remains closed all the time power is required. It is opened by a command from the driving controller,no-volts detected, overload detected and (were required) wheel spin or slide detected. It is linked to the overload and no-volt control circuits so that it actually functions as a protective circuit breaker.Master ControllerDriver’s power control device located in the cab. The driver moves the handle of the master controller to apply or reduce power to the locomotive or train.Motor BlowersTraction motors on electric locomotives get very hot and to keep their temperature at a reasonable level for long periods of hard word, they are usually fitted with electric fans called motor blowers. On a modern locomotive,they are powered by an auxiliary 3-phase AC supply of around 400 volts supplied by an auxiliary inverter.RectiferA converter consisting of thyristors and diodes which is used to convert AC to DC. A modern locomotive will usually have at least two, one for the power circuits and one or more for the auxiliary circuits.Synchronous MotorTraction motor where the field coils are mounted on the drive shaft and the armature coils in the housing, the inverse of normal practice.Favoured by the French and used on the high speed TGV Atlantique trains, this is a single-phase machine controlled by simple inverter. Now superseded by the asynchronous motor.TransformerA set of windings with a magnetic core used to step down or step up a voltage from one level to another.The voltage differences are determined by the proportion of windings in the input side compared with the proportion on the output side. An essential requirement for locomotives and trains using AC power, where the line voltage has to be stepped down before use on the train.Equipment LayoutVentilation SystemEquipment layout and ventilation systems 设备布置和通风系统设计Equipment layout and design of the ventilation system电力机车简介机车是为列车提供驱动力,而自身并没有效装载能力的车辆;他的唯一目标是沿着轨道牵引列车。

铁路专业词汇(中英对照版)机车locomotive机车种类types of locomotive蒸汽机车steam locomotive内燃机车;曾用名"柴油机车" diesel locomotive电力机车electric locomotive燃气轮机车gasturbine locomotive动车组motor train unit;motor train set动车motot car拖车trailer铁路干线机车railway trunk line locomotive工矿机车industrial and mining locomotive客运机车passenger locomotive货运机车freight locomotive;goods locomotive调车机车shunting locomotive;switcher小运转机车locomotive for district transfer;transfer locomotive train路用机车locomotive of service train;service locomotives配属机车allocated locomotive非配属机车un-allocated locomotive支配机车disposal locomotive非支配机车un-disposal locomotive运用机车locomotive in operation检修机车locomotive under repairing备用机车locomotive in reserve封存机车locomotive stored up待修机车locomotive waiting for repair机车出租leased locomotive机车报废locomotive retirement机车储备locomotive reservation;locomotive storage机车整备locomotive servicing;locomotive running preparation机车整备能力locomotive service capacity机车技术规范locomotive technical specification转向架中心bogie pivot center转向架中心距离distance between bogie pivot centers;bogie pivot pitch机车全轴距locomotive total wheel base机车转向架轴距locomotive wheel base of bogie机车固定轴距locomotive rigid wheel base机车长度locomotive overall length机车宽度locomotive width机车高度locomotive height机车计算重量calcuated weight of locomotive机车整备重量locomotive service weight机车重量locomotive weight机车粘着重量locomotive adhesive weight 轴重转移;轴荷载转移axle load transfer粘着重量利用系数adhesive weight utility factor机车重量分配weight distribution of locomotive轮对横动量lateral play of wheel set机车噪声locomotive noise热值;发热量heat value机车万吨公里能耗energy consumption per 10;000 t-km of locomotive机车用煤coal for locomotive机车用柴油diesel oil for locomotive机车用电electricity for locomotive机车用换算煤converted coal for locomotive标准煤standard coal机车用润滑剂lubricant for locomotive给水water supply水鹤water crane给水处理water [supply] treatment炉内软水water softened in boiler炉外软水water softened out of boiler软水water softened净水water purified机务段locomotive depot机车运用段locomotive running depot机车检修段locomotive repair depot机车折返段locomotive turnaround depot列车无线电调度系统train radio dispatching system机车监控记录装置locomotive supervise and record apparatus 机车故障locomotive failure机车牵引特性locomotive tractive characteristic机车效率total locomotive efficiency机车轮周效率efficiency of locomotive at wheel rim机车传动功率transmission efficiency of locomotive机车牵引特性曲线locomotive tractive characteristic curve机车轮周功率曲线locomotive power curve at wheel rim机车牵引力曲线locomotive tractive effort curve机车预期牵引特性曲线predetermined tractive characteristic curve of locomotive机车功率locomotive power轮周功率output power at wheel rim比功率power/weight ratio比重量weight/power ratio单位体积功率specific volume power机车牵引力locomotive teractive effort轮周牵引力tractive effort at wheel rim车钩牵引力tractive effort at coupler;drawbar pull起动牵引力stsrting tractive effort粘着牵引力adhesive tractive effort持续牵引力continuous tractive effort基本阻力basic resistance运行阻力running resistance惰行阻力idle runing resistance;coasting resistance起动阻力starting resistance附加阻力additional resistance坡道阻力gradient resistance曲线阻力curve resistance空气阻力air resistance单位阻力unit resistance;specific resistance换算阻力;加算阻力converted resistance速度控制系统speed control system加速acceleration减速deceleration恒速constant speed加速力acceleration force减速力deceleration force列车制动train braking制动方式brake mode空气制动air brake真空制动vacuum brake动力制动dynamic brake液力制动hydraulic brake电阻制动rheostatic brake再生制动regenerative brake电空制动electropneumatic brake蓄能制动energy-storing brake涡流制动eddy current brake磁轨制动electromagnetic rail brake踏面制动tread brake盘型制动disc brake机车制动周期locomotive braking period机车制动距离locomotive braking distance机车每轴闸瓦作用力brake shoe force per axle of locomotive 制动braking常用制动service braking;service application最大常用制动;常用全制动full servive braking;full service application阶段制动graduated application自然制动unintended braking;undesired braking紧急制动emergency braking;emergency application意外紧急制动undesirable emergency braking;UDE缓解release直接缓解;一次缓解direct release阶段缓解graduated release自然缓解unintended release;undesired release漏泄leakage充风;充气charging阶段提升graduated increasing保持位suppression;maintaining position;holding position 制动管减压量brake pipe pressure reduction 过量减压over reduction局部减压local reduction分段减压split reduction最大常用减压full servive reduction常用局减quick service紧急局减quick action前后风压差false gradient列车管压差train pipe pressure gradient保压停车stopping at maintaining position缓解停车stopping at release缓解波速release propagation rate制动波速braking propagation rate机车制动机locomotive brake gear空气压缩机air compressor调压器pressure regulator给风阀feed valve减压阀reducing valve机车分配阀locomotive distributing valve切换阀transfer valve自动制动阀automatic brake valve单独制动阀independent brake valve滤尘止回阀strainer check valve机车紧急放风阀locomotive emergency vent valve高压保安阀high pressure safety valve低压保安阀low pressure safety valve无载起动电空阀no-load starting electropneumatic valve 油水分离器oil-water separator总风缸main air reservoir空气干燥器air dryer撒砂装置sanding device砂箱sand box撒砂阀sanding valve撒砂器sandingsprayer紧急撒砂emergency sanding自动撒砂automatic sanding间隙效应slack actionL/V比值L/V ratio弓网关系pantograph-contact line relation机车牵引区段locomotive tractive district机车交路locomotive routing单肩回交路single-arm routing双肩回交路double-arm routing半循环交路semi-loop routing循环交路loop routing环形交路circular routing短交路short routing长交路long routing直通交路through routing机车乘务制度locomotive crew working system机车包乘制system of assigning crew to designated locomotive 机车轮乘制locomotive crew pooling system机车随乘制locomotive caboose crew system机车乘务组locomotive crew司机driver副司机assisant driver指导司机driver instructor司炉fireman机车运用指标index of locomotive operation机车出入段作业preparation of locomotive for leaving and arriving at depot机车全周转complete turnround of locomotive机车在段停留时间detention time of locomotive at depot机车全周转距离diatance of one complete turnround of locomotive机车全周转时间period of one complete turnround of locomotive机车走行公里locomotive running kilometers换算走行公里converted running kilometers沿线走行公里running kilometers on the road辅助走行公里auxiliary running kilometers本务走行公里leading locomotive running kilometers单机走行公里light locomotive running kilometers重联机车走行公里multi-locomotive running kilometers机车日车公里average daily locomotive running kilometers机车平均牵引总重average gross weight hauled by locomotive 机车日产量average daily output of locomotive运用机车台数number of locomotive in service机车需要系数coefficient of locomotives requirment单机运行light locomotive running双机牵引;双机重联牵引double locomotive traction多机牵引multi-locomotive traction主机;本务机车leading locomotive机车超重牵引traction for train exceed mass norm机车调度命令locomotive diapatching order机务段运行揭示running service-bulletin of depot司机运转保单driver’s service-report;driver’s log司机室driver’s cab司机操纵台driver’s desk司机模拟操纵装置simulator for driver train-handling优化操纵optimum handling;optimum optimum operation机车自动操纵automatic locomotive operation机车保养locomotive maintenance机车检修locomotive inspection and repair机车检修修程classification of locomotive repair机车大修locomotive overhaul [repair];locomotive general overhaul架修intermediate repair定修periodical repair;light repair 蒸汽机车洗修steam locomotive boiler washout repair机车厂修locomotive repair in works机车段修locomotive repair in depot日常检查routine inspection机车临修locomotive temporary repair定期检修repair based on time or running kilometers状态检修repair based on condition of component换件大修component exchange repair配件互换修repair with interchangeable component预防维修制preventive maintenance system检修周期period of inspection and repair月检monthly inspection定检公里running kilometers between predetermined repairs 定检时间time between predetermined repairs检修范围scope of repairing course;scope of repair超范围修理repair beyond the scope of repairing course检修停时standing time under repair集中化修理;集中修centralization of repair检修基本技术条件fundamental technical requirements for repair and inspection检修工艺规程technological regulations for repair and inspection检修作业程序repair procedure;shop program磨耗限度limit of wear检修限度locomotive repair limit第一限度1st limit第二限度2nd limit使用限度operation limit中间工艺检验intermediate inspection at the technological process转向设备turning facilities转盘turntable机务设备通过能力carrying capacity of locomotive facilities 机车专用设备special equipment for locomotive operation机车验收acceptance of locomotive机车试运转locomotive trial run形式试验type test性能试验performance test鉴定试验homologation test出厂试验predelivery test制动试验brake test牵引试验traction test负载试验loaded test;load test牵引热工试验traction and thermodynamique de traction定置试验stationary test;test at standstill动力学试验dynamics test强度试验strength test运用试验service test;operation test耐久性试验durability test可靠性试验reliability test例行试验routine test特殊试验special test研究性试验investigation test抽样试验sampling test模拟试验analogue test机车履历簿locomotive logbook直流电力机车DC electric locomotive单向交流电力机车single-phase AC electric locomotive单相工频交流电力机车single-phase industrial frequency AC electric locomotive双电压制电力机车dual voltage electric locomotive双频率制电力机车dual frequency electric locomotive多电流制电力机车multiple system electric locomotive硅整流器电力机车silicon rectifier electric locomotive晶闸管整流器电力机车thyristor rectifier electric locomotive经闸管变流器电力机车thyristor converter electric locomotive 电动车组electric multiple unit;motor coach set;electric motor train unit单相交流电动车组single-phase industrial frequency AC motor train unit地下铁道电动车组subway motor train unit电流制current system直流制DC system单相工频交流制single-phase industrial frequency AC system 单相低频交流制single-phase low frequency AC system受电弓标称电压nominal voltage at pantograph调压方式voltage regulation mode高压侧调压high voltage regulation低压侧调压low voltage regulation分级调压stepped voltage regulation无级调压stepless voltage regulation相控调压phase control斩波调压chopper control变阻调压rheostatric control整流方式mode of rectification牵引变流器traction convertor牵引逆变器traction invertor牵引变频器traction frequency convertor可调牵引变频器variable frequency convertor直流斩波器DC chopper单相桥式整流器single-phase bridge rectifier三相桥式整流器three-phase bridge rectifier可控桥式整流器controlled bridge rectifier对称半控桥式整流器symmetric half-controlled bridge rectifier 非对称半控桥式整流器asymmetric half-controlled bridge rectifier多段桥[联结] bridges in cascade;multi rectifier bridge硅整流装置silicon rectifier device 晶闸管整流装置thyristor rectifier device励磁整流装置excitation rectifier device电力传动方式mode of electric drive直流传动DC drive交-直流传动AC-DC drive交-直-交流传动AC-DC-AC drive调速方式mode of speed control变压调速variable voltage speed control变频调速variable frequency speed control变极调速pole changing speed control车轴驱动方式mode of axle drive弹性齿轮驱动resilient gear drive刚性齿轮驱动solid gear drive单侧减速齿轮驱动single reduction gear drive双侧减速齿轮驱动double reduction gear drive单电动机驱动monomotor drive车轴空心轴驱动quill drive;hollow axle drive电机空心轴驱动hollow shaft motor drive万向轴驱动cardan shaft drive直接驱动gearless drive;direct drive独立驱动individual drive组合驱动coupled axle drive连杆驱动rod drive组合传动机车coupled axle drive locomotive独立传动机车individual drive locomotive齿轨[传动]机车;齿条传动机车rack locomotive牵引电动机供电制式traction motor power supply system 机车集中供电locomotive centralized power supply转向架独立供电bogie individual power supply电动机独立供电motor individual power supply主电路power circuit;main circuit高压电路high voltage circuit;high tension circuit低压电路low voltage circuit;low tension circuit网侧电路circuit on side of overhead contact line牵引电路traction circuit制动电路braking circuit滤波电路filter circuit辅助电路auxiliary circuit列车供电电路power supply circuit for train控制电路control circuit控制电源control source蓄电池电路battery circuit指令电路command circuit照明电路lighting circuit仪表电路instrument circuit联锁电路interlocking circuit信号电路signal circuit起动电路starting circuit保护电路protective circuit电子控制电路electronic control circuit电空制动电路electropneumatic brake ciucuit;E-P brake circuit 防空转防滑行保护电路anti-slip/slide protection circuit音频通讯电路audio communication circuit电连接器electric coupler自动电连接器electric automatic coupler机车重联电连接器multi-locomotive electrc coupler牵引电动机traction motor直流牵引电动机DC traction motor脉流牵引电动机pulsating current traction motor交流牵引电动机AC traction motor单向交流牵引电动机single-phase AC traction motor三相交流牵引电动机three phase AC traction motor抱轴式牵引电动机axle hung traction motor;nose suspension traction motor架承式牵引电动机frame mounted traction motor转向架架承式牵引电动机bogie mounted traction motor底架架承式牵引电动机underframe mounted traction motor串励电动机series excited motor并励电动机shunt excited motor复励电动机compound excied motor他励电动机separately excited motor同步电动机synchronous motor异步电动机asynchronous motor交流换向器电动机alternating current commutator motor全封闭式电动机totally-enclosed motor通风式电动机ventilated motor自通风式电动机self-ventilated motor强迫通风式电动机force ventilated motor直线电动机;线性电动机linear motor直线同步电动机linear synchronous motor直线异步电动机;直线感应电动机linear asynchronous motor;linear induction motor电动机转速motor speed电动机超速runaway speed电动机特性motor characteristic电动机转矩;电动机扭矩motor torque启动转矩starting torque峰值转矩peak torque制动转矩braking torque最大输出功率maximum output启动电流starting current峰值电流peak current标称电压nominal voltage变压器电势transformer EMF片间平均电压mean voltage between segments片间最高电压maximum voltage between segments消弱磁场weakened field最大磁场maximum field 最小磁场minimum field磁场消弱率field weakening磁场消弱系数coefficient of field weakening恒功调速比speed ratio on constant power转向器commutator换向片commutator segment电枢线圈armature coil均压线equalizer;cable bond转轴shaft定子stator转子rotor主极铁心mainpole core主极线圈mainpole coil换向极铁心interpole core换相极线圈interpole coil补偿线圈compensating coil机座frame铸造机座cast frame焊接机座welding frame半叠片机座semi-laminated frame全叠片机座full-laminated frame电刷装置brush gear刷握brush-holder刷盒brush box电刷brush端盖end shield抱轴悬挂装置suspension bearing主发电机main generator直流主发电机DC main generator交流主发电机main alternator辅助发电机auxiliary generator直流辅助发电机DC auxiliary generator直流启动发电机DC starting generator;dynastarter 直流控制发电机DC control generator直流励磁机DC exciter劈相机Arno converter;phase splitter辅助电动机auxiliary motor直流辅助电动机DC quxiliary motor异步辅助电动机asynchronous auxiliary motor空压机电动机air compressor motor通风机电动机blower motor泵电动机pump motor控制电机control electric machine自整角机synchro测速发电机tachogenerator机车牵引变压器traction transformer of locomotive心式牵引变压器core-type traction transformer壳式牵引变压器shell-type traction transformer自藕牵引变压器traction autotransformer调压牵引变压器regulating traction transformer分接牵引变压器tapped traction transformer油浸式牵引变压器oil-immersed type traction transformer 整流变压器rectifier transformer电源变压器supply transformer隔离变压器;绝缘变压器isolating transformer同步变压器synchronous transformer脉冲变压器pulse transformer控制变压器control transformer信号变压器signal transformer励磁变压器excitation transformer高压绕组high voltage winding;high tension winding低压绕组low voltage winding;low tension winding调压绕组regulating winding励磁绕组excitation winding辅助绕组auxiliary winding列车供电绕组train coach supply winding自然循环natural circulation强迫循环forced circulation强迫导向循环forced guided circulation牵引电抗器traction tractor平波电抗器smoothing reactor过渡电抗器transition reactor接地电抗器earthing reactor;grounding reactor制动电抗器braking reactor分流电抗器divert shunt reactor;inductive shunt滤波电抗器filter reactor均流电抗器sharing reactor限流电抗器inductive reactor;current limiting reactor 换相电抗器commutation reactor起动电阻器staring resistor制动电阻器braking resistor过渡电阻器transistion resistor分流电阻器divert shunt resistor;shunting resistor稳定电阻器stabilizing resistor调节电阻器regulating resistor制动电阻柜braking resistor cubicle制动电阻元件braking resistor grid非线性电阻器non-linear resistor滤波电容器filter capacitor换相电容器commutating capacitor保护电容器protective capacitor起动电容器starting capacitor补偿电容器compensation capacitor主断路器line circuit-breaker真空主断路器line vacuum circuit-breaker空气主断路器line air-blast circuit-breaker直流高速断路器DC high speed circuit-breaker受电器current collector 受电弓pantograph单臂受电弓single arm pantograph双臂受电弓double arm pantograph弓头pantograph bow受电弓滑板pantograph pan弓角pantograph horn受电弓气缸pantograph cylinder支持绝缘子supporting insulator第三轨受电器conductor rail collector受电靴装置shoegear集电靴collector shoe电磁接触器electromagnetic contactor直流接触器DC contactor交流接触器AC contactor电空接触器electropneumatic contactor组合接触器grouping contactor线路接触器line contactor磁场削弱接触器field weakening contactor制动接触器braking contactor励磁接触器excitation contactor辅助接触器auxiliary contactor调压开关tap changer低压调压开关low voltage tap changer;low tension tap changer高压调压开关high voltage tap changer;high tension tap changer位置转换开关position changeover switch鼓形位置转换开关drum position changeover switch凸轮位置转换开关cam position changeover switch牵引-制动位转换开关power/brake changeover switch反向器reverser电流制转换开关current system changeover switch主电路库用转换开关main circuit transfer switch for shed supply辅助电路库用转换开关auxiliary circuit transfer switch for shed supply短路器short-circuiting device接地开关earthing switch牵引电动机隔离开关traction motor isolating switch受电弓隔离开关pantograph isolating switch主整流柜隔离开关isolating switch for main silicon rectifier cubicle劈相机故障隔离开关fault isolating switch for phase splitter控制电源隔离开关isolating switch for control supply司机控制器driver controller调车控制器shunting controller电空制动控制器E-P brake controller按键开关button switch;key switch自复式按键开关self-reset push-key switch非自复式按键开关non-self-reset push-key switch主按键开关组main button switch group;main key switch set 副按键开关组secondary push-key switch group;secondary key switch set电磁阀electromagnetic valve电空阀clectropneumatic valve电液阀electro-hydraulic valve保护阀protective valve受电弓电空阀pantograph valve防空转撒沙电空阀anti-slip sanding valve防空转防滑行保护装置anti-slip/slide protection device轴重转移补偿装置axle load transfer compensation device功率因数补偿装置power factor compensation device电压继电器voltage relay电流继电器current relay时间继电器time relay中间继电器intermediate relay速度继电器speed relay温度继电器temperature relay压力继电器pressure relay欠电压继电器under-voltage relay过电流继电器over-current relay转速继电器tachometric relay流速继电器flow relay接地继电器earth fault relay风压继电器air pressure relay油压继电器oil-pressure relay起动继电器starting relay主电路库用插座main circuit socket for shed supply辅助电路库用插座auxiliary circuit socket for shed supply控制电路库用插座control circuit socket for shed supply重联插座multiple unit socket印制电路板插座printed circuit board socket电压调整器voltage regulator温度调整器temperature regulator位置指示器notch indicator数字显示器digital display司机室取暖电炉driver’s cab electric heater司机室热风装置driver’s cab air heater司机室空调装置driver’s cab air conditioner电热玻璃electric heating glass电测仪表electrical measuring instrument牵引电机电压表traction motor voltmeter牵引电机电流表traction motor ammeter励磁电流表excitation ammeter网侧电压表voltmeter on side of overhead contact line;overhead side voltmeter辅助电路电压表auxiliary circuit voltmeter控制电源电压表control supply voltmeter 控制电源电流表control supply ammeter机车速度表locomotive speedometer单相电度表single-phase wat-hour meter速度记录仪tachograph传感器sensor;transducer电压传感器voltage sensor电流传感器current sensor压力传感器pressure sensor速度传感器speed sensor温度传感器temperature sensor直流电流互感器DC current transformer阀形避雷器valve type arrester放电器discharger轮缘喷油器flange lubricator接地安全棒earthing pole接地回流电刷earth return brush前照灯head lamp;head light副前照灯subhead lamp;dim head light标志灯marker lamp走行部灯bogie lamp车号灯side number plate lamp路签灯train staff lamp记事灯writing lamp照明灯illuminating lamp指示灯indicator lamp风喇叭air horn高音风喇叭high tone air horn低音风喇叭low tone air horn警笛siren警惕装置vigilance device机车组装后的检查与试验inspection and test of locomotive after completion of construction一般性检查general inspection称重试验weighing test压缩空气设备全面的气密性试验test for over-all air-tightness of compressed air equipments车体及外部装备密封试验test for sealing of body and external equipment受电弓试验pantograph test介电强度试验dielectric test事故预防措施的检查checks for prevention of accidents安全设备试验test on safety equipments蓄电池充电系统试验checks of battery charging-arrangement 通风冷却试验test on ventilation and cooling空气制动试验test on air brake曲线通过实验curve negotiation test机车振动参数测试measurements of vibration parameters辅助机组试验test on auxiliary machines机车调速试验test on speed regulation主电路短路保护系统试验test on short-circuit protection system of main circuit主电路过载保护系统试验test on overload protection system of main circuit内部过电压试验test on internal overvoltage外部过电试验test on external overvoltage机车功率试验locomotive [traction] power test机车功率因数测定measurment of power factor机车效率测定measurement of efficiency of locomotive谐波电流百分比测定measurement of percentage of harmonic current起动加速试验starting and acceleration test运行阻力试验test for running resistance电气制动试验electric braking test滤尘效果试验test on filter efficiency撒沙装置试验test on sanding gear重联运行试验test on coupled operation;test on multi unit operation司机室工作条件检查check on working conditions in the driver’s cab4。

俄汉电力机车术语汇编Сборник русско-китайских терминов, употребляемых в области электроподвижного состава韩宝军编株洲ЧжучжоуАвтоматическая локомотивная сигнализация(АЛС)机车自动信号(装置)Автономная тяга(独立式)动车牵引Азотизация氮化处理Акт на простой вагона (机车)车辆停留记录Антенна 天线биконическая ~双锥天线логопериодическая ~对数周期天线Антивирусная программа抗病毒软件Армировка保护装置,加强装置Асбобумага石棉板Аэродинамика поезда列车空气动力学Балл землетрясения地震震级Балластировка 铺道渣Бандажное кольцо绑线环Башня охлаждения冷却塔Безбандажное колесо整体车轮Бесконтактный 无触点的Биконическая антенна双锥天线Биполярный транзистор с изолированным затвором (IGBT)绝缘门极双级晶体管Блокировка стрелки道岔锁闭Блокирующий компьютер联锁计算机Блок-пост闭塞(信号)所промежуточный ~中间闭塞(信号)所путевой ~线路闭塞所Бодрствование守夜Болт грузовой装载螺栓Бамбардье Транспортейшн庞巴迪公司Брак в работе机破Бросок急冲(指针),骤增~ намагничивающего тока起磁电流骤增~ напряжения电压骤增(急冲)~ тока电流骤增(急冲)Буксование колѐс 车轮空转Бункерный полувагон漏斗车Буферный фонарь标志灯Вагон车辆крытый ~棚车Вагонная шина车辆总线Вагоностроительный завод车辆辆制造厂Вакуумнагнетательный способ真空加压法Вариатор变速器Варистор压敏电阻,可变电阻,可调电阻Версия софтвера软件版本Вес тары自重Весовая норма тяги牵引定数Взаимоблокировочный клапан互锁阀Взаимозаменяемость互换性Взрез стрелки挤岔Водопроводимость 水导率Возбуждение 励磁независимое ~постороннее ~Волноразрезатель 斩波器~ перенапряжения过压斩波器Волоконно-оптический провод光纤导线Воображаемая реальность虚拟现实Воронка направляющая 导向喇叭口~ дозаторная计量漏斗~ кабельная电缆端,电缆终端套管~ концевая终端接线盒Встряхивание颠簸Входная площадка пониженного уровня地板上下车通道Выброс浪涌Выпрямитель整流器игнитронный ~引燃管整流器однофазный мостиковый ~单相桥式整流器селеновый ~硒整流器четырѐхквадрантный ~四象限整流器Высокоскоростной 高速的Гальваноскоп验电器Гибридный тяговый привод混合牵引传动装置Гистограмма柱状图Гироскоп 陀螺,回转仪;回转器Гироскопический накопительГлавный выключатель (ГВ)主断路器Глубина замерзания冻结深度Глянцевая поверхность光面Горловина咽喉Горочная мастерская驼峰机械修理室График движения поездов列车运行图表Гудение 蜂音,蜂鸣声Двигатель电动机опорно-осевой тяговый ~抱轴式牵引电动机опорно-рамный тяговый ~架承式牵引电动机~ закрытого исполнения全封闭式电动机~ с независимым возбуждением他励电动机Двутактная модуляция双拍调制Двутактная электроцепь双拍电路Двухтактный дизель 二冲程柴油机Детектирование检波Диагональная связь斜支撑,对角联杆;对角联系Диаграмма框图Динамика поезда 列车动力学Диоптрический прибор折射仪Дишифратор解码器,译码器Для обеспечения удобств лицам с ограниченной подвижностью以便行动不便的旅客(上、下车)Доски печатных цепей印制电路板Единичный толчок单钩溜放Жестянка钣金Задвижная дверь拉门Заклевание粘接Закоротить短接Замазка粘接剂Замыканиепроходящее ~贯穿短路Занятие перегона占用空间Запоминание存储~ данных数据存储~ информации信息存储Запоминающая ячейка存储单元Запоминающий 存储的внешнее ~ устройство外存储器внутреннее ~ устройство内存储器Запрессовка обмоток绕阻压接Запускающее устройство触发装置Защита от буксования防空转Защита от недонапряжения欠压保护Защита от перегрузки超载保护Защита от юза防滑行Зеркало заднего (левого, правого) видения后(左,右)视镜Изолирующий стык(电车路的)轨端绝缘接头Импеданс 阻抗Импульсный пакет脉冲群Инвертор逆变器трѐхфазный ~三项逆变器ИнжекцияИнициализация初始化Ннициализировать初始化Инструмент для рихтовки пути拨道器Интеллектуальная собственность知识产权Интенсивность землетрясения地震烈度Интерактивный интерфейс交互接口Интернет 因特网,国际互联网Интернет-адрес网址Интерьер内部装饰Инициализация初始化Испытание试验диэлектрическое ~介电强度试验коммуникационное ~通讯试验модулирующее ~型式试验стендовое~定置试验,台架试验~ на пробой耐压试验~ на антизамерзание防冻试验~ на внезапное погружение нагрузки负载突投试验~ на переменные влажности交变湿热试验~ под напряжением耐压试验;应力试验~ при переменной частоте变频试验~ скатывания при торможении поезда溜放试验~ сопротивления изоляции绝缘电阻试验Камера коллекторная换向器室Капсюльподшипника轴承座Картер曲轴箱Касательная линия切线Кассетоприѐмник接收盒Катушка компенсационной обмотки补偿线圈Катушка полюсная磁极线圈,极线圈Квазивысокоскоростной准高速的Квазипиковое напряжение准峰值电压Кинескоп 显像管цветной ~彩色显像管Кинетическая энергия动能Клетка保持架Клетка ротора转子笼КлиентураКлин из пресс-массы填塞楔Клин фрикционный 摩擦楔Клон兼容机(知名品牌微机产品的仿制机)Коаксиальный кабель同轴电缆Кокоша橄榄簧Колѐсные пары轮对Коллапс 死机Коллектор 换向器Колпак罩КольцеваниеКоманда позиции级位指令Комплексное унифицированное локомотивное устройство безопасности (КЛУБ-У)机车通用成套安全装置Комфорт舒适,安逸,方便,(室内水暖电空调等)设备Конденсатор电容器сглаживающий ~平滑电容器Конструкционная скорость构造速度Контактор 接触器Контактная сеть接触网Контрольно-регистрирующее устройство机车监控记录装置Конфигурация配置~ состава车身结构Концевой кран уравнительной трубы平衡管端阀Концентр同心圆Концентрация тяги动力集中Концептуальный 理性的Концепция概念,观念;构思,构想~ маркетинга营销理念Коробчатая балка箱形梁Коэффициент сцепления粘着系数Кремневокарбид碳化硅Криоскоп 冰点检测仪Курсирование в международных сообщениях国际联运Кузов车体обтекальный ~流线型车体~ маятникового типа摆式车体Лавинообразование 雪崩形成Лампа накаливания白炽灯Литиемый батарей锂电池Линейный разъединитель 线路隔离开关Лобовое столкновение поездов列车正面冲突Логопериодическая антенна对数周期天线Локализация производства本地化生产Локомотивное депо机务段Логистические услуги后勤服务Локомотивная бригада乘务组самоуплотняющаяся ~自封式涨圈,自封式盘根~ кабеля电缆护套~ коллектора换向器去线圈Лыжа пантографа受电弓滑板Масленка реборды колеса轮缘喷油器Машинист司机Помощник~副司机Машинный шлюз网关Межвагонные переходы车辆间通道Международное железнодорожное сообщение国际铁路联运Мембрана тифона высокого тона高音风笛膜Место для сидения座位Метрополитен 地铁Микалента 云母带Миканит 云母,云母胶板Микропроцессорная система 微(处理)机系统Модификация 改型высокотемпературная ~高温变形Модульная конструкция模块化结构МодуляцияМолярная масса摩尔质量Мониторинг监测,监控Монокльный микропроцессор单板机Монокристальный микропроцессор (лущилка)单板机Моторная ось 动轴Моторная тележка电动转向架Наведенное напряжение 感应电压Наезд поезда列车追尾Нажимной конус(车钩缓冲装置的)压缩楔Накипь水垢Наклейка标签,表示牌~«верх»“请勿倒置”表示牌~ «взрывоопасно»“爆炸危险”表示牌~ «воспламеняется от воды»“遇水发火”表示牌~ «легкобьющийся»“易碎”表示牌~ «не толкать»“请勿碰撞”表示牌Наклонность倾斜度Накопитель энергии储能器,蓄能器Насекомое страдание虫害Национальное общество国营公司Неправильное размыкание错误解锁Нормальная операция стрелки 道岔定操Нормально-закрытый контракт动断触点,常关触点Нормально-открытый контракт动合触点,常开触点Нулевое положение零位Обшивка станины 机座外壳Объѐм перевозок运输量Окислитель氧化剂Окружная скорость圆周速度Опорный изолятор支持绝缘子Опрокидывание поезда列车颠覆Оптический кабель光缆Осевая формула轴(列)式Осмотрпредрейсовый~上线前检查послерейсовый ~上线后检查Остов 骨架,构架~ двигателя发动机机架~ корпуса车身构架,机身骨架~ ротора转子外壳,转子框架Осциллограф 示波器Ответвитель耦合器Ответственная организация归口单位Откос(铁路等的)边坡Отличительная черта 特点,特征Паз открытой формы开口形槽Палец щѐточный刷杆Панель переключения электропитания电源转换板Пантограф (电力机车上的)导电弓架,滑板несимметричный ~ 单臂受电弓симметричный ~ 双臂受电弓Пара полюсов极对,磁极偶Парк 总数,总额,台数Пассажировместимость 载客量Пассивирование 钝化处理Патрон ламп 灯头Первая гармоника基波Первичное напряжение原边电压Переводный механизм转辙机Перегон区间Переезд道口,通道,铁道道叉железнодорожный ~铁道道口охраняемый ~有防护设施的道口,有人看守的道口Перепрессованная сварка压型焊接Перепускная труба回流管Перераспределение нагрузок на осях轴重转移Периферийные устройства外围设备Персональный компьютер个人电脑Песочница撒砂器Пиккерный аппарат采集装置Плавное регулирование平滑调节Плата电路板Плечо交路Плоскость катания踏面Плохое ответвление分路不良Пневматическая шина 充气轮胎Поверхность катания踏面Поводок (机车)结合杆буксовой ~Повышенная пассажировместимость大客容量Поглощающий аппарат缓冲器Подвешивание悬置,吊,挂люлечное подвешивание ~摇动台悬挂(装置)магнитное ~磁悬浮сбалансированное рессорное ~均衡弹簧悬挂(装置)центральное рессорное ~中央弹簧悬挂装置~ провода架线Подвижной состав机车车辆Подгар 烧焦,烧损Поддерживающий конденсатор支撑电容器Подпятник 下心盘Подсвечка прибора仪表照明Подталкивание补机推进Подход 办法,途径,门径;靠近,接近,走近;探讨,接洽,协商;方法,学说вероятностный ~概率求解法интегрированный ~综合法каузальный ~因果法эвристический ~启发法Подшипник 轴承моторно-осевой ~电动机抱轴承опорно-осевой ~ 抱轴轴承Подшипниковыйщит轴承端盖,轴承套Поездсосредоточеннойтягой动力集中的列车Поезднаяшина列车总线Поездноеположение运行位Полипропиленовый конденсатор 聚丙烯电容器Политетрафторэтиленовая труба聚四氟乙稀管Полоз 滑道,滑轨,滑板Помеха骚扰Помехоустойчивость抗扰度~от импульсного тока浪涌抗扰度Поперечное поле横向场Поперечный поток横向流,交叉流Постоянный магнит永久磁铁Почтовое послание电子邮件Предварительное изучение выполнимости预可行性研究Предварительное проектирование初步设计Презентация交付Преобразователь变流器водоохлаждаемый ~水冷变流器Прессмасса压制塑料Прикосновение 接触Прилив для крепления固定凸座,固定凸缘Принудительный стоп切除Принцип распределѐнной тяги 动力分散原理Пристальное внимание注意力集中Пробег спаренных локомотивов重联机车走行公里Пробег электровоза机车走行公里数Пробойдуговой ~电弧击穿импульсный ~脉冲击穿ионизационный ~电离击穿лавинный ~(半导体)雪崩式击穿сквозной ~贯通击穿тепловой ~热击穿Провозная способность运输能力Проволока накаливания热丝Программные средства软件Прожектор头灯,前照灯Промчастота工频Пропадание сигнала信号消失Проходящее замыкание贯穿短路Пульсирующий ток脉电Путь следования行程нечетный~下行线тракционный ~段管线четный ~上行线Пятник上心盘Рабочий парк локомотива 重联机车台数Радиостанция электровоза电力机车电台Радиочастота射频Разблокировка отказа зоны区域故障解锁Развитие发展скачкообразное ~跨越式发展продолжительное ~可持续发展Разметка放线Разные категории пассажиров不同层次的乘客Разрядник 放电器Разъезд错车道Распределение тяги动力分散Расстояние утечки爬电距离Раствор门极Расщепитель фаз分相器Реактивная энергия无功能量Реверсер 换向手柄Реверсивная операция стрелки道岔反操Регулирование напряжения调压Ступенчатое регулирование напряжения分级调压Плавное регулирование напряжения无级调压Фазовое регулирование напряжения相控调压Импульсное регулирование напряжения斩波调压Резервуар风缸Рекуперативное торможение再生制动РекуперацияРельсовая цепь轨道电路Ремонтопригодность 可维修性Реостат 变阻器,可变电阻Рессора (机车)迭板弹簧листовая ~板簧Рог пантографа弓角Салон 乘客室Санузел卫生间Сателлит 行星齿轮Сапун 通气管,注油孔Сверхвозбуждение过激磁Светодиод для разъединителя при заземлении接地隔离开关发光二级管Сглаживающий фильтр平滑滤波器,平流滤波器Селеновыйвыпрямитель硒整流器Семейство家族Сенсорное устройство传感装置Сенсорный экран触摸屏Серия系列Сертификационное испытание验证试验Сигнал-светофор色灯信号机Сигнализация, централизация и блокировка(CЦП)信号、集中和闭塞,信集闭Силовой трансформатор 主变压器Синусоидальная кривая正弦曲线Силовая цепь主回路Силовой трансформатор主变压器Символ字符Система контроля доступа门禁系统Система многих единиц(СМЕ)重联Скатывание溜放Сквозняк 风口Скол 缺口,破口,断口,断裂Скольжение колѐс车轮滑行Скоростемер测速表Скоростной 快速的Слепящее действие幌眼Служебная массалокомотива列车整备重量Соединительный зажим接线柱Сопрягаемая поверхность结合面Сортировка 分选Сочлененные четырѐхвагонные дизель-поезды铰接4辆编组内燃动车组Списание报废Станина 底座,机座шестерѐнная ~齿轮座~ прибора仪表座~ подшипника轴承座Статический разряд静电放电Стеклолента 玻璃钢Стекломикалента 玻璃云母带Стреляющая предохранительная плавка喷逐式熔断器Стрелка 道岔воздушные ~线岔~ ответвления 分路道岔Ступенчатый мост多段桥Супервизор 管理器,管理程序,监控器~ системы系统管理程序~ страничного обмена分页管理程序~ текущего контроля监督管理程序Схема на контактной сети网侧电路Сход с рельсов脱轨Сцепка 车钩Счетчик колесных осей计轴设备Тамбур车厢端门Текстолит 层压胶布板Текущее содержание пассажирских вагонов на путях парка库检Тележка转向架моторная ~电动转向架Телеметрическая система测距装置Терминал<铁>终点站;(计算机的)终端装置Термостатирование 恒温调节Техническая реконструкция железных дорог铁路技术改造Техническое развитие 技术开发Тип 类型Типаж 型谱Типичное испытание型式试验Тиристор 晶闸管~ с выключением по управляющему электроду 门极可关断晶闸管Токоприѐмник受电弓Торможение 制动аварийное ~应急制动вихревое ~涡流制动вынужденное ~ 强迫制动принудительное ~强迫制动рекуперативное ~再生制动реостатное ~电阻制动реостатное ~ с подпиткой加馈电阻制动стояночное ~停放制动,停车制动фрикционное ~摩擦制动экстренное ~紧急制动электродинамическое ~电动制动~ сцеплением粘着制动Тормозная сила制动力Тормозная магистраль 制动主管Тормозной путь制动距离Точка ледообразования冰点Траверса 刷架~ для щѐткодержателей刷握架Травматизм创伤病;伤人事故Травмирование людей人身事故Транзистор 晶体管биполярный ~双极晶体管Трансмитер发射机Транспортное обслуживание运输服务Транспортные услуги运输业务Транспортный узел 交通枢纽Трансформатор变压器~ тока电流互感器Трансформация 变压Треск 杂音,噪音Триангель(三角)制动架Триггерная ячейка触发单元Тяга牵引двойная ~双机牵引многократная ~多机牵引(重联)Тяговое усилие牵引力Тяговый привод牵引电动机Тяговый редуктор齿轮箱Тяжелое машиностроение(ТМ)重型机械制造Убедить источник в разомкнутом состоянии确认电源断开Убежище避车洞Ударная сила поезда列车冲击力Укрепляющее кольцо扣环Управлениев масштабе реального времени实时控制Управление сцепления粘着控制Уравнитель 均压线Устройство сигнализации электровоза机车信号装置Участок区段Участковое замыкание区段锁闭Фазорасщепитель分相机Фаркопф齿轮箱Фильтр нижних частот低通滤波器Форкопф花蓝螺丝Форматировать格式化Формирование состава列车编组Формирователь импульсов脉冲整形器Формировать из разного числа секций由不同数量的单元编组而成Характеристика по сцеплению粘着特性Хлоропрен氯丁橡胶Целлюлоза纤维素Центробежная сила поезда列车离心力Цепь电路,回路активная ~有源电路воздушная ~架空线路двухпроводная ~双线电路обесточенная ~无电电路,死电路пассивная ~无源电路последовательная ~串联电路разветвлѐнная ~支路эквивалентная ~等效电路Часовой режим 小时制Чека开尾销Шайба для защиты от пыля防尘垫Шевронное зубчатое колесо人字齿轮Штампованный лист электротехнической стали电工钢冲片Шток тормозных цилиндров制动缸推杆Щѐтка电刷Щѐткодержатель刷握Экипажная часть车架行走部分Экипировка локомотива 机车整备Экологическое требование环保要求Экранированная камера屏蔽室Экспресс特速列车Электрическая искра电火花Электрический стеклоочиститель电动雨刷Электрическое и механическое сопряжение电气和机械接口Электромагнитное излучение电磁辐射Электропневматический клапан(ЭПК) 电空阀Электроподвижной состав电力机车Электропоезд电动车组Эллипс 椭圆Этиленгликоль乙二醇Якорь电枢Доводочный精加工的Прототип样机Тангенсугланаклона斜率Усеченный截短的Квантиль分位数Опция〈计算机〉选项Притягательность吸引力ЧислоРейнольдса雷诺数Изоляционнаяоболочка(电缆)绝缘外皮Логистическийцентр物流中心Фотогальваническаяненерация光伏发电Черновой粗加工的Упорныйбурт支撑轴肩Кривизна弧度锻造比Подпятник下心盘Скользун滑板Фрикционный клин摩擦楔Металлическое включение金属杂质Испытание на разбрызгивание喷淋试验Канат绳оттяжной канат牵引绳пеньковый канат麻绳многопрядный канат多股钢丝绳Мозаика马赛克Осколки边角料Предупредительная плаката警告牌Кремнестальной лист硅钢片Растоможивание清关Перепускная труба回流管Буферное напряжение浮充电压Разделительный трансформатор隔离变压器Держащая подушка保持线圈Скользящий подшипник滑动轴承Контактный провод滑触线Пневматический исполнитель气浮致动器Несимметричный токоприемник单臂受电弓Равноосный электродвигатель等轴电机Винтовой клапан旋压阀Втягивающая катушка吸引线圈Радиус кривизны曲率半径Разделительный диод隔离二级管Разъединитель隔离开关Реле мгновенногодействия瞬动继电器Расцепляющий механизм脱扣器Расцепляющий механизм недонапряжения欠压脱扣器Расцепляющий механизм перегрузки обратного зависимой выдержки времени反时限过负荷脱扣器Бинарная система二进制Напряжение на переходе结电压Зигзаг蛇形法Зигзагообразный蛇形的ЗигзатироватьЦанговый патрон卡套Шнейлер卡簧Реборда轮缘Рельсовая подушка轨座Костыль道钉Путеукладчик铺轨机Дискретный сигнал不连续信号Мегагенри (мгн)兆亨利Индуктивный шунт有感分流器Эргономия人类工程学Ранжир按大小排列ОпрокидываниеЕдиноличное предприятиеДефлекторДугогасяющее устройствоНесущая конструкцияТранскрипция шрифта。

电动汽车中英文对照外文翻译文献(文档含英文原文和中文翻译)电动车:正在进行的绿色交通革命?随着世界上持续的能源危机,战争和石油消费以及汽车数量的增加,能源日益减少,有一天它会消失得无影无踪。

石油并不是可再生资源。

在石油消耗枯竭之前必须找到一种能源与之替代。

随着科技的发展和社会进步,电动车的发明将会有效的缓解这一燃眉之急。

电动汽车将成为理想的交通工具。

面临能源成本居高不下、消费者和政府更加重视环境保护的情况下,世界汽车制造商正加大对可替代能源性混合动力汽车技术的开发投资。

该技术能极大削减燃料消费,减少温室气体排放。

许多人把目光投向了日本和美国的汽车制造商,关心他们开发混合动力和电池电动车的进展情况。

丰田普锐斯一跃成为世界上销量最好的混合动力车。

美国的新兴汽车制造商,Tesla Motors,推出了该公司首部电池电力车,名为Tesla Roadster。

截至2010年底,通用汽车公司计划推出备受赞誉的V olt混合动力汽车,而克莱斯勒公司最近已经宣布同样的计划正在进行之中。

目前,中国在新能源汽车的自主创新过程中,坚持了政府支持,以核心技术、关键部件和系统集成为重点的原则,确立了以混合电动汽车、纯电动汽车、燃料电池汽车为“三纵”,以整车控制系统、电机驱动系统、动力蓄电池/燃料电池为“三横”的研发布局,通过产学研紧密合作,中国混合动力汽车的自主创新取得了重大进展。

形成了具有完全自主知识产权的动力系统技术平台,建立了混合动力汽车技术开发体系。

混合动力汽车的核心是电池(包括电池管理系统)技术。

除此之外,还包括发动机技术、电机控制技术、整车控制技术等,发动机和电机之间动力的转换和衔接也是重点。

从目前情况来看,中国已经建立起了混合动力汽车动力系统技术平台和产学研合作研发体系,取得了一系列突破性成果,为整车开发奠定了坚实的基础。

截止到2009年1月31日,在混合动力车辆技术领域,中国知识产权局受理并公开的中国专利申请为1116件。

电力机车主电路的发展概述电力机车(electric locomotive)本身不带原动机、靠接受沿线接触网送来的电流作为能源、由牵引电动机驱动车轮的机车。

所需的电能,可以由多种形式(火力、水力、风力、核能等)转换而来。

电力机车具有功率大、热效率高、速度快、过载能力强和运行可靠边等主要优点,而且不污染环境,特别适用于运输繁忙的铁路干线和隧道多、坡度大的山区铁路。

发展概况【top】最早造出第一台标准轨距电力机车的是苏格兰人R·戴维森,时间是1842年,由40组蓄电池供电,但没有实用价值。

1879年5月,德国人W·VON西门子设计制造了一台能拉乘坐18人的三辆敞开式“客车”的电力机车,它由外部150V直流发电机通过第三轨供电,这是电力机车首次成功的试验。

1881年,法国在巴黎展出了第一条由架空导线供电的电车线路,这就为提高电压,采用大功率牵引电动机创造条件。

1895年,美国在巴尔的摩—俄亥俄间5. 6 km长的遂道区段修建了直流电气化铁路,在该区段上运行的干线电力机车自重97 t,采用675 V直流电,功率为1 070 kW。

1903年德国的三相交流电力机车创造了每小时210km 的高速记录。

中国最早使用电力机车在1914年,是抚顺煤矿使用的1 500 V直流电力机车。

1958年中国成功地生产出第一台电力机车,从采用引燃管整流器到硅整流器,机车性能不断改进和提高,到1976年制成韶山型(SS1型)131号时已基本定型。

截止到1989年停止生产,SS1型电力机车总共制造出厂926台,成为中国电气铁路干线的首批主型机车。

1966年SS2型机车制成。

1978年研制成功的SS3型机车,不仅改善了牵引性能,还把机车的小时功率从4 200kW提高到4 800kW,载止到1997年底,共生产了987台,成为中国第二种主型电力机车。

1985年又研制成功了SS4型8轴货运电力机车,它是国产电力机车中功率最大的一种(6 400kW),已成为中国重载货运的主型机车。

TCN网络技术TCN(Train communication network)是用于列车通信的网络技术,符合IEC61375标准。

我国的列车推荐使用TCN标准。

在列车通信网络方面,除了TCN之外,还有lonworks标准。

目前我国使用的列车通信与控制网络是引进技术,到目前为止,还没有完全自治知识产权的技术。

由于列车行业的特殊性,造成了技术开发的滞后。

随着WTO的加入,铁路行业也在放开,因此我们也在开发列车控制系统技术,希望我们的技术给我内的机车行业带来好的推动作用。

TCN技术包括MVB总线、WTB总线、网关等关键技术。

持续速度持续速度:在1995年版的《内燃机车总体与机车走行部》中,“持续速度”被定义为机车持续速度是指机车在全功率工况下,其冷却装置的能力所能容许的持续运行的最低速度。

持续速度是由液力传动工作油的冷却能力(液力传动机车)或牵引电动机的冷却能力(电传动机车)决定的。

也就是说,大体来讲,机车的功率是有限的,根据功率等于速度乘以牵引力的公式,速度越快,牵引力越小,反过来,也就是速度低的时候能提供更大的牵引力。

但是牵引系统如牵引电动机的发热是基本和电流成正比的,而电流又基本和牵引力成正比,所以牵引力越大,牵引系统发热就越厉害,这样当速度低到一定程度,机车再全功率持续运行发热就超过牵引系统的冷却能力了,只能降低功率。

所以低于持续速度牵引力几乎持平(实际随速度降低会略有增加),而高于持续速度牵引力则明显随速度的增加而下降,基本可以按功率除以速度来计算(功率指有效功率,而非柴油机装机功率,一般可以按机车标称功率来估算,低速时由于发热损耗大些,略低于标称功率)。

变流器变流器converter使电源系统的电压、频率、相数和其他电量或特性发生变化的电器设备。

包括整流器(交流变直流)、逆变器(直流变交流)、交流变流器和直流变流器。

变流器除主电路(分别为整流电路、逆变电路、交流变换电路和直流变换电路)外,还需有控制功率开关元件通断的触发电路和实现对电能的调节、控制的控制电路。

电力机车简介机车是为列车提供驱动力,而自身并没有效装载能力的车辆;他的唯一目标是沿着轨道牵引列车。

通常自带动力的车辆不被视为机车,在客运方面自带动力的车辆用得越来越普遍,但是很少用在货运。

自带驱动力的车辆以驱动列车的车辆,通常它们不视为机车,因为它们具有有效装载能力,并且很少从列车上摘挂,它们称之为动车。

一般来说,机车牵引列车。

现今在客运业务上拖拉式运营方式越来越常见,采用这种运营方式的特点是:机车在一端牵引列车,然而却由在另一端的司机室控制。

机车的优点:在一般情况下,为什么将为列车提供驱动力的机车和车辆是分开的,而不是车辆自带动力的原因包括以下几点:1.易于维修—维修一台机车和维修自带动力的车辆相比要容易。

2.安全—通常将列车牵引动力装置安装在远离乘客的地方比较安全,这一点对于蒸汽机车来说显得相当重要,但是有时会仍然会出现一些不如意的情况。

3.易于更换动力—如果动力装置损坏,用一个新的来更换它即可,这样地来显得比较容易,从而一个动力装置产生故障时不至于整台机车无法工作。

4.效率—当列车空载运行时可以将机车从列车上摘卸下来。

机车再去执行其它牵引业务,这意味着不但可以降低列车运营成本,还可以提高机车的使用效率。

5.将机车和车辆分离开来意味着当机车出现故障时,只需更换机车就可以这样就可以不影响列车的运营。

在有些情况下车辆比机车先报废,如果机车和车辆不可摘挂,那么即使机车完好也得跟着报废,这样就意味着浪费和成本高,然而机车可以从列车上摘下来,只需更换车辆即可,这样五来大大的降低了成本提高了经济效益。

电力机车电力机车是通过接触网或第三轨由外部提供电能。

尽管电气化铁道的造价相当高,然而运营成本却比内燃机车低,良好的加速性能和可再生制动,使得它们在繁忙干线地区成为客运业务的理想选择。

几乎所有的高速铁路都采用电力牵引(例如ICE,TGV),由于具有如此高的性能,机车所需要的电能是不容易得到提供。

例如应用在海底隧道货运业务的现今最大功率的机车的功率高达7MW。

第一台电力机车由Scotsman和Robert Davidson于1837年设计并生产,该电力机车由电流单元提供动力。

现代电力机车包括从由蓄电池提供能量的用于矿山的机车到功率高达6000马力(4.5M)甚至功率更高的干线电力机车。

事实上,现代许多机车它们是电力驱动的,纯电力机车是从外部获得电能,然而内燃电力机车它们却自带发电装置。

干线电力机车第一次出现在20世纪初,电力机车的诞生是由于蒸汽机车产生在运行过程产生的烟雾给驾乘带来不便和不安全,特别是在隧道。

在英国引入电力机车的是由于地铁系统的需要。

然而在美国引入电力机车却是由于河底隧道这样一个特殊的工作环境下采用内燃牵引无法满足要求。

早期电力机车全都依靠外部提供电能,尽管它们运行可靠和效率高,但是建造接触网是一笔相当大的投资,并且需要不断维护。

基于此,电气化铁道仅仅在繁忙干线采用。

在市郊采用电气化铁道可以减轻由蒸汽机车燃烧所带来的粉尘污染。

世界列车最高运行速度纪录由法国TGV在1990年创立。

速度高达515.3千米每小时(320mph)。

然而,近来所设计的电气化铁道几乎都采用交流制,当然许多已有的直流供电制仍然在用,例如:南非,西班牙,英国(750V和1500V),挪威(1500V),安哥拉,意大利,波兰(3000V),芝加哥和Mumbai(它们将由2025转换成交流供电制)。

早期的机车有各种型式。

通常它们设计成与供电制相匹配的机车。

于是采用直流供电制的电气化铁道的铁路系统,电力机车的牵引电机为直流电机。

采用交流供电制的电气化铁道的铁路系统,电力机车的牵引电机为交流电机。

交流可以是单相,也可以是三相,单相需要两根导线,一根是接触网,另一根是钢轨。

三相需要三根导线,因此三相电力机车有两根接触网,钢轨作为第三根。

直流供电可以用接触网或钢轨供电,通常称之为第三轨。

交流牵引电机体积比直流牵引电机的体积小。

通常这就意味着直流电机可以做得体积小些。

安装驱动轴,通常采用齿轮传动。

但是在早期也有采用轴的。

即便如此,一些著名的直流电力机车采用直流电动机驱动车轮。

采用电力机车作为牵引动力的一种可能就是在制动期间电动机可作为发电机并把发出的电能反馈给接触网,这种被称之为再生抽动。

这是一个新的想法,这就是三相交流供电制为什么要采用的原因。

特别是在山区,机车下坡时产生的能量以供机车使用。

瑞士铁路采用这种系统。

三个下程供给一个上程。

现今,所有电力机车都趋于将驱动电机安装在靠近车轮轴的位置,尽管仍有些电力机车将驱动电机安装在车体内通过传动装置来驱动车轮。

现代实体状态电控系统的采用意味着电机并不需要和供电制相匹配。

因而在今天,多电压等级的机车已相当普遍。

通常驱动电机是直流电机,但是在一些机车上也有三相驱动电机。

蓄电池机车在矿场和由内燃机产生的烟是一个不安全隐患的其它地下作业和外部电能不可获得的情况下利用。

蓄电池机车在许多地铁系统当供电被暂时切断而需要维修作为维修作业车。

电力机车的各组成部分:异步电动机现代牵引电机主要采用三相牵引电机,并被广泛应用于现代列车牵引系统.采用适当的控制电子装置后,三相牵引电机可以用在直流或交流制的电气化铁道和内燃机车.电池所有的列车都备有电池以提供起动电流和为一些装置提供电源,例如当接触网供电失败时的紧急照明,通过电池是和直流控制供电装置相连.断路器电力机车通常备有一定型式的空气断路器以将从接触网隔离,当机车发生故障,或者需要维修时。

在交流制供电式中,断路器通常安装在机车顶部靠近受电弓的一侧。

现有两种类型的断路器:空气断路器和真空断路器(VCB)。

空气或真空是用来灭当断路器的两连接端分开时产生的电弧。

真空断路在英国用得比较多,而空气断路器在欧洲大陆用得比较广泛。

逆变器将交流转变成直流称之为整流,将直流转变成交流称之为逆变。

逆变这一词起源于美国,但是现在这一学术用语在其它地方也被用。

冷却风扇为了冷却整流装置和其它电子装置,现代机车都装有空气管理系统,电子控制装置使所有的系统都运行在允许的温度范围内。

风扇由一台产生400伏电源的三相交流的辅助逆变装置供电。

直流连接器在三相和单相整流器中,直流连接器用在现代电子电源系统中。

通过将交流电整流成直流,然后将直流逆变成三相交流,很容易将从接触网获得的单相交流电转变成所需要的三相交流电。

线路断路器在列车上安装电力电子器件可将直流电转换为交流电。

当今采用直流供电制的铁路系统也广泛采用三相牵引电机和一些辅助设备也采用三相交流电。

电子机械开关安装在牵引电机上电子机械式开关以断开和接通牵引电机电路,通常情况下开关是闭合的。

它受牵引控制器的指令控制,而并非电压检测传感器的控制。

它和过载检测装置和非电压控制电路相连接以便在发生过载时切断电机电路以保护牵引电机。

司机控制器驱动力控制装置安装在司机室。

司机移动司机操纵手柄以提高或减小机车牵引力。

牵引电机冷却风机电力机车上的牵引电机很容易发热,牵引电机在长时间满负荷运行式况下,为了使其温升在允许的范围内,通常给牵引电机安装有风扇称之为冷却风机。

在现代机车上,风扇由一台产生400伏左右电源的三相交流辅助逆变装置供电。

整流器整流器由将交流转换为直流的可控硅和二极管组成。

通常现代电力机车至少有两个整流器,一个用于主电路的整流,一个用于辅助电路的整流。

同步电动机牵引同步电机是励磁线圈安装在驱动轴上电枢线圈安装在定子上的电机, 这和通常的电机刚好相反。

这种电机在广泛应用在法国用于高速列车用得由法国和它采用了高速的TGV大西洋列车这是一种由简单逆变器控制的单相电机。

现在已被异步电动机取代了。

变压器变压器是由铁芯和绕组组成且将电压由一个等级升高或降低到另一个等级的设备。

变压器的输出电压由输入侧和输出侧绕组匝数之比决定。

变压器作为电力机车不可缺少的设备其将从接触网的电压变换成机车在牵引工况下所需电压。

Introduction to LocmotiveA locomotive is a railway vehicle that provides the motive power for a train,and has nohy detached from their trains, are known as power cars.Traditionally,locomotive hual their trains. Increasingly common these days in passenger service is push-pull operation,where the locomotive push the trains in one direction and are controled from a control cab at the opposite end of the train in the other.Beniefits of locomotivesThere are many reasons why the motive power for trains has been traditonally isolated in a locmotive,rather than is self-propelled vehicles.these include: Ease of maintenance –it is easier to maintain one locomotive than many self-propelled cars.Safety –it is often safer to locate the train’s power system away from passenger. This was particularly the case for the steam locomtive,but still has some relevance.Easy replacement of motive power –should the locomotive break down, it is easy to replace it with a new one . Failure of the motive power unit does not require taking the whoole train out of service.Efficiency – idle trains do not waste expensive motive power resources. Separate locomotives mean that the costly motive power assets can be moved around as needed.Obsolescence cycles –separating the motive power from the payload-hauling cars means that either can be replaced without affecting the other. At some times, locomotive have become obsolete when their cars are not, or vice versa..Electric LocomotivesThe electric locomotive is supplied externally with electric power, either through an overhead pickup or through a third-rail. While the cost of electrifying track is rather high, electric trains and locomotives are significantly cheaper to run than diesel ones, and are capable of superior acceleration as well as regenerative braking, making them ideal for passenger service in densely populated areas. Almost all high speed train systems(e.g..IEC,TGV, bullet train) use electric power, because the power needed for such performance is not easily carried on board. Fot example the most powerfu electric locomotives that are used today on the channel tunnel freight services use 7Mwatts of power.The first known electric locomotive was buit by a Scotsman, Roert Davidson of Aberdeen in 1837 and was powered by galvanic cells.Modern electric locomotive range from small battery-powered machines for use in mines to large main-line locomotives of 6,000 horsepower(4.5MW) or more.In reality most modern locomotives are electricaly driven. Pure electric locomotives take their electrical supply from an external source while diesel-electric locomotives carry their own generating station.Main line electric locomotives first appeared at the beginning of the 20thcentury.The reason for their introduction was the problem of smoke, especially in tunnlels caused by steam locomotives. In the UK this was the London underground system while in the USA, it was under river tunnles and needs to eliminate smoke in built up areas.Early electric locomotives all relied on external power sourcing. Once up and running they tend to be reliable and efficint, but the supply infrastructure is a large capital expense that does require ongoing maintenance. For this reason only heavily used lines could justify electrification. For suburban lines the reduction in pollution from steam locomotives was a benefit all were aware oflThe world speed record for a wheeled train was set in 1990 ba a French TGV which reached a speed of 515.3km/h (320mph).While recently designed electrififed railway systems invariably operate on alternating current, many existing direct current sytems are still in use –e.g. in South Africa,Spain,and the United Kingdom(750v and 1500v); Netherlands(1500v); Belgiu, Italy, Poland (3000 v), and the cites of Mumbia and Chicagio (which will be switched to AC by 2025).Early locomotives came in a variety of forms. Generally they were designed to run off the supplied current. so locomotives with a direct current (DC) supply had DC motors while a alterntating current(AC) supplied locomotives with AC motors. AC can be either single or three phase. While the former requies two wire supply, one overhead the other being the track, three phase require three supply wire.Three phase locomotives therefore had two overhead supplies,the track being the third.DC supplies were either overhead or by means of a track level supply, commonly called the third rail.AC traction motors tended to be smaller than DC motors. This often meant electric locomotives with steam engine type cranks. DC motors could be smaller and set up to drive the ually through a gear ,but in some early examples by being part of the axle. Even so, some notable DC electric locomotives had large DC motors driving large driving wheels.One possibility with electric locomotives is that the motor can be used as a generator during braking, feeding electricity back into the supply system; this is called regenerative barking. This is not a new idea, it was one reason for the adoption by some railways of 3 phase AC suppies. Especially in mountainous aresa where the locomotive going down would generate much of the suppy for a locomotive going up. The Swiss railway uses the system; three modern locomotives heading downwards generate enough power to power a single locomotive in its upward journey.Today all eclctric locomotives tend to have drive motors close to the axles, although some still have the motor in the body driving the wheels through internal drive shafts.Modern solid state electrical control systems means the motor does not need to match the supply. This meams multi-voltage cross border locomotives are now quite common. Drive motors are generally DC, but there are 3 phase motors on some locomotives.A small number of electric locomotives can also operate off batery power toenable short journeys or shuting to occur on non-electrified lines or yards. Pure battery locomotives also found usage in mines and other underground workings where diesel fumes or smoke are not safe aand where external electricity supplies could not be used. Battery locomotives are also used on many underground railways for maintenance operations as they are required to operate in areas where the electricity supply has been temmporarily disconnected..Parts of Electric LocomotiveAwynchronoux MotorModern traction motor type using three phase AC electrical supply and now the favoured deisgn for modern train traction systems . Can be used on DC and AC electrified. railways with suitable control electronics and on diesel-electric locomtives.Axle BrushThe means by which the power supply ciruit is completed with the substation once power has been drawn on the locomotive. Current collected from the overhead line or third rail is returned via the axle brush and one of the running rails.BatteryAll trains are provided with a battery to provide start up current for supplying essential circuitts, such as emergency lighting ,when the line supply fails. The battery is usually connected across the DC control supply circuit.Circuit BreakerAn electric train is almost always provied with some sort of circuit breaker to isolate the power supply when there is a fault, or for maintenance. On AC systems they are usually on the roof near the pantograph. There are two types-the air blast circuit breaker and the vacuum circuit breaker or VCB. The air or vacuum part is used to extinguish the arc which occurs as the two tips of the circuit breaker are opened. The VCB is popular in the UK and the air blast circuit breaker is more often seen on the continent of Europe.ConverterGeneric term for any solid state electronic system for converting alternating current to direct current or vice versa. Where an AC supply has to be converted to DC it is called a rectifier and where DC is converted to AC it is called an inverter. The word originated in the US but is now common elsewhere.Cooling FansTo keep the thyristors and other electronic power systems cool, the interior of a modern locomotive is equipped with an air management system, electronically controlled to keep all systems operating at the correct temperature. The fans are powered by an auxiliary inverter producing 3-phase AC at about 400 volts.DC linkUsed on modern electronic power systems between the single phase rectifier and the 3-phase inverter. It is easier to convert the single phase AC from the overheak line to the 3-phase required for the motors by rectifying it to DC and then inverting the DCto 3-phase AC.InverterElectronic power device mounted on trains to provide alternating current from direct current. Popular nowadays for DC railways to allow three phase drive or for auxiliary supplies which need an AC supply.Line BreakerElectro-mechanical switch in a traction motor power circuit used to active or disable the circuit the circuit. It is nomally closed to start the train and remains closed all the time power is required. It is opened by a command from the driving controller,no-volts detected, overload detected and (were required) wheel spin or slide detected. It is linked to the overload and no-volt control circuits so that it actually functions as a protective circuit breaker.Master ControllerDriver’s power control device located in the cab. The driver moves the handle of the master controller to apply or reduce power to the locomotive or train.Motor BlowersTraction motors on electric locomotives get very hot and to keep their temperature at a reasonable level for long periods of hard word, they are usually fitted with electric fans called motor blowers. On a modern locomotive,they are powered by an auxiliary 3-phase AC supply of around 400 volts supplied by an auxiliary inverter.RectiferA converter consisting of thyristors and diodes which is used to convert AC to DC. A modern locomotive will usually have at least two, one for the power circuits and one or more for the auxiliary circuits.Synchronous MotorTraction motor where the field coils are mounted on the drive shaft and the armature coils in the housing, the inverse of normal practice.Favoured by the French and used on the high speed TGV Atlantique trains, this is a single-phase machine controlled by simple inverter. Now superseded by the asynchronous motor.TransformerA set of windings with a magnetic core used to step down or step up a voltage from one level to another.The voltage differences are determined by the proportion of windings in the input side compared with the proportion on the output side. An essential requirement for locomotives and trains using AC power, where the line voltage has to be stepped down before use on the train.Equipment LayoutVentilation SystemEquipment layout and ventilation systems 设备布置和通风系统设计Equipment layout and design of the ventilation system。