贴片LED灯珠规格书

- 格式:pdf

- 大小:412.40 KB

- 文档页数:11

2025led灯珠规格书摘要:1.2025LED 灯珠概述2.2025LED 灯珠规格参数3.2025LED 灯珠的特点与优势4.2025LED 灯珠的应用领域5.2025LED 灯珠的环保与节能性正文:一、2025LED 灯珠概述2025LED 灯珠是一款具有高性能、环保节能特点的LED 灯珠产品,其设计理念源于对未来照明市场的前瞻性预测和对客户需求的深度挖掘。

该款LED 灯珠采用了先进的制造工艺,具有卓越的照明性能和稳定的使用寿命。

二、2025LED 灯珠规格参数1.尺寸:2.0mm x 2.5mm x 1.0mm2.功率:0.06W3.电流:20mA4.电压:3.0-3.4V5.光效:90-110lm6.色温:2700K-6500K7.显色指数:Ra>758.寿命:50,000 小时三、2025LED 灯珠的特点与优势1.高光效:2025LED 灯珠采用高效率的芯片设计,使得光效达到90-110lm,为客户带来更高亮度的照明体验。

2.宽电压范围:该款LED 灯珠具有宽电压范围,可在3.0-3.4V 之间稳定工作,适应不同应用场景的需求。

3.良好的散热性能:2025LED 灯珠采用了优良的散热设计,有效降低了芯片温度,提高了使用寿命。

4.丰富的色温选择:从2700K 到6500K,满足客户对不同场合的照明需求。

5.环保材料:LED 灯珠采用环保材料制造,符合RoHS 标准,不对环境造成污染。

四、2025LED 灯珠的应用领域1.家庭照明:适用于台灯、吸顶灯、筒灯等各种家居照明场景。

2.商业照明:适合用于办公室、酒店、餐厅等商业场所的照明。

3.工业照明:适用于工厂、仓库等需要高亮度、节能环保的工业照明环境。

4.景观照明:可用于城市景观照明、公园照明等户外照明场合。

五、2025LED 灯珠的环保与节能性1.节能:相较于传统照明产品,2025LED 灯珠具有更高的光效和更低的功率,可为客户节省电力消耗,降低运营成本。

3528蓝光规格书3528 BLUE SPECIFICATION 产品型号 Model NO.:HT-K3528BC版次 REV NO.:V01版文件编号Document NO.:YT-DG201303日期 DATE :2013.3.041.外形尺寸D imensions单位(Units):毫米(mm)2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.½ Rja = Heat resistance from Dice to Ambient temperature (Ta) Rjs = Heat resistance from Dice to Solder temperature of Cathode Side (Ts) (3) 原始光电参数Initial Electrical/Optical Characteristics (TA=25ºC)(4)发光强度范围Luminous Intensity Ranking (TA=25ºC)允许误差± 10%Luminous Intensity Measurement allowance is ± 10%.(5)颜色范围Color Ranking (TA=25ºC)允许误差± 0.01Color Coordinates Measurement allowance is ± 0.01.3.包装PACKAGING(1)LEDS在装带之后纸箱包装. The LEDs are packed in cardboard boxes after taping.(2)装带规格Taping Specifications (单位:毫米Units:mm)(3)卷轴尺寸Reel Dimension装带数量2000个/卷2000Pcs/Reel(3) 最小包装标签注明以下:产品名称.批号.光电范围.数量.The label on the minimum packing unit shows ; Part Number, Lot Number, Ranking, Quantity.(4)请注意防水防潮Keep away from wate r, moisture in order to protect the LEDs.(5) 须采取适当防护措施,以防包装箱跌落或受到强力撞击造成对产品的损伤.The LEDS may be damaged if the boxes are dropped or receive a strong impact against them. so precautions must be taken to prevent any damage.4.可靠性RELIABILITY5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)有铅回焊(Lead Solder ) 无铅回焊(Lead-Free Solder)推荐焊盘式样(Recommended Soldering Pattern ) 单位:毫米( Units:mm)(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs. 所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED 会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F =0.5mA 时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F =0.5mA)(3)防潮包装Moisture Proof Package使用防潮包装It is recommended that moisture proof package be used .(4)储藏Storage打开包装袋之前,LED在温度为30°C或更低湿度70%RH以下,可保存一年.Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).下列情况发生时,须要在焊接前重新烘烤60 ± 5°C,24小时以上。

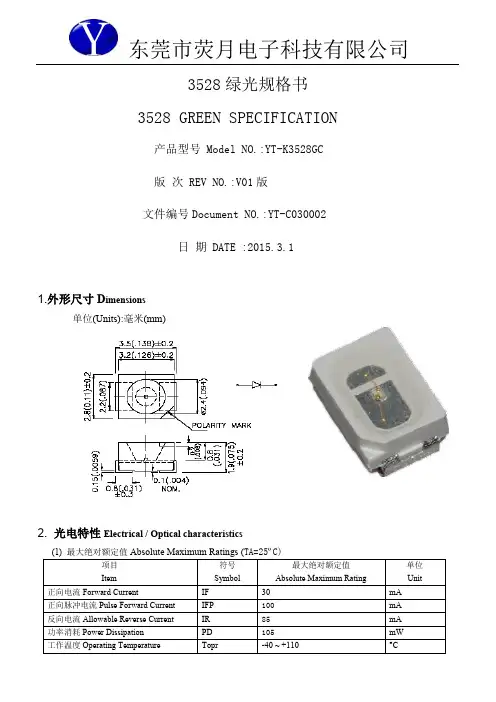

东莞市荧月电子科技有限公司3528绿光规格书3528 GREEN SPECIFICATION产品型号 Model NO.:YT-K3528GC版次 REV NO.:V01版文件编号Document NO.:YT-C030002日期 DATE :2015.3.11.外形尺寸D imensions单位(Units):毫米(mm)2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.Rjs = Heat resistance from Dice to Solder temperature of Cathode Side (Ts) (3) 原始光电参数Initial Electrical/Optical Characteristics (TA=25ºC) Array(4)发光强度范围Luminous Intensity Ranking (TA=25ºC)允许误差± 10%Luminous Intensity Measurement allowance is ± 10%.(5)颜色范围Color Ranking (TA=25ºC)允许误差± 0.01Color Coordinates Measurement allowance is ± 0.01.3. 包装PACKAGING(1)LEDS 在装带之后纸箱包装. The LEDs are packed in cardboard boxes after taping.(2)装带规格Taping Specifications (单位:毫米Units:mm )(3)卷轴尺寸 Reel Dimension装带数量2000个/卷2000Pcs/Reel(3) 最小包装标签注明以下:产品名称.批号.光电范围.数量.The label on the minimum packing unit shows ; Part Number, Lot Number, Ranking, Quantity.(4)请注意防水防潮Keep away from wate r, moisture in order to protect the LEDs.(5) 须采取适当防护措施,以防包装箱跌落或受到强力撞击造成对产品的损伤.The LEDS may be damaged if the boxes are dropped or receive a strong impact against them. so precautions must be taken to prevent any damage.4.可靠性RELIABILITY*) U.S.L.:Upper Standard Level **) L.S.L.:Lower Standard Level5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)推荐焊盘式样(Recommended Soldering Pattern ) 单位:毫米( Units:mm )(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs.所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F=0.5mA时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F=0.5mA)(3)防潮包装Moisture Proof Package使用防潮包装It is recommended that moisture proof package be used .(4)储藏Storage打开包装袋之前,LED在温度为30°C或更低湿度70%RH以下,可保存一年.Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).下列情况发生时,须要在焊接前重新烘烤60 ± 5°C,24小时以上。

0603灯珠,0603贴片led参数,0603灯珠尺寸都在这里!(附0603灯珠系列规格书)0603灯珠,0603灯珠尺寸,0603贴片led参数不管是汽车仪表灯,还是跑马灯,还是广告软屏灯。

0603灯珠因为它的体积小,型号多,一直受到很多家用电器,仪表指示灯应用中设计师们很喜欢的选型灯珠型号之一。

正是因为0603灯珠应用极广,在LED灯珠应用选型时,对了解0603灯珠的参数、尺寸,电流、电压和规格书尺寸都比较了解时,可以更好地快速确定选型方案。

还有一点,因为0603灯珠尺寸小,LED灯珠厂家做的型号和颜色比较多,这样,设计时不用单独去开模具和夹具,性价比上也会好很多。

所以,这也是LED灯珠0603系列在LED应用中越来越广的原因。

我们先来看看LED灯珠0603参数型号和尺寸。

— 1 —0603灯珠参数0603灯珠参数:1、0603灯珠尺寸:1.6mm*0.8mm*0.6mm;(0603灯珠厚度有三种要供选择0.4mm/0.6mm/0.8mm,选型时可咨询客服看哪款更适合你)2、0603灯珠白光:色温:6000-9000K, 显色指数:70-80-90RA (高显指需订做),其它冷白色温或暖白色温均可根据客户需求定做;3、0603灯珠应用:0603灯珠系列主要应用在汽车仪表、家用电器、电子消费、LED背光源、电子电器指示及应用、电脑、手机数码产品等。

4、0603灯珠特性:贴片led灯珠0603可靠性高,亮度一致性高、发光角度大,外观体积及尺寸小,灯珠经过严格的信赖性实验,市场已经大批量产使用,是目前市场上使用很广泛的一款微型LED灯珠。

5、单色0603灯珠包括:0603白光,0603红光,0603橙光,0603黄光,0603翠绿,0603黄绿,0603蓝光、0603双色灯珠、0603三色、全彩灯珠等。

6、0603灯珠常规包装:4000PCS每盘。

— 2 —0603灯珠型号一、0603灯珠型号:(单色)0603白光:暖白色温:2800-3200k ,正白光(冷白色温):6000-9000K-15000K以上。

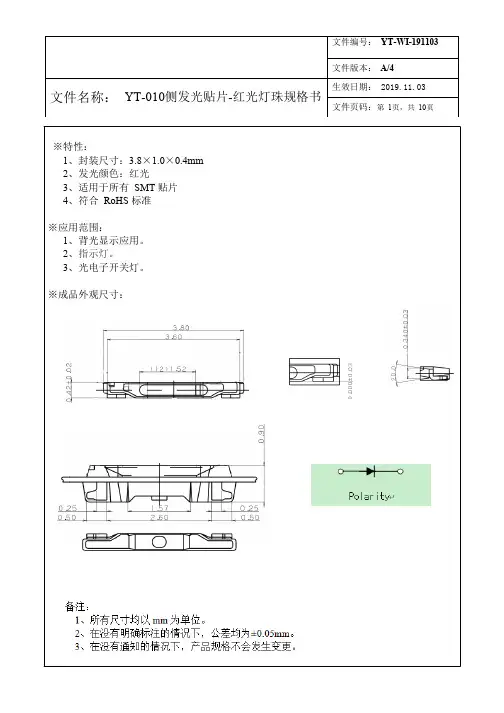

※特性:1、封装尺寸:3.8×1.0×0.4mm2、发光颜色:红光3、适用于所有SMT 贴片4、符合RoHS 标准※应用范围:1、背光显示应用。

2、指示灯。

3、光电子开关灯。

※成品外观尺寸:※典型光电参数曲线:※客户使用建议红外回流焊条件:印制板焊盘尺寸(单位:mm):包装标识要求:1.产品型号;2.规格;3.光电参数:波长,亮度,电压;4.生产批号及实际数量。

※可靠性测试:失效判定标准:※ 使用注意事项:1、焊接SMD LED 灌封胶较软,外力易损坏发光面及塑料壳,焊接时要轻拿轻放。

A.建议使用免洗型的助焊剂,依照回流曲线条件回流焊接,回流次数最多两次,确保LED 发光面干净,异物会影响发光颜色。

B.仅在修补时进行手动焊接,建议使用25W 防静电烙铁,烙铁焊头温度不可高于300摄氏度,烙铁焊头不可碰及发光面及塑料件,焊接时间不超过 3 秒钟。

C.焊接机实验过程中,不能用力扭曲LED,否则,容易使LED 死灯。

2、清洗A.不能用超声波清洗。

建议使用异丙醇、纯酒精擦拭或浸渍,时间不超过1 分钟,清洗后,在室温下放置15 分钟再使用。

确保LED 发光面干净,异物会影响发光颜色。

B.应避免接触或污染三氯乙烯、丙酮、硫化物、氮化物、酸、碱、盐类,这些物质会损伤LED。

3、灌封A.钠离子、硫化物会使荧光粉颜色变淡,灌封时,避免使用钠离子、硫化物的灌封胶。

B.使用正常灌封胶时,建议先以少量试验,常温点亮168 小时,确定没有问题再作业。

4、保存A.打开包装前,LED 应存储在温度30℃以下,相对湿度在60%RH 以下,一年内使用。

B.打开包装后,LED 应存储在温度30℃以下,相对湿度在30%RH 或更低环境下,使用时间为7 天。

LED 吸潮后,回流焊时可能裂胶,影响发光颜色。

对于未使用的散件,请去潮处理(对于卷装品:烘烤60℃±5℃,12 小时;对于散装品:烘烤105℃±5℃,1 小时),使用铝防潮袋密封后保存。

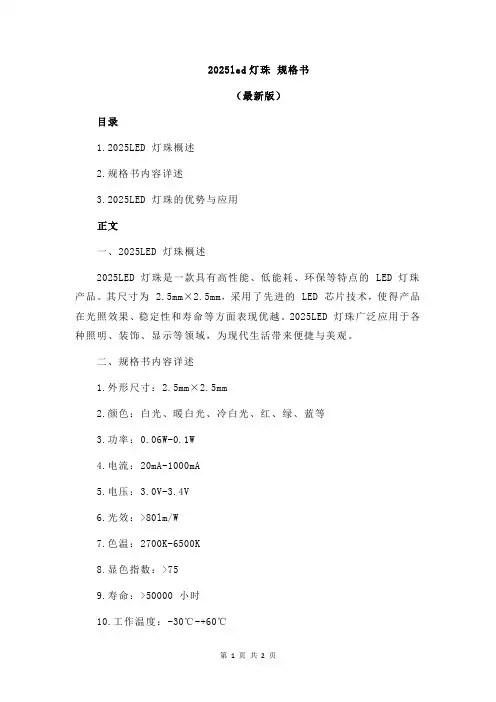

2025led灯珠规格书(最新版)目录1.2025LED 灯珠概述2.规格书内容详述3.2025LED 灯珠的优势与应用正文一、2025LED 灯珠概述2025LED 灯珠是一款具有高性能、低能耗、环保等特点的 LED 灯珠产品。

其尺寸为 2.5mm×2.5mm,采用了先进的 LED 芯片技术,使得产品在光照效果、稳定性和寿命等方面表现优越。

2025LED 灯珠广泛应用于各种照明、装饰、显示等领域,为现代生活带来便捷与美观。

二、规格书内容详述1.外形尺寸:2.5mm×2.5mm2.颜色:白光、暖白光、冷白光、红、绿、蓝等3.功率:0.06W-0.1W4.电流:20mA-1000mA5.电压:3.0V-3.4V6.光效:>80lm/W7.色温:2700K-6500K8.显色指数:>759.寿命:>50000 小时10.工作温度:-30℃-+60℃11.储存温度:-40℃-+80℃12.抗震性能:1000 次三、2025LED 灯珠的优势与应用1.节能环保:2025LED 灯珠具有低能耗特点,较传统照明产品节能 60% 以上,有助于减少碳排放,保护环境。

2.长寿命:2025LED 灯珠寿命长达 50000 小时,是传统照明产品的数倍,大大降低了维护成本。

3.良好的光照效果:2025LED 灯珠光效高,显色指数优良,能提供舒适、自然的光线环境。

4.广泛的应用领域:2025LED 灯珠可用于各类照明产品,如台灯、吸顶灯、筒灯等;以及显示屏、交通信号灯、车灯等特殊应用领域。

总之,2025LED 灯珠凭借其优异的性能和环保特点,已成为照明市场的主流产品。

2025led灯珠规格书(原创版)目录1.2025LED 灯珠概述2.2025LED 灯珠规格参数3.2025LED 灯珠的特点与优势4.2025LED 灯珠的应用领域5.2025LED 灯珠的环保与节能性正文一、2025LED 灯珠概述2025LED 灯珠是一款具有高性能、环保节能的 LED 灯珠产品,其设计理念源于对未来照明需求的深度挖掘,以满足市场对高效、绿色照明产品的期待。

二、2025LED 灯珠规格参数1.尺寸:2.0mm x 2.5mm x 1.0mm2.电压:3.0-3.4V3.电流:30-60mA4.功率:0.06-0.18W5.色温:2700K-6500K6.显色指数:Ra>757.光效:>150lm/W8.寿命:>50000 小时三、2025LED 灯珠的特点与优势1.高亮度:2025LED 灯珠具有高光效,能提供充足的光线,满足照明需求。

2.宽色温范围:可根据不同场景和需求选择合适的色温,满足多样化照明需求。

3.高显色指数:Ra>75,能真实还原物体颜色,提供舒适视觉体验。

4.长寿命:使用寿命长达 50000 小时,降低了维护成本。

5.节能环保:低功耗设计,节约能源,减少碳排放。

四、2025LED 灯珠的应用领域1.家庭照明:适用于台灯、吸顶灯、吊灯等各类家居照明产品。

2.商业照明:适合用于办公室、餐厅、酒店等商业场所的照明。

3.工业照明:可应用于工厂、仓库等场所的照明,提高工作效率。

4.景观照明:适用于城市景观、公园、广场等户外照明场合。

五、2025LED 灯珠的环保与节能性2025LED 灯珠的节能性能表现在其低功耗设计,相较于传统照明产品,能节约大量能源。

同时,其环保特性体现在长寿命、无汞、无紫外线辐射等方面,减少了对环境的污染。

C ustomer:·Technical Data Sheet PN:XGS-PB2012UB-02 For:IF=20mAContents1.Features2.Applications3.Package dimensions4.Absolute maximum rating5.Electrical optical characteristics6.BIN range7.Package label8.Soldering pad dimensions9.Soldering conditions10.Package tape specifications11.T ypical electro-optical characteristics curves12.Reliability test items and conditions13.Cautions14.Note◆F eatures:Compatible with automatic placement equipmentCompatible with reflow solder processLow power consumption and wide viewing angleThis product doesn’t contain restriction Substance, comply ROHS standard.◆A pplications:Automotive and TelecommunicationFlat backlight for LCD ,switch and symbol in telephone and faxGeneral use for indicators◆P ackage Dimensions:Unit:mmTolerenc e±0.1Electrodes: Ag Plating◆A bsolute Maximum Rating (Ta=25℃)* I FP condition: pulse width ≤1ms ,duty cycle ≤1/10◆E lectrical Optical Characteristics(Ta=25℃)Notes: 1.Tolerance of Luminous Intensity ±10%2.Tolerance of Dominant Wavelength ±2nm3.Tolerance of Forward Voltage ±0.05V4.Luminous Intensity is measured by XGSLED’s equipment on bare chips◆ Soldering Pad Dimensions:◆ S oldering Conditions (Maximum allowable soldering conditions)Reflow soldering profile<Pb-free solder>Time• Reflow soldering should not be done more than two times. • Do not stress its resin while soldering.• After soldering,do not warp the circuit board.T e m p e r a t u r e◆ P ackage Tape Specifications: (3000 pcs/Reel)Reel Lead Min.60mm No LEDs5 Reels in one Box10 Boxes in one Carton◆ T ypical Electro-Optical Characteristics Curves :Forward Current Vs Ambient Temperature5040302010100250Forward Current Vs Relative Luminosity204060801001020304050Ambient Temperature Ta (° C)Forward Current (mA)200 15010050 Relative Luminosity VsAmbient TemperatureIf=15mA-50° -60°-70°-80°-90°-40°-30°-20°-10°0°10°20°30°40°50°60°70°80°90° 0 0204060801001.00.50.5Radiation Angle1.0Ambient Temperature Ta (° C)R e l a t i v e L u m i n o s i t y (%)F o r w a r d C u r r e n t (m A )R e l a t i v e L u m i n o s i t y (%)◆Reliability(1)Test Items and Conditions(2)C riteria of judging the damage◆C autions1、PackageWhen moisture is absorbed into the package it may vaporize and expand during soldering. There is apossibility that this can cause exfoliation of the contacts and damage to the optical characteristics of the LEDs. So the moisture proof package is used to keep moisture to a minimum in the package.2、StorageBefore opening the package: The LEDs should be kept at 5~30°C and 60%RH or less. The LEDs should be used within a year.After opening the package: The LED must be used within 24 hours, else should be kept at 5~30℃and 30% RH or less. The LEDs should be used within 7days after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, recommended to return the LEDs to the original moisture proof bag and to reseal the moisture proof bag again.If the LEDs have exceeded the storage time, baking treatment should be performed more than 24hours at 60±5°C.3、Soldering IronEach terminal is to the tip of soldering iron temperature less than 300℃ for 3 seconds within once inless than the soldering iron capacity 25 W.Leave two seconds and more internals, and do soldering of each terminal. Be careful because the damage of the product is often started at the time of the hand solder.4、RepairingRepairing should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.5、The LED electrode sections are comprised of a gold plated. The gold surface may be affected by environments which contain corrosive gases and so on. Please avoid conditions which may cause the LED to corrode or discolor. This corrosion or discoloration may cause difficulty during soldering operations. It is recommended that the User use the LEDs as soon as possible.6、Please avoid rapid transitions in ambient temperature, especially in high humidity environments where condensation can occur.◆Notes:1、Above specification may be changed without notice. We will reserve authority on material change for above specification.2 、When using this product, please observe the absolute maximum ratings and the instructions for the specification sheets. We assume no responsibility for any damage resulting from use of the product which does not comply with the instructions included in the specification sheets.。

Customer Service Hotline :400-676-8616TEL :0769-8200 5999 0769-8200 2226 FAX :0769-8200 2227E-MIAL ∶WEB :Customer: (客戶)chenmo@Lighting LED Specification1.FeaturesEach Lead can be individually controlledHigh power white color surface mount TOPLED Highest flux per LED family in the worldCompact package outline (LxW) of 5.6 x 3.0mm.Ultra low height profile – 0.8mm. Reflowable LED Wide view angle :120degCompatible to both IR reflow soldering and TTW soldering. 2000unit / reel .tapingApplications : back light unit, General light2.DimensionsUnit : mm General Tolerance : ±0.10CathodeTAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD3.Recommended Solder Pad DesignThe following soldering patterns are recommended for reflow soldering.4.Absolute Maximum Ratings (TA=25¢)ParameterSymbolRating Unit0.5W LEDDC Forward CurrentI FD 180 mAPeak Pulse Current (tp 10ms,Duty cycle 1/10)I FP 400mA Reverse VoltageV R 5 V LED Junction Temperature T j 125 J Operation Temperature T opr -40~80 J Storage Temperature T stg -40~80 J Peak Soldering Temperature T sol 260° JESD Sensitivity (HBM)V B 2000 VTAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD5. Electrical/Optical Characteristics For Individual LED(TA=25¢)LED CHIPCOLOR RANKSFORWARD VOLTAGE (V) @150mA REVERSE CURRENT LUMINOUSINTENSITY(Lm/Mcd) @150mAVIEWANGLE2θ1/2(DEG)@ 150mA MATERIALEMITTINGCOLORXYMIN TYP MAX IRVR=5(V) MIN TYP MAX TYPTJ1-5630CW0Y-DN InGaN White 0.44±0.0550.41±0.053.03.33.65µA35.0 12300 42.51600051.318000120Notes¡G 2θ1/2 is the off axis angle from lamp centerline where the luminous intensity is the 1/2 of the6. General Characteristics6.1 Electro-Optical Characteristics (T Ambient =25)ParameterSymbolBin CodeMinMaxConditionLuminous Flux (1)ΦVUnit Lm Mcd Lm Mcd I F =60mA K35.0 12300 38.5 13500 L 38.5 13500 42.4 14800 M 42.4 14800 46.6 16300 N46.6 16300 51.3 18000Forward Voltage (2)V FUnit Volt 1 3.0 3.1 2 3.13.2 3 3.2 3.3 4 3.3 3.4 5 3.4 3.5 6 3.53.6Color TemperatureCIE ALL Follow Detail RankNotes¡G 1. Luminous flux is measured with an accuracy of ±10%.2. Forward Voltage measurement tolerance: ±0.1V .TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD6.2 Typical Electro-Optical Characteristics Curves6.2.2 Forward Voltage vs. Forward Current,T Ambient=25¢6.2.3 Relative Luminous Intensity vs ForwardCurrent, T Ambient=25¢6.2.4 Typical Spatial Radiation Pattern,T Ambient=25¢ 6.2.5 Current Derating Curves6.2.1 Relative Spectrum Distribution, I F=150mA, T Ambient=25¢TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD7. Chromaticity Coordinate GroupsWarm WhiteTAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDx,y¡G Tolerance of the CIE¡G ± 0.01Bin Code Rank30ACIE x 0.4388 0.4328 0.4456 0.4524CIE y 0.43570.42170.42650.4408 30BCIE x 0.4328 0.4263 0.4389 0.4456CIE y 0.42170.40760.41220.4265 30CCIE x 0.4263 0.4179 0.4307 0.4389CIE y 0.40760.38980.39480.4122 30DCIE x 0.4179 0.4120 0.4235 0.4307CIE y 0.38980.37580.37990.3948 30ECIE x 0.4524 0.4456 0.4590 0.4655CIE y 0.44080.42650.43110.4449 30FCIE x 0.4456 0.4389 0.4506 0.4590CIE y 0.42650.41220.41590.4311 30GCIE x 0.4389 0.4307 0.4424 0.4506CIE y 0.41220.39480.39870.4159 30HCIE x 0.4307 0.4235 0.4336 0.4424CIE y 0.39480.37990.38360.3987 27ACIE x 0.4655 0.4590 0.4719 0.4795CIE y 0.44490.43110.43440.4484 27BCIE x 0.4590 0.4506 0.4634 0.4719CIE y 0.43110.41590.41970.4344 27CCIE x 0.4506 0.4424 0.4541 0.4634CIE y 0.41590.39870.40160.4197 27DCIE x 0.4424 0.4336 0.4458 0.4541CIE y 0.39870.38360.38680.4016 27ECIE x 0.4795 0.4719 0.4844 0.4935CIE y 0.44840.43440.43670.4516 27FCIE x 0.4719 0.4634 0.4753 0.4844CIE y 0.43440.41970.42180.4367 27GCIE x 0.4634 0.4541 0.4642 0.4753CIE y 0.41970.40160.40350.4218 27HCIE x 0.4541 0.4458 0.4552 0.4642CIE y0.40160.38680.38860.4035TAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD8. Reel Specification8.1 Emitter Pocket Tape Packing8.2 Emitter Reel PackagingTAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD9. Reliability Test Items and ResultsStress TestStress ConditionStress Duration Room Temperature Operation Life, RTOLTa=25¢J , If=150mA1000 hoursHigh Temperature Operation Life, HTOL Ta=65¢J , If=150mA 1000 hoursLow Temperature Operation Life, LTOL Ta=-40¢J , If=150mA 1000 hoursHigh Temperature/High Humidity Operation Life,WHTOLTa=85¢J , RH=85%, If=150mA 1000 hoursThermal Shock-40~125, 3J 0min~30min 100 cyclesFailure Criteria¡G1. Light output has more than 30% degradation than initial light output.2. Forward voltage variation more than ±20%.10. Storage(1) Do not open moisture proof bag before the products are ready to use. (2) Before open the package. The LEDs should kept at 30¢J and 90%RH or less (3) After open the package, the SMD LED should be kept at 28¢J , 60%RH or less. (4) If the moisture absorbent material has faded away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: 60¢J for 24 hoursTAIWAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTDDONGGUAN TONGJIA OPTOELECTRONICS TECHNOLOGY CO., LTD。

1206贴片发光管参数(原创实用版)目录1.贴片发光二极管的概述2.贴片发光二极管的参数3.贴片发光二极管的应用领域正文一、贴片发光二极管的概述贴片发光二极管,又称 LED 贴片灯珠,是一种采用半导体材料制作而成的发光器件。

它具有低功耗、高亮度、长寿命、环保等特点,广泛应用于各类照明、显示、装饰等领域。

二、贴片发光二极管的参数1.尺寸:贴片发光二极管的尺寸包括长、宽、高三个方向,通常以毫米为单位表示。

常见的尺寸有 3mm×3mm、5mm×5mm 等。

2.颜色:贴片发光二极管的颜色由其发出的光谱决定,常见的颜色有红、橙、黄、绿、蓝等。

3.亮度:贴片发光二极管的亮度是指其发出的光线的强度,单位为烛光(cd)。

亮度越高,光线越亮。

4.视角:贴片发光二极管的视角是指观察者能看到的发光二极管发出的光束的角度范围。

视角越大,光线覆盖的范围越广。

5.工作电压:贴片发光二极管的工作电压是指其正常工作所需的电压,单位为伏特(V)。

一般来说,工作电压越低,越节能。

6.工作电流:贴片发光二极管的工作电流是指其正常工作时通过的电流,单位为安培(A)。

一般来说,工作电流越小,越节能。

7.寿命:贴片发光二极管的寿命是指其正常工作的时间,通常以小时为单位表示。

寿命越长,使用寿命越久。

三、贴片发光二极管的应用领域贴片发光二极管广泛应用于各类照明、显示、装饰等领域,例如:1.照明:包括室内照明、室外照明、交通信号灯等。

2.显示:包括显示屏、广告牌、指示灯等。

3.装饰:包括圣诞树装饰、节日彩灯、室内装饰等。

以上就是关于贴片发光二极管参数的相关信息。

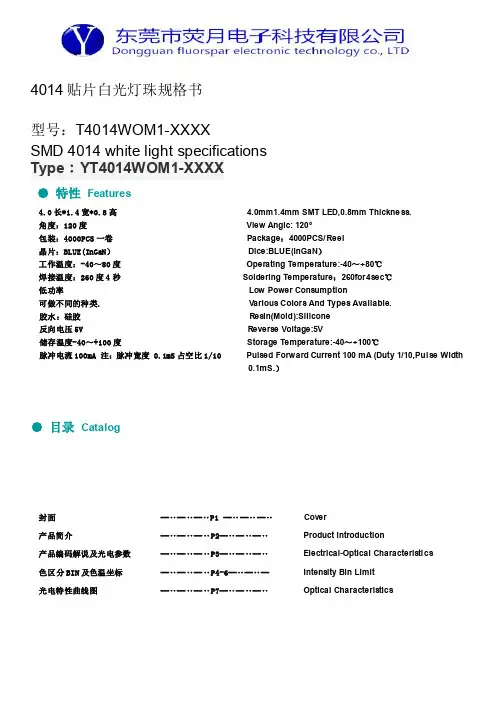

东莞市荧月电子科技有限公司2835绿光规格书2835GREEN SPECIFICATION产品型号 Model NO.:YLT-led2835GC-520描述:led2835绿光贴片发光二极管是行业内标准的封装产品,此类产品为高可靠性及应用范围非常广泛,此高可靠性的产品非常适用于半户外及户外灯具相关,高可靠性要求的应用场合。

特性:尺寸(mm): 2.8 x 3.5 x 0.8mm 表面贴片发光二极管胶体颜色:透明发光颜色:绿光发光角度:120°版次 REV NO.:V01版文件编号Document NO.:TY-C030002日期 DATE :2015.3.11.外形尺寸D imensions单位(Units):毫米(mm)2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.½ Rja = Heat resistance from Dice to Ambient temperature (Ta) Rjs = Heat resistance from Dice to Solder temperature of Cathode Side (Ts) (3) 原始光电参数Initial Electrical/Optical Characteristics (TA=25ºC)(4)发光强度范围Luminous Intensity Ranking (TA=25ºC)允许误差± 10%Luminous Intensity Measurement allowance is ± 10%.(5)颜色范围Color Ranking (TA=25ºC)允许误差± 0.01Color Coordinates Measurement allowance is ± 0.01.3.包装PACKAGING(1)LEDS在装带之后纸箱包装. The LEDs are packed in cardboard boxes after taping.(2)装带规格Taping Specifications (单位:毫米Units:mm)(3)卷轴尺寸Reel Dimension装带数量2000个/卷2000Pcs/Reel(3) 最小包装标签注明以下:产品名称.批号.光电范围.数量.The label on the minimum packing unit shows ; Part Number, Lot Number, Ranking, Quantity.(4)请注意防水防潮Keep away from wate r, moisture in order to protect the LEDs.(5) 须采取适当防护措施,以防包装箱跌落或受到强力撞击造成对产品的损伤.The LEDS may be damaged if the boxes are dropped or receive a strong impact against them. so precautions must be taken to prevent any damage.4.可靠性RELIABILITY*) U.S.L.:Upper Standard Level **) L.S.L.:Lower Standard Level 5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)有铅回焊(Lead Solder ) 无铅回焊(Lead-Free Solder)推荐焊盘式样(Recommended Soldering Pattern ) 单位:毫米( Units:mm)(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs. 所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED 会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F =0.5mA 时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F =0.5mA) (3)防潮包装Moisture Proof Package使用防潮包装It is recommended that moisture proof package be used .(4)储藏Storage打开包装袋之前,LED在温度为30°C或更低湿度70%RH以下,可保存一年.Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).下列情况发生时,须要在焊接前重新烘烤60 ± 5°C,24小时以上。