光通信行业胶水 胶粘剂性能参数表 EPOTEK

- 格式:xls

- 大小:45.50 KB

- 文档页数:11

![[实用生产表格]环氧树脂胶分胶记录表](https://uimg.taocdn.com/8a2cbca0240c844769eaeeb8.webp)

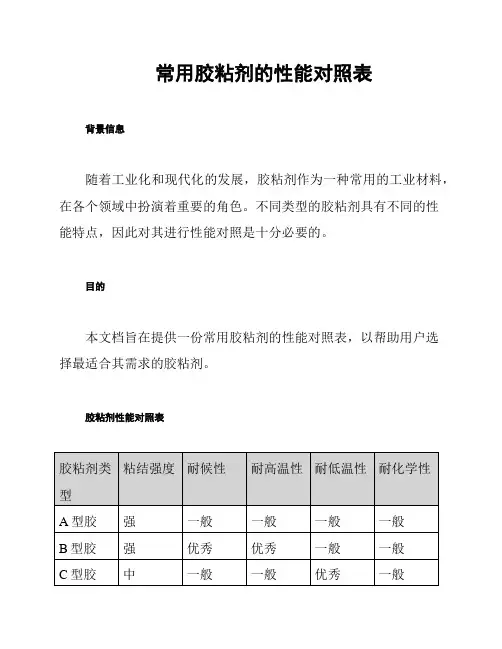

常用胶粘剂的性能对照表

背景信息

随着工业化和现代化的发展,胶粘剂作为一种常用的工业材料,在各个领域中扮演着重要的角色。

不同类型的胶粘剂具有不同的性

能特点,因此对其进行性能对照是十分必要的。

目的

本文档旨在提供一份常用胶粘剂的性能对照表,以帮助用户选

择最适合其需求的胶粘剂。

胶粘剂性能对照表

结论

根据以上性能对照表,不同类型的胶粘剂在粘结强度、耐候性、耐高温性、耐低温性和耐化学性方面表现出不同的特点。

根据用户

的具体需求,在选择胶粘剂时需要综合考虑这些性能特点。

注意事项

本性能对照表所列举的数据仅供参考,实际使用中应根据具体

情况进行实验和测试,以确保最佳的使用效果。

粘度 颜色@23℃@100rpm固化前/后301-1双组份65℃-1小时;23℃-24小时80-100cps 1.5168400-1600nm >96%;1600-2000nm >92%;无色/无色1100psi80≥65℃ 175×10-6 /54×10-61-2小时1年301-2双组份80℃-3.0小时;室温-2天225-425cps 1.5318320nm >94%;400-1200nm >99%无色/无色2000psi8080℃118×10-6 /37×10-6 8小时1年301-2FL双组份80℃-3小时;室温-3天100-200cps 1.51151000-1600nm>97%;400-1000nm>99%无色/无色2000psi7045℃211×10-6 /56×10-610小时1年302双组份室温-2小时5500-10000;cps @20rpm1.5442340-420nm >75%;440-900nm >85%;900-1600nm >88%淡黄/淡黄1756psi7340℃191×10-6 /52×10-610分钟1年302-3M 双组份65℃-3小时;室温 隔夜800-1600cps 1.544460-1620nm >95%;无色/无色2000psi8055℃193×10-6 /56×10-61小时1年305双组份65℃-1小时;室温 隔夜150-250cps 1.4763250nm >91%;300nm >97%;400-1600nm >98%无色/淡黄1880psi6635℃148×10-6 /31×10-61小时1年310M双组份65℃-2小时;室温-24小时555cps 1.497400-1300nm >99%;1400-2200nm>90%无色/无色306psi69-1.7℃222×10-6 /78×10-62小时1年折光指数nD透光率剪切强度psi操作时保质期光通信行业胶水、胶粘剂性能参数表(EPOTEK)硬度D某固化条件下的Tg温度热膨胀系数in/in/℃操作时间(室温)保质期(室温)EPOTEK类型固化条件310T-M双组份65℃-2小时;23℃-24小时1,800-3,300cpsN/A N/A棕褐色/ 无色500psi75≤30℃236×10-6 /74×10-635分钟1年314双组份150℃-60分钟120℃-3小时300-600cps 1.496595% /400-600nm98%/700-1600nm无色/琥珀色N/A8375℃134×10-6 /39×10-64天1年320双组份65℃-2小时 ;室温 隔夜700-1200cps 1.5261%/300-2500nm黑色/黑色2000psi8355℃100×10-6 /29×10-61小时1年320-3双组份95°C/1小时;150°C/10分钟5800-8200;cps@50rpmN/A1%/300-2500nm黑色/黑色2000psi8870℃109×10-6 /27×10-61–2天1年320LV双组份65℃-2小时;23℃-24小时350-650cPs@100rpmN/A<1%/300-2500nm黑色/无色1680psi84≥55℃170×10-6 /48×10-61小时1年320NC双组份70℃-1小时;23℃-24小时1000-3000cps@100rpmN/A<1%/300-2500nm黑色/无色>2,000psi85≥50℃94×10-6 /28×10-620分钟1年320NC-2双组份70°C/1小时;室温/过夜1500–3000;cPs@100rpmN/A1%/300-2500nm黑色/黑色1576psi8950℃82×10-6/20×10-60.5小时1年323LP双组份90C/30 分钟4500cps@23°C/10rpm1.57N/A浅黄2700psi88125 °C130×10-6/35×10-624小时1年保质期操作时330双组份150℃-1分钟;80℃-0.5小时350–550;cPs@100rpm1.5345500nm >51%;600nm >88%;700-1600nm >97%琥珀色/红色2700psi87>90℃ 175×10-6 /39×10-66小时1年353ND 双组份150℃-1分钟;80℃/30分钟3000-5000;cPs@50rpm1.5694550nm >50%;700-1000nm>98%; 1100-1600nm >95%琥珀色/深红2000psi8590℃206×10-6 /54×10-63-4小时1年353ND BLACK双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟3000-5000cPs@23°C/50rpmN/A1500nm >3%/2,000psi85≥ 90°C206×10-6/54×10-63-4小时1年353ND-4双组份150℃-15分钟;80℃/3小时36,000-66,000cPs@5rpm1.590197% /900nm96%/800nm88%/700nm琥珀色/红色1472psi87125℃ 186×10-6 /48×10-6<2小时6个月353ND-T双组份150℃-1分钟;120℃-5分钟;100℃-10分钟9,000-15,000cps@20rpmN/A N/A棕褐色/琥珀色1953psi80≥90℃231×10-6 /43×10-63小时1年353ND-T BLACK 双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟9,000 -15,000cPs@23°C/20rpm///2,000psi80≥ 90°C231×10-6/43×10-63小时1年353ND-T1双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟12,000 -20,000cPs@23°C/20rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月353ND-T3双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟12,000 -20,000cPs@23°C/20rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月操作时保质期353ND-T4双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟11,000 -17,000cPs@23°C/20rpm///>2,000psi80≥ 90 °C231×10-6/43×10-63小时6个月353ND-T5双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟4,000 -7,000cPs@23°C/50rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月354双组份150℃-10分钟;80℃/2小时4000-6000;cPs@50rpm1.573496% /600nm ;99%/800nm琥珀色/红色1,5734psi8295℃49×10-6 /165×10-63天1年354-T双组份150C/10分钟;120C/30分钟;80C/2小时;11000-20000cPs@23°C/20rpm1.5612>90% (900nm-2,500nm)琥珀色/深褐色2000psi85> 95°C165×10-6/49×10-63天半年375双组份150C/5分钟;120C/20分钟;100C/60分钟;80C/90分钟;3,000-5,000cps@50rpm1.5692>94%@600-900nm透明/透明>2000psi88≥ 100°C192×10-6/48×10-64小时1年377双组份150℃-1小时150-300cPs@23°C/100rpm1.519599% /600nm ;95%/1000-1500nm琥珀色/琥珀色1456psi6795 °C210×10-6 /57×10-624小时1年383ND双组份90C/20分钟4500cps@23°C/10rpm1.57//2100psi88120124×10-6/33×10-68小时1年390单组份溶剂挥发30分钟然后200℃/1小时<40cPs 1.472>95% 350-900nm琥珀色/琥珀色800psi85>200℃95×10-6 /29×10-6N/A6个月保质期操作时CF6-2双组份150C/1小时; 800-1200cPs@23°C/100rpm1.5336700-2000 nm/97%浅黄/琥珀色1144psi84110°C175×10-6/69×10-618小时1年MA-5单组份B-stage: 70°C/1小时;Cure: 150°C/15 分钟100-300 cPs 1.4898>95%@ 500-1600 nm透明/透明1836psi85120°C128×10-6/63×10-63小时1年OD2002双组份150C/5分钟;120C/15分钟;100C/30分钟;36,122cps@2.5rpm;35,625cps @5rpm1.5728>98%@800-1640nm;69%@600nm无色/琥珀色1570psi69168°C187×10-6/46×10-64小时1年OE100T双组份150C/1分钟;80C/30分钟4,500-7,000cps@50rpm1.5657>94%@880-1600nm;88%@800nm无色/棕褐色>2,000psi87≥100 °C165×10-6/43×10-63小时1年OE101双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟1,500 -2,500 cPs1.5459 @589 nm>50%@400nm;>92%@600nm;>97%@675 nm浅黄/琥珀色2,000 psi82≥ 65 °C210×10-6/41×10-64小时1年OE107M双组份80°C/90分钟;65°C/2小时;室温/两天1,200cPs 1.4997>97%@350–900nm无色透明/无色透明234psi(65°C /2小时);196psi(室温/48小时)108°C235×10-6/42×10-62小时1年OE120双组份120°C/2分钟;100°C/10分钟;80°C/20分钟12,000 -16,000cPs@23°C/20rpm//黑色/琥珀色2,000psi85≥ 90 °C121×10-6/28×10-63.5小时6个月 粘度 颜色剪切强度保质期(室硬度D某固化条件热膨胀系数in/in/℃操作时间(室EPOTEK类型固化条件折光指数nD透光率OE121-BLACK双组份室温/48小时;90°C/1小时800cps//黑色/黑色//室温/7天:65°C;80°C/2小时:75°C157×10-6/45×10-66小时1年OE132单组份涂层:200°C/1小时;粘结:350°C/30 to 60分钟.150 cPs//琥珀色/琥珀色80085A> 200°C(200C/1小时)95×10-6/29×10-6/6个月OE138双组份150°C/2分钟;80°C/30分钟4,000 -7,000 cPs@23°C/20rpm///>2,000psi85≥ 90 °C128×10-6/21×10-62小时1年OE188双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟20,000–30,000cps@23°C/10rpm///1,584psi91≥ 90 °C68×10-6/19×10-61.5小时1年OH101双组份80°C/1.5小时; RT/ 2天300 -600cPs@23°C/100rpm1.5643000埃/90%;100埃-2.5微米/98-99%透明/透明1600psi82> 65°C62×10-68小时1年OH105双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟1,700-2,700cps@100rpmN/A<1% @300-2000nm黑色/棕褐色>2,000psi90≥ 90 °C139×10-6/39×10-64小时1年OH105-T双组份150C/1分钟;120C/2-5分钟;80C/30分钟; 60C/90分钟;3,000-4,000cPs@23°C/100rpm/1% @ 300-200 nm黑色/黑色2000psi8390°C179×10-6/43×10-6<4小时1年OE125双组份80°C/1小时;65C/90 分钟2400-5400cPs@23°C/50rpm1.55297% @ 800 nm;98%@ 1000 nm;96%@1500 nm深蓝色808psi8180°C114×10-6/28×10-61小时1年操作时保质期310T-M双组份65℃-2小时;23℃-24小时1,800-3,300cpsN/A N/A棕褐色/ 无色500psi75≤30℃236×10-6 /74×10-635分钟1年314双组份150℃-60分钟120℃-3小时300-600cps 1.496595% /400-600nm98%/700-1600nm无色/ 琥珀色N/A8375℃134×10-6 /39×10-64天1年320双组份65℃-2小时 ;室温 隔夜700-1200cps 1.5261%/300-2500nm黑色/黑色2000psi8355℃100×10-6 /29×10-61小时1年320-3双组份95°C/1小时;150°C/10分钟5800-8200;cps@50rpmN/A1%/300-2500nm黑色/黑色2000psi8870℃109×10-6 /27×10-61–2天1年320LV双组份65℃-2小时;23℃-24小时350-650cPs@100rpmN/A<1%/300-2500nm黑色/无色1680psi84≥55℃170×10-6 /48×10-61小时1年320NC双组份70℃-1小时;23℃-24小时1000-3000cps@100rpmN/A<1%/300-2500nm黑色/无色>2,000psi85≥50℃94×10-6 /28×10-620分钟1年320NC-2双组份70°C/1小时;室温/过夜1500–3000;cPs@100rpmN/A1%/300-2500nm黑色/黑色1576psi8950℃82×10-6/20×10-60.5小时1年323LP双组份90C/30 分钟4500cps@23°C/10rpm1.57N/A浅黄2700psi88125 °C130×10-6/35×10-624小时1年操作时保质期330双组份150℃-1分钟;80℃-0.5小时350–550;cPs@100rpm1.5345500nm >51%;600nm >88%;700-1600nm >97%琥珀色/ 红色2700psi87>90℃ 175×10-6 /39×10-66小时1年353ND 双组份150℃-1分钟;80℃/30分钟3000-5000;cPs@50rpm1.5694550nm >50%;700-1000nm>98%; 1100-1600nm >95%琥珀色/ 深红2000psi8590℃206×10-6 /54×10-63-4小时1年353ND BLACK双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟3000-5000cPs@23°C/50rpmN/A1500nm >3%/2,000psi85≥ 90°C206×10-6/54×10-63-4小时1年353ND-4双组份150℃-15分钟;80℃/3小时36,000-66,000cPs@5rpm1.590197% /900nm96%/800nm88%/700nm琥珀色/ 红色1472psi87125℃ 186×10-6 /48×10-6<2小时6个月353ND-T双组份150℃-1分钟;120℃-5分钟;100℃-10分钟9,000-15,000cps@20rpmN/A N/A棕褐色/琥珀色1953psi80≥90℃231×10-6 /43×10-63小时1年353ND-T BLACK 双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟9,000 -15,000cPs@23°C/20rpm///2,000psi80≥ 90°C231×10-6/43×10-63小时1年353ND-T1双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟12,000 -20,000cPs@23°C/20rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月353ND-T3双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟12,000 -20,000cPs@23°C/20rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月操作时保质期353ND-T4双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟11,000 -17,000cPs@23°C/20rpm///>2,000psi80≥ 90 °C231×10-6/43×10-63小时6个月353ND-T5双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟4,000 -7,000cPs@23°C/50rpm///1,953psi80≥ 90 °C231×10-6/43×10-63小时6个月354双组份150℃-10分钟;80℃/2小时4000-6000;cPs@50rpm1.573496% /600nm ;99%/800nm琥珀色/红色1,5734psi8295℃49×10-6 /165×10-63天1年354-T双组份150C/10分钟;120C/30分钟;80C/2小时;11000-20000cPs@23°C/20rpm1.5612>90% (900nm-2,500nm)琥珀色/深褐色2000psi85> 95°C165×10-6/49×10-63天半年375双组份150C/5分钟;120C/20分钟;100C/60分钟;80C/90分钟;3,000-5,000cps@50rpm1.5692>94%@600-900nm透明/透明>2000psi88≥ 100°C192×10-6/48×10-64小时1年377双组份150℃-1小时150-300cPs@23°C/100rpm1.519599% /600nm ;95%/1000-1500nm琥珀色/琥珀色1456psi6795 °C210×10-6 /57×10-624小时1年383ND双组份90C/20分钟4500cps@23°C/10rpm1.57//2100psi88120124×10-6/33×10-68小时1年390单组份溶剂挥发30分钟然后200℃/1小时<40cPs 1.472>95% 350-900nm琥珀色/ 琥珀色800psi85>200℃95×10-6 /29×10-6N/A6个月保质期操作时CF6-2双组份150C/1小时; 800-1200cPs@23°C/100rpm1.5336700-2000 nm/97%浅黄/琥珀色1144psi84110°C175×10-6/69×10-618小时1年MA-5单组份B-stage: 70°C/1小时;Cure: 150°C/15 分钟100-300 cPs 1.4898>95%@ 500-1600 nm透明/透明1836psi85120°C128×10-6/63×10-63小时1年OD2002双组份150C/5分钟;120C/15分钟;100C/30分钟;36,122cps@2.5rpm;35,625cps @5rpm1.5728>98%@800-1640nm;69%@600nm无色/琥珀色1570psi69168°C187×10-6/46×10-64小时1年OE100T双组份150C/1分钟;80C/30分钟4,500-7,000cps@50rpm1.5657>94%@880-1600nm;88%@800nm无色/棕褐色>2,000psi87≥100 °C165×10-6/43×10-63小时1年OE101双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟1,500 -2,500 cPs1.5459 @589 nm>50%@400nm;>92%@600nm;>97%@675 nm浅黄/琥珀色2,000 psi82≥ 65 °C210×10-6/41×10-64小时1年OE107M双组份80°C/90分钟;65°C/2小时;室温/两天1,200cPs 1.4997>97%@350–900nm无色透明/无色透明234psi(65°C /2小时);196psi(室温/48小时)108°C235×10-6/42×10-62小时1年OE120双组份120°C/2分钟;100°C/10分钟;80°C/20分钟12,000 -16,000cPs@23°C/20rpm//黑色/琥珀色2,000psi85≥ 90 °C121×10-6/28×10-63.5小时6个月OE121-BLACK双组份室温/48小时;90°C/1小时800cps//黑色/黑色//室温/7天:65°C;80°C/2小时:75°C157×10-6/45×10-66小时1年OE132单组份涂层:200°C/1小时;粘结:350°C/30 to 60分钟.150 cPs//琥珀色/琥珀色80085A> 200°C(200C/1小时)95×10-6/29×10-6/6个月OE138双组份150°C/2分钟;80°C/30分钟4,000 -7,000 cPs@23°C/20rpm///>2,000psi85≥ 90 °C128×10-6/21×10-62小时1年OE188双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟20,000–30,000cps@23°C/10rpm///1,584psi91≥ 90 °C68×10-6/19×10-61.5小时1年OH101双组份80°C/1.5小时; RT/ 2天300 -600cPs@23°C/100rpm1.5643000埃/90%;100埃-2.5微米/98-99%透明/透明1600psi82> 65°C62×10-68小时1年OH105双组份150C/1分钟;120C/5分钟;100C/10分钟;80C/30分钟1,700-2,700cps@100rpmN/A<1% @300-2000nm黑色/棕褐色>2,000psi90≥ 90 °C139×10-6/39×10-64小时1年。

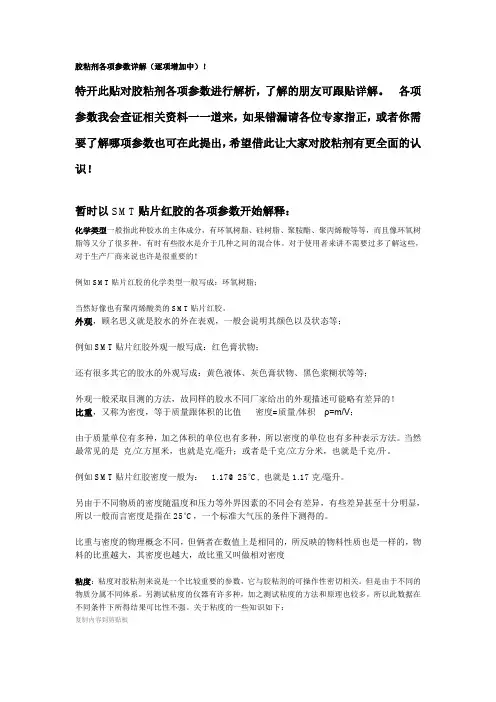

胶粘剂各项参数详解(逐项增加中)!特开此贴对胶粘剂各项参数进行解析,了解的朋友可跟贴详解。

各项参数我会查证相关资料一一道来,如果错漏请各位专家指正,或者你需要了解哪项参数也可在此提出,希望借此让大家对胶粘剂有更全面的认识!暂时以SMT贴片红胶的各项参数开始解释:化学类型一般指此种胶水的主体成分,有环氧树脂、硅树脂、聚胺酯、聚丙烯酸等等,而且像环氧树脂等又分了很多种。

有时有些胶水是介于几种之间的混合体。

对于使用者来讲不需要过多了解这些,对于生产厂商来说也许是很重要的!例如SMT贴片红胶的化学类型一般写成:环氧树脂;当然好像也有聚丙烯酸类的SMT贴片红胶。

外观,顾名思义就是胶水的外在表观,一般会说明其颜色以及状态等;例如SMT贴片红胶外观一般写成:红色膏状物;还有很多其它的胶水的外观写成:黄色液体、灰色膏状物、黑色浆糊状等等;外观一般采取目测的方法,故同样的胶水不同厂家给出的外观描述可能略有差异的!比重,又称为密度,等于质量跟体积的比值密度=质量/体积ρ=m/V;由于质量单位有多种,加之体积的单位也有多种,所以密度的单位也有多种表示方法。

当然最常见的是克/立方厘米,也就是克/毫升;或者是千克/立方分米,也就是千克/升。

例如SMT贴片红胶密度一般为: 1.17@25°C, 也就是1.17克/毫升。

另由于不同物质的密度随温度和压力等外界因素的不同会有差异,有些差异甚至十分明显,所以一般而言密度是指在25°C,一个标准大气压的条件下测得的。

比重与密度的物理概念不同,但俩者在数值上是相同的,所反映的物料性质也是一样的,物料的比重越大,其密度也越大,故比重又叫做相对密度粘度:粘度对胶粘剂来说是一个比较重要的参数,它与胶粘剂的可操作性密切相关。

但是由于不同的物质分属不同体系,另测试粘度的仪器有许多种,加之测试粘度的方法和原理也较多,所以此数据在不同条件下所得结果可比性不强。

关于粘度的一些知识如下:复制内容到剪贴板以SMT贴片红胶为例,其粘度(25°C 5rpm)一般为300,000mPa.S(300,000cps;300Pa.S;300,000厘泊),此处所指粘度为动力粘度。

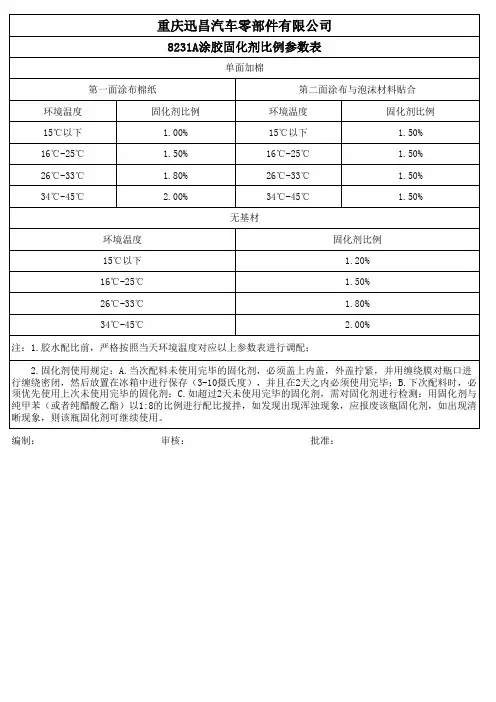

重庆迅昌汽车零部件有限公司8231A涂胶固化剂比例参数表单面加棉第一面涂布棉纸第二面涂布与泡沫材料贴合环境温度固化剂比例环境温度固化剂比例15℃以下 1.00%15℃以下 1.50%16℃-25℃ 1.50%16℃-25℃ 1.50%26℃-33℃ 1.80%26℃-33℃ 1.50%34℃-45℃ 2.00%34℃-45℃ 1.50%无基材环境温度固化剂比例15℃以下 1.20%16℃-25℃ 1.50%26℃-33℃ 1.80%34℃-45℃ 2.00%注:1.胶水配比前,严格按照当天环境温度对应以上参数表进行调配;2.固化剂使用规定:A.当次配料未使用完毕的固化剂,必须盖上内盖,外盖拧紧,并用缠绕膜对瓶口进行缠绕密闭,然后放置在冰箱中进行保存(3-10摄氏度),并且在2天之内必须使用完毕;B.下次配料时,必须优先使用上次未使用完毕的固化剂;C.如超过2天未使用完毕的固化剂,需对固化剂进行检测:用固化剂与纯甲苯(或者纯醋酸乙酯)以1:8的比例进行配比搅拌,如发现出现浑浊现象,应报废该瓶固化剂,如出现清晰现象,则该瓶固化剂可继续使用。

编制:审核:批准:重庆迅昌汽车零部件有限公司8310涂胶固化剂比例参数表单面加棉第一面涂布棉纸第二面涂布与泡沫材料贴合环境温度固化剂比例环境温度固化剂比例15℃以下 1.30%15℃以下 1.50%16℃-25℃ 1.80%16℃-25℃ 1.80%26℃-33℃ 1.80%26℃-33℃ 1.80%34℃-45℃ 1.80%34℃-45℃ 1.80%无基材环境温度固化剂比例15℃以下 1.20%16℃-25℃ 1.50%26℃-33℃ 1.70%34℃-45℃ 1.90%注:胶水配比前,严格按照当天环境温度对应以上参数表进行调配2.固化剂使用规定:A.当次配料未使用完毕的固化剂,必须盖上内盖,外盖拧紧,并用缠绕膜对瓶口进行缠绕密闭,然后放置在冰箱中进行保存(3-10摄氏度),并且在2天之内必须使用完毕;B.下次配料时,必须优先使用上次未使用完毕的固化剂;C.如超过2天未使用完毕的固化剂,需对固化剂进行检测:用固化剂与纯甲苯(或者纯醋酸乙酯)以1:8的比例进行配比搅拌,如发现出现浑浊现象,应报废该瓶固化剂,如出现清晰现象,则该瓶固化剂可继续使用。

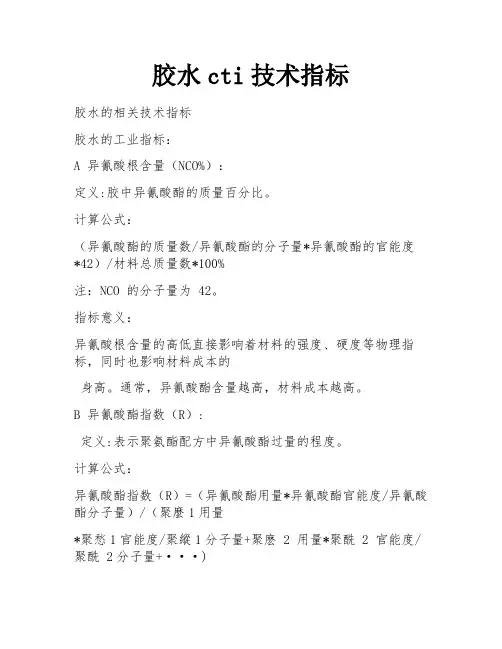

胶水cti技术指标胶水的相关技术指标胶水的工业指标:A 异氰酸根含量(NCO%):定义:胶中异氰酸酯的质量百分比。

计算公式:(异氰酸酯的质量数/异氰酸酯的分子量*异氰酸酯的官能度*42)/材料总质量数*100%注:NCO 的分子量为 42。

指标意义:异氰酸根含量的高低直接影响着材料的强度、硬度等物理指标,同时也影响材料成本的身高。

通常,异氰酸酯含量越高,材料成本越高。

B 异氰酸酯指数(R):定义:表示聚氨酯配方中异氰酸酯过量的程度。

计算公式:异氰酸酯指数(R)=(异氰酸酯用量*异氰酸酯官能度/异氰酸酯分子量)/(聚麼1用量*聚愁1官能度/聚縱1分子量+聚麽 2 用量*聚酰 2 官能度/聚酰 2分子量+···)注意:公式中涉及的其他概念要自己去找。

指标意义:异氰酸酯指数对胶水的熟化速度、硬度、黏度、与水反应的剧烈强度等指标都有影响,也影响成本。

通常,异氰酸酯指数越高,材料成本越高。

C 固含量:定义:胶水中不挥发物质的含量(百分比)。

计算公式:(材料总质量数一挥发性物质的质量数)/材料总质量数*100%。

指标意义:固体含量直接影响材料的粘度和环保指数。

对成本、强度等物理指标影响不大,对成品影响不大自收缩率影响很大。

(1.沥青烧完了。

2.包装沉降太快,收缩不一致)D 增塑剂含量:定义:胶水中增塑剂的含量(百分比)。

计算公式:增塑剂的质量数/材料总质量数*100%。

E 黏度:指标意义:胶水的粘度会影响材料在施工过程中的可操作性。

F 聚謎结构:定义:拼图结构是指胶水中不同贡献的匹配比例。

指标意义:合适的聚酰亚胺结构直接影响胶的综合性能和性价比。

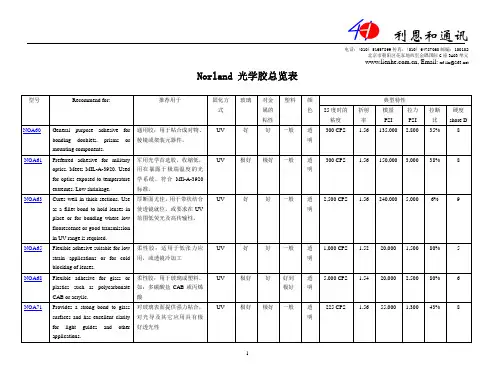

电话:(010) 51657899传真:(010) 64787060邮编:100102北京市朝阳区花家地西里金隅国际G座3A03单元, Email: xf-lin@Norland 光学胶总览表型号Recommend for: 推荐用于固化方式玻璃对金属的粘性塑料颜色典型特性25度时的粘度折射率模量PSI拉力PSI拉断比硬度shore DNOA60General purpose adhesive forbonding doublets, prisms ormounting components. 通用胶:用于粘合成对物、棱镜或架装元器件。

UV 好好一般透明300 CPS 1.56 135,000 2,800 35% 8NOA61Preferred adhesive for militaryoptics. Meets MIL-A-3920. Usedfor optics exposed to temperatureextremes. Low shrinkage. 军用光学首选胶,收缩低,用在暴露于极端温度的光学系统,符合MIl-A-3920标准。

UV 极好极好一般透明300 CPS 1.56 150,000 3,000 38% 8NOA63Cures well in thick sections. Useas a fillet bond to hold lenses inplace or for bonding where lowfluorescence or good transmissionin UV range is required. 厚断面尤佳,用于带状结合使透镜就位,或要求在UV范围低荧光及高传输性。

UV 好好一般透明2,500 CPS 1.56 240,000 5,000 6% 9NOA65Flexible adhesive suitable for lowstrain applications or for coldblocking of lenses. 柔性胶:适用于低张力应用,或透镜冷加工UV 好好一般透明1,000 CPS 1.52 20,000 1,500 80% 5NOA68Flexible adhesive for glass orplastics such as polycarbonateCAB or acrylic. 柔性胶:用于玻璃或塑料,如:多碳酸盐CAB或丙烯酸UV 极好好好到极好透明5,000 CPS 1.54 20,000 2,500 80% 6NOA71Provides a strong bond to glasssurfaces and has excellent clarityfor light guides and otherapplications. 对玻璃表面提供强力粘合,对光导及其它应用具有极好透光性UV 极好极好一般透明225 CPS 1.56 55,000 1,300 43% 8电话:(010) 51657899传真:(010) 64787060邮编:100102北京市朝阳区花家地西里金隅国际G 座3A03单元, Email: xf-lin@NOA72Lowviscosityadhesivefor bonding glass or plastics such as polycarbonate, CAB or acrylic. Cures with UV or visible light.低粘性胶:用于粘合玻璃或塑料,如:多碳酸盐CAB 或丙烯酸,UV 或可见光固化。

常用胶粘剂成分及特点(实用版)编制人:__________________审核人:__________________审批人:__________________编制单位:__________________编制时间:____年____月____日序言下载提示:该文档是本店铺精心编制而成的,希望大家下载后,能够帮助大家解决实际问题。

文档下载后可定制修改,请根据实际需要进行调整和使用,谢谢!并且,本店铺为大家提供各种类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by this editor. I hope that after you download it, it can help yousolve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you!In addition, this shop provides you with various types of practical materials, such as educational essays, diary appreciation, sentence excerpts, ancient poems, classicarticles, topic composition, work summary, word parsing, copy excerpts, other materials and so on, want to know differentdata formats and writing methods, please pay attention!胶粘剂是一种常用的粘合材料,广泛应用于工业生产和日常生活中。

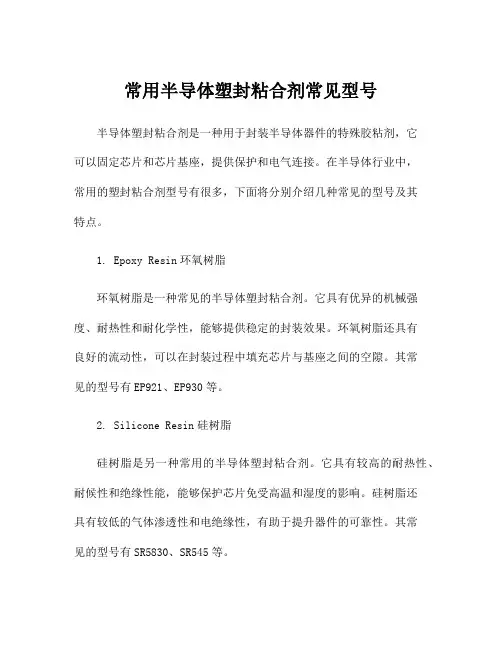

常用半导体塑封粘合剂常见型号半导体塑封粘合剂是一种用于封装半导体器件的特殊胶粘剂,它可以固定芯片和芯片基座,提供保护和电气连接。

在半导体行业中,常用的塑封粘合剂型号有很多,下面将分别介绍几种常见的型号及其特点。

1. Epoxy Resin环氧树脂环氧树脂是一种常见的半导体塑封粘合剂。

它具有优异的机械强度、耐热性和耐化学性,能够提供稳定的封装效果。

环氧树脂还具有良好的流动性,可以在封装过程中填充芯片与基座之间的空隙。

其常见的型号有EP921、EP930等。

2. Silicone Resin硅树脂硅树脂是另一种常用的半导体塑封粘合剂。

它具有较高的耐热性、耐候性和绝缘性能,能够保护芯片免受高温和湿度的影响。

硅树脂还具有较低的气体渗透性和电绝缘性,有助于提升器件的可靠性。

其常见的型号有SR5830、SR545等。

3. Polyurethane Resin聚氨酯树脂聚氨酯树脂是一种具有优良机械性能和耐化学性的半导体塑封粘合剂。

它可以提供较好的耐冲击性和耐腐蚀性,适用于一些特殊环境下的封装需求。

聚氨酯树脂还具有较高的粘接强度和较低的线性热膨胀系数,有助于减少热应力对芯片的影响。

其常见的型号有PU515、PU823等。

4. Acrylic Resin丙烯酸树脂丙烯酸树脂是一种常见的半导体塑封粘合剂。

它具有良好的粘接性能和较低的介电常数,可以提供可靠的电气连接和绝缘性能。

丙烯酸树脂还具有较短的固化时间和较低的挥发性,有助于提高生产效率。

其常见的型号有AP230、AP238等。

5. Polyimide Resin聚酰亚胺树脂聚酰亚胺树脂是一种高性能的半导体塑封粘合剂。

它具有优异的耐高温性、耐腐蚀性和电绝缘性能,可以应对极端的环境条件。

聚酰亚胺树脂还具有较低的热膨胀系数和较高的粘接强度,适用于高功率半导体器件的封装。

其常见的型号有PI2555、PI2607等。

除了以上几种常见的半导体塑封粘合剂型号,还有许多其他型号可根据具体的封装需求进行选择。

光学常用胶水资料文稿归稿存档编号:[KKUY-KKIO69-OTM243-OLUI129-G00I-FDQS58-种类性能指标适用环境04002粘度:60000;承受温度148℃;可操作时间22min@25℃缝隙填充不含溶剂,固化后不会收缩,适用于填充缝隙。

适于粘接不锈钢、铝、酚醛塑料、聚酯、木头、陶瓷、石头、玻璃纤维、玻璃、皮革。

可机械加工,喷砂,钻洞和开孔04004粘度:15000;承受温度82℃;可操作时间120min@25℃修补涂层用来覆盖和填充划痕,如修理印刷电路板、光纤、镜头、光学仪器、珠宝、艺术品等需要透明粘接的地方。

适于粘接不锈钢、铝、铜、酚醛塑料、环氧塑料、玻璃、陶瓷。

353ND——环氧树脂胶粘度3000-5000;可操作时间小于等于3小时,2小时易操作,皮肤过敏性低;易渗入光纤束中;是一种理想的用于固定光纤、金属、玻璃、陶瓷和多种塑料的粘接剂。

乐泰480——乙基快干胶200mPa.S;工作温度40-80℃,固化时间20-50s;用于大面积金属物质粘合,可谓金属粘合提供良好的解决办法,此外乐泰480还能够轻松地粘接塑料或是弹性体材料。

GD406脱醇型单组份室温硫化硅橡胶固化时间100-200min。

适用温度-60——200℃。

高强度、粘接性好、无腐蚀。

电绝缘性、密封性、硫化性能好。

可用于密封、粘接、绝缘、防潮、防震;弹性胶粘剂。

UV胶——丙烯酸酯单体固化时间20s塑料与塑料、塑料与玻璃、塑料与金属等材料粘接。

粘接强度高,固化后完全透明,产品长期不变黄,不白化。

GN511,GN512有机硅凝GN511:粘度5000-硫化不放热,收缩率胶(二甲基硅氧烷)6000;允许操作时间>5h;固化时间4h(70-80) ℃。

GN512:允许操作时间10-30min,室温下24h固化。

温度-60——200℃正常使用。

小,无腐蚀性、防潮;主要用于电子元器件的灌封、粘接、涂覆材料。

起到防潮、绝缘、防震作用。

ET、APET塑料粘接UV无影胶水的特性

★彻底清洁被粘接物表面,确保其干燥、无油污并吻合良好,将本品涂胶后进行粘接或复合,并固持,然后使用紫外线光源(日光或紫外光)照射被粘接物表面,在40W紫外照射下,定位时间为1-3分钟,用400W以上的紫外灯照射则只要30秒内就可凝固,24小时达到最佳效果。

【PET、APET塑料粘接UV无影胶水注意事项】

★本品对皮肤和眼睛有轻微刺激。

★操作时,请戴隔离手套,若触及皮肤或眼睛,应立即用清水冲洗或就医。

★为避免污染原胶,请勿将已倒出的胶倒回原包装。

★贮存于阴凉、干燥、通风处并远离高温。

★用户批量使用时,请先做试验。

避免因操作不当而影响粘接效果。

SG5000 SeriesMethacrylate AdhesivesNOTES:1. Polyolefins, thermoplastic polyesters, fluorocarbon plastics and other low surface energy plastics are generally not bondable.2. Prepare metal by removing dust, loose scale, rust and other surface residue including oil and grease. For maximum bond strength on steel, abrade surface prior to bonding. See important notes a, b and c on reverse side.3. Tensile modulus as measured in the linear portion of the stress strain curve.4. Lap shear strength of unprimed aluminium to aluminium bond based on ASTM D1002 method.Cartridge Adhesive / Activator Working Time (minutes)Fixture Time (minutes)SG5000-03 SG5000-03A / SG5000-03B 2 – 5 6 – 8SG5000-06 SG5000-06A / SG5000-06B 5 – 8 10 – 12SG5000-13SG5000-13A / SG5000-13B14 – 1920 – 25PRODUCT PROPERTIES @ 24°C (75°F) – Fixture Time (time to achieve 70% of ultimate strength in lap shear)4Characteristics Part A (Adhesive) Part B (Activator) Mix (Part A + B)ColourAmber Amber or BlackAmber or BlackMix ratio by volume 1 1 —Mix ratio by weight 1 1 —Density, g/cc 0.96 0.97 0.97Density, lb/gallon 8.018.098.09Viscosity, cps90,000 – 150,000150,000 – 250,000—TYPICAL ADHESIVE CHARACTERISTICS @ 24°C (75°F)DESCRIPTIONSCIGRIP ® SG5000 Series Methacrylate Adhesives are high strength two-component products for bonding metals 2, plastics 1 and composites. They offer a unique combination of convenient 1:1 mix ratio and ability to adhere to a wide variety of materials. Most metals, including steel and aluminium, can be bonded without surface pretreatment. A choice of 3, 6 and 15 minute working times, fast cure and rapid strength build make this series of adhesives an ideal first choice for diverse bonding applications. Packaging options include 50 and 400 ml cartridges and in 19 and 189 litres (5 and 50 gallon) bulk containers for application with meter-mix dispense equipment.Tensile Strength MPa (psi) 35 – 40 (5,076 – 5,802) Lap Shear Strength 4 MPa (psi) 18 – 25 (2,611 – 3,626)Maximum Tensile Elongation (%) 5 – 10 Service Temperatures °C (°F)-40 to 100 (-40 to 212 )Tensile Modulus 3 MPa (psi) 1,100 – 1,240 (160,000 – 180,000)TYPICAL PHYSICAL PROPERTIES @ 24°C (75°F)CompositesMetals 2 Thermoplastics 1✓ Epoxy laminates✓ Aluminium ✓ ABS, Acrylics ✓ FRP (Polyester / Vinyl Ester) ✓ Carbon Steel ✓ Vinyl✓ Gelcoats✓ Stainless Steel✓ PVC, PolycarbonatesRECOMMENDED SUBSTRATESuse shims or spacers to set the gap. Test the curing adhesive at the edges for fingernail hardness before removing clamps or fixtures. Use a soft faring tool to remove excess adhesive from the bonded assembly. Masking tapes or other protective barriers should be used to prevent contamination on any cosmetically sensitive areas. Partially cured adhesive can be removed with a sharp knife and any cured adhesive may be removed by sanding or scraping.CLEAN UPAdhesive components and mixed adhesive should be removed from mixing and application equipment with a suitable industrial solvent or cleaner before the mixed adhesive cures. Once the adhesive cures, soaking in a strong solvent or paint remover will be required to soften the adhesive for removal. If the bonds are exposed to UV rays then use of plasticizers such as Benzoflex 2088 is recommended, or contact your SCIGRIP representative for additional information. Any clean-up of the bonded assembly using industrial solvents is not recommended as it could affect the cure.STORAGE AND SHELF LIFEThe shelf life of components A and B in unopened containers is approximately six months from the date the product is shipped from SCIGRIP facilities. Shelf life is based on steady state storage between 13°C and 27°C (55°F and 80°F). Exposure, intermittent or prolonged, above 27°C (80°F) will result in a reduction of the stated shelf life. Exposures above 38ºC (100ºF) during shipping or storage can quickly degrade component B in cartridges or bulk containers, and must be prevented. Shelf life of both components can be extended by air-conditioned or refrigerated storage between 10°C and 18°C (50°F and 65°F). KEEP FROM FREEZING.IMPORTANT NOTESa. SUBSTRATE AND APPLICATION COMPATIBILITY: The user must determine the suitability of a selected adhesive for a given substrate and application. SCIGRIP strongly recommends laboratory, shop and end-use testing that simulates the actual manufacturing and end-use environment.b. SURFACE PREPARATION: The need for surface preparation must be determined by comparative testing of prepared and unprepared substrates to assure that unprepared bonding is equivalent to or acceptable for the application relative to prepared bonding. Initial bonding tests must be followed up with simulated or actual durability tests to assure that surface conditions do not lead to degradation of the bond over time under service conditions. Subsequent changes in substrates or bonding conditions will require re-testing.c. TECHNICAL ASSISTANCE: Contact your SCIGRIP representative for questions or assistance with the selection of adhesives and methods for evaluating adhesives for your intended application.NOTE: This product is intended for use by skilled individuals at their own risk. Recommendations contained herein are based on information w e believe to be reliable. The properties and strength values presented above are typical properties obtained under controlled conditions at the SCIGRIP laboratory. They are intended to be used only as a guide for selection for end-use evaluation. The ultimate suitability for any intended application must be verified by the end user under anticipated test conditions. Since specific use, materials and product handling are not controlled by SCIGRIP, our warranty is limited to the replacement of defective SCIGRIP product.SAFETY AND HANDLINGRead Material Safety Data Sheet before handling or using this product. Adhesive components A and B contain methyl methacrylate monomer and are flammable. Always use in a well-ventilated area. Floor-level extraction and large quantities of moving air greatly facilitate ventilation. Both materials must be stored in a cool place away from sources of heat and open flames or sparks. Keep containers closed when not in use. Prevent contact with skin and eyes. In case of skin contact, wash with soap and water. In case of eye contact, flush with water for 15 minutes and seek immediate medical attention. Harmful if swallowed. Keep out of reach of children.MIXING AND APPLICATIONEXOTHERM: The chemical curing reaction that occurs when components A and B are mixed generates heat. The amount of heat generated is dependent on the mass and thickness of the mixed product. Large masses over 39 mm (1.5 inch) thick can develop heat in excess of 121°C (250°F) and can generate vapours that should be avoided from direct personal contact.CURINGOpen working time is the approximate time after mixing components A and B, depending on bonding conditions, that the adhesive remains fluid and bondable. Fixture time is the approximate time after mixing components A and B required for the adhesive to react the partial state of cure necessary to allow careful movement, unclamping or de-molding of assembled parts. Parts can generally be put in service when 80 percent of full strength is developed. The time to achieve 80% cure is approximately 2-3 times that required for fixturing. The working and fixture times presented in this bulletin are based on laboratory tests performed at 24°C (75°F). Higher temperatures speed the curing reaction and reduce open working time. The reverse is true for lower temperatures. If significant variation in temperatures or application at very high or low temperatures is anticipated, contact your SCIGRIP representative for technical assistance. DISPENSING EQUIPMENTDispensing from disposable cartridges or meter-mix dispense equipment is highly recommended. Both methods employ convenient static motionless mixer technology. Product supplied in pre-measured cartridges is dispensed from approved manual or pneumatic powered guns. While using pneumatic dispensing guns, it is mandatory to use the gun’s regulator to regulate the air pressure. Manufacturers recommended maximum operating pressure and maximum compressed air supply pressure are 5.9 and 8.3 bars (85 and 120 psi) respectively. Removal of the regulator from the dispensing unit can lead to over pressurizing and rupture of the cartridge cylinder. Contact your SCIGRIP representative for information and availability.When meter-mix dispense systems are used, care must be taken to assure compatibility between the adhesive components and the materials in the equipment that they contact. All wetted metal components should be constructed of stainless steel, aluminium or a sufficient thickness of chemically resistant material that prevents contact between the adhesive components and the base metal. Contact with copper, brass, zinc or alloys containing these materials must be strictly avoided. All nonmetallic seals and gaskets should be fabricated from PTFE, or polyethylene based materials. Natural rubber, nitrile rubber (BUNA), neoprene and Viton® are not acceptable.APPLICATIONFollow instructions provided or contact your SCIGRIP representative for proper preparation of dispensing equipment and substrates prior to starting the bonding process. Always dispense a quantity of adhesive at start-up to assure that the adhesive exiting the tip of the mixer is the proper colour and is uniform, without streaks. If aged material is being used, allow the purged material to cure to assure quality before proceeding. Carefully dispense a sufficient quantity of adhesive on the substrate to assure that the bond gap is completely filled when the parts are mated. Allow for squeeze-out at the edges of the bond to assure filling. Carefully secure or clamp parts to prevent joint movement while the adhesive sets. Do not apply excessive pressure that can cause excessively thin gaps and starve thebond line. A minimum gap of 0.50 mm (0.02 inch) is recommended. If in doubt,。

光纤封装胶水:白色单组份环氧1. 介绍光纤封装胶水是一种用于光纤封装和固定的胶水。

白色单组份环氧胶是其中一种常用的胶水类型。

本文将对光纤封装胶水的应用、特性、制备方法和注意事项进行详细介绍。

2. 应用光纤封装胶水广泛应用于光纤通信、光纤传感和光纤制造等领域。

它主要用于固定和保护光纤连接点,提高光纤的性能和使用寿命。

光纤封装胶水可以在光纤连接处形成坚固的保护层,防止光纤受到外界环境的影响,如湿气、灰尘和机械振动等。

3. 特性•白色单组份环氧胶具有良好的粘结性能和耐候性,能够在不同环境条件下保持稳定的性能。

•具有较高的抗拉强度和耐冲击性,能够有效保护光纤连接点。

•具有较低的粘度和表面张力,易于涂覆和固化。

•耐高温性能良好,适用于高温环境下的光纤封装。

4. 制备方法步骤一:材料准备准备以下材料:•环氧树脂•硬化剂•填充剂(可选)•溶剂(可选)步骤二:配方设计根据所需的性能要求和应用环境,设计合适的配方。

根据环氧树脂和硬化剂的比例确定配方中各组分的含量。

步骤三:混合将环氧树脂和硬化剂按照配方比例混合均匀。

如果需要改变胶水的特性,可以添加填充剂和溶剂。

步骤四:搅拌使用搅拌器将混合好的胶水搅拌均匀,确保各组分充分混合。

步骤五:涂覆使用刷子、滴管或喷涂器将胶水涂覆在需要封装的光纤连接点上。

注意涂覆的均匀性和厚度。

步骤六:固化根据胶水的固化条件,将涂覆好的光纤连接点置于适当的环境中进行固化。

可以使用烘箱、紫外线灯或自然固化等方法。

5. 注意事项•在制备和使用过程中,注意安全防护,避免直接接触胶水。

•在涂覆过程中,避免产生气泡和污染。

•混合好的胶水应尽快使用,避免固化前的过长储存时间。

•根据胶水的固化时间和温度要求,合理安排工作进度。

•使用胶水时,注意环境通风,避免吸入有害气体。

结论光纤封装胶水是一种重要的材料,用于固定和保护光纤连接点。

白色单组份环氧胶是其中一种常用的胶水类型,具有良好的粘结性能和耐候性。

制备和使用光纤封装胶水需要注意安全防护和操作规范,以确保胶水的性能和使用效果。

Product DescriptionELOTEX® MP2100 is a redispersible binder based on a copolymer of vinyl acetate and ethylene. Protective colloid Polyvinyl alcoholAdditives Mineral anti-block agentsPlasticisers noneSolvents noneFilm-forming agents noneSpecificationsAppearance free-flowing, white powderBulk density 500 - 630 g/lResidual moisture < 1.0%Ash TGA 1000°C 10.5% +/- 1.5%pH value 6.5 – 8.0 (as a 10% dispersion in water)Min. film building temp. + 3°CFilm properties opaque, viscoplasticApplication AreasFor modification of hydraulically and non-hydraulically curing systems.Main application areas– Ideal for use in manually and pump applied finished products– Multi-purpose use in hydraulically curing systemsKey PropertiesDuring processing– Excellent rheology and workability– Reduced water demand– Ideal wetting behaviour– Fast redispersibilityIn the cured state– High final strengths– High cohesive force (cohesion)– Increased adhesive bond strength (adhesion)– Improved freeze-thaw cycling resistancePowder ProcessingElotex redispersible powders can be blended in all commercial positive mixers with other dry additives to produce finished products in powder form. Since Elotex redispersible powders exhibit thermoplastic behaviour, mixing times should be as short as possible, and significant temperature rise caused by strong shear forces should be avoided. All hydraulically and non-hydraulically curing dry mixtures with Elotex redispersible powder may be easily mixed with water before application.For mixing finished products in powder form, one usually places the required amount of mixing water in a suitable vessel and add the powder mixture under agitation. Too intensive agitation of the mixture may result in unwanted air inclusion. Before application, one should allow the mixture to stand for a short time. Depending on the properties of the other additives, the standing time will be in the range of approx. 1-5 minutes.Packaging and StorageStandard packaging: 25 kg paper sacks with polyethylene liners.Other types of packaging such as Big Bags or silo wagons are possible on request.As a basic rule it is recommended to store Elotex powder in a dry location at temperatures below 25°C and to process within six months. Sacks that are stored under pressure, damaged or left open for an extended period tend to cause blocking of the powder.Quality, Safety and EnvironmentElotex powders are non-toxic and are unclassified according to Regulation 88/379/EEC. We recommend all individuals using Elotex powder, or coming in contact with it, to observe the separate Safety Data Sheets. Our safety specialists will be pleased to advise you regarding safety, health and environmental issues of our products. Akzo Nobel Chemicals AG has been certified according to DIN EN ISO9001 and DIN EN ISO14001.Product LiabilityThe above information and recommendations are based upon our experience and are offered merely for advice. They do not absolve the consumer from making his own tests. Akzo Nobel Chemicals AG, their representatives or distributor organizations have no control over the conditions under which Elotex powders are transported, stored, handled or used. Responsibility for damage arising from the use of our products cannot be derived from the recommendations given. The observance of any intellectual property rights of third parties is the responsibility of the consumer in each case.Technical information may not be passed on to any third party without our previous consent.Other InformationVersion 7/ 1.12.2012Replaces version from 16.9.2009Date of issue 29.8.2002Akzo Nobel Chemicals AGIndustriestrasse 17a, CH-6203 Sempach StationT +41 41 469 69 69 F +41 41 469 69 00****************************/elotex。

353ND胶特性353ND胶特性EPO-TEK 胶)广泛用于光纤连接器,光无源器件353ND光纤粘接剂是美国EPOXY Technology公司研制开发并生产的产品,适用于光通信器件的生产,广泛用在光纤连接器的生产上。

一.应用EP0—TEK 353ND是双组分,100%实体,为高温条件下研制的一种热固化环氧树脂胶,虽然EP0—TEK 353ND设计在200℃连续工作,但它在300—400℃也能工作若干分钟,EP0—TEK 353ND对多种溶剂和化学品具有优异的抵抗性,是一种理想的用于邦定光纤、金属、玻璃、陶瓷和多数塑料的粘接剂。

EPO—TEK 353ND具有如下独特性能:混合后寿命长;易操作;皮肤过敏性低;易渗入光纤束中;固化时颜色从琥珀色变成深红色。

EP0—TEK 353ND一般被推荐用于薄膜或厚膜,需要应用于其它超厚断面时,推荐在室温或略高于室温时变成胶状体,然后升高温度完全固化。

EP0—TEK 353ND适用于涂刷、点滴、浇灌或者机械滴胶工艺上。

依据美国航空航天署(NASA)的出气(Outgassing)测试结果,批准用于太空飞行项目。

技术参数成分:双组份混合比例:按重量A组分:10B:组分:1不用时密封储存,最大混合量建议不要超过25克固化条件:60度……………… 1/2~1小时80度………………15分钟100度………………5分钟120度………………2分钟150度……………1分钟物理特性:储存条件:无需冷藏温室储存12个月工作温度范围(连续):-50——200 96℅湿度条件下7天时间重量增加百分比:0.03℅抗热冲击-55—150度 10次循环:通过可燃性:阻燃可操作时间:2小时。