本安隔离转换器we77ex-1 we77ex-2

- 格式:pdf

- 大小:336.44 KB

- 文档页数:5

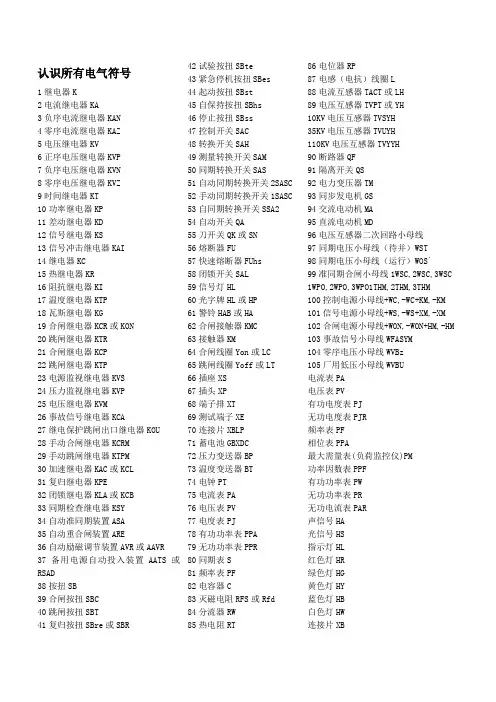

认识所有电气符号1继电器K2电流继电器KA3负序电流继电器KAN4零序电流继电器KAZ5电压继电器KV6正序电压继电器KVP7负序电压继电器KVN8零序电压继电器KVZ9时间继电器KT10功率继电器KP11差动继电器KD12信号继电器KS13信号冲击继电器KAI14继电器KC15热继电器KR16阻抗继电器KI17温度继电器KTP18瓦斯继电器KG19合闸继电器KCR或KON20跳闸继电器KTR21合闸继电器KCP22跳闸继电器KTP23电源监视继电器KVS24压力监视继电器KVP25电压继电器KVM26事故信号继电器KCA27继电保护跳闸出口继电器KOU28手动合闸继电器KCRM29手动跳闸继电器KTPM30加速继电器KAC或KCL31复归继电器KPE32闭锁继电器KLA或KCB33同期检查继电器KSY34自动准同期装置ASA35自动重合闸装置ARE36自动励磁调节装置AVR或AAVR 37备用电源自动投入装置AATS或RSAD38按扭SB39合闸按扭SBC40跳闸按扭SBT41复归按扭SBre或SBR 42试验按扭SBte43紧急停机按扭SBes44起动按扭SBst45自保持按扭SBhs46停止按扭SBss47控制开关SAC48转换开关SAH49测量转换开关SAM50同期转换开关SAS51自动同期转换开关2SASC52手动同期转换开关1SASC53自同期转换开关SSA254自动开关QA55刀开关QK或SN56熔断器FU57快速熔断器FUhs58闭锁开关SAL59信号灯HL60光字牌HL或HP61警铃HAB或HA62合闸接触器KMC63接触器KM64合闸线圈Yon或LC65跳闸线圈Yoff或LT66插座XS67插头XP68端子排XT69测试端子XE70连接片XBLP71蓄电池GBXDC72压力变送器BP73温度变送器BT74电钟PT75电流表PA76电压表PV77电度表PJ78有功功率表PPA79无功功率表PPR80同期表S81频率表PF82电容器C83灭磁电阻RFS或Rfd84分流器RW85热电阻RT86电位器RP87电感(电抗)线圈L88电流互感器TACT或LH89电压互感器TVPT或YH10KV电压互感器TVSYH35KV电压互感器TVUYH110KV电压互感器TVYYH90断路器QF91隔离开关QS92电力变压器TM93同步发电机GS94交流电动机MA95直流电动机MD96电压互感器二次回路小母线97同期电压小母线(待并)WST98同期电压小母线(运行)WOS`99准同期合闸小母线1WSC,2WSC,3WSC1WPO,2WPO,3WPO1THM,2THM,3THM100控制电源小母线+WC,-WC+KM,-KM101信号电源小母线+WS,-WS+XM,-XM102合闸电源小母线+WON,-WON+HM,-HM103事故信号小母线WFASYM104零序电压小母线WVBz105厂用低压小母线WVBU电流表PA电压表PV有功电度表PJ无功电度表PJR频率表PF相位表PPA最大需量表(负荷监控仪)PM功率因数表PPF有功功率表PW无功功率表PR无功电流表PAR声信号HA光信号HS指示灯HL红色灯HR绿色灯HG黄色灯HY蓝色灯HB白色灯HW连接片XB插头XP插座XS端子板XT电线,电缆,母线W直流母线WB插接式(馈电)母线WIB电力分支线WP照明分支线WL应急照明分支线WE电力干线WPM照明干线WLM应急照明干线WEM滑触线WT合闸小母线WCL控制小母线WC信号小母线WS闪光小母线WF事故音响小母线WFS预告音响小母线WPS电压小母线WV事故照明小母线WELM避雷器F熔断器FU快速熔断器FTF跌落式熔断器FF限压保护器件FV电容器C电力电容器CE正转按钮SBF反转按钮SBR停止按钮SBS紧急按钮SBE试验按钮SBT复位按钮SR限位开关SQ接近开关SQP手动控制开关SH时间控制开关SK液位控制开关SL湿度控制开关SM压力控制开关SP速度控制开关SS温度控制开关,辅助开关ST 电压表切换开关SV 电流表切换开关SA整流器U可控硅整流器UR控制电路有电源的整流器VC变频器UF变流器UC逆变器UI电动机M异步电动机MA同步电动机MS直流电动机MD绕线转子感应电动机MW鼠笼型电动机MC电动阀YM电磁阀YV防火阀YF排烟阀YS电磁锁YL跳闸线圈YT合闸线圈YC气动执行器YPA,YA电动执行器YE发热器件(电加热)FH照明灯(发光器件)EL空气调节器EV电加热器加热组件EE感应线圈,电抗器L励磁线圈LF消弧线圈LA滤波电容器LL电阻器,变阻器R电位器RP热敏电阻RT光敏电阻RL压敏电阻RPS接地电阻RG放电电阻RD启动变阻器RS频敏变阻器RF限流电阻器RC光电池,热电传感器B压力变换器BP温度变换器BT速度变换器BV时间测量传感器BT1,BK液位测量传感器BL温度测量传感器BH,BMCAD快捷键:A圆弧B创建块C圆D标注样式管理器E删除F圆角G群组H图案填充I插入块L直线M移动O偏移P平移S拉伸W外部块V视图对话框X分解Z显示缩放T多行文字co复制MI镜像AR阵列RO旋转SC比例LE引线管理器EX延伸TR修剪ST文字样式管理器DT单行文字PO单点XL参照线ML多线PL多段线POL多边形REC矩形SPL样条曲线EL椭圆CH特性CHA倒角BR打断DI查询距离AREA面积ID点坐标MA特性匹配MASSPROP质量特性LS列表显示TIME时间SETTVAR设置变量LA图层COLOR颜色LT线型管理LW线宽管理UN单位管理TH厚度捕捉TT临时追踪点FROM从临时参照到偏移ENDP捕捉到圆弧或线的最近端点MID捕捉圆弧或线的中点INT线、圆、圆弧的交点APPINT两个对象的外观交点EXT线、圆弧、圆的延伸线CEN圆弧、圆心的圆心QUA圆弧或圆的象限点TAN圆弧或圆的限象点PER线、圆弧、圆的重足PAR直线的平行线NOD捕捉到点对象INS文字、块、形、或属性的插入点NEA最近点捕捉A圆弧B创建块C圆D标注样式管理器E删除F圆角G群组H图案填充I插入块L直线M移动O偏移P平移S拉伸W外部块V视图对话框X分解Z显示缩放T多行文字co复制MI镜像AR阵列RO旋转SC比例LE引线管理器EX延伸TR修剪ST文字样式管理器DT单行文字PO单点XL参照线ML多线PL多段线POL多边形REC矩形SPL样条曲线EL椭圆CH特性CHA倒角BR打断DI查询距离AREA面积ID点坐标MA特性匹配MASSPROP质量特性LS列表显示TIME时间SETTVAR设置变量LA图层COLOR颜色LT线型管理LW线宽管理UN单位管理TH厚度标注DLI线型标注DAL对齐标注DOR坐标标注DDI直径标注DAN角度标注QDIM快速标注DBA基线标注DCO连续标注LE引线标注TOL公差标注DLE圆心标注DRA半径标注CAL计算器Alt+N+Q快速Alt+N+L线型Alt+N+G对齐Alt+N+O坐标Alt+N+R半径Alt+N+D直径Alt+N+A角度Alt+N+B基线Alt+N+C连续Alt+N+E引线Alt+N+T公差Alt+N+M圆心Alt+N+Q倾斜Alt+N+S样式Alt+N+V替代Alt+N+U更新F1:获取帮助F2:实现作图窗和文本窗口的切换F3:控制是否实现对象自动捕捉F4:数字化仪控制F5:等轴测平面切换F6:控制状态行上坐标的显示方式F7:栅格显示模式控制F8:正交模式控制F9:栅格捕捉模式控制F10:极轴模式控制F11:对象追踪式控制Ctrl+B:栅格捕捉模式控制(F9)Ctrl+C:将选择的对象复制到剪切板上Ctrl+F:控制是否实现对象自动捕捉(f3)Ctrl+G:栅格显示模式控制(F7)Ctrl+J:重复执行上一步命令Ctrl+K:超级链接Ctrl+N:新建图形文件Ctrl+M:打开选项对话框AA:测量区域和周长(area) AL:对齐(align) AR:阵列(array) AP:加载*lsp 程系AV:打开视图对话框(dsviewer) SE:打开对相自动捕捉对话框 ST:打开字体设置对话框(style) SO:绘制二围面(2dsolid) SP:拼音的校核(spell) SC:缩放比例(scale) SN:栅格捕捉模式设置(snap) DT:文本的设置(dtext) DI:测量两点间的距离 OI :插入外部对相Ctrl+1:打开特性对话框 Ctrl+2:打开图象资源管理器 Ctrl+6:打开图象数据原子 Ctrl+O:打开图象文件 Ctrl+P:打开打印对说框 Ctrl+S:保存文件 Ctrl+U:极轴模式控制(F10) Ctrl+v:粘贴剪贴板上的内容 Ctrl+W:对象追踪式控制(F11) Ctrl+X:剪切所选择的内容 Ctrl+Y:重做Ctrl+Z:取消前一步的操作AV:打开视图对话框(dsviewer)SE:打开对相自动捕捉对话框ST:打开字体设置对话框(style)SO:绘制二围面(2dsolid) SP:拼音的校核(spell) SC:缩放比例(scale)SN:栅格捕捉模式设置(snap)DT:文本的设置(dtext) DI:测量两点间的距离 OI :插入外部对相Ctrl+1:打开特性对话框 Ctrl+2:打开图象资源管理器Ctrl+6:打开图象数据原子 Ctrl+O:打开图象文件 Ctrl+P:打开打印对说框 Ctrl+S:保存文件Ctrl+U:极轴模式控制(F10) Ctrl+v:粘贴剪贴板上的内容Ctrl+W:对象追踪式控制(F11)Ctrl+X:剪切所选择的内容作。

使用手册Instruction manual安徽运诚科技集团有限公司2019.06 版金属管 浮子流量计应运而生因诚而存EMERGE AS THE TIMES REQUIREDEVELOPMENT BASED ON INTEGRITY金属管浮子流量计01概述金属管浮子流量计(金属管转子流量计)是工业自动化过程控制中常用的一种变面积流量测量仪表。

它具有体积小,检测范围大,使用方便等特点,它可用来测量液体、气体以及蒸汽的量,特别适宜低流速小流量的测量。

多年来,金属管浮子流量计以其优良性能和可靠性,以及较好的性能价格比,在石化、钢铁、电力、冶金、轻工、食品、制药、水处理等行业得到了广泛的应用。

本手册面向专业技术人员,适用于金属管浮子流量计的设计选型,也可用于最终用户在使用时的参考。

手册分别介绍了本系列金属管浮子流量计的工作原理、功能特点、技术参数、仪表类型及外形、流量计算、接线方法和安装、维护等。

本手册只针对本系列金属管浮子流量计的设计选型和使用,同时厂家保留某些技术参数改进而不预先通知的权利。

02测量原理本系列金属管浮子流量计主要由两大部分组成:传感器和指示器。

传感主要由连接法兰、测量锥管、浮子和上下导向器组成;指示器主要由壳体、磁传动系统、刻度盘和电远传系统组成。

在垂直的锥形测量管内,有一可上下移动的测量部件——浮子(图1),当流体自下而上通过锥形管时,浮子受到流体的作用力,沿锥形管向 上移动。

当流体的流量增大时,浮子的位移量增大;反之,流体的流量减少时,浮子的位移量变小。

也就是说,流体流量的大小,决定了浮子在测量管中的位置,从而决定了浮子和锥形管之间环形面积的大小。

当流体的流量保持在一个恒定的流量Q时,浮子也处于一动平衡状态,停留在锥形管中的一位置h,此时,浮子和锥形管之间的环形面积保持恒定。

浮子受到三个力的作用:浮子的重力G,浮子受到的浮力F,浮子受到流体的作用力P,这三个力达到平衡。

根据流体动力学的柏努力方程、力平衡原理和流体连续性定律,可以计算出此时通过环形面积的瞬时流体流量,所以,金属管浮子流量计是采用可变面积测量流量的原理。

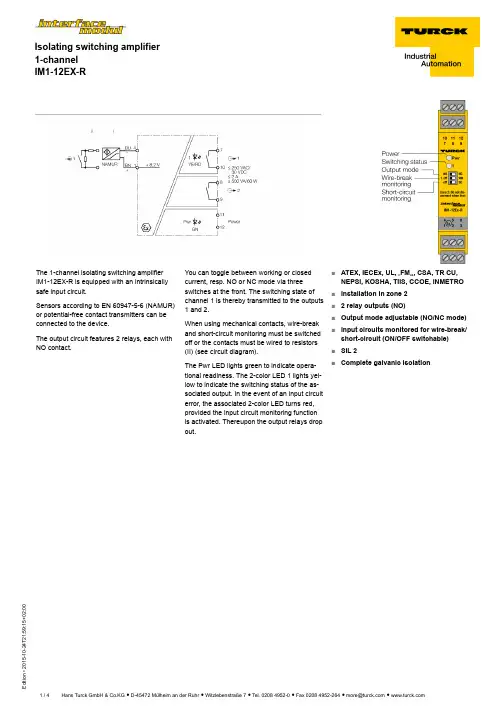

T 21:59:15+02:00The 1-channel isolating switching amplifier IM1-12EX-R is equipped with an intrinsically safe input circuit.Sensors according to EN 60947-5-6 (NAMUR)or potential-free contact transmitters can be connected to the device.The output circuit features 2 relays, each with NO contact.You can toggle between working or closed current, resp. NO or NC mode via three switches at the front. The switching state of channel 1 is thereby transmitted to the outputs 1 and 2.When using mechanical contacts, wire-break and short-circuit monitoring must be switched off or the contacts must be wired to resistors (II) (see circuit diagram).The Pwr LED lights green to indicate opera-tional readiness. The 2-color LED 1 lights yel-low to indicate the switching status of the as-sociated output. In the event of an input circuit error, the associated 2-color LED turns red,provided the input circuit monitoring function is activated. Thereupon the output relays drop out.■ATEX, IECEx, UL, FM , CSA, TR CU,NEPSI, KOSHA, TIIS, CCOE, INMETRO■Installation in zone 2■ 2 relay outputs (NO)■Output mode adjustable (NO/NC mode)■Input circuits monitored for wire-break/short-circuit (ON/OFF switchable)■SIL 2■Complete galvanic isolationT 21:59:15+02:00Type code IM1-12EX-R Ident no.7541226Nominal voltage Universal voltage supply unit Operating voltage 20…250 VAC Frequency40…70 Hz Operating voltage range 20…125 VDC Power consumption ð 3 WNAMUR input NAMUREN 60947-5-6Input circuit monitoring on/off switchable No-load voltage 8.2 VDC Short-circuit current 8.2 mA Input resistance 1 k òCable resistance ð 50 òSwitch-on threshold 1.75 mA Switch-off threshold1.55 mA Wire breakage threshold ð 0.06 mA Short-circuit threshold ï 6.4 mAOutput circuits (digital) 2 x relays (NO)Relay switching voltage ð 250 VAC/30 VDC Switching current per output ð 2 ASwitching capacity per output ð 500 VA/60 W Switching frequency ð 10 Hz Contact quality AgNi, 3µ AuGalvanic isolation Test voltage 2.5 kVImportant noteFor safety applications the values specified in the safety manual or the relevant Ex certificates (ATEX,IECEx, UL, etc.) apply.Ex approval acc. to conformity certificate TÜV 04 ATEX 2553Application areaII (1) G, II (1) Dignition protection category [Ex ia Ga] IIC; [Ex ia Da] IIIC Max. values:Terminal connection: 1+4Max. output voltage U ð 9.6 V Max. output current I ð 11 mA Max. output power P ð 26 mW CharacteristiclinearInternal inductance/capacitance L /C Li = 65 µH, Ci negligibly small External inductance/capacitance L /C Ex ia IICIIB Lo [mH]151021020Co [µF]1,10,830,745,23,83,4Ex approval acc. to conformity certificate TÜV 06 ATEX 552968 X Application area II 3 GProtection type Ex nA nC [ic Gc] IIC/IIB T4 Gc Max. values:Terminal connection: 1+4Max.output voltage U ð 9.6 V Max. output current I ð 11 mA Max. output power P ð 26 mW CharacteristiclinearInternal inductance/capacitance L /C Li = 65 µH, Ci negligibly small External inductance/capacitance L /CEx icIICIIBLo [mH]15101510Co [µF]1.91.41.2117.5 6.6DimensionsOutput relay – Load curveOutput relay – Electrical lifetimeT 21:59:15+02:00IndicationOperational readiness green Switching state yellow Error indicationredMechanical Data IP RatingIP20Flammability class acc. to UL 94V-0Ambient temperature -25 …+70 °C-25 ... +60 °C für UL, FM, TIIS Storage temperature -40…+80°C Relative humidity ð 95 %Dimensions 104 x 18 x 110 mm Weight154 gMounting instruction for DIN rail / panel Housing material polycarbonate/ABSElectrical connection 4 x 3-pin removable terminal blocks, reverse polarity protected, screw connection Terminal cross-section 1 x 2.5 mm / 2 x 1.5 mm Tightening torque0.5 NmT 21:59:15+02:00AccessoriesType codeIdent no.DescriptionDesignIM-CC-3X2BU/2BK6900475Cage clamp terminals for IM modules (Ex-devices with 18mm overall width); includes: 2 pcs. 3-pin blue terminals and 2pcs. 3-pin black terminals.WM1 WIDER-STANDSMODUL0912101The resistor module WM1 meets the requirements for line monitoring between a mechanical contact and a TURCK signal processor. The input circuit of the signal processor is designed for sensors acc. to EN60947-5-6 (NAMUR) and equipped with a wire-break and short-circuit monitoring func-tion.。

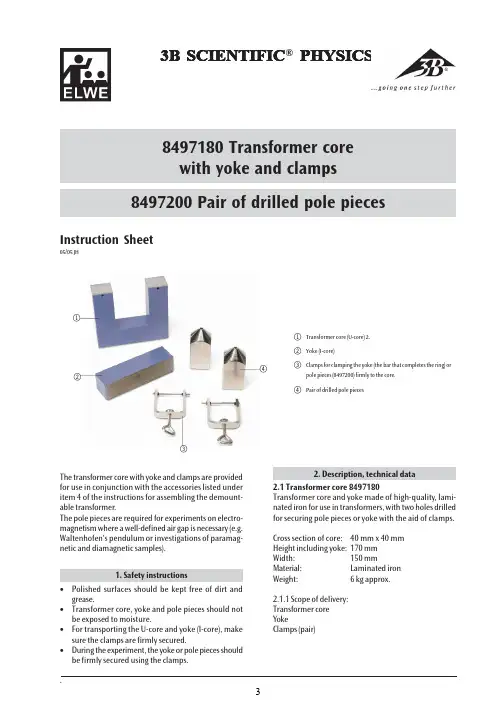

3Instruction Sheet05/05 JH3B SCIENTIFIC ® PHYSICS®8497200 Pair of drilled pole pieces8497180 Transformer core 1Transformer core (U-core) 2.2Yoke (I-core)3Clamps for clamping the yoke (the bar that completes the ring) orpole pieces (8497200) firmly to the core.4Pair of drilled pole pieces1234The transformer core with yoke and clamps are provided for use in conjunction with the accessories listed under item 4 of the instructions for assembling the demount-able transformer.The pole pieces are required for experiments on electro-magnetism where a well-defined air gap is necessary (e.g.Waltenhofen’s pendulum or investigations of paramag-netic and diamagnetic samples).1. Safety instructions•Polished surfaces should be kept free of dirt and grease.•Transformer core, yoke and pole pieces should not be exposed to moisture.•For transporting the U-core and yoke (I-core), make sure the clamps are firmly secured.•During the experiment, the yoke or pole pieces should be firmly secured using the clamps..2. Description, technical data2.1 Transformer core 8497180Transformer core and yoke made of high-quality, lami-nated iron for use in transformers, with two holes drilled for securing pole pieces or yoke with the aid of clamps.Cross section of core:40 mm x 40 mm Height including yoke:170 mm Width:150 mmMaterial:Laminated iron Weight:6 kg approx.2.1.1 Scope of delivery:Transformer core YokeClamps (pair)with yoke and clamps45. Cleaning, maintenance and storage•Polished surfaces should be kept free of dirt and grease.•Store in dry conditions.•Remove any rust with fine steel wool or sandpaper.Accessories for step-up transformer ItemCat. no.Winding turnsTap(s)Mains coil 220 V 8497420600 Mains coil 115 V Available on request300 High current coil for 84974066Coil 8497410726/30/54/66/72Coil 8497430600200 Coil 84974401200400 Coil 849745060002000Melting ladle84973101 Coil with 5 winding turns 84973205High-tension coil with849746024000High current coil for spot weldingneedle-point melting ex-periments horn-shaped spark electrodes2.2 Pair of drilled pole pieces 8497200Pole pieces made of soft iron each with one plane and one conical end. The pole pieces have a bore drilled through the middle of them.Cross section of core:40 mm x 40 mm Bore at conical end: 5 mm Bore at plane end:12 mm Material:Soft iron Weight: 1.7 kg approx.Step-up transformerSpark discharge along horn-shaped electrodesWaltenhofen’s pendulum4. Example experiments3. Operation•The safety instructions for the coils must be observedat all times.•Mount the primary and secondary coils on the core.•Lay the polished side of the yoke or pole pieces on top of the U-core.•Attach the clamps.•Firmly secure the yoke or pole pieces with the clamps.ELWE Didactic GmbH • Steinfelsstr. 5 • 08248 Klingenthal • Germany • 3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • Technical amendments are possible。

笔记本电脑隔离器用户手册第一章硬件安装一、外观示意图:二、连线:插入PC一个选择器第二章硬盘分区一、相关说明1.目前PC上所使用的硬盘,无论是IDE还是SATA借口,一个硬盘最多可以分成四个物理区(四个主分区,或者一个扩展分区+最多三个主分区,扩展分区又可分成若干个逻辑盘/分区),命名为分区0、分区1、分区2、分区3;2.单硬盘隔离方案就是将硬盘划分成上述四个区,分区0和分区1对应于内网,分区2 和分区3对应于外网,由隔离卡分别进行控制与管理,实现络网数据的逻辑隔离;3.可使用PQ等多种硬盘工具软件进行硬盘分区工作。

我们推荐使用DM这一功能强大、操作简洁的软件,使用操作前请仔细阅读《DM简介》。

随卡的启动光盘中已刻录DM,且在光盘引导后自动运行。

二、硬盘分区步骤重要提示:硬盘分区将破坏硬盘中原有的数据。

所以,若您要对使用过的硬盘进行分区,则请您务必先将该硬盘中的重要数据信息进行备份。

切切!1.安装好隔离卡,将光盘放入光驱,在PC系统加电自检、初试化后,系统进入光盘启动。

若硬盘尚未按要求进行分区,则屏幕显示以下菜单按下回车键,系统从光盘自动运行DM;2.请将硬盘按照实际使用的空间大小分为四个区:分区0、分区1、分区2、分区3,其中分区1必须为扩展分区,且可随意再分成几个逻辑盘/分区,存盘更新分区表后将分区0和分区1(含逻辑盘/分区)格式化,但不必格式化分区2和分区3,然后退出DM,请手动复位PC;3.系统重启从光盘引导后屏幕仍显示出1.中的菜单,请按下s或S键隔离卡保存已分好的分区0和分区1的相关数据,然后PC自动重启。

4.系统重启从光盘引导后,屏幕显示以下菜单按下回车键,系统从光盘自动运行DM;5.再次进入DM后,可以看到隔离卡将分区0和分区1屏蔽、分区3改为扩展分区,这时可将分区3随意再分成几个逻辑盘/分区,存盘更新分区表后将分区2和分区3(含逻辑盘/分区)格式化,然后退出DM,请手动复位PC;6.重启系统从光盘引导后屏幕仍显示出4.中的菜单,按下s或S键隔离卡保存已分好的分区2和分区3的相关数据,屏幕显示请取出光盘,按下任一键PC重启后,您可以进入外网所使用的硬盘分区,在上面安装操作系统和各种应用软件。

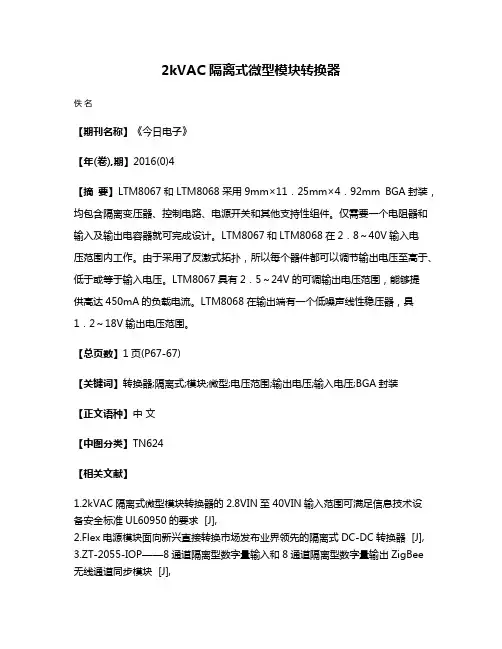

2kVAC 隔离式微型模块转换器佚名【期刊名称】《今日电子》【年(卷),期】2016(0)4【摘要】LTM8067和LTM8068采用9mm×11.25mm×4.92mm BGA封装,均包含隔离变压器、控制电路、电源开关和其他支持性组件。

仅需要一个电阻器和输入及输出电容器就可完成设计。

LTM8067和LTM8068在2.8~40V输入电压范围内工作。

由于采用了反激式拓扑,所以每个器件都可以调节输出电压至高于、低于或等于输入电压。

LTM8067具有2.5~24V的可调输出电压范围,能够提供高达450mA的负载电流。

LTM8068在输出端有一个低噪声线性稳压器,具1.2~18V输出电压范围。

【总页数】1页(P67-67)【关键词】转换器;隔离式;模块;微型;电压范围;输出电压;输入电压;BGA封装【正文语种】中文【中图分类】TN624【相关文献】1.2kVAC隔离式微型模块转换器的2.8VIN至40VIN输入范围可满足信息技术设备安全标准UL60950的要求 [J],2.Flex电源模块面向新兴直接转换市场发布业界领先的隔离式DC-DC转换器 [J],3.ZT-2055-IOP——8通道隔离型数字量输入和8通道隔离型数字量输出ZigBee 无线通道同步模块 [J],4.ECAT-2057-8P8N:8个隔离型数字Source-type输出信道及8个隔离型数字Sink-type输出信道的EtherCAT Slave I/O模块 [J],5.采用隔离式∑-△型调制器、隔离式DC/DC转换器和有源滤波器的新型模拟/模拟隔离器 [J],因版权原因,仅展示原文概要,查看原文内容请购买。

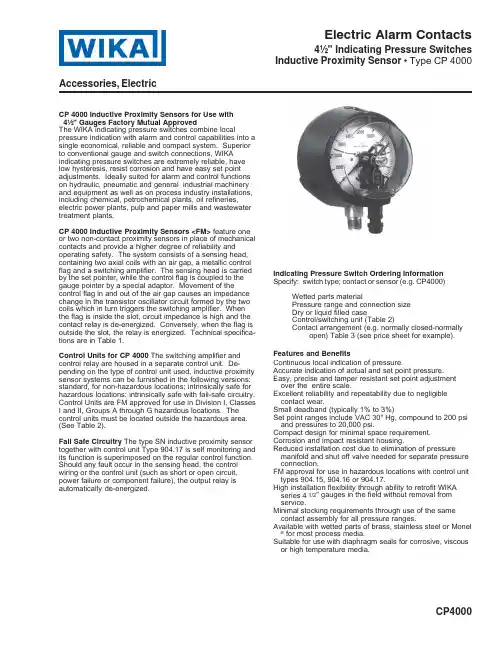

Electric Alarm Contacts4½" Indicating Pressure SwitchesInductive Proximity Sensor • Type CP 4000CP4000Accessories, ElectricCP 4000 Inductive Proximity Sensors for Use with 4½" Gauges Factory Mutual ApprovedThe WIKA indicating pressure switches combine localpressure indication with alarm and control capabilities into a single economical, reliable and compact system. Superior to conventional gauge and switch connections, WIKA indicating pressure switches are extremely reliable, have low hysteresis, resist corrosion and have easy set point adjustments. Ideally suited for alarm and control functions on hydraulic, pneumatic and general industrial machinery and equipment as well as on process industry installations,including chemical, petrochemical plants, oil refineries,electric power plants, pulp and paper mills and wastewater treatment plants.CP 4000 Inductive Proximity Sensors <FM> feature one or two non-contact proximity sensors in place of mechanical contacts and provide a higher degree of reliability and operating safety. The system consists of a sensing head,containing two axial coils with an air gap, a metallic control flag and a switching amplifier. The sensing head is carried by the set pointer, while the control flag is coupled to the gauge pointer by a special adaptor. Movement of thecontrol flag in and out of the air gap causes an impedance change in the transistor oscillator circuit formed by the two coils which in turn triggers the switching amplifier. When the flag is inside the slot, circuit impedance is high and the contact relay is de-energized. Conversely, when the flag is outside the slot, the relay is energized. Technical specifica-tions are in Table 1.Control Units for CP 4000 The switching amplifier and control relay are housed in a separate control unit. De-pending on the type of control unit used, inductive proximity sensor systems can be furnished in the following versions:standard, for non-hazardous locations; intrinsically safe for hazardous locations; intrinsically safe with fail-safe circuitry.Control Units are FM approved for use in Division I, Classes I and II, Groups A through G hazardous locations. The control units must be located outside the hazardous area.(See Table 2).Fail Safe Circuitry The type SN inductive proximity sensor together with control unit Type 904.17 is self monitoring and its function is superimposed on the regular control function.Should any fault occur in the sensing head, the control wiring or the control unit (such as short or open circuit,power failure or component failure), the output relay is automatically de-energized.Indicating Pressure Switch Ordering Information Specify:switch type; contact or sensor (e.g. CP4000)Wetted parts materialPressure range and connection size Dry or liquid filled caseControl/switching unit (Table 2)Contact arrangement (e.g. normally closed-normally open) Table 3 (see price sheet for example).Features and BenefitsContinuous local indication of pressure.Accurate indication of actual and set point pressure.Easy, precise and tamper resistant set point adjustment over the entire scale.Excellent reliability and repeatability due to negligible contact wear.Small deadband (typically 1% to 3%)Set point ranges include VAC 30" Hg, compound to 200 psi and pressures to 20,000 psi.Compact design for minimal space requirement.Corrosion and impact resistant housing.Reduced installation cost due to elimination of pressure manifold and shut off valve needed for separate pressure connection.FM approval for use in hazardous locations with control unit types 904.15, 904.16 or 904.17.High installation flexibility through ability to retrofit WIKA series 4 1/2" gauges in the field without removal from service.Minimal stocking requirements through use of the same contact assembly for all pressure ranges.Available with wetted parts of brass, stainless steel or Monel ®for most process media.Suitable for use with diaphragm seals for corrosive, viscous or high temperature media.Indicating Pressure SwitchesKEYA*B*C D E F*G H J K mm 12910369.512.798.519.014.0102.6 5.6038.0in4.50 4.06 2.740.50 3.870.750.55 4.040.22 1.50KEY L M N O PRS T W mm 98.0148137141113.625.012.5--22in3.855.835.395.554.470.980.491/2"0.87A* Nominal SizeB* Gauges with 1/4"NPT connection - dimension changes to 97mm/3.81in.F* Gauges with 1/4"NPT connection - dimension changes to 13mm/.51in.PG9 CABLE GLAND FITTINGSupplied with PG9 Electrical cable glandT A B L E 2T A B L E 1CONTACT TYPE CONTROL SYSTEMAREA OF INSTALLATION NUMBER OF CONTACTSCONTROL UNITTYPE ¹Inductive Proximity Standard Non-Hazardous 1904.25Inductive Proximity Standard Non-Hazardous 2904.26Inductive Proximity Intrinsically Safe Hazardous 1904.15Inductive Proximity Intrinsically Safe Hazardous 2904.16Inductive ProximityType SN Intrinsically Safe with Fail-Safe Control Hazardous 1904.17Inductive ProximityType SNIntrinsically Safe with Fail-Safe ControlHazardous2904.17 ²combination power supply, switching modules for panel or relay rack mount.904.15 & 904.25 units are 1.57" (40mm)wide, 2.76" (70mm) high and 4.33"(110mm) deep with mounting holes on 1.18" (30mm) horizontal & 2.36" (60mm)vertical centers. The wider 904.16/.17and 904.26 units are 2.35" (60mm) wide with 1.96" (50mm) horizontal mounting centers. Minimum mounting screw clearance is .19" (4.8mm).2Requires 2 units, one per contact.Typical Wiring Diagram10/03WIKA Instrument Corporation 1000 Wiegand BoulevardLawrenceville, Georgia 30043-5868Tel: 770-513-8200 Fax: 770-338-5118e-mail:*************Ordering Information:State computer part number (if available) / model number / size /range / connection size and location / options required.Specifications given in this price list represent the state of engineering at the time of printing.Modifications may take place and the specified materials may change without prior noticeControl Unit Designation(required for inductive-proximity contacts)Type Identification No. Terminal Configuration Connect To:904.25MSR-010-1Control Unit for nonhazardous applications - for one inductive contact-with built-in power supply unit 24VDC904.26MSR-020-1Control Unit for nonhazardous applications - for two inductive contact-with built-in power supply unit 24VDC904.1501666S - WE77EX1Control Unit for hazardous applications- for one inductive contact (intrinsically safe)- factory mutual approvedNOTE: Change bridge 3-4 to 4-5 to reverse LOAD relay grade.904.1601669S - WE77EX2Control Unit for hazardous applications- for two inductive contact (intrinsically safe)- factory mutual approvedNOTE: Change bridge 3-4 and 7-8 to 4-5 and 6-7respectively to reverse local relay.904.1709051 - WE77EX-SH-03Control Unit for hazardous applications (Intrinsically fail-safe requirement)- for one inductive fail-safe contact (SN)- dual output relaysGeneral Information: applicable to all control units.- check supply voltage of control unit before connecting to your source.- control unit is protected against wrong input connection. If LOAD relay does not work, reverse input signal polarity.L-N supply voltage 11 CP terminal #114 CP terminal #242 LOAD common 41 LOAD cont. N.C.43 LOAD cont. N.O.81-82 Power Supply 24VDCL-N supply voltage 11 CP terminal #114 CP terminal #221 CP terminal #324 CP terminal #442/52 LOAD common 41/51 LOAD cont. N.C.43/53 LOAD cont. N.O.81-82 Power Supply 24VDC1 CP terminal #22 CP terminal #14 LED relais energized 7 LOAD common 8 LOAD cont. N.C.9 LOAD cont. N.O.10 Ground11-12 Supply Voltage1 CP terminal #22 CP terminal #14 LED relais 1 energized 7 LED relais 2 energized 8 CP terminal #39 CP terminal #410/13 LOAD common 11/14 LOAD cont. N.C.12/15 LOAD cont. N.O.16 Ground17-18 Supply Voltage1 CP terminal #22 CP terminal #17 LED relais energized 10/13 LOAD common 11/14 LOAD cont. N.C.12/15 LOAD cont. N.O.16 Ground17-18 Supply Voltage。

LZ型金属管转子流量计使用手册江苏省苏科仪表有限公司概述LZ系列金属管转子流量计是基于浮子位置测量的一种变面积流量仪表。

采用全金属结构,具有体积小、压损小、量程比大(10~20:1)、安装维护方便等特点,故广泛应用于各行业复杂、恶劣环境下、对小流量、低流速、各种苛刻介质条件的流量测量与过程控制。

LZ系列金属管转子流量计的系列产品,针对不同的用户需求、不同场合,有多种测量形式供用户可选;按输出形式分有就地指示型、远传输出型、控制报警型;按防爆要求分类,又可分为普通型、本质安全型、隔离防爆型三种。

LZ系列金属管转子流量计采用无接触检测磁场角度变化的磁测传感器、并配以高性能MCU,可实现液晶指示、累积、远传输出(4~20mA)、脉冲输出、上下限报警输出等功能,该型智能信号变送器具有及高的精度和可靠性,完全可以取代进口同类型仪表,且具有性价比高、在线参数标定、掉电保护等特点。

LZ系列金属管转子流量计的设计制作还考虑了用户工艺流向要求,有LZ50垂直安装式、LZ51上进下出安装式、LZ52侧进侧出安装式、LZ53底进侧出安装式、LZ54螺纹连接式、LZ56R/L水平安装式等安装方式可选。

一.结构及原理LZ系列金属管转子流量计由二部分组成:✧传感器---测量管及浮子;✧信号变送器----指示器;传感器的触液材质有四种:不锈钢、哈氏合金、钛材、不锈钢衬PTFE;用户可根据不同的工艺压力及介质的腐蚀性要求,选择不同的触液材质,来满足工艺的耐压及介质防腐的需要。

根据不同的测量要求,用户在选型时,可以选择不同的指示器组合,来实现不同的测量要求。

具体指示器形式与其对应功能见指示器型谱表。

流量的测量是由指示器内的变送器通过耦合磁钢感受浮子位置的变化来完成流量的指示和信号的远传输出的。

当被测介质自下而上流经测量管时,浮子受重力、浮力及流体流速对浮子垂直向上的推动力三者平衡时,浮子即相对静止在某个位置,这个位置随浮子与锥管的环面积、流体流速而变化,浮子的位置即对应被测介质流量的大小。

一、主要技术参数■接口形式:RJ-45(标准以太网口)■兼容性:100BASE-TX/1000BASE-T■100BASE-TX支持全双工最大通讯速率:100MBit/s最大通讯距离长度:90m(±10m)■1000BASE-T支持全双工最大通讯速率:1000MBit/s最大通讯距离长度(受媒介影响)超五类/六类线:MAX.60m(±10m);同轴电缆:MAX.25M;■隔离能力:1500V AC/1min50HZ■绝缘电阻:≥100MΩ(输入/输出)■电磁兼容:EMC符合IEC61326-3-2017■以太网标准符合IEEE802.3标准符合IEEE802.3AT标准■强制实施标准:符合CNCA-C23-01:2019■生产标准:符合GB/T3836.1-2021、GB/T3836.4-2021■生产体系:符合ISO9001、ISO14001■防爆参数(国家防爆电气产品质量监督检验中心)防爆合格证号:CNEx21.4686防爆等级标志:[Ex ia Ga]IIC[Ex ia Da]IIIC安全认证参数:Um:250V AC/DCUo:5.5VDC,Io:462mA,Po:635mW,Co:40uF,Lo:0.15mH;■关联设备适用于:0区,1区,2区;20区,21区,22区;IIA,IIB,IIC;IIIA,IIIB,IIIC;I类(矿用);■产品结构尺寸:W16.5×D110×H108(mm)重量:170g材质:ABS防护等级:IP20阻燃等级:UL94/V0安装方式:DIN35mm导轨安装工作环境温度:-20℃~60℃产品简介:EXCOM-A3-77型隔离安全栅,接收现场安全区域的以太网信号,经过本质安全限能和电气隔离的处理,输出至危险区的控制系统或其它单元组合仪表。

■接口形式:RJ-45(标准以太网口);■通讯速率:100M/1000M Bit/s;■输入-输出之间电气隔离;■安全栅安装在安全区,DIN标准导轨安装;■关联设备适用于:0区,1区,2区;20区,21区,22区;IIA,IIB,IIC;IIIA,IIIB,IIIC;I类(矿用);二、应用接线图(图1)图1EXCOM-A3隔离式安全栅接线图三、尺寸结构图(图2)图2EXCOM-A3隔离式安全栅尺寸图(单位:mm)四、安装注意事项⏹安全栅本安端(蓝色)和非本安端电路的接线导线配在汇线槽中应分开铺设,各自采用独立的保护套管。

目 录1. 简述 (1)2. 优点 (1)3. 主要技术数据 (2)4. 流量表 (3)5. 仪表类型及材料 (4)6. 口径计算 (4)7. 电信号输出和电气接线 (5)8. 仪表结构及外形尺寸 (8)9. 安装与维护 (10)10. 安装示意图 (11)11. 选型代码 (12)浮子流量计技术数据单 (13)HF 金属管浮子流量计承德海富盛自动化仪表有限公司1HF 系列金属管浮子流量计,是按照JB/T6844-93行业标准生产制造的。

它利用流体的动力作用,使浮子在垂直安装的测量管中顺流向上移动,浮子的位移量与流量的大小成比例。

通过磁传递系统,以不接触方式,将浮子位移量传给指示器直接指示流量的大小。

在指示器内安装符合HART @通讯协议的流量计智能卡,用户就能够通过PC 机,利用HART @通讯软件进行管理和调整运行过程中HART @的仪表和监测过程变量。

HF 流量计结构简单,维修方便,工作可靠,适用性广,可用来测量液体、气体和蒸汽的流量。

1.简述1.2 HF 结构HF 流量计由传感器和指示器(图一)两部分组成。

传感器亦称测量管,它主要由锥形管,浮子,导向器,止动器和安装法兰组成。

1.3 分类根据管道的安装形式分类◆ 垂直安装形式HF1◆ 水平安装形式HF3◆ 底进侧出安装形式HF4◆ 侧进侧出安装形式HF5◆ 上进下出安装形式HF2根据流体腐蚀性分类◆ 标准型◆ 防腐型根据流体性质分类◆ 液体:普通型 ◆ 气体:气阻尼型根据流体温度分类◆ 高温:冷却夹套型 ◆ 低温:保温夹套型按指示器形式分类◆ M0就地瞬时流量指示◆ M1就地瞬时流量指示,带上下限位报警功能◆ M2远传型,带HART 通讯协议,本安防爆◆ M3远传型,带HART 通讯协议,本安隔爆◆ M4电池供电,现场指示瞬时和累积流量HF金属管浮子流量计在浮子内部,嵌有一个高性能永久磁钢,这样就会在浮子周围产生磁场。

当流体的流量趋于稳定,浮子处于动平衡状态时,其周围的磁场分布也趋于稳定。